Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Play a leak-proof role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil and gas field fracturing fluid, oil and gas field well cementation agent and oil and gas field fracturing temporary plugging agent

InactiveCN107286923AAdequate mechanical propertiesLow mass lossDrilling compositionConjugated synthetic polymer artificial filamentsFiberPolyvinyl alcohol

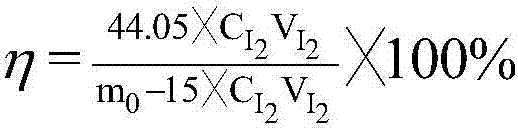

The invention provides oil and gas field fracturing fluid, an oil and gas field well cementation agent and an oil and gas field fracturing temporary plugging agent, which contain PVA (Polyvinyl Alcohol) fibers. The PVA fibers are papered from polyvinyl alcohol with the polymerization degree of 1000 to 3000 and the alcoholysis degree of 80 mole percent to 99.5 mole percent through spinning; the hydroformylation degree eta of the PVA fibers is 25 percent to 35 percent and Rp is 120 DEG C to 180 DEG C. The PVA fibers have the monofilament density of 1.0dtex to 1.8dtex at normal temperature and have the elongation at break of 10 percent to 25 percent; the slenderness ratio of the fibers is 200 to 600 and the real density of the fibers is 0.8g / cm<3> to 1.4g / cm<3>. The yield increasing range of the oil and gas field can reach 30 percent to 50 percent; the strength and toughness of the well cementation agent are remarkably improved and the well cementation agent can also have an anti-leakage effect; when being used in the fractured oil and gas field, the oil and gas field fracturing temporary plugging agent aims at plugging old cracks and breaking new cracks; when the fracturing temporary plugging agent is used, the pressure is raised by 6MPA or above and the yield of the oil and gas field is improved by two times or above.

Owner:CHINA PETROCHEMICAL CORP +1

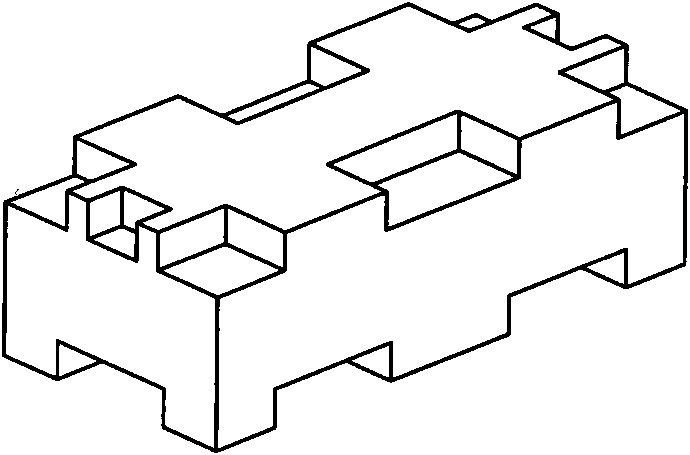

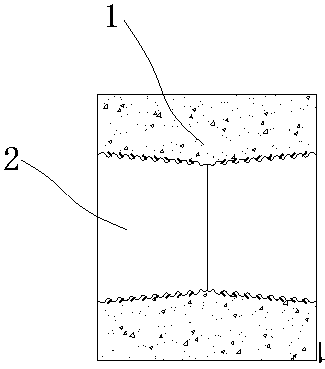

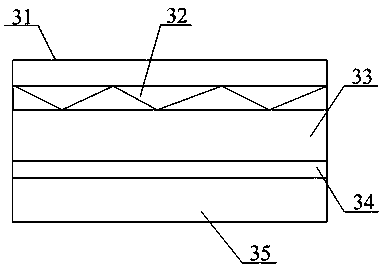

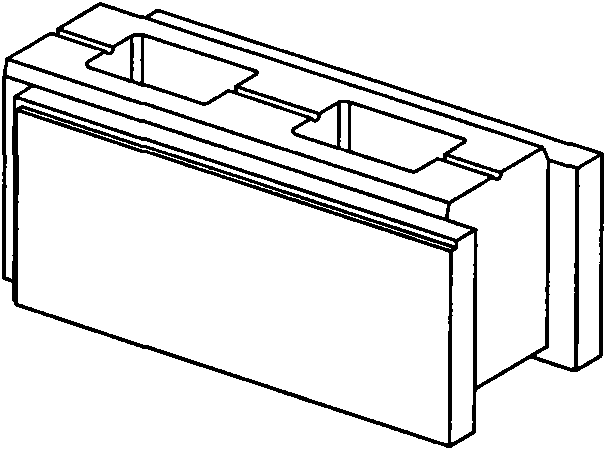

Building block for forming wall structure

InactiveCN101775867ASolve the double-sided leak-proof problemSolve the problem of permeable soilBuilding insulationsShock proofingWater leakageArchitectural engineering

The invention relates to a building block for forming a wall structure. A plurality of similar building blocks are alternately superposed continuously in the wall. The building block is a longitudinal section material and comprises a top surface, a bottom surface and two end surfaces; the cross section of the building block is integrally in a downward horn mouth shape; the middle part of the top surface has a ridge, and two sides of the top surface are low, thereby forming a left supporting slope and a right supporting slope; the building block has the shape and the size, thus when three similar building blocks are superposed from top to bottom, the ridge of the undermost building block is higher than the base part of the topmost building block; the lower part of each supporting slope is provided with a shoulder table which comprises an upper table surface, a table bottom surface and a transverse lateral surface; the upper table surface, the upper slope and the middle ridge form the top surface; and when the building block is superposed with the upper similar building blocks to form the wall, protrusions formed by slopes at two sides are bonded with horn notches on the bottom surfaces of the upper similar building blocks. The invention can prevent water leakage of any surface of the formed wall, simultaneously enables the wall to have stable shock resistance, and is suitable for various buildings and various construction methods.

Owner:汪荣勋

Oil-gas field fracturing fluid, oil-gas field well cementing agent and oil-gas field fracturing temporary plugging agent containing PVA (Polyvinyl alcohol) fiber

InactiveCN107286922AEasy to plug inIncrease formation pressureProductsReagentsFiberPolyvinyl alcohol

The invention discloses an oil-gas field fracturing fluid, a temporary plugging agent and a well cementing agent containing a PVA (Polyvinyl alcohol) fiber. The PVA fiber is prepared by spinning PVA being 1000 to 3500 in polymerization degree, and 80 to 99.9 mole percent in alcoholysis degree. The oil-gas field fracturing fluid has the advantages of higher temperature resistance and shearing resistance, small environmental damage, low cost, environmental friendliness, very good sand carrying function and facilitation of fracturing fluid flowback; the oil-gas field well cementing agent can enhance the strength and the toughness of a well cementing material, can play a role in preventing leakage, is degradable and has low environmental damage; the oil-gas field fracturing temporary plugging agent has a good filtration reduction effect, forms a shielding layer at a position to be plugged temporarily to realize successful steering of the fracturing fluid, and is degradable; components left underground do not cause environmental pollution.

Owner:CHINA PETROCHEMICAL CORP +1

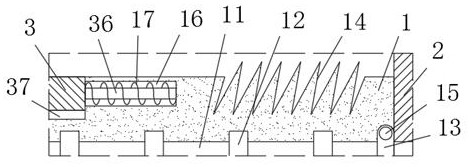

Cementing technology for 5.5-cun sleeve windowed side drilled slim hole

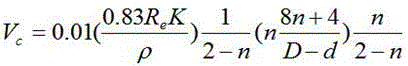

InactiveCN104963653AMeet the requirements for reducing the pressure of the annular hydrostatic columnPlay a leak-proof roleFlushingSealing/packingFiberWell cementing

The invention relates to the cementing technology for a 5.5-cun sleeve windowed side drilled slim hole, and the technology is that prepared cement mortar replaces the cementing technology under the condition of small gaps. The cementing technology is characterized in that the cement mortar is prepared by the following components, by weight, 100 parts of G-grade oil well cement, 15 to 25 parts of floaters, 10 to 20 parts of reinforcing agent, 2 to 3 parts of fluid loss additive, 0.4 to 0.8 part of drag reducer,0.2 to 0.4 part of retarder, 75 to 95 parts of water and 1 to 2 parts of inorganic fiber. A method replacing a method about annular plug flow state is provided. The annular hydrostatic fluid column pressure in the cementing technology for a slim hole can be reduced, a leakproof function can be achieved, and defects caused by a thin cement ring can effectively overcome.

Owner:SINOPEC EAST CHINA PETROLEUM ENG CO LTD

Deformed block and wall body structure formed with the same

ActiveCN101067340APlay a blocking rolePlay a leak-proof roleWallsStructural engineeringAbnormal shaped

Owner:汪浩

Macromolecule nano selfreparing memory adhesive and use method thereof

InactiveCN106833436AHigh strengthImprove impact resistanceNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentAdhesiveFumed silica

The invention discloses a macromolecule nano selfreparing memory adhesive which consists of the following components in parts by mass: 48-54 parts of butyl rubber, 24-32 parts of polyisobutene, 5-10 parts of a styrene-butadiene copolymer, 1-6 parts of polyacrylate, 0.05-0.15 part of boron trifluoride, 3-9 parts of calcium carbonate, 0.5-1.7 parts of fumed silica and 0.05-0.15 part of carbon black. The macromolecule nano selfreparing memory adhesive disclosed by the invention is capable of rapidly sealing tire holes and is relatively good in malleability and impact resistance, and due to addition of the memory adhesive, the strength of a tackifier and adhesion of tires can be improved; the macromolecule nano selfreparing memory adhesive is capable of repairing air leakage of a tire which is punctured by a nail, a function of leakage prevention can be achieved, relatively good adhesion can be achieved, relatively good ductility and impact resistance can be achieved, and the adhesive can never be peeled off.

