Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Promotes microphase separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functional resin tectorial membrane proppant and preparation method thereof

ActiveCN101531893AThrough highPrevent passageFluid removalDrilling compositionTectorial membraneSide chain

The invention relates to a functional resin tectorial membrane proppant and a preparation method thereof, and belongs to the technical field of oil-gas field development. The functional resin tectorial membrane proppant comprises aggregate and a resin film coated on the aggregate. Said resin film comprises organic silicon compounds of one or more active groups of amino, hydroxyl, carboxyl, alkoxyl and hydrosulphonyl. The side chain of the organic silicon compound is a hydrophobic group. The cured resin film has different wetting qualities for oil and water. The functional resin tectorial membrane proppant of the invention has a function of allowing the smooth permeation of oil gas and preventing water from penetrating through the proppant. Such a function improves the separation effect ofoil gas and water and reduces the oil production cost. The excellent hydrophobicity of the resin film facilitates the proppant to have excellent water resisting property and improves the crushing resistance of the proppant, so that the stream guidance effect is good for a long time.

Owner:围场满族蒙古族自治县津通铸造材料有限公司

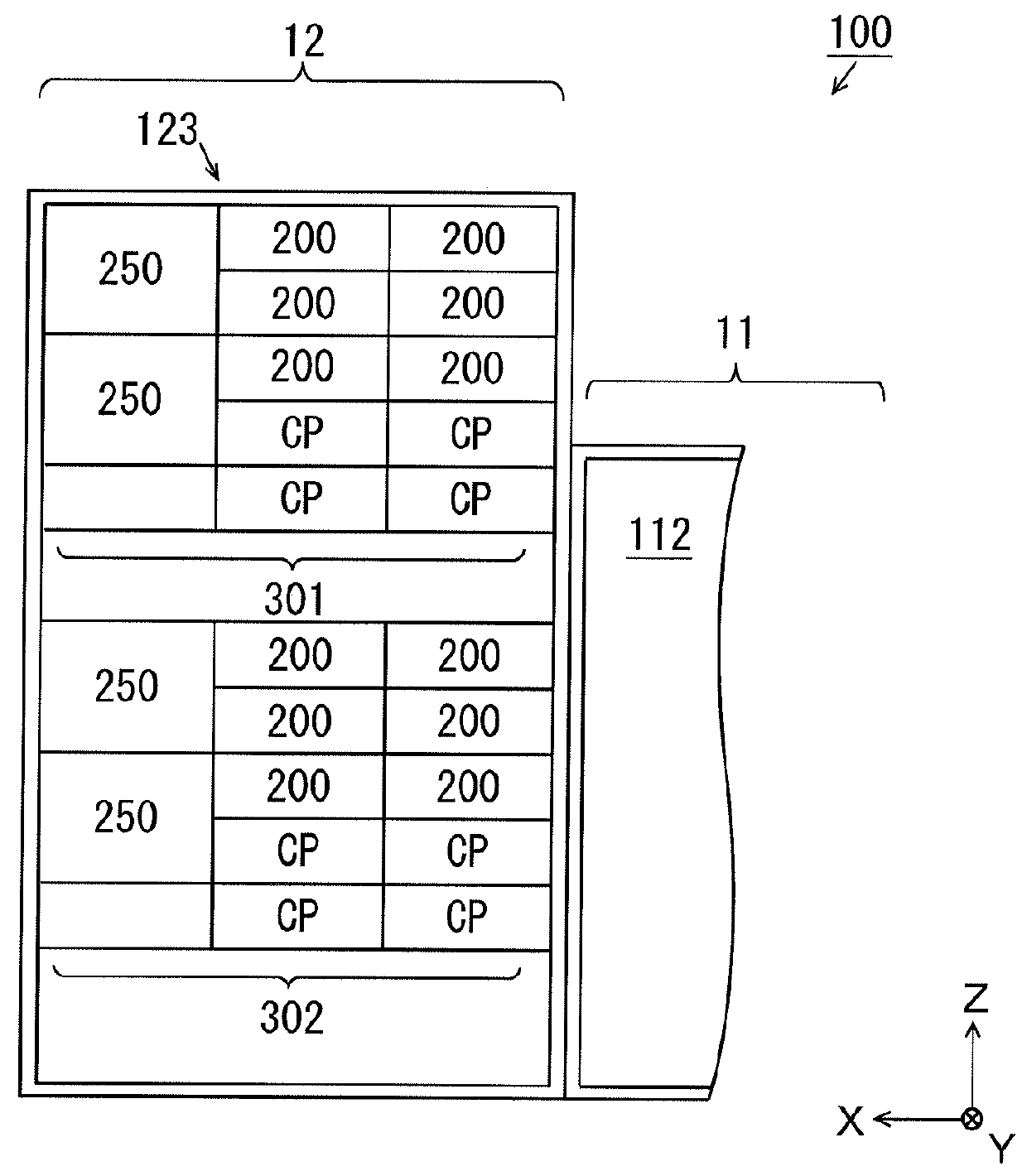

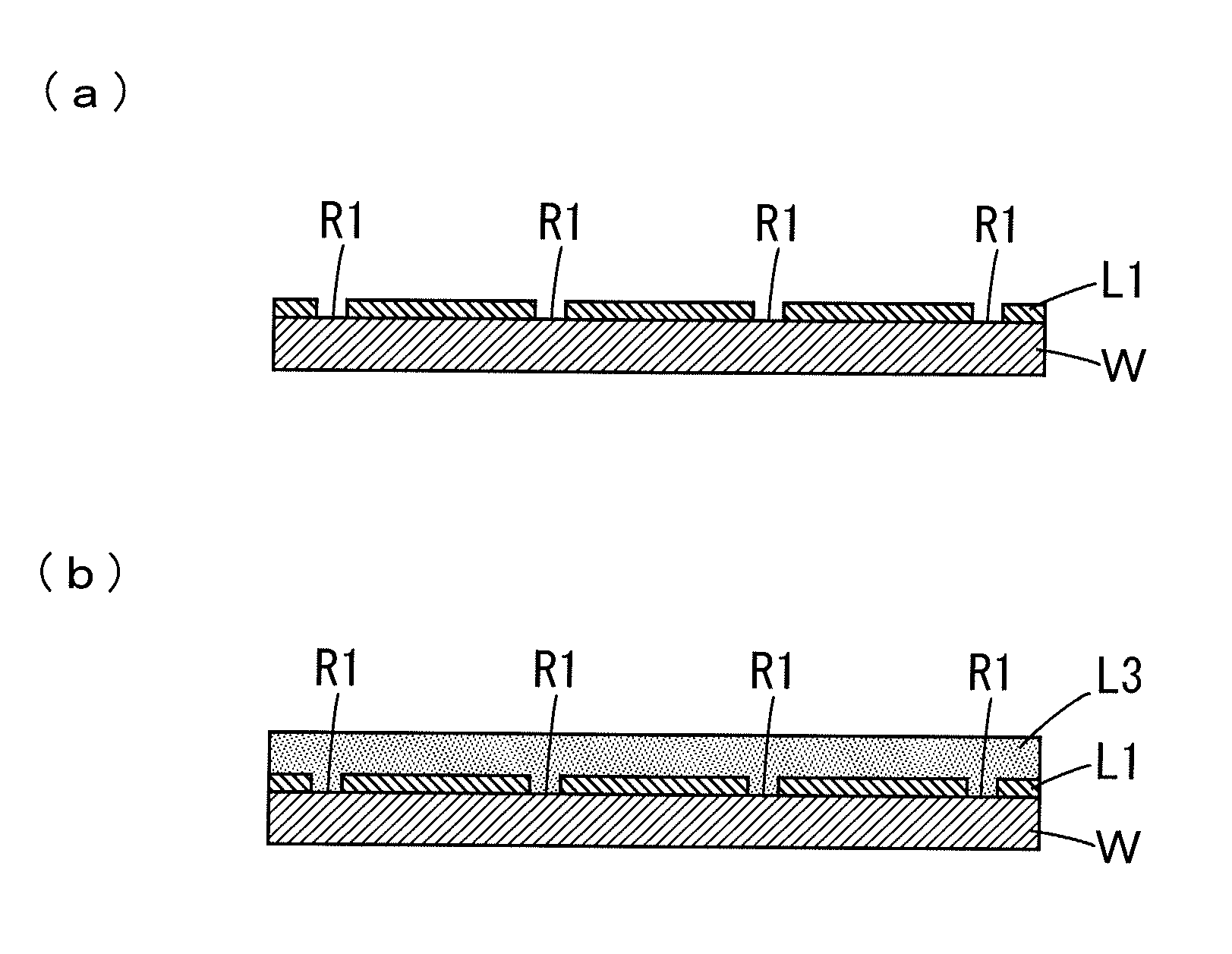

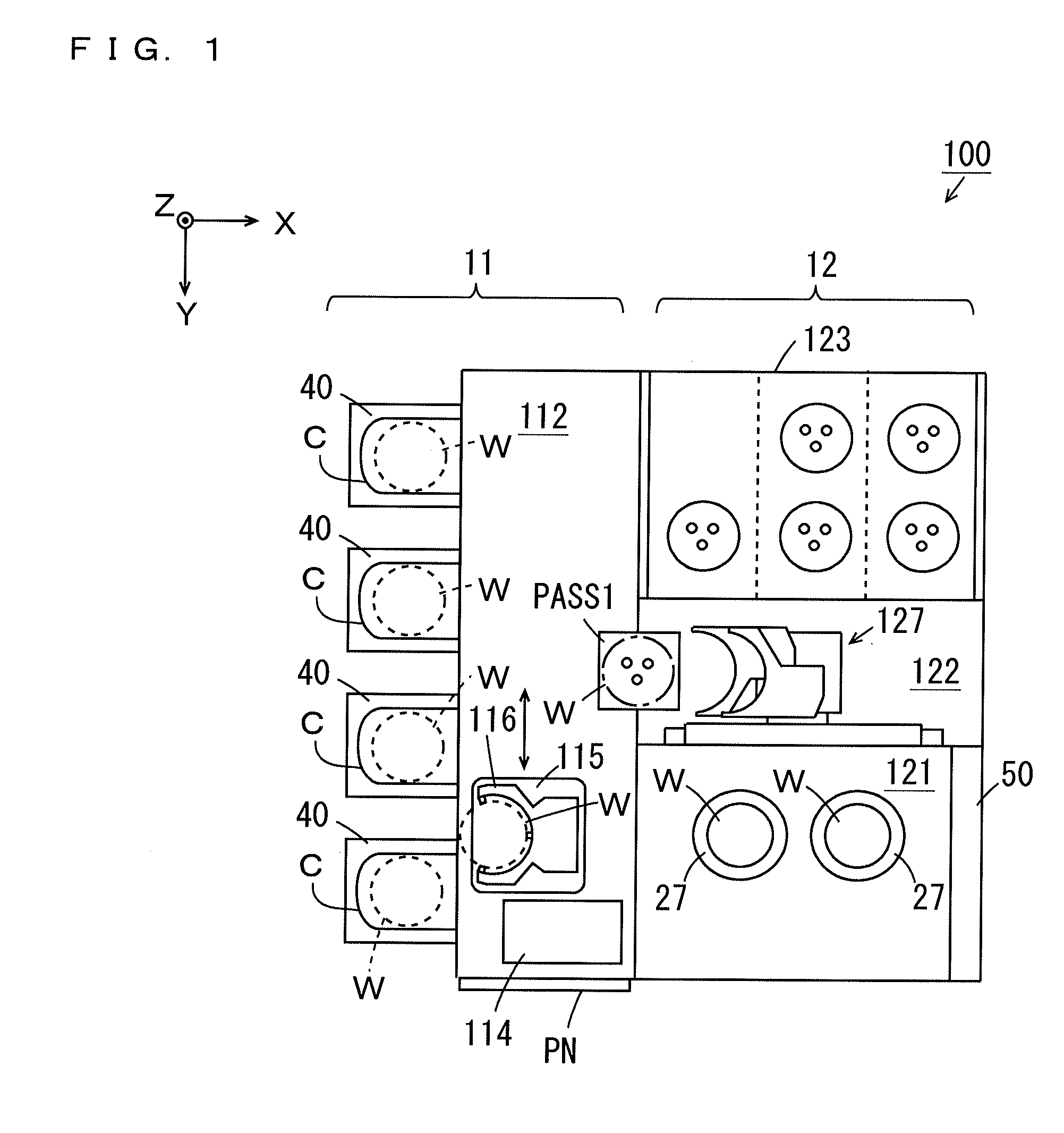

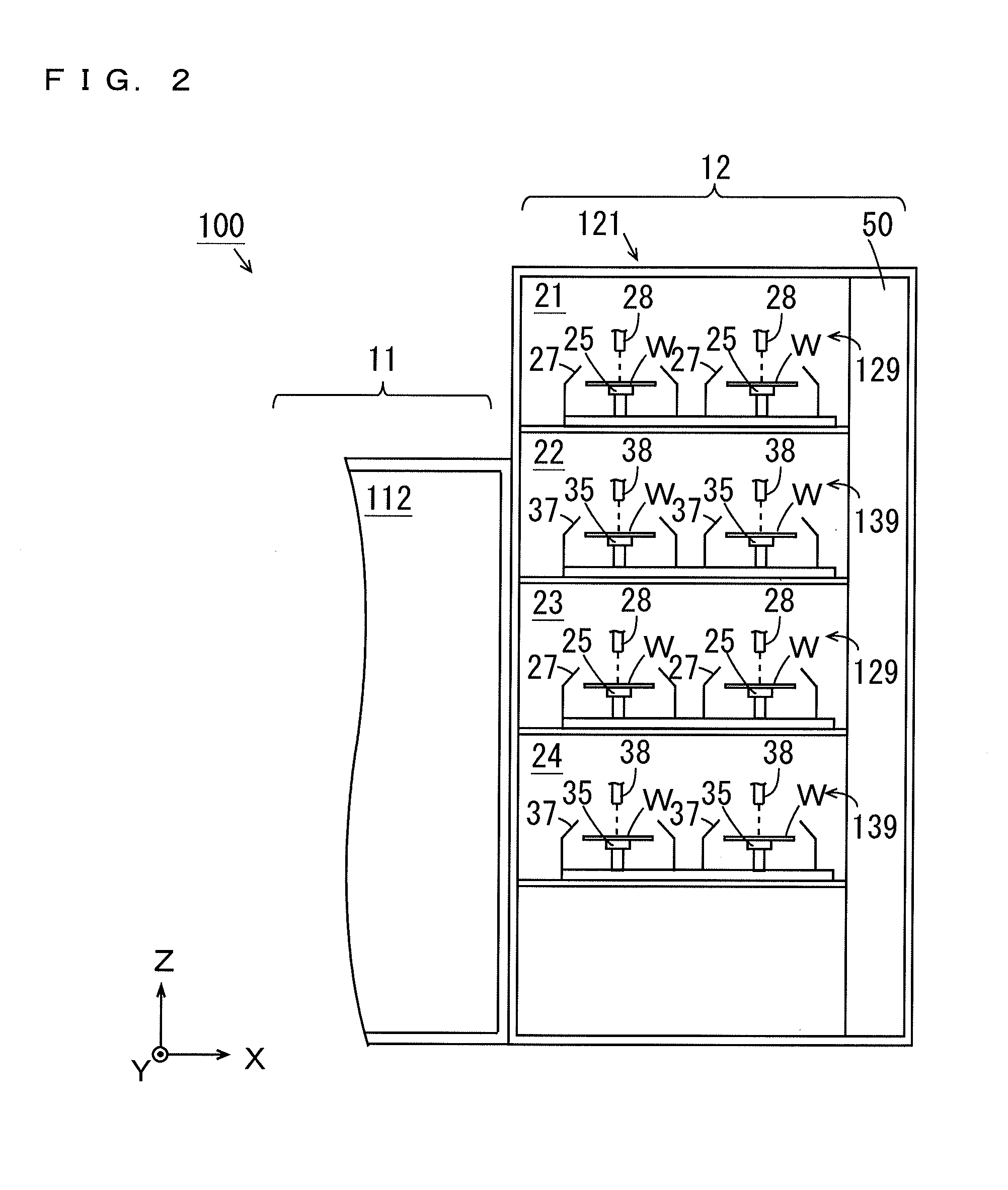

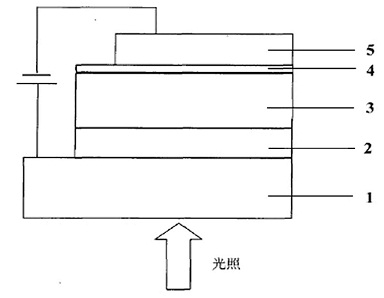

Substrate processing apparatus and substrate processing method

ActiveUS9375748B2Forming accuratelyPromotes microphase separationLiquid surface applicatorsLiquid processingEngineeringSolvent

