Oil and gas field fracturing fluid, oil and gas field well cementation agent and oil and gas field fracturing temporary plugging agent

A technology for oil and gas fields and fracturing fluids, which is applied in the directions of conjugated synthetic polymer artificial filaments, drilling compositions, chemical instruments and methods, etc. and other problems, to achieve good sand-carrying function, improve stability, and good alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

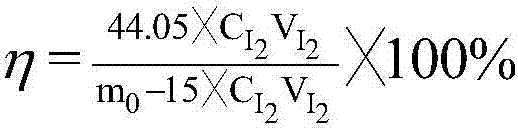

Embodiment 1

[0051] Example 1: Mix guar gum, PVA fiber and other components to prepare an oil and gas field fracturing fluid with a viscosity of 100mPa·s at room temperature. Based on the prepared oil and gas field fracturing fluid, the concentration of guar gum accounts for 0.2wt %, PVA fiber concentration accounts for 1.2wt%. PVA fiber is prepared by spinning polyvinyl alcohol with a degree of polymerization of 2800 and a degree of alcoholysis of 99.5 (mol)%. The degree of hydroformylation η of the PVA fiber is 28%, its Rp=170°C, and the linear density of a single fiber is 1.3dtex , the elongation at break is 18%, the fiber slenderness ratio is 300, and the true density of the fiber is 0.98g / cm 3 , the tensile strength in 120 water is 8cN / dtex, the PVA fiber is kept in the alkaline solution of pH=10 for 12 hours, and the mass loss rate of the fiber is 0.3%.

Embodiment 2

[0052] Example 2: Mix guar gum, PVA fiber and other components to prepare an oil and gas field fracturing fluid with a viscosity of 150mPa·s at room temperature. Based on the prepared oil and gas field fracturing fluid, the concentration of guar gum accounts for 0.6wt %, PVA fiber concentration accounts for 0.8wt%. PVA fiber is prepared by spinning polyvinyl alcohol with a degree of polymerization of 1900 and an alcoholysis degree of 99.5 (mol). The degree of hydroformylation η of the PVA fiber is 30%, its Rp=175°C, and the linear density of a single fiber is 1.35dtex , the elongation at break is 22%, the fiber slenderness ratio is 450, and the true density of the fiber is 1.25g / cm 3 , the tensile strength in water at 150° C. is 12 cN / dtex, and the PVA fiber is kept in an alkaline solution with pH=10 for 12 hours, and the mass loss rate of the fiber is 0.3%.

Embodiment 3

[0053] Example 3: Mix guar gum, PVA fiber and other components to prepare an oil and gas field fracturing fluid with a viscosity of 120mPa·s at room temperature. Based on the prepared oil and gas field fracturing fluid, the concentration of guar gum accounts for 0.8wt %, PVA fiber concentration accounts for 1.2wt%. PVA fiber is prepared by spinning polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 98 (mol)%. The degree of hydroformylation of the PVA fiber η is 32%, its Rp=160°C, and the linear density of the single fiber is 1.65dtex , the elongation at break is 18%, the fiber slenderness ratio is 500, and the real density of the fiber is 1.29g / cm 3 , the tensile strength in water at 160° C. is 9 cN / dtex, and the PVA fiber is maintained in an alkaline solution with pH=10 for 12 hours, and the mass loss rate of the fiber is 0.3%.

[0054] In addition to the above-mentioned PVA fiber and hydroxypropyl guar gum, the above-mentioned oil and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com