Owner:兴华安防科技(广州)有限公司

Oil-immersed power transformer that is easy to install and avoids oil leakage

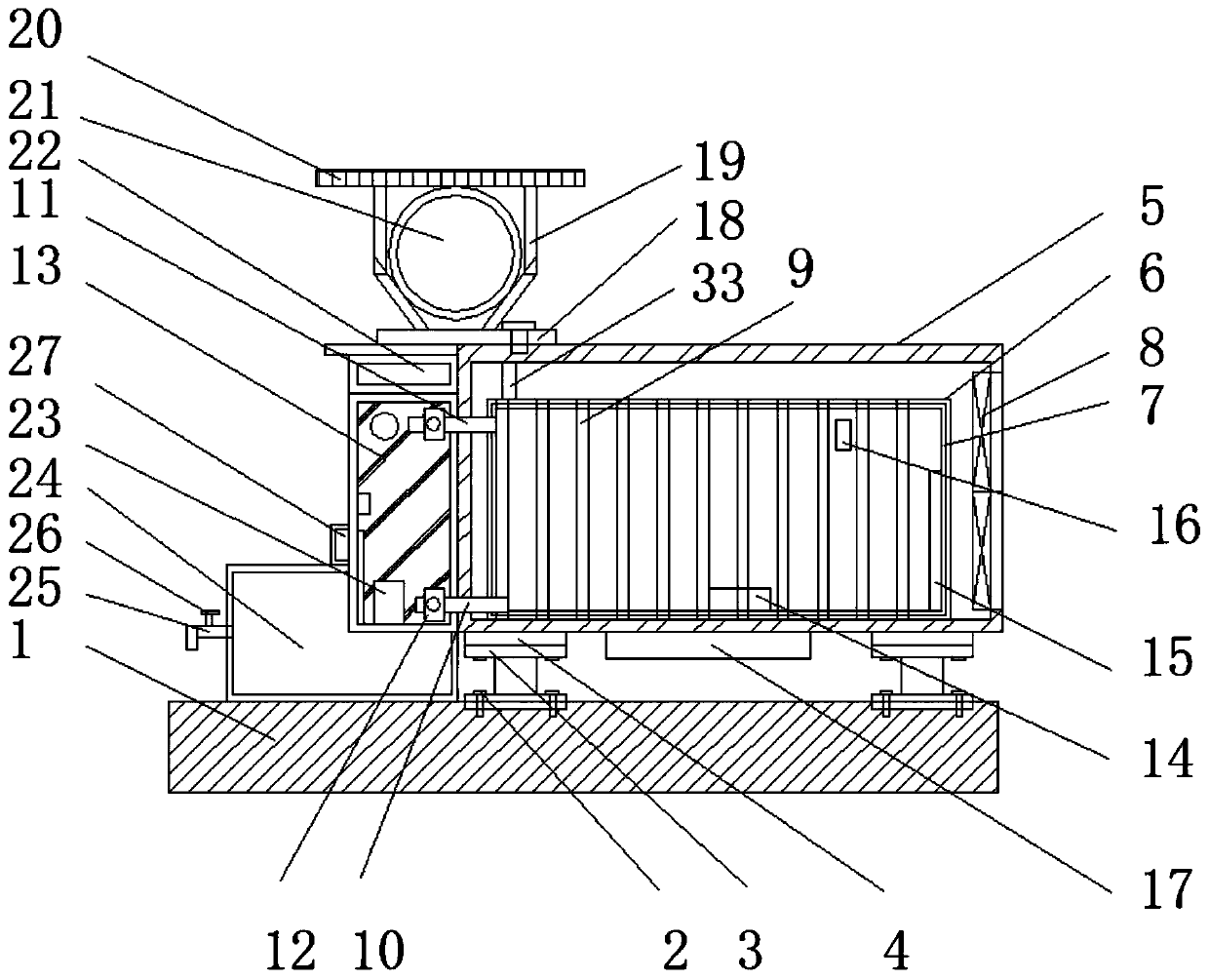

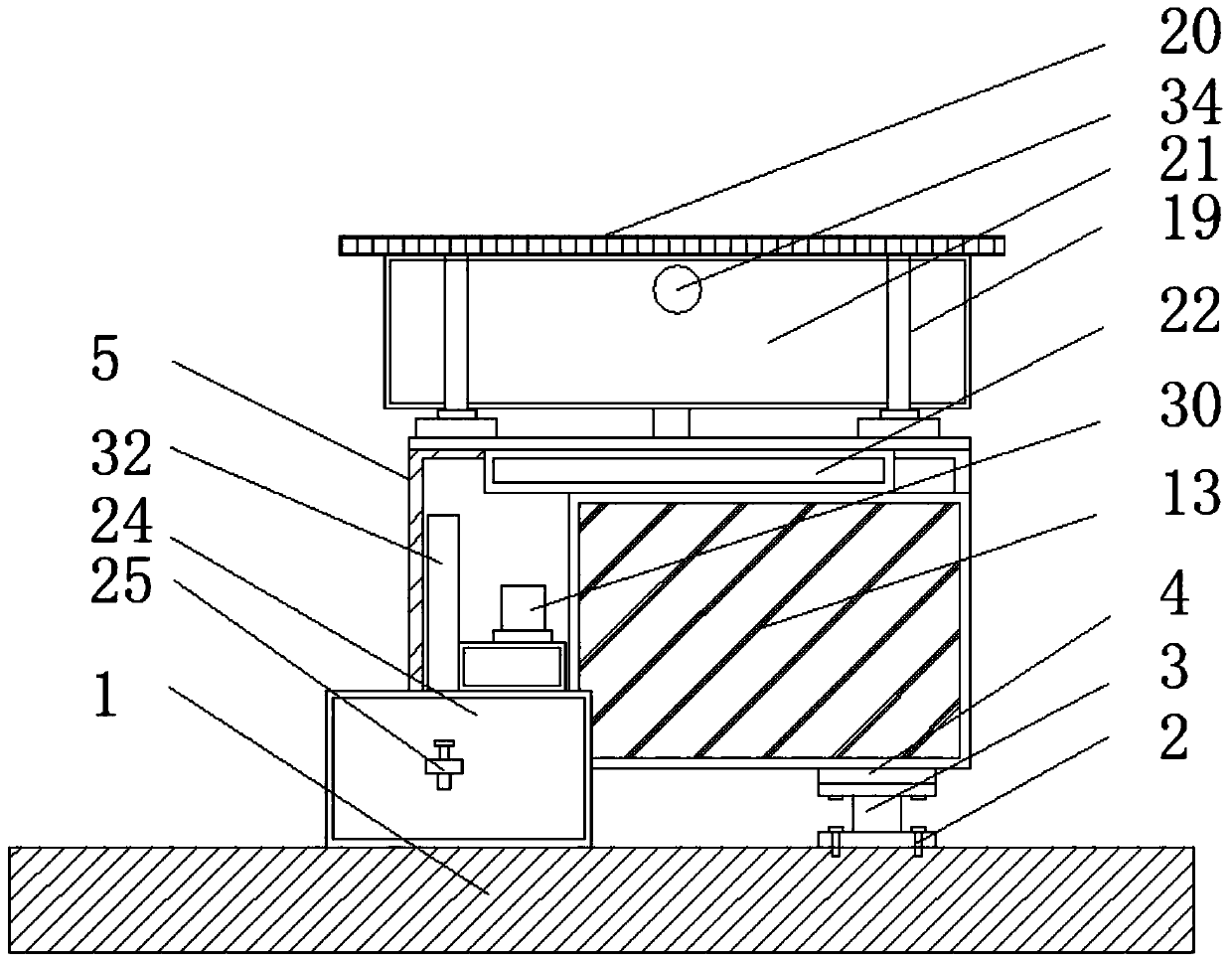

InactiveCN110808145AEasy to fixWork lessTransformers/reacts mounting/support/suspensionTransformers/inductances coolingTransformerElectric power

The invention discloses an oil-immersed power transformer that is easy to install and avoids oil leakage. The oil-immersed power transformer includes a fixed base, a pressure pump, a second oil storage tank, and a second oil pipeline. The fixed base is in threaded connection with an I-shaped fixing member by bolts. The bolts penetrate the I-shaped fixing member and a rubber shock pad to be in threaded connection with a transformer casing. The transformer casing is provided therein with a first oil tank housing. A cooling fan passes through the right side of the transformer housing. The pressure pump is disposed in a water tank. A fixing plate is in threaded connection with the upper left side of the transformer casing by bolts. A photovoltaic panel is fixed to the upper side of a support frame. The water tank is disposed on the front side of the second oil storage tank. The oil-immersed power transformer that is easy to install and avoids oil leakage is provided with the bolts, the I-shaped fixing member and the rubber shock pad. The I-shaped fixing member are detachably installed on the fixed base and the transformer casing by the bolts, so as to facilitate the later installationof the transformer casing.

Owner:江苏浚泽电气有限公司

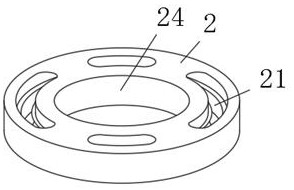

Anti-leakage water outlet pipe of water heater

The invention discloses an anti-leakage water outlet pipe of a water heater. The water outlet pipe comprises a valve mechanism, wherein the valve mechanism comprises a first seal, a piston rod and pistons; the first seal is fixed at the top end of the valve mechanism, the piston rod is movably installed at the lower end inside the valve mechanism, and a plurality of pistons are fixed on the outersurface of the piston rod; a motor is fixedly installed on one side of the valve mechanism by an installation seat, a threaded rod is fixedly installed at the output shaft end of the motor by a coupling, the end, close to the motor, of the piston rod extends to the outside of the valve mechanism, a connecting rod is fixedly installed at the end, close to the motor, of the piston rod, and a threaded hole is formed in the upper end of the connecting rod. The water outlet pipe has simple structure and good use effect; the pipe can be anti-leakage and remind water leakage in case of plastic agingand leakage, another pipe can be used for water outlet by switching via the valve mechanism after the pipe leaks, and normal use of the water heater cannot be affected.

