A leak-proof electrolytic copper plate washing chain conveyor

A technology of electrolytic copper plate and chain conveyor, which is applied in the electrolysis process and electrolysis components, etc., can solve the problems of easy leakage of stainless steel sealing plates, and achieve the effects of saving materials, strengthening rigidity, and beautiful appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

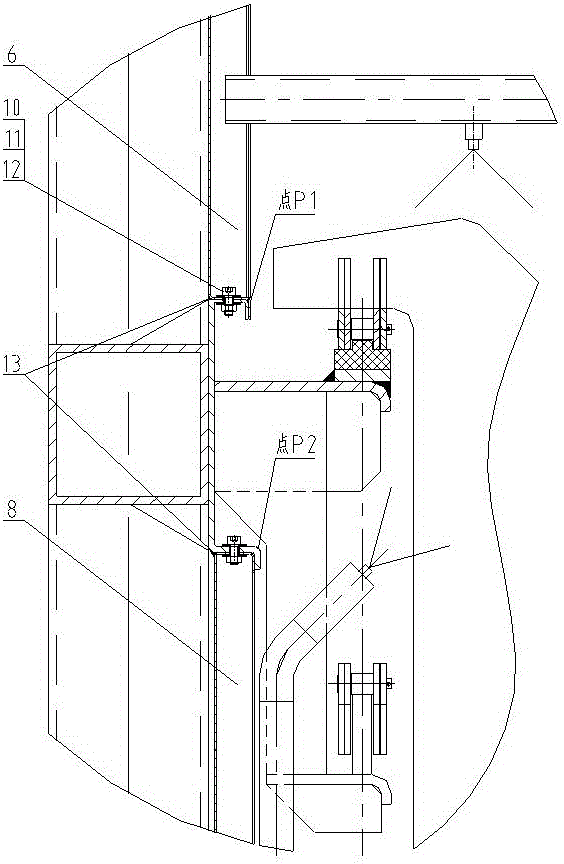

[0012] Now in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0013] Such as figure 1 Shown: a leak-proof structure of electrolytic copper plate washing chain transport machine, including the main frame 1, the transmission chain 4 drives the electrolytic copper plate 5, through the upper spray pipe 2 and the side spray pipe 3 for spray washing, the upper spray pipe 2 The cleaning solution 14 sprayed out with the side spray pipe 3 cleans the acidic solution on the electrolytic copper plate 5 . There will be a large amount of foggy acid solution in the space formed by the chain support plate 7, the upper sealing plate 6, the lower side sealing plate 8, and the bottom sealing plate 9, and will adhere to their inner surfaces to form a liquid flow. 6. The bottom sealing plate 9 is folded into a U shape with a flat plate. There is no gap at the crease, and there is no leakage point on the top and bottom planes, and it is impos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com