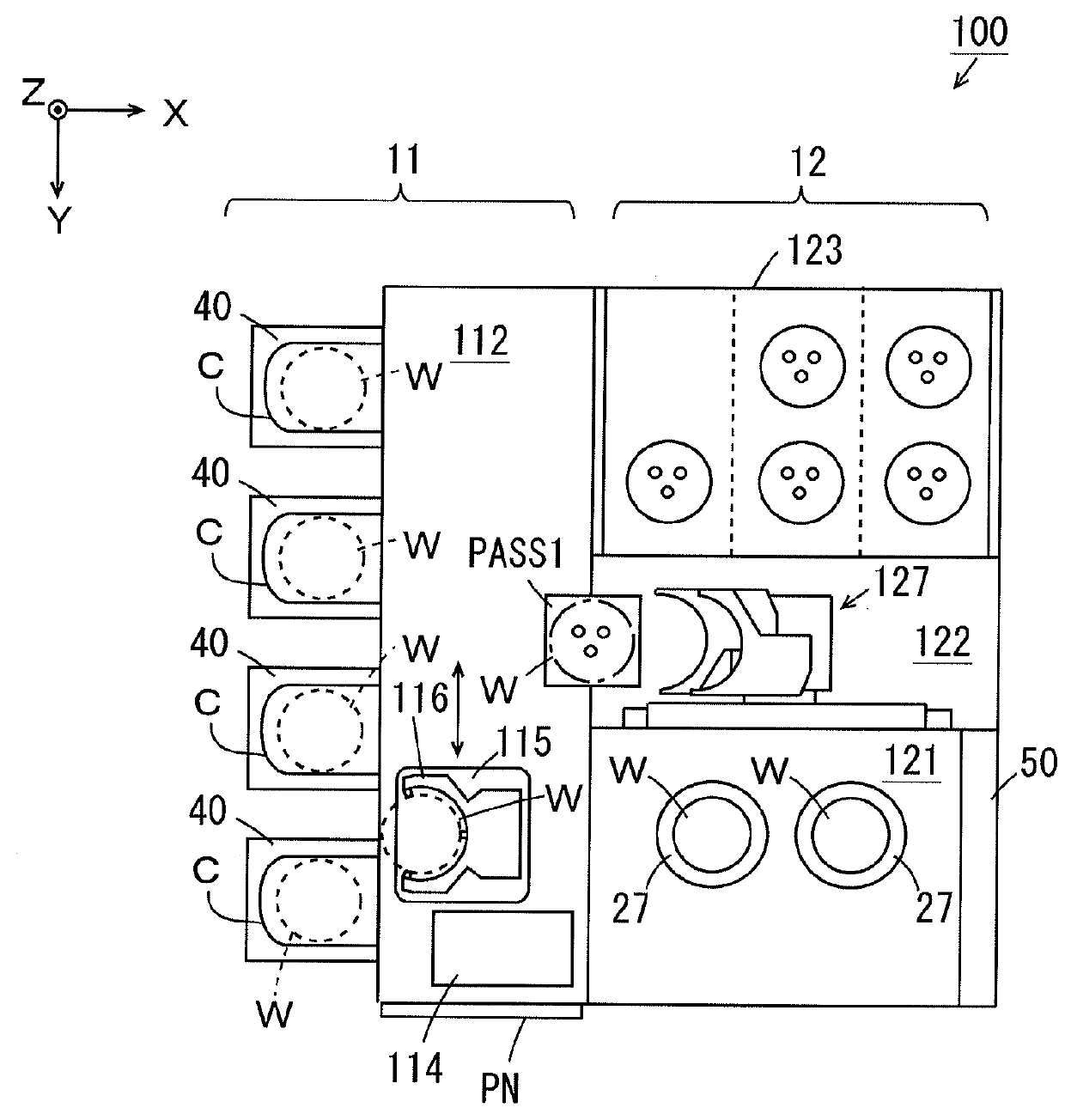

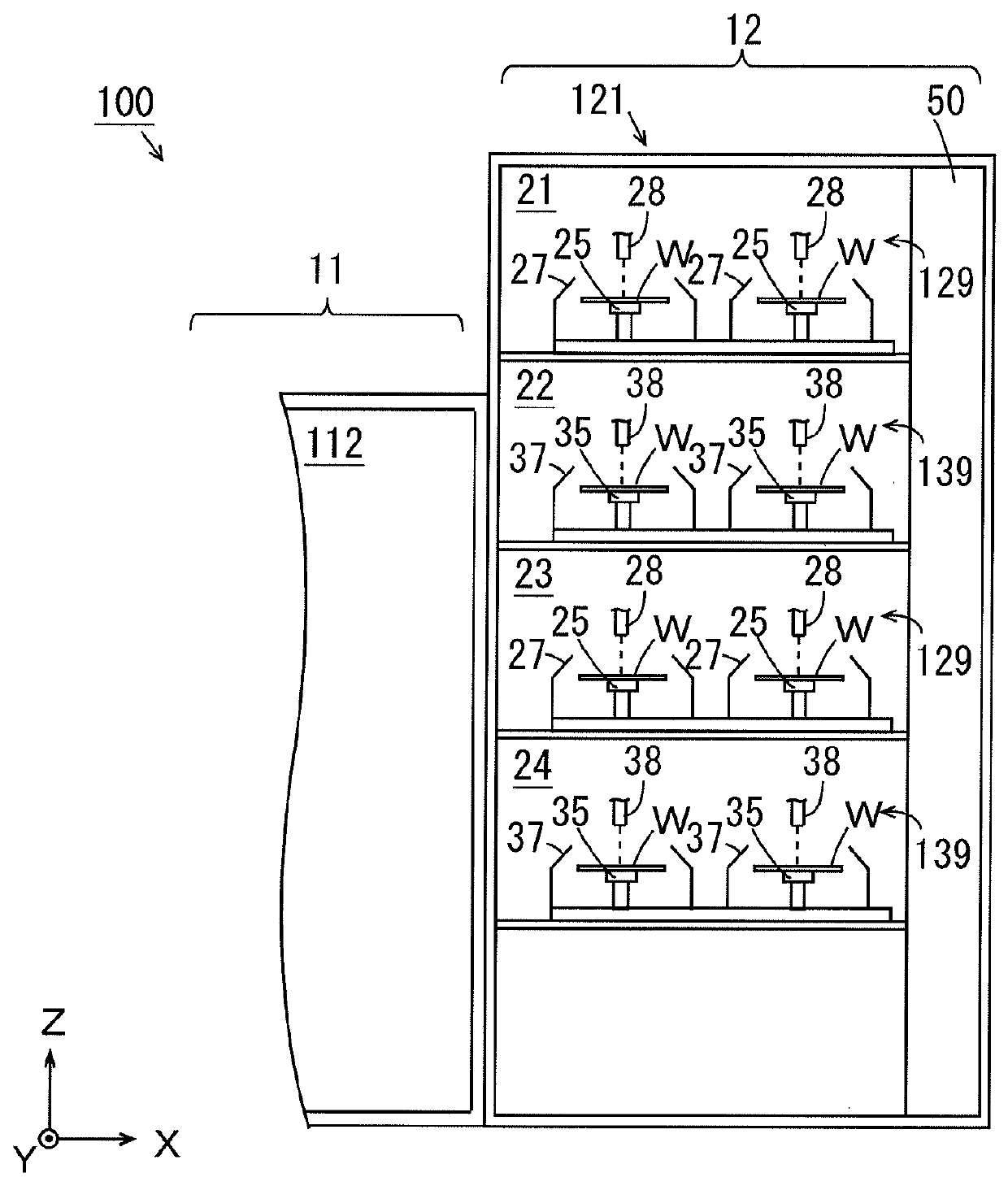

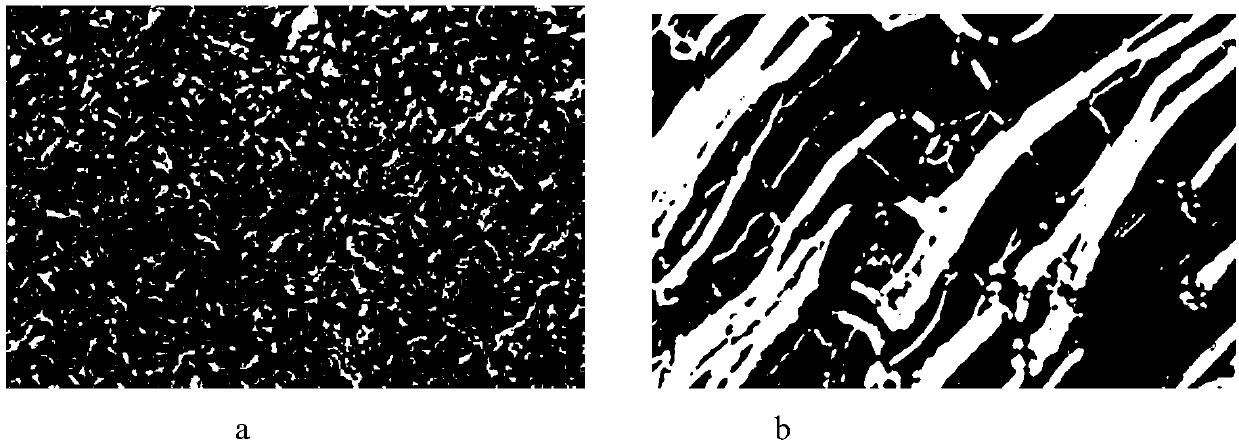

An underlayer is formed to cover the upper surface of a substrate and a guide pattern is formed on the underlayer. A DSA film constituted by two types of polymers is formed in a region on the underlayer where the guide pattern is not formed. Thermal processing is performed while a solvent is supplied to the DSA film on the substrate. Thus, a microphase separation of the DSA film occurs. As a result, patterns made of the one polymer and patterns made of another polymer are formed. Exposure processing and development processing are performed in this order on the DSA film after the microphase separation such that the patterns made of another polymer are removed.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Substrate processing apparatus and substrate processing method

ActiveUS20140022521A1Forming accuratelyPromotes microphase separationElectric discharge tubesPretreated surfacesPolymer sciencePolymer chemistry

An underlayer is formed to cover the upper surface of a substrate and a guide pattern is formed on the underlayer. A DSA film constituted by two types of polymers is formed in a region on the underlayer where the guide pattern is not formed. Thermal processing is performed while a solvent is supplied to the DSA film on the substrate. Thus, a microphase separation of the DSA film occurs. As a result, patterns made of the one polymer and patterns made of another polymer are formed. Exposure processing and development processing are performed in this order on the DSA film after the microphase separation such that the patterns made of another polymer are removed.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Fluorinated polyurethane and preparation method thereof

ActiveCN106674473AEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesDiolFluorine containing

The invention discloses fluorinated polyurethane and a preparation method thereof. The fluorinated polyurethane is prepared through the steps: fluoroalkyl-containing polyether glycol and diisocyanate perform addition polymerization reaction, a tin catalyst is utilized to catalyze, a chain extender is utilized to extend a chain, and an amino silane coupling agent is added to seal ends. A product contains a fluorine-containing polyether block, the fluorine content is high, fluoroalkyl on a polyether lateral group is prone to generating microphase separation and surface migration, polyurethane surface energy is low, and the fluorinated polyurethane is easy to store and cure as the silane coupling agent is utilized to seal the ends. A water contact angle of a coating prepared from the fluorinated polyurethane is higher than 110 degrees, and the coating has excellent water repellency.

Owner:UPCHEM CHINA

Inner crosslinking type caster oil-based waterborne polyurethane emulsion and preparation method thereof

InactiveCN106188457AImprove cross-linking efficiencySimple processPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolEmulsion

The invention relates to inner crosslinking type caster oil-based waterborne polyurethane emulsion and a preparation method thereof. The preparation method of the inner crosslinking type caster oil-based waterborne polyurethane emulsion is characterized by comprising the following steps of (1) adding polymer polyol, castor oil, diisocyanate, a catalyst and a small molecule chain extender into a reactor for reaction, so as to obtain caster oil-based waterborne polyurethane low polymers; (2) adding a hydrophilic chain extender and a polyfunctional-group crosslinking agent into the caster oil-based waterborne polyurethane low polymers, then, performing reaction; adding butanone to regulate the viscosity to be 16.5mPa*S, so as to obtain inner crosslinking type caster oil-based waterborne polyurethane; (3) adding a neutralizer into the inner crosslinking type caster oil-based waterborne polyurethane; after reaction, adding deionized water; performing high-speed shearing emulsification, thus obtaining the inner crosslinking type caster oil-based waterborne polyurethane emulsion after butanone is steamed out. The method has the advantages that the technical process is simple; the crosslinking efficiency is greatly improved; the mechanical property of the product is good.