Owner:江苏乾诚环境科技有限公司

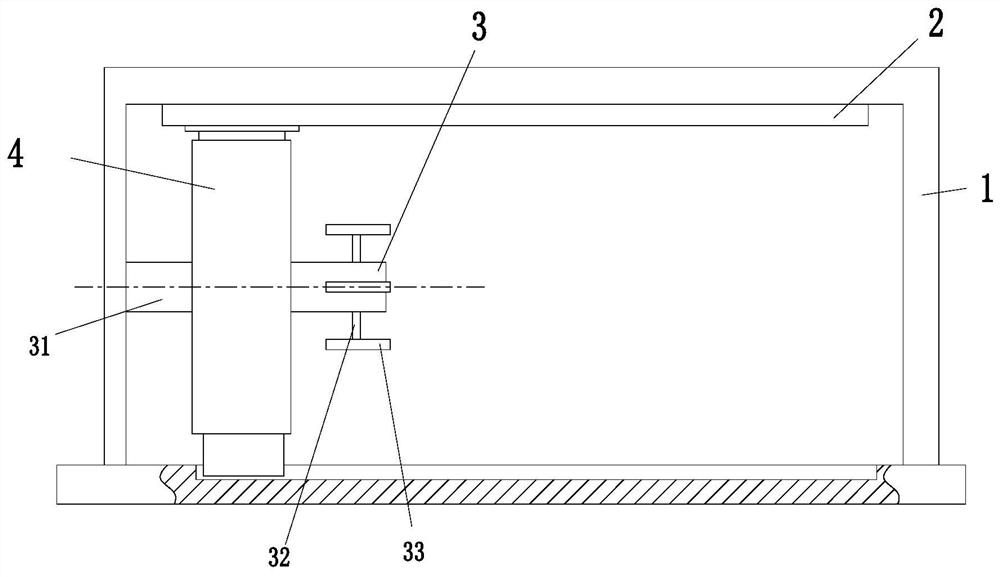

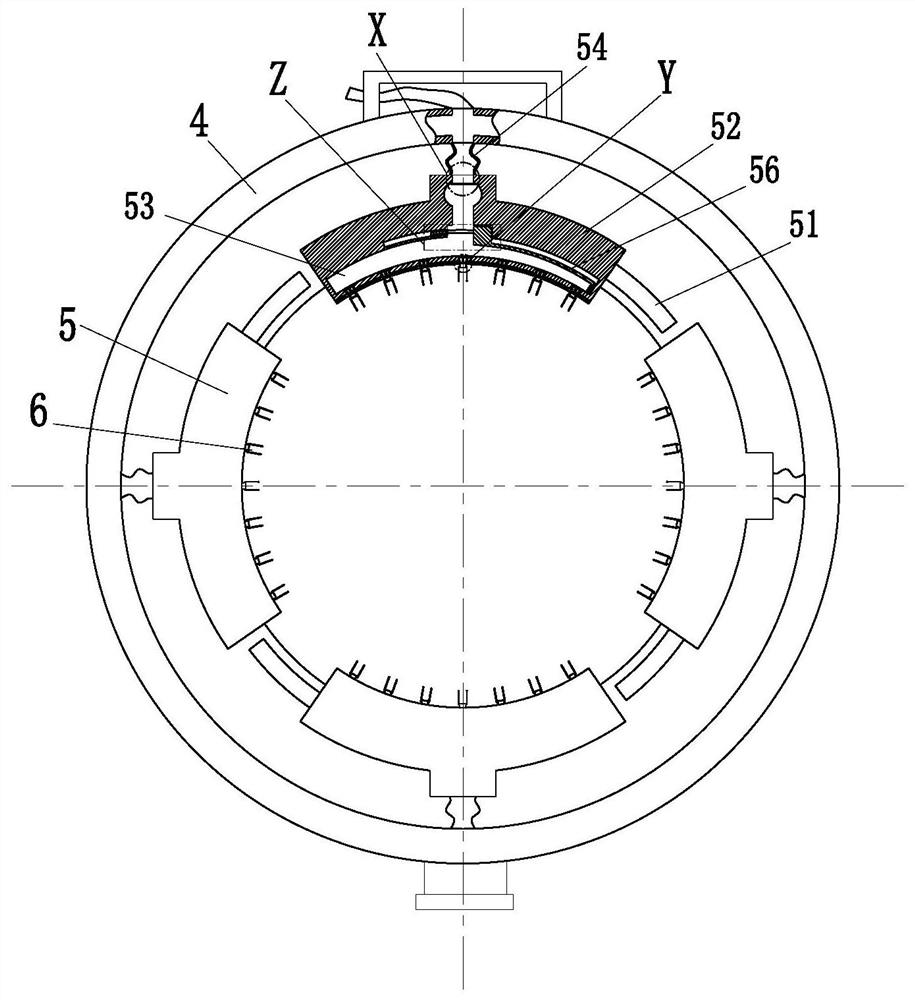

Steamer coating production line of steam turbine and coating method thereof

ActiveCN110293014AExpand the spraying areaAvoid cases that are thinner than the top halfSpraying apparatusPretreated surfacesProduction lineEngineering

The invention relates to a steamer coating production line of a steam turbine and a coating method thereof. An electric rotary disc, an inner diameter clamp, an electric lifting rod, a connecting frame, two angle adjusting frames, first nozzles and second nozzles are included; the inner diameter clamp is installed at the upper end of the electric rotary disc, the right end of the electric rotary disc is equipped with the electric lifting rod, the upper end of the electric lifting rod is provided with the connecting frame, the lower end of the connecting frame is provided with the two angle adjusting frames, the outer side of the lower end of each angle adjusting frame is provided with the corresponding first nozzle, and the inner side of the lower end of each angle adjusting frame is provided with the corresponding second nozzle. The steamer coating production line can solve the problems that in the conventional coating process, most common coating nozzles adopt a fixed connecting manner so that the common coating nozzles cannot conduct spraying according to blade shapes, the thickness of a spraying layer on the upper half part of a blade is often larger than the thickness of a spraying layer on the lower half part after spraying with the common coating nozzles, and vestigital coating liquid still drips after spraying with the common coating nozzles is completed.

Owner:哈尔滨重核电力有限公司

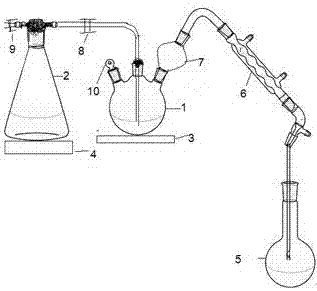

Hollow PVA fiber as well as preparation method and application thereof

ActiveCN107268104APromote secondary mining to increase incomeGood dispersionMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberPolymer science

Hollow PVA fiber is prepared from PVA with the polymerization degree being 1,000-3,500 and the alcoholysis degree being 99.0-99.9(mol)% through spinning, wherein the section of the PVA fiber adopts a hollow structure, and the diameter of the hollow part is 0.1-100 mu m. The hollow PVA fiber is added to an oil and gas field fracturing fluid, so that the fracturing fluid has very good sand-carrying capacity, flowback of the fracturing fluid is facilitated, the usage amount of guar gum and other components which are difficult to dissolve completely and difficult to discharge from the bottom of a well can be reduced, and damage to environment is reduced; the hollow PVA fiber can improve the strength and the toughness of a cementing material and can also perform a leakage prevention function after being added to an oil and gas field cementing agent; the hollow PVA fiber has good filtration reduction function after being added to a temporary plugging agent used during fracturing of an oil and gas field and can form a shielding layer at to-be-temporarily plugged part, so that smooth diversion of the fracturing fluid can be realized. Components remaining in the environment can be decomposed into non-toxic hydrocarbon finally and cannot damage to the environment.

Owner:CHINA PETROCHEMICAL CORP +1

Bipolar zinc ion battery

PendingCN110690512ASimple processSimple structureCell seperators/membranes/diaphragms/spacersFinal product manufactureZinc compoundsBattery cell

The invention discloses a bipolar zinc ion battery, which includes at least one unit group. The unit group includes at least one battery unit. The battery unit includes: an anode plastic current collector, an isolation film, and a cathode plastic current collector which are successively stacked and attached and sealed to each other, and a cathode active material layer as a cathode disposed insidethe cathode current collector, an anode active material layer as an anode disposed inside the anode current collector, and an electrolyte in the gaps of the cathode, anode, and the isolation film andcontaining a zinc compound and a porous ion channel disposed on the isolation film between the anode and the anode for the movement of zinc ions. The bipolar zinc ion battery has simple structure andlight weight, and has good safety performance and use performance.

Owner:邦泰宏图(深圳)科技有限责任公司

Leakage preventing assembly for pipeline connection

The invention provides a leakage preventing assembly for pipeline connection. The leakage preventing assembly for the pipeline connection comprises a connecting block, wherein connecting holes penetrates two sides of the connecting block; inclined threaded pipelines are in thread connection with parts, corresponding to the connecting holes, at two sides of the connecting block; a first magnetic pole is fixedly connected to the inner side of the connecting block; a spring is fixedly connected to one side, close to each connecting hole, of the first magnetic pole; a second magnetic pole is fixedly connected to one side, far away from the first magnetic pole, of the spring; an arc-shaped block is fixedly connected to one side, far away from the spring, of the second magnetic pole; and a connecting seam is embedded into the connecting block and each inclined threaded pipeline. When the leakage preventing assembly is in use, the first magnetic pole and the second magnetic pole are like poles, the first magnetic pole applies repulsive force to the second magnetic pole to enable the second magnetic pole to slide in a chute; and meanwhile, the second magnetic pole drives the arc-shaped block to be in close contact with the corresponding inclined threaded pipeline, thus the inclined threaded pipelines can be prevented from sliding relative to the connecting block, and moreover, the connecting seam between the connecting block and each inclined threaded pipeline can be sealed through the arc-shaped block, and as a result, the leakage preventing effect is good.

