Functional resin tectorial membrane proppant and preparation method thereof

A resin coating and proppant technology, applied in the chemical field, can solve the problems of increasing the difficulty of oil-water separation and high oil production costs, and achieve the effects of improving long-term diversion capacity, long validity period and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

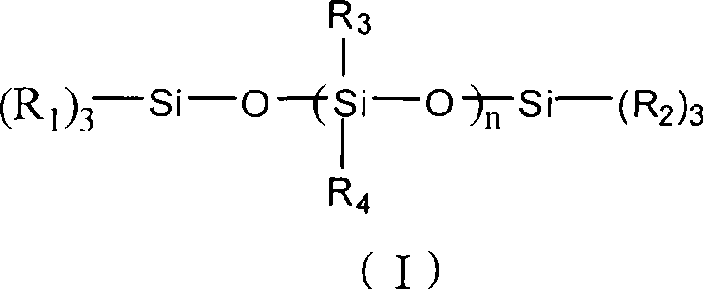

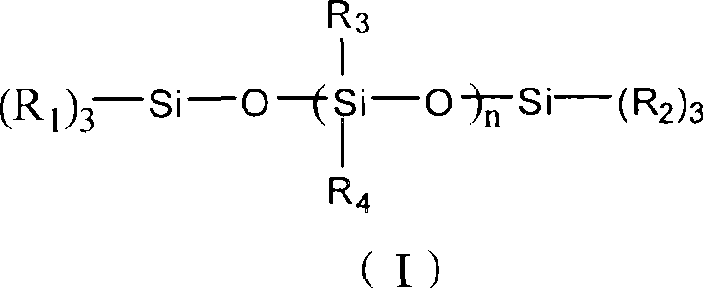

Method used

Image

Examples

Embodiment 1

[0037] Heat 2 kg of quartz sand (particle size 0.425 / 0.85mm) to 170°C and pour it into a mixer, stir to cool down to 160°C, 1) add 0.5 g of γ-aminopropyltriethoxysilane and phenolic Stir 40 grams of resin for 50 seconds to make it evenly coated on the quartz sand, add 8.0 grams of hexamethylenetetramine and stir for 60 seconds; 2) Add 50 grams of epoxy resin and stir for 60 seconds, add 12.0 grams of alicyclic polyamine Stir and solidify for 60 seconds; 3) Add 4.2 g of an amino-terminated organosilicon compound, stir and solidify for 150 seconds, cool and sieve to obtain a functional resin-coated quartz sand proppant.

Embodiment 2

[0039] The first two steps are the same as example 1, 3) when the material starts to agglomerate, add 6 grams of calcium stearate and continue to stir and solidify for 150 seconds, cool, crush, and sieve to obtain the resin-coated quartz sand proppant.

[0040] Example result comparison

[0041] Proppant proppant resistance to water and oil

Embodiment 3

[0043] Heat 2kg of quartz sand (particle size 0.425 / 0.85mm) to 270°C and pour it into a mixer, stir and cool down to 250°C. 1) Add 40 grams of bisphenol A epoxy resin and stir for 25 seconds to make it Evenly coat the quartz sand, add 7.2 grams of aromatic polyamine and stir for 70 seconds; 2) Add 40 grams of bisphenol A epoxy resin and stir for 60 seconds, add 10 grams of Mannich-added polyamine and stir for curing; 3) Add 3.5 grams of organosilicon compounds whose end groups are hydroxyl groups were stirred and solidified for 150 seconds, cooled and sieved to obtain a functional resin-coated quartz sand proppant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com