Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Quick and easy on-site installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

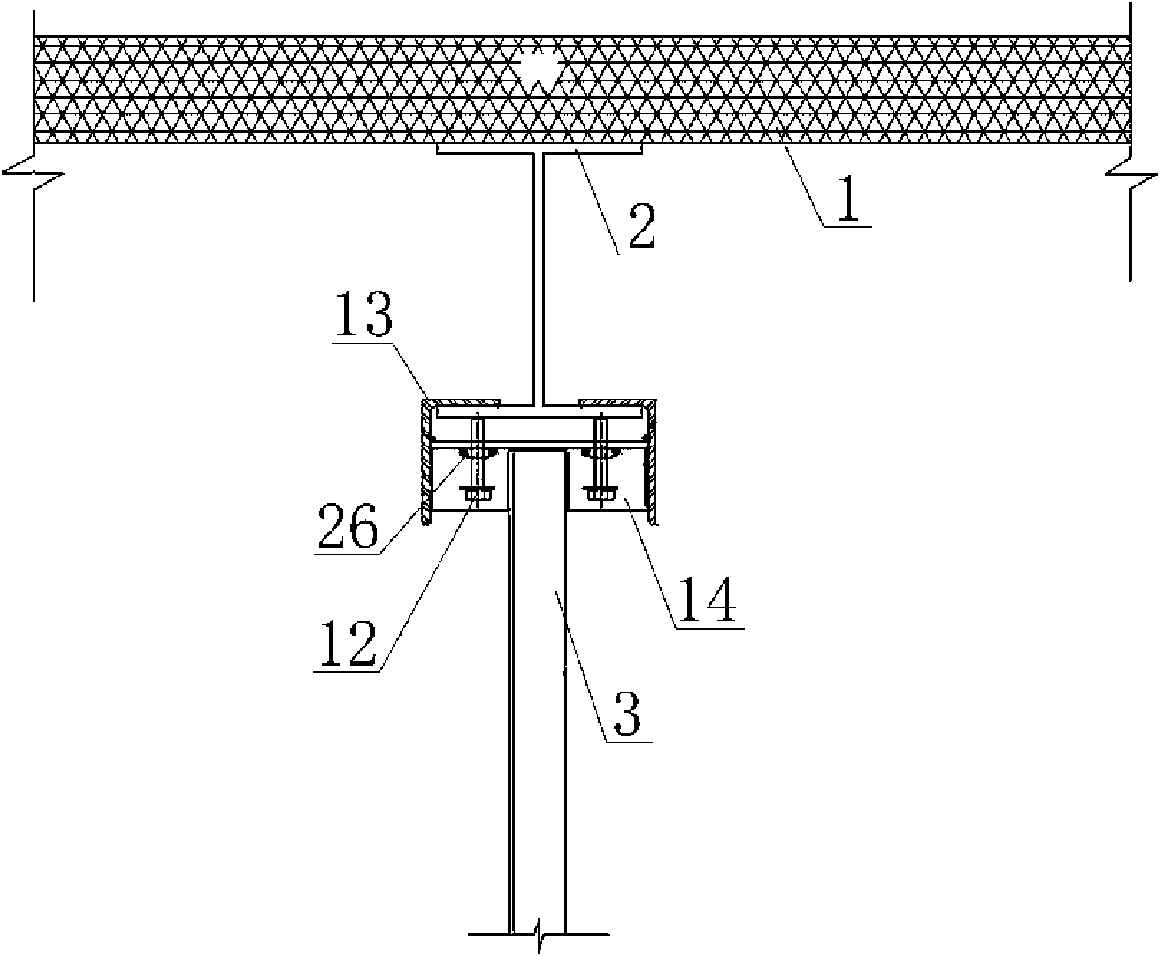

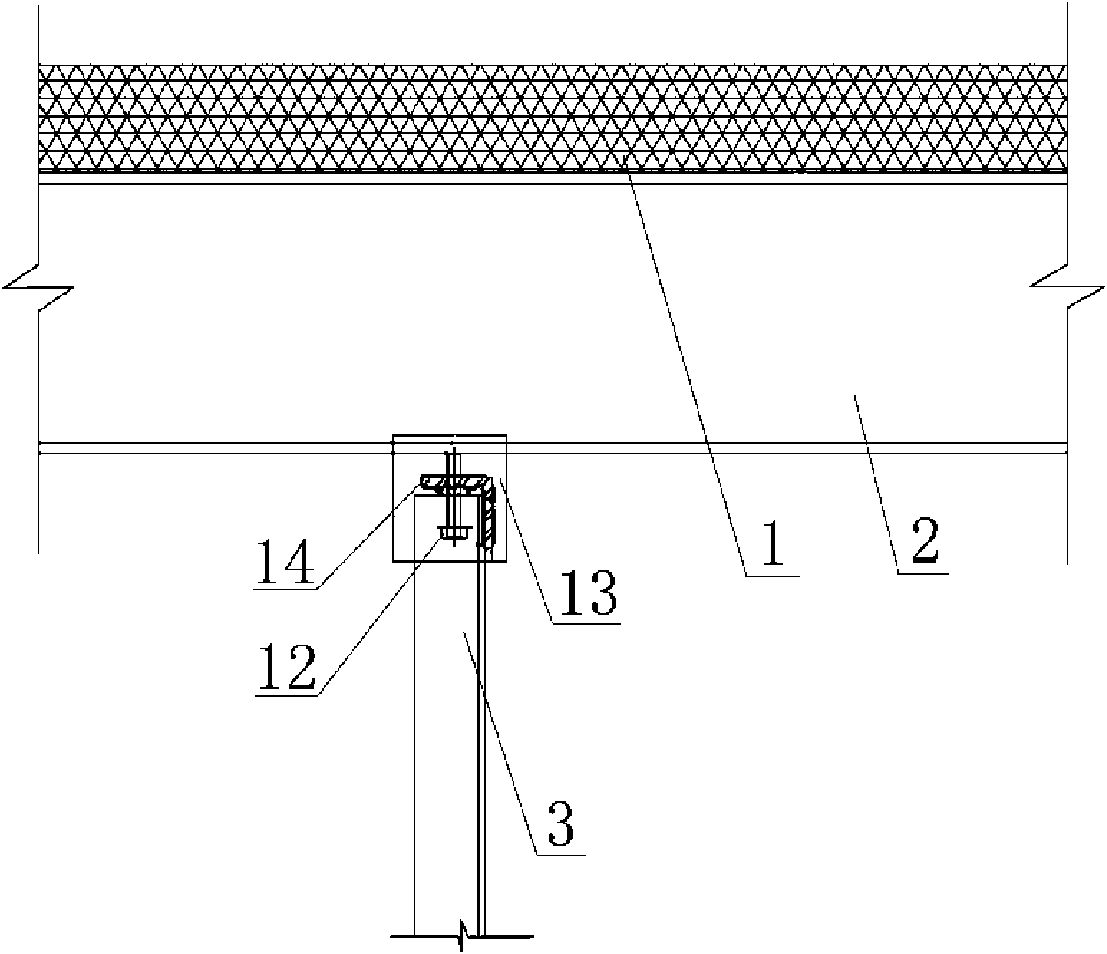

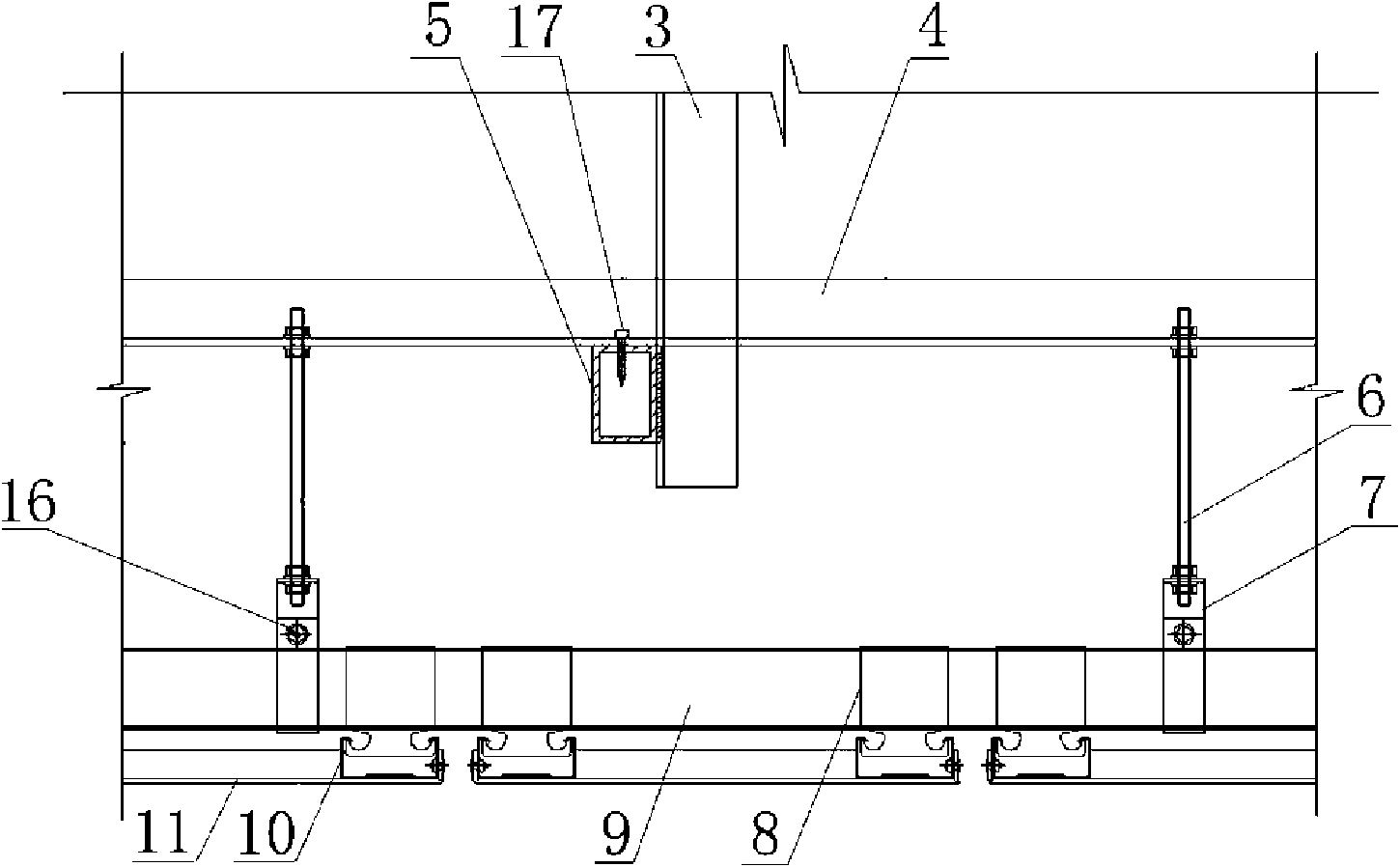

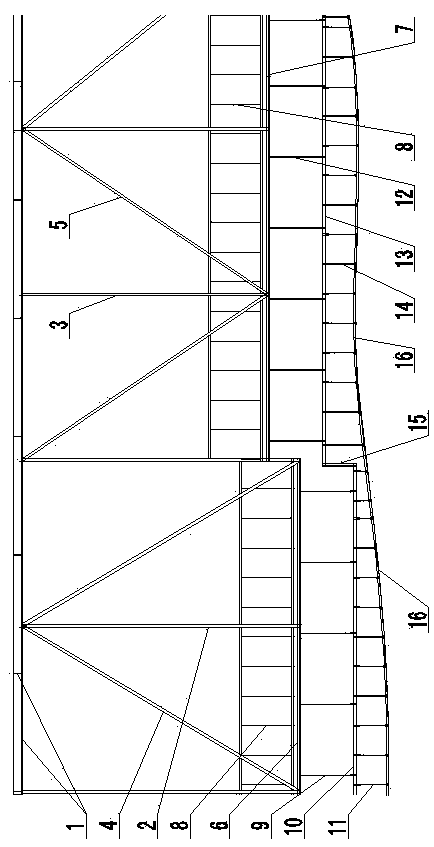

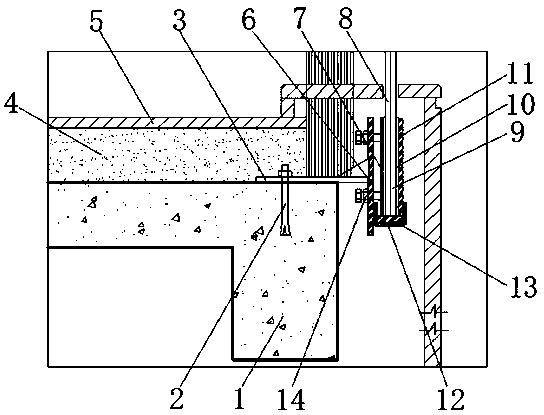

Large-area lower edge nested aluminum plate curved hung ceiling with high punching rate and construction method thereof

The invention provides a large-area lower edge nested aluminum plate curved hung ceiling with high punching rate and a construction method thereof. The bottom flange of an I-shaped steel beam is suspended and connected with a U-shaped fastener. The U-shaped fastener comprises a pair of main suspending angle steel and a piece of transverse angle steel connected between the two pieces of main suspending angle steel. The transverse angle steel is connected with an angle steel suspender in a T shape. The two pieces of main suspending angle steel of the U-shaped fastener are nested and connected to the upper surface of the bottom flange of the steel beam. The horizontal flange of the transverse angle steel thereon is provided with two circular holes. The lower end of each circular hole is welded with a nut. The upper end of a jackscrew passes through the nut and the circular holes and is pressed on the lower surface of the bottom flange of the steel beam. The lower end of the angle steel suspender is connected with a conversion layer steel frame, and the conversion layer steel frame is connected with a primary steel keel and a secondary steel keel in the shape of meshes and connected with a lightweight steel suspender, the lower end of the lightweight steel suspender is connected with a lightweight steel keel system by a hanger and a connecting bolt. The lightweight steel keel system is fixedly connected with a metal ceiling plate. The invention solves the technical problem of ceiling ultra-large space curved steel structure roof.

Owner:北京市建筑工程装饰集团有限公司

Manufacturing method of steel structure box girder

ActiveCN103639671AEasy to produceImprove quality and efficiencyArc welding apparatusWear resistantSpot welding

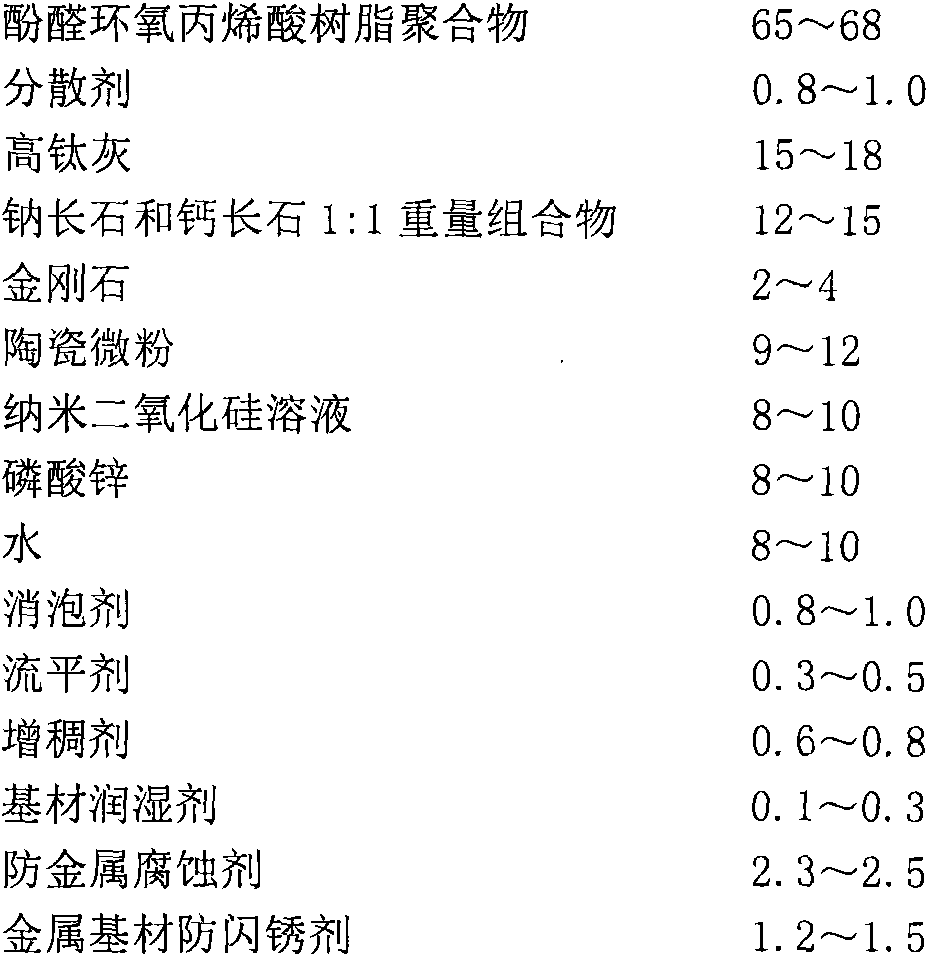

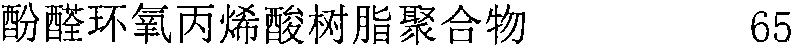

A manufacturing method of a steel structure box girder comprises steps as follows: 1), a computer is used for controlling sizes of a cover plate, webs, lining plates of the webs, a baffle and a lining plate of the baffle for blanking; 2), spot welding lining plates are assembled on back surfaces of grooves of the webs and the baffle respectively; 3), a bottom plate and the two webs are assembled into a U shape and welded on a box girder mould; 4), the baffle is placed and welded in a U-shaped groove; 5), the cover plate is assembled and welded on the U-shaped groove; and 6), the steel box girder is subjected to shot blasting and paint spraying, and paint adopts anticorrosive paint and comprises a component A and a component B. According to the steel structure box girder manufactured with the method, materials are saved, the production efficiency is improved, the integrally formed anticorrosive paint is corrosion-resistant and wear-resistant, and the requirement for inner wall coating of the steel structure box girder is met.

Owner:GUIZHOU LIHONG STEEL STRUCTURE

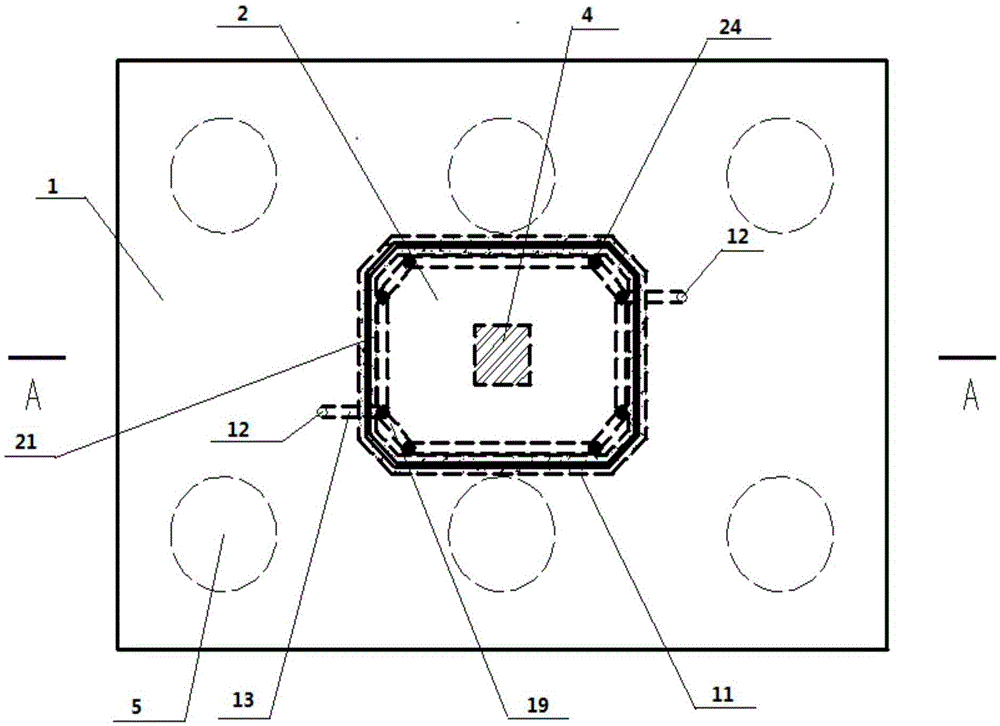

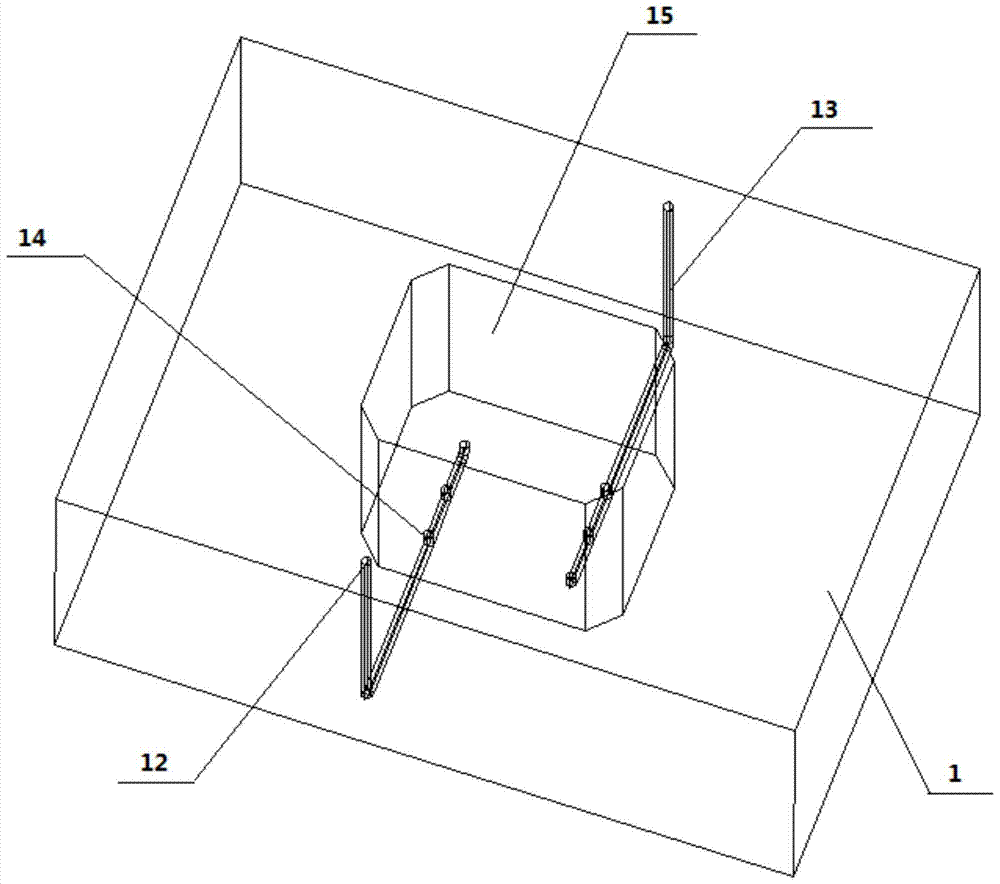

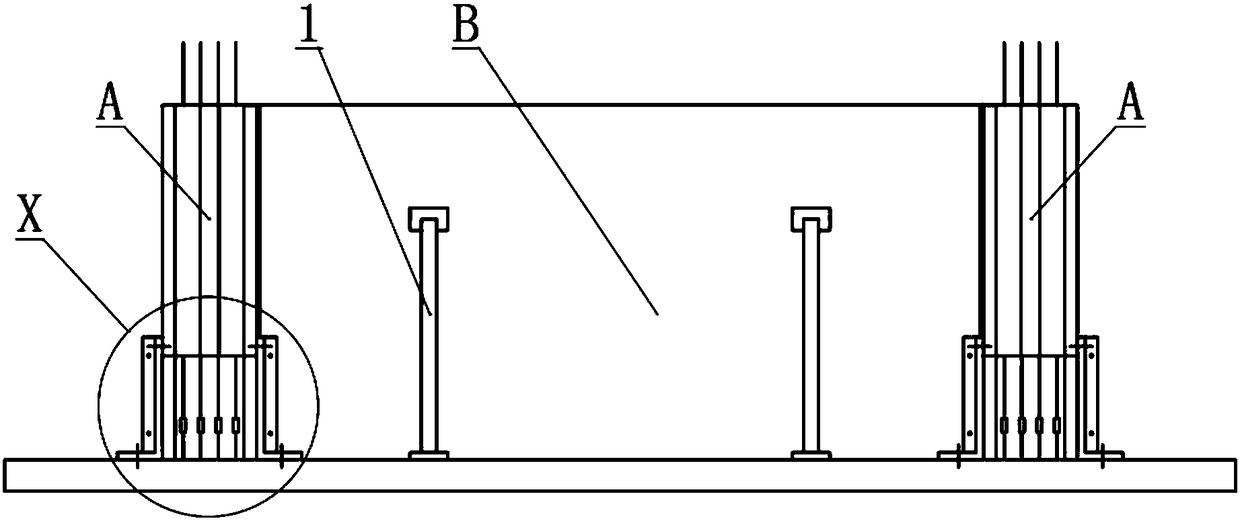

Prefabricated pier upright column, cushion cap spigot and insertion groove combined connection structure and splicing method

ActiveCN105421223AIncreasing the thicknessEnhance the strength of the embedded connectionBridge structural detailsBridge erection/assemblyRebarUltimate tensile strength