Owner:WUHAN UNIV OF TECH

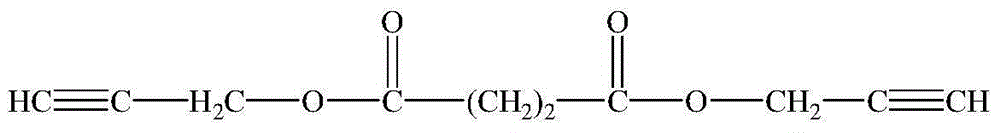

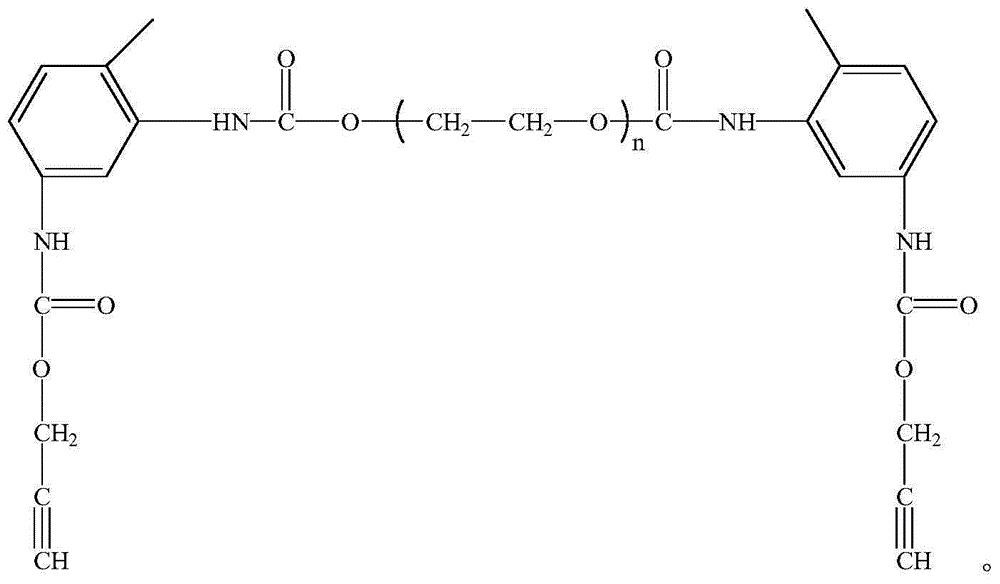

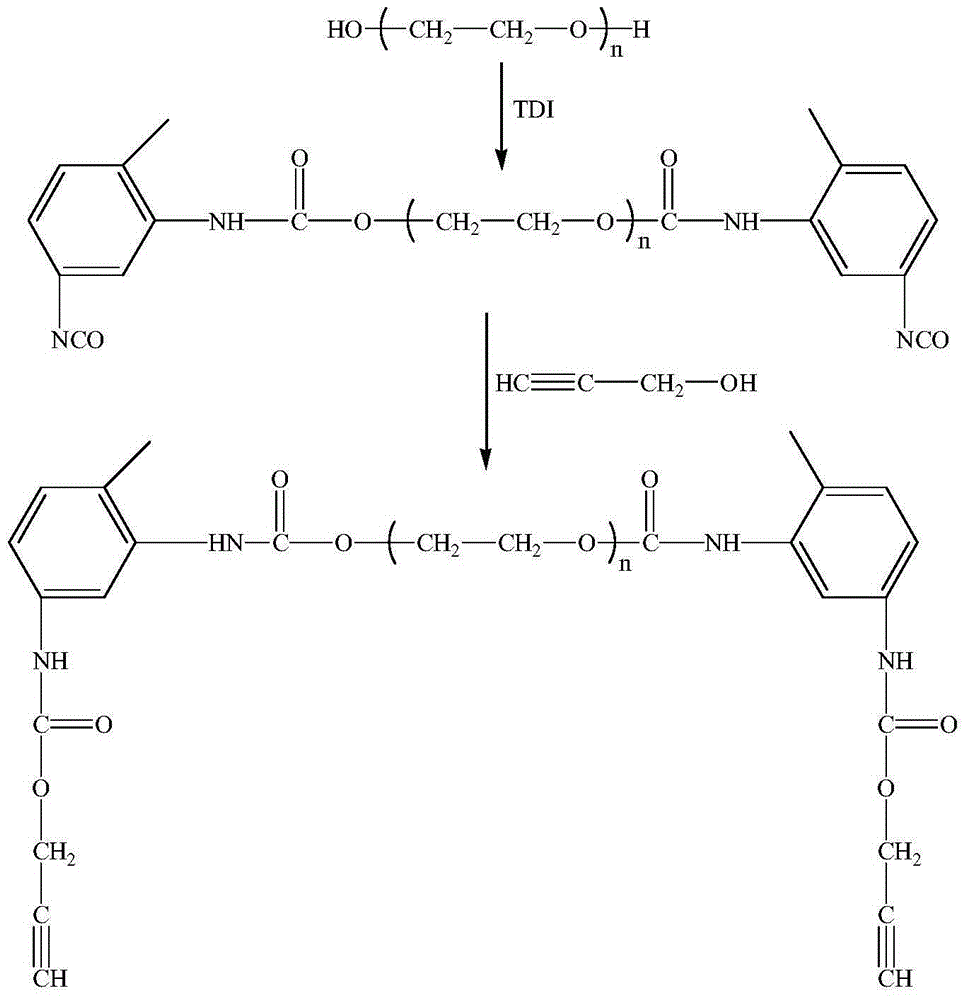

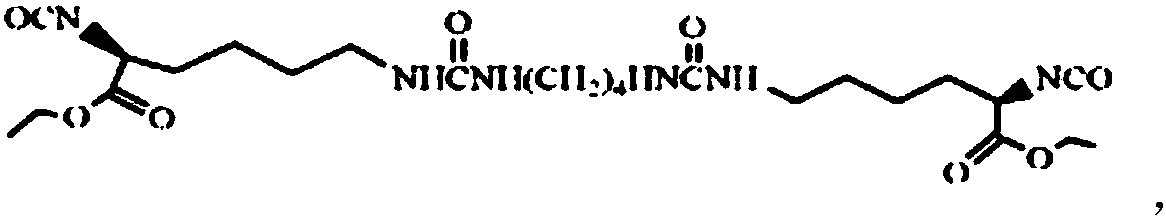

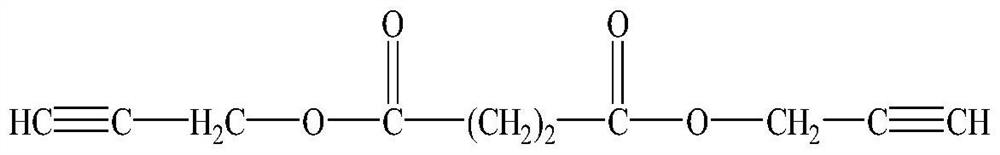

Alkynyl-terminated curing agent and preparation method thereof

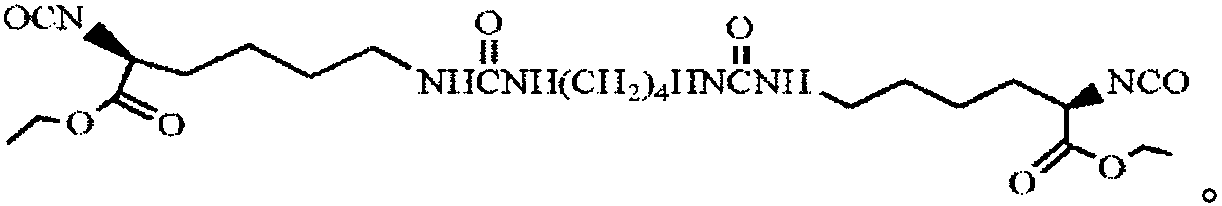

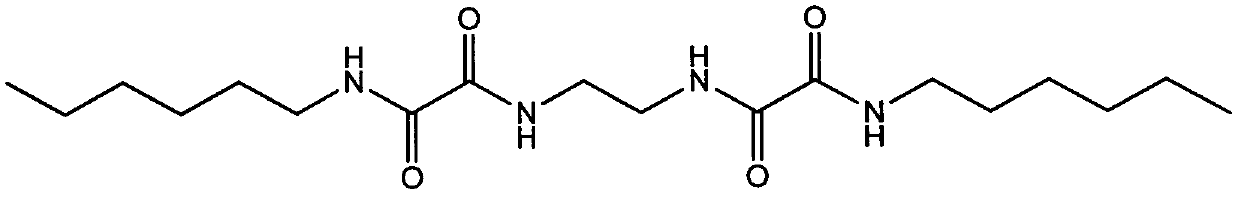

ActiveCN105175707APromotes microphase separationHigh elongationCarbamic acid derivatives preparationOrganic compound preparationAlcoholToluene diisocyanate

The invention discloses an alkynyl-terminated curing agent of which the structural formula is disclosed in the specification, wherein n is a whole number ranging from 5 to 20. The preparation method comprises the following steps: reacting hydroxyl-terminated polyethyleneglycol and toluene diisocyanate by using dibutyltin dilaurate as a catalyst and tetrahydrofuran as a solvent to generate isocyanate-terminated polyethyleneglycol, and adding propiolic alcohol into the reaction system to perform termination reaction, thereby forming the alkynyl-terminated curing agent containing urethano polyether chain. The alkynyl-terminated curing agent is mainly used for solid propellants.

Owner:XIAN MODERN CHEM RES INST

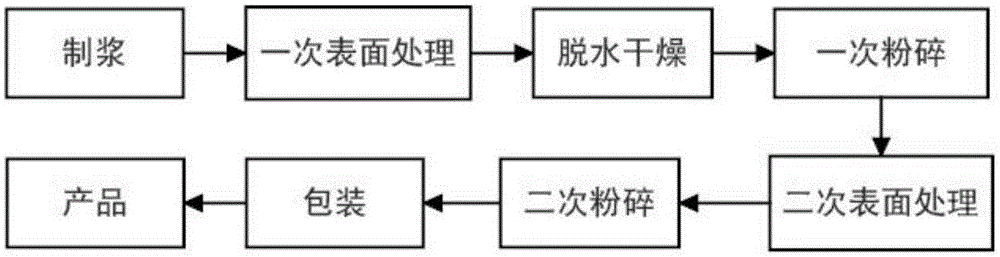

Surface treatment method of special nanometer calcium carbonate for polyurethane sealant

ActiveCN105255218AShorten drying timeGood compatibilityPigment treatment with organosilicon compoundsPigment physical treatmentDrying timeSealant

The invention discloses a surface treatment method of special nanometer calcium carbonate for polyurethane sealant. The surface treatment method includes the steps that 1, paste making is performed; 2, in primary surface treatment, a mixed saponification solution of fatty acid and lysine is added for stirring; 3, in dehydration and drying, modified nanometer calcium carbonate is dehydrated and dried; 4, in primary crashing, powder is crashed; 5, in secondary surface treatment, nanometer calcium carbonate is added into a stirring machine to be stirred in a heating mode, when material temperature is increased to 80 DEG C-90 DEG C, a mixed modifying agent of dimethicone and 3-(3- aminophenoxy) propyl trimethoxy silane is added, and when the material temperature is increased to 100 DEG C-110 DEG C, stirring is stopped, and discharging is performed; 6, in secondary crashing, nanometer calcium carbonate is crashed again. The polyurethane sealant is filled with nanometer calcium carbonate modified through the method, and therefore the mechanical property of the polyurethane sealant is remarkably improved, and surface drying time is shortened. The preparation method is simple, the production cost is low, and good economic benefits are achieved.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

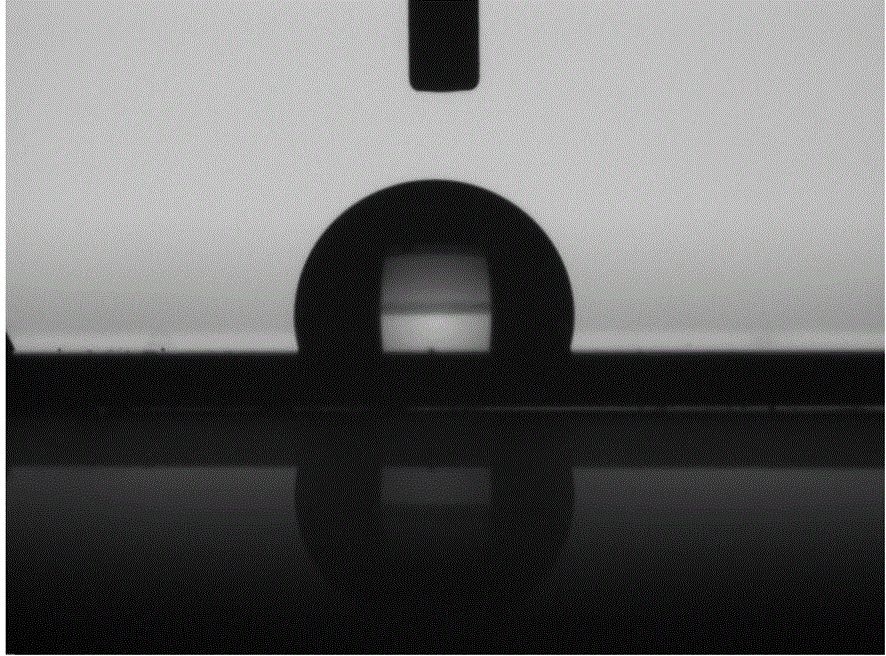

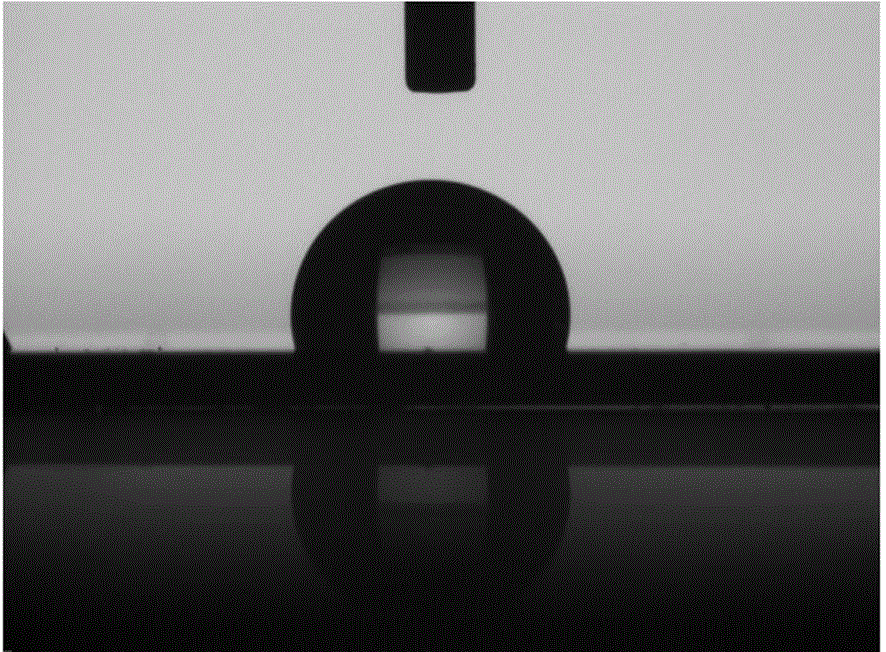

Hydrophobic membrane based on fluorine-containing polyurethane and preparation method of hydrophobic membrane

ActiveCN106750432AEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesPolymer scienceDiol

The invention discloses a hydrophobic membrane based on fluorine-containing polyurethane and a preparation method of the hydrophobic membrane. The preparation method comprises the following steps: spin-coating the fluorine-containing polyurethane into a film; curing to obtain the hydrophobic membrane based on the fluorine-containing polyurethane; taking fluorine-containing alkyl polyether glycol and diisocyanate to be subjected to addition polymerization reaction; and catalyzing through a tin catalyst and extending a chain through a chain extender; and adding an amino silane coupling agent and capping an end to prepare the fluorine-containing polyurethane. The product has a fluorine-containing polyether block and high fluorine content; perfluoroalkyl located at a polyether side easily has micro-phase separation and surface migration; the surface energy of the polyurethane is low; and the fluorine-containing polyurethane is subjected to end capping by the silane coupling agent and is easy to store and easy to cure. The hydrophobic membrane based on the fluorine-containing polyurethane, disclosed by the invention, has a water contact angle higher than 110 degrees and good water repellency.

Owner:SUZHOU UNIV

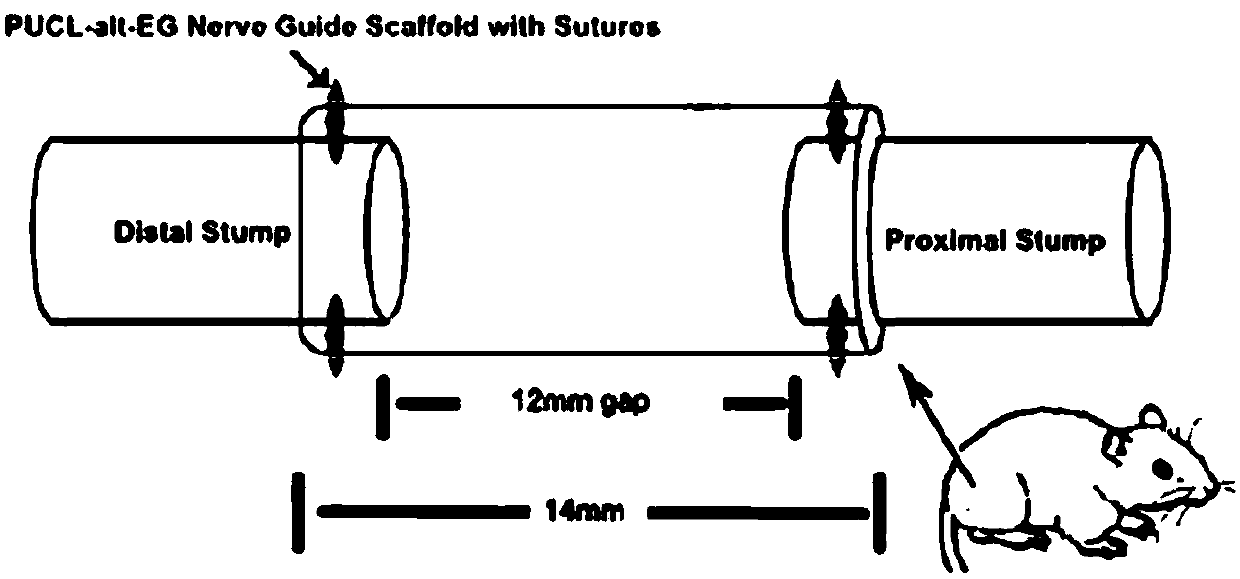

Novel degradable polyurethane biological material as well as preparation method and application thereof

InactiveCN107686546AControllable Surface MicrostructureWell-controlled surface microstructureTissue regenerationProsthesisChemical structureMicro structure

The invention relates to a novel biodegradable polyurethane biomaterial, its preparation method and its application in degradable implant and non-implant medical devices. The new material is an alternating block polyurethane polymer material based on biodegradable polyester diol and hydrophilic polyether diol. It is obtained by the selective coupling reaction between intermediate or aliphatic polyester diols and diisocyanate-terminated aliphatic polyester blocks. The product of the present invention has a controllable and predictable chemical structure and regular polymer chain arrangement, and has a surface microphase patterned structure, and can be widely used in many medical and non-medical device fields, among which peripheral nerve repair catheters, half-moon Excellent performance has been shown in applications such as plate repair, anti-adhesion films, meninges, eyelid reconstruction scaffolds, trauma dressings, bone composite porous repair scaffolds, and other tissue regeneration of soft and hard tissues.

Owner:许开天

Nano composite soy protein plastic and preparation method thereof

InactiveCN104861662ARealize resource utilizationImprove and increase water resistancePlasticizerIsolated Soy Protein

The invention relates to a nano composite soy protein plastic and a preparation method thereof. The nano composite soy protein plastic is prepared by the following steps: with soy isolate protein as a base material, dialdehyde polysaccharide with the aldehyde content of 5%-80% as a cross-linking agent, and amino nano clay as a nano filler, adding a plasticizer which is 10%-30% of dry weight of the soy isolate protein and a certain amount of deionized water; carrying out hot-pressing by using a hot press at 80-140 DEG C and 5-50MPa for 3-30 minutes. The nano composite soy protein plastic prepared by the method has relatively high water resistance, mechanical property and heat stability, is an environment-degradable high-strength protein plastic, and has a wide application prospect in the fields such as biological materials, foods and medicine packaging.

