Acid pickling and phosphating production wastewater integrated treatment device and treatment process thereof

A technology for treating device and production wastewater, which is applied in the fields of metallurgical wastewater treatment, special compound water treatment, biological water/sewage treatment, etc. The operation and operation and maintenance are convenient, the operation effect is good, and the effect of the treatment effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

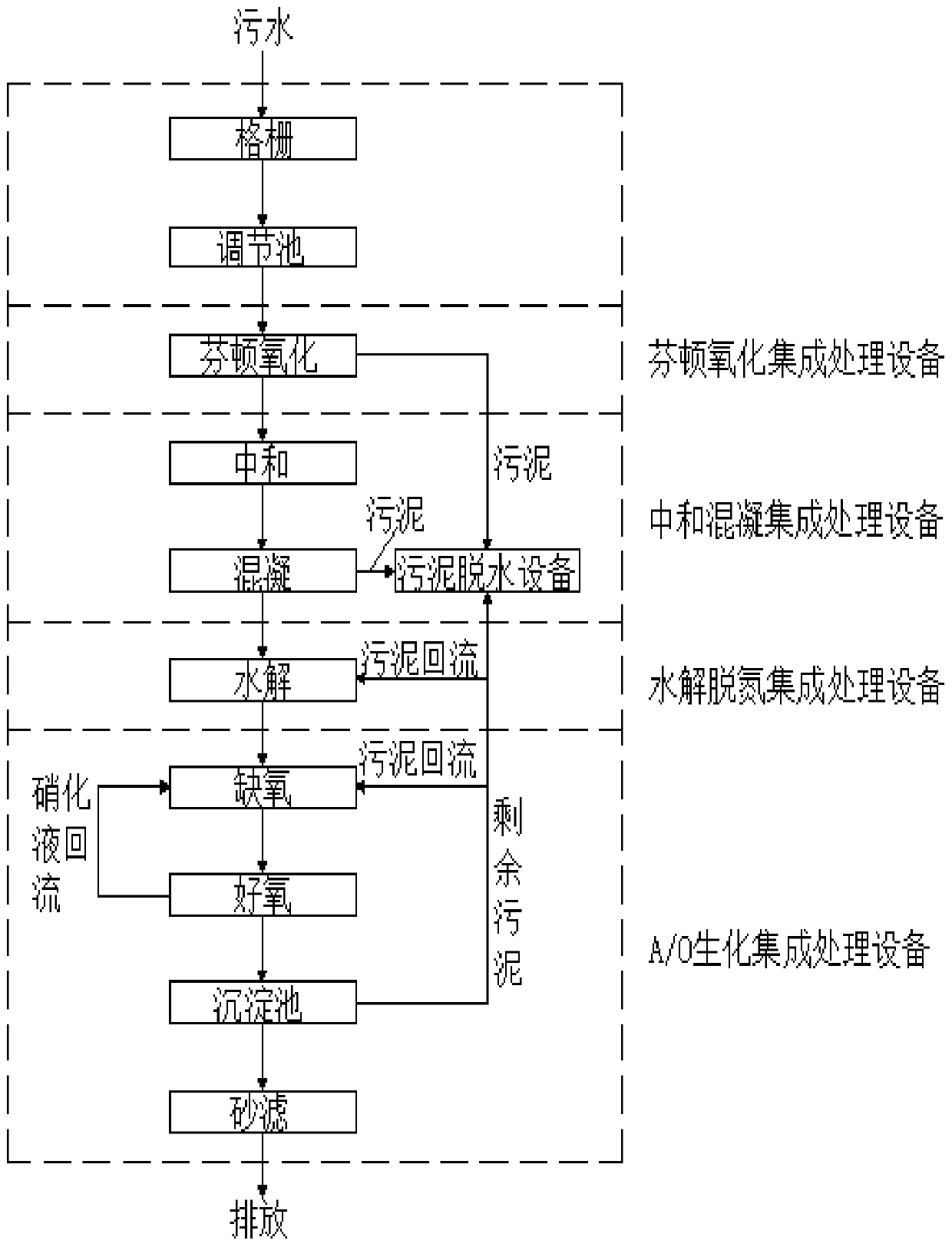

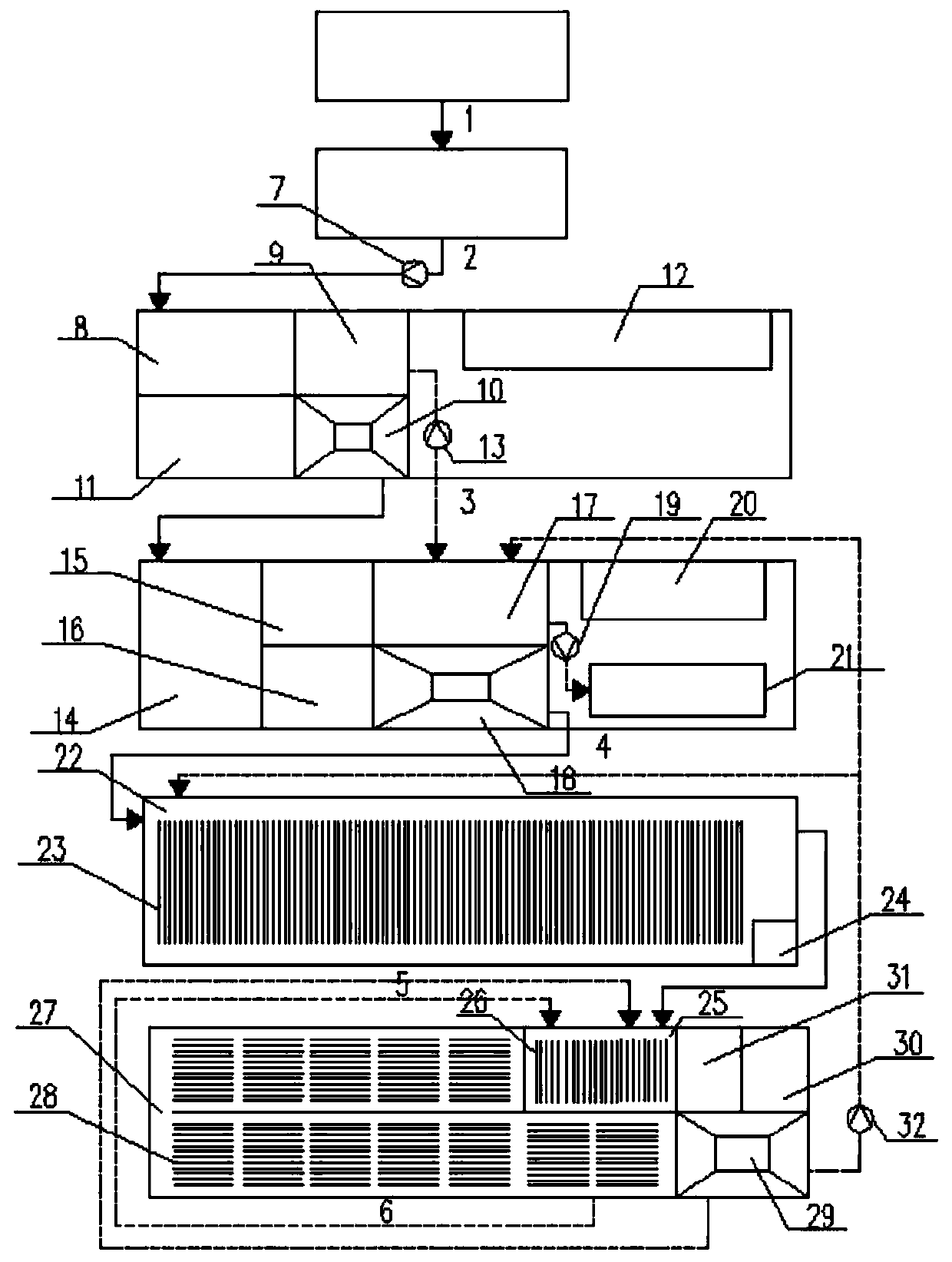

[0040] Such as figure 1 with figure 2 As shown, an integrated treatment device for pickling and phosphating production wastewater of the present invention includes a grid 1, a regulating tank 2, an integrated treatment device for Fenton oxidation 3, an integrated treatment device for neutralization and coagulation 4, and an integrated treatment device for hydrolysis and denitrification 5. A / O biochemical integrated processing device 6, the grid 1, regulating tank 2, Fenton oxidation integrated processing device 3, neutralization coagulation integrated processing device 4, hydrolysis denitrification integrated processing device 5, A / O The biochemical integrated treatment devices 6 are connected sequentially, the water inlet pump 7 is arranged between the regulating tank 2 and the Fenton oxidation integrated treatment device 3, the first sedimentation tank 10 is connected with the neutralization tank 14, and the The second sedimentation tank 18 is connected with the hydrolysis...

Embodiment 2