The invention discloses a prefabricated pier upright column, cushion cap spigot and insertion groove combined connection structure which comprises a prefabricated upright column and a cushion cap. The upright column comprises an exposed end and an embedded end, a plurality of steel ribs are embedded in the upright column, and the steel ribs extend from the bottom end of the upright column by a certain length to form free ends; an upright column installation hole groove is formed in the vertical direction of the cushion cap, and a plurality of steel rib insertion grooves are formed in the bottom of the upright column installation hole groove; the section shape and the size of the upright installation hole groove are matched with the section shape and the size of the embedded end of the upright column so that the embedded end of the upright column can be embedded into the upright column installation hole groove, and the number, the setting positions and the depths of the steel rib insertion grooves are matched with the number, the setting positions and the lengths of the free ends of the steel ribs so that the free ends of the steel ribs can be embedded in the steel rib insertion grooves. The embedded and fixed connection strength between the upright column and the cushion cap are enhanced in the mode that the number of the steel ribs extend from the bottom of the upright column is increased and the steel ribs are matched and connected with the steel rib insertion grooves of the cushion cap so that increase of the thickness of the cushion cap can be avoided when the section area of the upright column is large, bridge manufacturing materials are saved, and cost is reduced.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

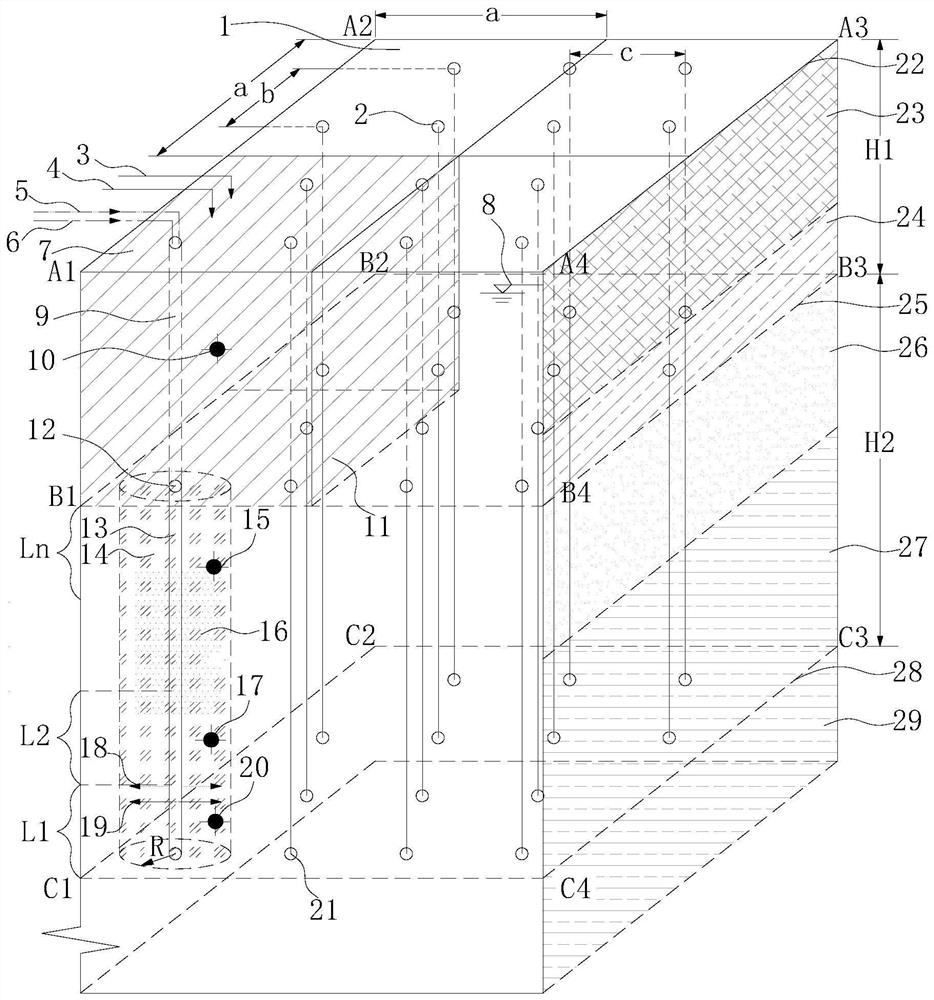

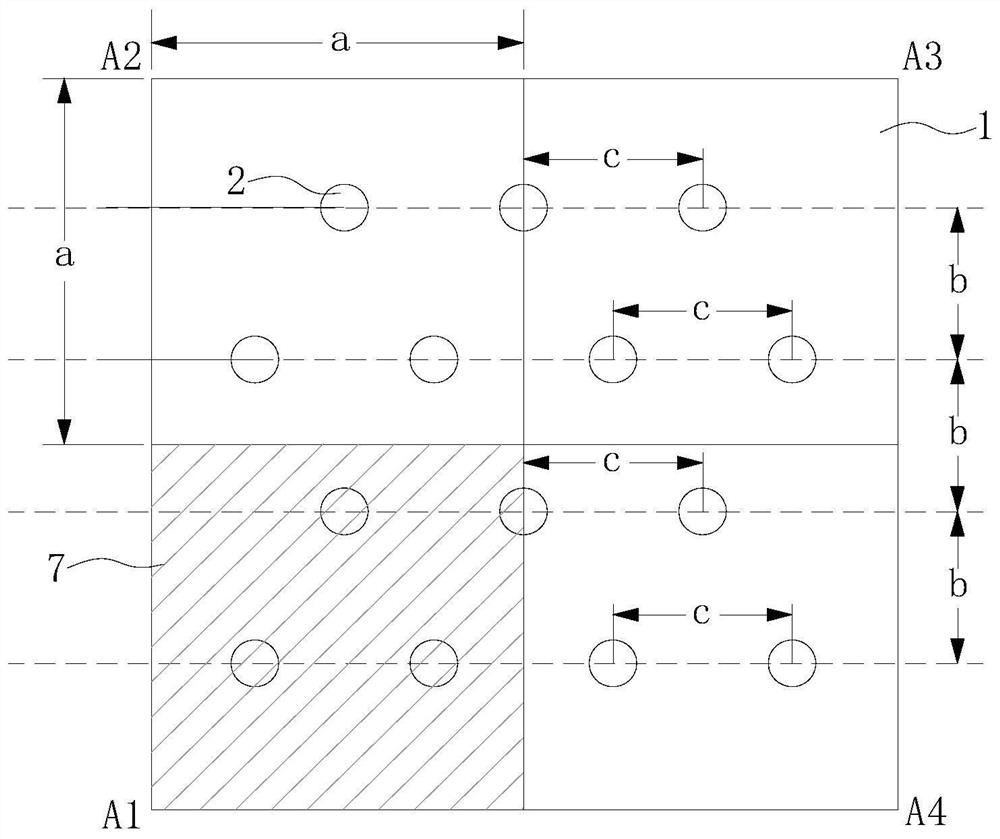

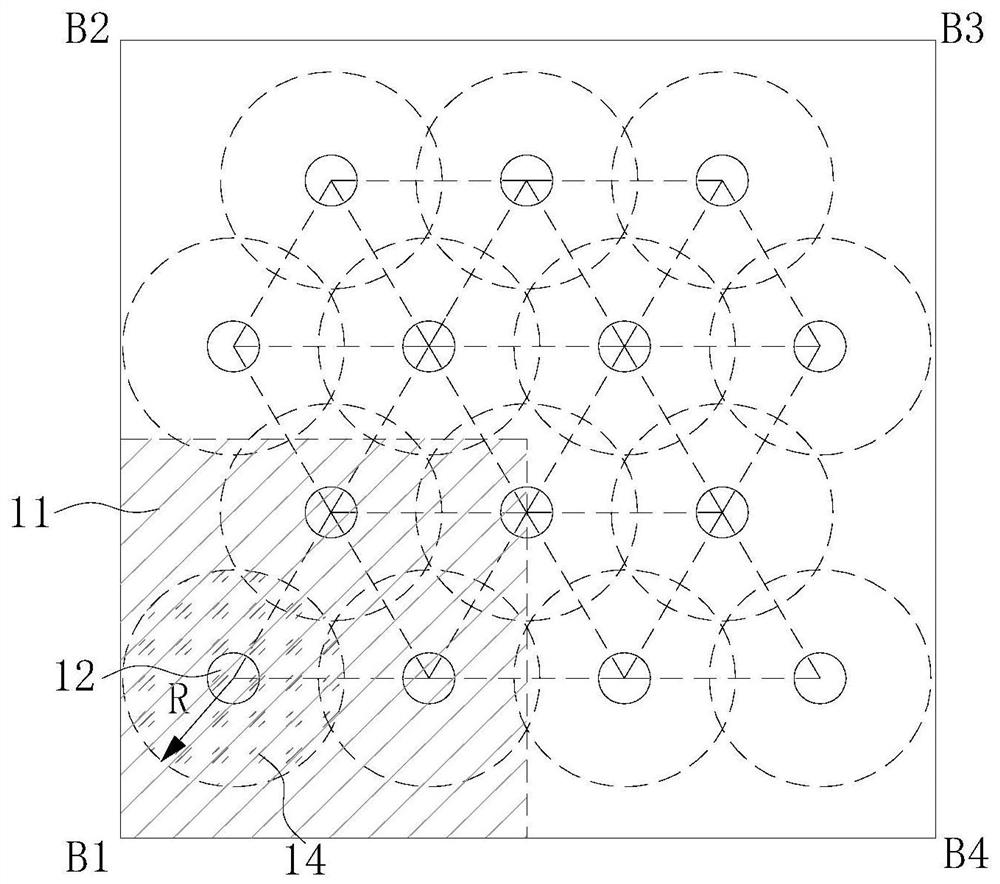

High-pressure jet grouting and shallow-layer stirring combination in-situ remediation method for soil and underground water

ActiveCN106799396AQuick and easy on-site installationEasy to operateContaminated soil reclamationIn situ remediationInjection point

The invention provides a high-pressure jet grouting and shallow-layer stirring combination in-situ remediation method for soil and underground water and belongs to the technical field of soil and underground water in-situ remediation methods. The combination in-situ remediation method comprises the following steps: distributing high-pressure jet grouting in-situ injection points, and carrying out measurement, locating and pre-boring; carrying out the high-pressure jet grouting injection of a deep layer in one to three times; carrying out the in-situ stirring of a shallow layer in one to two times; carrying out agent reaction and underground water monitoring; and carrying out self-inspection and acceptance. Agents which are injected for high-pressure jet grouting injection in three times are sequentially C+N1+N2, K and K+B. Agents which are added for the in-situ stirring of the shallow layer are C+F+N1+N2. The highest adding ratio of part of the high-pressure jet grouting injection of the deep-layer zone is as follows: the agent C accounts for 1.6-2.4%, and the agent K accounts for 1-5.4%. Being used as the remediation solution of an organic pollution engineering with sporadic pollution spots in part of severe soil and underground water plots, the remediation method has the advantages of being short in construction period, being great in effect and being capable of adapting to various strata and is used as an important technical means for replenishing remediation.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

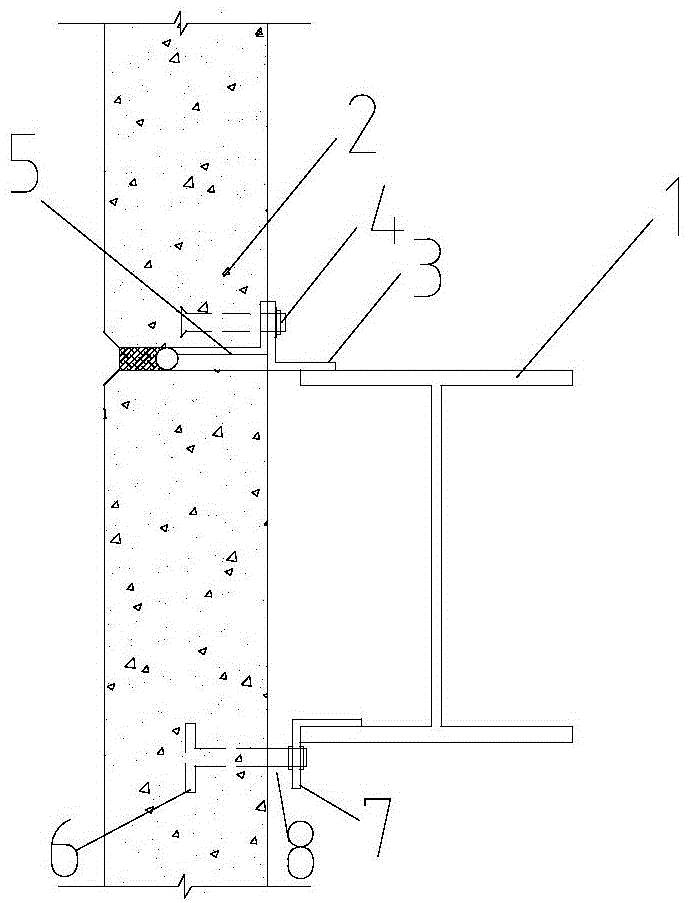

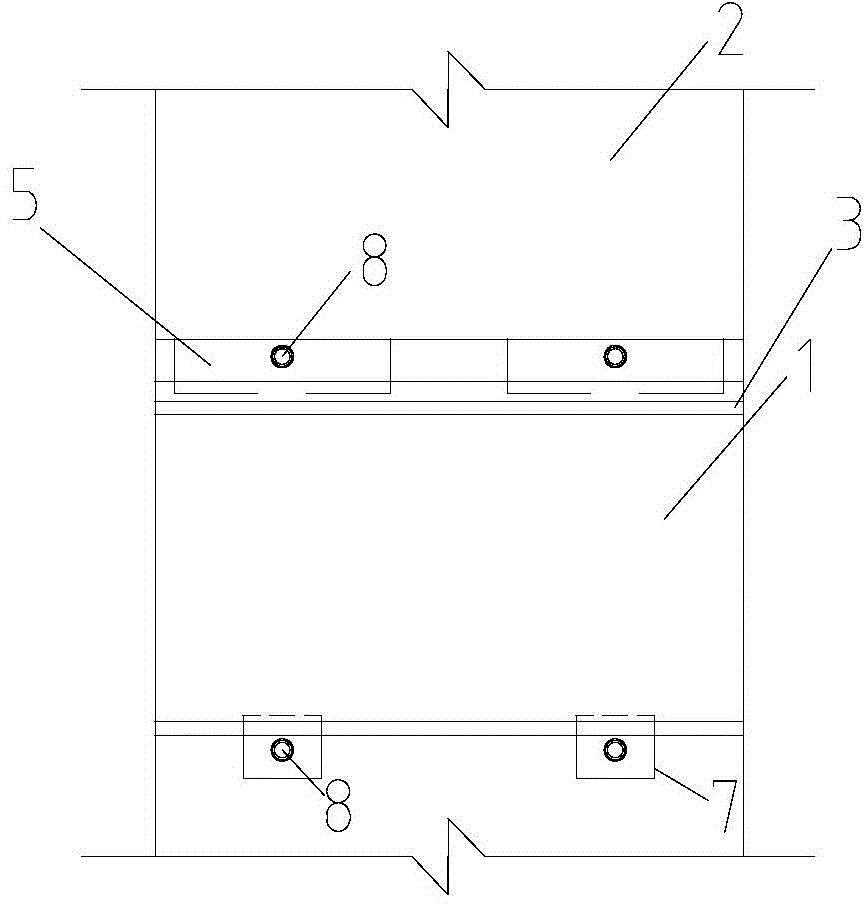

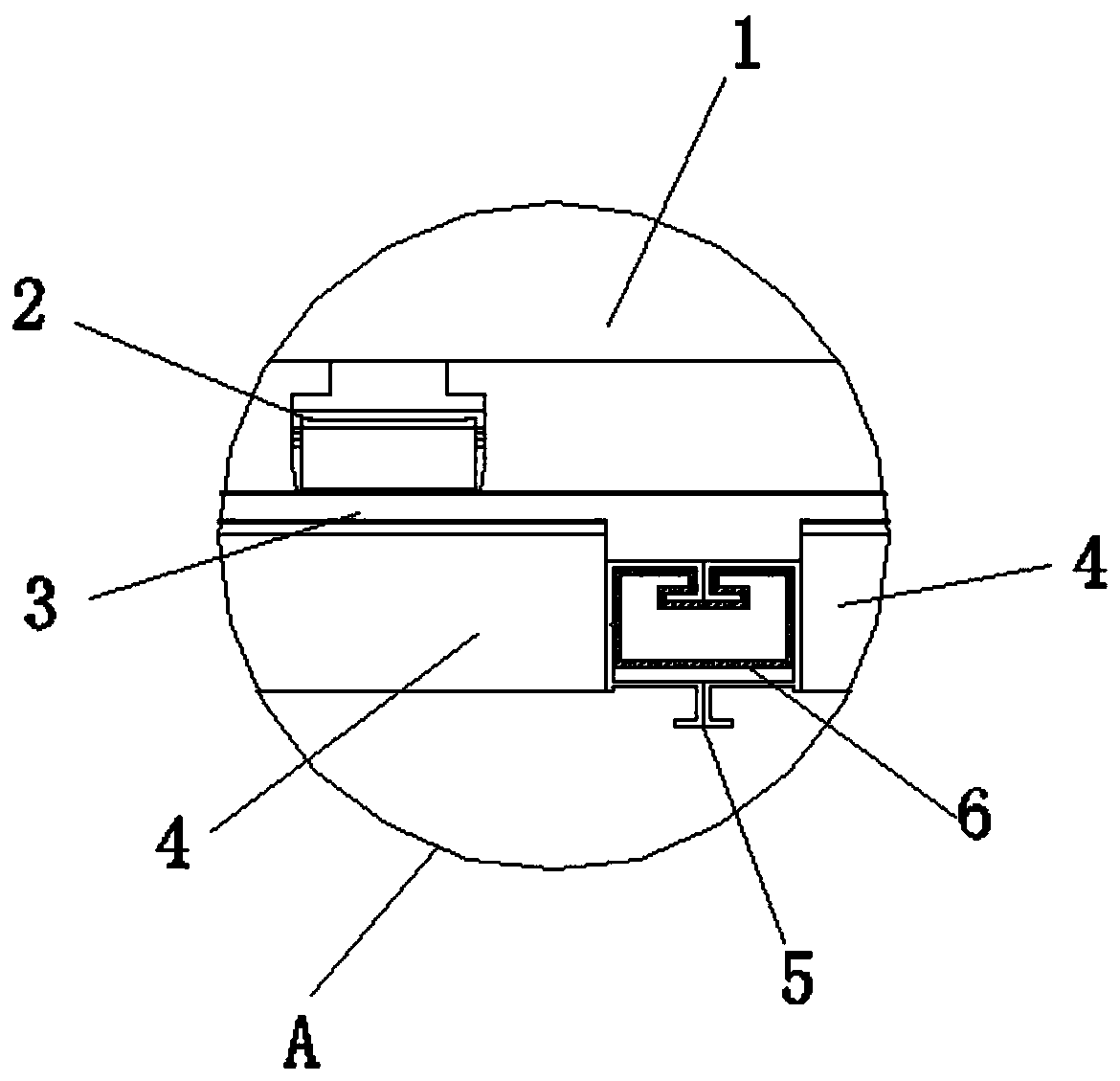

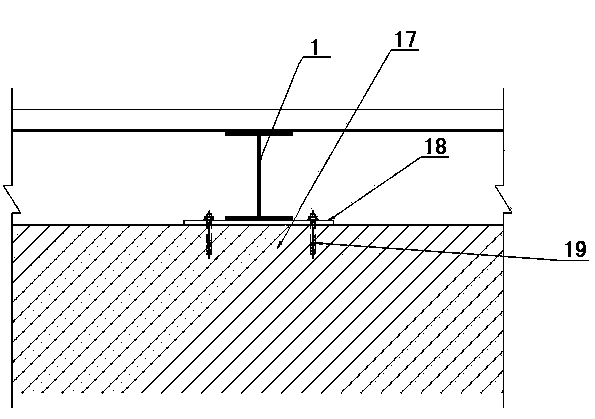

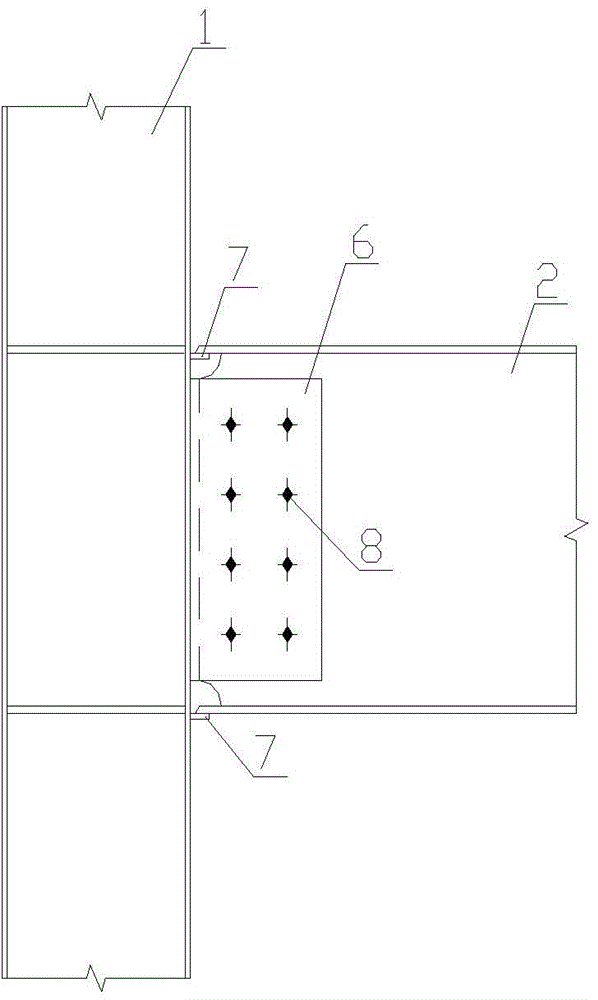

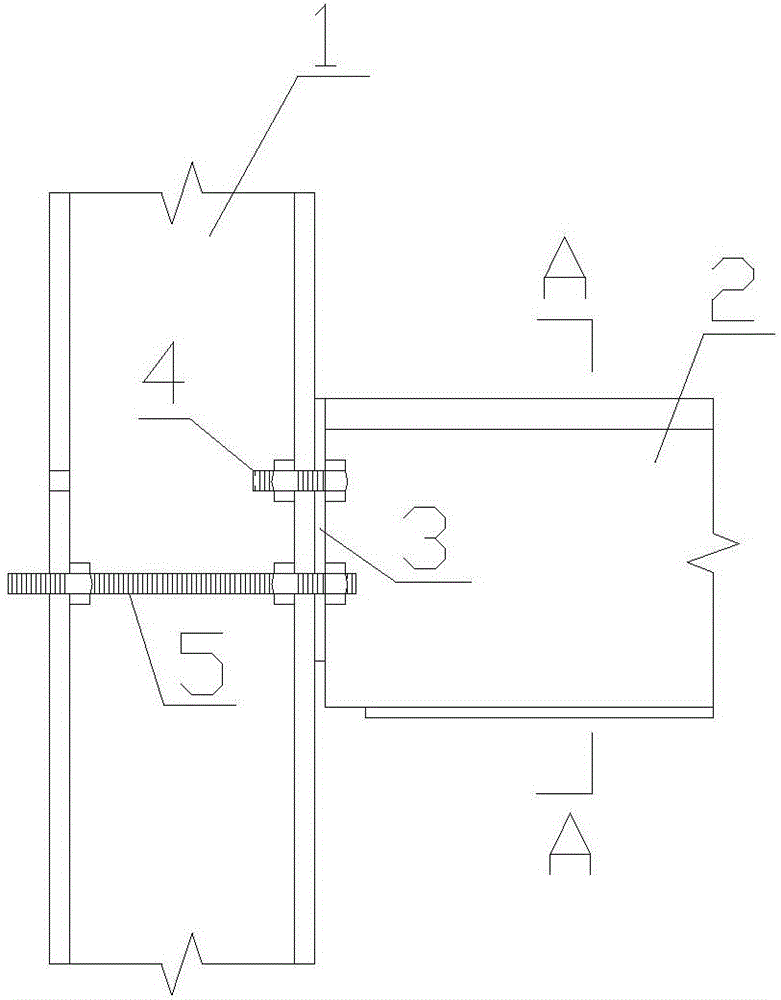

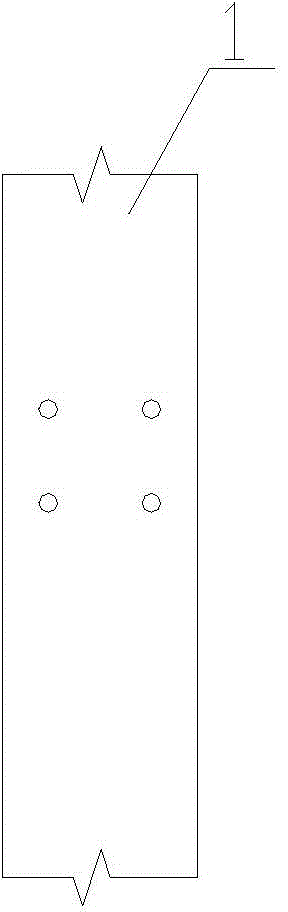

Connection structure of fabricated steel structure building enclosure outer wall and H-shaped steel beam