Owner:蔡嘉丽

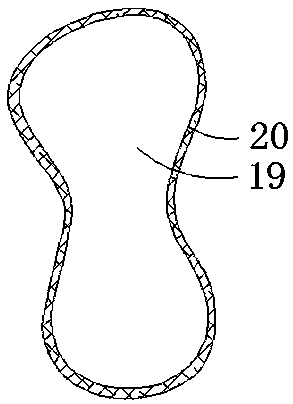

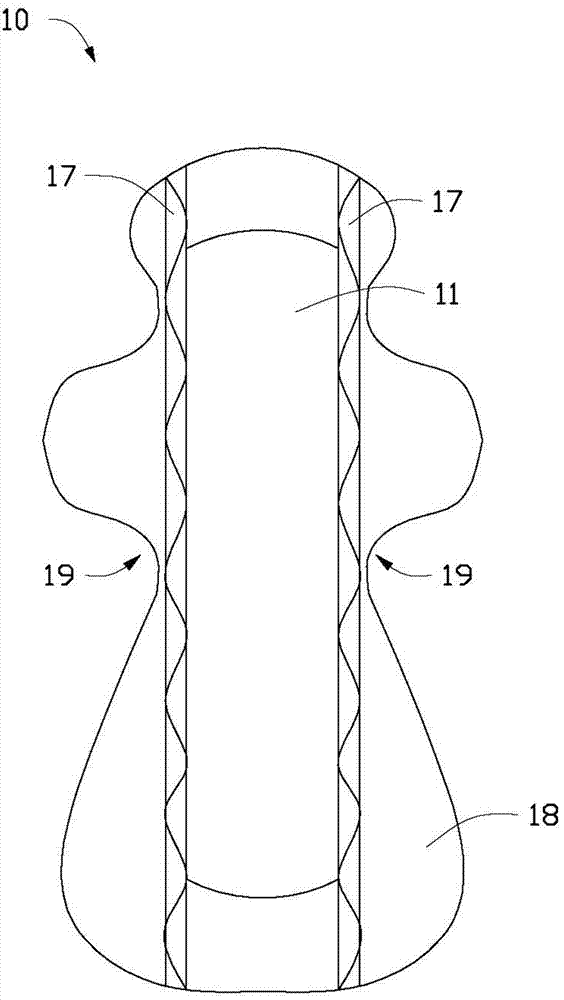

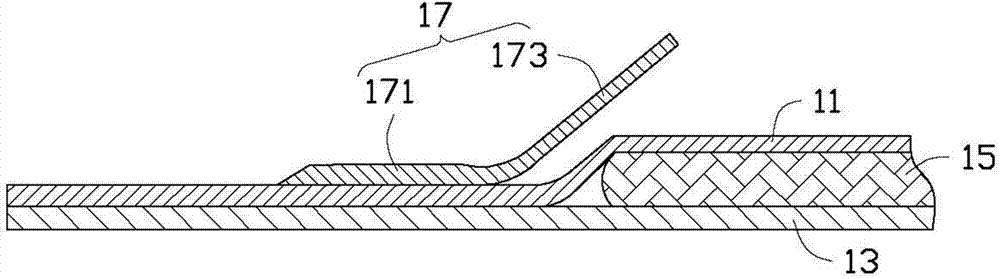

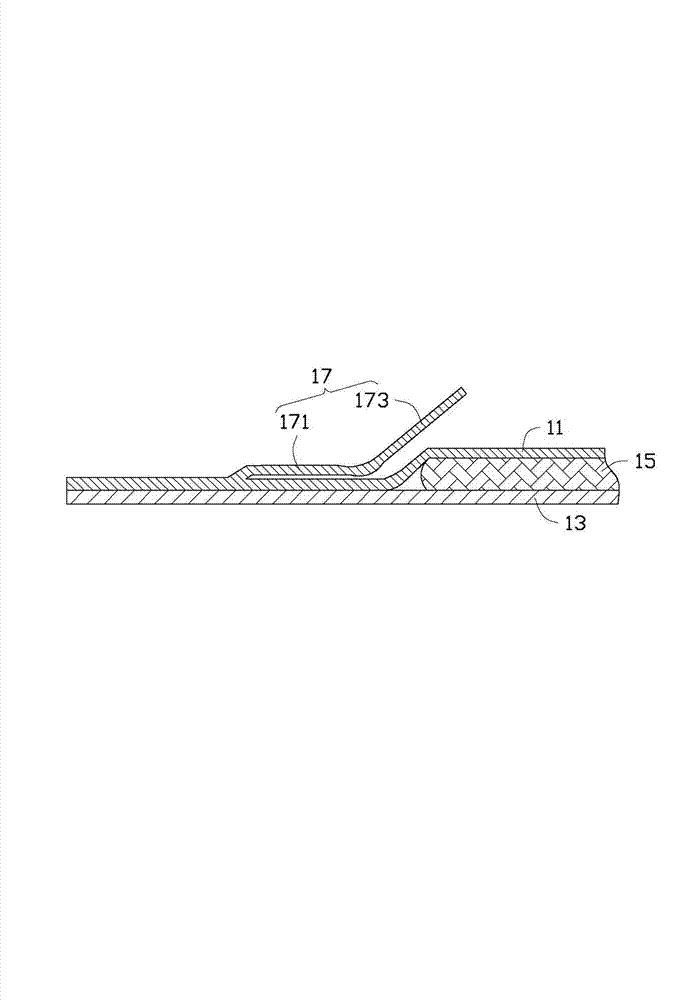

Disposable absorption product

Provided is a disposable absorption product. The disposable absorption product comprises a liquid pervious surface layer, a liquid non-pervious bottom layer, an absorption core arranged between the liquid pervious surface layer and the liquid non-pervious bottom layer, and two leakage prevention separating edges arranged on the liquid pervious surface layer. The two leakage prevention separating edges respectively extend along the length direction of the disposable absorption product to be in a long strip shape, and the two leakage prevention separating edges are respectively adjacent to an outer edge of the disposable absorption product. Each leakage prevention separating edge comprises a connecting end which is connected with the liquid pervious surface layer and a free end which is formed by extension of the connecting end. The free end is closer to the center of the disposable absorption product than the connecting end. An elastic extensible part is arranged on the edge of the free end, and therefore the free end of the leakage prevention separating edge tilts / stands up relative to the connecting end. Patterns are printed on each leakage prevention separating edge. When the disposable absorption product is in use, the leakage prevention separating edges stand up, and the patterns on the leakage prevention separating edges present standing layering, and feelings that consumers are in good mood can be achieved.

Owner:GOLD HONG YE PAPER

Expansion joint with flow guiding device

InactiveCN105156827AAvoid breakingReduced service lifePipeline expansion-compensationEngineeringExpansion joint

The invention discloses an expansion joint with a flow guiding device. The expansion joint comprises flanges, a first bellows, a second corrugated pipe, a middle pipe, an end pipe, a connecting rod, a flow guiding pipe and a check valve, wherein the first corrugated pipe is connected with the second corrugated pipe through the middle pipe; one end not connected with the middle pipe of the first corrugated pipe and one end not connected with the middle pipe of the second corrugated pipe are respectively connected with the end pipe through the corresponding flanges; the connecting rod is arranged between the flanges; the flow guiding pipe is arranged on the middle pipe and communicates with the end pipe; the check valve is arranged in the flow guiding pipe. According to the expansion joint, the problem that the expansion joint is damaged when the subsidiary stress in a conventional expansion joint pipeline is beyond the elastic range of a compensating element, so that the service life of the expansion joint is greatly shortened is solved.

Owner:江苏广通管业制造有限公司

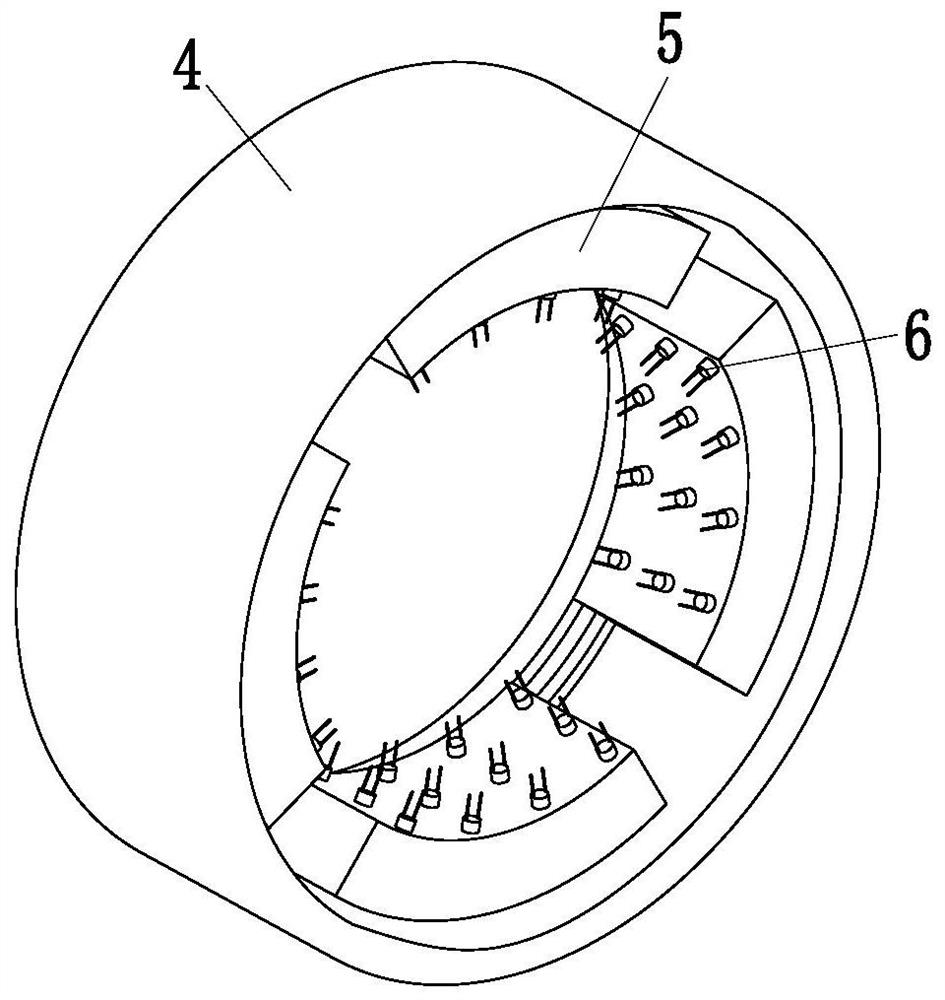

Surface dust-free coating production line for auto parts

ActiveCN110302922ASolve the problem of not spraying the coating liquid on the inner wall of the exhaust pipeAvoid spraying on the inner wall of the exhaust pipeSpraying apparatusExhaust gasEngineering

The invention relates to a surface dust-free coating production line for auto parts. The surface dust-free coating production line for auto parts comprises a portal frame, a driving electric slide block, an inner diameter clamp, an externally connected ring, connecting frames and equally spaced spray heads. The driving electric slide block is mounted at the upper end of the portal frame, the externally connected ring is mounted at the lower end of the driving electric slide block, the lower end of the externally connected ring is connected to the portal frame in a sliding fit manner, the connecting frames are uniformly arranged on the inner wall of the externally connected ring along the circumferential direction, the equally spaced spray heads are uniformly arranged on the inner end surface of each connecting frame, the inner diameter clamp is mounted at the left end of the portal frame, and the inner diameter clamp is located in the externally connected ring. The surface dust-free coating production line can solve the problems that the thicknesses of coating liquids in parts of an exhaust tube are different as the coating distances from existing spray heads to the parts of the exhaust tube are different as the bore diameters of the parts of the exhaust tube are different, and the existing spray heads are likely to spray the coating liquids to the inner wall of the exhaust tube as the orifice of part of the exhaust tube is of an inclined structure and the like.

Owner:马鞍山六金智能装备有限公司

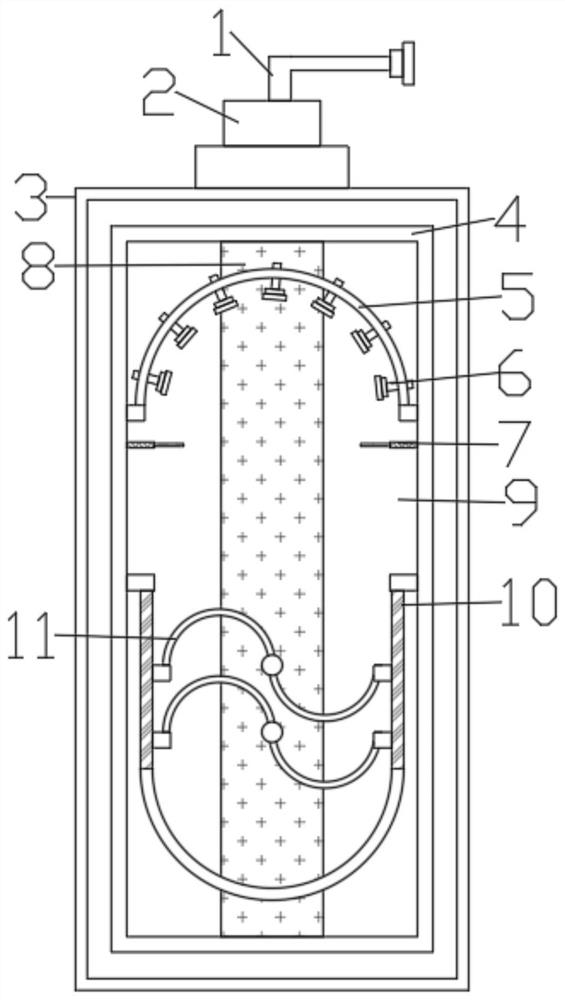

Peony peptide production equipment and production process

InactiveCN113069814APlay a fixed rolePlay a leak-proof rolePeptide preparation methodsStationary filtering element filtersEngineeringStructural engineering

The invention discloses peony peptide production equipment and a production process and relates to the field of peony byproducts. The peony peptide production equipment comprises a filter tank, a first filter casing, a second filter casing and filter cloth. A mounting opening is formed in the top of the filter tank, a liquid outlet is formed in the bottom, and an exhaust pipe is arranged on the side wall. A mounting groove is formed in the inner wall of the mounting opening, the inner wall of the mounting opening is sunken to form the mounting groove, and the mounting groove continuously extends in the circumferential direction of the mounting opening to be in a ring shape. And an annular air bag is accommodated in the mounting groove and is communicated with an inflation inlet of the inflation assembly. The first filter casing is used for being mounted at the mounting opening and attached to the inner wall of the mounting opening, the filter cloth is used for being laid and attached to the inner side of the first filter casing, the second filter casing is used for being mounted in the first filter casing and enabling the filter cloth to abut against the inner wall of the first filter casing, and the filter cloth is clamped between the first filter casing and the second filter casing. Peony seeds and a solvent can be efficiently separated, the separation effect is good, and the filter cloth is convenient to clean and replace.

