Building construction discharging platform device

A technology of unloading platform and building construction, which is applied in the processing of building materials, construction, building construction, etc., and can solve problems such as inconvenient operation and reducing the contact stress between the unloading platform and the limit baffle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

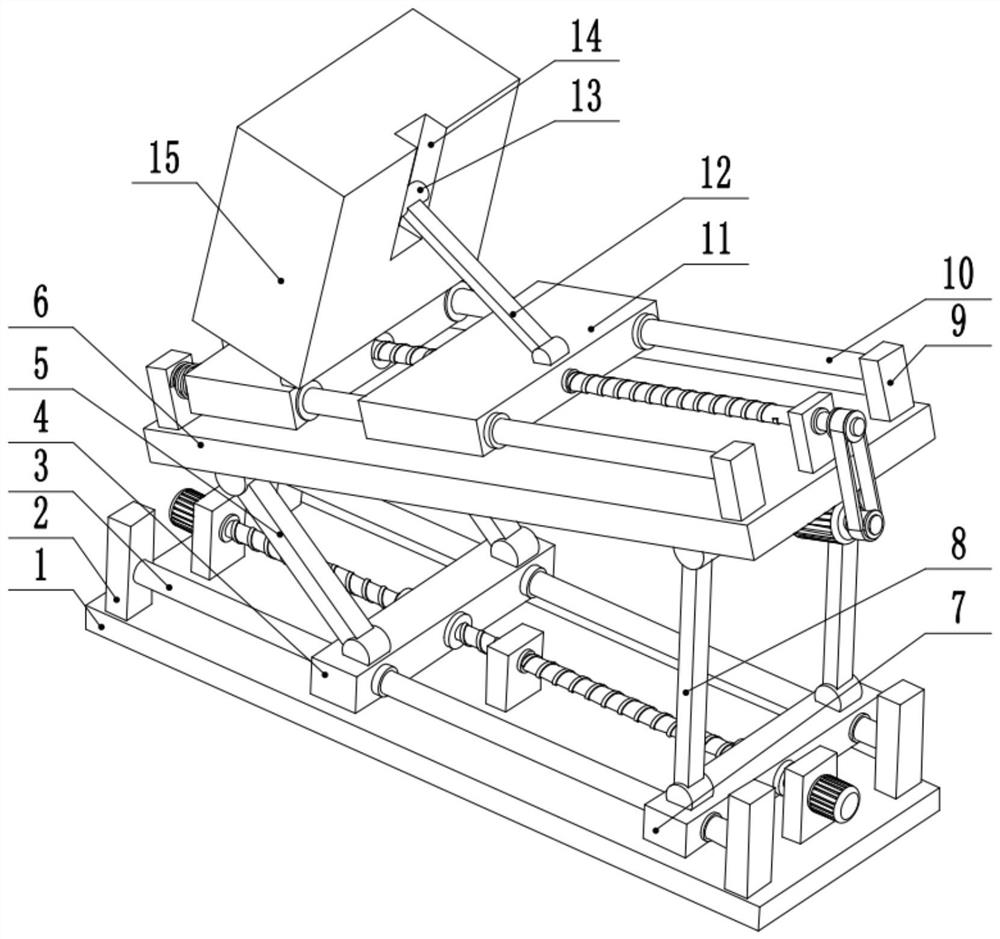

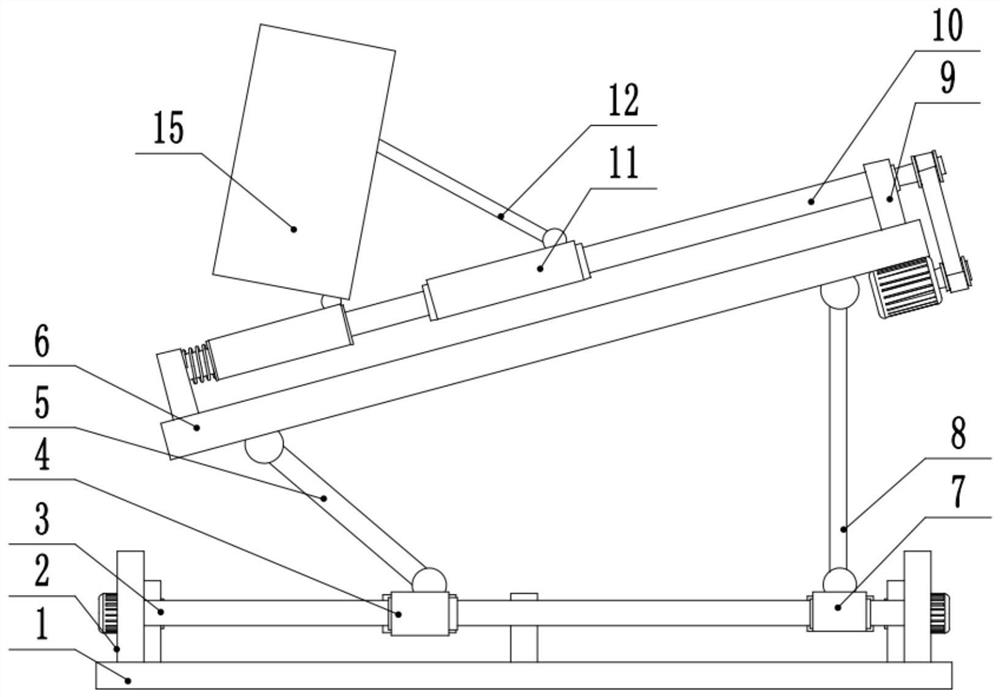

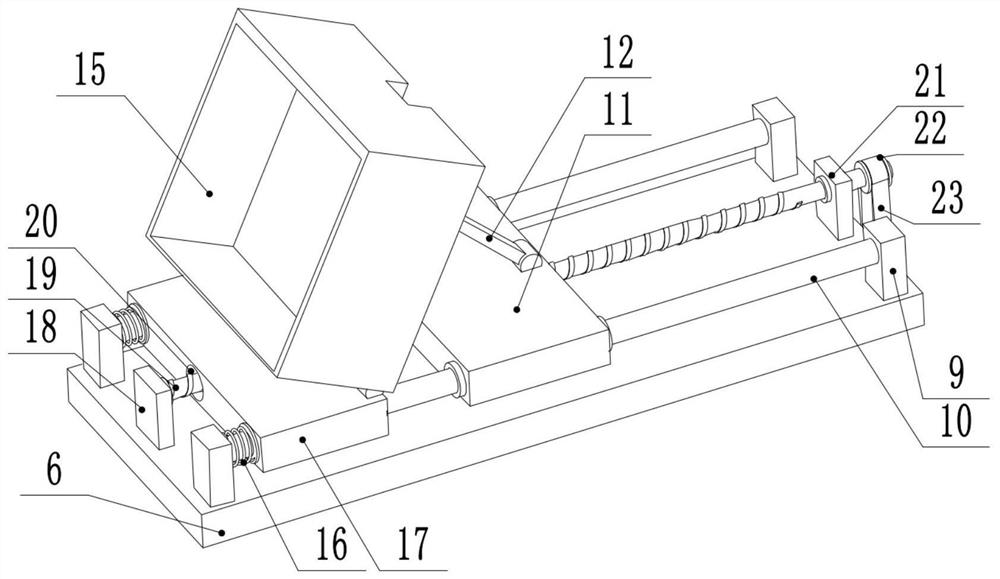

[0028] see Figure 1-6 , a construction unloading platform device, comprising a turntable 6, the upper surface of the turntable 6 is provided with a second fixed plate 9 on the front and rear sides, the middle part of the second fixed plate 9 is provided with a second guide rod 10, and the second guide The left side of bar 10 slides and connects the fourth sliding seat 17, and the right side of the fourth sliding seat 17 rotates and connects the left end of hopper 15, and the lower surface right end of described turntable 6 is provided with first drive motor 25, and the first drive motor 25 The output shaft of the output shaft is fixedly connected to the first pulley 24, the first pulley 24 is connected to the second pulley 22 through the belt 23, the second pulley 22 is fixedly connected to the right end of the first screw mandrel 19, and the middle part of the first screw mandrel 19 is threaded. The middle part of the 3rd slide seat 11, the upper surface right side of the 3r...

Embodiment 2

[0032] see image 3 , the other content of this embodiment is the same as that of the first embodiment, except that: the left side of the second guide rod 10 is sheathed with a spring 16 . In order to avoid the collision between the fourth sliding seat 17 and the second fixed plate 9 when moving, a spring 16 is provided on the left side of the second guide rod 10, so that the second fixed plate 9 and the fourth sliding seat 17 are buffered by the spring 16 As a result, rigid contact is avoided.

[0033]In the implementation process of the present invention, start the second drive motor 26, the second drive motor 26 drives the second screw mandrel 28 to rotate, the second screw mandrel 28 drives the first sliding seat 4 to slide to the right, and starts the third drive motor 32 at the same time , the third driving motor 32 drives the third screw mandrel 30 to rotate, the third screw mandrel 30 drives the second sliding seat 7 to slide to the left, when the first sliding seat 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com