Disclosed is a connection structure of a fabricated steel structure building enclosure outer wall and an H-shaped steel beam. The connection structure of the fabricated steel structure building enclosure outer wall and the H-shaped steel beam is characterized in that the lower end of an outer wall board is fixedly connected with the top flange of the H-shaped steel beam by welding a steel angle on the top flange of the H-shaped steel beam, welding a support board on the reverse side of the steel angle, placing the lower edge of the outer wall board on the support board, and fixedly connecting the lower end of the outer wall board, the support board and the steel angle into a whole through high strength friction type bolts A embedded in the outer wall board, and the upper portion of the outer wall board is fixedly connected with the bottom flange of the H-shaped steel beam by welding a steel angle connection piece on the bottom flange of the H-shaped steel beam, fixedly connecting the upper portion of the outer wall board and the steel angle connection piece into a whole through a bolt B embedded in the outer wall board, arranging a steel cap at the end of the high strength friction type bolt B, placed in the outer wall board, and setting the distance between the other end of the high strength friction type bolt B, stretched out of the outer wall board, and the steel angle connection piece as 30mm. The connection structure of the fabricated steel structure building enclosure outer wall and the H-shaped steel beam has the advantages of being strong in shear resistance capacity, good in shock resistance performance, needless of a cold and hot bridge, and convenient and quick to install at site, enabling a wall body to move along with a steel frame and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

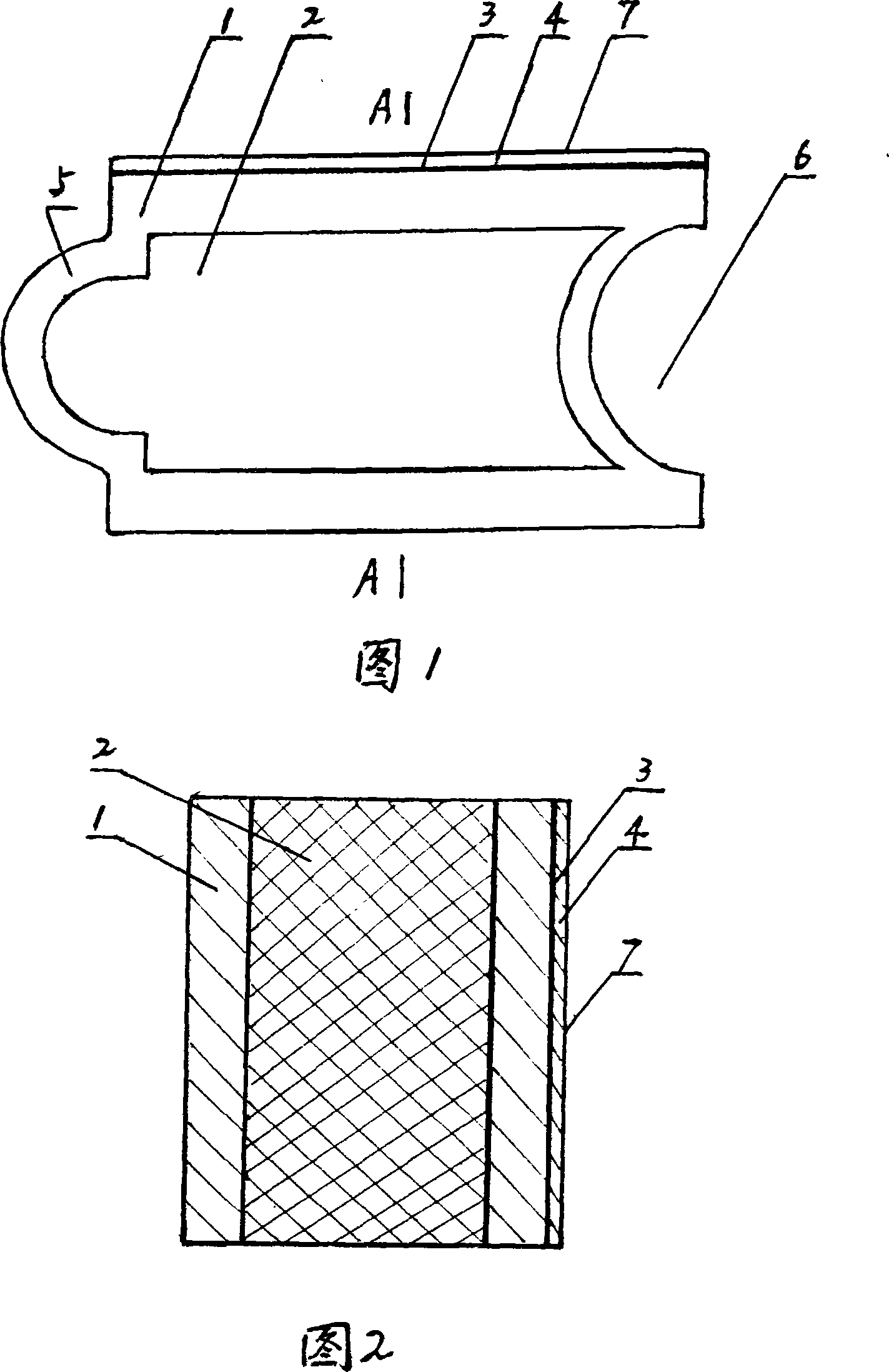

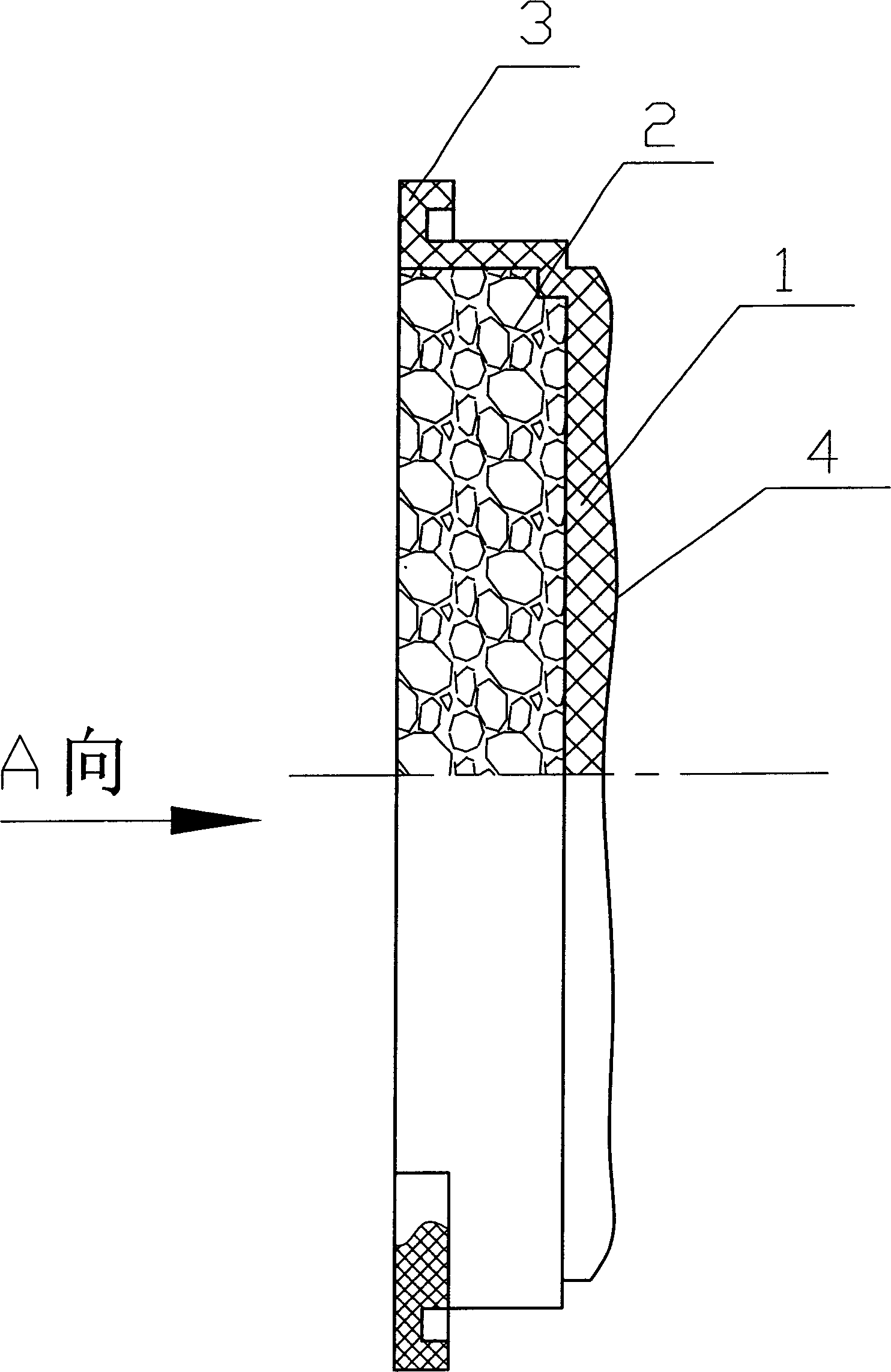

Thermal insulation decorative brick and producing method thereof

InactiveCN101168983AGood heat insulationFast constructionConstruction materialCeramic shaping apparatusEngineeringSurface layer

The invention relates to an insulation facing tile, and a production method thereof. The insulation facing tile is characterized in that the hollow tile is made of the low weight insulation material, either the left side or the right side of the hollow tile is produced to be raised head shaped, the other side is produced to be a groove shape which can be put into the raised head, the hollow part of the hollow tile is filled with an insulation body made of the insulation material and tightly combined with the inner surface of the hollow tile, and a colored ornament surface is adhered on an adhesive layer on the outer surface of the hollow tile. The ornament surface of the tile is directed outward, the raised head of another tile is inserted into the groove and leveled, and the joint is filled with insulation mortar, to form an outer wall. The tile integrates three construction processes of a wall enclosure structure, an insulating layer, and the ornament surface layer together, the on-site installation is simple, convenient, and quick, the quality is easy to be ensured, with safety and reliability, and crack, falling off, cold bridge, alkali resistance and molding of the outer wall surface are avoided; the requirements on energy conservation, environmental protection and aesthetic appearance are met, and the insulation effect is good; the invention can replace a hollow tile, an outer wall insulation adhesive ornament surface and an invention ornament plate.

Owner:薛井生

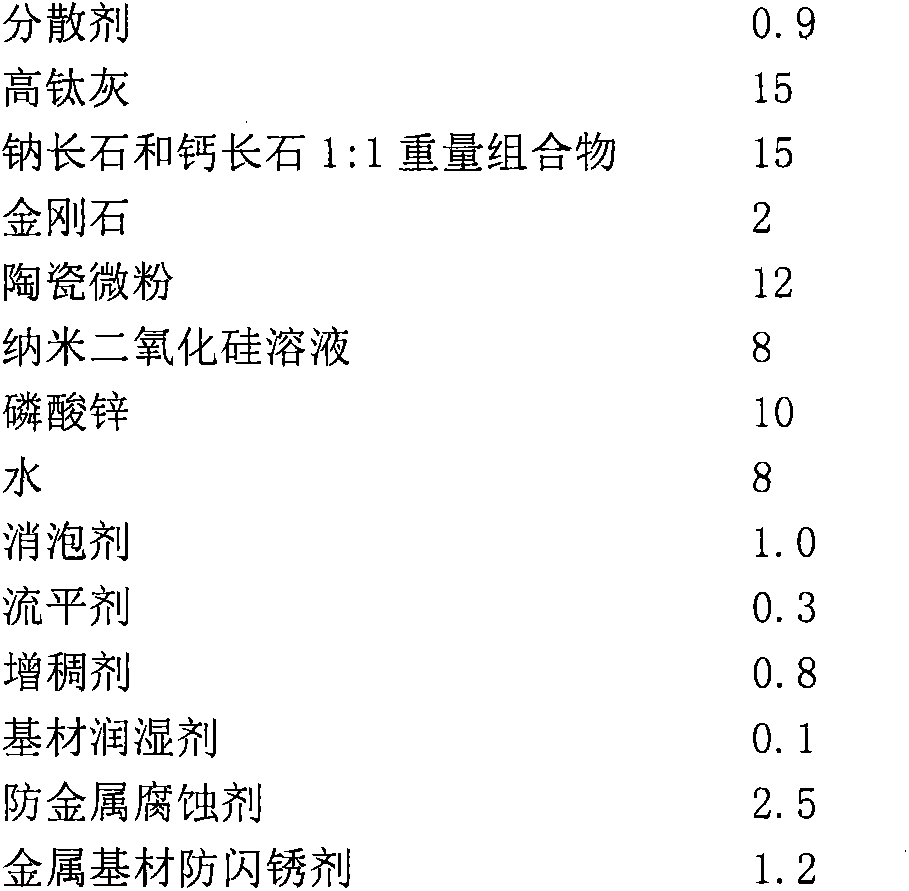

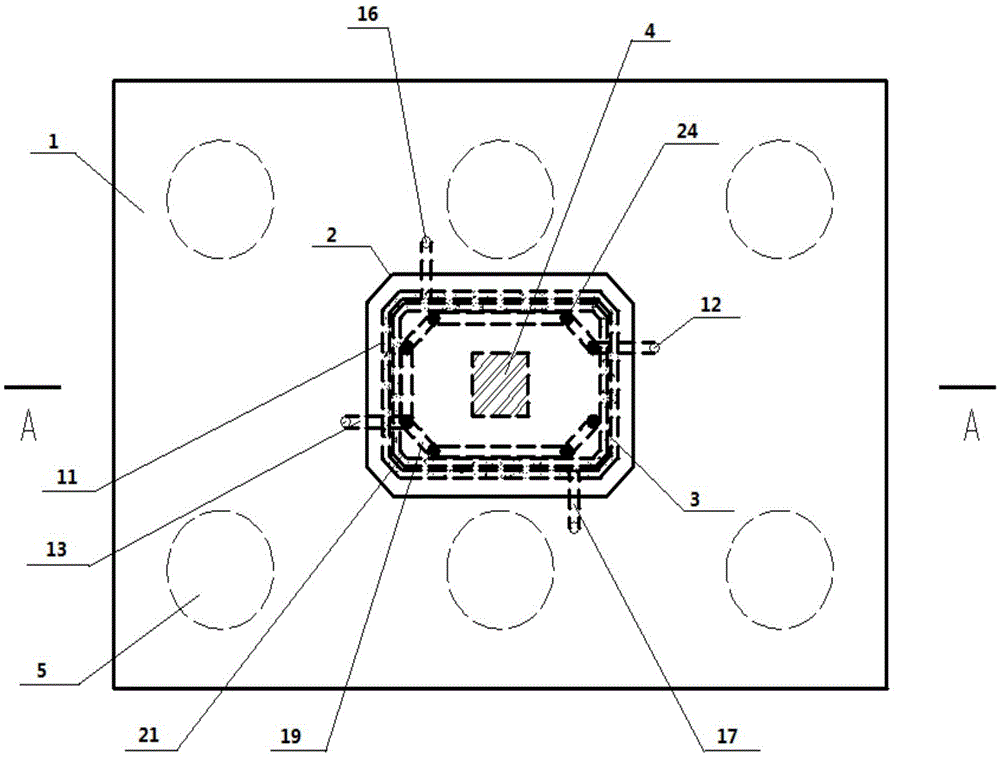

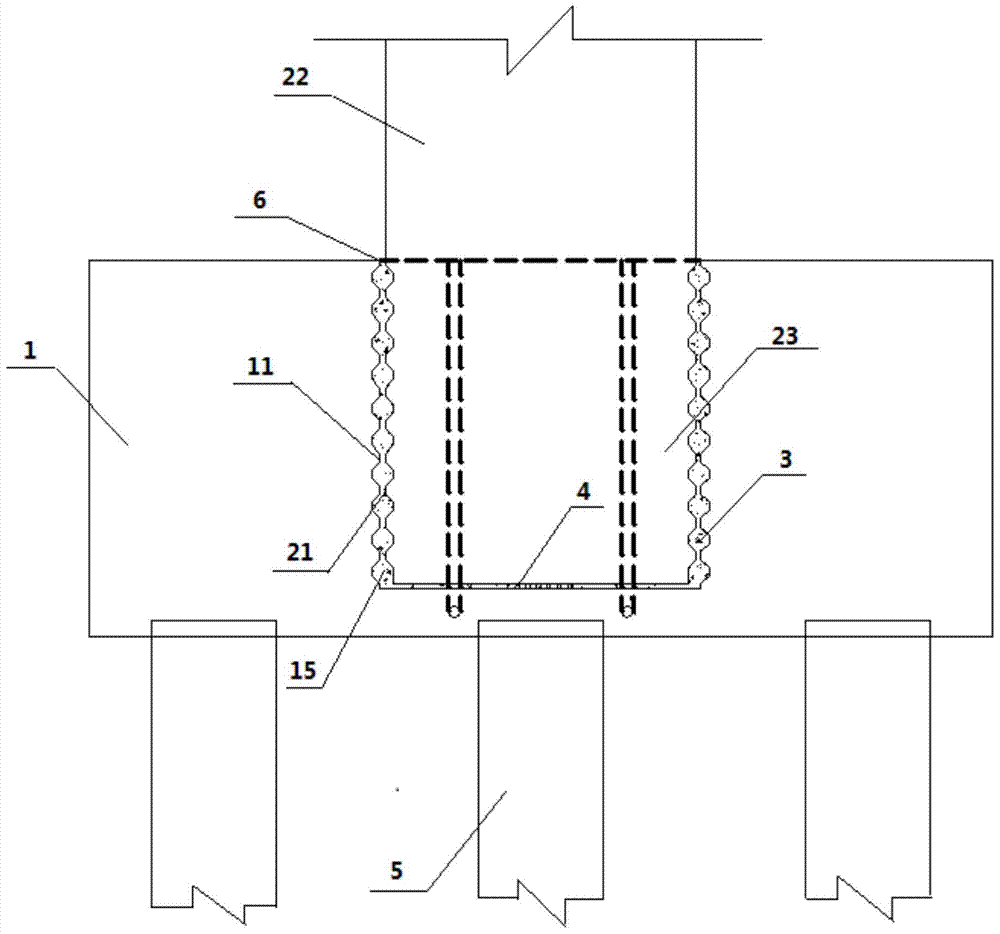

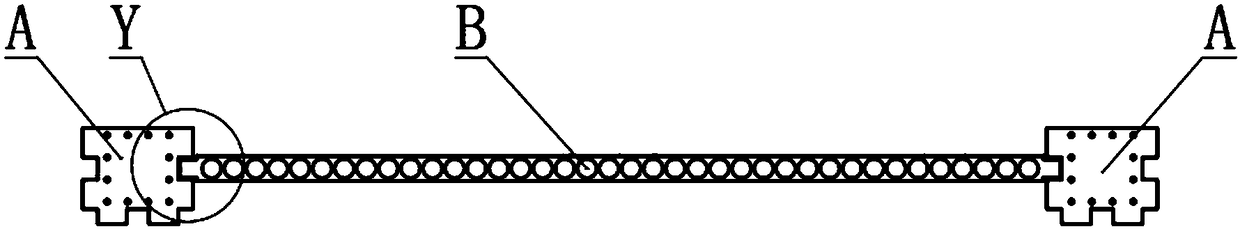

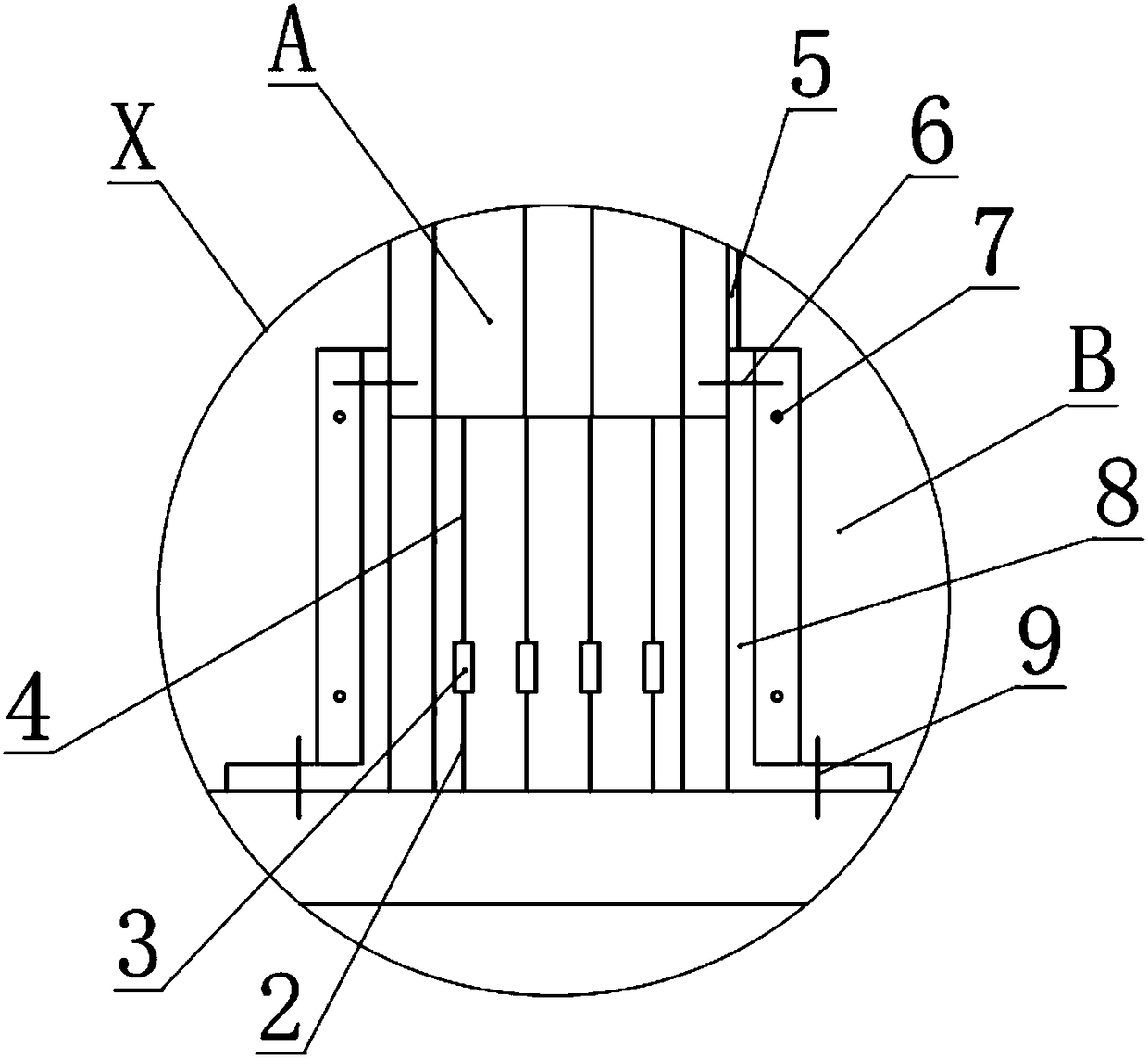

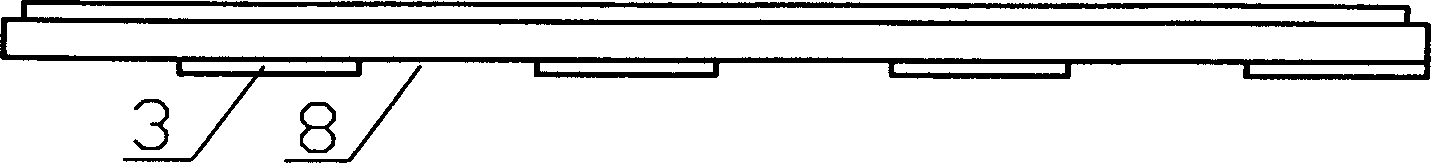

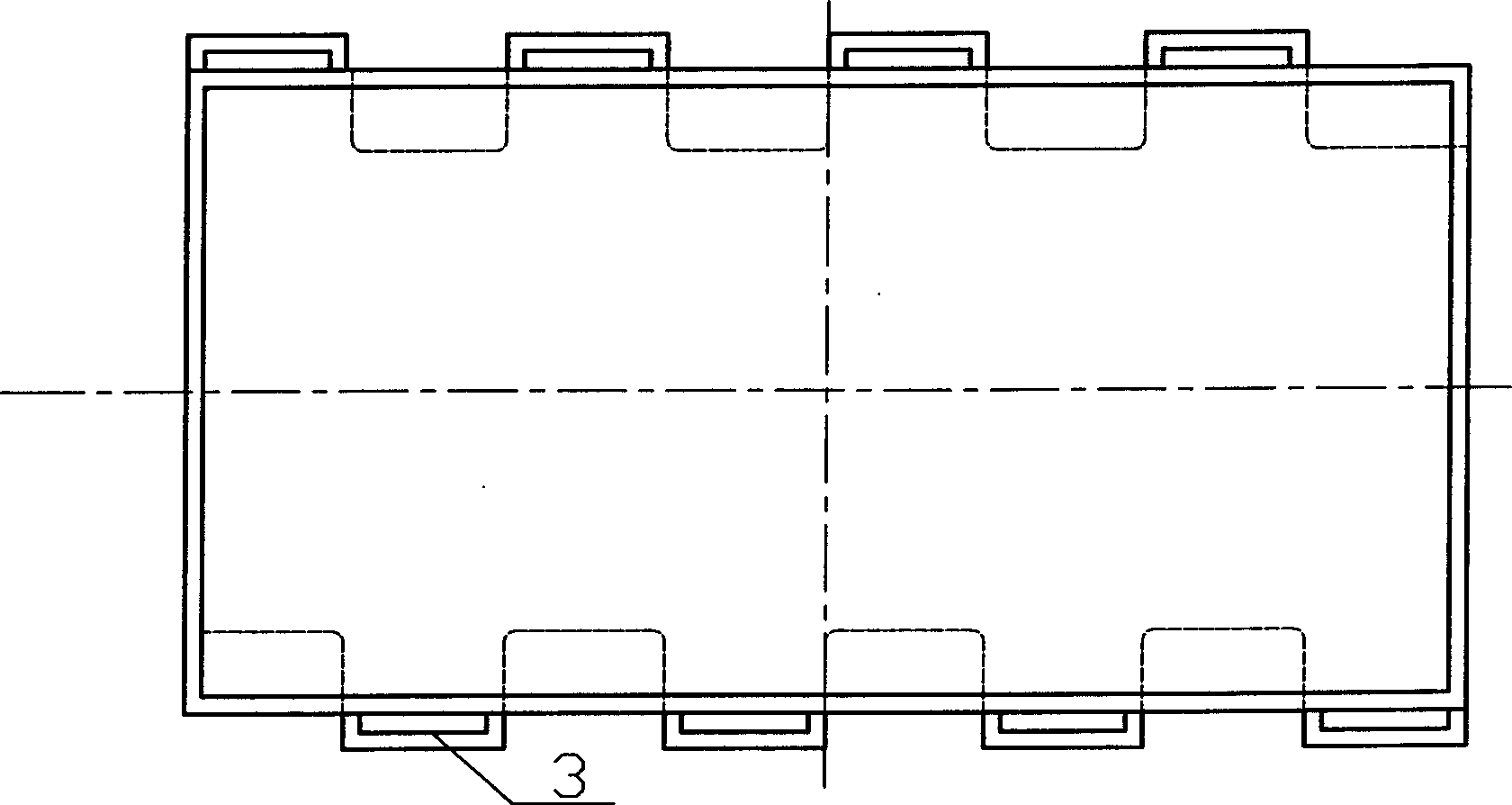

Refrigerated container combined refrigeration house

InactiveCN102889010AEasy to install on siteQuick and easy on-site installationHeat proofingBuilding insulationsThermal insulationApplication areas

The invention discloses a refrigerated container combined refrigeration house belonging to the technical field of a container. According to the combined refrigeration house, a sealing space is formed by splicing two container units with single-side wall boards, or a sealing space is formed by splicing the two container units with the single-side wall boards and at least one container unit without the side wall board; the container units without the lateral wall board are arranged between the container units with the single-side wall boards, connection devices are respectively connected between two adjacent top angle pieces (11) and two adjacent bottom angle piece (15) between the container units; a gap between the adjacent container units is 5-80mm; and thermal insulation sealing devices are respectively arranged in gaps among the two top beams (4), the two bottom beams (10) and two angle posts (21) of the adjacent container units. The refrigerated container combined refrigeration house provided by the invention has the advantages of being reasonable and simple in structure, easy in production assembly, good in intensity, economical and practical, and convenient to transport, manufacture, assemble and use, enlarging the application field of the refrigerated container, and having a high cost performance.

