Large-area lower edge nested aluminum plate curved hung ceiling with high punching rate and construction method thereof

A large-area, perforation-rate technology, applied to ceilings, building components, buildings, etc., can solve problems such as slow installation speed, high construction cost, and difficulty in suspending steel structure roofs with super-large spaces, achieving fast construction on site and reducing construction costs. Easy effect on cost, flatness and straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

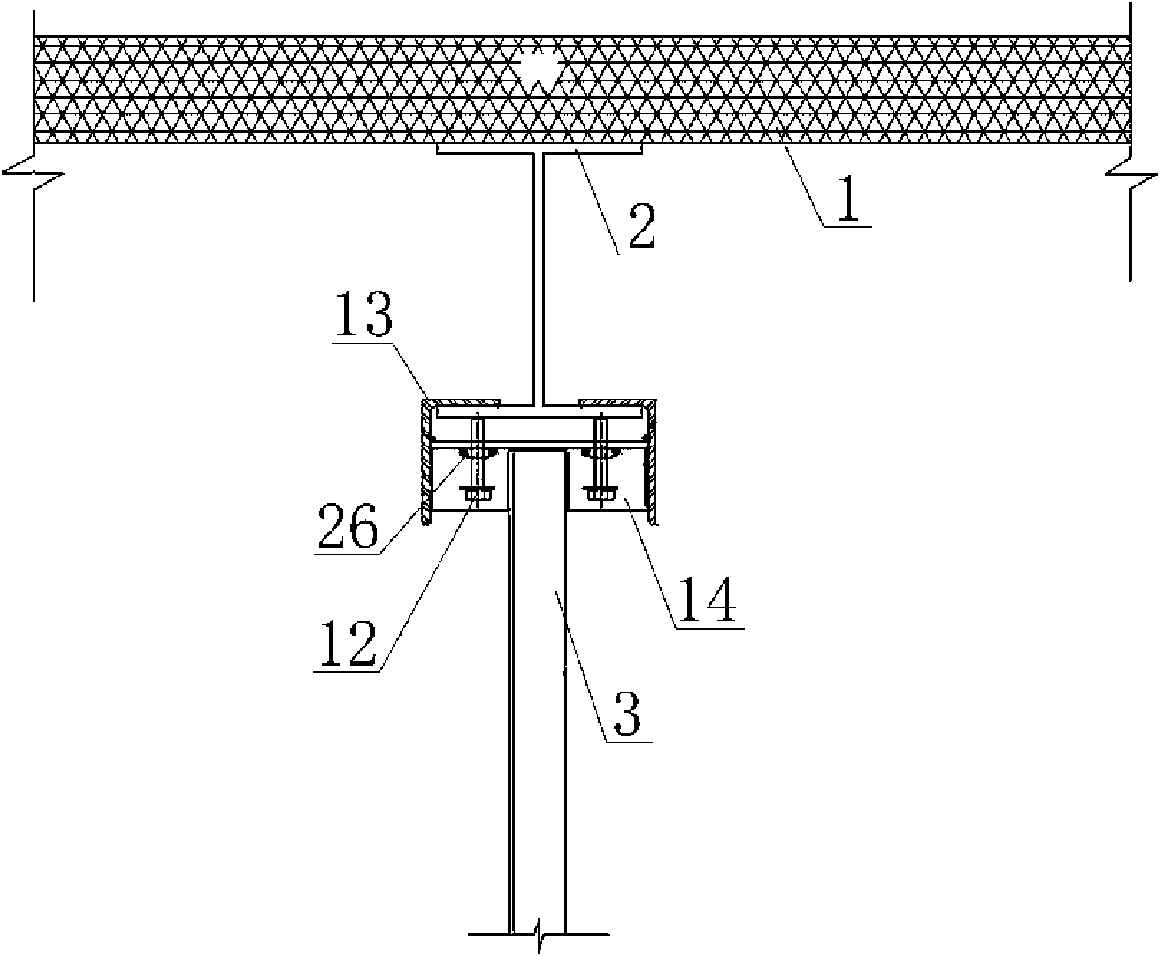

