Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Not easy to jump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

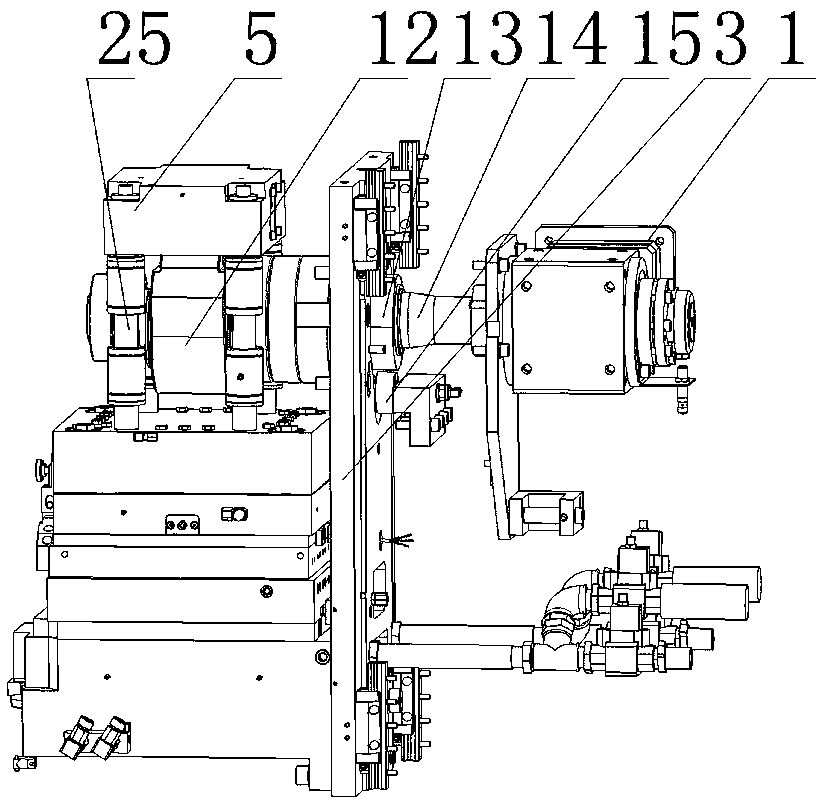

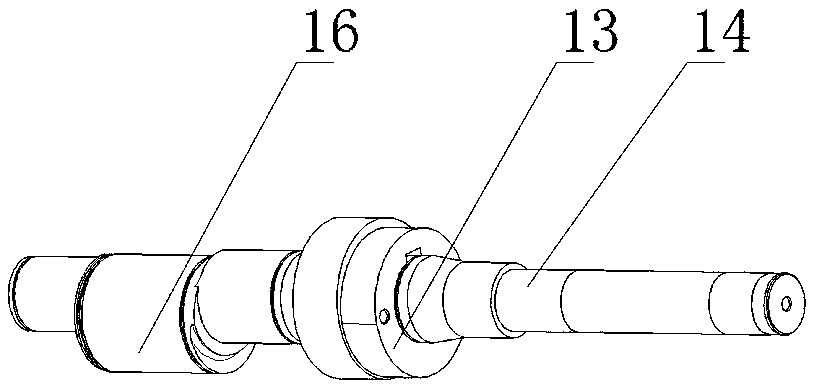

Self-propelled corn harvester

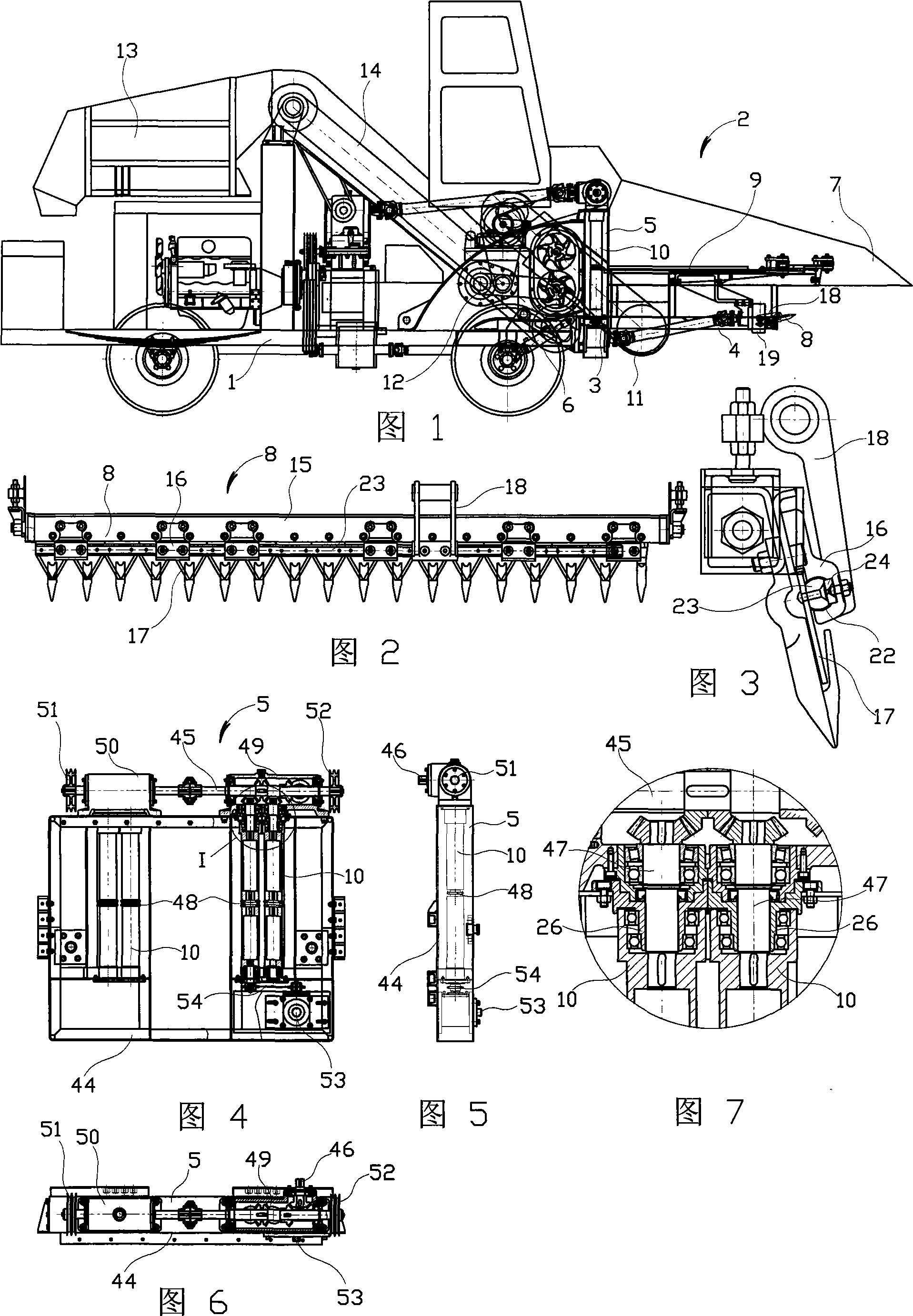

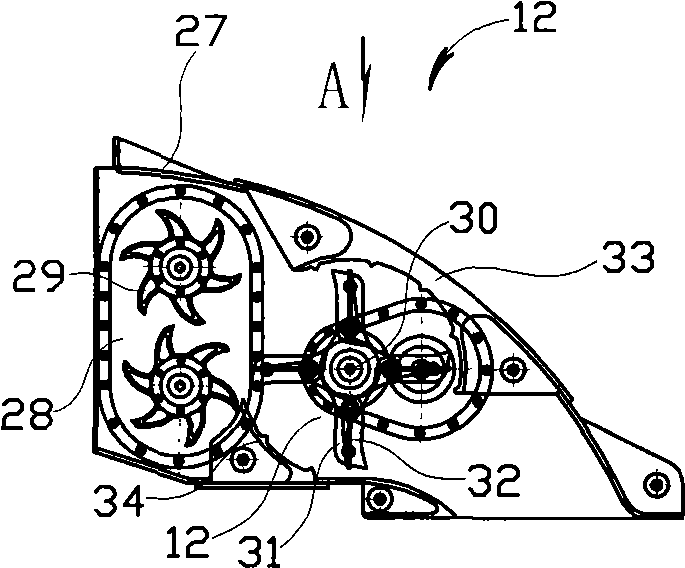

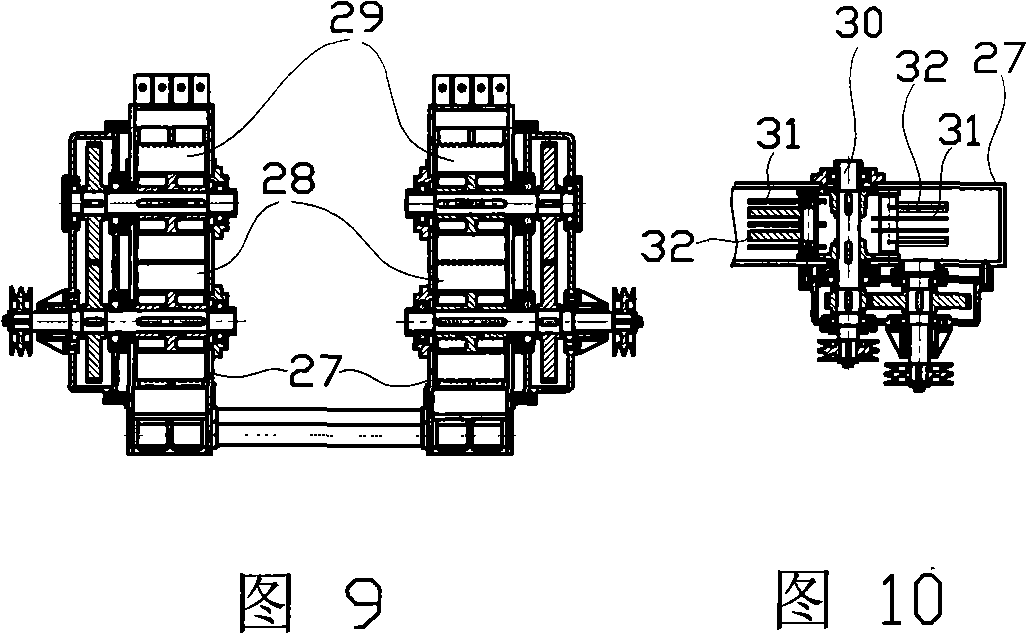

InactiveCN101530036AFirmly restrainedNot easy to jumpCrop conditionersMowersVehicle frameEngineering

The invention relates to a self-propelled corn harvester. A cutting platform is hinged at the front part of an automotive vehicle frame and is provided with a grain lifter, a cutting knife, a gripping conveyor chain, a snapping roll and a stalk crusher, wherein the middle part of the frame is provided with a corn ear conveyor, while and the rear part is provided with a fruit ear box, the cross sections of a chute below pressing plates evenly distributed on a cross beam of the cutting knife and a sliding rod in the chute are mutually matched drum shapes, an anti-attrition lining plate is arranged between the pressing plates and the sliding rod, the snapping roll is arranged on the frame through an unloading sleeve, a crankshaft in a shell of the straw grinder is hinged with hammer leaves, a radial material-throwing plate is arranged between the hammer leaves on the crankshaft, the inner wall of the shell is provided with an upper screw plate and a lower screw plate, and a full rubber corrugated flange conveying belt is arranged between a driving roller and a driven roller of the core ear conveyor. The sliding rod of the cutting knife is not easy to beat and is advantageous for cutting operations, and the bearing load of an input bearing of the snapping roll is small so that the snapping roll is not easy to be damaged; corn stalk grains after crushing are small and does not influence farming after being applied to fields; and the full rubber corrugated flange conveying belt conveys corn ears with small power consumption in the process of conveying the core ears, and is not easy to go wrong.