Owner:YANGZHOU TONGLEE REEFER CONTAINER

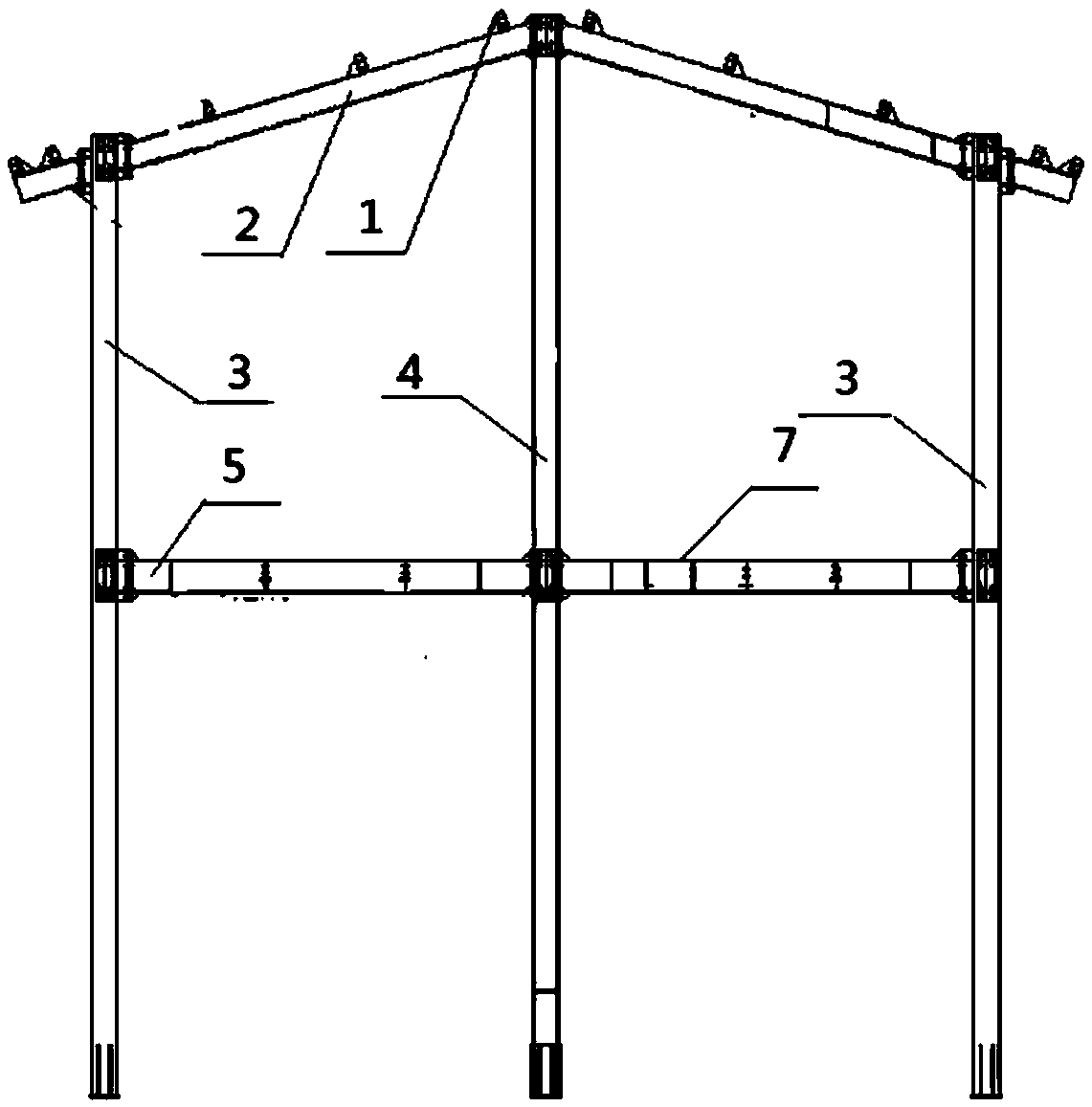

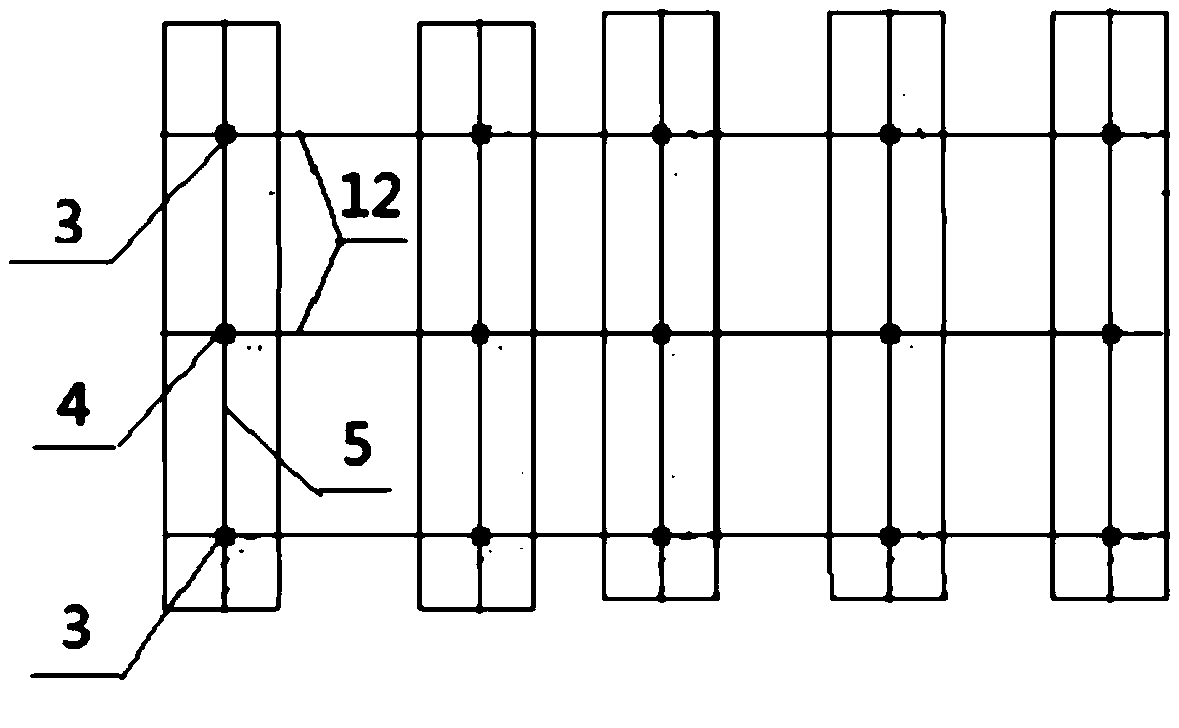

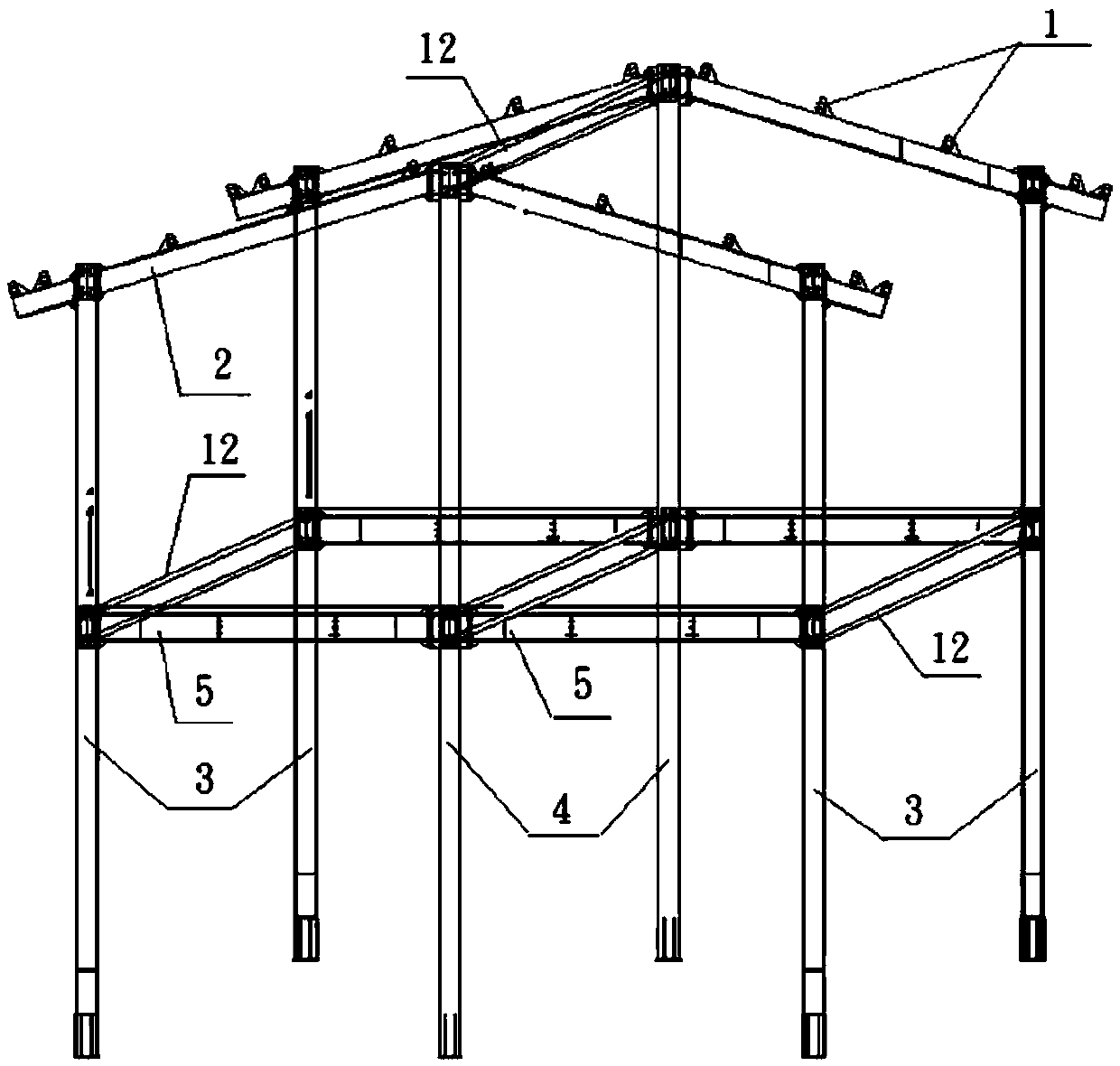

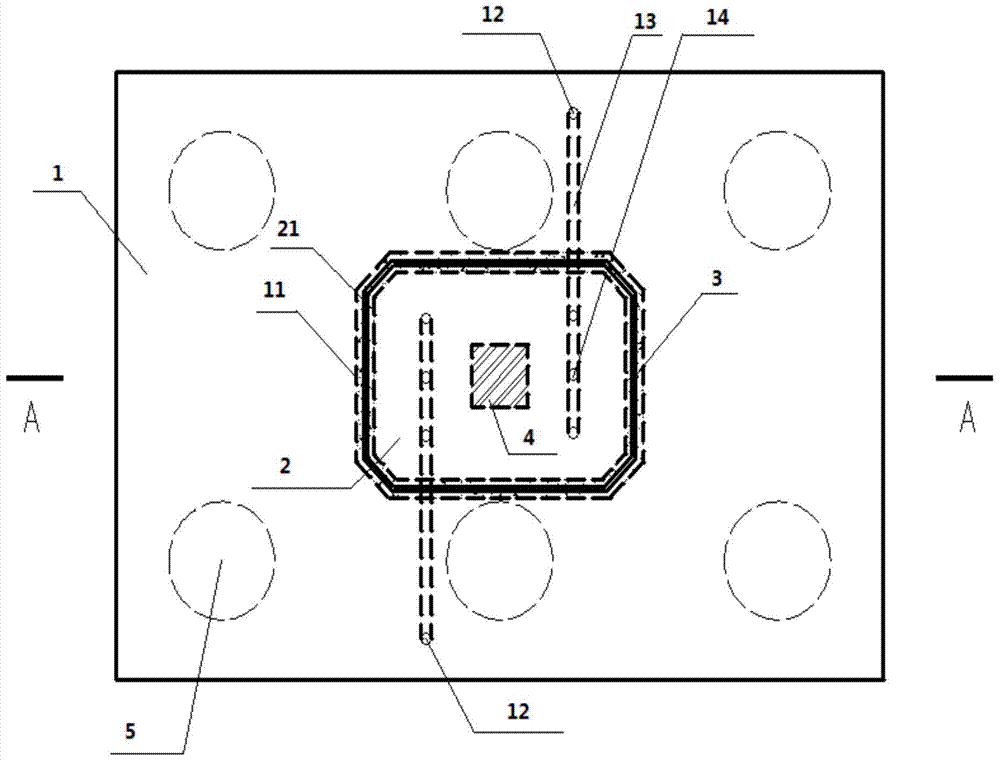

Earthquake-proof folk house steel framework and installation method thereof

The invention discloses an earthquake-proof folk house steel framework and an installation method thereof. The earthquake-proof folk house steel framework comprises a plurality of beam and column integration units, and a plurality of horizontal floor support plate integration units; each beam and column integration unit comprises two roof beams in lap joint to form a herringbone shape, a middle column in lap joint between the two roof beams and downwards extending, edge columns respectively in lap joint with the edge parts or the end parts of the two roof beams and downwards extending, and horizontal cross beams in lap joint between the middle column and the edge columns and perpendicular to the middle column and the edge columns; the beam and column integration units are arranged side by side at intervals according to the length of a built house; the beam and column integration units are connected through a plurality of horizontal longitudinal beams; the horizontal floor support plate integration units are arranged on a rectangular frame formed by the horizontal cross beams and the horizontal longitudinal beams; and the horizontal floor support plate integration units comprise baseplates, skeletons arranged on the baseplates at intervals, and concrete filled between the upper sides of the baseplates and the skeletons. The earthquake-proof folk house steel framework is convenient and fast in field installation, high in efficiency, high in installation precision, short in construction period, safe and reliable, effectively saves both manpower and material resources, and has a better operability.

Owner:云南昆钢钢结构股份有限公司

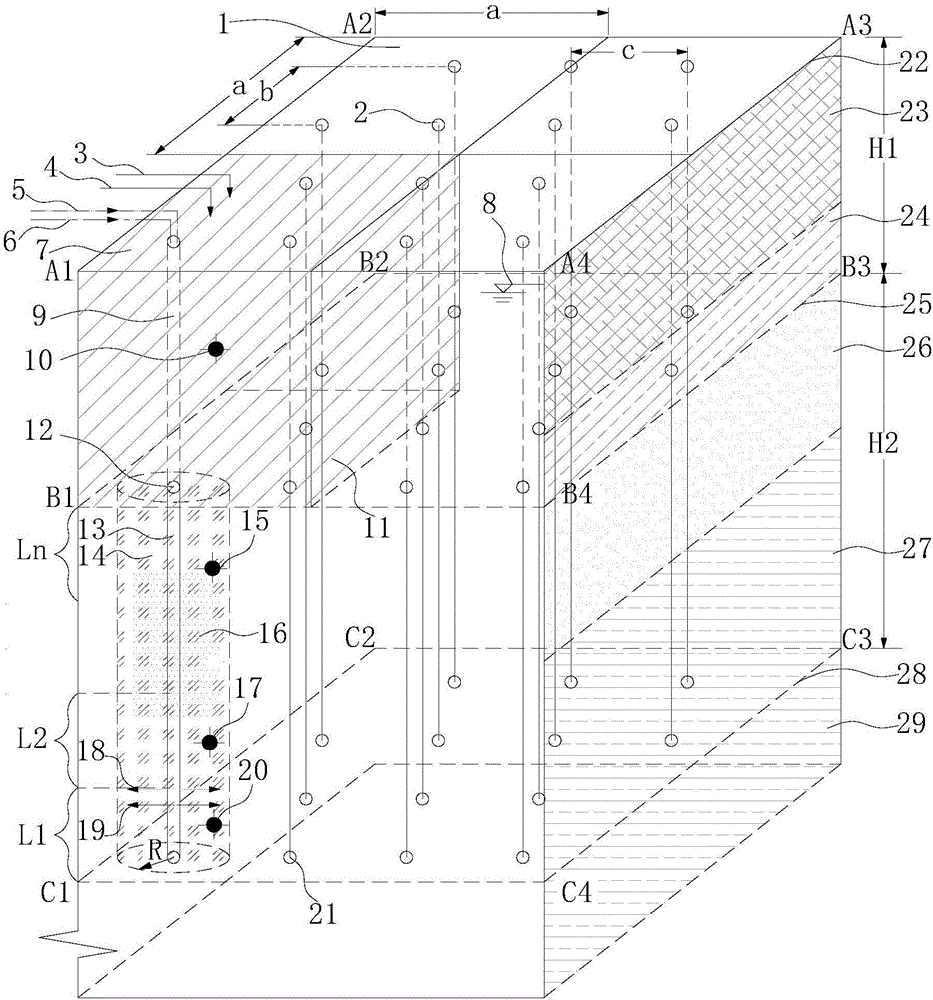

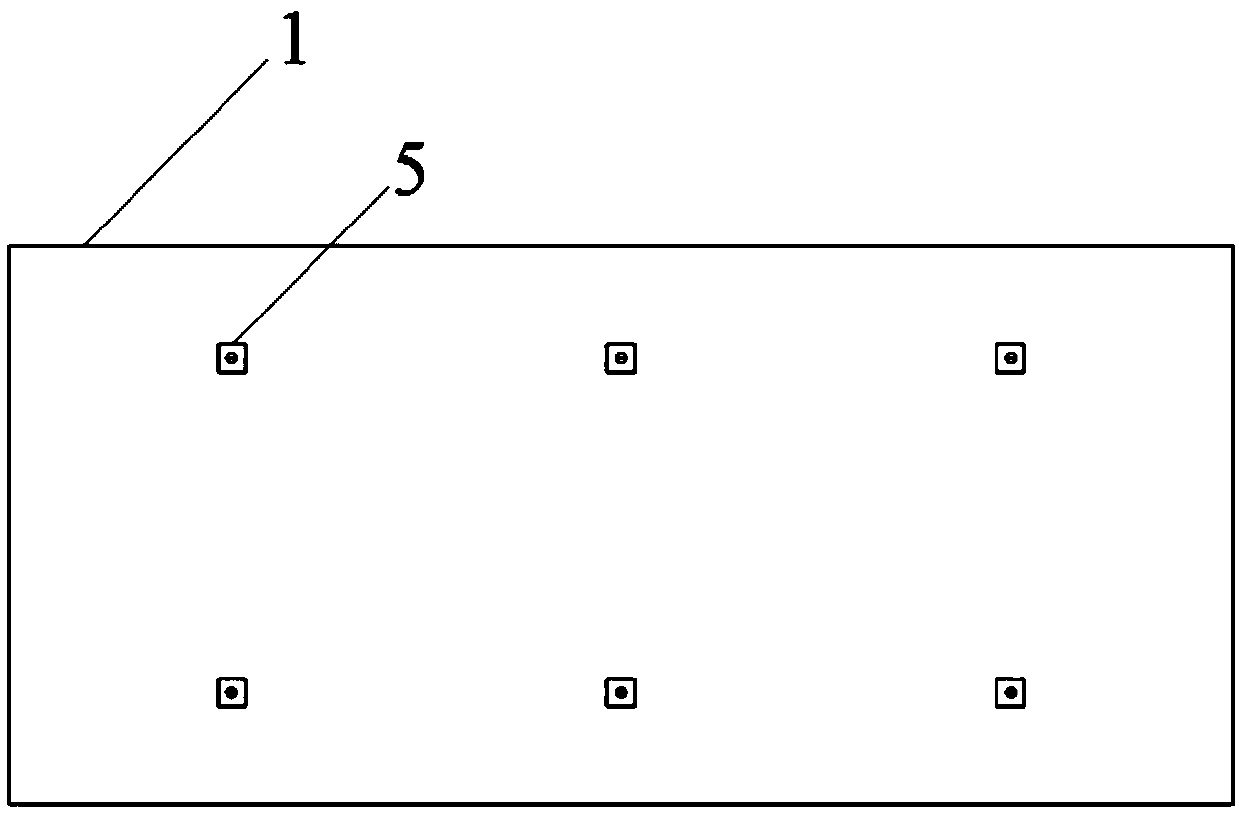

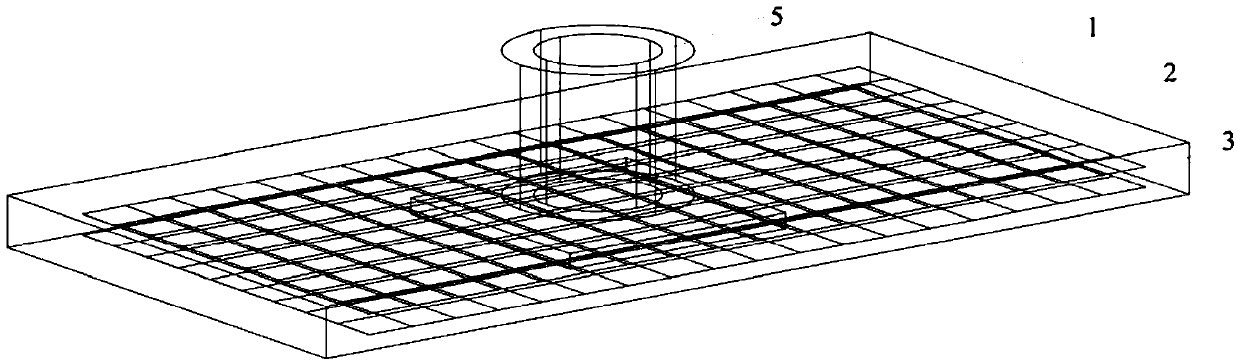

Cast-in-place skeleton net hollow filler wall

InactiveCN102758492AIncreased out-of-plane stiffnessLess materialWallsHeat proofingStructural engineeringMaterials science

The invention discloses a cast-in-place skeleton net hollow filler wall which comprises a skeleton net (1). A cast-in-place surface layer (4) and a seal surface layer (5) are arranged at outer ends of two sides of the skeleton net (1) respectively, and vertical ribs (2) and horizontal ribs (3) are sequentially arranged between the skeleton net (1) and the cast-in-place surface layer (4). According to integration of economic indicators and construction periods, the cast-in-place skeleton net hollow filler wall has an advantage over an existing air-entrapping concrete building block filler wall and a hollow internal mold metal net cement internal partition wall, has the advantages of being high in industrialized production degree and simple in site operation process, and overcomes the shortcomings in the prior art.

