Mounting structure for fabricated hung wall surface

An installation structure and prefabricated technology, applied in building structure, covering/lining, construction, etc., can solve problems such as poor installation effect and shaking of wall panels, achieve good overall installation effect, fast installation, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

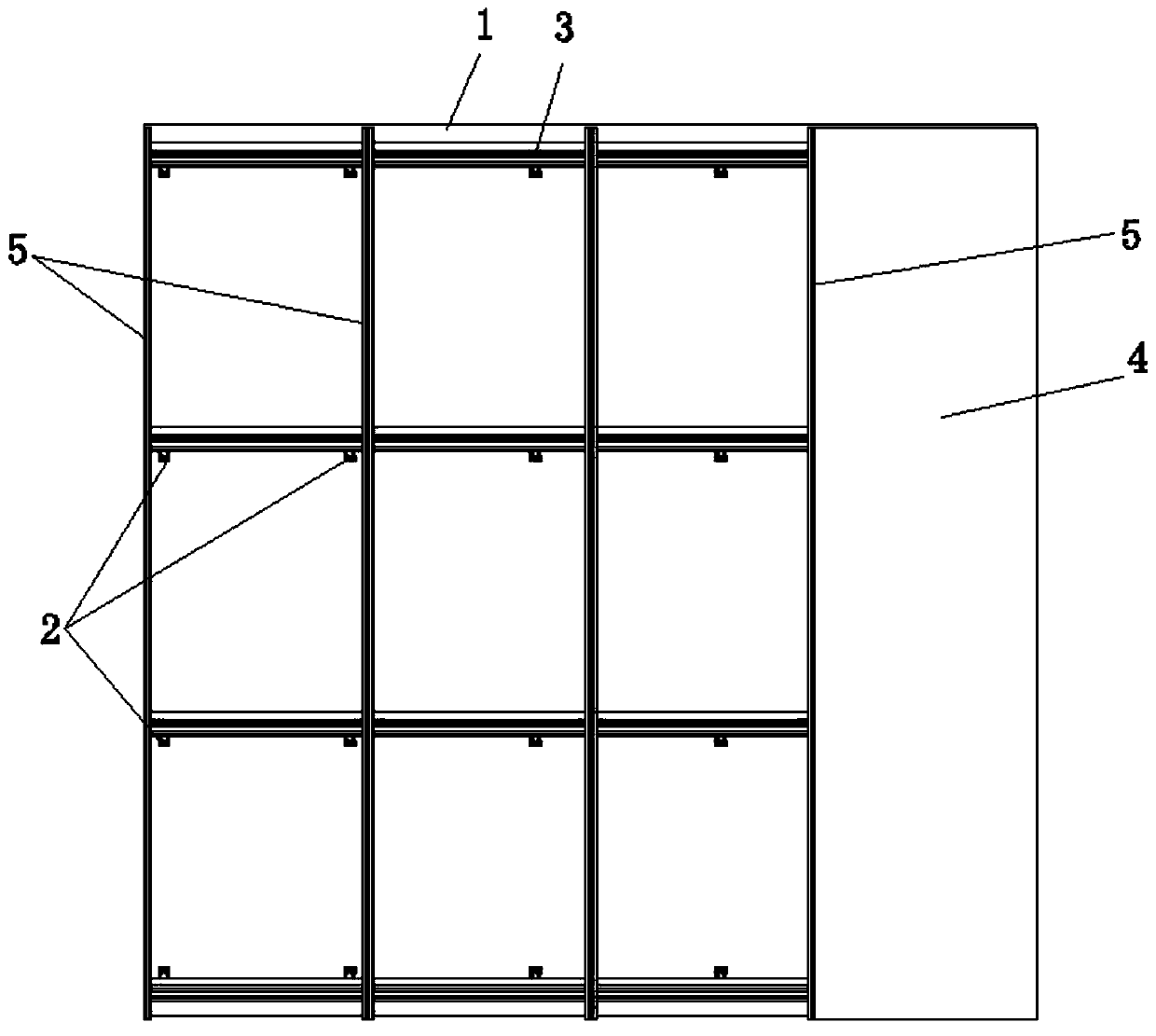

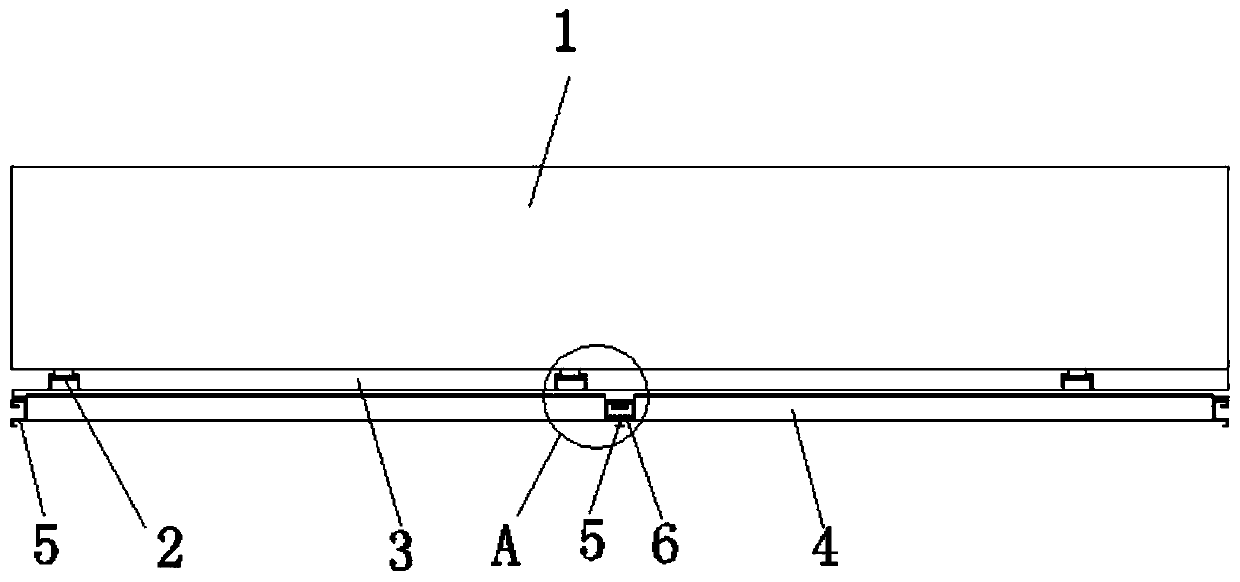

[0038] see Figure 1 to Figure 3 , the figure shows a prefabricated hanging wall installation structure provided by Embodiment 1 of the present invention, which includes: a wall 1; leveling parts 2, which are arranged in a row on the wall 1; , which is connected to the leveling member 2, and each horizontal profile 3 corresponds to a row of leveling members 2; the base plate unit is arranged in multiples, and the base plate unit includes the base plate 4 and the vertical profile 5, and the base plate 4 is located in the horizontal profile 3, and connect the leveling member 2, the vertical profile 5 is arranged on both sides of the base plate 4; the fastener 6, which is clamped with the adjacent vertical profile 5 of the adjacent base plate unit; the decorative panel 7 , which is clamped with the vertical profile 5 .

[0039] The installation structure of a prefabricated hanging wall provided in this embodiment mainly includes a wall 1, a leveling piece 2, a transverse profile...