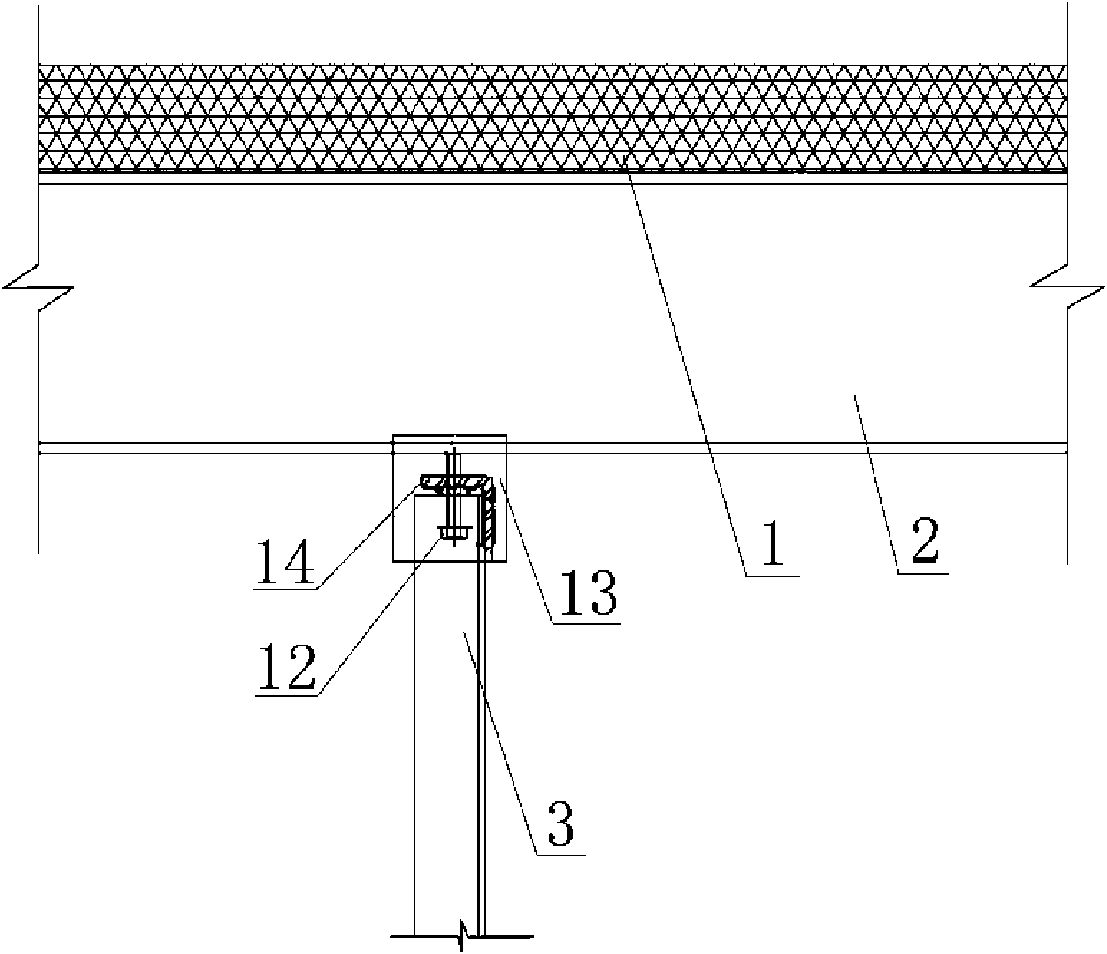

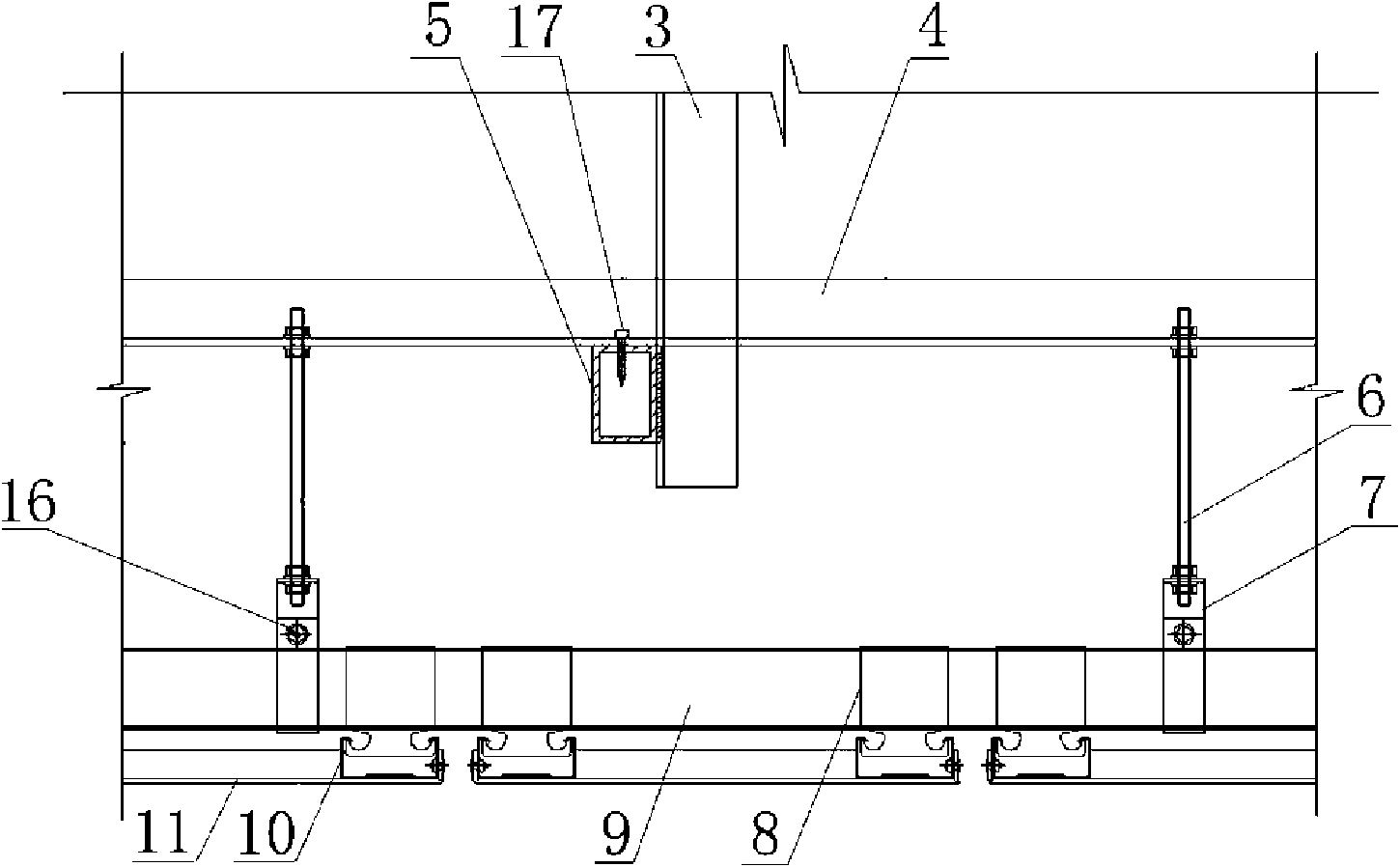

[0037] Examples see figure 1 , figure 2 As shown, this large-area lower edge embracing type high-perforation aluminum plate curved surface ceiling includes suspenders, light steel keel systems and metal ceiling panels under the steel structure beams, and is characterized in that: the steel structure beam 2 is a work The lower flange of the steel structure beam hangs and connects U-shaped clips.

[0038] The U-shaped clip includes a pair of main hanging angle steels 13 and a transverse angle steel 14 connected between the two main hanging angle steels 13, and the above transverse angle steels 14 are connected with the angle steel suspenders 3 in a T shape.

[0039] The two main hanging angle steels 13 of the U-shaped fastener are hugged and connected to the upper surface of the lower flange of the steel structure beam 2, and at least two round holes are opened on the horizontal flange of the transverse angle steel 14, and a welding nut 26 is welded under each round hole, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com