Owner:贵州皆盈科技开发有限公司

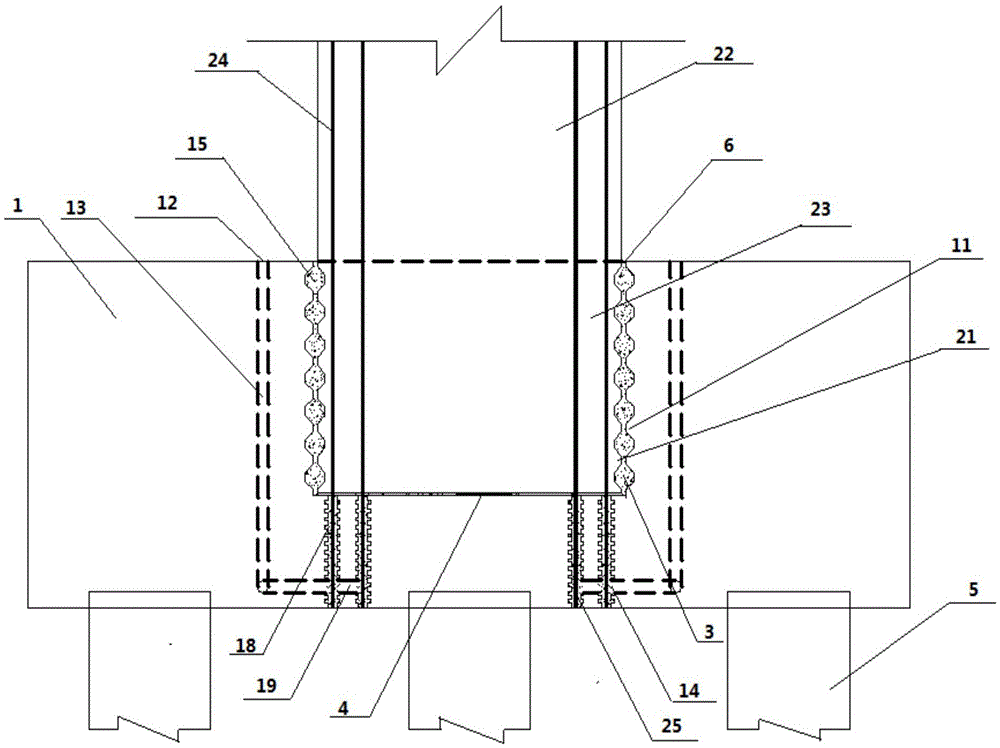

Bridge prefabricated pier column and cap socket socket connection structure and its assembly method

ActiveCN105421222BOn-site construction positioning accuracy requirements are lowIncrease redundancyBridge structural detailsBridge erection/assemblyJoints typesRebar

The invention discloses a socket and spigot joint type connection structure for a bridge prefabricated pier stand column and a bearing platform. The structure comprises the stand column and the bearing platform, the stand column comprises an exposed end and an embedded end, the bearing platform is provided with a stand column installing groove in the vertical direction, the cross section shape and the size of the stand column installing groove are matched with the cross section shape and the size of the embedded end so that the stand column can be embedded in the stand column installing groove, and the gap between the outer wall of the embedded end of the stand column and the inner wall of the stand column installing groove is greater than or equal to 2 cm; mud jacking holes are formed in the top face of the bearing platform, first mud outlets are formed in the bottom face of the stand column installing groove, and a mud jacking channel is formed between each mud jacking hole and the corresponding first mud outlet. The invention discloses a splicing method of the socket and spigot joint type connection structure. According to the socket and spigot joint type connection structure for the bridge prefabricated pier stand column and the bearing platform and the splicing method of the socket and spigot joint type connection structure, it is not needed to pre-bury a large number of pre-buried parts in the prefabricated stand column or the bearing platform, the positioning accuracy requirement for site operation is low, the adjusting redundancy is large, and requirements for construction machinery and the like are not high; site steel bar binding and welding and large-scale concrete pouring work are not needed, and site installation is fast, convenient and small in working load.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

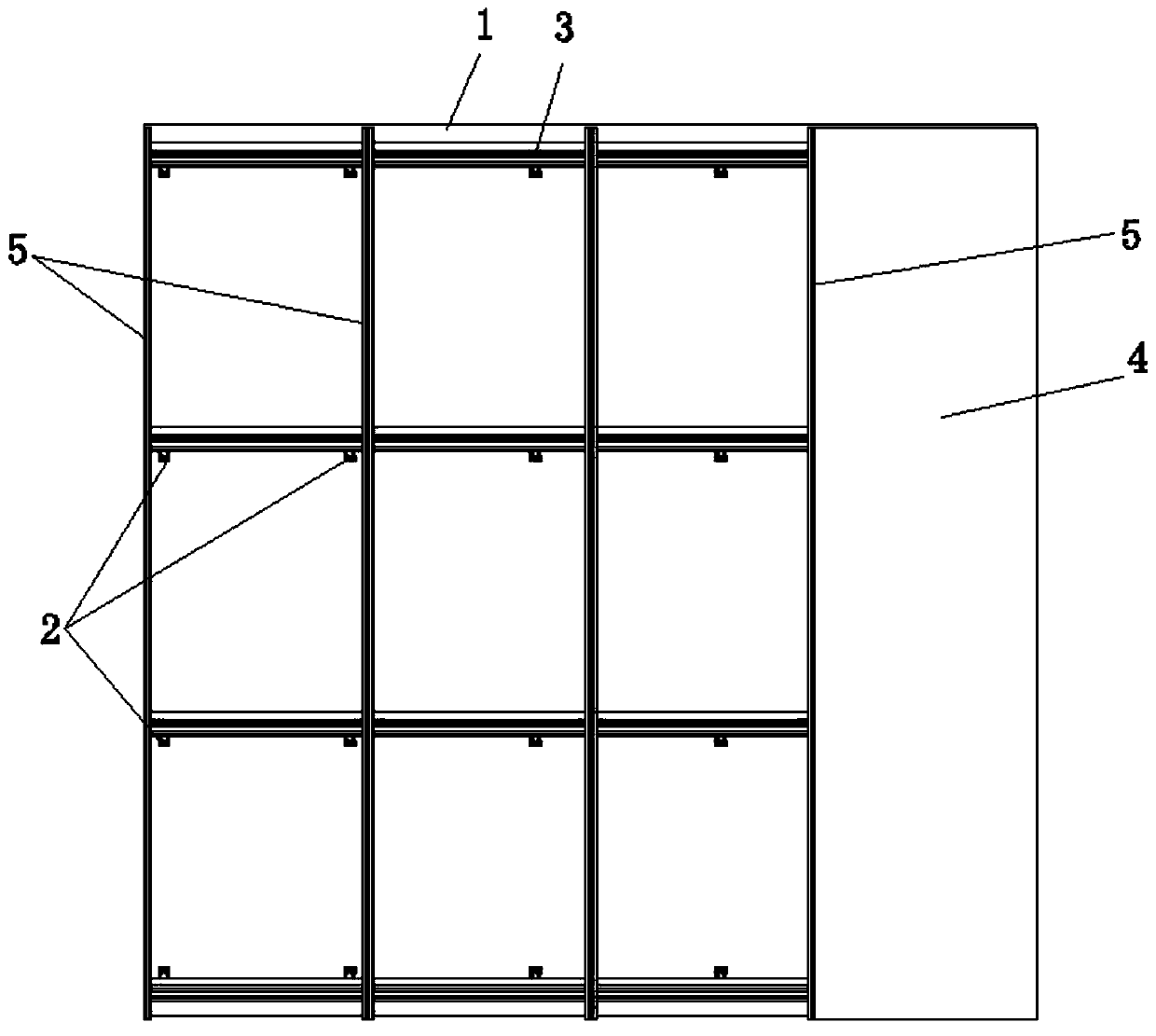

Mounting structure for fabricated hung wall surface

The invention provides a mounting structure for a fabricated hung wall surface. The mounting structure comprises a wall, leveling members, transverse sectional materials, baseplate units, fasteners and a veneer, wherein the leveling members are arranged on the wall in rows; the transverse sectional materials are connected to the leveling members; each transverse sectional material is correspondingto a row of the leveling members; multiple baseplate units are arranged; the baseplate units comprise baseplates and vertical sectional materials; the baseplates are located on the outer sides of thetransverse sectional materials, and are further connected to the leveling members; the vertical sectional materials are arranged on the two sides of the baseplates; the fasteners are connected to theadjacent vertical sectional materials of the adjacent baseplate units in a clamping manner; and the veneer is connected to the vertical sectional materials in the clamping manner. Compared with the prior art, the mounting structure has the following advantages that the structure is compact; the connection strength is good; a swaying phenomenon cannot be generated; the overall mounting quality isimproved; further, the mounting is rapid; and the construction efficiency is improved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

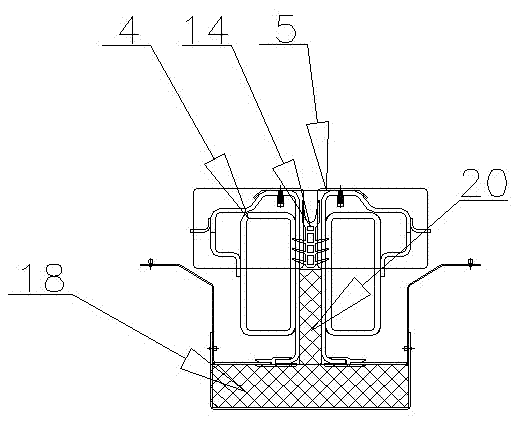

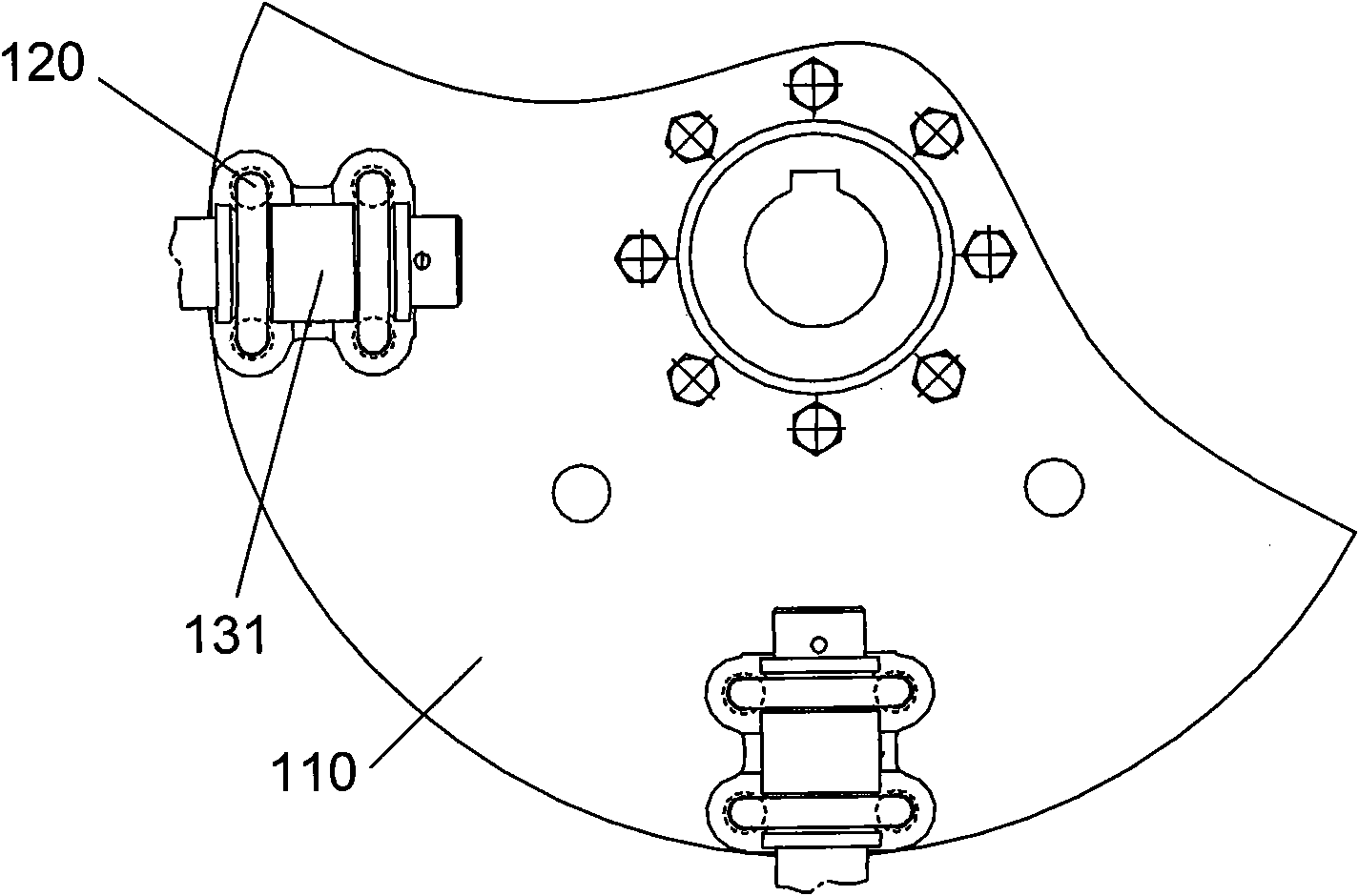

Fan impeller for cooling

ActiveCN101832285AEasy to adjust the installation angleEliminate bending momentPump componentsPump installationsImpellerEngineering

The invention discloses a fan impeller for cooling, wherein, the impeller comprises a wheel hub and a plurality of blades; blade installation seats are arranged around the wheel hub; a swing connection component is arranged on the blade handle of each blade; and swing connection is carried out by the swing connection component and the corresponding blade installation seats. As swing connection is adopted, the blades can swing and shimmy when the fan is operating, thus eliminating the bending moment in the vertical direction of the blade handle, decreasing bending stress of the blade handle, avoiding the damage on the blade handle, and being beneficial for implementing effective application of the large-diameter impeller; and the fan impeller also has the advantage of conveniently adjusting the installation angles of the blades, thus the installation angles can be preset according to the use requirements of a customer before delivery to achieve more convenient and faster field installation.

Owner:SHANGHAI ERHUAJIE ELECTROMECHANICAL EQUIP MFG

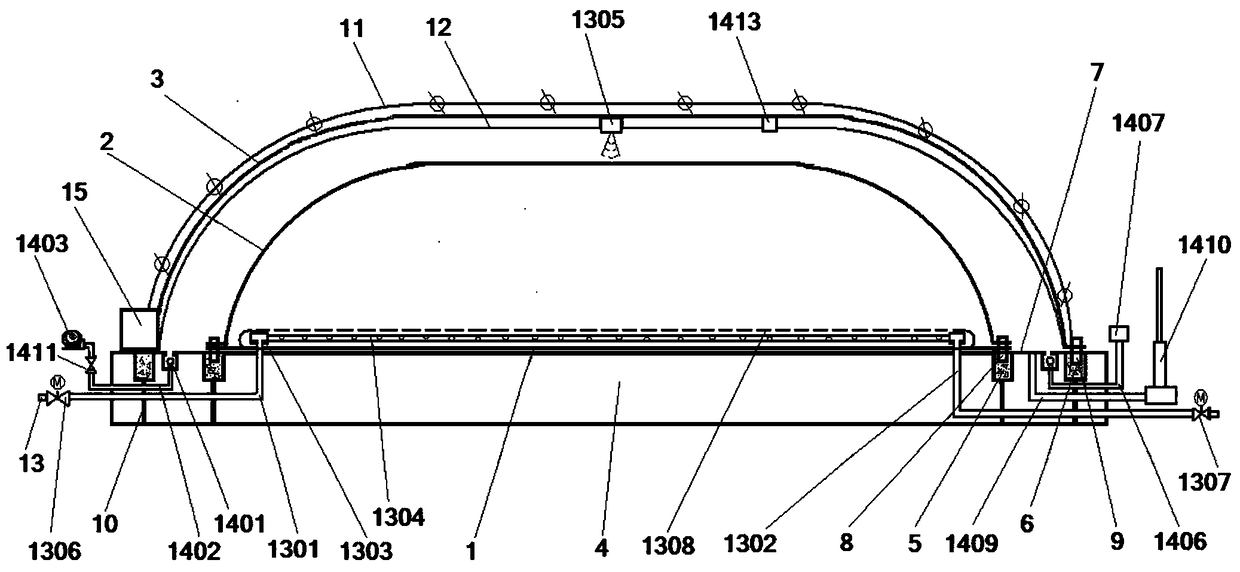

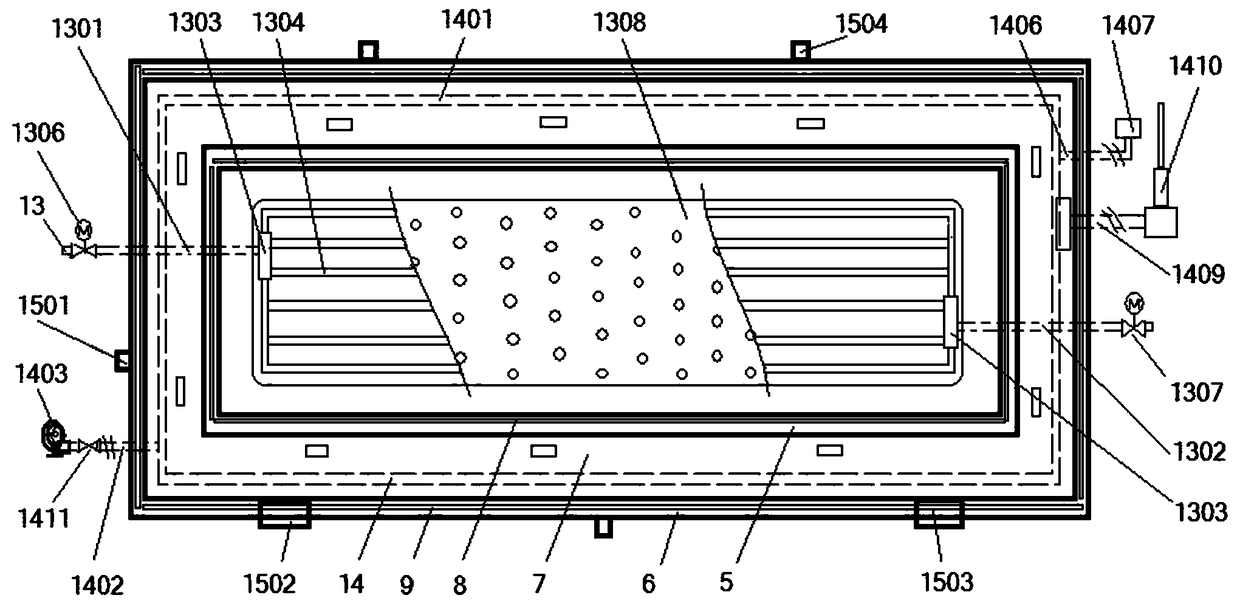

Super large dimension soft gas storing storage and method

PendingCN109335366AGuaranteed safe operationEnsure safetyLarge containersProduct gasProcess engineering

The invention discloses a super large dimension soft gas storing storage and method. The gas storing storage comprises a bottom film, an inner film and an outer film, and further comprises gas storingstorage foundations, a gas inlet and outlet pipeline system and a gas supplying-pressure releasing system; the gas storing storage foundations comprise an inner ring beam foundation and an outer ringbeam foundation, and an annular passage is arranged between the inner ring beam foundation and the outer ring beam foundation; the inner film and the bottom film are fixed to the inner ring beam foundation; the periphery of the lower edge of the outer film is fixedly to the outer ring beam foundation; and the gas inlet and outlet pipeline system comprises a gas inlet main pipe, a gas outlet mainpipe, distributing heads, a gas distributing pipe network, a screened platform and a level meter; and the gas supplying-pressure releasing system comprises annular air distributing pipes, a gas supplying main pipe, a gas supplying fan assembly, a pressure sensor, a wind speed sensor, a safe pressure releasing device, a gas leakage sensor, a gas discharging device and the like. The method comprisesthe steps of gas inlet of a gas storage chamber, gas outlet from the gas storage chamber to outside, safe operation under the condition of gale and safe operation when gas is subjected to leakage. Gas storage quantity of the super large dimension soft gas storing storage and method is huge, assembly on the spot is rapid and convenient, a working period is short, the cost is low, maintenance is convenient, and sit selection is loose.

Owner:曾勇军

Large-altitude-difference non-planar modeling suspended ceiling structure and construction method thereof

InactiveCN104234289ASimple structureGuaranteed construction speedCeilingsStructural engineeringMechanical engineering

The invention relates to a large-altitude-difference non-planar modeling suspended ceiling structure. A switching layer main skeleton is provided with a first-level switching layer assistant skeleton through a first-level connecting rod and a second-level switching layer assistant skeleton through a second-level connecting rod, wherein the first-level switching layer assistant skeleton is lower than the second-level switching layer assistant skeleton; the lengths of the first-level connecting rod and the second-level connecting rod are both not greater than 6000mm; the first-level switching layer assistant skeleton is provided with a first-level light steel keel through a first-level upper hanging rib and a first-level lower hanging rib; the second-level switching layer assistant skeleton is provided with a second-level light steel keel through a second-level upper hanging rib and a second-level lower hanging rib; the first-level light steel keel is lower than the second-level light steel keel; the lengths of the first-level upper hanging rib and the second-level upper hanging rib are both not more than 1000mm; the lengths of the first-level lower hanging rib and the second-level lower hanging rib are both not more than 500mm; the lower ends of the first-level lower hanging rib and the second-level lower hanging rib are connected with the surface layer of the suspended ceiling. According to the invention, the structure is simple, a multi-layer gradual retreating type bearing skeleton structure is adopted, the non-planar display of the surface layer of the suspended ceiling is realized through close joint connection and the construction speed and integral precision are ensured.

Owner:THE CONSTR DECORATION OF CHINA CONSTR NO 7 ENG BUREAU

Prefabricated partition wall construction method

InactiveCN108204131AQuality improvementImprove connection strengthWallsBuilding material handlingRebarCement mortar

The invention discloses a prefabricated partition wall construction method. The prefabricated partition wall construction method comprises the following steps that (1) columns are erected, specifically, outward-extending rebars of the columns and reserved rebars at the bottom are connected and fixed by using rebar connecting buckles; (2) a partition wall plate is hoisted, specifically, the mounting protruding edges at the two ends of the partition wall plate are inserted into mounting grooves in the two columns, the partition wall plate is pressed into mortar laid at the bottom, and partitionwall plate oblique supporting pieces are mounted; (3) after the partition wall plate is completely mounted, column combining molds are arranged at the bottoms of the columns in a supporting mode; (4)the connecting space in the bottoms of the columns is fully poured by using the mortar, meanwhile, cement mortar is smeared in the connecting joints of the mounting protruding edges of the partition wall plate and the mounting grooves in the columns; (5) the mortar is laid at the upper end of the partition wall plate, and floorslabs are erected, so that the floorslabs are pressed into the mortar at the upper end of the partition wall plate; and (6) after mounting is finished, all the column combining molds and the partition wall plate oblique supporting pieces are dismantled. According to theprefabricated partition wall construction method, the connection strength of the columns and the partition wall plate is high, waterproof performance is good, the partition wall plate is wholly subjected to machine hoisting, the integrality is good, mounting is simple, and the work efficiency is high.

Owner:李聪

Exposed wall thermal insulated decorative face brick, and its production method

The invention relates to an outer wall heat-insulation face brick and the producing method thereof, belonging to a building material and a producing process thereof, firstly making a face brick mould; arranging a metal injection mould of face brick shell on an injection machine, where the face brick shell injection-molded by antioxidant high molecular materials, comprises raised head and groove on side frame; placing the face brick shell in a foaming mould and injecting heat-insulation material, reacting, filling and solidifying, and then taking out and finishing the shell and thus making the finished product. And it is a novel building material integrated with heat insulation function and high-grade face, simple to install in the construction field, safe and reliable, saving raw materials, having low manufacturing cost, able to replace the existing ceramic tiles and stone materials, able to be used indoor, and able to be made into heat-insulation tiles for decorating roofs.