Owner:聂小平

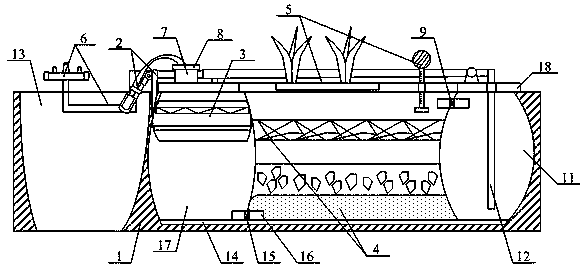

Lake sewage treatment device based on ecological structure

ActiveCN108503147AMeet the needs of extractionProtection securityTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisWater storageHydraulic cylinder

The invention provides a lake sewage treatment device based on an ecological structure; the lake sewage treatment device includes a foundation layer, an adjustable anti-blocking water suction pump, aneco-physical purifying box structure, a secondary filter pool structure, a lake ecological maintenance board structure, a backwater oxygenation fountain structure, a water inlet pool port pipe, a protective flange, a secondary electromagnetic valve, a secondary guide pipe, a clear water storage pool, a water suction pipe, a lake pool, a leak-proof layer, a primary electromagnetic valve, a primaryguide pipe, a primary treatment pool, a top-layer protective plate and a control cabinet; the adjustable anti-blocking water suction pump is inserted at the left side of the upper surface of the foundation layer. Through arrangement of a hydraulic cylinder and a telescopic rod, the length of an inlet water suction pump is advantageous to adjust according to the depth of different lakes, and the needs of the extraction of lake sewage are met; with arrangement of a protective cover of the water suction pump, sundries and fishes in the lakes are advantageous to block and are prevented from beingsucked into the inlet water suction pump, and the safety of the inlet water suction pump is protected.

Owner:薛维晋

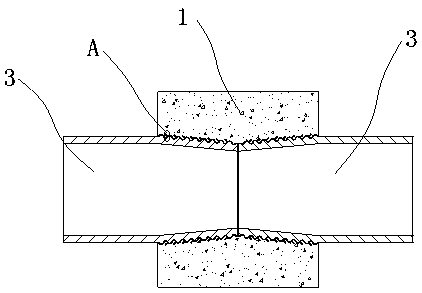

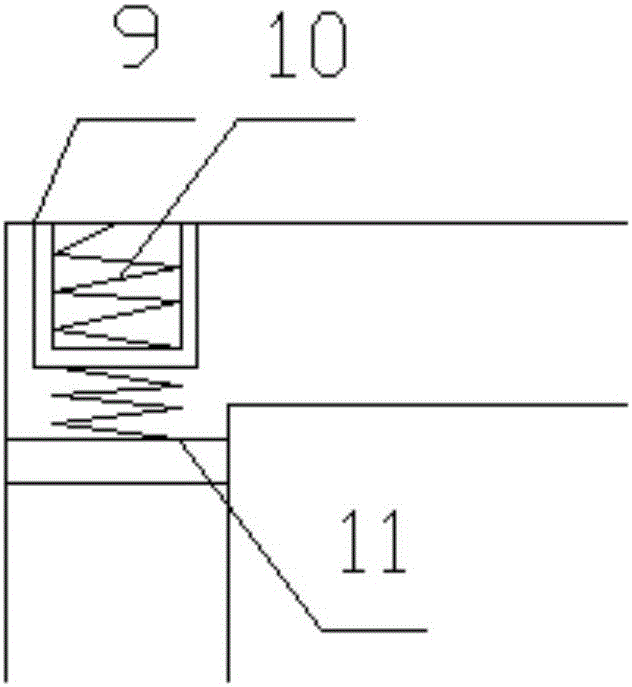

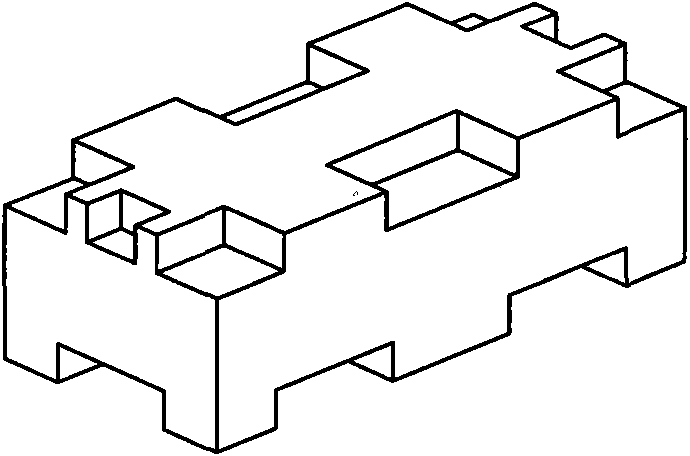

Building block used for forming wall body structure

InactiveCN101793071ASolve the double-sided leak-proof problemSolve the problem of permeable soilBuilding insulationsShock proofingWater leakageArchitectural engineering

The invention relates to a building block used for forming a wall body structure. A plurality of similar building blocks in the wall are continuously overlapped and placed in a staggered way, the building blocks are section bars in vertical direction. Each building block comprises a top surface, a bottom surface and two end surfaces, the cross section of the building block is integrally in a downward horn mouth shape, the top surface is provided with a middle ridge, both sides of the top surface are low, and a left supporting slop and a right supporting slop are formed. The top surface and the bottom surface are formed in the following way: when the building block is overlapped and placed on a lower similar building block for forming the wall body, the left supporting slop and the right supporting slop of the top surface of the lower building block are in contact with the bottom surface of the building block, so the two building blocks are locked, and the relative transverse movement is prevented. The shape and the size of the building block meet the requirement that when three similar building bocks are overlapped and placed up and down, the ridge of the lowest building block is higher than the bottom foot part of the highest building block. The invention has the advantages that any side of the formed wall body has the water leakage prevention effect, can simultaneously resist shock, and is firm and stabile, and in addition, the invention is applicable to various buildings and various construction methods.