Owner:SICHUAN UNIV

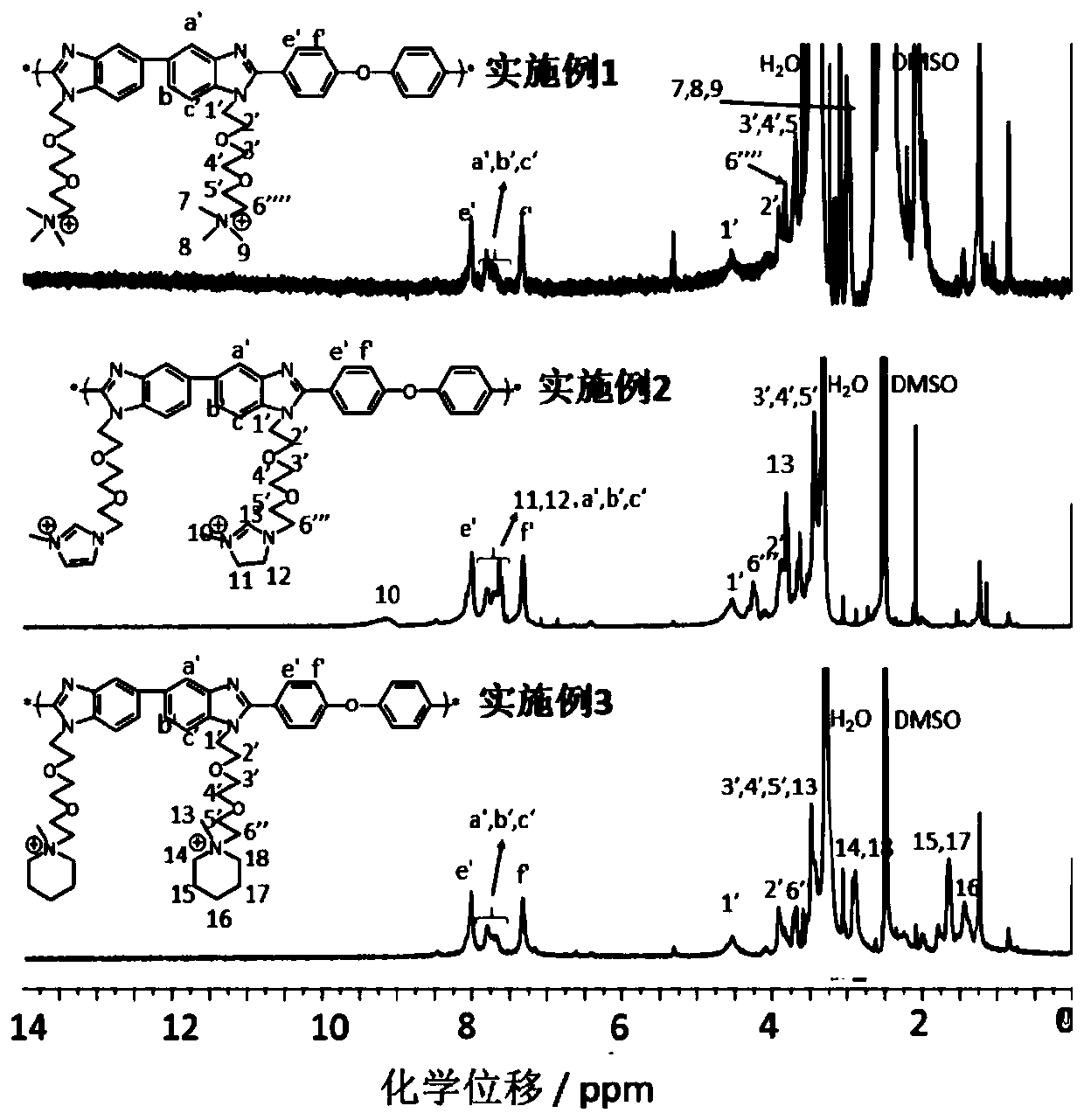

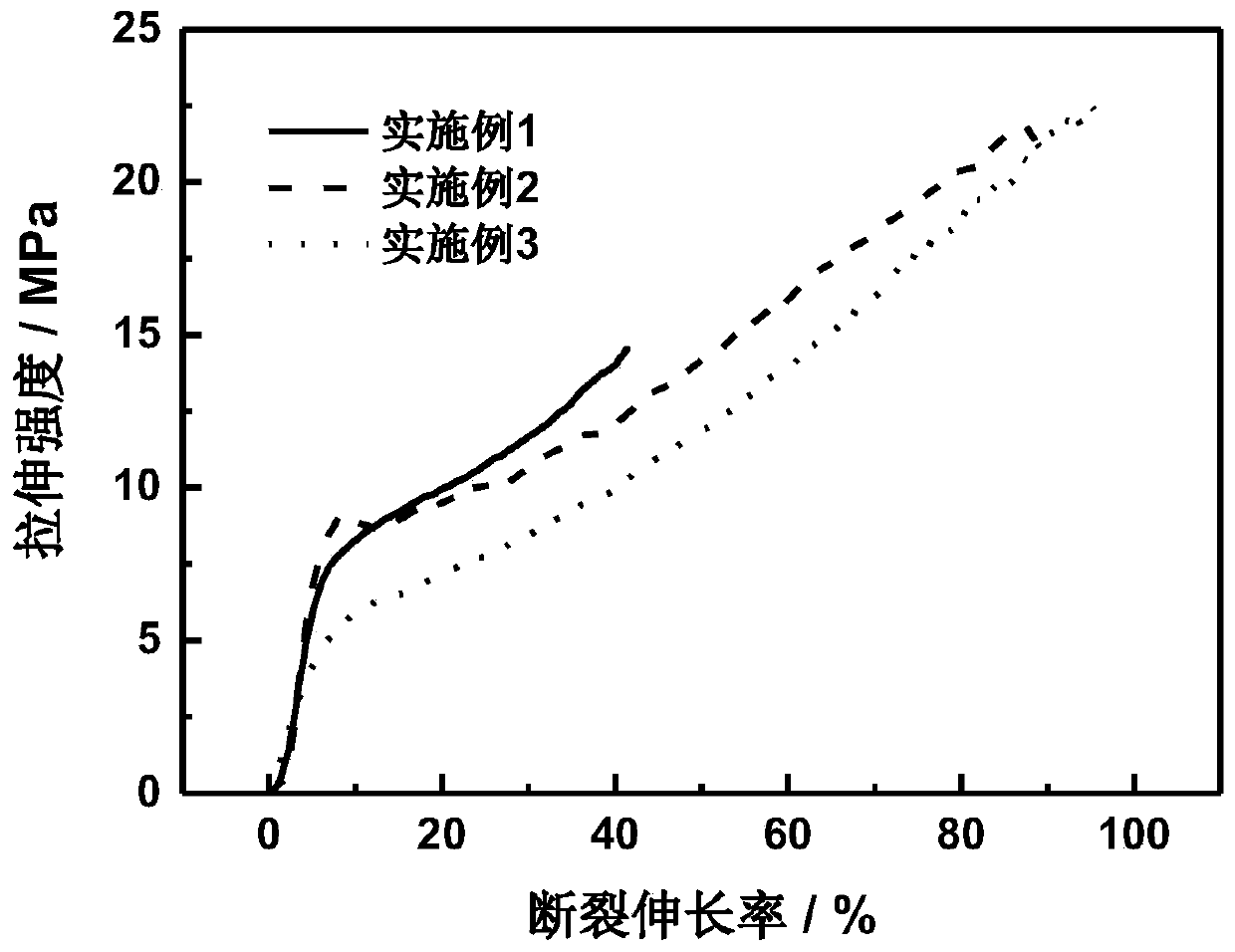

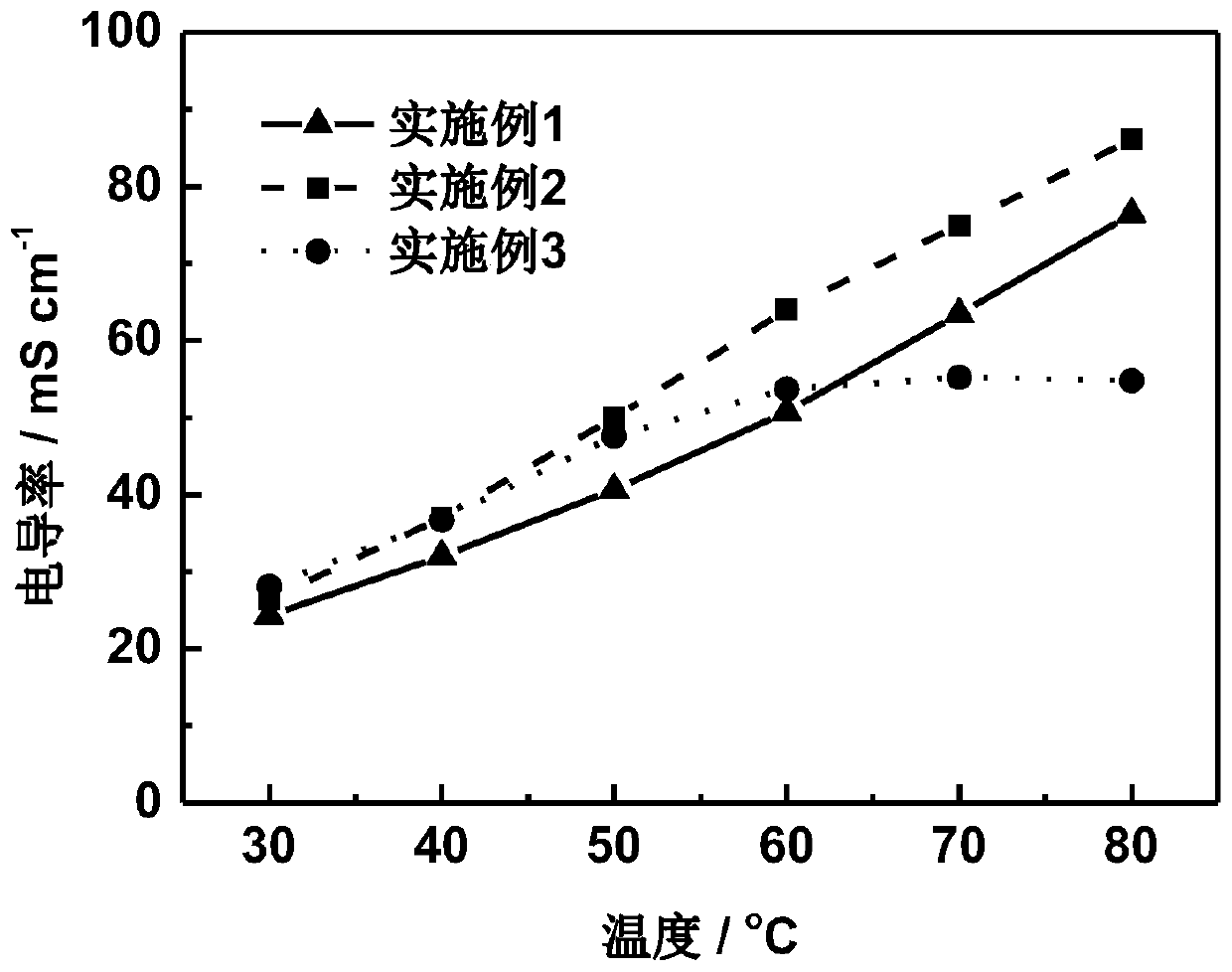

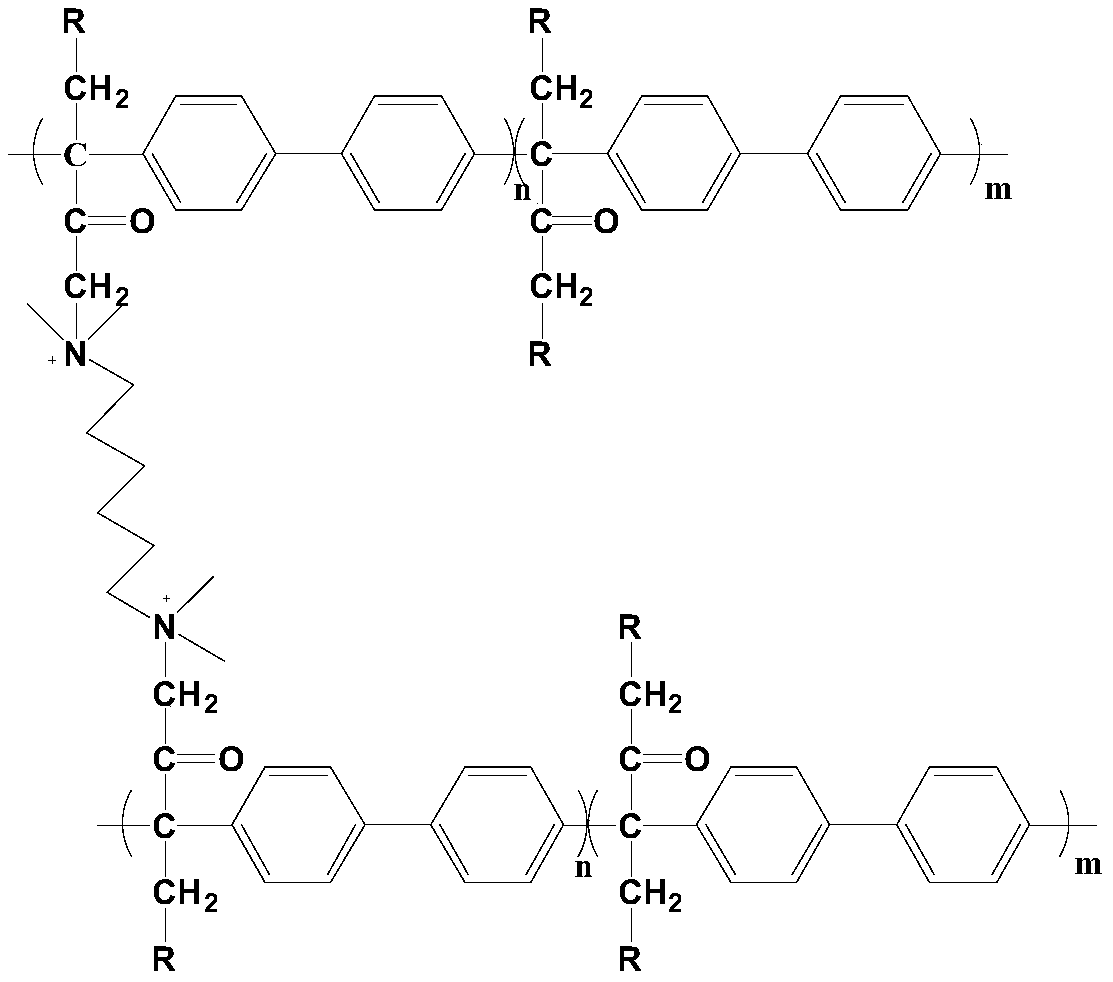

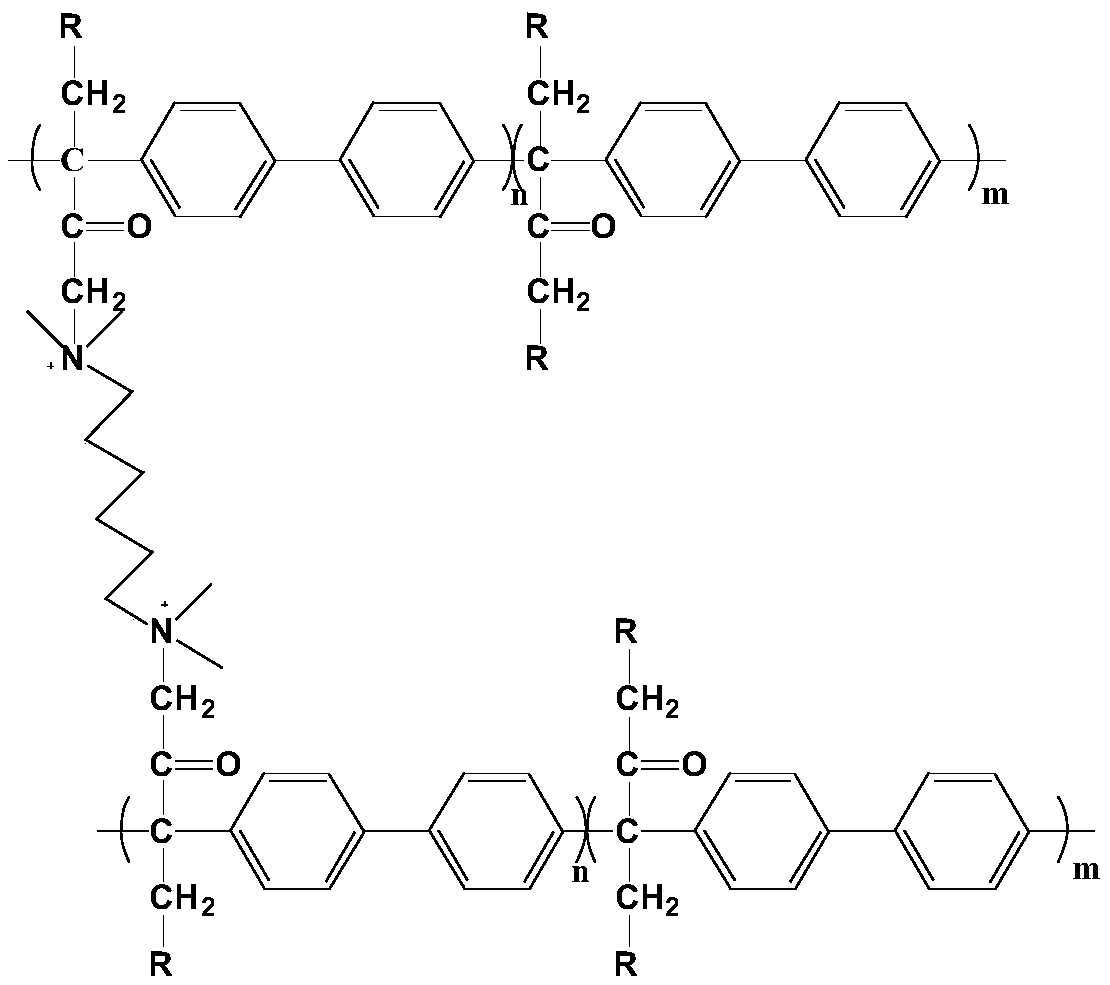

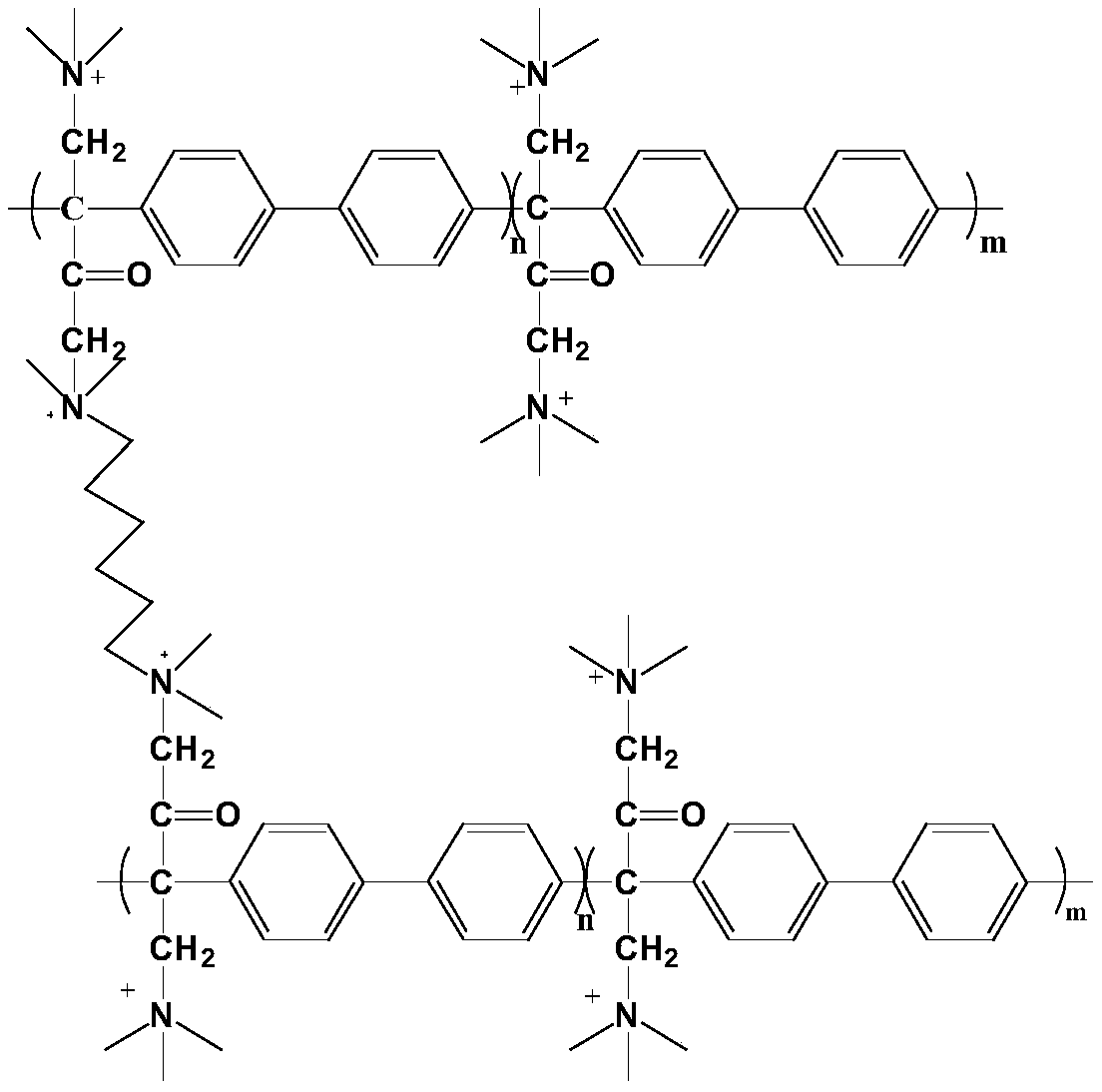

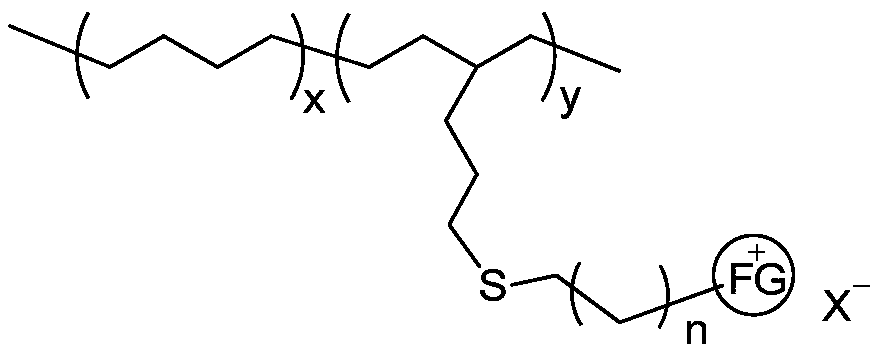

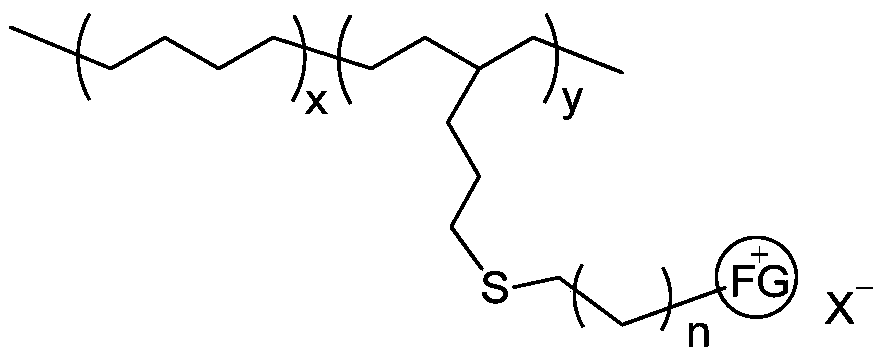

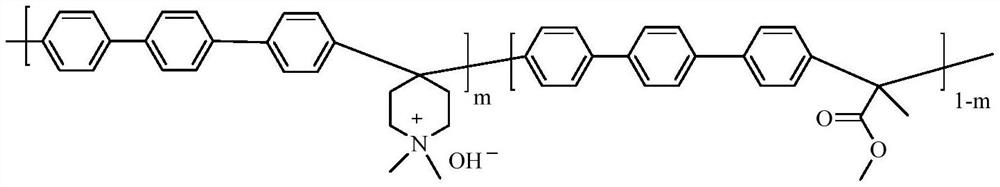

Comb structure high-conductivity polybenzimidazole anion exchange membrane and preparation method thereof

ActiveCN110112448AFacilitates microphase separation in the membraneImprove conductivityFinal product manufactureFuel cellsIon-exchange membranesChemistry

The invention belongs to the technical field of alkaline polymer electrolyte membranes, and relates to a comb structure high-conductivity polybenzimidazole anion exchange membrane and a preparation method thereof. The method comprises the steps of firstly, subjecting the polybenzimidazole and a branch having no cationic functional group to a grafting reaction so as to synthesize a deprotonated comb-like grafted polybenzimidazole material, thereby maximizing the grafting ratio and preventing the N-H in the polybenzimidazole from forming an acid-base pair with the cationic functional group and further reducing its reactivity and activity; and then reacting the deprotonated comb-like grafted polybenzimidazole material with a quaternization agent to connect the tail end of the branch to the cationic functional group to form an ion cluster which is easy to aggregate and a hydrophilic / hydrophobic microphase separation structure. The anion exchange membrane prepared by the method has excellent electrical conductivity, mechanical property and alkali stability.

Owner:DALIAN UNIV OF TECH

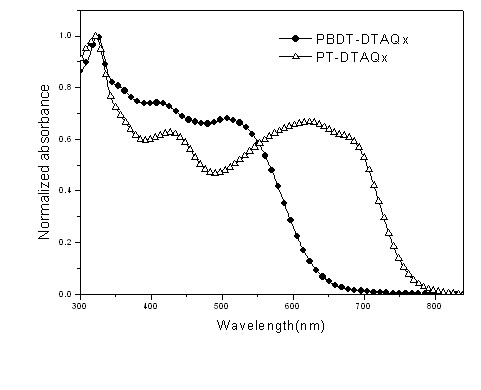

Conjugated polymer of polyacenaphthylene and quinoxaline, as well as preparation method and application of conjugated polymer