Owner:周克正

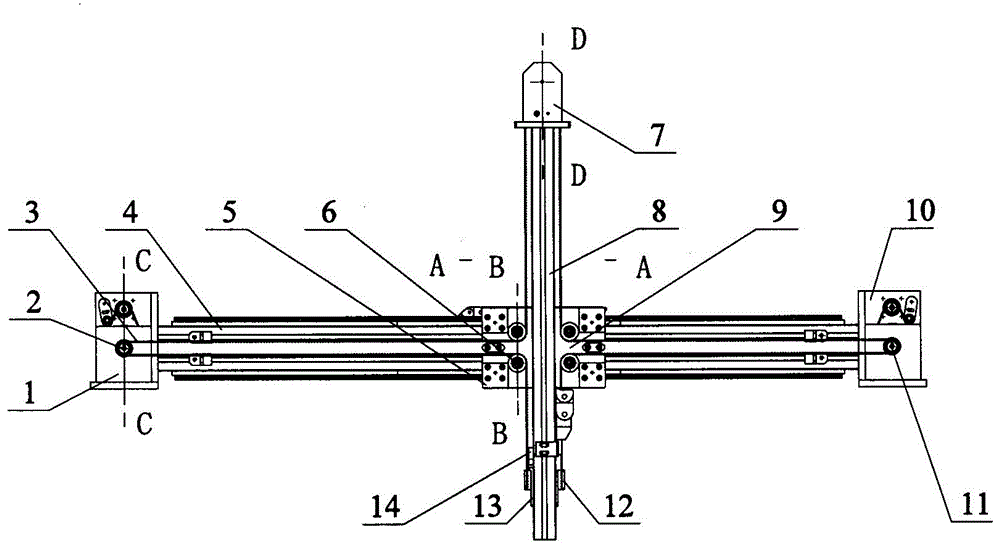

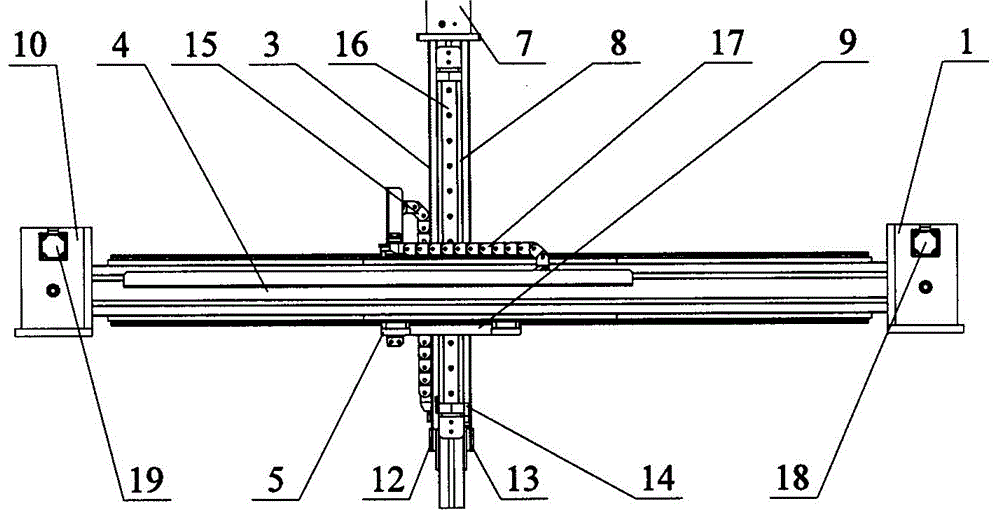

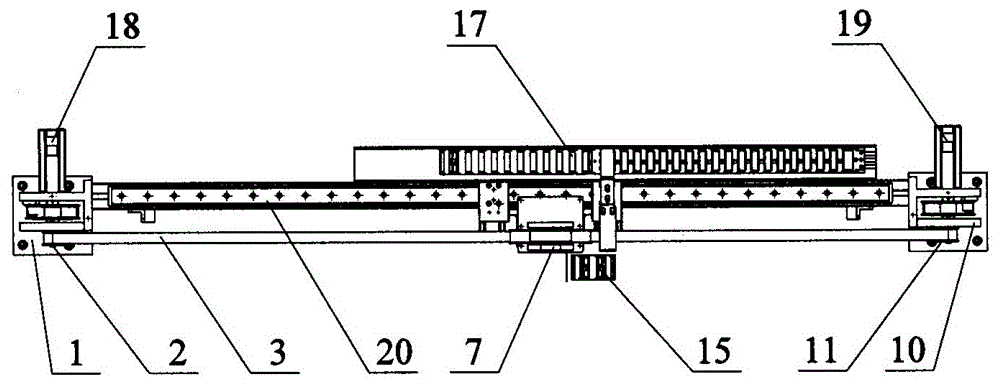

Synchronous driving type rectangular coordinate robot

ActiveCN106181980AIncrease profitReduced Power RequirementsProgramme-controlled manipulatorFailure rateRectangular coordinates

The invention discloses a synchronous driving type rectangular coordinate robot. The problems that a system is large in inertia and slow in dynamic response, and the failure rate is increased due to the fact that an existing rectangular coordinate robot adopts a multi-shaft superposed mode are solved. The synchronous driving type rectangular coordinate robot comprises a transverse frame main body, a transverse sliding base body, a longitudinal main body and a driving mechanism which are connected with one another. The synchronous driving type rectangular coordinate robot is characterized in that a transverse fixed beam of the transverse frame main body is connected with a longitudinal base beam of the longitudinal main body through a linkage slide plate of the transverse sliding base body, and thus, a transverse motion shaft and a longitudinal motion shaft which are driven by the same driving mechanism and are perpendicular to each other are formed and synchronously driven by two motors of the same driving mechanism so as to be in transmission with a transmission synchronous belt engaged with transmission wheels of transmission assemblies; and driving motors are both assembled at the two ends of the transverse fixed beam and do not move along with any motion shaft. The synchronous driving type rectangular coordinate robot is reasonable in design, simple in structure, quick in field installation, easy to maintain, wide in application range, low in inertia and quick in dynamic response, high-speed operation is easier to achieve, and forming of multi-axis motion is facilitated by additionally arranging the auxiliary motion shafts.

Owner:SHANGHAI FORTREND TECH CO LTD

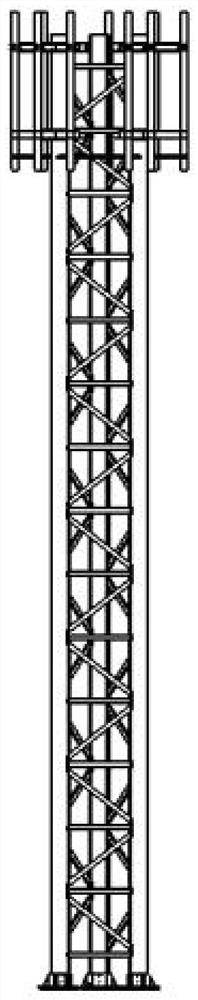

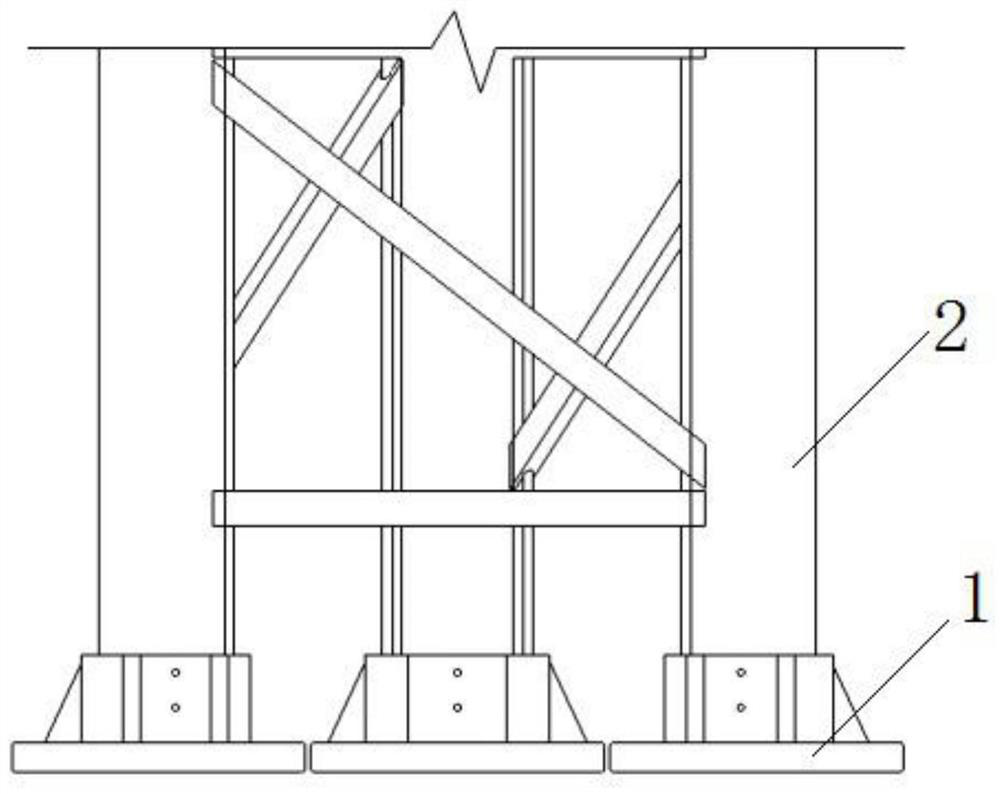

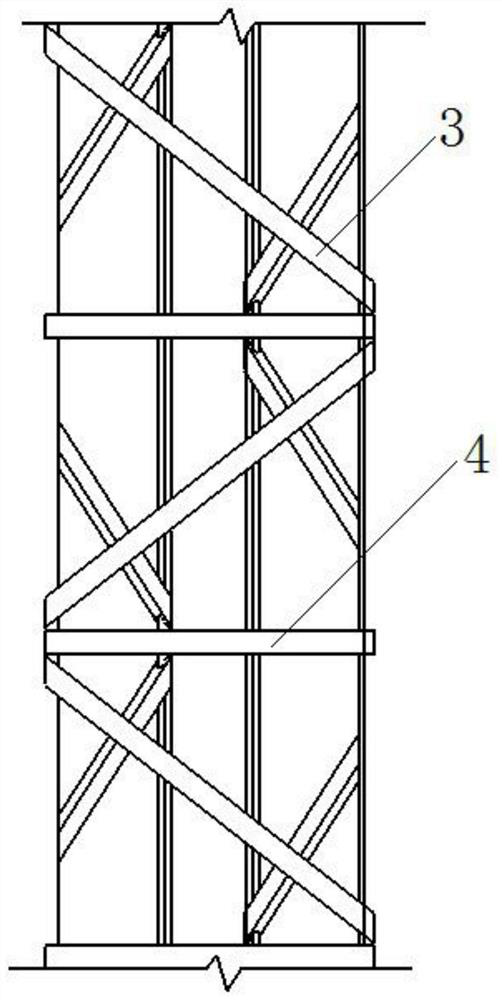

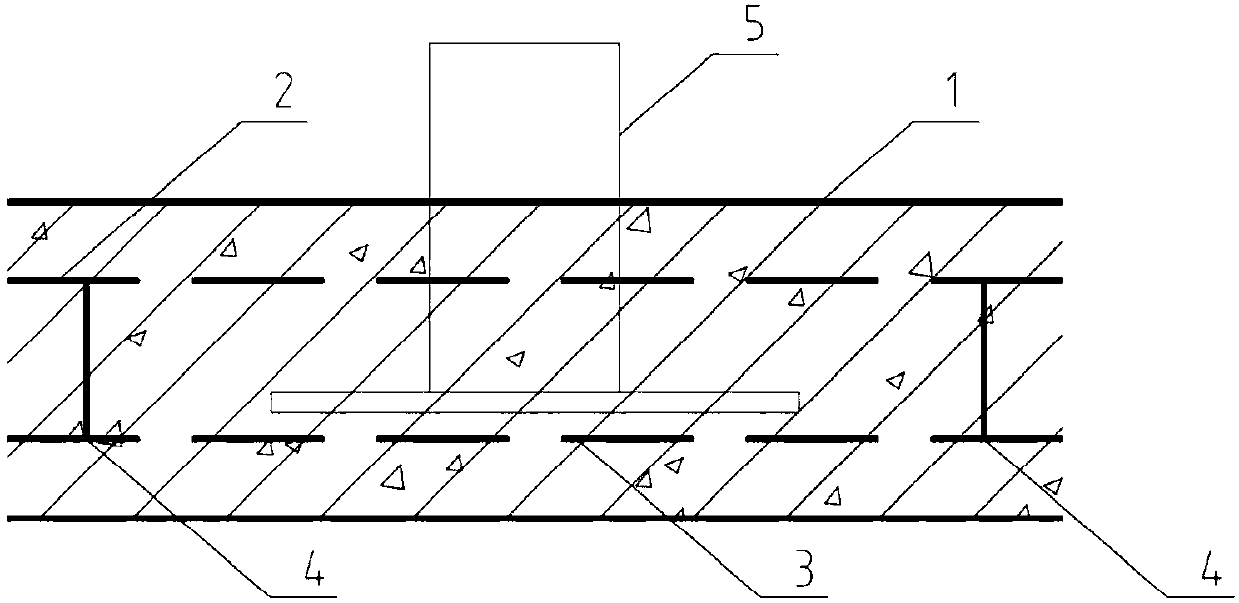

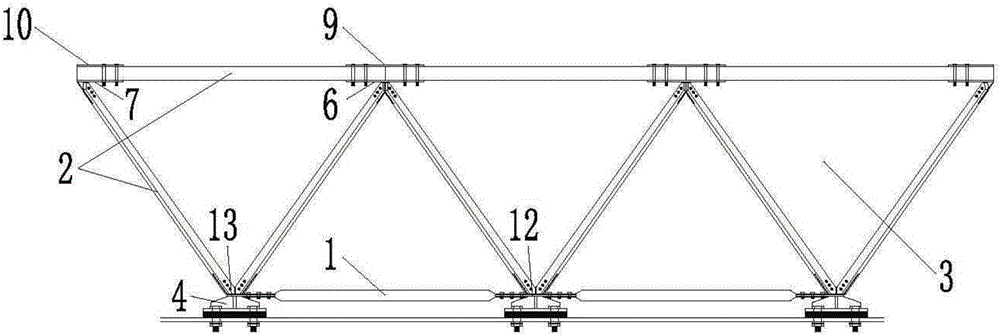

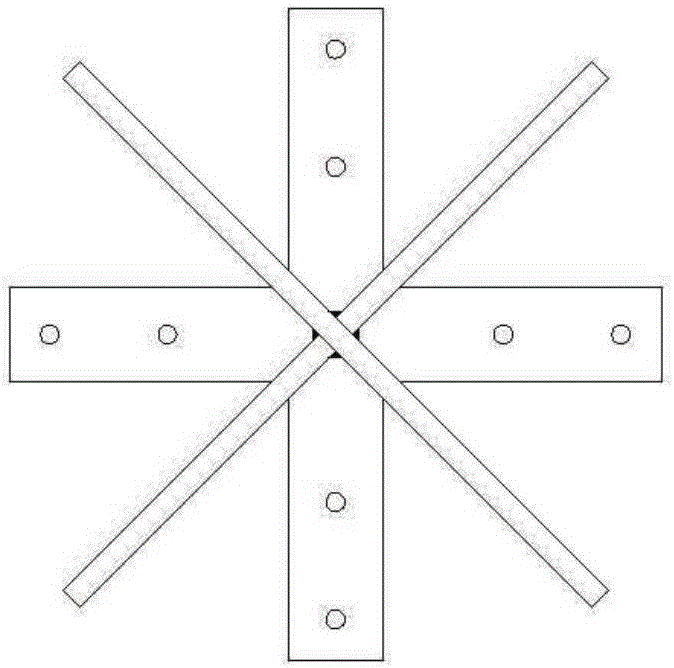

Lattice composite-material tower

The invention provides a lattice composite-material tower and belongs to the field of tower structures. The problem that an existing tower is poor in bearing capability is solved. The lattice composite-material tower comprises multiple bases, girders, diagonal draw bars, transverse draw bars, adapters, a grooved profile and embracing bars, wherein the multiple bases are distributed in an angular point form and fixedly connected with the ground, each base is fixedly connected with one girder, multiple diagonal draw bars and transverse draw bars are connected between the adjacent girders, the transverse draw bars are arranged between the adjacent diagonal draw bars, the top of each girder is fixedly connected with the grooved profile through one adapter, the multiple embracing bars are fixedly connected to the grooved profile, the tower is made of a composite material, and the composite material consists of reinforced fibers and a base material. The lattice composite-material tower is mainly used as a communication tower or an electric tower.

Owner:HARBIN FRP INST

Concrete hanging board and manufacture method thereof

The invention provides a concrete hanging board and a manufacture method thereof. The hanging board comprises a board body, an embedded part and grid layers, wherein two grid layers or more are arranged in the board body and are in parallel with the surface of the board body; one end of the embedded part is arranged in the board body; the other end of the embedded part is higher than or level withthe outer surface of the board body. According to the concrete hanging board disclosed by the invention, the plurality of grid layers are configured in the board body of the concrete to solve the problem that a concrete panel cracks due to insufficient strength, and the concrete hanging board has the advantages of low production cost, high product strength, simple preparation method, easiness informing and the like.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

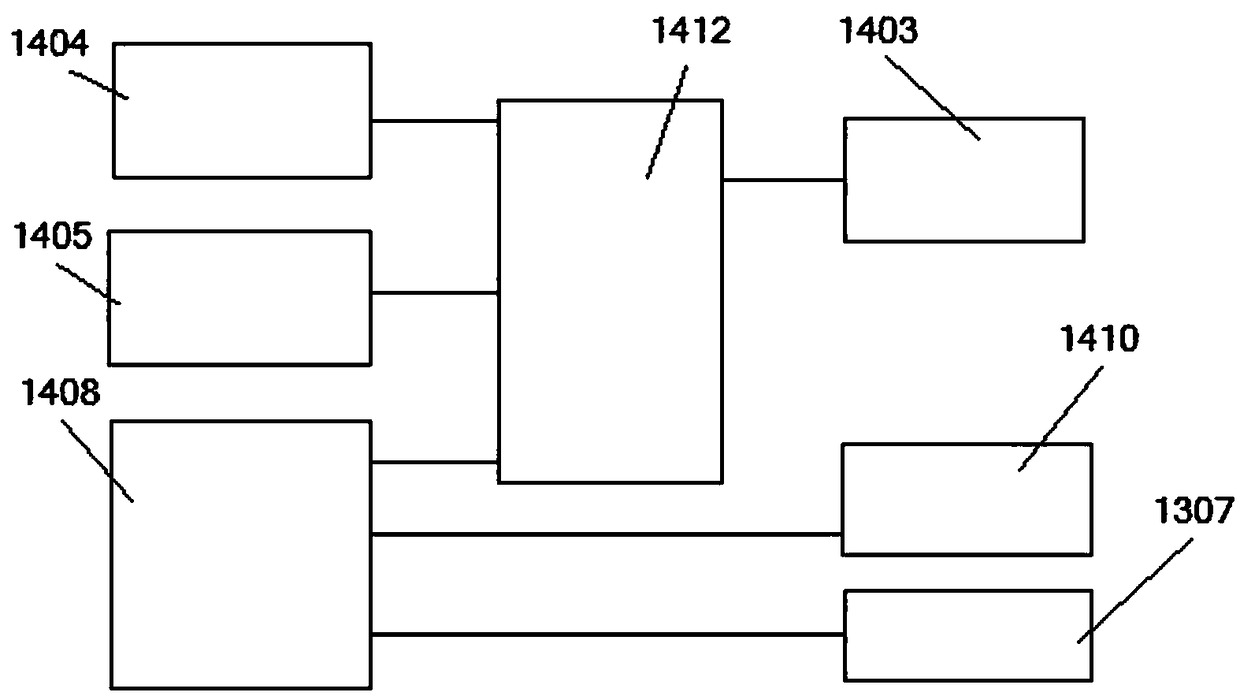

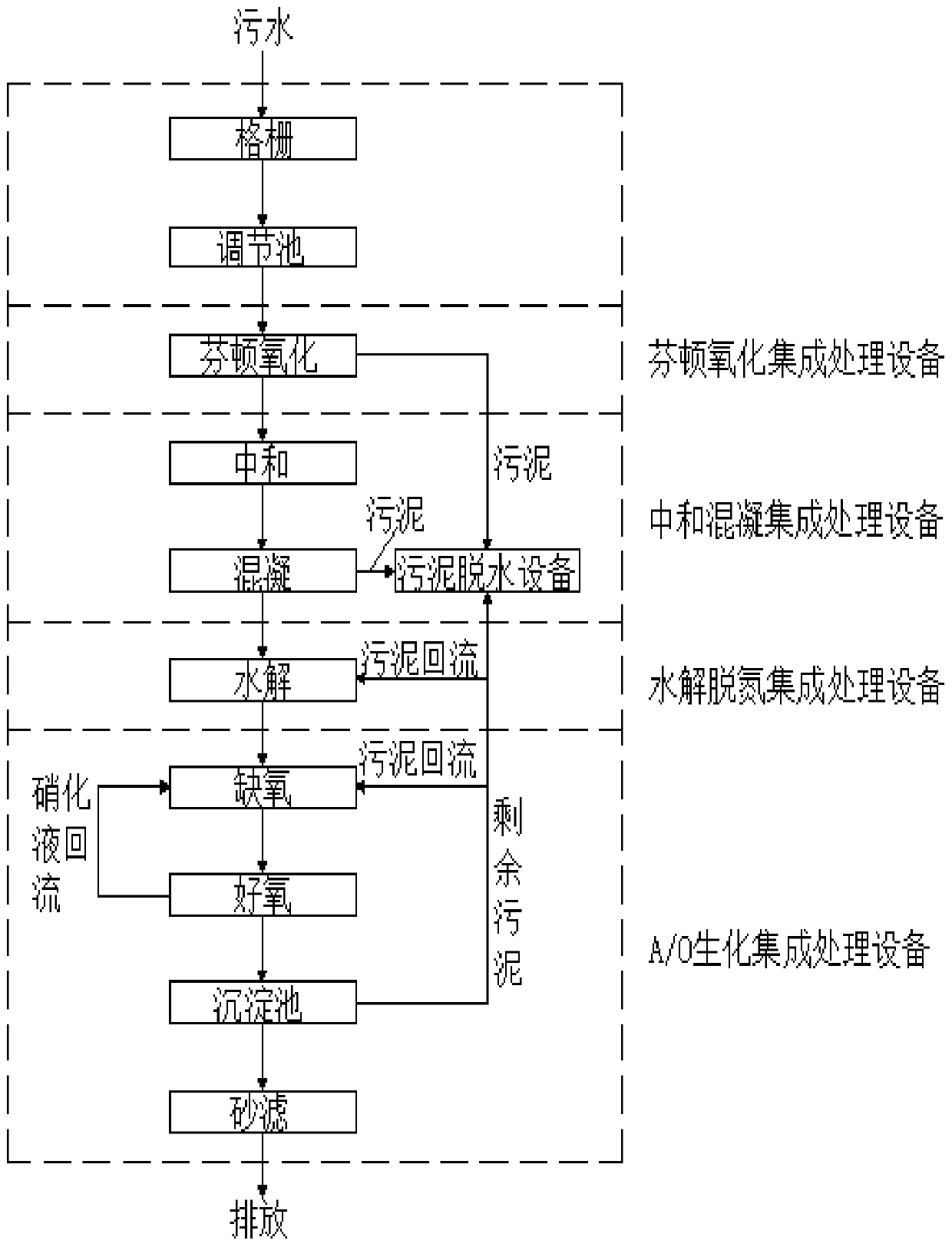

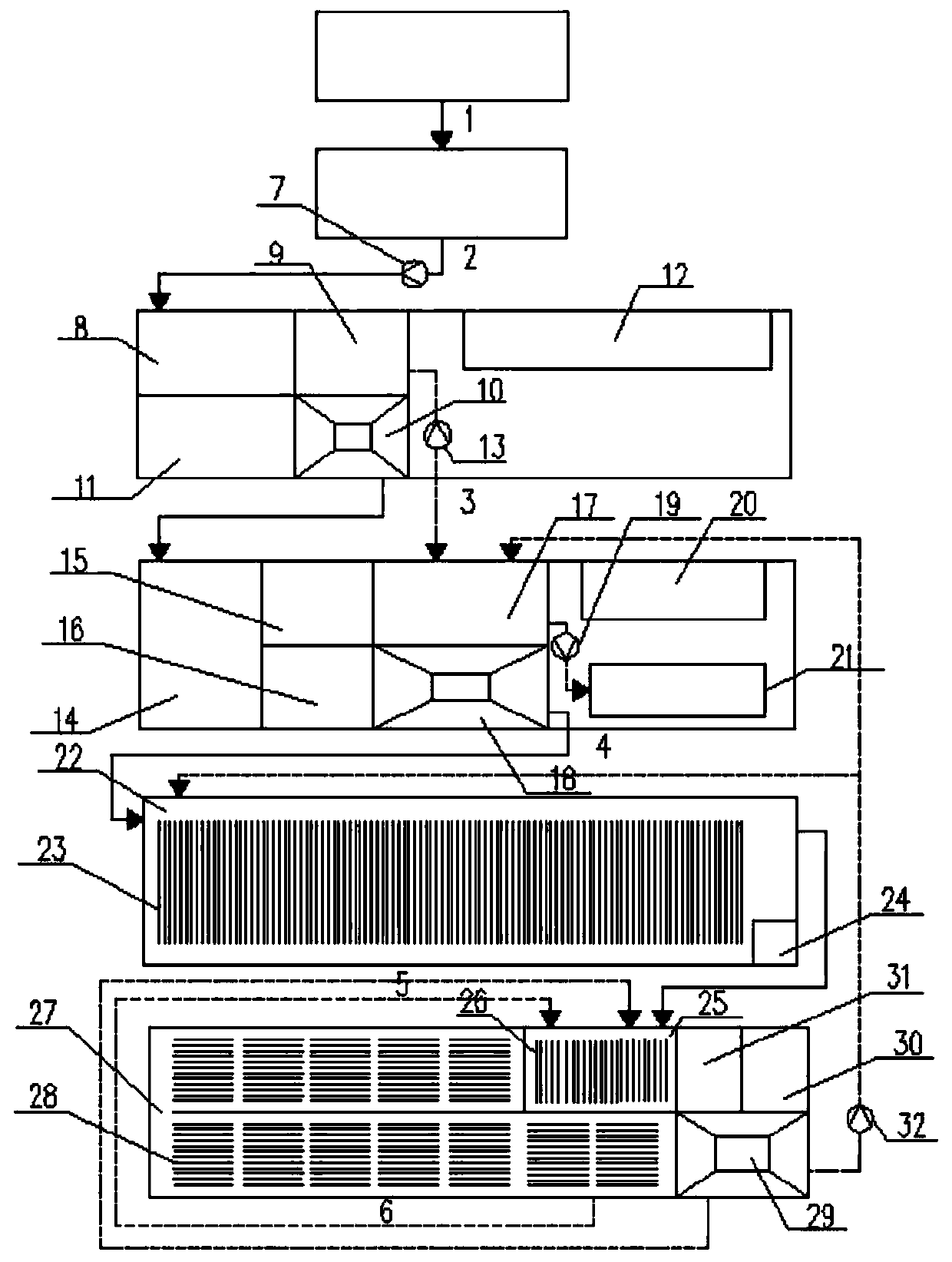

Acid pickling and phosphating production wastewater integrated treatment device and treatment process thereof

