Composite material for absorbing mid-infrared and far-infrared, preparation method and application thereof

A composite material and raw material technology, which is applied in the field of mid-infrared and far-infrared-absorbing composite materials and their preparation, and can solve the problem of low heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: the preparation of composite material

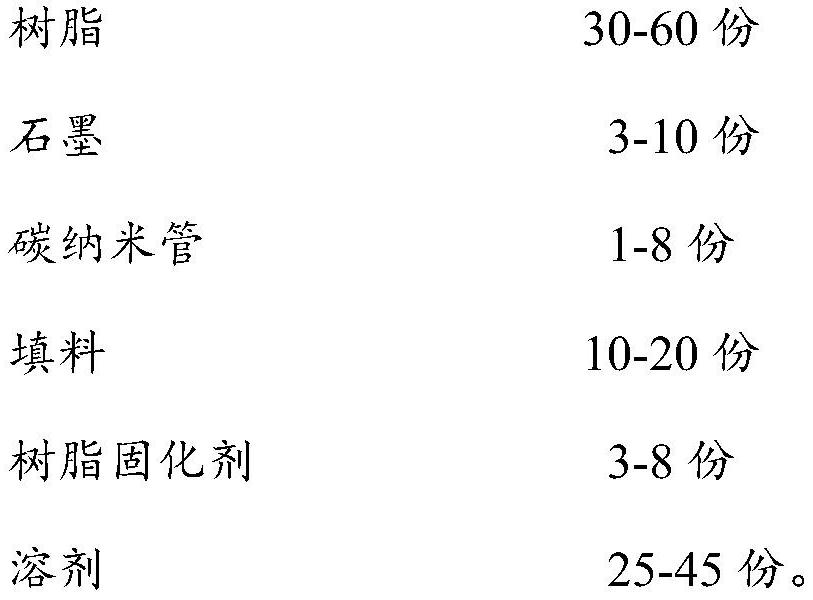

[0050] A composite material that absorbs mid-infrared and far-infrared, mainly made of the following raw materials:

[0051]

[0052] The preparation method of above-mentioned composite material, comprises the following steps:

[0053]Add carbon nanotubes and graphite in chloroform, stir for the first time, the speed of stirring for the first time is 150 rpm, the time of stirring is 20 minutes, then add epoxy resin and cycloaliphatic polyamine curing agent, the second Stir for the second time, the speed of stirring for the second time is 260 rev / min, and the time of stirring is 40 minutes, then add nano-calcium carbonate, stir for the third time, the speed of stirring for the third time is 400 rev / min, and the time of stirring is After 30 minutes, vacuum-dried to obtain a composite material.

Embodiment 2

[0054] Embodiment 2: the preparation of composite material

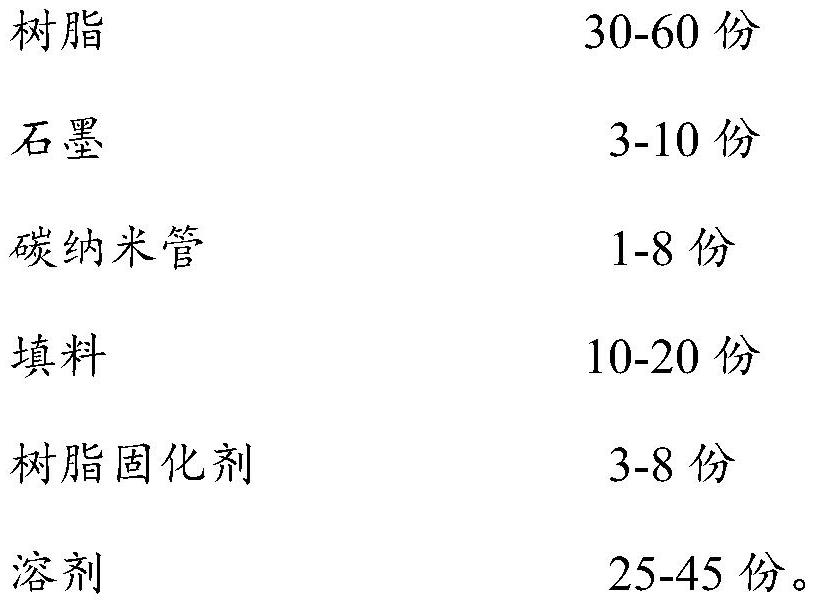

[0055] A composite material absorbing mid-infrared and far-infrared is mainly prepared from the following raw materials in parts by weight:

[0056]

[0057] The preparation method of above-mentioned composite material, comprises the following steps:

[0058] Add carbon nanotubes and graphite to toluene, stir for the first time, the speed of the first stirring is 150 rpm, and the stirring time is 20 minutes, then add fluorocarbon resin and isocyanate curing agent, and stir for the second time, The speed of stirring for the second time is 360 rev / min, the time of stirring is 45 minutes, then add nano-zinc oxide, stir for the third time, the speed of stirring for the third time is 400 rev / min, the time of stirring is 30 minutes, vacuum dried to obtain a composite material.

Embodiment 3

[0059] Embodiment 3: the preparation of composite material

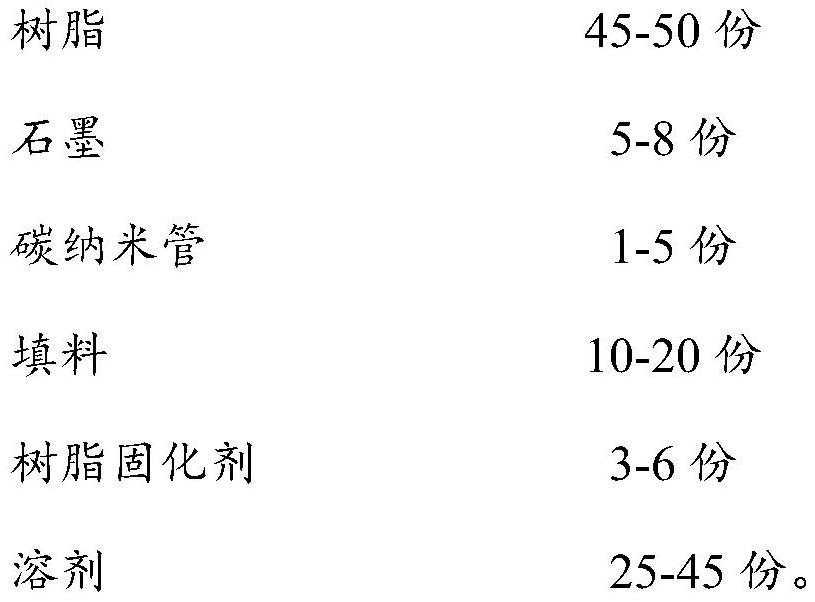

[0060] A composite material absorbing mid-infrared and far-infrared is mainly prepared from the following raw materials in parts by weight:

[0061]

[0062] The preparation method of above-mentioned composite material, comprises the following steps:

[0063] Add carbon nanotubes, graphite and nano-silica to chloroform, stir for the first time, the speed of the first stirring is 180 rpm, and the stirring time is 20 minutes, then add silicone resin and alicyclic polymer Amine curing agent, stirring for the second time, the speed of stirring for the second time is 400 rpm, and the time of stirring is 40 minutes, then adding nano-zinc oxide and nano-magnesium carbonate, stirring for the third time, the speed of stirring for the third time is 400 rpm, stirring time is 30 minutes, and vacuum-dried to obtain a composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com