Owner:程辉 +1

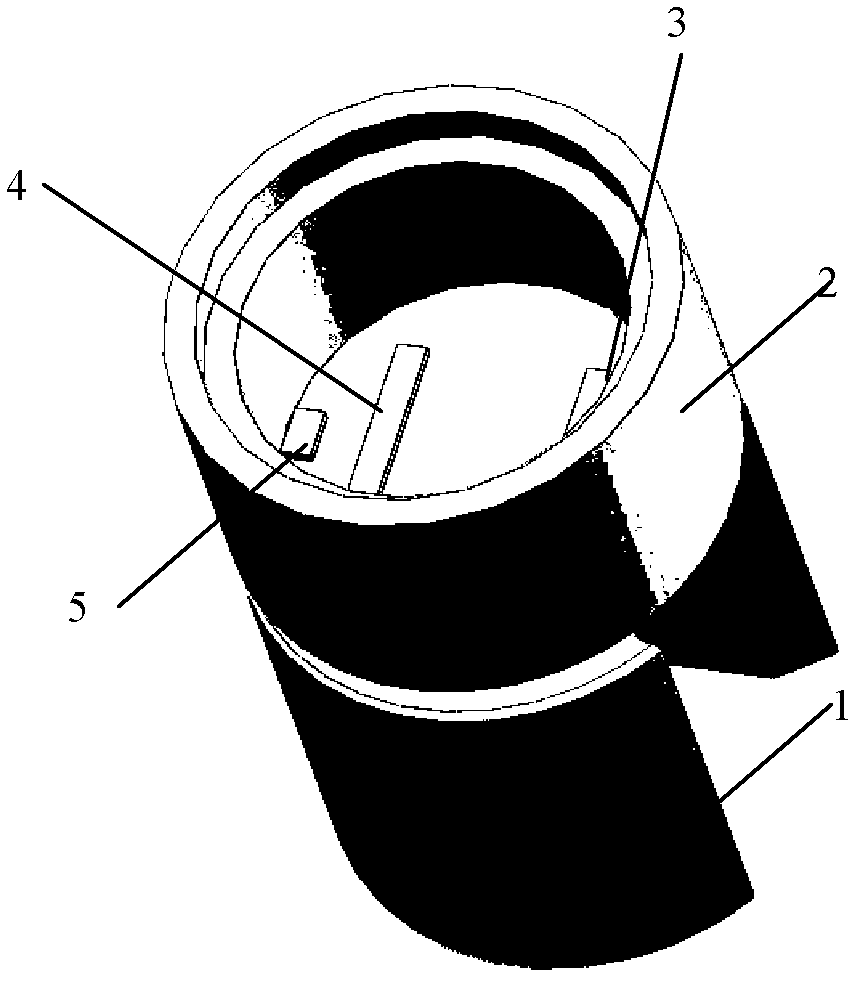

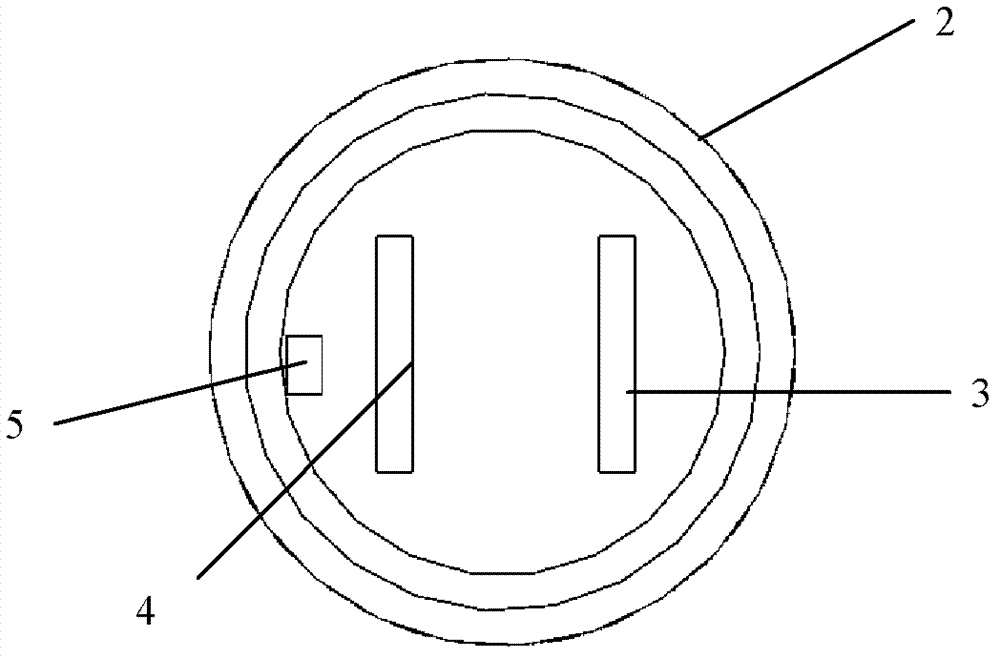

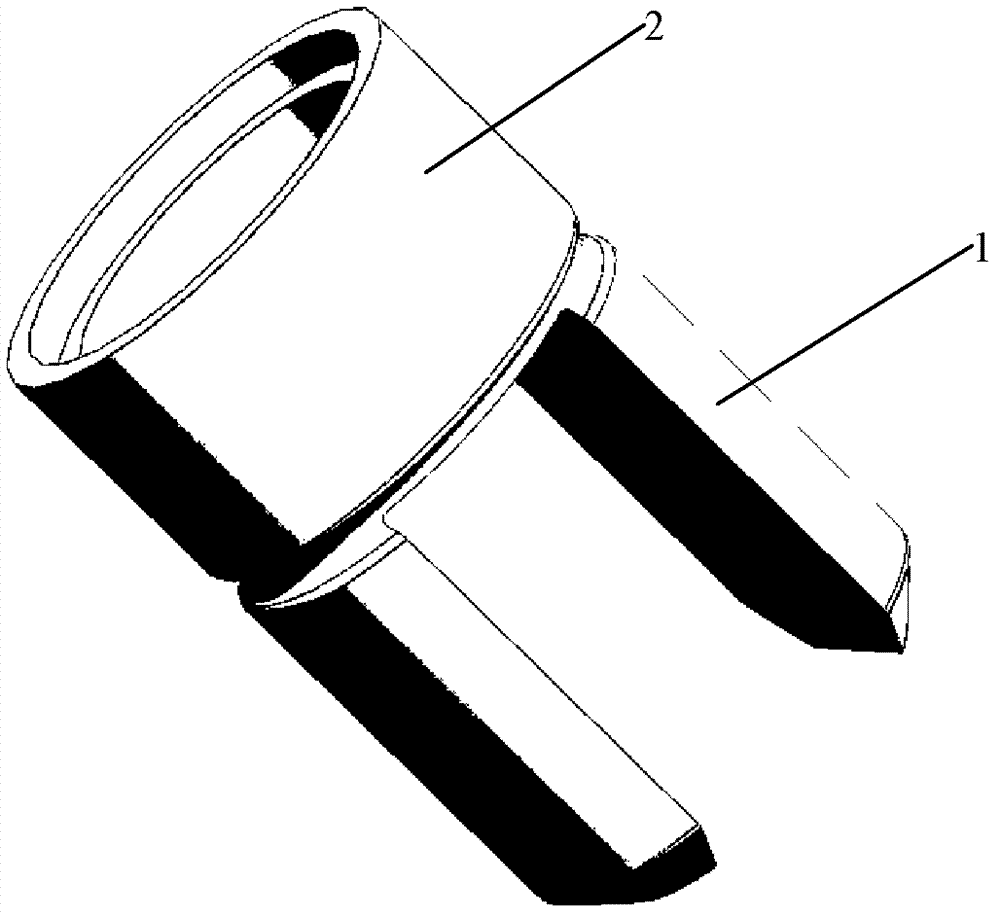

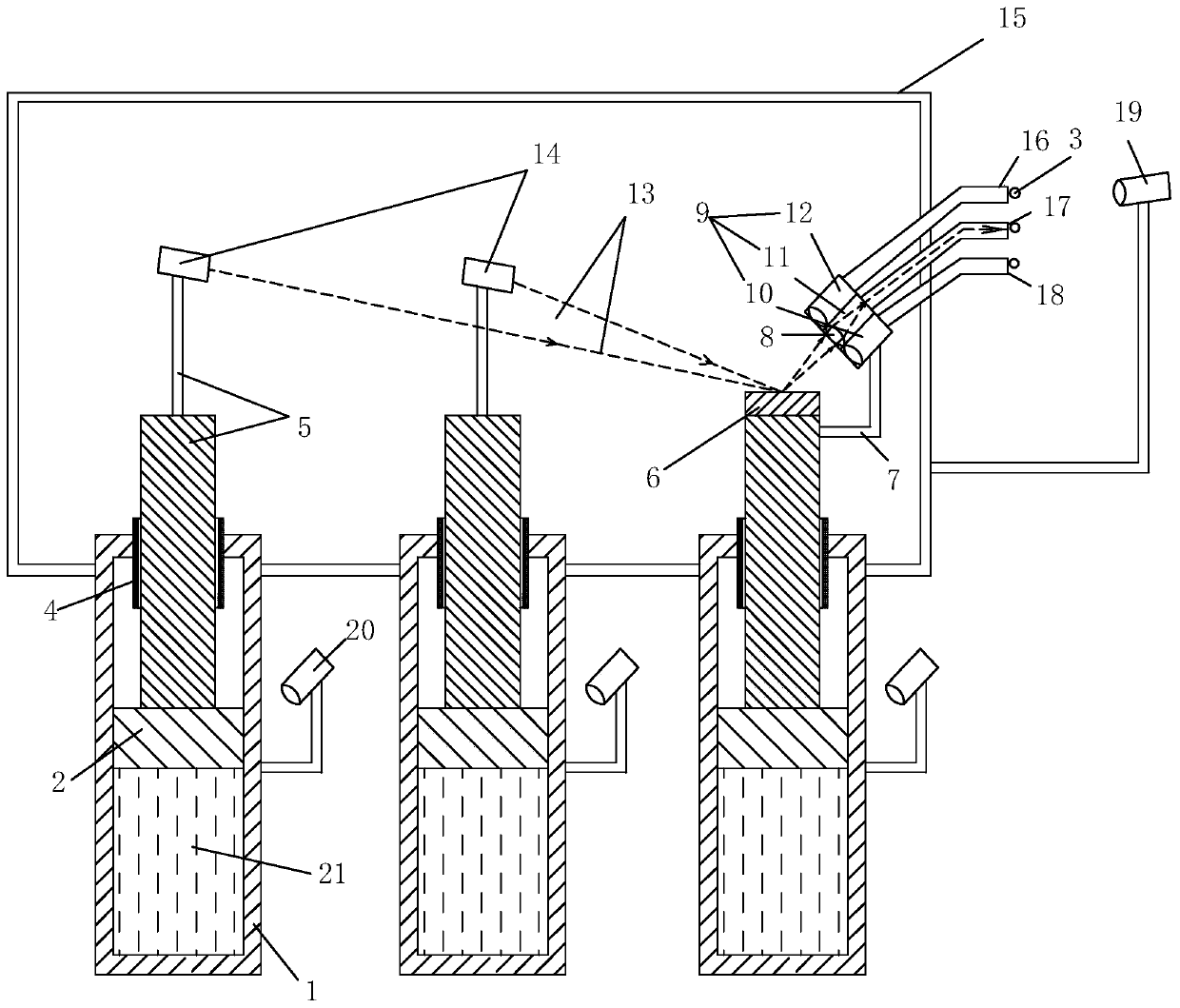

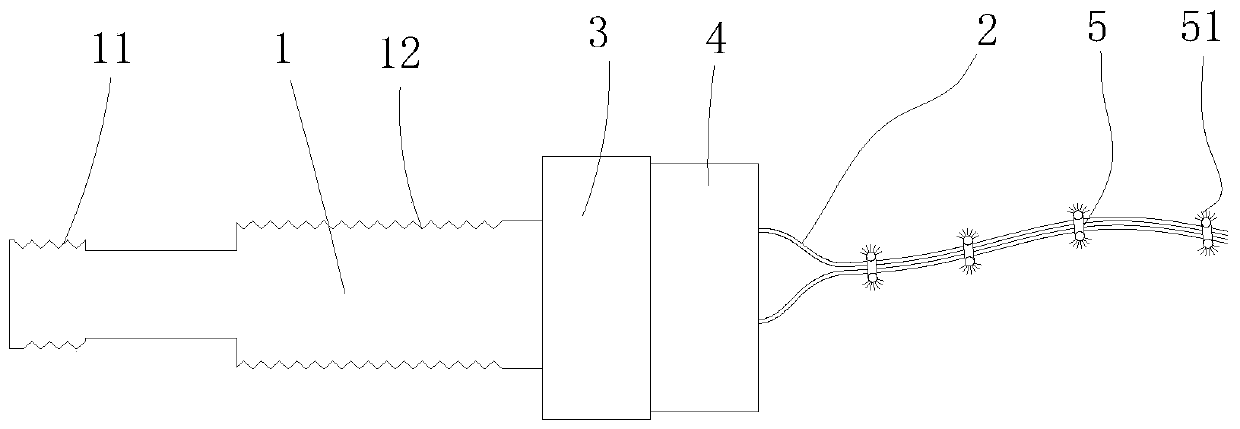

Resonant tuning fork liquid density sensor with piezoelectric actuation and piezoelectric detection

ActiveCN102353612AReal-time online measurementReal-time detectionSpecific gravity measurementLiquid densityPiezoelectric actuators

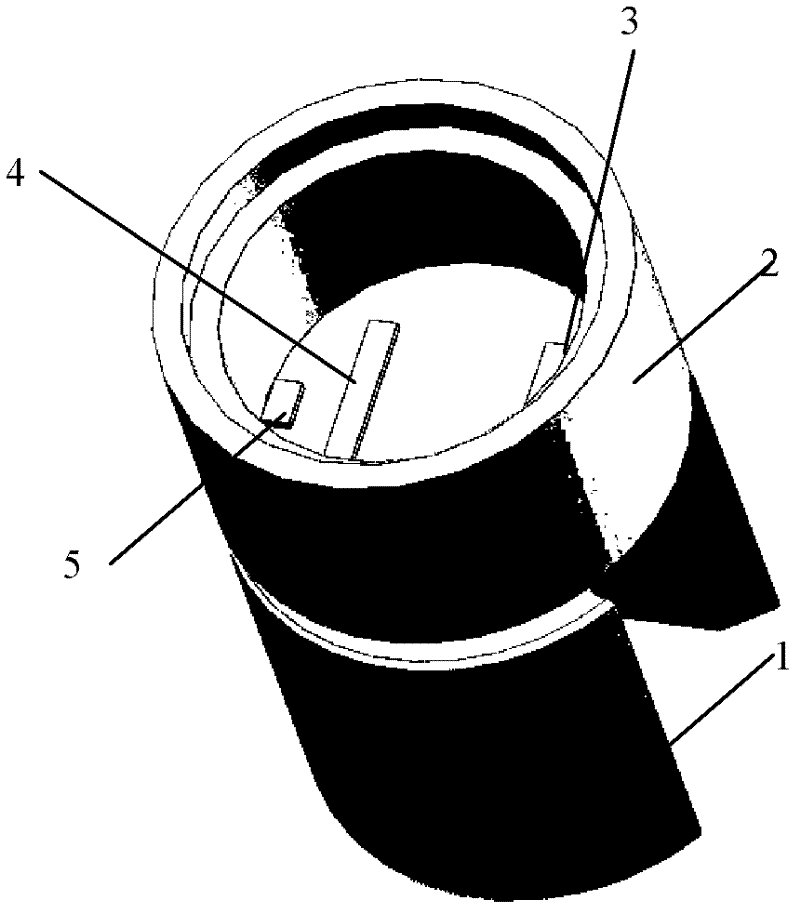

The invention discloses a resonant tuning fork liquid density sensor with piezoelectric actuation and piezoelectric detection, comprising a tuning fork body, a clamped body, a piezoelectric actuator, a piezoelectric vibration pickup, and a temperature sensor, wherein, the piezoelectric actuator and the piezoelectric vibration pickup are arranged on the clamped body, the generated alternating force is transmitted to the tuning fork body by the piezoelectric actuator to let the tuning fork body produce simple harmonic vibration with intrinsic frequency itself; when immersing the tuning fork body in a liquid under test, the additional mass of the tuning fork body changes so as to let the vibration frequency of the tuning fork body change; by picking up the vibration signal with the piezoelectric vibration pickup, the detection of the vibration frequency of the tuning fork body is realized; because the vibration frequency of the tuning fork body is a monotone function of the liquid density, thus the real-time on-line detection of the liquid density is realized; and the temperature sensor is arranged on the clamped body for real-time detection of the temperature of the liquid under test, and is used for compensating the variation of the elastic modulus of the tuning fork body. According to the invention, the high precision on-line detection of densities of various liquids at different temperature can be realized.