InactiveCN102617835ALower HOMO levelPromotes microphase separationSolid-state devicesSemiconductor/solid-state device manufacturingQuinoxalinePolymer science

The invention relates to novel conjugated polymer of polyacenaphthylene and quinoxaline, a preparation method of the conjugated polymer, as well as an application of the conjugated polymer in polymer solar cells. The conjugated polymer of polyacenaphthylene and quinoxaline, provided by the invention, has the structure formula as follows: Ar takes electron-rich aromatic ring as a structure unit; R1 is a linear chain or branch chain alkyl with the hydrogen atom number or carbon atom number of 1 to 20; and R2 is a linear chain or branch chain alkoxy with the hydrogen atom number or carbon atom number of 1 to 20.

Owner:SICHUAN UNIV

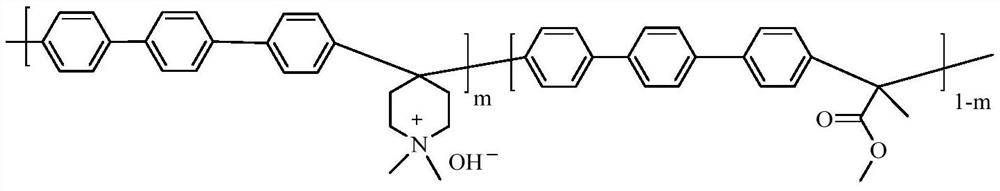

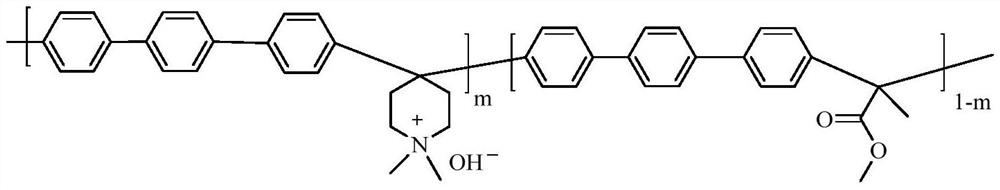

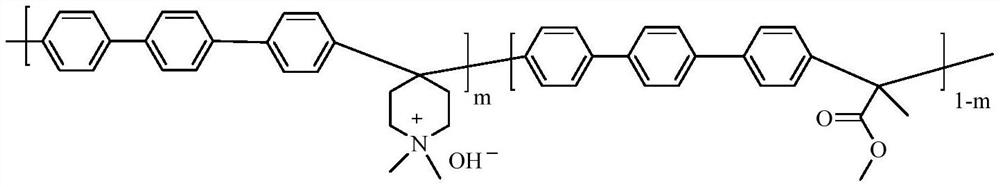

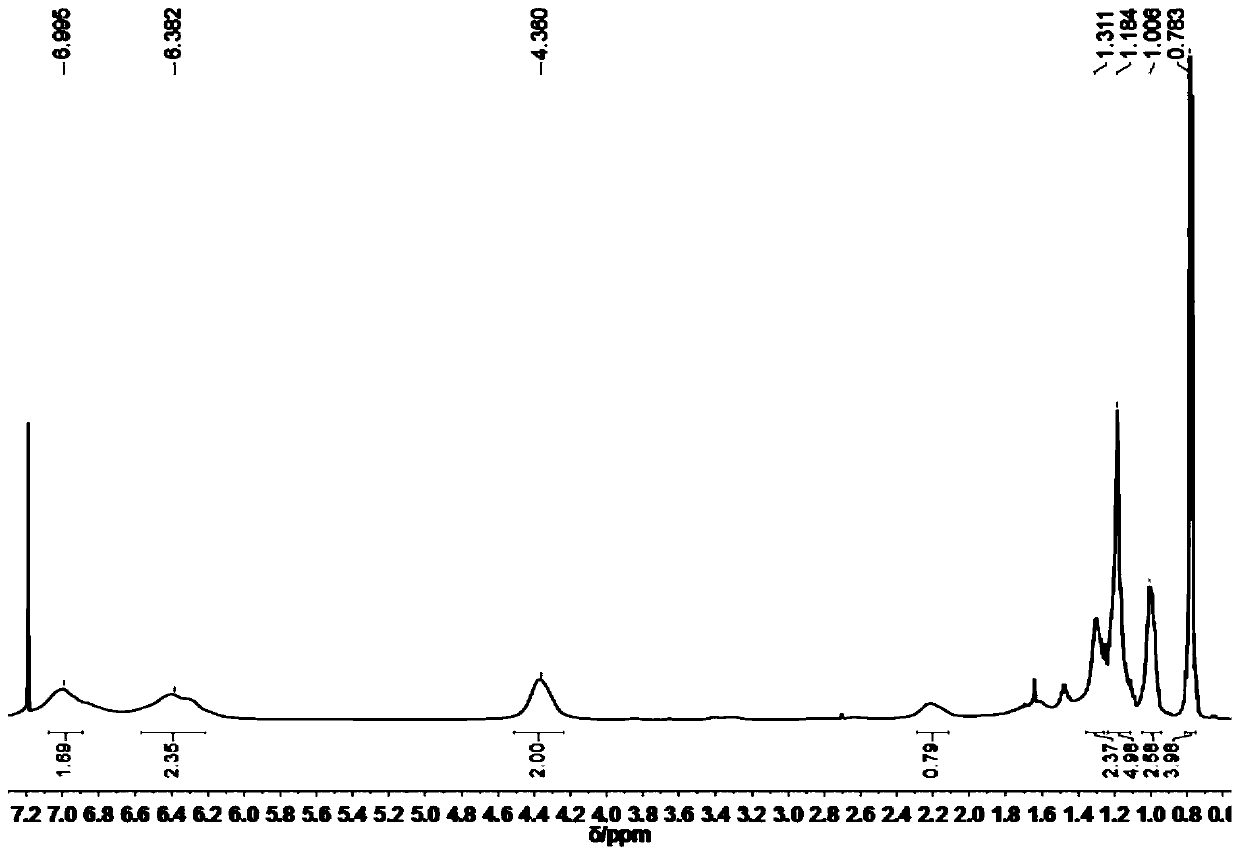

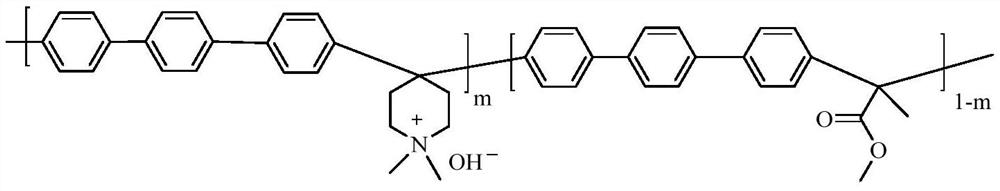

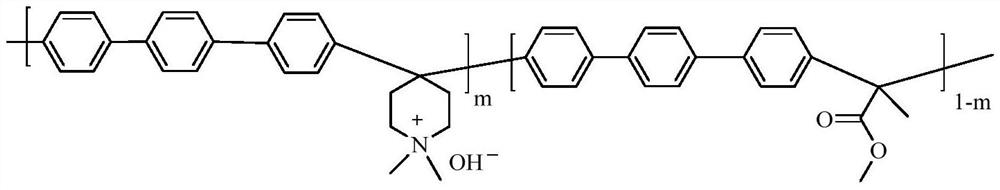

Piperidine type anion exchange membrane for alkaline electrolytic tank and preparation method thereof

The invention discloses a piperidine type anion exchange membrane for an alkaline electrolytic tank and a preparation method thereof, and belongs to the technical field of alkaline anion exchange membranes. The preparation method comprises the following steps: firstly, synthesizing piperidine type trimonomer polymers with different substitution degrees, then directly taking piperidone of the polymer as a grafting site to carry out quaternization on the polymer to obtain a membrane material, and preparing the membrane. The prepared membrane has good alkali stability and mechanical strength, and can be applied to an alkaline electrolytic tank.