Embodiment 2

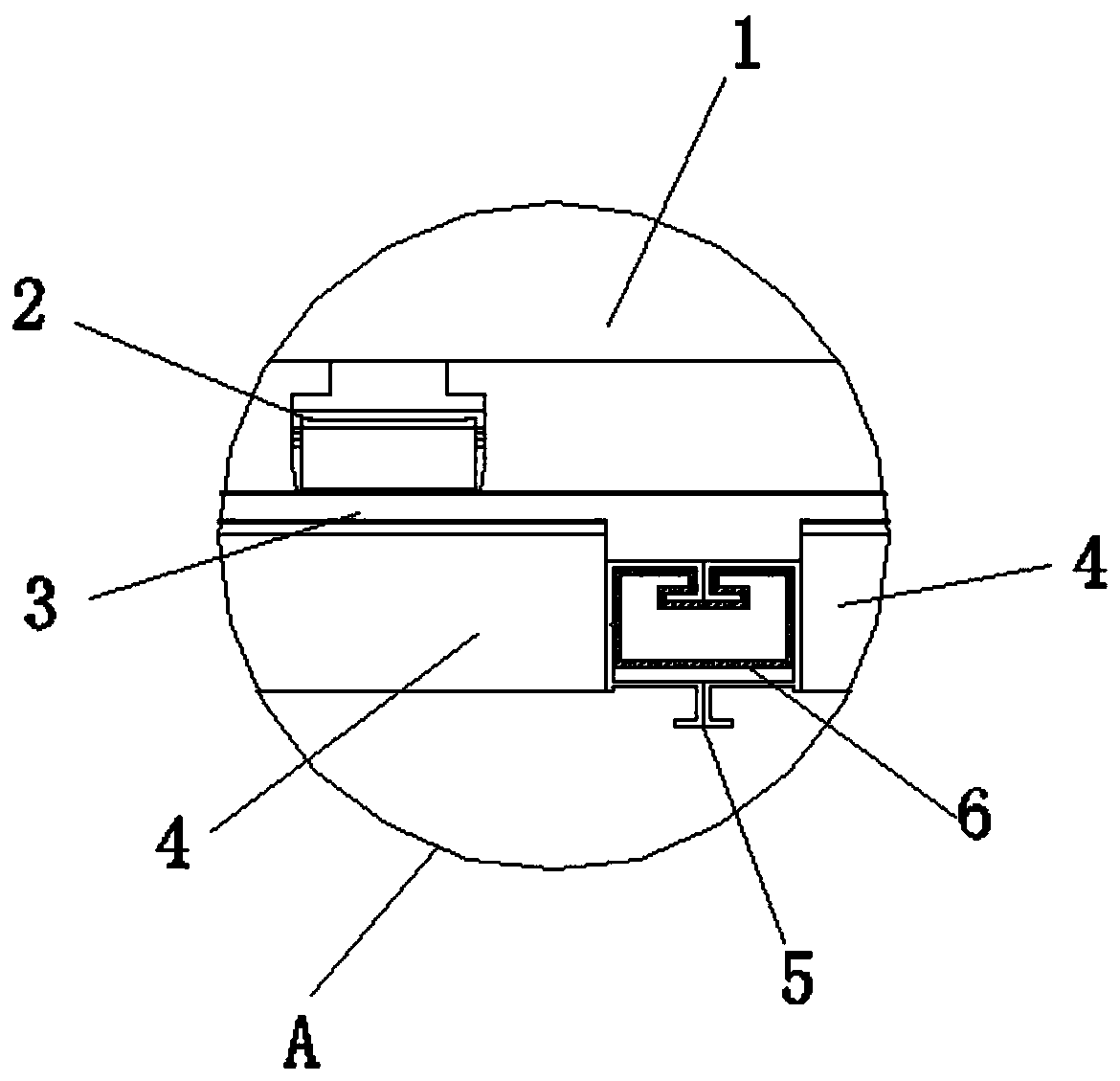

[0047] see Figure 4-5 , the figure shows a prefabricated hanging wall installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: The profile 5 is "U"-shaped, and its two free ends are respectively provided with a first clamping edge 51 and a second clamping edge 52; the first clamping edge 51 and the second clamping edge 52 are both in an "L" shape The first clamping edge 51 is located on the inner side of the vertical profile 5, and the second clamping edge 52 is located on the outside of the vertical profile 5; the bending directions of the first clamping edge 51 and the second clamping edge 52 are consistent. Through the setting of the above structure, not only the clamping connection of the two vertical profiles 5 is facilitated, but also the clamping connection between the veneer and the vertical profile 5 can be realized, and t...

Embodiment 3

[0049] see Figure 5 to Figure 7 , the figure shows a prefabricated hanging wall installation structure provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The fastener 6 is "C"-shaped, and the material of the fastener 6 is plastic; the fastener 6 is provided with a "T"-shaped connecting groove 61; after the two first clamping edges 51 are connected, they are "T"-shaped, tight The firmware 6 is clamped in the two vertical frames 5 ; the two second clamping sides 52 are connected to form a “T” shape, and the decorative panel 7 is clamped with the second clamping sides 52 . Through the setting of the above structure, the use of plastic fasteners 6 to clamp two adjacent vertical frames 5 can not only increase the connection strength between the two, but also prevent friction between the fasteners 6 and the vertical frames 5 The resulting abnormal noise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com