Plug-and-play steel structure beam and column connector and method

A beam-column connection, plug-and-play technology, used in building construction, building material processing, construction, etc., can solve the problem that beam-column installation is easily affected by wind, affects the promotion and application of steel structures, and affects the surrounding environment and construction. progress and other issues, to achieve the effect of fast on-site installation, reliable installation, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

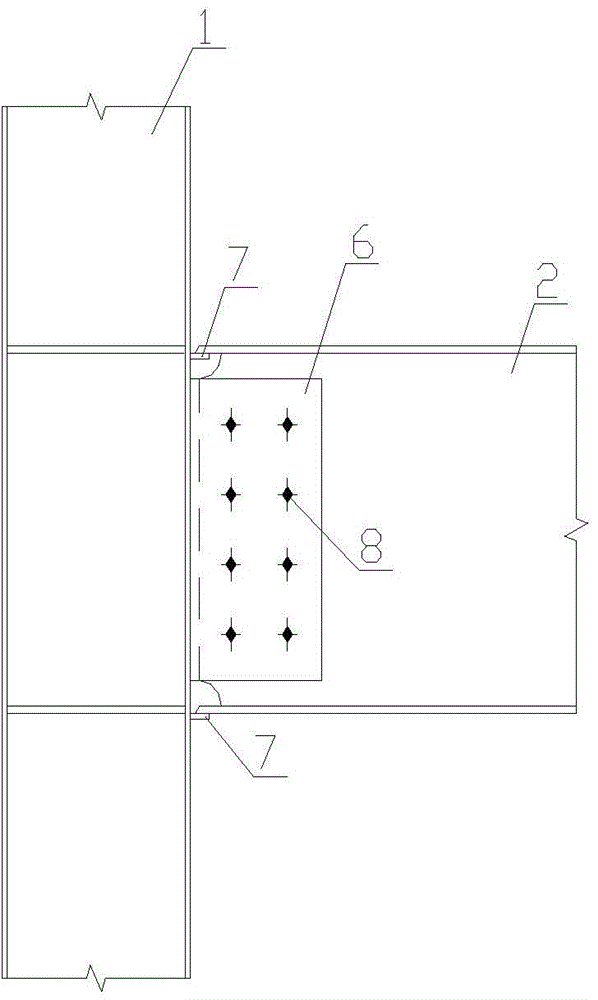

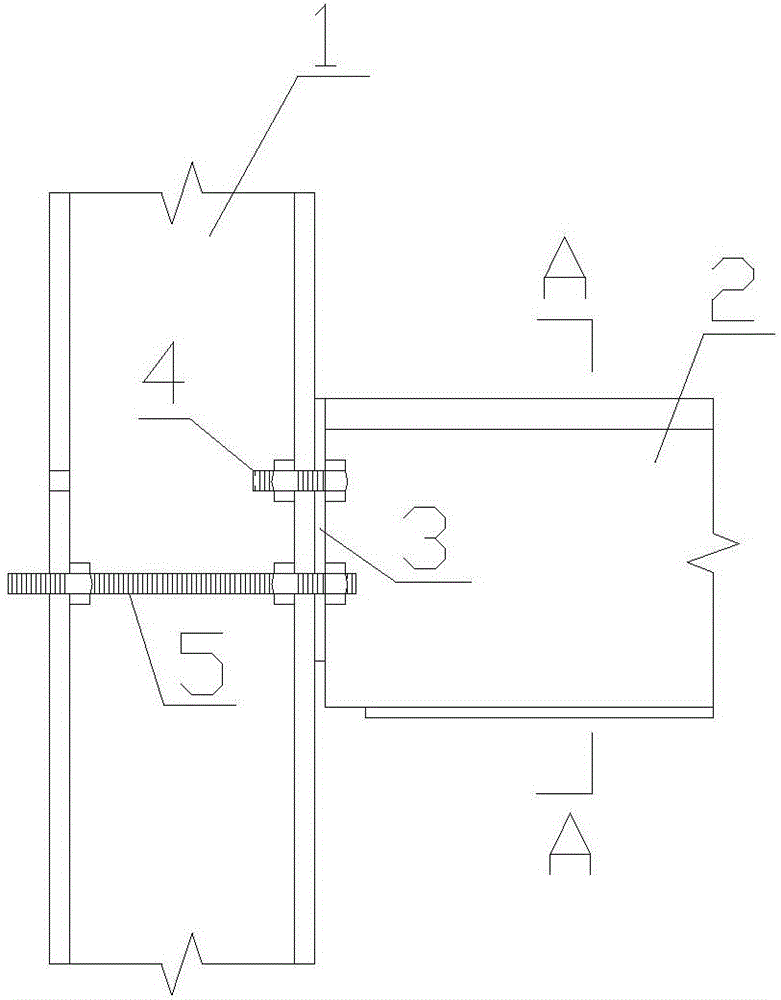

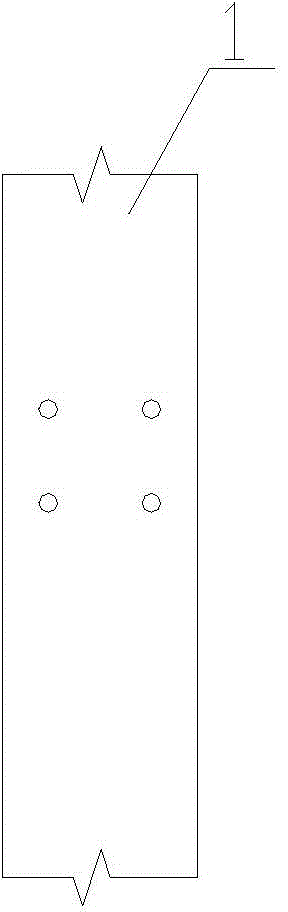

[0027] Such as figure 2 As shown, it is a plug-and-play steel structure beam-column connection device of the present invention, which includes an I-shaped steel column 1 and an I-shaped steel beam 2, both of which are I-shaped steel. Such as image 3 As shown, there are four round holes on the flange plates on both sides of the column 1 through which the short bolts 4 and the long bolts 5 are inserted, and are arranged symmetrically along the web of the column 1 in two horizontal rows. Such as image 3 , Figure 4 As shown, a rectangular steel connecting plate 3 is arranged between the column 1 and the beam 2, and the connecting plate 3 is welded to the end face of the beam 2; Figure 4 , Figure 5 As shown, the width of the connecting plate 3 is equal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com