PendingCN111153557AImprove processing efficiencyLow investment costSludge treatmentWater treatment compoundsProcess engineeringHydrolysis

The invention discloses an acid pickling and phosphating production wastewater treatment device which comprises a grid, an adjusting tank, a Fenton oxidation integrated treatment device, a neutralization and coagulation integrated treatment device, a hydrolysis and denitrification integrated treatment device and an A / O biochemical integrated treatment device, wherein the grid, the adjusting tank,the Fenton oxidation integrated treatment device, the neutralization and coagulation integrated treatment device, the hydrolysis and denitrification integrated treatment device and the A / O biochemicalintegrated treatment device are connected in sequence. The acid pickling and phosphating production wastewater treatment device has the advantages of strong impact load resistance, high treatment efficiency, low investment cost and low operating cost.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

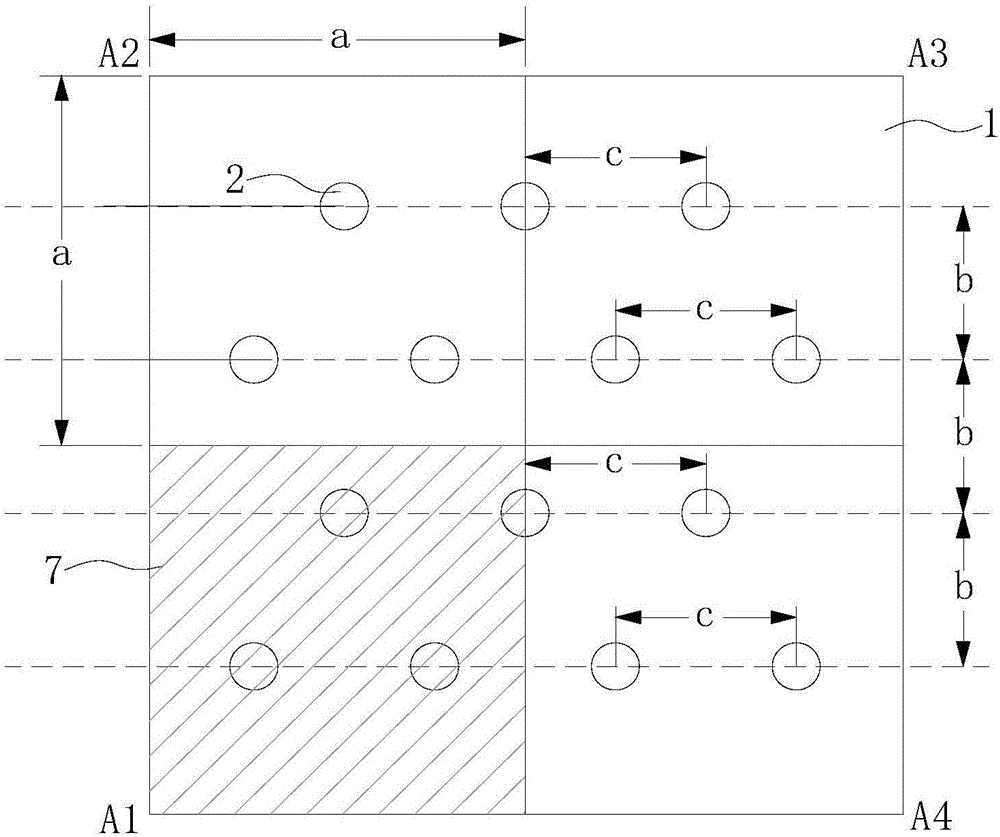

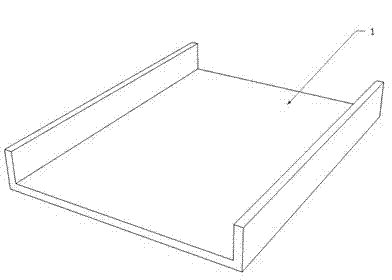

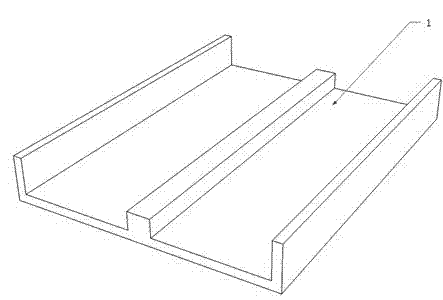

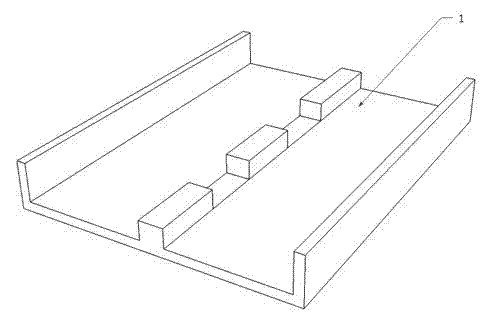

Hollow combined filling wall and construction method thereof

ActiveCN102767261AImprove sound insulationImprove heat insulationBuilding componentsBuilding material handlingChinese charactersThermal insulation

The invention discloses a hollow combined filling wall using prefabricated grooved members and a construction method of the hollow combined filling wall. The hollow combined filling wall comprises the prefabricated grooved members (1), wherein the cross sections of the prefabricated grooved members (1) are shaped like a Chinese character ''ao'' (namely, concave), are E-shaped or are both shaped like a Chinese character ''ao'' and E-shaped alternatively. In the construction process, a plurality of prefabricated grooved members are arranged and combined together according to different combination methods, and integrated by caulking through cementing materials; prefabricated ribs or cast-in-place ribs are added according to specific conditions; thermal insulation materials are filled in the grooves. The hollow combined filling wall has overall economic indexes and a construction period, which are better than those of the existing autoclaved aerated block filling wall or hollow inner mould metal net cement interior partition wall, has the advantages of high industrialized production degree and simple site operation process, thereby making up the defects in the prior art.

Owner:盐城市双新建设投资有限公司

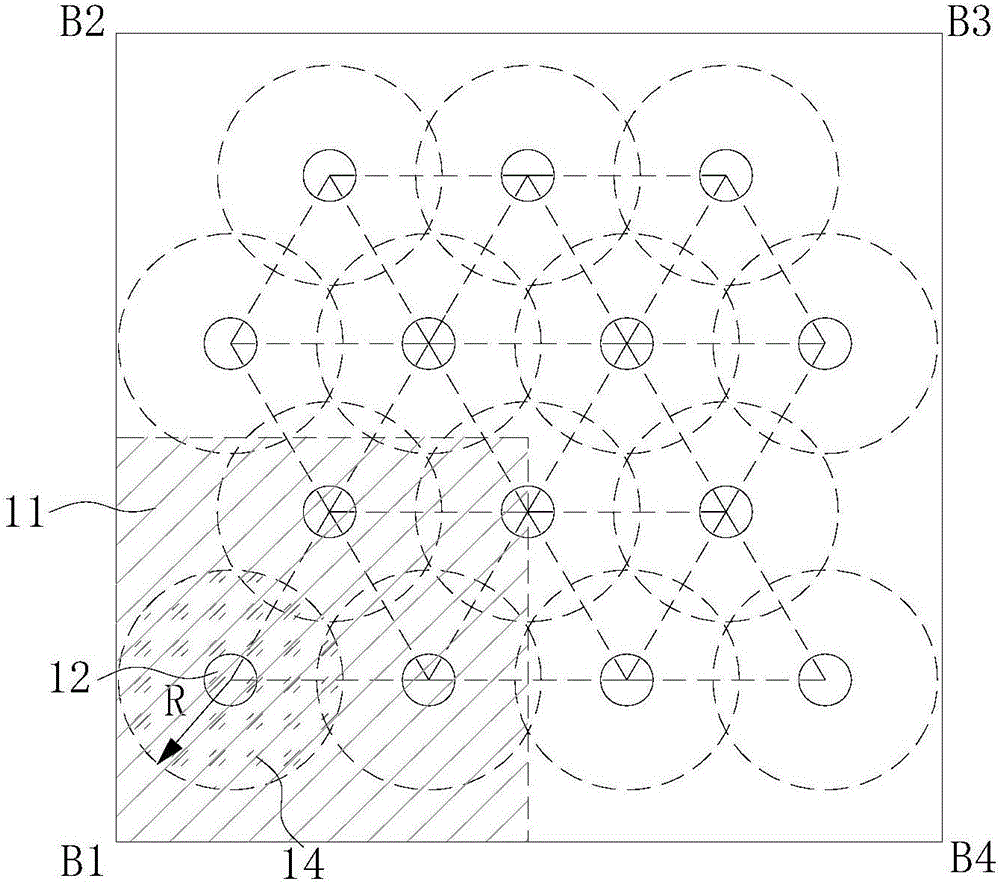

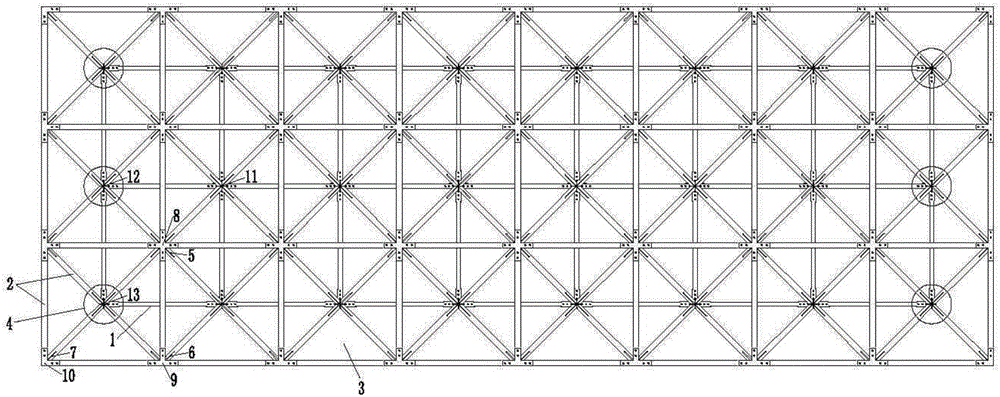

Combined net rack

ActiveCN106088468AFlexible section formImprove carrying capacityGirdersJoistsEngineeringHigh pressure

The invention discloses a combined net rack and belongs to the technical field of building combined structures. The net rack is a quadrangular pyramid spatial net rack formed by combining tubes with high tension resistance with members made from other materials with high pressure resistance. Lower chord members are made from the tubes, upper chord members and web members are formed by the members made from the other materials, and all the members are connected through plate-type joints. Supports are arranged in the proper positions of the lower portions of lower chord joint plates, so that the whole structure is fixed to supporting structures. The net rack is suitable for square or rectangular structures such as roofs and canopies. Compared with net racks of traditional steel structures, the net rack has the advantages of being small in steel consumption, low in self weight, simple in structure, convenient to manufacture and mount, low in cost, good in mechanical performance and the like.

Owner:NANJING UNIV OF TECH

Manufacturing process for accurate connection of large-scale steel structure members and flanges

ActiveCN101844279AGuarantee welding qualitySolve the problem that the production accuracy is difficult to controlWelding apparatusNon destructiveNumerical control

The invention relates to a manufacturing process for the accurate connection of large-scale steel structure members and flanges, which is characterized in that: rough selvedges on edges of the flanges are removed, and the two flanges are in close connection and are drilled commonly by using a numerical control drilling machine; a plurality of code plates are distributed on peripheral edges of the two flanges uniformly by using a spot-welding method; the end part of a box beam or an I beam which is machined into a semi-finished product is cut to form a beveled edge; lofting is performed on a working platform to mark off a structure size line, the box beam or the I beam, after being put on the working platform straightly, is fixed by using a baffle and a wedge, the flanges are put to the connection positions of connected pieces and are fixed by adopting a spot-welding method, and then the flanges are welded completely, cooled for 24 to 48 hours and subjected to non-destructive inspection; and a reinforcing rib plate is welded at the joint of the box beam or the I beam. The manufacturing process has the advantages that: the problem of difficult control of the accuracy of the connection among the large-scale steel structure members and the flanges is solved; the field installation and operation are quick; and the welding quality of flange connection is ensured and the production cost and time are saved while high machining efficiency is realized.

Owner:天津重钢机械装备股份有限公司

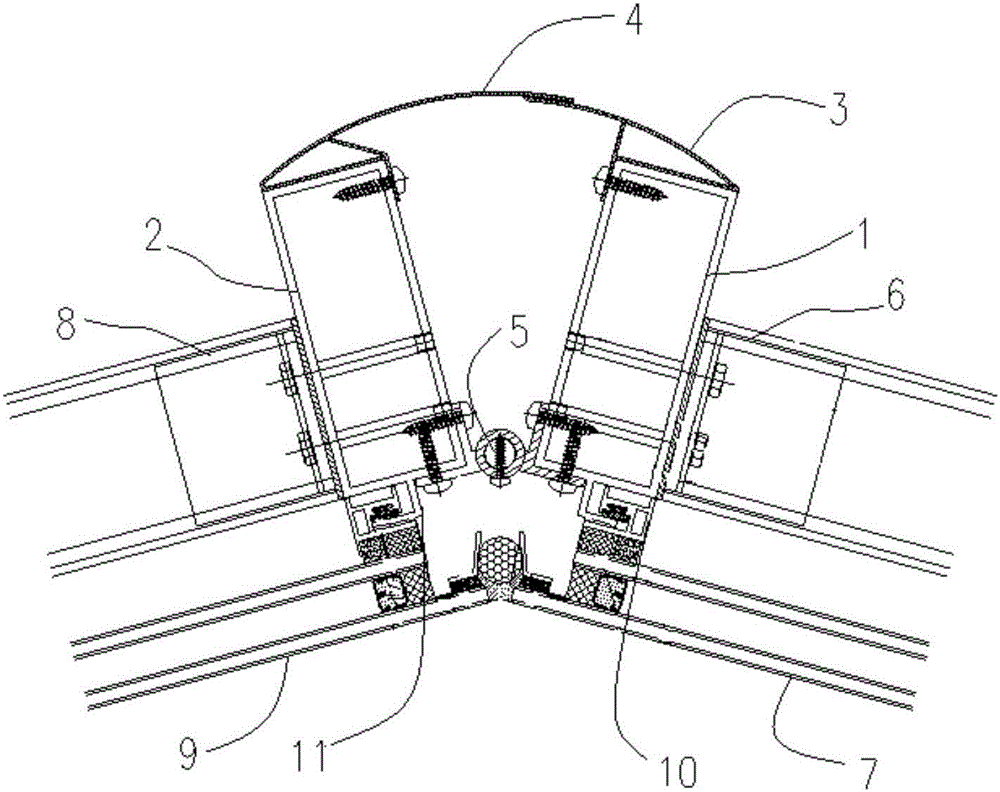

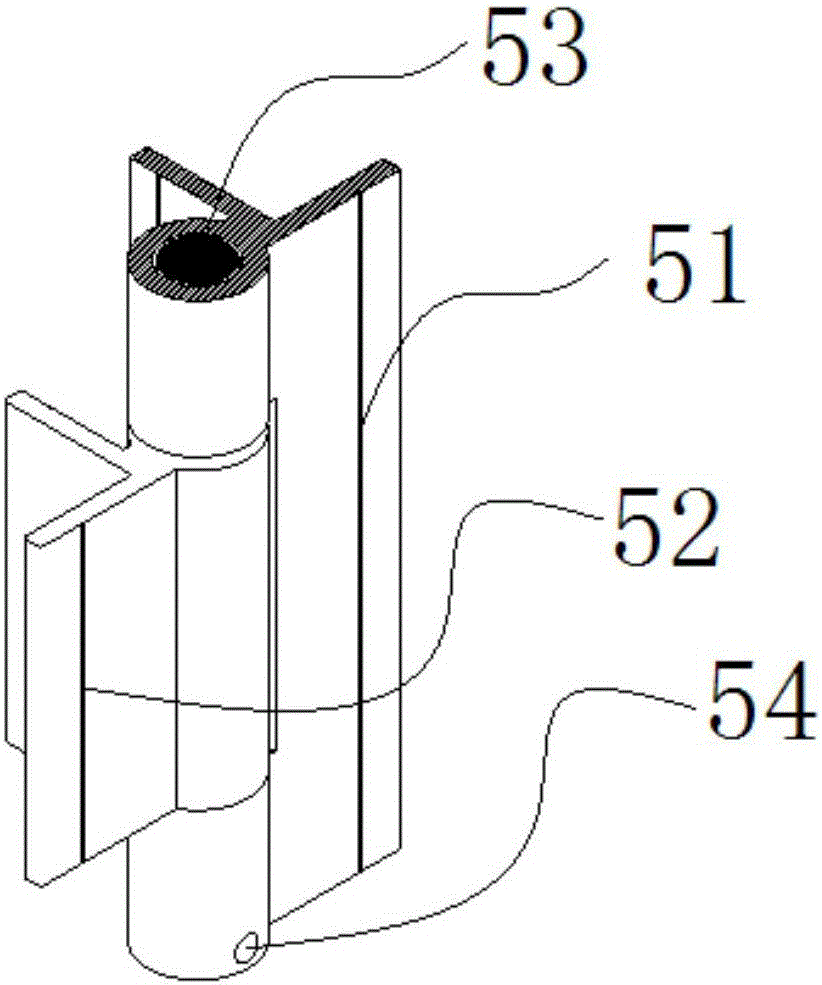

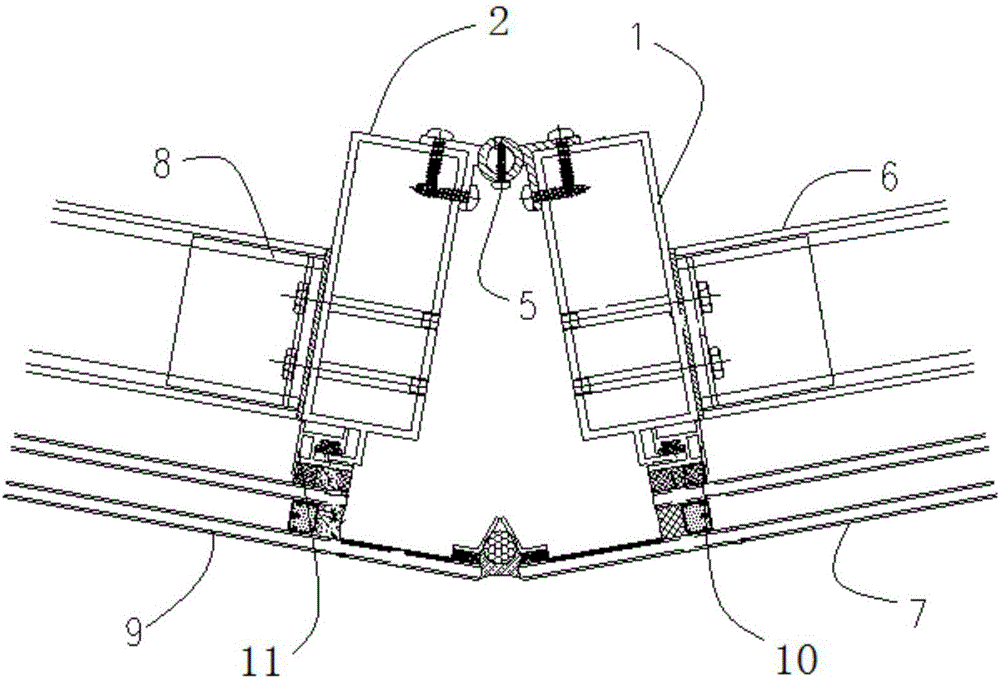

Multi-angle corner of concealed-frame curtain wall

The invention discloses a multi-angle corner of a concealed-frame curtain wall. The multi-angle corner comprises a left fixed frame and a right fixed frame which are installed on a building outer wall, a left-handed rotation part used for fixing a left glass wall on the left fixed frame and a right-handed rotation part used for fixing a right glass wall on the right fixed frame, wherein certain ends of the left-handed rotation part and right-handed rotation part are respectively provided with a rotation apparatus capable of freely adjusting the openness, the other ends are respectively provided with a sealing mechanism for blocking an opening gap between the left-handed rotation part and the right-handed rotation part, and the sealing mechanism comprises a left arc plate and a right arc plate which can be in sliding fit with each other. The angle of the corner can be adjusted by virtue of the rotation apparatus capable of freely adjusting the openness, so that the application range of the corner is enlarged, the type of the corner is reduced, the mold expense is saved, the multi-angle random switching of an inner corner and an external corner can be realized, and the on-situ installation is convenient and rapid.