Owner:汪荣勋

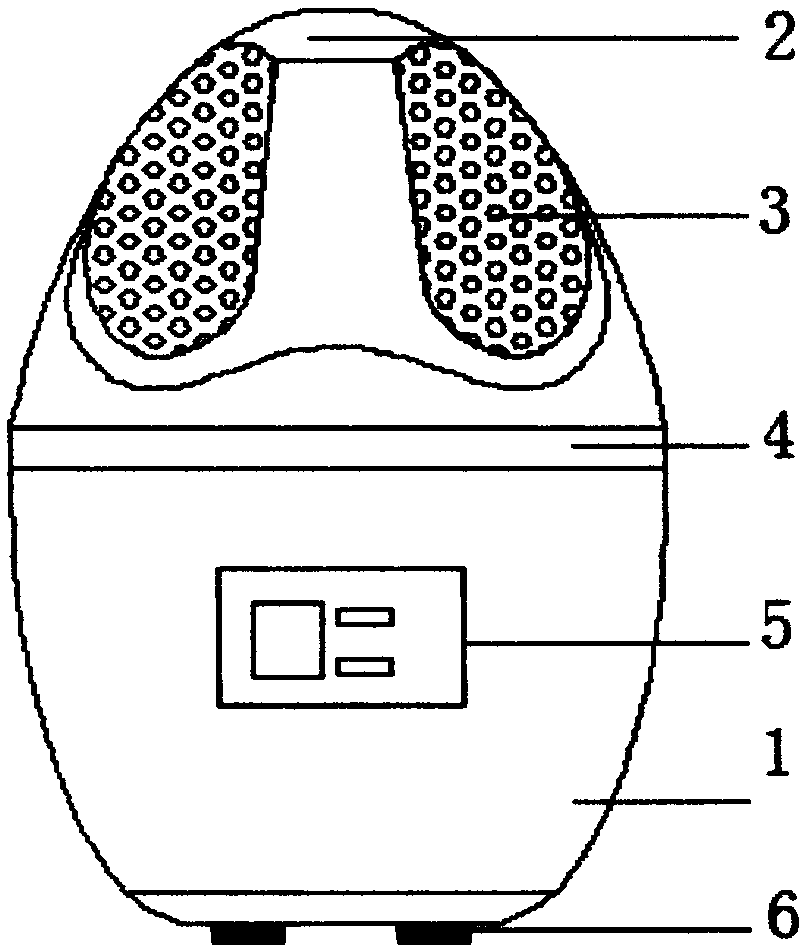

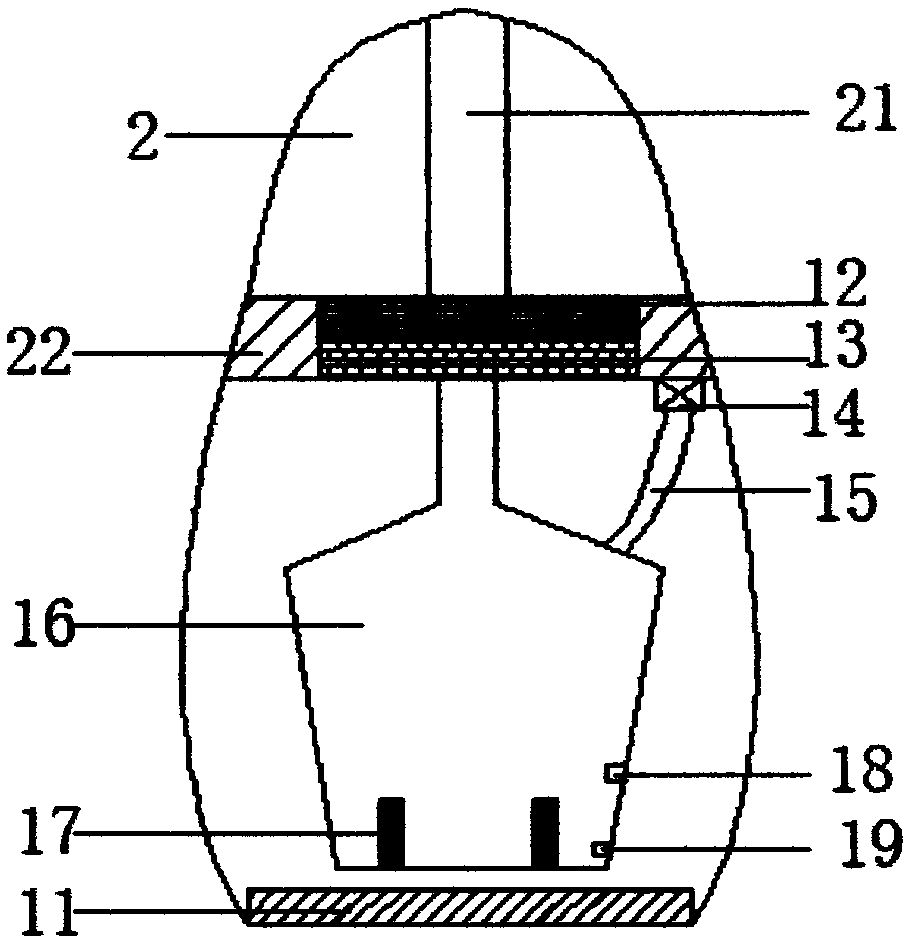

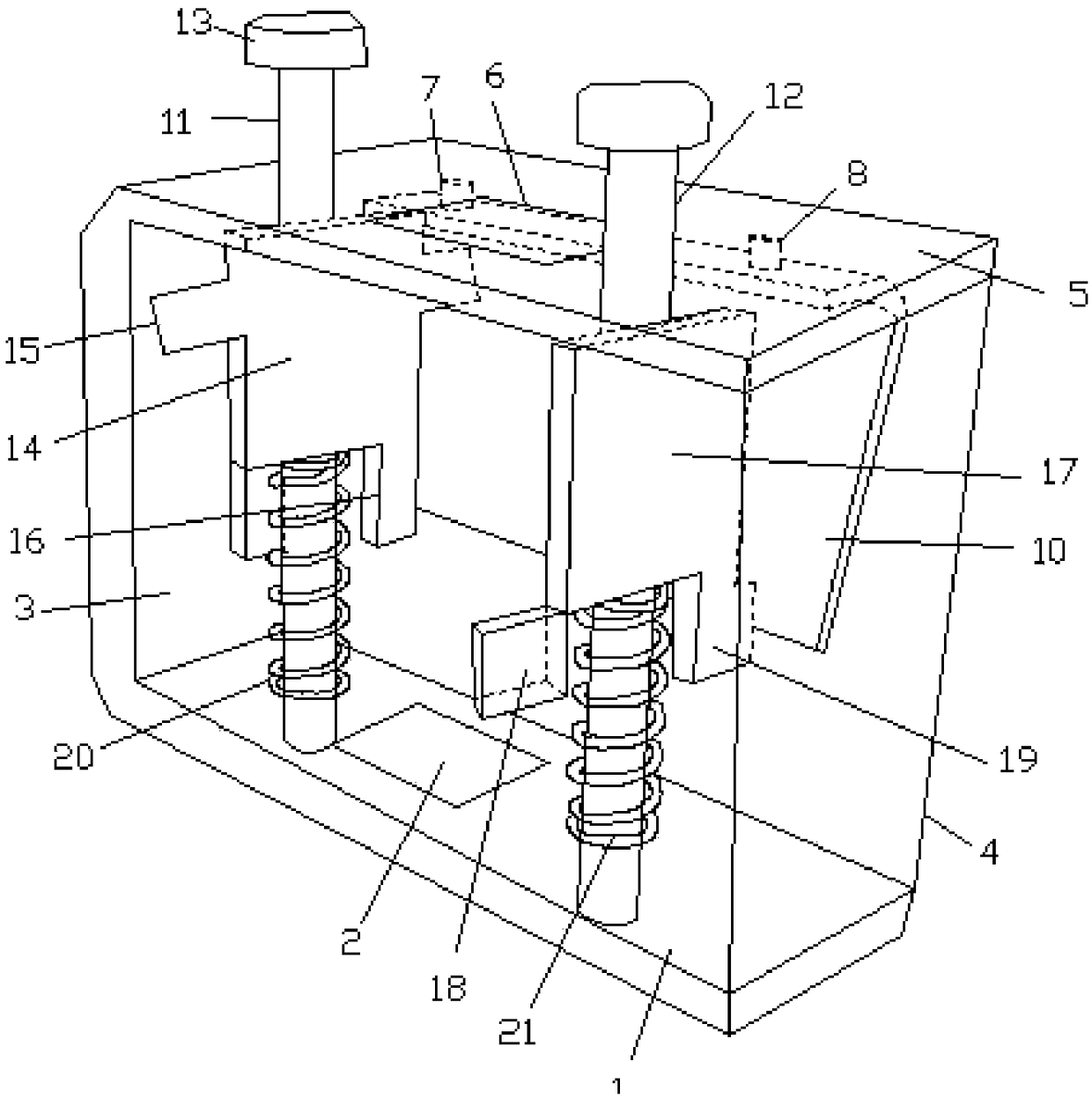

Safe humidifier capable of supplementing water automatically

InactiveCN106765804AReasonable designSimple structureMechanical apparatusSpace heating and ventilation safety systemsArchitectural engineeringWater level

The invention discloses a safe humidifier capable of supplanting water automatically. The top of a humidifier body is in screw joint with an upper cover through a sealing ring. A rubber foot pad is installed at the bottom of the humidifier body. A mist spraying opening is formed in the upper cover. An ultraviolet sterilizing lamp is installed in an inner cavity of the upper cover. A water condensing groove is formed in the bottom of the inner cavity of the upper cover. A filtering net and a negative ion filter are connected in an inner cavity of the water condensing groove in an inserted manner. The bottom of the negative ion filter is connected with a mist outlet of a water tank. A micro draught fan is arranged at the bottom of the water tank. A heating electrode plate is arranged in an inner cavity of the water tank, and a first water level sensor and a second water level sensor are installed on the inner wall of the water tank. The bottom of the water condensing groove is connected with an electromagnetic valve which is connected to the inner cavity of the water tank through a hose, and a heat insulation bar is arranged in the inner cavity of the water condensing groove. The safe humidifier capable of supplementing water automatically is easy to operate, a clean humidifying effect can be effectively provided, and the service life of the humidifier is prolonged.

Owner:岑利娜

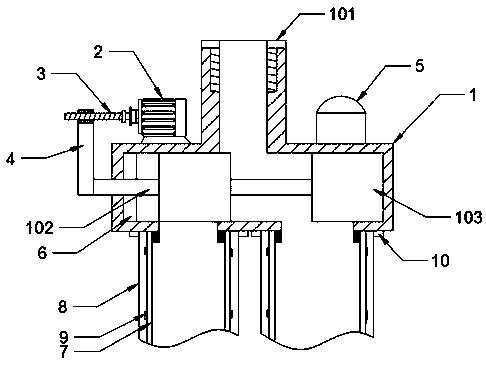

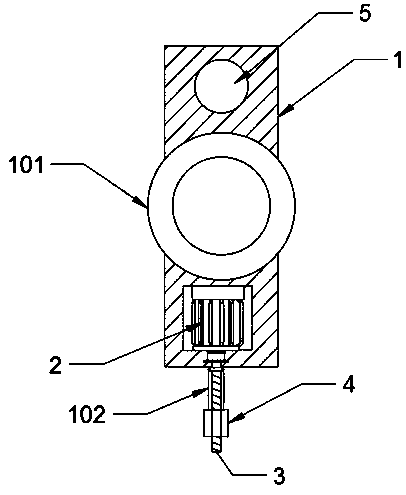

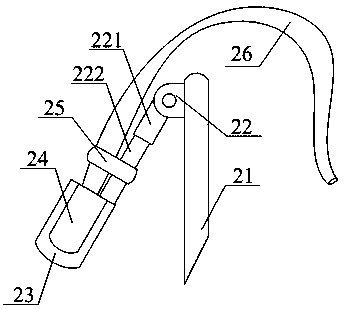

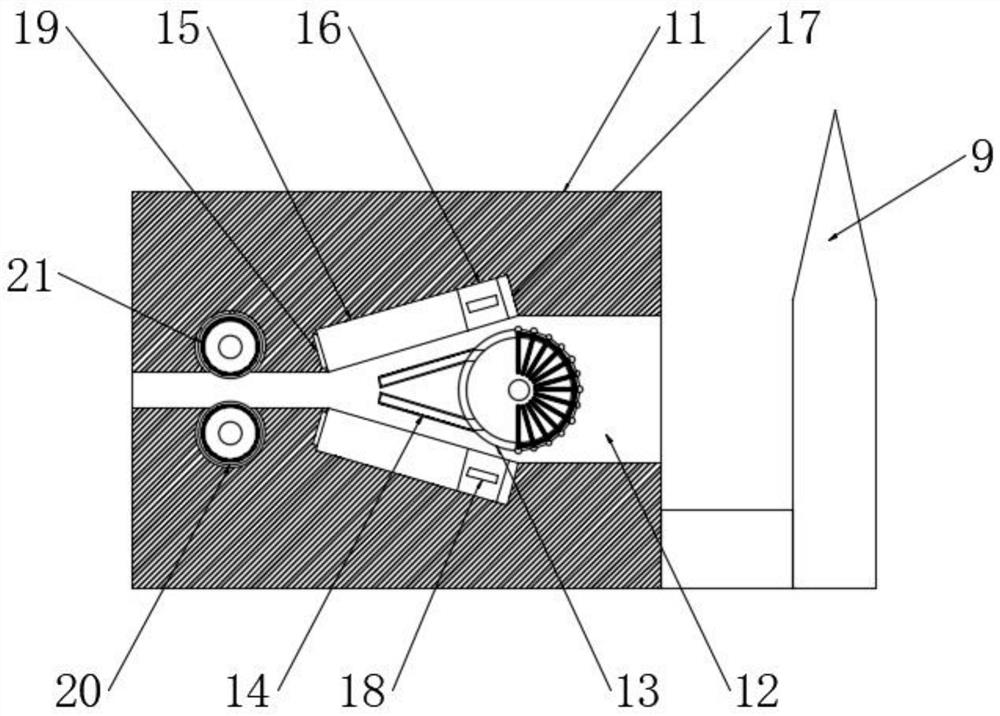

Pipeline pressure tapping branching device

InactiveCN114215985AImprove sealingPlay a leak-proof roleBranching pipesBoring/drilling machinesEngineeringStructural engineering

The invention discloses a pipeline pressure tapping branching device which comprises a pressure pipe body, a lower saddle, an upper saddle, a pipeline sealing gasket, a knife switch, a nut and a cut-off sealing ring, a long kidney-shaped knife switch inserting groove is formed in the outer side of the upper saddle, and a through hole is formed in the center of the upper saddle. An inner thread, an annular cut-off sealing groove and a pipeline sealing groove matched with the pipeline sealing gasket are sequentially arranged in the through hole from top to bottom, the knife switch inserting groove is communicated with the cut-off sealing groove and corresponds to the position where the cut-off sealing groove is located, and installation bosses are arranged on the two sides of the lower portion of the upper saddle. And the bolt ends at the two tops of the lower saddle penetrate through the mounting bosses and form a locking structure with the nuts. The pipeline sealing gasket can be arranged to be of a U-shaped structure, the outer side part of the upper portion of the pipeline sealing gasket is matched with the pipeline sealing groove, the inner side of the upper portion of the pipeline sealing groove is matched with the inner wall of the through hole, compared with a traditional sealing gasket, the sealing effect is better, and the leakage-proof effect can also be achieved under large pressure.