Owner:DALIAN UNIV OF TECH

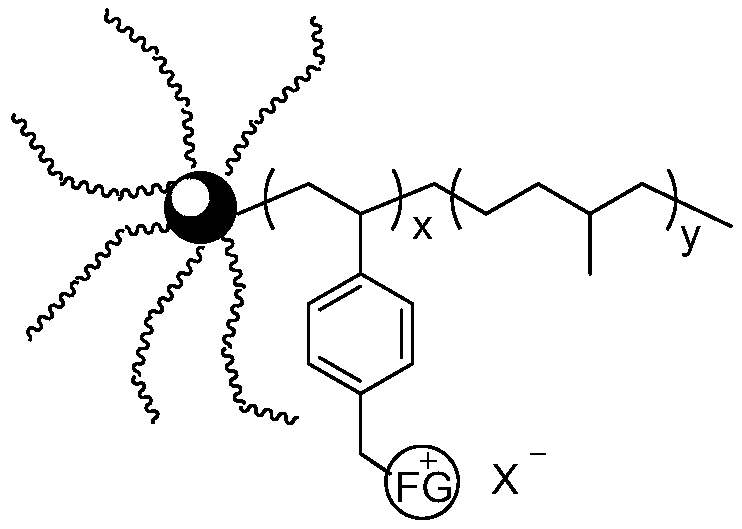

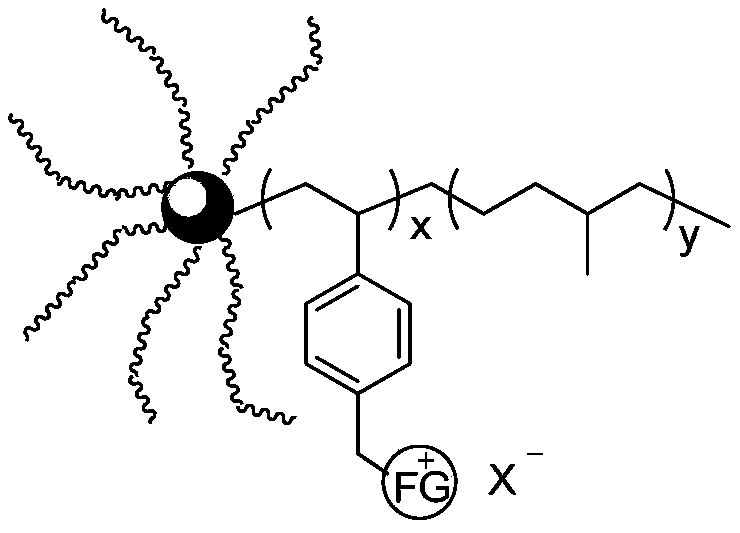

Star topology polyolefin anion exchange membrane, preparation method and application

ActiveCN110752398AGood chemical stabilityHigh mechanical strengthFuel cellsPolymer sciencePolyolefin

The invention discloses a star topology polyolefin anion exchange membrane, a preparation method and an application thereof, and belongs to the technical field of basic anion exchange membranes. A star topology polyolefin block main chain membrane material with good solubility and stability is synthesized by anionic polymerization. Benzyl sites are brominated by catalytic hydrogenation and a bromination reagent, ionic conductive groups are grafted by Menschutkin reaction to obtain a star topology polyolefin film material, and a membrane is prepared. The prepared membrane has good alkali stability and high ionic conductivity, and can be applied to alkaline fuel cells.

Owner:DALIAN UNIV OF TECH

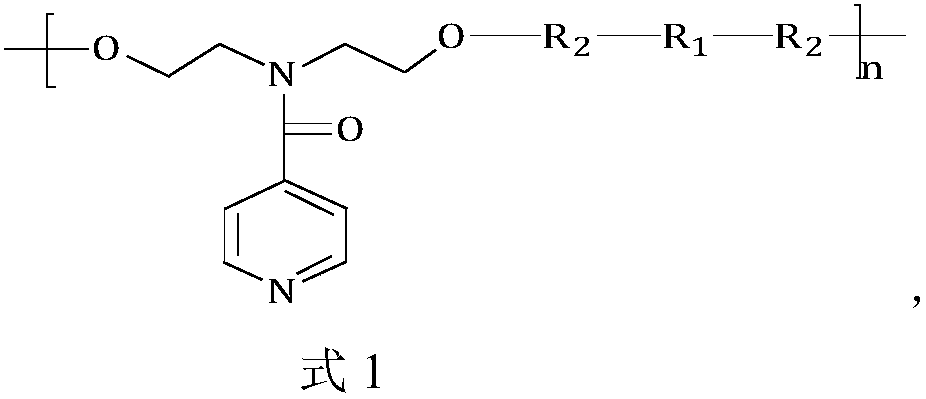

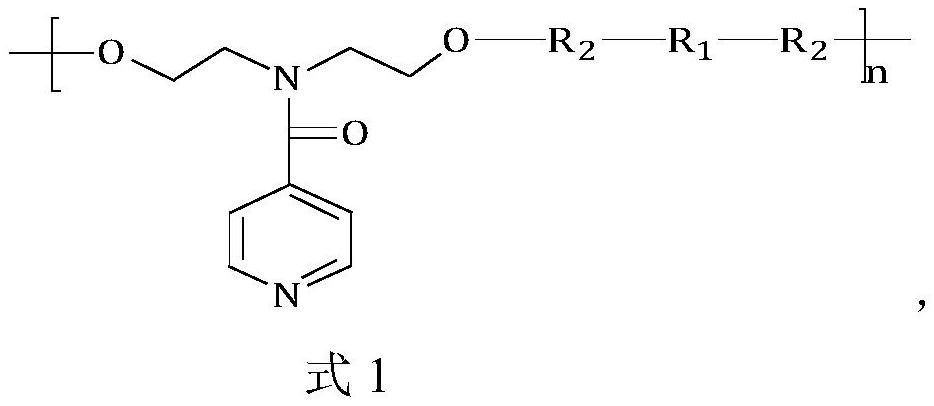

PH-sensitive biodegradable polyurethane-urea material and preparation method thereof

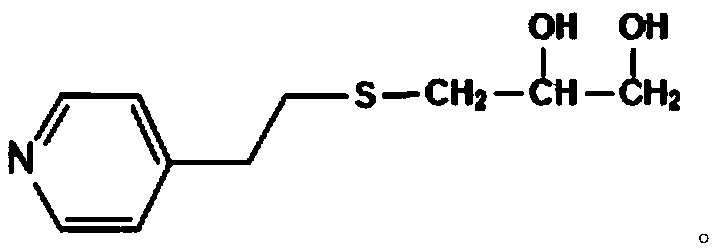

ActiveCN108559048APH sensitivity hasPH sensitive biodegradable withPharmaceutical non-active ingredientsSheet deliveryDrug release rateSide chain

The invention discloses a pH-sensitive biodegradable polyurethane-urea material and a preparation method thereof. The polyurethane-urea is pH-sensitive biodegradable polyurethane-urea prepared by mixing dihydroxy-terminal polyether ester with N,N-bis(2-ethoxy) 4-pyridinccarbox amide, carrying out chain expansion by using carbamido-containing diisocyanate and purifying; the polyether ester is usedas a main soft segment, a chain segment containing carbamido and urethane group is used as a hard segment and a pyridine ring is positioned on a side chain. The polyurethane-urea has the characteristics of biodegradability, absorbability of a degradation product, pH sensitivity, high expanding and degrading rate in acidic mediums, as well as basically no expansion and low degrading rate in neutraland alkaline mediums; in addition, the pH sensitivity is not basically affected by temperature and can be applied to the field of controlled release as a drug carrier, and further the drug release rate is controlled according to pH values of different parts of an organism. The hard segment formed by carbamido-containing structure diisocyanate contains dense hydrogen bonds, so that the mechanicalproperty of the material is improved.