Owner:CMCU ENG

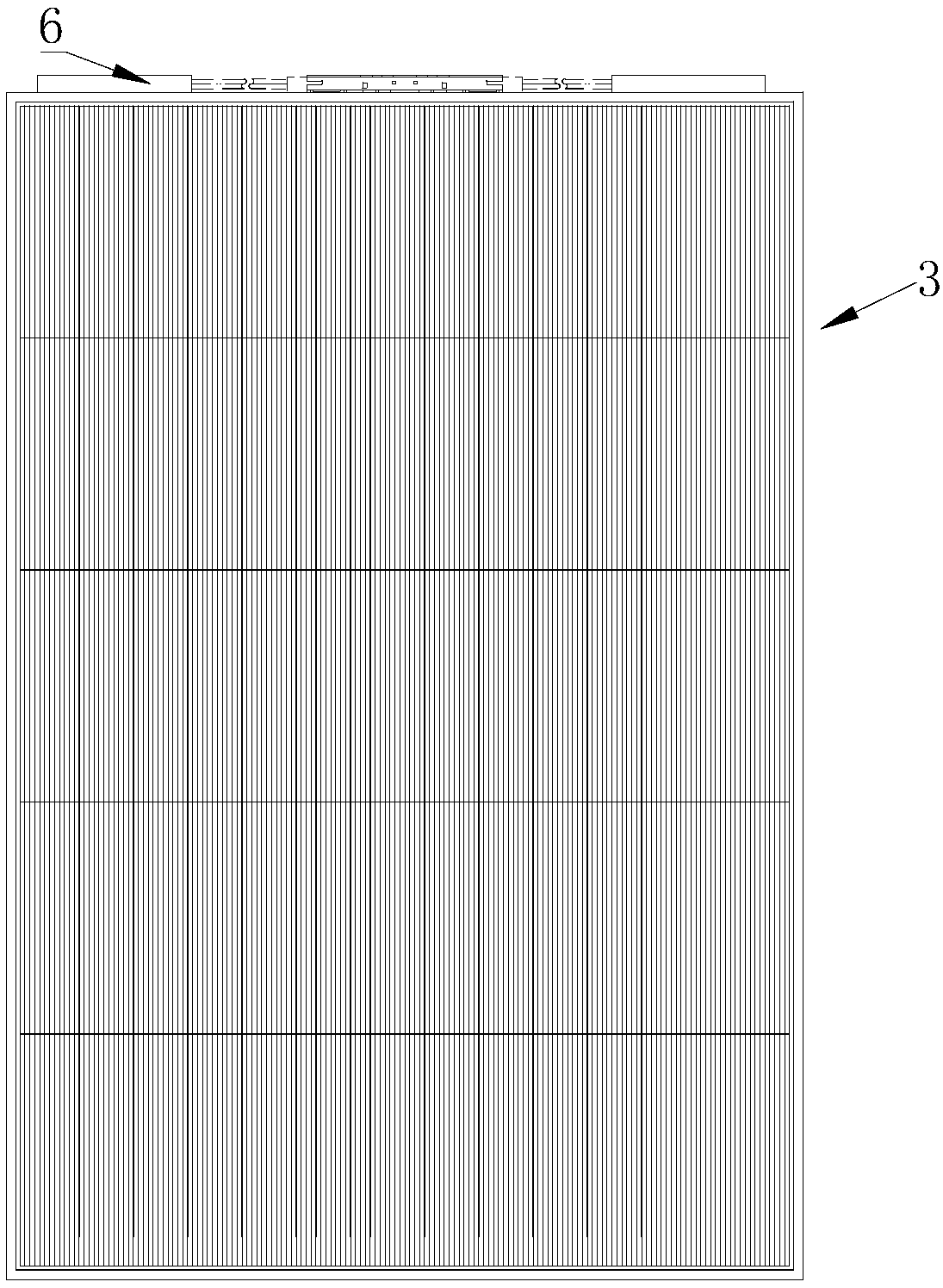

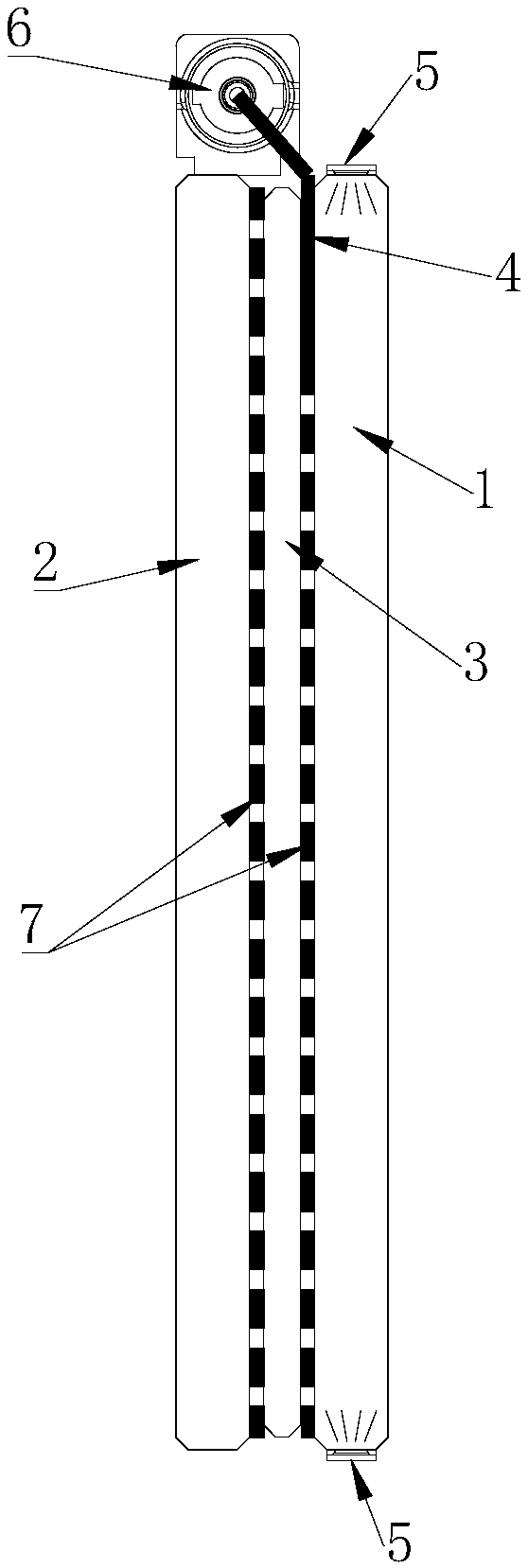

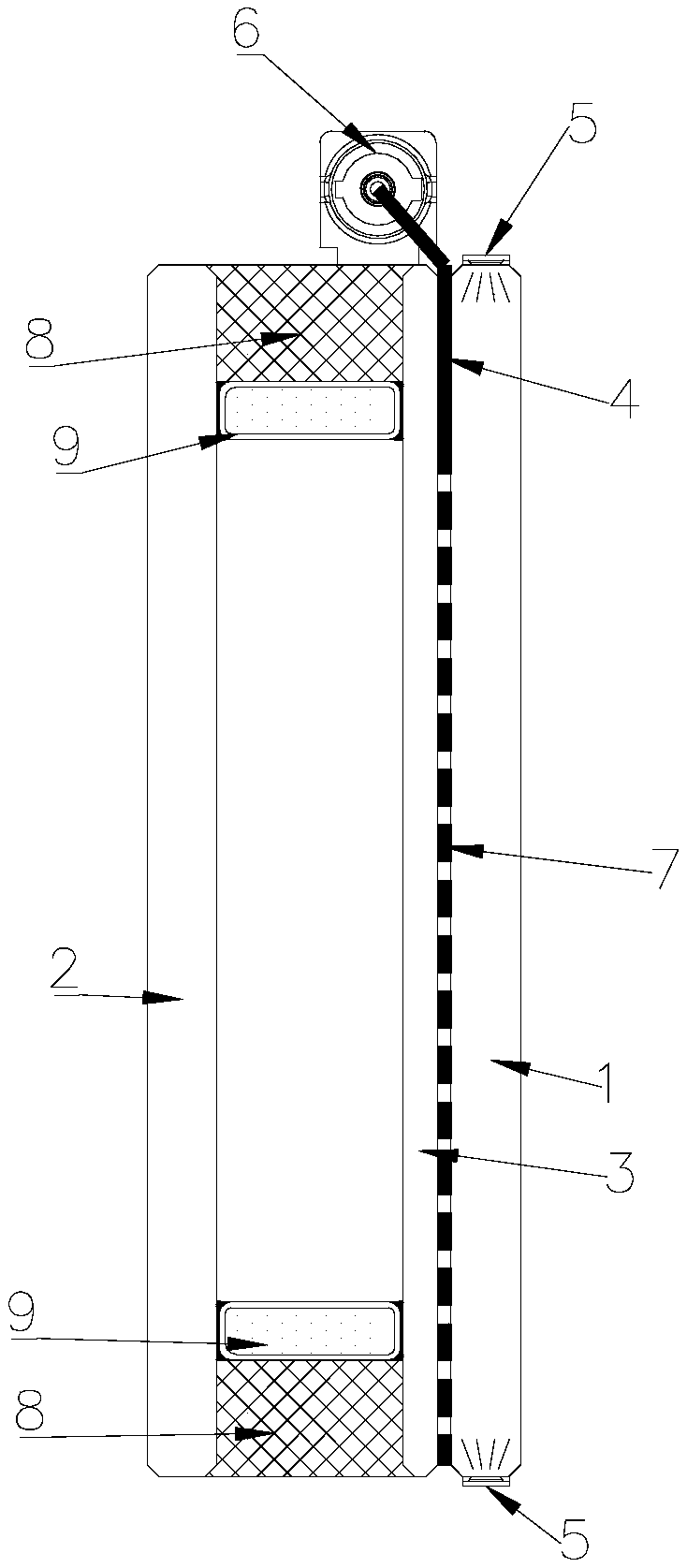

LED light-emitting photovoltaic assembly

PendingCN109578916AEasy to installGuaranteed dustproofElectric circuit arrangementsLighting elementsElectric energyElectricity

The embodiment of the invention provides an LED light-emitting photovoltaic assembly. The LED light-emitting photovoltaic assembly comprises a front plate, a rear plate arranged opposite to the platesurface of the front plate, a solar cell panel, a display system and an energy storage element. The solar cell panel is arranged between the front plate and the rear plate; the display system comprises at least two protection lamp strips; the protection lamp strips are arranged on the two opposite outer end surfaces of the front plate or the rear plate so as to project complete contents; the energy storage element is arranged on the outer end surface of the solar cell panel; the energy storage element is electrically connected with the solar cell panel and the protection lamp strips so as to store the electrical energy produced by the solar cell panel and used for supplying electricity for the display system. The LED light-emitting photovoltaic assembly is an integrated assembly and is convenient and quick to mount in the field; sealing glue is applied among integrated assemblies so as to ensure that the integrated assemblies are dust-proof and water-proof; moreover, the protection lamp strips are placed in open environment and can radiate naturally without arranging a cooling system independently, so that the cost is low.

Owner:上海祖强能源有限公司

A combined in-situ restoration method of soil and groundwater with high-pressure rotary spraying and shallow mixing

ActiveCN106799396BQuick and easy on-site installationEasy to operateContaminated soil reclamationSoil scienceSpinning

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

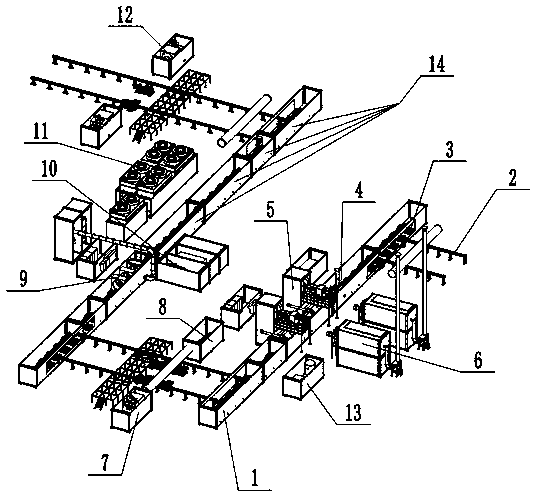

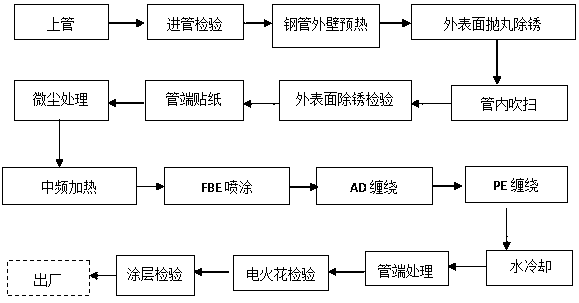

Modularized skid-mounted 3PE/epoxy powder anti-corrosion pipe production line

PendingCN110216906AQuick on-site installationEasy to install on siteTubular articlesEpoxyProduction line

The invention discloses a modularized skid-mounted 3PE / epoxy powder anti-corrosion pipe production line, and relates to the field of anti-corrosion pipe production. The modularized skid-mounted 3PE / epoxy powder anti-corrosion pipe production line comprises a first spiral transmission line module, a pipe feeding rack module, a second spiral transmission line module, a flame preheating furnace module, a steel pipe outer wall impeller blasting machine module, a dust collector module, an in-pipe blowing trolley module, an in-pipe blowing dust recovery trolley module, a medium frequency heating module, a spraying extruder module, a cooling module, a pipe end processing module, an electric control module and a water cooling processing module; the medium frequency heating module is connected withthe spraying extruder module; one side of the cooling module is provided with the water cooling processing module; the pipe end processing module is arranged on one side of the water cooling processing module; and the electric control module is arranged on the side of the dust collector module. After the technical scheme is adopted, the modularized skid-mounted 3PE / epoxy powder anti-corrosion pipe production line has the beneficial effects of being reasonable in design, quick and convenient to install onsite, and capable of being directly applied to construction fields, and has the characteristics of being high in efficiency, low in investment, excellent in quality and the like.

Owner:廊坊市鼎盛机械设备有限公司 +1

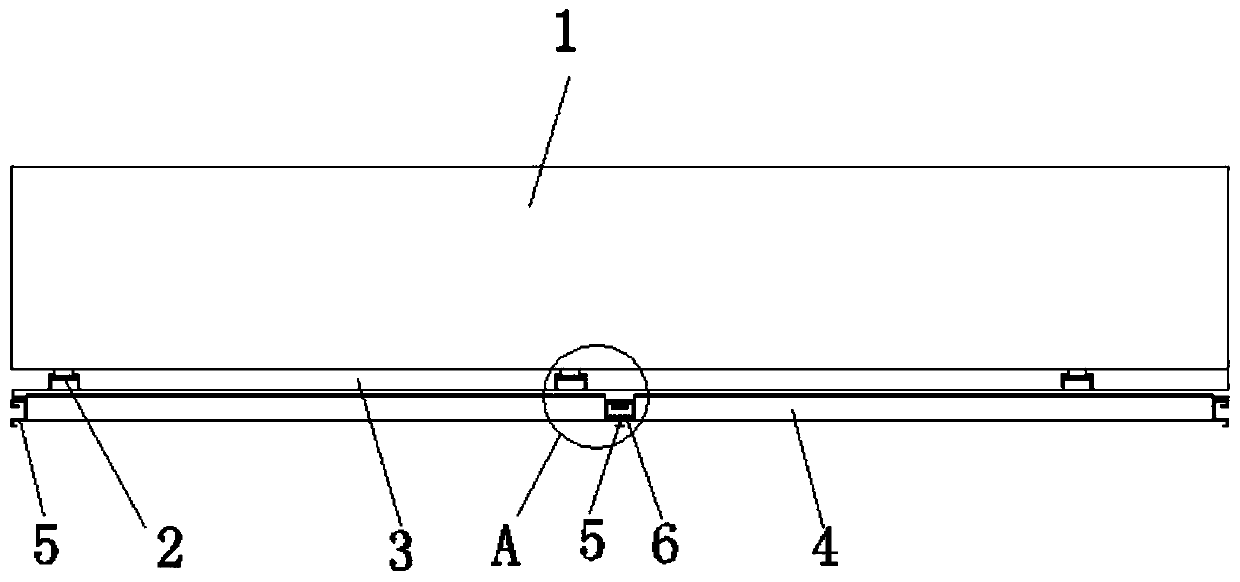

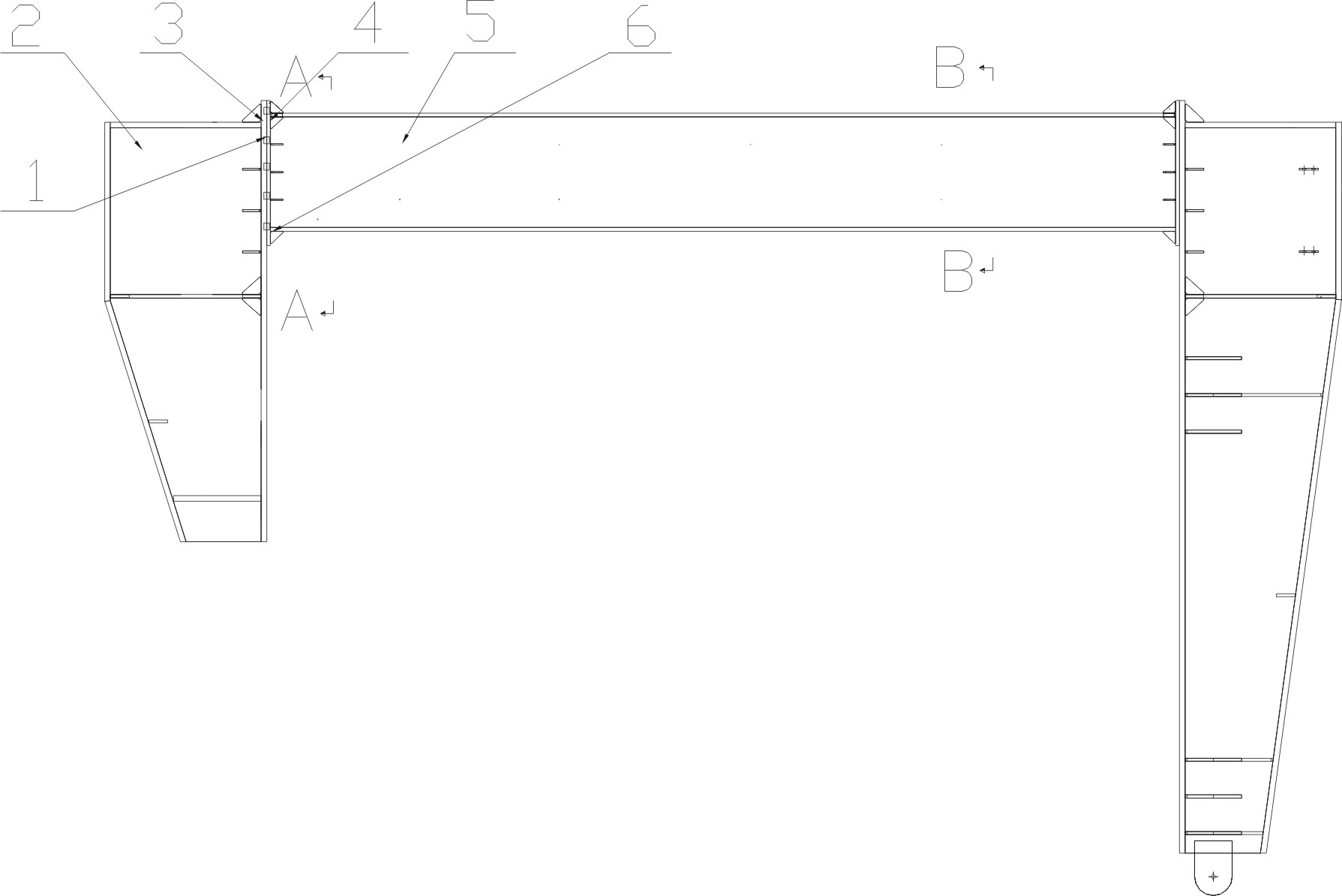

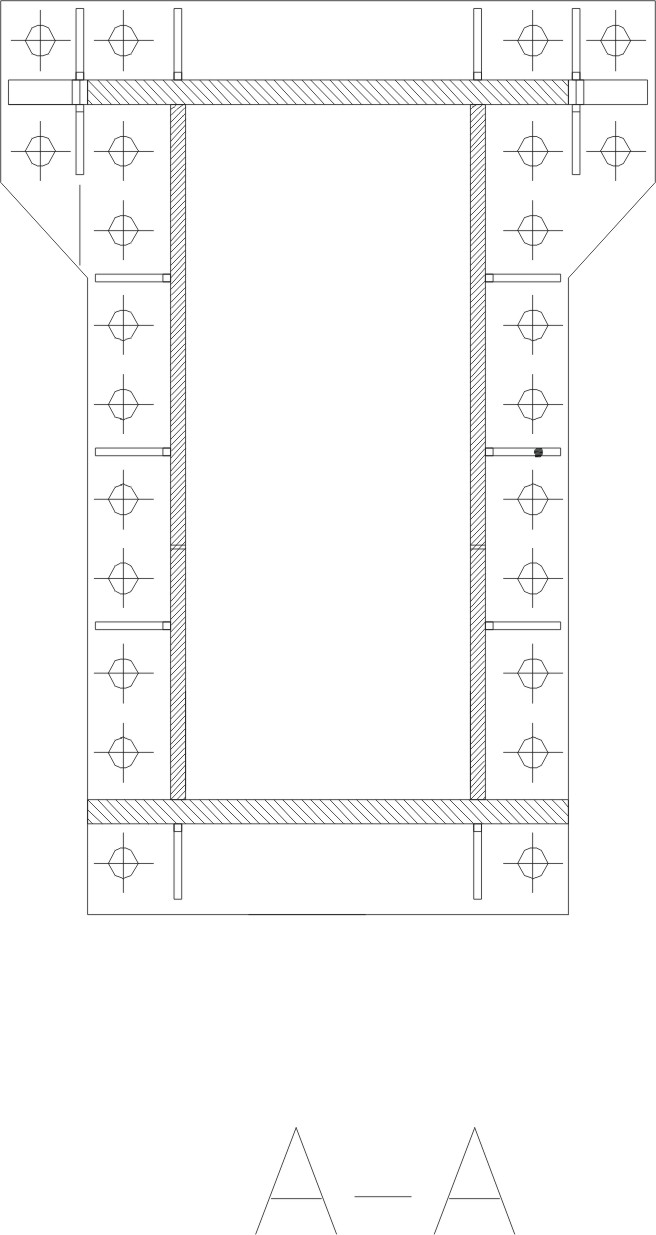

Plug-and-play steel structure beam and column connector and method

ActiveCN104805901AFirmly connectedQuick and easy on-site installationBuilding material handlingSteel columnsConnection form

The invention discloses a plug-and-play steel structure beam and column connector, which comprises an I-shaped steel column and an I-shaped steel beam, the flange plates of both sides of the column are respectively provided with two round holes which are symmetrically arranged from the top down and used for the insertion of a short bolt and a long bolt, the end surface of the end of the beam is connected with a connecting plate, the connecting plate is provided with holes which correspond to the round holes formed in the column, wherein the shape of each of the lower row of holes is an inverted U of which the lower end is open, and a section of lower flange, the length of which is greater than the length, extending out of the outer surface of the flange of the column, of the long bolt is also cut off from the end of the beam along the length direction. The connection form of the plug-and-play steel structure beam and column connector is simple, and the plug-and-play steel structure beam and column connector is quick and reliable to install on the site, is plug-and-play, greatly increases the speed of construction, and also decreases workload. The invention also discloses an implementation method of the plug-and-play steel structure beam and column connector.

Owner:常熟市宝成机械有限公司

Method for accurately positioning arc-shaped railing glass

InactiveCN109914721APrecise positioningQuick and easy on-site installationBuilding material handlingStairway-like structuresWear resistantArchitectural engineering

The invention relates to the technical field of location of arc-shaped railing glass, and discloses a method for accurately positioning arc-shaped railing glass. The method comprises the following steps: S1, using a measuring tool to perform field measurement and sending out, and recording data; S2, leaving a margin at an arc-shaped railing with a width dimension consistent with the width of the railing, and placing a steel channel along the length direction; S3, welding inner and outer steel plates, and then arranging same in the steel channel in a locating way; S4, welding a steel plate on the side face of the inner steel plate, arranging a wear-resistant rubber plate at the outer side of the welded steel plate and then fixing by using bolts; S5, finally, fixing a steel plate transversely on the floor ground by using expansion bolts, and performing fine finishing so as to realize accurate positioning of the arc-shaped railing glass. The method for accurately positioning the arc-shaped railing glass adopts welding at the glass fixing position, thus enabling positioning to be more accurate; furthermore, fixed-length processing is adopted, so that on-site installation is quick; a glass base is formed in a way of fixing the steel plate with the bolts, so that the safety factor is higher.

Owner:SHENZHEN OVERSEAS DECORATION ENG

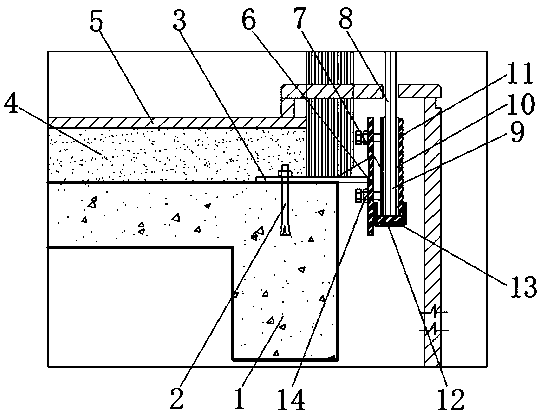

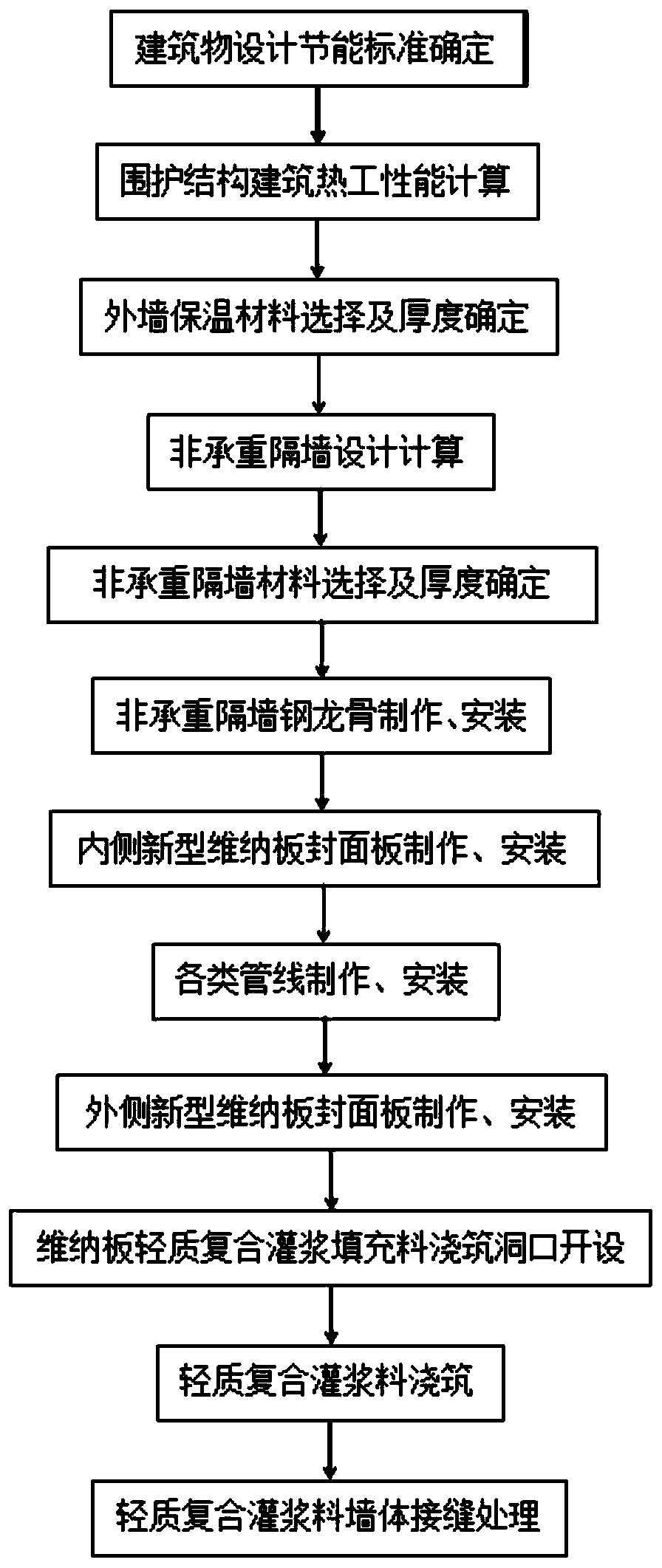

Construction method of wiener plate light composite grouting wall system

InactiveCN110984437AFireproofWith insulationWallsClimate change adaptationLine tubingArchitectural engineering

The invention relates to a construction method of a wiener plate light composite grouting wall system. The method comprises the following steps of material selection and thickness determination, non-bearing partition wall steel keel manufacturing and installation, wiener plate installation, pipeline manufacturing and laying, light composite grouting filler filling and light composite grouting material wall joint treatment. A grouting wall constructed by the construction method can achieve the performances of light weight, high strength, water resistance, fire resistance, heat insulation, goodsound insulation performance, environmental protection and the like. A face plate and a keel can be directly installed and grouted after being machined in a factory and reaching the site, complex construction procedures such as ring beams, structural columns, steel bars and the like existing in a traditional wall body are avoided, the construction speed is high, no pollution such as waste materials, dust and noise is caused, the construction quality and the construction safety of the wall body can be better guaranteed, the site civilized construction is facilitated, and the construction methodhas the obvious characteristics of reliable, safe and efficient construction and advanced technology.

Owner:SHANGHAI BAOYE GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com