Owner:安徽欧泰祺智慧水务科技有限公司

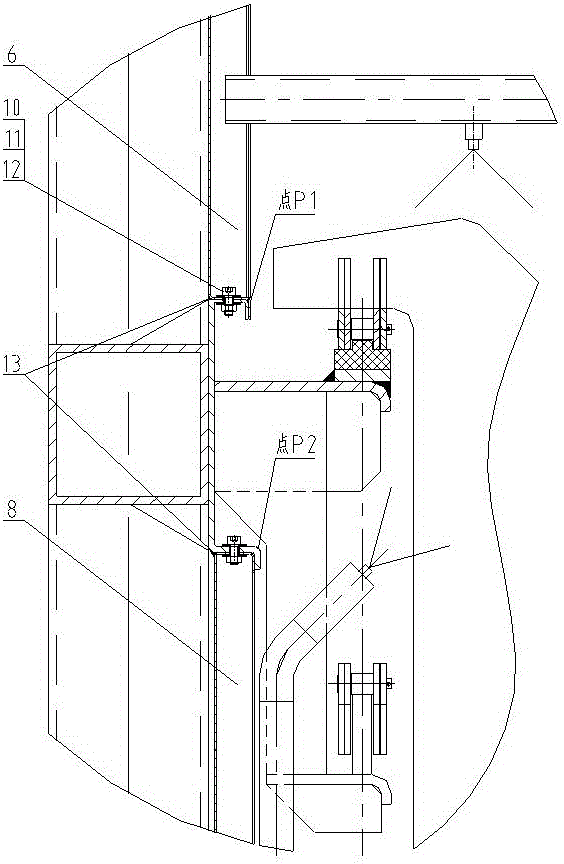

Heating and ventilation condensate water leakage preventing device for constructional engineering

InactiveCN113091296AEasy to adjustExpand the scope of detectionMechanical apparatusCondensate preventionCondensed waterStructural engineering

The invention discloses a heating and ventilation condensate water leakage preventing device for constructional engineering, belongs to the technical field of constructional engineering, and solves the problems that a drainage pipe of an existing collecting device is prone to leak, and electric power accident is prone to occur. The leakage preventing device comprises a connecting cavity and an outer cover; the connecting cavity is fixedly installed on the outer cover; a connecting pipe is arranged on the connecting cavity, and the connecting cavity communicates with one end of the connecting pipe; an inner cover is arranged in the outer cover, and a drying area is arranged between the outer cover and the inner cover; a water collecting cavity is arranged in the inner cover; a drainage pipe is fixedly installed in the water collecting cavity; and a collecting assembly and a drying assembly are further arranged in the water collecting cavity. According to the embodiment of the invention, an adjusting assembly is arranged, the position of a detection assembly can be conveniently adjusted through arrangement of the adjusting assembly, so that a detection range is enlarged, the detection precision is improved; and air in the water collecting cavity is rapidly dried through arrangement of the drying assembly, so that leakage water is prevented from escaping, and a leakage prevention effect is achieved.

Owner:TONGZHOU CONSTR GENERAL CONTRACTING GROUP

A kind of automatic equipment for one-time forming of protective clothing and its use method

ActiveCN111546656BImprove wearing safetyShorten the production cycleDomestic articlesProcess engineeringIndustrial engineering

The invention discloses an automatic equipment for one-time molding of protective clothing and a method for using the same. It belongs to the technical field of protective clothing production and can realize on-site production. After the user stands and stretches his limbs, the protective clothing material is driven by the instrument to cover the user. After the armpit and crotch are automatically cut, the opening is innovatively used to connect the sealing molding, and a certain amount of protective solid powder is filled after heating and melting. On the one hand, it can improve the sealing performance of the protective clothing material when docking. Bond strength, on the other hand, can strengthen the disinfection and sterilization effect of the joint, significantly improve the protective effect, and at the same time have the function of gap self-display phase, which is used to remind the user to replace it in time, improve the wearing safety of the protective clothing, and greatly shorten the time spent on protective clothing. The production cycle of protective clothing, efficient production of protective clothing for different users, fast and simple one-time molding, can well solve the problem of shortage of protective clothing resources in emergency situations.

Owner:台州市中心医院

Deformed blocks and wall body structure formed with the same

InactiveCN101067341BFit closelyHas a blocking effectBuilding componentsStructural engineeringEngineering

Owner:汪浩

A leak-proof electrolytic copper plate washing chain conveyor

The invention provides a leakproof structural washing chain conveyor of an electrolytic copper plate. The leakproof structural washing chain conveyor comprises a main rack, an upper spraying pipe, a side face spraying pipe, a transmission chain, a chain supporting plate and close plates. The leakproof structural washing chain conveyor is characterized in that single close plate is a quadrate blocky stainless steel close plate with two folding sides at 90 degrees; the blocky close plates are matched in a convex-concave staggering manner and are fixed through stainless steel bolts and acid-resistant plastic spacers; a strong acid solution in the washing chain conveyor does not flow from a clearance between every two close plates by gravity under such structure; a glass silica gel layer used for sealing is additionally arranged in a joint at the outermost side of each close plate; spray-like acid liquid in the washing chain conveyor also does not overflow from such structure. According to the leakproof structural washing chain conveyor of the electrolytic copper plate, the natural rigidity of the close plates can be enhanced through the folding side structures at four sides of the close plates, and the close plates can be firm and durable; the close plates also can be manufactured from thinner stainless steel plates, so that the materials can be saved. The structure under bolt connection is dismountable and can be replaced by simply releasing the bolts during maintaining, so that the maintenance cost is saved.

Owner:GANZHOU NONFERROUS METALLURGICAL MACHINERY

Environment-friendly material cutting machine

ActiveCN108927695AReduce health damagePlay a fixed roleMetal working apparatusMaintainance and safety accessoriesPulp and paper industry

The invention discloses an environment-friendly material cutting machine. The cutting machine comprises a bottom plate, wherein a discharging port is formed in the middle of the bottom plate, a firstsupporting plate and a second supporting plate are symmetrically arranged on the two sides of the top of the bottom plate, a top plate is arranged at the tops of the first supporting plate and the second supporting plate, and a feeding port is formed in the middle of the top plate; a first connecting piece and a second connecting piece are symmetrically arranged at the bottom of the top plate, andthe bottom of the top plate is fixedly connected with a first baffle and a second baffle correspondingly through the first connecting piece and the second connecting piece; a first pressing rod and asecond pressing rod are symmetrically arranged on the top plate, pressing caps are arranged at one end of the first pressing rod and one end of the second pressing rod correspondingly, and the otherends of the first pressing rod and the second pressing rod penetrate through the top plate correspondingly and extend forwards; and a first mounting plate is arranged in the middle of the first pressing rod, first pushing blocks are symmetrically arranged on the two sides of the first mounting plate, and second pushing blocks are symmetrically arranged at the bottom of the first mounting plate. The cutting machine has the beneficial effects that the material cutting speed is controlled, dust generated during cutting is sucked, and the environment is protected.

Owner:山东宏阳型材科技股份有限公司

Storage device for dangerous chemicals

PendingCN112499010AAvoid spill contaminationRealize the protective effectProtective foundationLarge containersElectric machineryElectrical and Electronics engineering

The invention discloses a storage device for dangerous chemicals. The storage device comprises a tank body; the tank body comprises an inner tank and an outer tank; the inner tank and the outer tank are coaxially connected in a sleeved mode; gaps are formed in the middle and the lower end; the gap in the lower end is coaxially and fixedly connected with a scraper device; the scraper device comprises a cylindrical block; the right end in the cylindrical block is fixedly connected with a spraying device; the spraying device comprises an outer pipe, an air inlet, an air pipe, a circular pipe, anair outlet pipe, a transverse plate, a horn mouth and a circular hole; the bottom end in the outer pipe is coaxially and fixedly connected with the air inlet; one end of the air pipe is inserted in the lower end of the air inlet; the other end of the air pipe is connected with a motor box; the outer circle of the upper end of the air inlet of the outer pipe is coaxially and fixedly connected withthe circular pipe; the two ends of the circular pipe are fixedly connected with supporting frames; and protection devices are arranged at the upper end and the lower end of the outer tank. During regular maintenance and inspection, the spraying device can be started, an aerostatic press in the motor box can drive compressed air to enter the outer pipe through the air pipe, a stabilizer is stored in the outer pipe, is crushed and atomized through the transverse plate along with compressed air flow, is emitted around the inner tank through the horn mouth and reacts with the leaked chemicals.

Owner:上海元捷供应链管理有限公司

An attitude acquisition method and a digital customization system for protective clothing based on the method

ActiveCN111418939BIncrease flexibilityImprove wearing safetyDigital data information retrievalCharacter and pattern recognitionEngineeringBody posture

The invention discloses a protective clothing digital customization system based on attitude collection, which includes a production platform and a model acquisition platform. The model acquisition platform includes a trajectory acquisition module, a classification module, and a model output module; The fixed-point posture image and the posture change image are converted into feature vectors with axis and time axis labels, and the feature vectors are input into the preset classification model to obtain the standard protective clothing size; based on the standard protective clothing size, the model output module searches the database from multiple Determine the cutting method that matches the size of the standard protective clothing among the three cutting methods, and control the manipulator to manufacture the protective clothing based on the cutting method; the trajectory acquisition module is used to collect changes in the user's body posture. The invention solves the technical problem of large manufacturing errors and low flexibility of conventional protective clothing, and can automatically customize according to the user's figure, with simple operation and good fit of the manufactured protective clothing.