Owner:BEIHANG UNIV

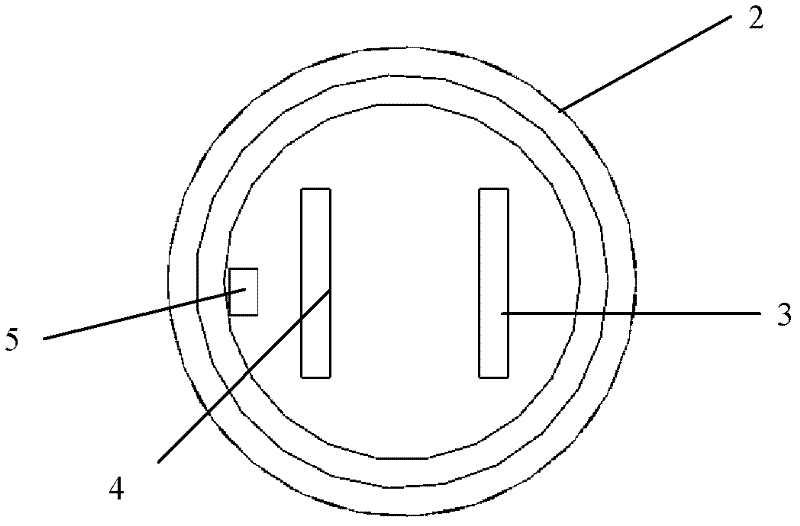

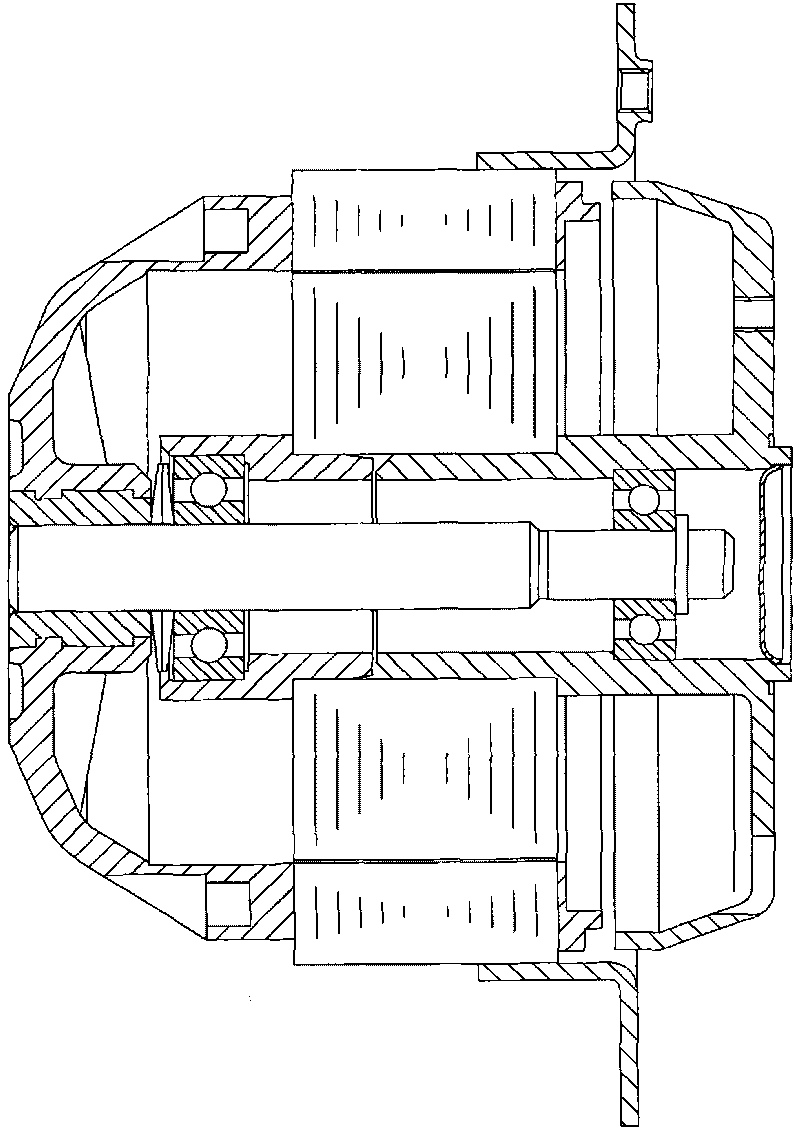

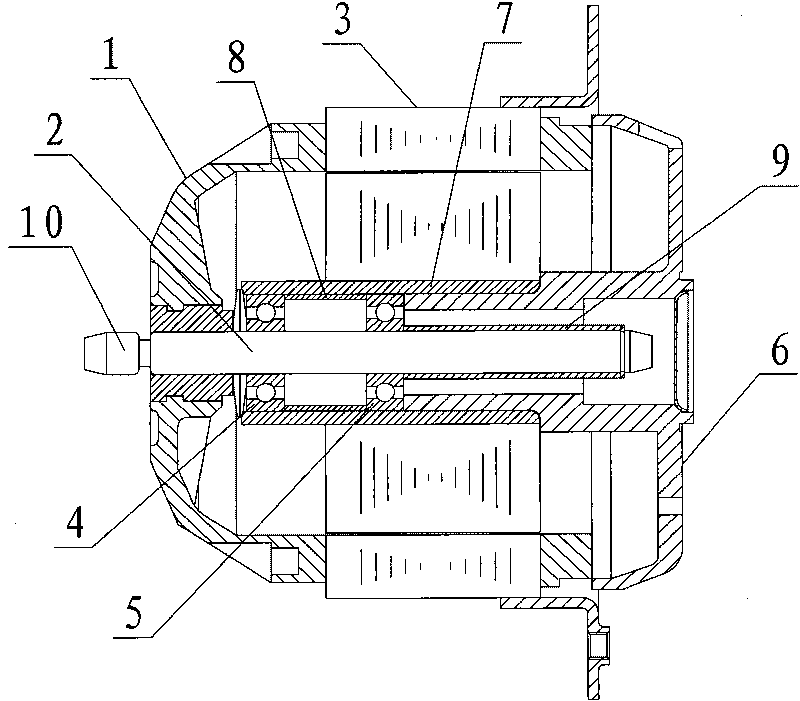

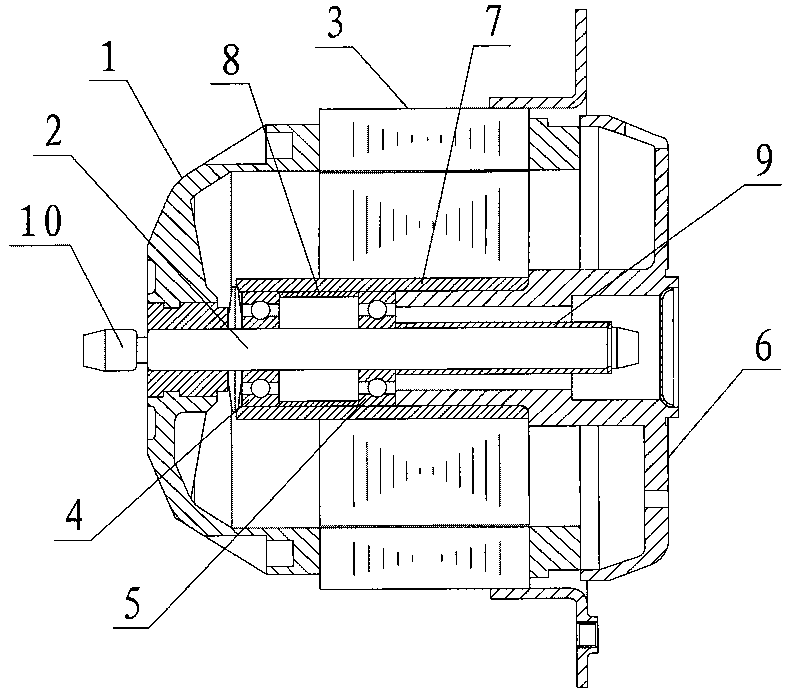

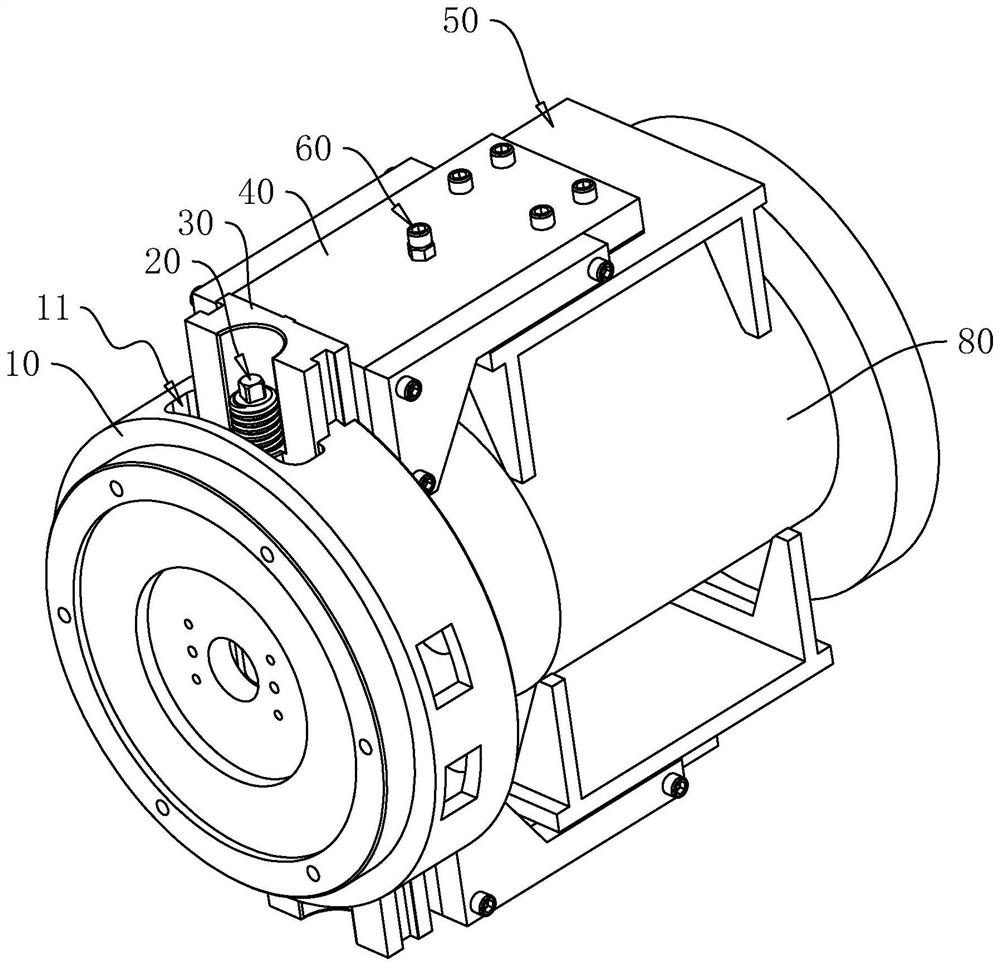

Outer rotor motor

ActiveCN101728893AGuaranteed concentricityNot easy to vibrateSupports/enclosures/casingsLow noiseEngineering

The invention relates to an outer rotor motor, comprising an outer rotor, a rotating shaft, a stator iron core, a first bearing, a second bearing and an end cover. The inner hole of the stator iron core is provided with a first bushing in a pressing manner; the first bearing and the second bearing have the same specification and are both arranged in the first bushing. The first bearing is arranged at the end of the first bushing close to one end of the outer rotor, and the second bearing and the first bearing are separated by a second bushing. A third bushing is clamped between one end of therotary shaft close to one end of the inner cavity of the end cover and the second bearing by a gasket. The end of the rotary shaft close to one end of the outer rotor is provided a guiding part convenient to press and mount by the rotating shaft. The first bearing and the second bearing n are mounted in the same part so as to ensure the concentricity of two mounted bearings; during the operation of the motor, the two bearings are not easy to vibrate, the outer rotor is not easy to move up and down, thus, the motor of the outer rotor has low noise and less bounce.