Owner:烟台研创聚氨酯科技有限责任公司

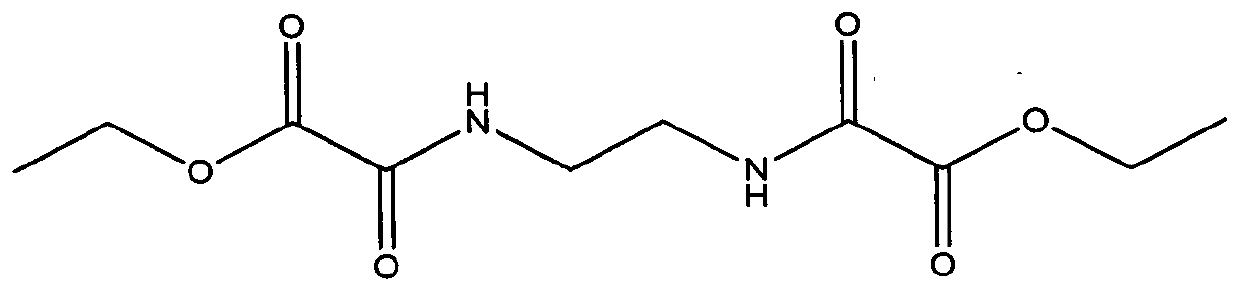

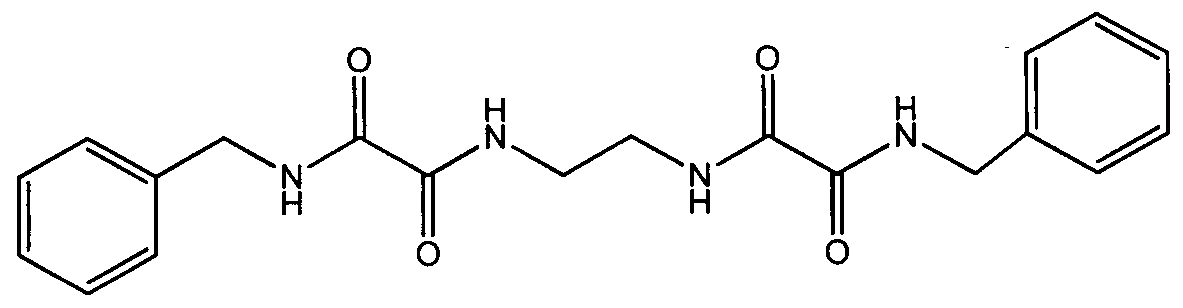

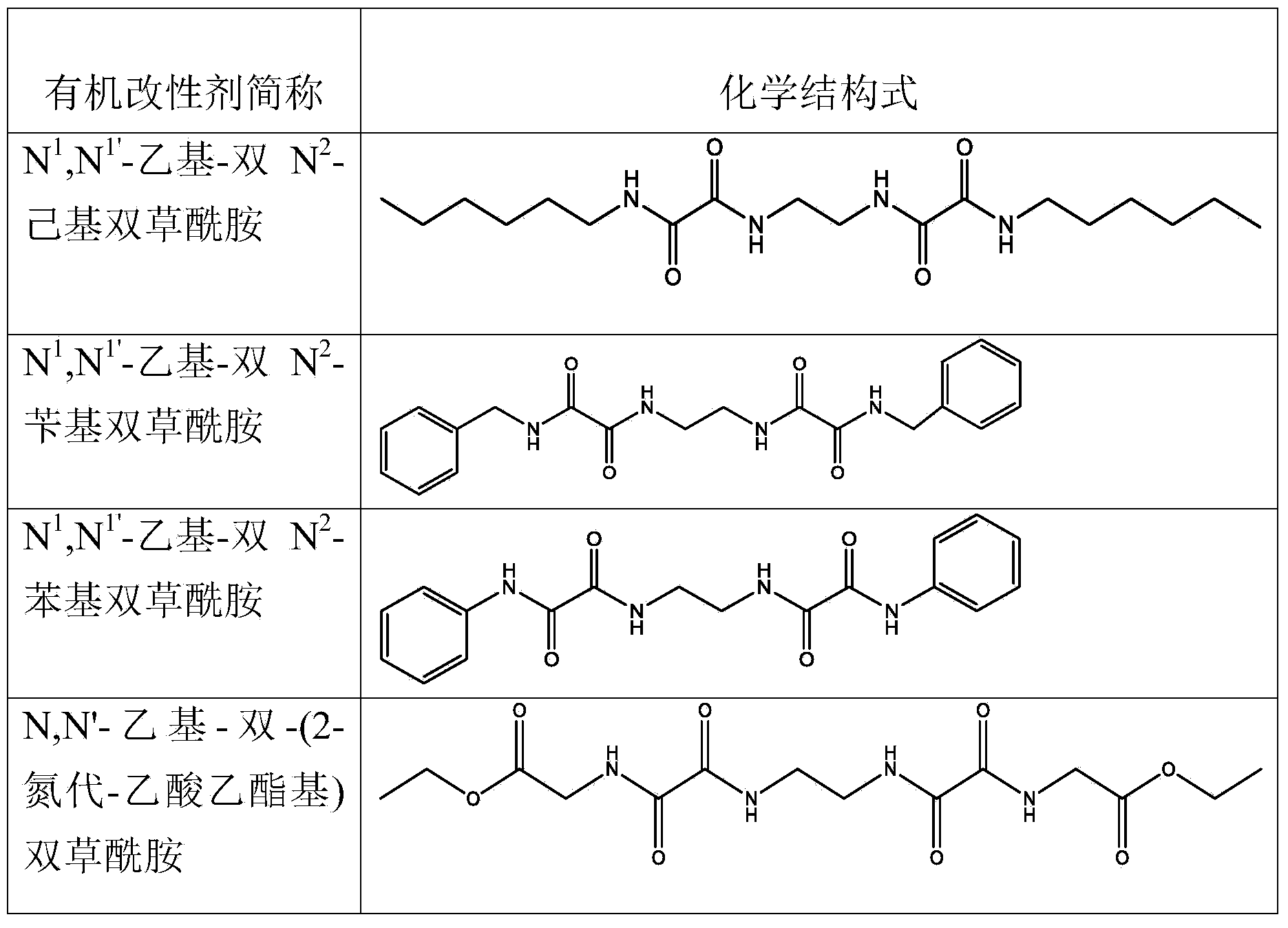

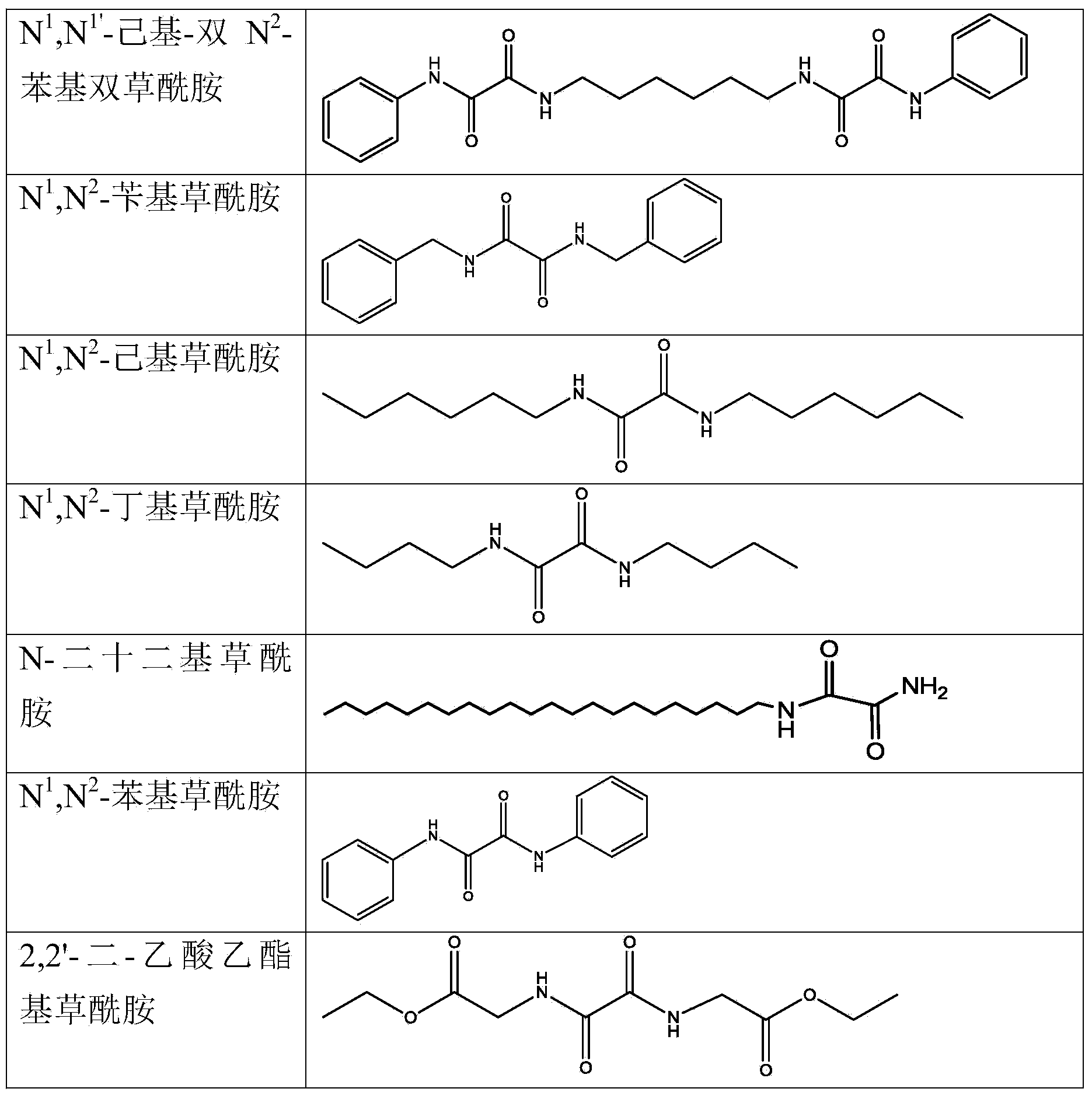

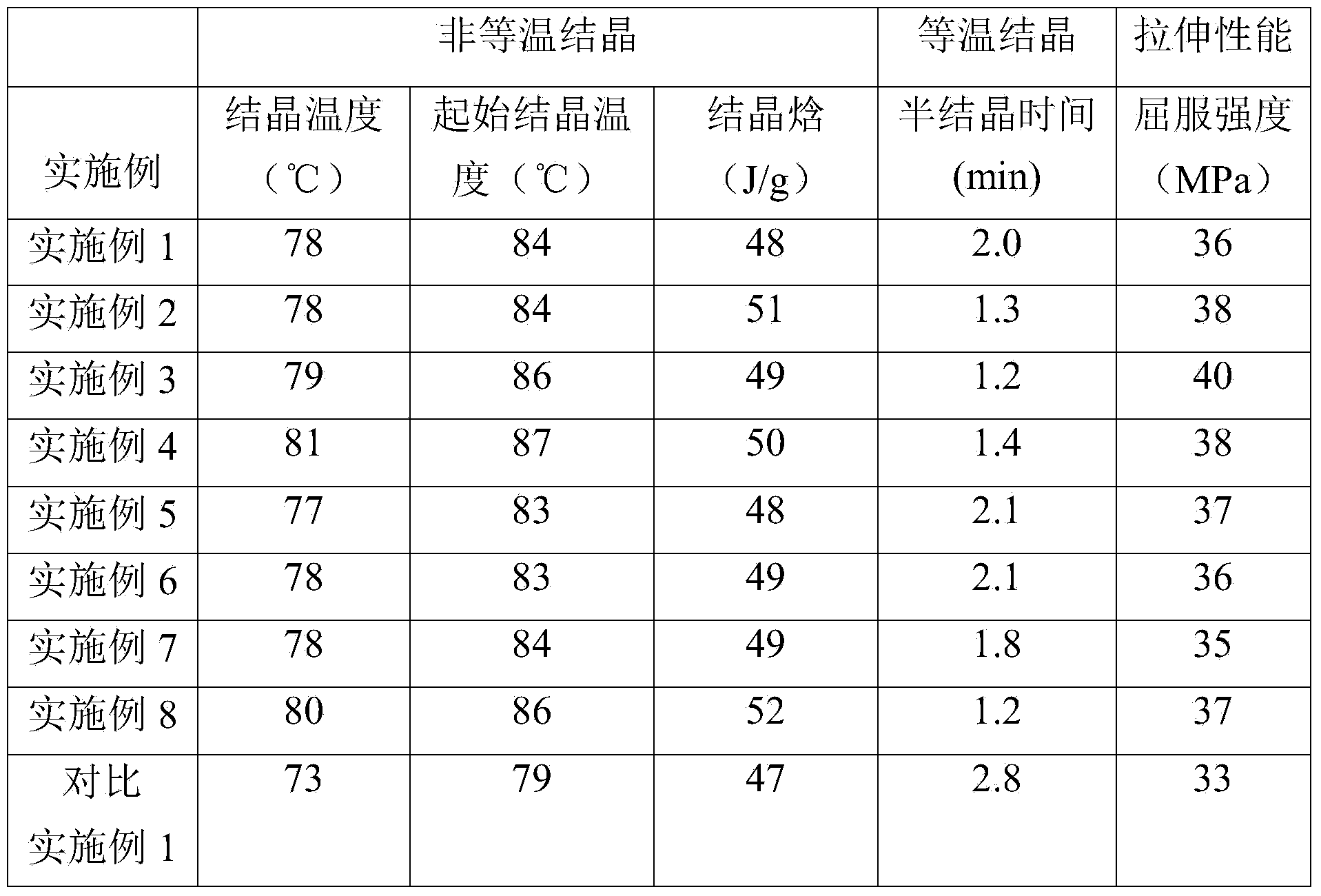

Organic nucleating agent used for ester polymer containing aromatic ring, composition, and preparation method and application thereof

The invention discloses an organic nucleating agent used for an ester polymer containing aromatic ring. The chemical structural formula of the nucleating agent is R2-NH-C(O)-C(O)-NH-R1-NH-C(O)-C(O)-NH-R3, wherein R1, R2 and R3 are independently selected from hydrocarbon group or hydrocarbon group containing substituent groups. The invention also discloses an aromatic ring ester polymer resin composition comprising the nucleating agent, and a preparation method thereof. The fast-crystallization aromatic ring ester polymer resin composition obtained with the preparation method provided by the invention has characteristics of high crystallization temperature, high crystallization speed, short half-crystallization time, and the like. With the method, forming period can be shortened, cost can be reduced, and performance can be improved. The preparation method is simple and environment-friendly. With the method, industrialization is easy to realize.

Owner:JIANGNAN UNIV

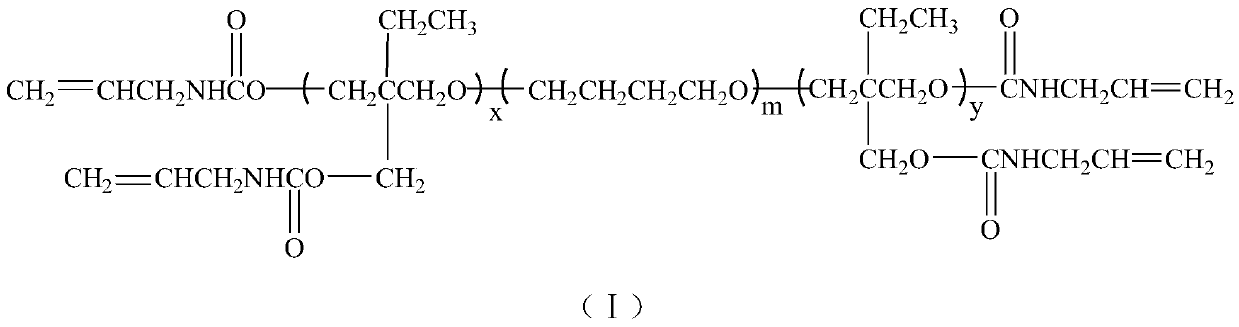

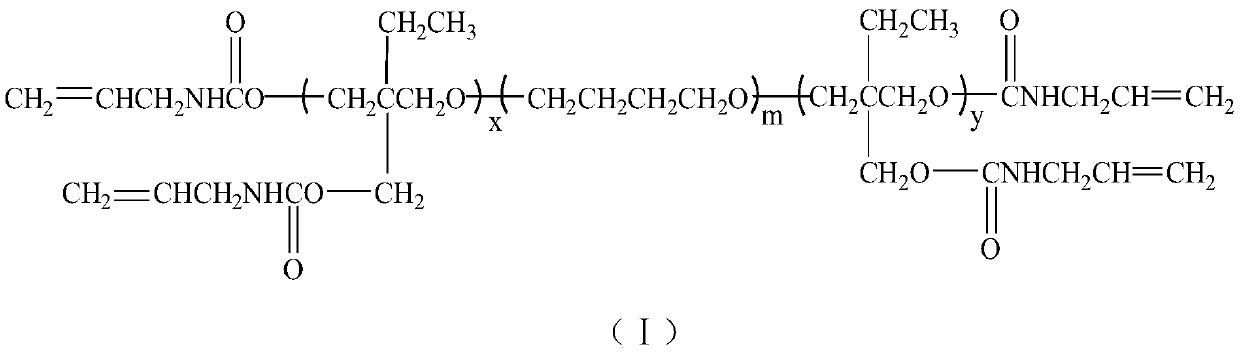

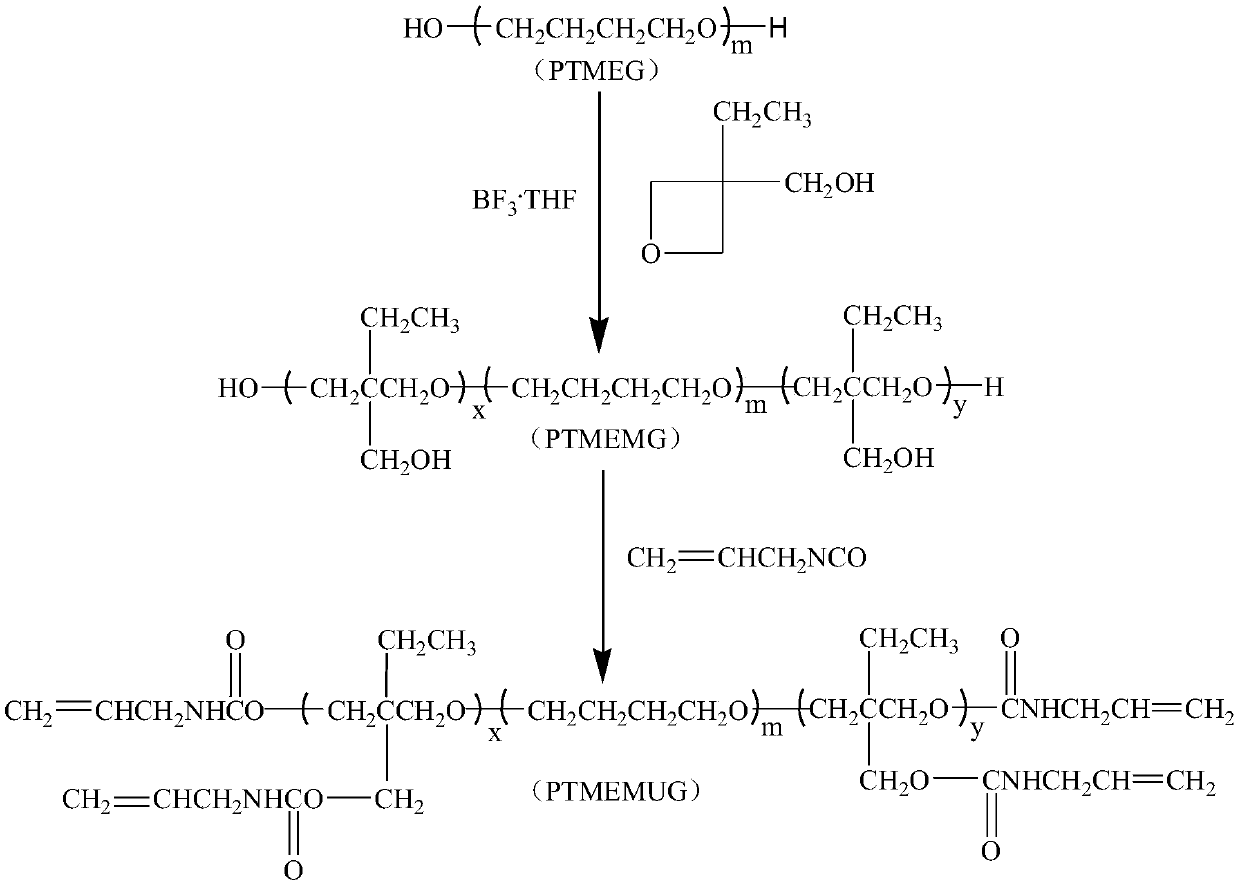

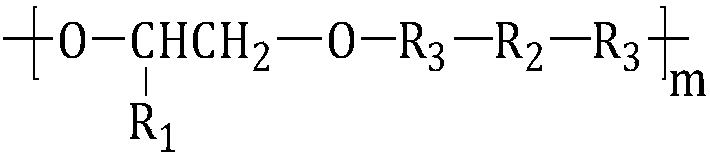

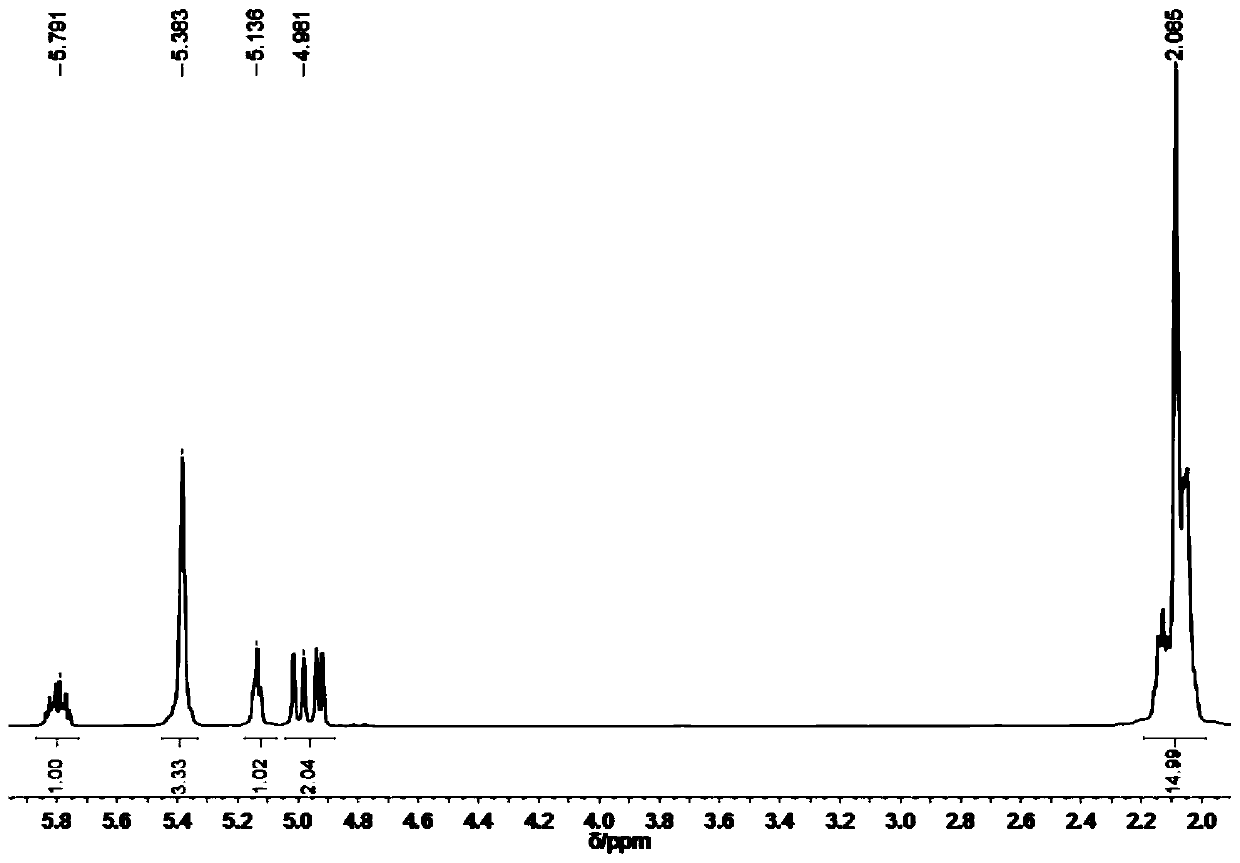

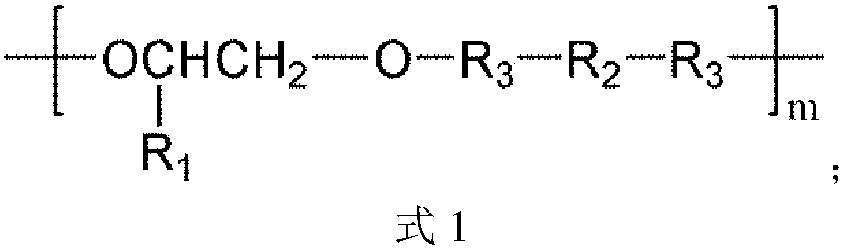

Polyalkenyl polytetrahydrofuran adhesive and synthesis method thereof

ActiveCN109837053AImprove tidinessIncrease crosslink densityPolyether adhesivesElastomerPolymer science

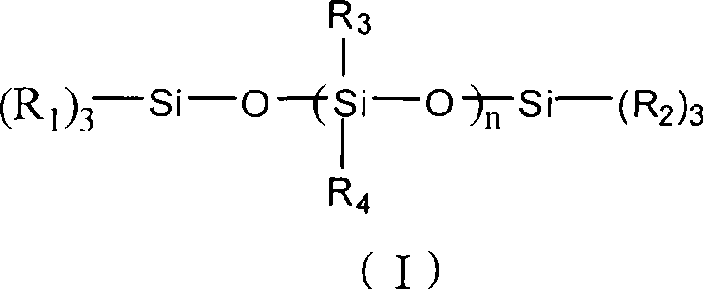

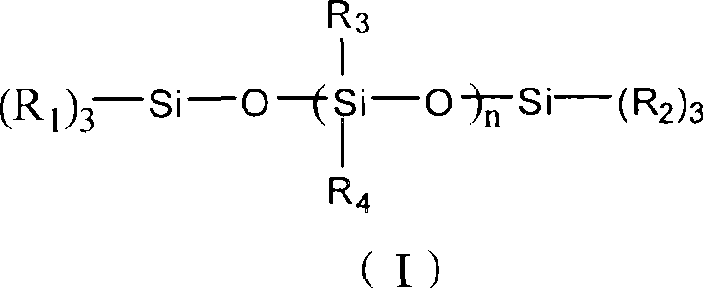

The invention discloses a polyalkenyl polytetrahydrofuran adhesive and a synthesis method thereof, the structural formula of the polyalkenyl polytetrahydrofuran adhesive is shown in a formula I. The synthesis process comprises the following steps: polytetrahydrofuran glycol triggers ring opening polymerization of 3-hydroxymethyl-3-ethyl-oxetane to obtain polyhydroxyl polytetrahydrofuran, the polyhydroxyl polytetrahydrofuran and allyl isocyanate are subjected to addition reaction to obtain the polyalkenyl polytetrahydrofuran. The synthesis method is simple, and the two ends of the polyalkenyl polytetrahydrofuran adhesive contain a plurality of alkenyl groups and carbamate groups, and can endow a polyisoxazoline elastomer with relatively high mechanical property. In the formula I, x + y is equal to 1-6, and is an integer; m is equal to 8-60, and is an integer.

