A kind of automatic equipment for one-time forming of protective clothing and its use method

A technology for automation equipment and protective clothing, applied in other household appliances, applications, household appliances, etc., can solve problems such as operational obstacles and large size of protective clothing, improve sealing and bonding strength, shorten production cycles, and improve wearability. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

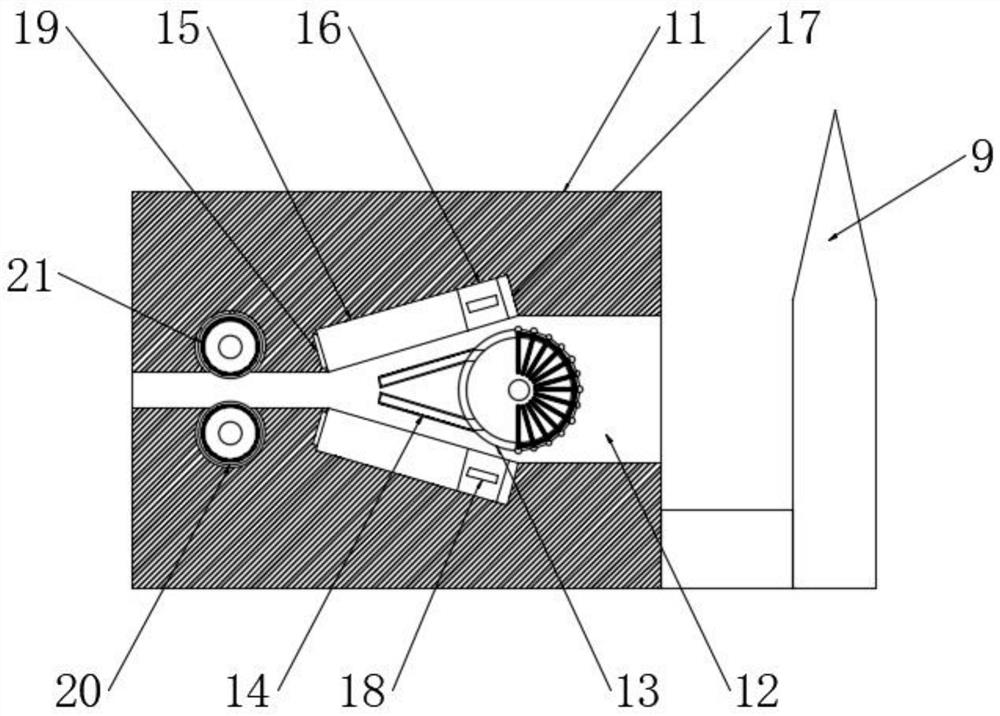

[0047] see Figure 1-2 , a kind of automatic equipment for one-time molding of protective clothing, including a production platform 1, a pair of symmetrically distributed instrument half-molds 2 are arranged on the upper side of the production platform 1, and the outer end of one instrument half-mold 2 is fixedly connected with a rotating shaft 3, and the production platform 1 is internally fixed. A stepper motor 4 is installed, and the output end of the stepper motor 4 is fixedly connected to the rotating shaft 3. The upper and lower ends of the instrument half-mold 2 and the end far away from the rotating shaft 3 are respectively provided with a head hole, a foot hole and a cloth feeding hole. A medical non-woven fabric 5 is inserted into the cloth inlet hole, and motor boxes 6 are installed at the four corners of the inner end of the instrument half-mold 2, and a pair of motor boxes 6 corresponding to the upper and lower sides are rotated and connected with guide rollers 7, ...

Embodiment 2

[0062] On the basis of Embodiment 1, combined with the Internet of Things technology, by setting up the present invention in a medical institution and adopting a fully automatic form, the wearer only needs to apply for an online review and pass the manufacturing instruction through the cloud to automatically manufacture a suit for the wearer. Protective clothing, and can only be used after the final protective material connection.

[0063] The invention can realize the mode of on-site production. After the user stands and stretches his limbs, the protective clothing material is driven by the instrument to cover the user's body. After automatic cutting under the armpit and crotch, the opening is innovatively used to seal the molded parts. Docking, after heating and melting, fill a certain amount of protective solid powder, on the one hand, it can improve the sealing and bonding strength of the protective clothing material when docking, on the other hand, it can strengthen the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com