Owner:常州威灵电机制造有限公司

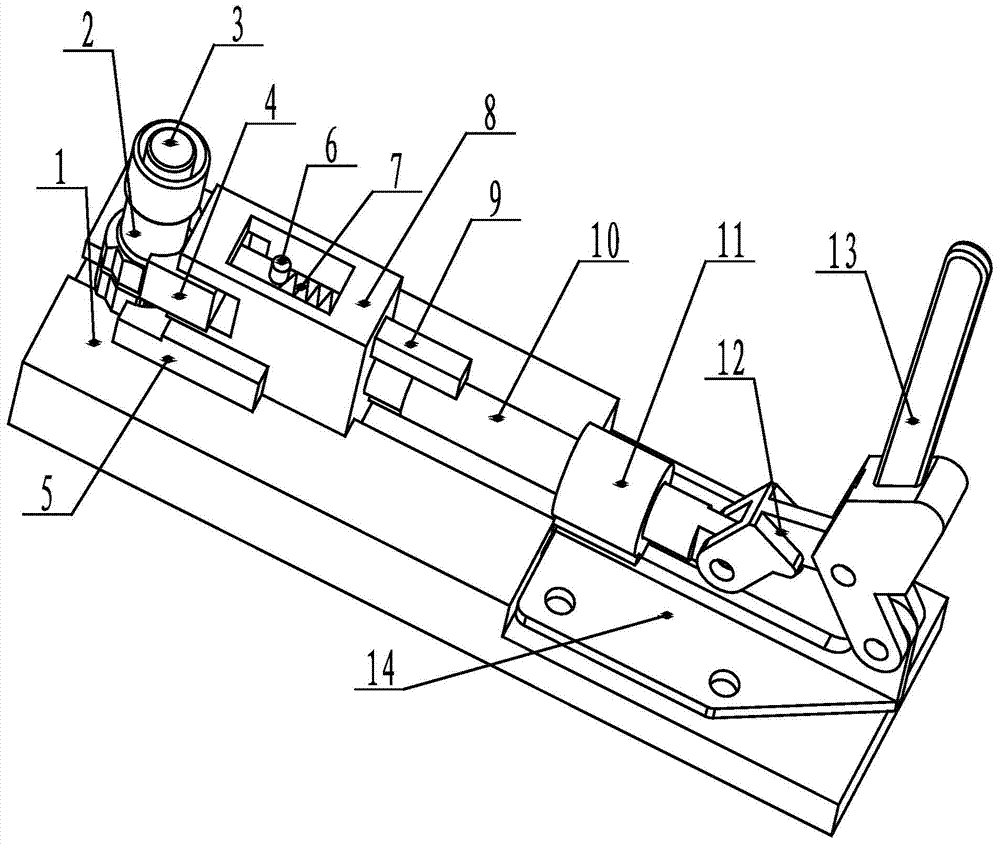

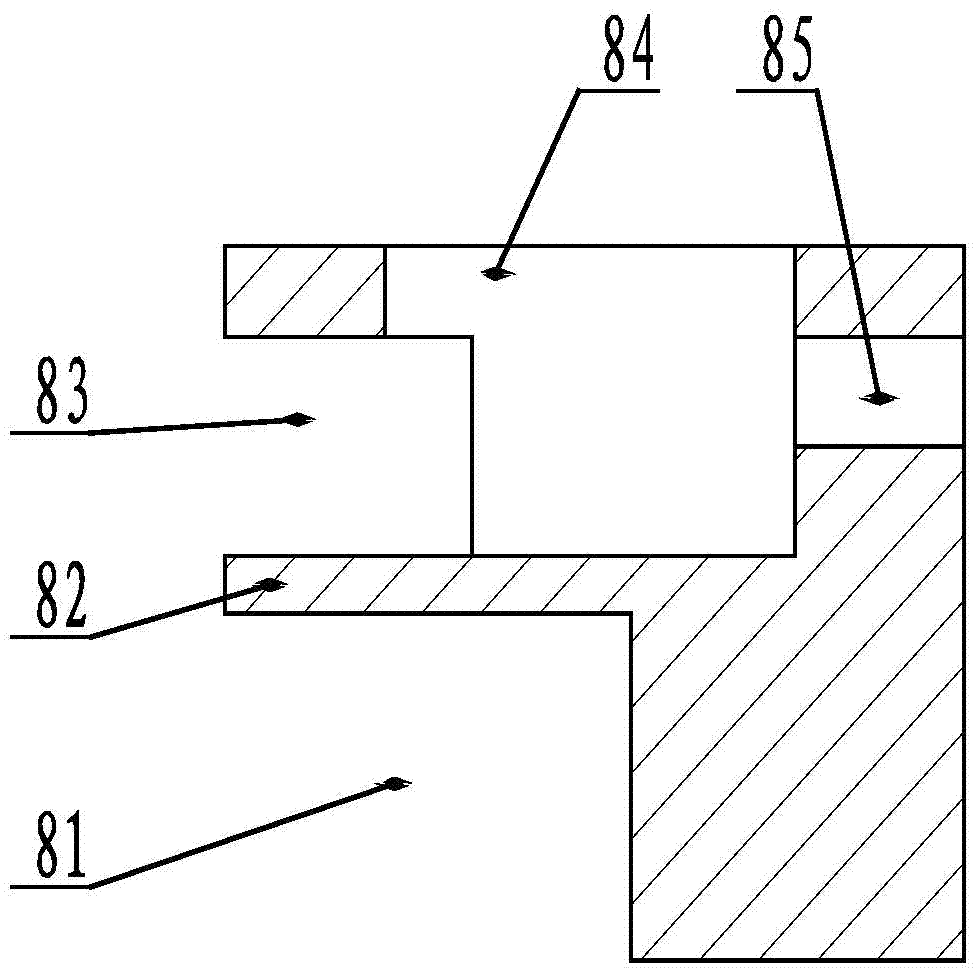

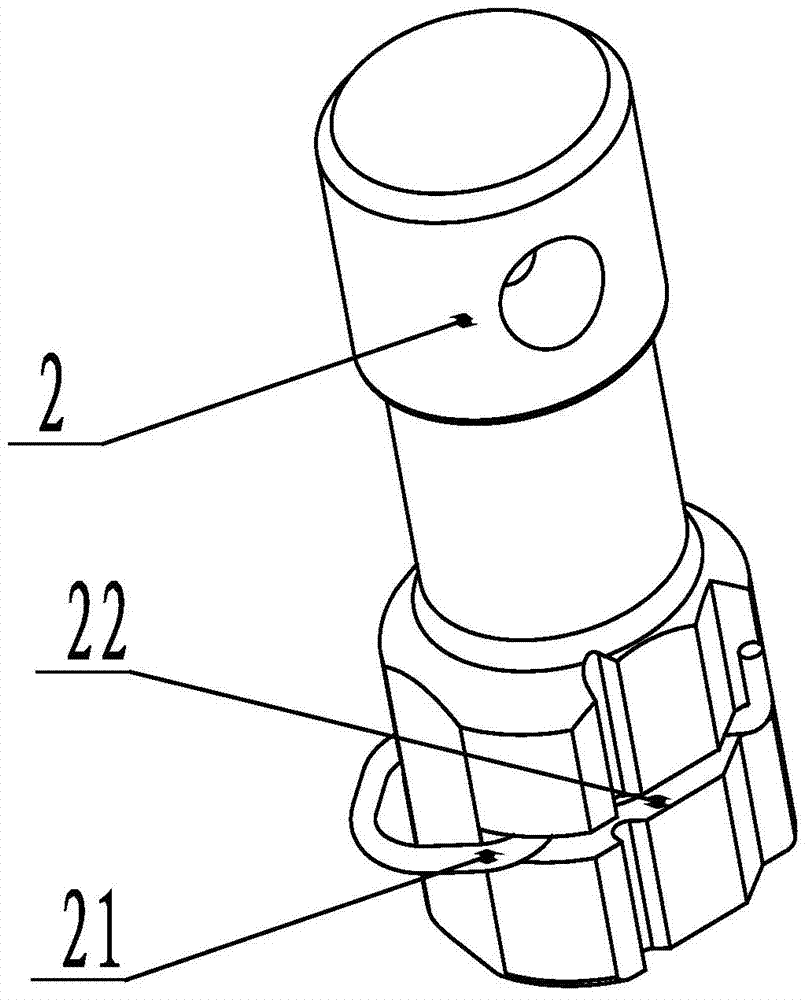

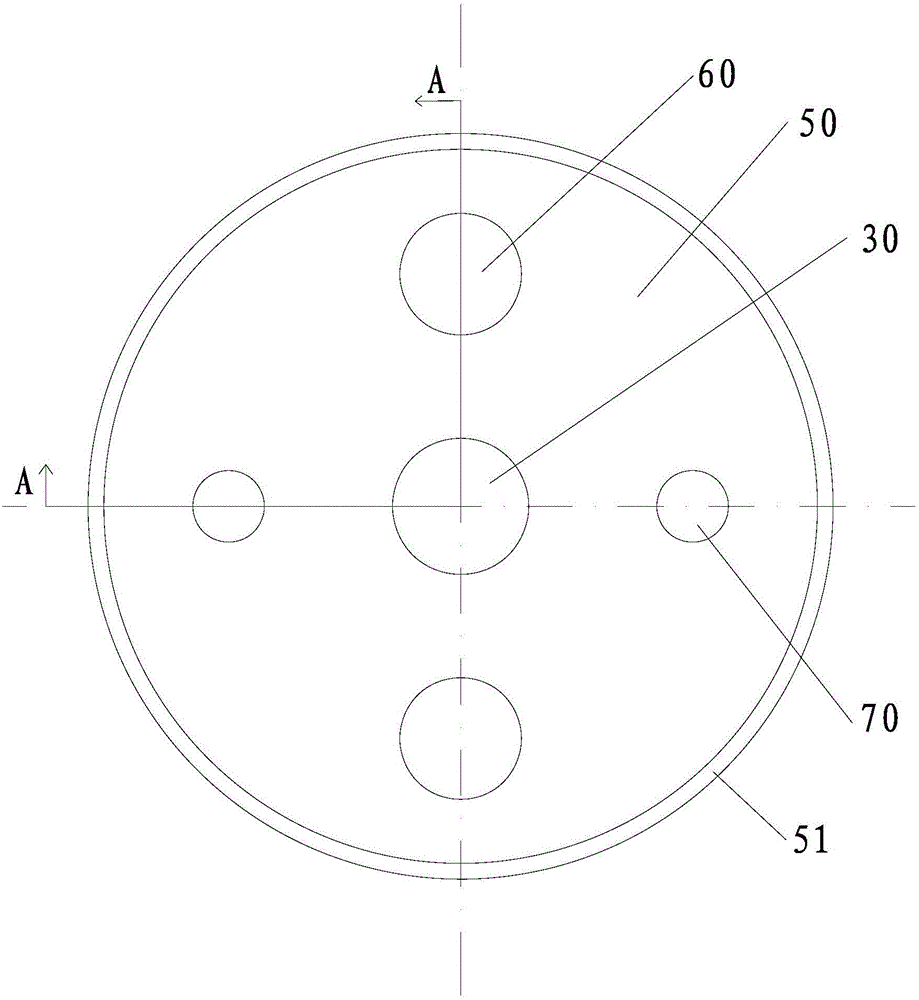

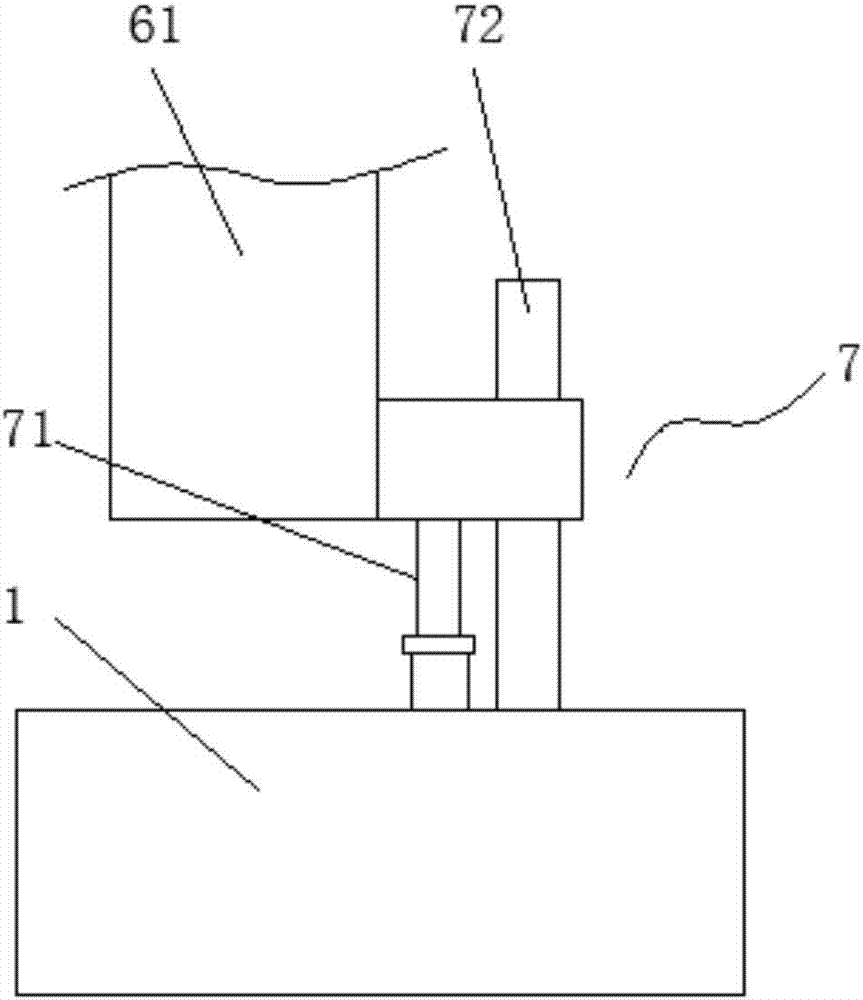

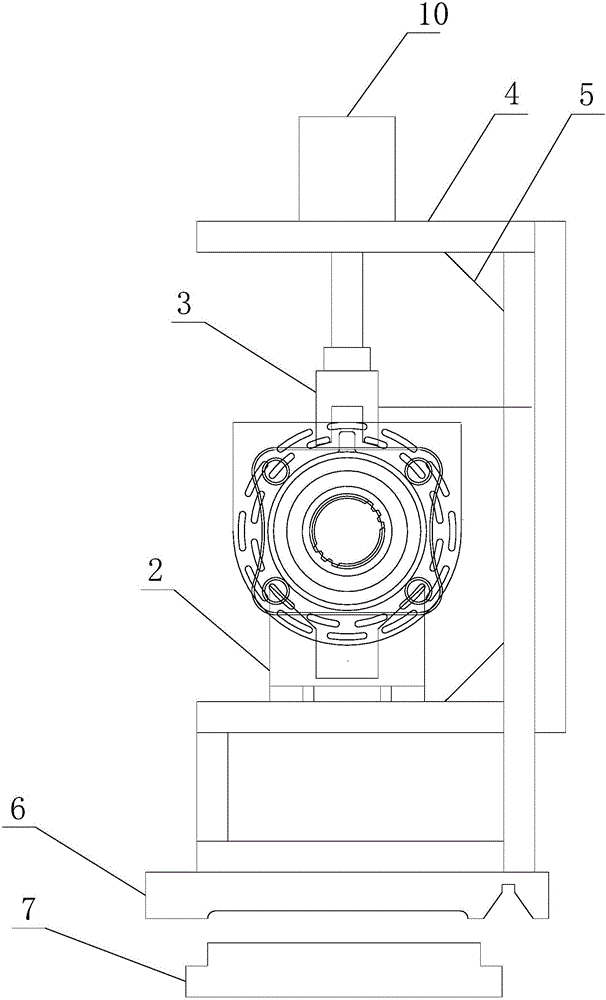

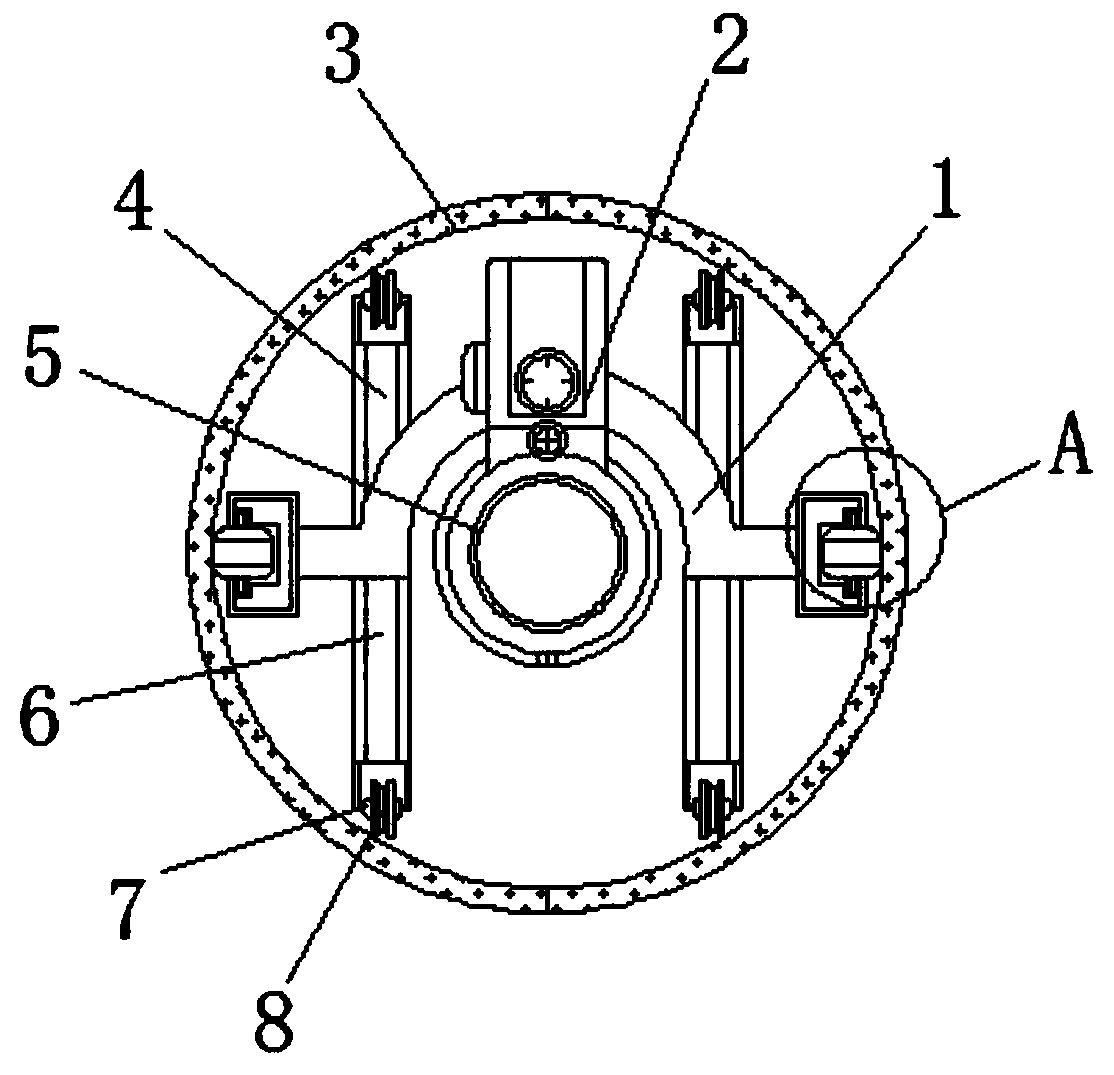

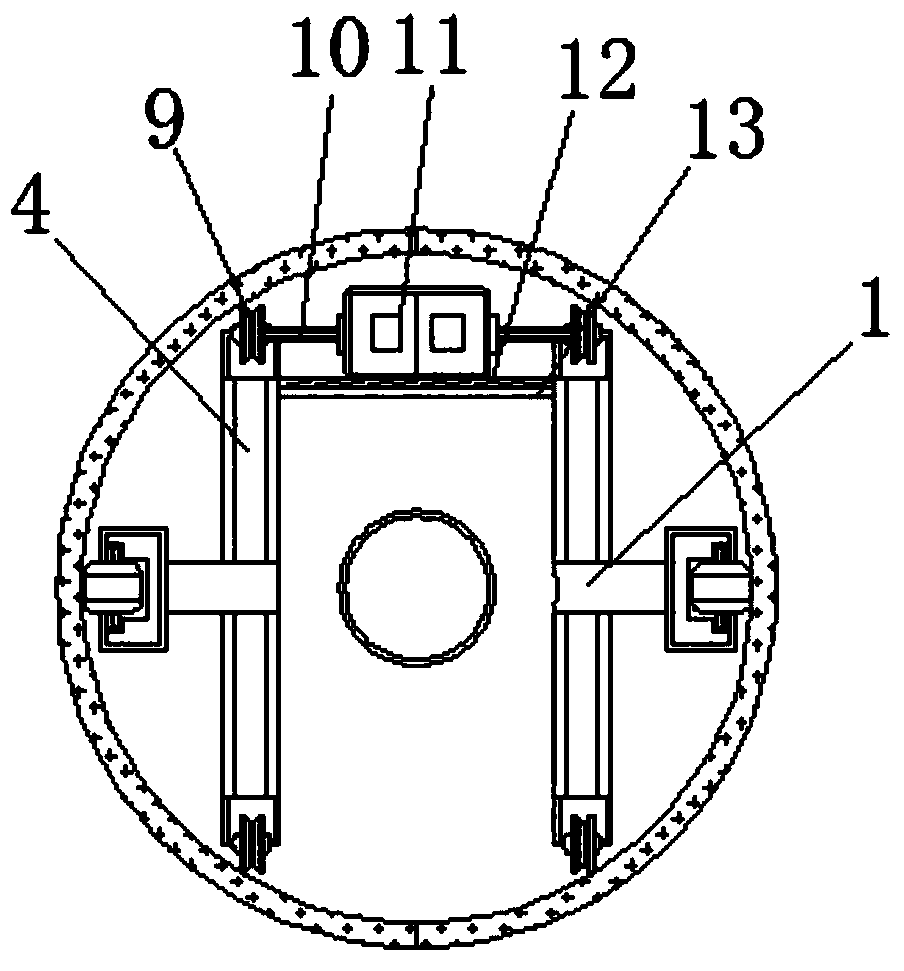

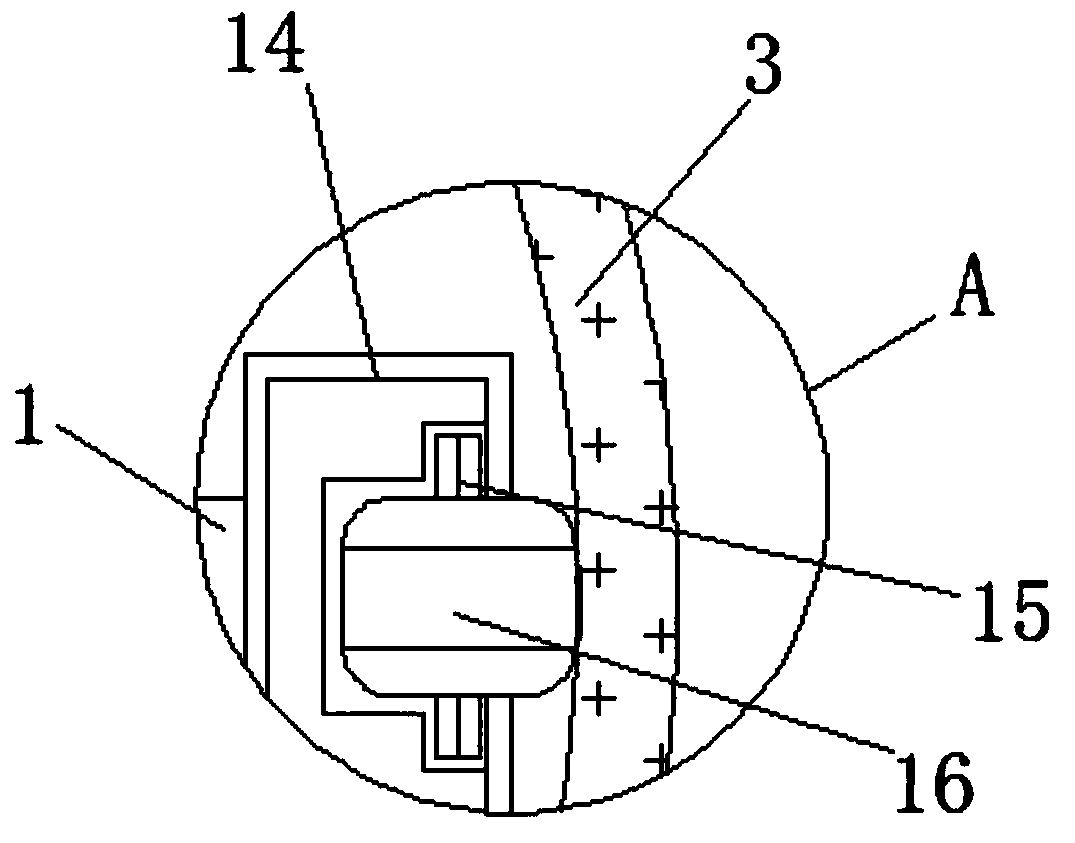

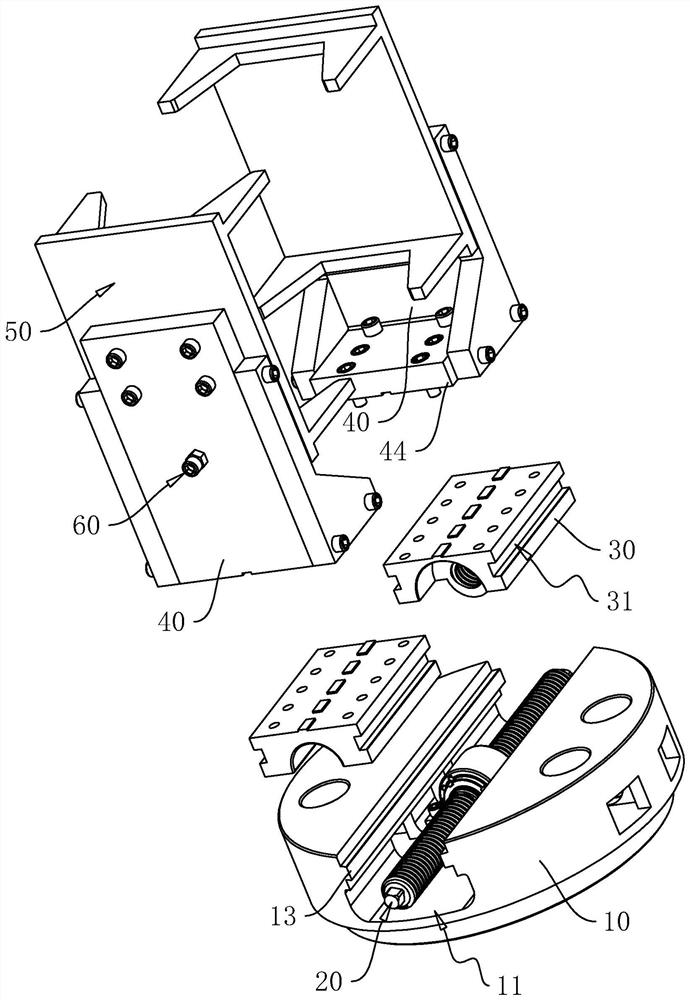

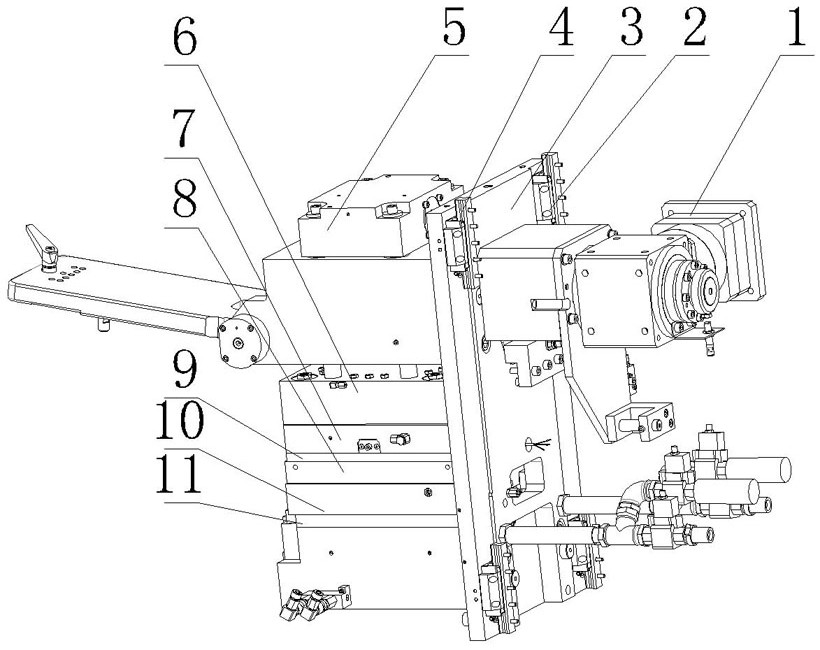

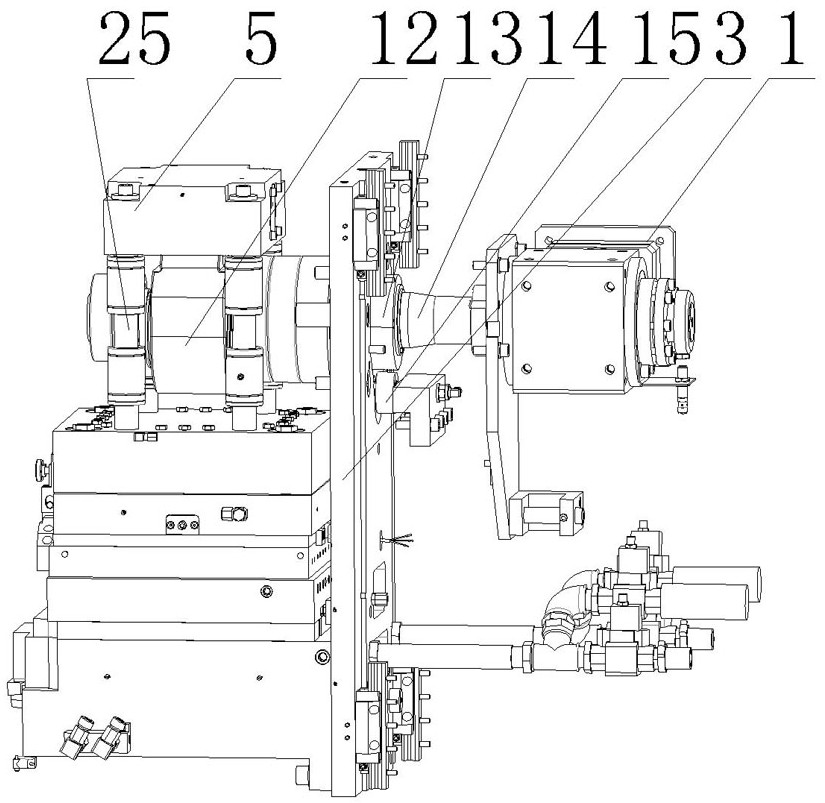