Owner:XIAN MODERN CHEM RES INST

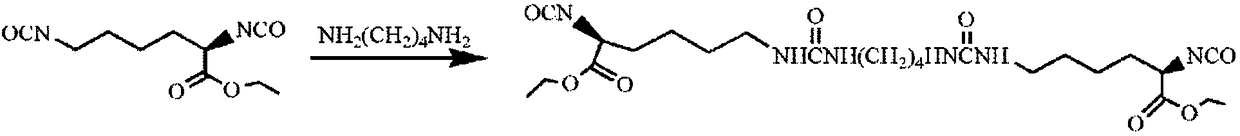

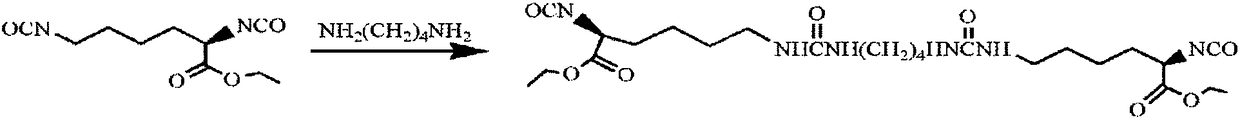

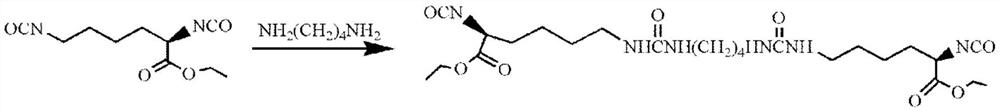

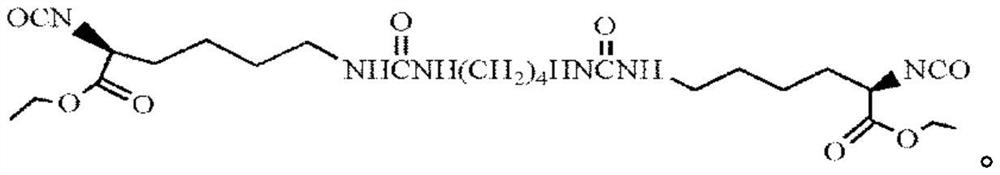

Preparation method and application of high-biocompatibility biodegradable bone filling material

ActiveCN108546321AImprove hydrophilicityAvoid depositionTissue regenerationProsthesisDiamineTissue engineering

The invention belongs to the technical field of biomaterials, and particularly relates to a preparation method and an application of a high-biocompatibility biodegradable bone filling material. The bone filling material is composed of polyurethane urea having phosphorylcholine at the end of a flexible side chain, and polyurethane urea is prepared from a single-ended dihydroxy polyethylene glycol phosphorylcholine compound, double-ended hydroxypolydioxanone and L-lysine diisocyanate-1,4-dibutyl diamine-L-lysine diisocyanate. The phosphorylcholine group located at the end of the flexible polyethylene glycol side chain is easily enriched on the surface of the material in order to greatly improve the hydrophilicity of the material, hinder the deposition of platelets and proteins and avoid theformation of thrombus, so the material has high biocompatibility, solves the problems of low biocompatibility and poor mechanical performances of polyurethane with the side chain simply being polyethylene glycol or phosphorylcholine, especially used a long-term implant material, in the biomedical field, and has widened applications in fields of tissue engineering, drug controlled release, gene therapy and cosmetics.

Owner:济南羽时信息科技有限公司

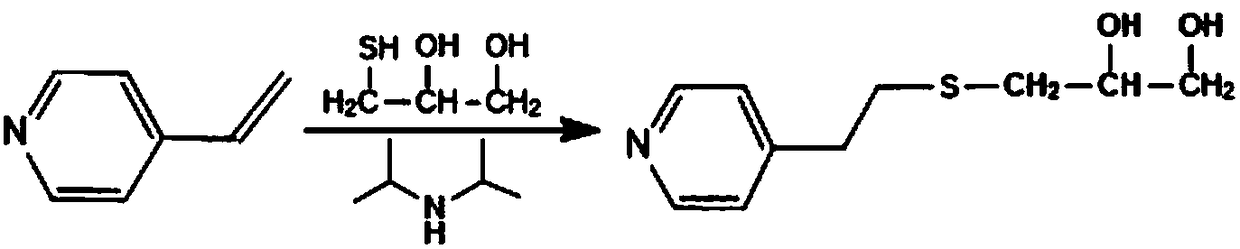

PH sensitive medical polyurethane urea material and preparation method thereof

ActiveCN108530606AGood pH sensitivityFast degradation ratePharmaceutical non-active ingredientsLysine diisocyanateCarbamate

The invention discloses a pH sensitive medical polyurethane urea material and a preparation method thereof. The preparation method comprises the following steps: mixing a terminal dihydroxypyridine compound and a double-end hydroxyl polyethylene glycol to obtain polyurethane urea, and dissolving by adding N,N-dimethylformamide, carrying out chain extension in the presence of urea-containing diisocyanate, and purifying to obtain pH-sensitive polyurethane urea, wherein diisocyanate is L-lysine diisocyanate-1,4-butylenediamine-L-lysine diisocyanate. The pyridine group on a side chain of polyurethane urea is Lewis base, which is able to decompose hydrogen bonds in a polyurethane urea network under acidic conditions, resulting in discontinuous volume expansion of material. According to the invention, H<+> is removed under neutral or alkaline conditions, and N on a pyridine ring and NH on carbamate or ureido form a hydrogen bond, approximating a network structure, so that the polyurethane urea molecular chain shrinks and the swelling degree decreases remarkably. Therefore, by controlling the change of the pH of a medium, the degree of swelling of polyurethane urea can be effectively controlled.

Owner:科莱新材料技术(广州)有限公司

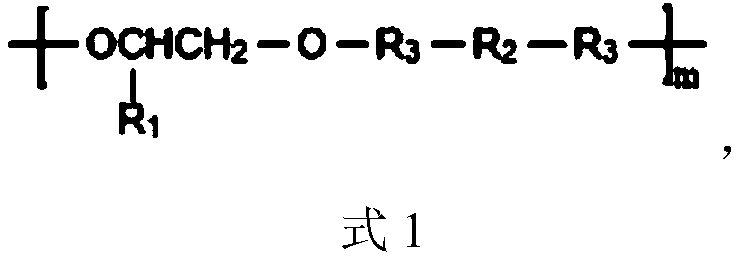

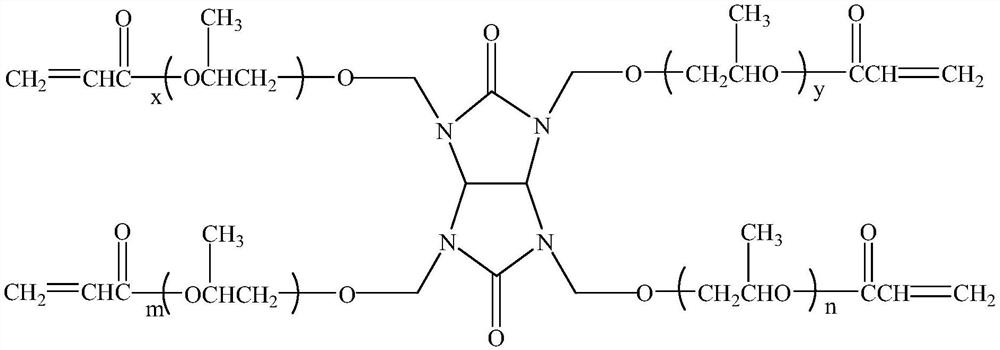

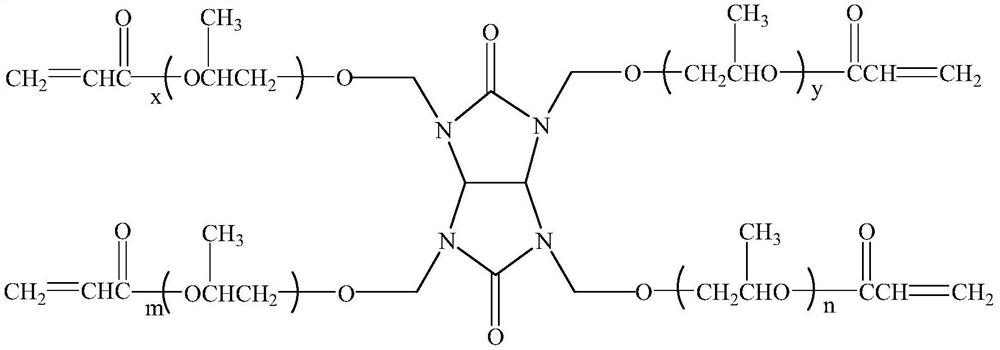

Acryloyloxy-terminated polyether curing agent

ActiveCN111718480AIncrease forcePromotes microphase separationMacromolecular adhesive additivesExplosivesPolymer scienceStructural formula

The invention discloses an acryloyloxy-terminated polyether curing agent, which has a structural formula as described in the specification. In the structural formula, the sum of x, y, m and n is in arange of 12-40 and is an integer. The acryloyloxy-terminated polyether curing agent of the invention is mainly used for solid propellants.

Owner:XIAN MODERN CHEM RES INST

Multifunctional crosslinked polyarylidene butanedione anion exchange membrane and preparation method thereof

The invention discloses a multifunctional crosslinked polyarylidene butanedione anion exchange membrane and a preparation method thereof, and belongs to the technical field of basic anion exchange membranes. The method comprises the steps that firstly, a dibromo-substituted polyarylidene butanedione polymer with good alkali resistance stability is synthesized, then thermal crosslinking is directlyperformed on the polymer by taking bromine of the polymer as a functionalization site, and then remaining sites are subjected to quaternization to obtain a film material. The prepared membrane has better alkali stability and dimensional stability and higher ionic conductivity, and can be applied to an alkaline fuel cell.

Owner:DALIAN UNIV OF TECH

A kind of fluorine-containing polyurethane and preparation method thereof

ActiveCN106674473BEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesWater contactDiol

The invention discloses a fluorine-containing polyurethane and a preparation method thereof. Addition polymerization reaction of fluorine-containing alkyl polyether diol and diisocyanate, catalyzed by tin catalyst, chain extension by chain extender, adding aminosilane coupling agent to end capping, to prepare a fluorine-containing polyurethane; the product has Fluorine-containing polyether block, high fluorine content, the fluoroalkyl group located in the polyether side group is prone to microphase separation and surface migration, low surface energy of polyurethane, fluorine-containing polyurethane is terminated with silane coupling agent, easy to store and easy to cure . The coating prepared by the fluorine-containing polyurethane of the present invention has a water contact angle higher than 110° and excellent water repellency.

Owner:UPCHEM CHINA

Polyolefin anion exchange membrane based on block structure and preparation method thereof

ActiveCN110760041AImproved chemical stability and mechanical strengthGood chemical stabilityFuel cellsIon-exchange membranesPolyolefin

The invention discloses a polyolefin anion exchange membrane based on a block structure and a preparation method thereof, and belongs to the technical field of alkaline anion exchange membranes. A polyolefin block main chain membrane material with good solubility and stability is synthesized through a coordination polymerization method, and then a polymer is directly subjected to a click reactionby taking terminal olefinic double bonds of a main chain as grafting sites to introduce nitrogen-containing sulfhydryl groups, and after a quaternization reaction, a hydrogenation reaction, ion exchange and membrane casting are carried out to obtain a 'crystalline-non-crystalline' membrane material. The prepared anion exchange membrane has excellent alkali stability and ion conductivity, and can be applied to alkaline fuel cells.

Owner:DALIAN UNIV OF TECH

Bio-compostable polyester material composition and preparation method thereof

The invention discloses a bio-compostable polyester material composition, which is mainly composed of the following components in parts by weight: 100 parts of bio-compostable polyester and 0.05 to 5 parts of organic modifier; wherein the chemical formula of the organic modifier is R1-NH-C(O)-C(O)-NH-R2 or R1-NH-C(O)-C(O)-NH-R0-NH-C(O)-C(O)-NH-R2, and the R0, R1 and R2 individually represent an alkyl group or an alkyl group containing a substituent. The bio-compostable polyester material composition prepared by the provided preparation method has the characteristics of high crystallization temperature, fast crystallization speed, short semi-crystallization period, and high mechanical strength, and can shorten the forming period, reduce the cost, and improve the performance. Moreover, the preparation method has the advantages of simpleness, environment-friendliness, and easiness for industrialization.

Owner:JIANGNAN UNIV

A nanocomposite soybean protein plastic and its preparation method

InactiveCN104861662BRealize resource utilizationImprove and increase water resistanceCross-linkPlasticizer

Owner:SICHUAN UNIV

Polyurethane microcellular foam material for railway under-rail backing plate and preparation method thereof

The invention discloses a polyurethane microcellular foam material for a railway under-rail backing plate and a preparation method thereof, the polyurethane microcellular foam material is composed of 100 parts by mass of a material A and 93-105 parts by mass of a material B. The material A is composed of 100 parts by mass of polyester polyol, 6-9 parts by mass of a micromolecule chain extender, 0.06-0.10 part by mass of a foaming agent, 0.4-0.6 part by mass of a foam stabilizer and 1.3-1.5 parts by mass of a catalyst; the material B is prepared from the following components in parts by mass: 47 to 50 parts of isocyanate and 50 to 53 parts of polyester polyol; the polyurethane microcellular foaming material disclosed by the invention has the characteristics of light weight, easiness in deformation, good folding resistance, impact resistance, easiness in molding and good buffering performance, can bear higher load, and avoids the problem of stress concentration of the under-rail backing plate; and under the stress deformation condition, the deformation is uniform, and the stress at each part is uniform, so that the service life is longer under the severe track state and huge transportation volume condition of the heavy-load existing line.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

A kind of hydrophobic membrane based on fluorine-containing polyurethane and its preparation method

ActiveCN106750432BEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention discloses a hydrophobic film based on fluorine-containing polyurethane and a preparation method thereof; the fluorine-containing polyurethane is spin-coated to form a film, and the hydrophobic film based on fluorine-containing polyurethane is obtained after curing; Addition polymerization of isocyanate, catalyzed by tin catalyst, extended by chain extender, and capped with aminosilane coupling agent to obtain fluorine-containing polyurethane; the product has a fluorine-containing polyether block with high fluorine content, located in the polyether The fluoroalkyl group of the side group is prone to microphase separation and surface migration, and the surface energy of the polyurethane is low. The fluorine-containing polyurethane is terminated with a silane coupling agent, which is easy to store and cure. The hydrophobic membrane based on fluorine-containing polyurethane disclosed by the invention has a water contact angle higher than 110° and excellent water repellency.

Owner:SUZHOU UNIV

A kind of piperidine type anion exchange membrane for alkaline electrolytic cell and preparation method thereof

The invention discloses a piperidine-type anion-exchange membrane used in an alkaline electrolytic cell and a preparation method thereof, belonging to the technical field of alkaline anion-exchange membranes. The invention firstly synthesizes piperidine-type three-monomer polymers with different degrees of substitution, and then directly uses the piperidone of the polymer as a grafting site to quaternize the polymer to obtain a membrane material and form a membrane. The prepared membrane has good alkali stability and mechanical strength, and can be applied in alkaline electrolytic cells.

Owner:DALIAN UNIV OF TECH

A kind of pH sensitive biodegradable polyurethane urea material and preparation method thereof

ActiveCN108559048BPH sensitivity hasPH sensitive biodegradable withPharmaceutical non-active ingredientsSheet deliveryDrug release ratePolymer science

Owner:烟台研创聚氨酯科技有限责任公司

Liquid crystal polyurethane urea material with cholesteric side chains and preparation method of liquid crystal polyurethane urea

ActiveCN108912305ALow biocompatibilityGood biocompatibilityLiquid crystal compositionsSide chainBiocompatibility Testing

The invention provides liquid crystal polyurethane urea with cholesteric side chains and a preparation method of the liquid crystal polyurethane urea. Cholesteric liquid crystal units are connected toa main chain through long flexible segments in a covalently mode, single-end dihydroxy cholesteric liquid crystal monomer (DAP) is mixed with double-end hydroxyl polyethylene glycol (PEG), chain extension is performed by using diisocyanate containing a urea-based structure, and the liquid crystal polyurethane urea with the cholesteric side chains is obtained through purification. The liquid crystal polyurethane has a number average molecular weight of 1.0*10<5>-5.0*10<5> and a dispersion coefficient of 1.20-1.51, the mass content of DAP in the liquid crystal polyurethane is 25-52%, and the mass content of PEG in the liquid crystal polyurethane is 12-52%. By combining a cholesteric liquid crystal into polyurethane through a condensation polymerization mode, not only can migration of the small molecule liquid crystal be avoided, but also the blood compatibility and biocompatibility of a polyurethane film can be improved; therefore, reference is provided for application of the modified polyurethane material in biomedical engineering, and good biodegradability can be obtained.

Owner:广州迈腾化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com