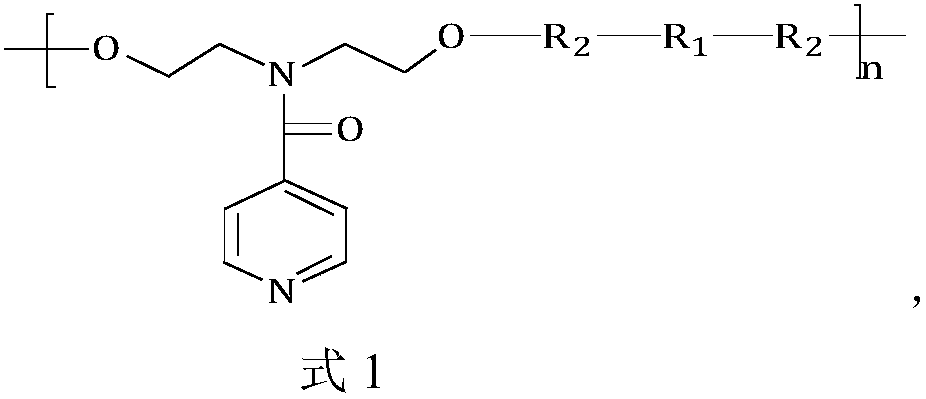

PH-sensitive biodegradable polyurethane-urea material and preparation method thereof

A polyurethane urea and biodegradation technology, applied in the field of polymer chemistry, can solve the problems of long time consumption and complicated preparation process, and achieve the effects of improving mechanical properties, simple process and avoiding acid inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

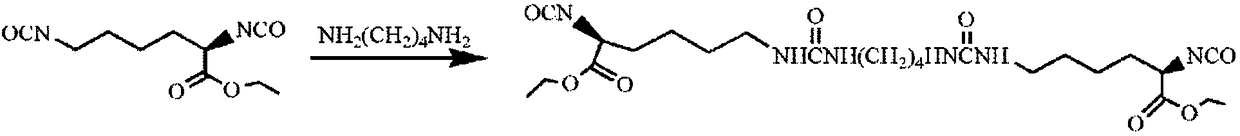

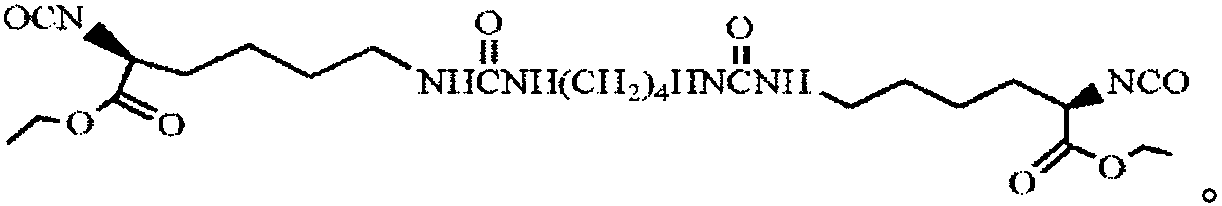

Method used

Image

Examples

Embodiment 1

[0057] Under the protection of dry nitrogen, 10.0g (5mmol) PLA-PEG-PLA (M n =2000, the mass content of PEG is 22.0%) mixed with 6.30g (30mmol) N,N-di(2-hydroxyethyl)isonicotinamide, added N,N-dimethylformamide (DMF) to dissolve (0.5 g / mL), the temperature of the reaction system was raised to 80°C, and the DMF solution (1.0g / mL) of LBL (35.7mmol) was added dropwise. About 10% solution, 8 times the volume of glacial ether is settled, and the obtained solid is vacuum-dried at 35°C to obtain pH-sensitive biodegradable polyurethane urea;

[0058] Dissolve the solid in the organic solvent chloroform to make a solution with a concentration of 6.0% (g / mL), volatilize it with a polytetrafluoroethylene film at 25°C under normal pressure for 80 hours, remove the film from the film, and then warm it at ordinary times. Vacuum-dried to obtain pH-sensitive biodegradable polyurethane urea film material I, and the drug-loaded film material was prepared in the same way.

Embodiment 2

[0060] Under dry nitrogen protection, 20.0g (10mmol) PCL-PEG-PCL (M n =2000, the mass content of PEG is 26.4%) mixed with 14.70g (70mmol) N,N-bis(2-hydroxyethyl)isonicotinamide, added N,N-dimethylformamide (DMF) to dissolve (0.5 g / mL), the temperature of the reaction system was raised to 85°C, and a DMF solution (1.0 g / mL) of LBL (82.1 mmol) was added dropwise. About 10% solution, 8 times the volume of glacial ether is settled, and the obtained solid is vacuum-dried at 35°C to obtain pH-sensitive biodegradable polyurethane urea;

[0061] Dissolve the solid in the organic solvent chloroform to make a concentration of 5.0% (g / mL), use a polytetrafluoroethylene film to volatilize at 28°C under normal pressure for 90 hours, remove the film from the film, and dry it in vacuum at room temperature , to obtain the pH-sensitive biodegradable polyurethane urea membrane material II, and prepare the drug-loaded membrane material by the same method.

Embodiment 3

[0063] Under the protection of dry nitrogen, 15.0g (5mmol) PLA-PEG-PLA (M n =3000, the mass content of PEG is 43.3%) mixed with 8.40g (40mmol) N,N-di(2-hydroxyethyl)isonicotinamide, adding N,N-dimethylformamide (DMF) to dissolve (0.6 g / mL), the temperature of the reaction system was raised to 90°C, and a DMF solution (1.0 g / mL) of LBL (45.7 mmol) was added dropwise. About 10% solution, 8 times the volume of glacial ether is settled, and the obtained solid is vacuum-dried at 35°C to obtain pH-sensitive biodegradable polyurethane urea;

[0064] Dissolve the solid in the organic solvent chloroform to make a concentration of 6.0% (g / mL), use a polytetrafluoroethylene film to volatilize at 22°C under normal pressure for 75 hours, remove the film from the film, and dry it in vacuum at normal temperature , to obtain the pH-sensitive biodegradable polyurethane urea membrane material III, and prepare the drug-loaded membrane material by the same method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com