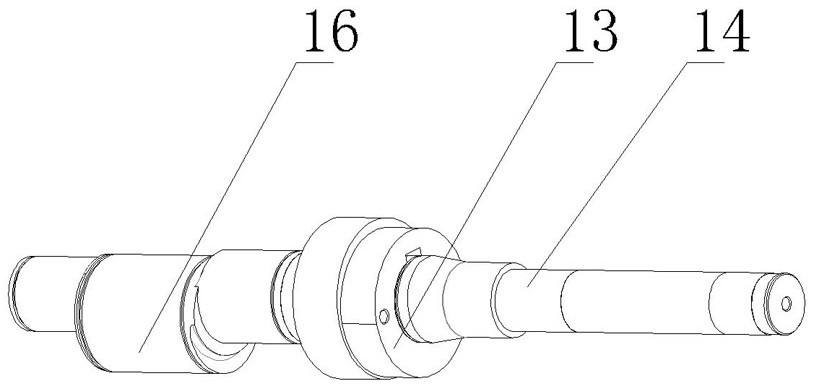

Tubing coupling buckle installation auxiliary device

ActiveCN104723061ANot easy to jumpNot easy to moveWork holdersMetal working apparatusMechanical engineeringExtrusion

The invention relates to a tubing coupling buckle installation auxiliary device. The tubing coupling buckle installation auxiliary device mainly comprises a base, a handle and a push rod. The handle is connected with the push rod through a connection rod. The push rod is located in a limiting sleeve which is connected with the base through a fixing plate. The handle is connected with the fixing plate through a hinge. The push rod is fixedly connected with a movable block. An extrusion block is arranged in the movable block. A buckle containing table and a fixing column are fixed to the left side of the base. The tubing coupling buckle installation auxiliary device has the advantages that positioning is conducted through a fixture, the problem that the pure manual assembly is low in efficiency is solved, and the assembly percent of pass is increased.