Owner:台州市中心医院

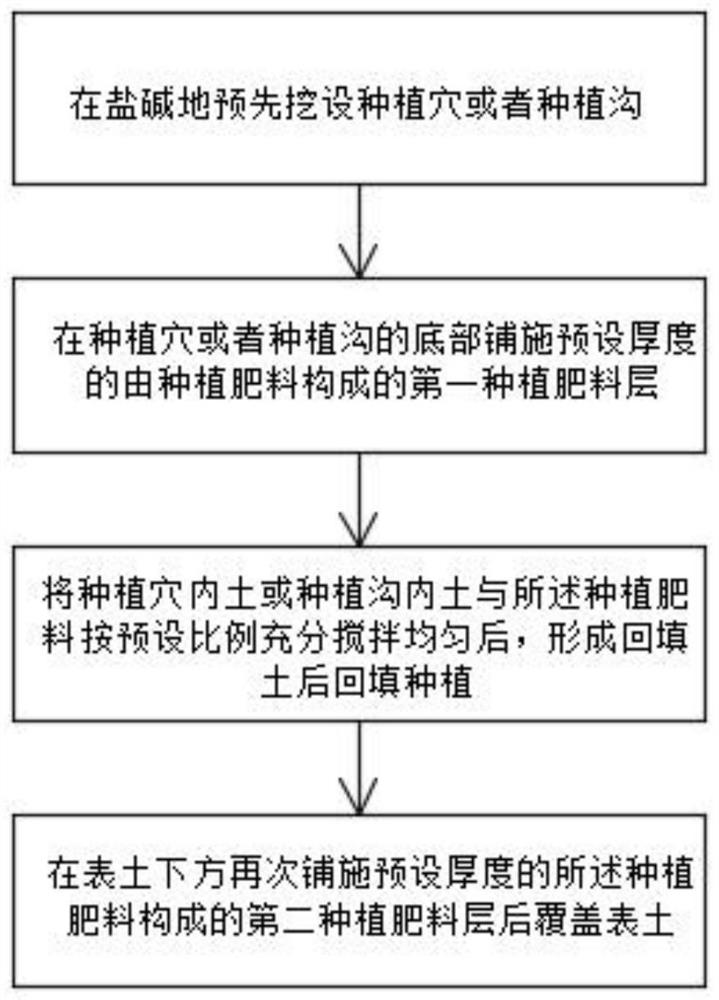

Planting method suitable for saline-alkali soil remediation and improvement

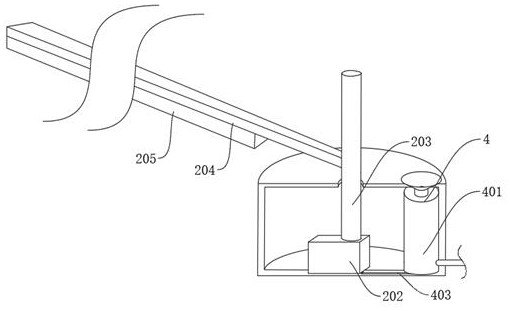

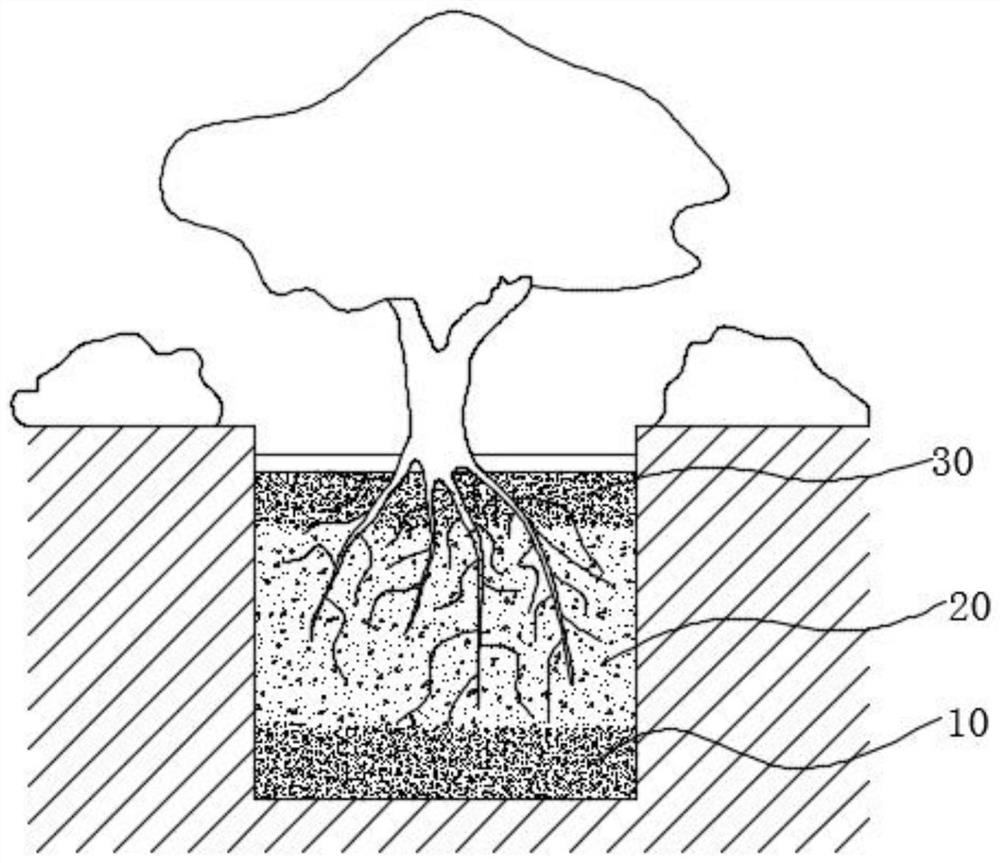

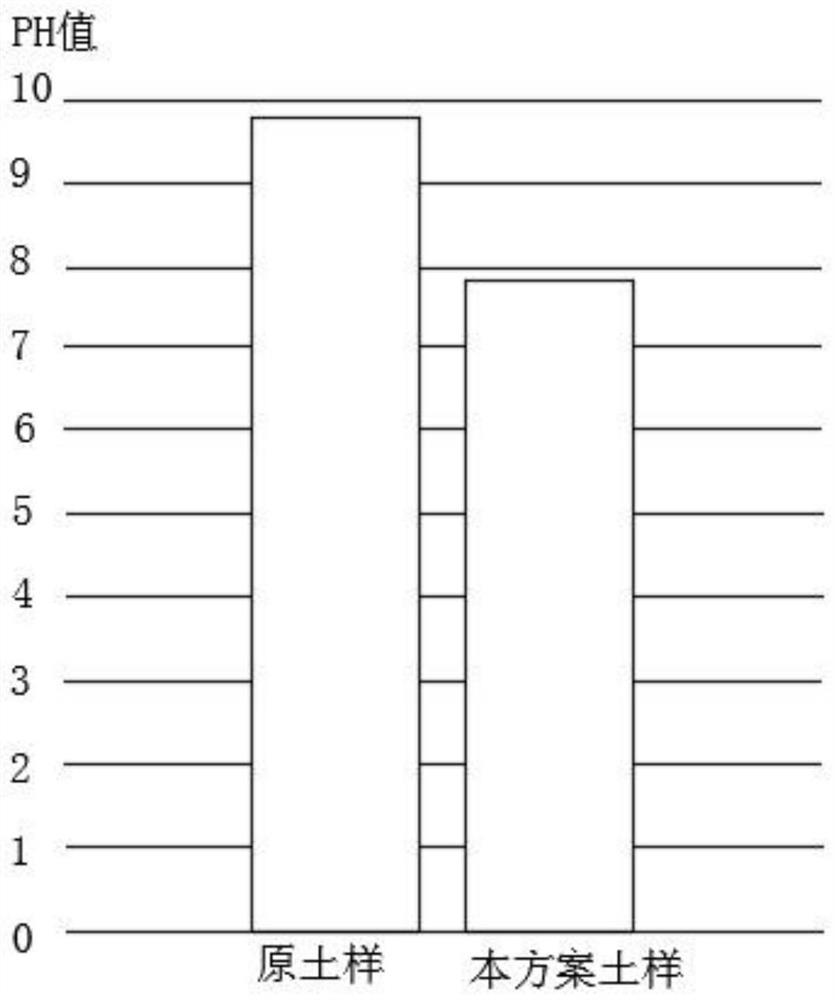

PendingCN114145095APlay a leak-proof roleBlock lossBioloigcal waste fertilisersPlant cultivationAlkali soilSoil science

The invention belongs to the technical field of soil improvement, and particularly relates to a planting method suitable for saline-alkali soil remediation and improvement, in the planting method, a first planting fertilizer layer with a preset thickness is laid at the bottom of a planting hole or a planting ditch, so that on one hand, moisture and nutrient loss is blocked, moisture and nutrient leakage is prevented and controlled, and soil remediation and improvement are facilitated; on the other hand, the water and soil conservation and leakage prevention effects are achieved, and later-period nutrient and fertilizer requirements of plant crops are met; after soil in the planting holes or soil in the planting ditches and planting fertilizer are fully and evenly stirred according to a preset proportion, backfill soil is formed and then backfill planting is conducted, and the growth nutrient and fertilizer requirements of planted crops are met; after a second planting fertilizer layer with the preset thickness is laid below the surface soil again, the surface soil is covered, and the effects of preventing salt from accumulating on the ground surface and permeating into the planting area and delaying water evaporation are achieved; by the adoption of the technical scheme, the purpose of restoring and improving the saline-alkali soil can be achieved only by simply adjusting and changing the planting method.

Owner:FRUIT TREE INST OF CHINESE ACAD OF AGRI SCI +1

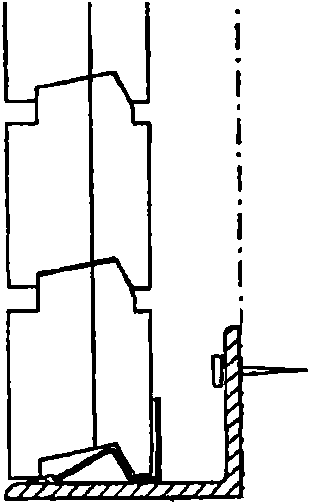

A guide sleeve for a hydraulic cylinder

ActiveCN110886740BEasy to assemble and disassembleImprove the protective effectFluid-pressure actuatorsHydraulic cylinderOil can

The invention discloses a guide sleeve of a hydraulic oil cylinder, which comprises a guide sleeve body, a fixed plate, a pipe sleeve and a No. 1 piston rod. A guide hole is provided inside, and a plurality of oil storage tanks are provided on the inner wall of the guide hole, and a fixed plate is welded at one end of the guide sleeve body. The present invention provides an oil storage tank and an oil suction tank inside the guide sleeve, and a rubber ring inside the sleeve. Ensure that the excess oil can be kept in the guide sleeve as much as possible, which can play a certain role in preventing leakage; by setting a movable sleeve, with the help of cooling holes and fins, the gap between the piston rod and the guide sleeve The heat generated by friction can be quickly discharged, and the dust-proof net is set in the heat dissipation hole, and two opposite oil suction grooves are set, and at the same time, it can also avoid the internal oil leakage and reduce the lubricating oil content; the whole new guide sleeve is easy to disassemble and protect Good performance and higher practicability.

Owner:HUNAN HAOTIAN AUTOMOBILE MFG

A dust-free coating production line for the surface of auto parts

ActiveCN110302922BAvoid spraying on the inner wall of the exhaust pipeChange work statusSpraying apparatusProduction linePortal frame

The invention relates to a surface dust-free coating production line for auto parts. The surface dust-free coating production line for auto parts comprises a portal frame, a driving electric slide block, an inner diameter clamp, an externally connected ring, connecting frames and equally spaced spray heads. The driving electric slide block is mounted at the upper end of the portal frame, the externally connected ring is mounted at the lower end of the driving electric slide block, the lower end of the externally connected ring is connected to the portal frame in a sliding fit manner, the connecting frames are uniformly arranged on the inner wall of the externally connected ring along the circumferential direction, the equally spaced spray heads are uniformly arranged on the inner end surface of each connecting frame, the inner diameter clamp is mounted at the left end of the portal frame, and the inner diameter clamp is located in the externally connected ring. The surface dust-free coating production line can solve the problems that the thicknesses of coating liquids in parts of an exhaust tube are different as the coating distances from existing spray heads to the parts of the exhaust tube are different as the bore diameters of the parts of the exhaust tube are different, and the existing spray heads are likely to spray the coating liquids to the inner wall of the exhaust tube as the orifice of part of the exhaust tube is of an inclined structure and the like.

Owner:马鞍山六金智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com