[0052] The difference between embodiment 2 and embodiment 1 is:

[0053] A treatment process of an integrated treatment device for pickling and phosphating production wastewater treatment according to the present invention comprises the following steps:

[0054] In step (1), the Fenton oxidation reagent is H 2 o 2 , FeSO4.

[0055] In step (2), after the wastewater enters the neutralization and coagulation treatment device, it is first 2 SO 4 Or HCl to properly adjust the pH of the incoming water to around 8.

[0056] In step (3), the average sludge concentration in the hydrolysis reaction tank can be increased by 2g / L.

[0057] In step (4), the dissolved oxygen in the anoxic tank 26 is controlled below 0.5 mg / L, and the sludge return ratio is controlled between 50-200%.

Embodiment 3

[0059] The difference between embodiment 3 and embodiment 1 is:

[0060] A treatment process of an integrated treatment device for pickling and phosphating production wastewater treatment according to the present invention comprises the following steps:

[0061] In step (1), the Fenton oxidation reagent is NaOH, Ca(OH) 2 , PAM.

[0062] In step (2), after the wastewater enters the neutralization and coagulation integrated treatment device, phosphate and SS are removed by adding PAC and PAM;

[0063] In step (3), the dissolved oxygen in the hydrolysis reaction tank is controlled below 0.5 mg / L.

[0064] In step (4), the dissolved oxygen in the aerobic pool 27 is controlled between 2-4 mg / L, and the reflux ratio of the nitrification solution is controlled between 200%-400%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com