Owner:ANHUI ZHONGDING KEUMAH AUTO HOSE & PIPE ASSEMBLY

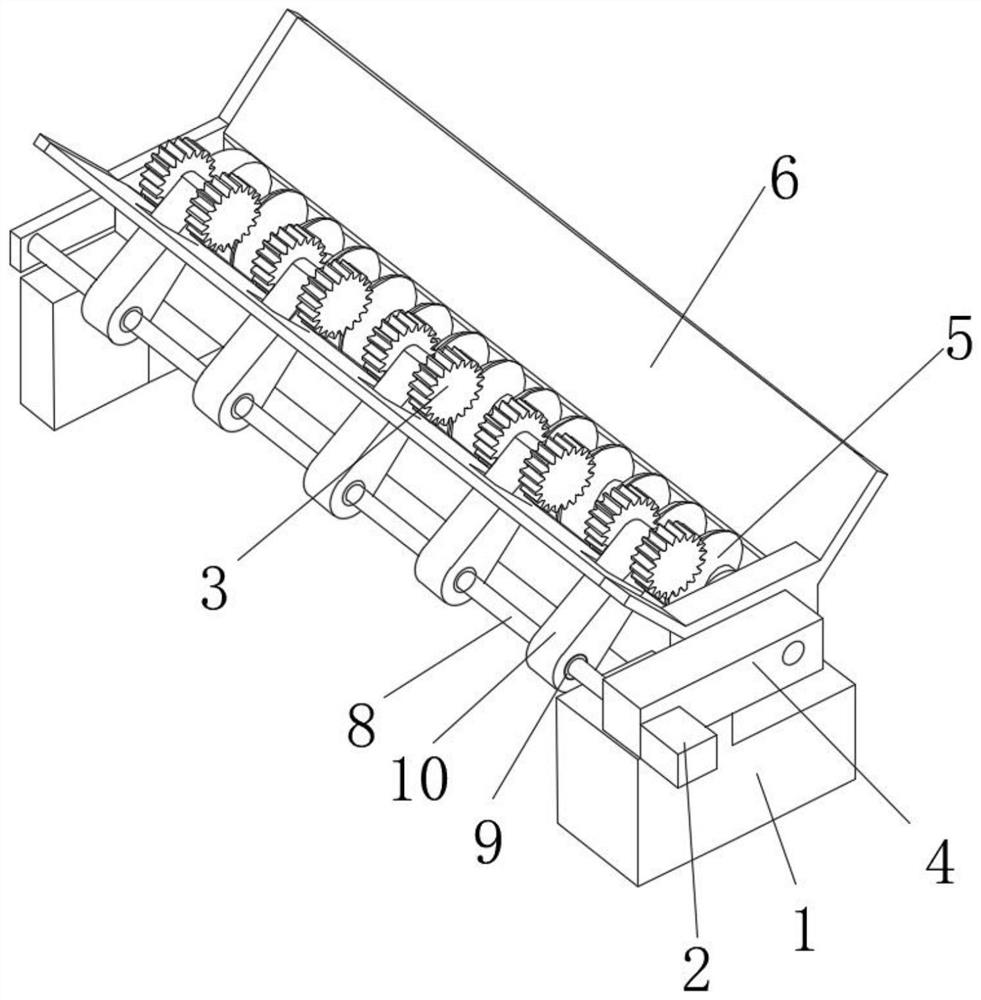

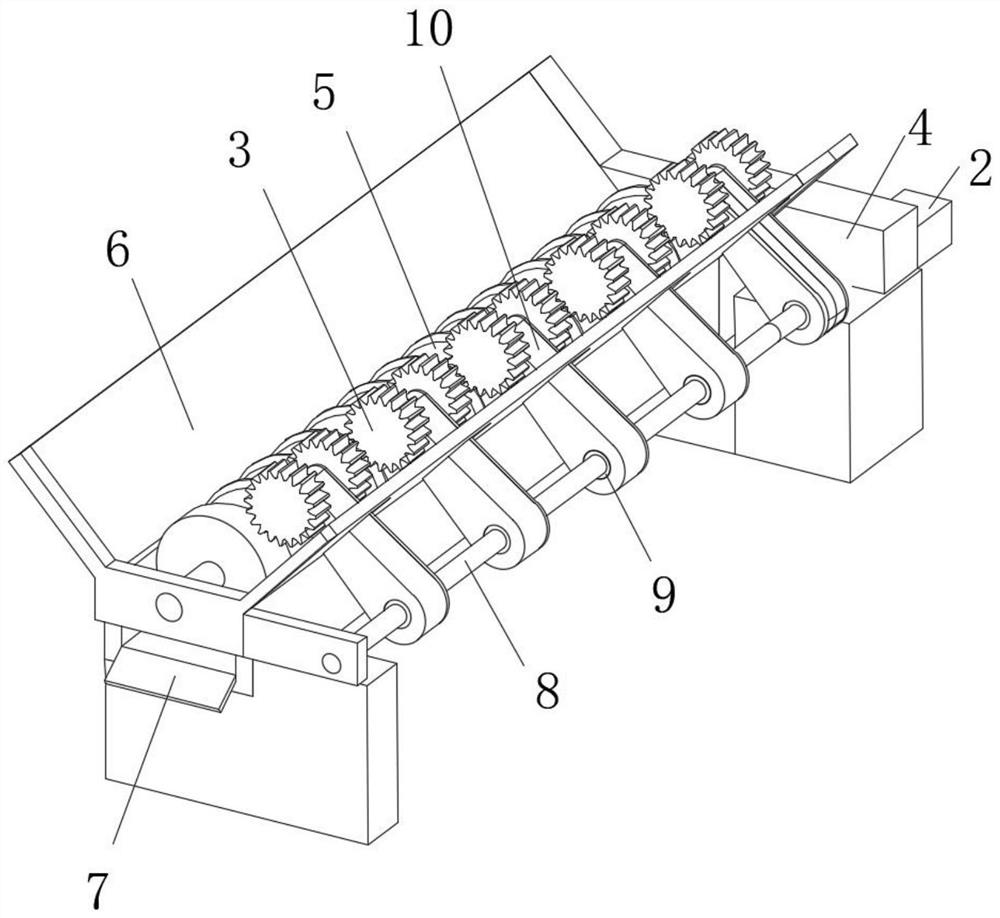

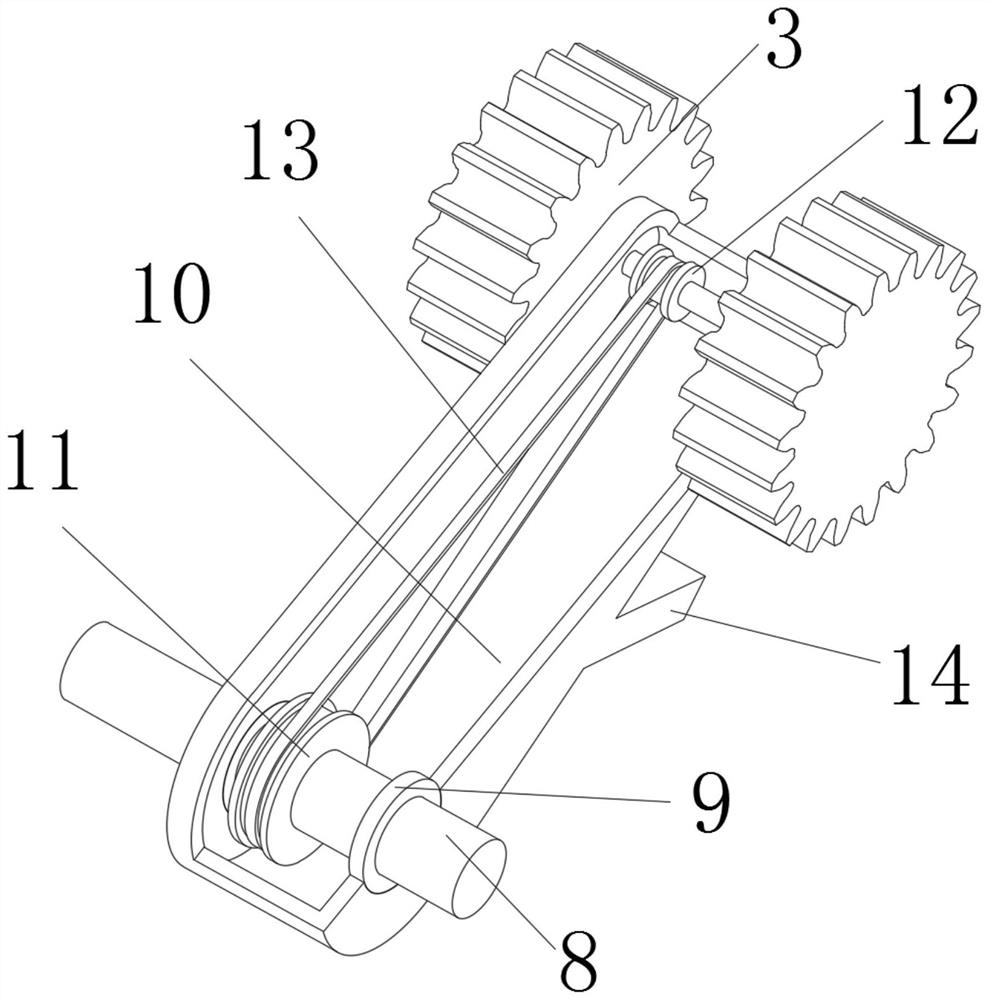

Single-input double-output transmission device

ActiveCN105782355AReduce volumeNot easy to jumpToothed gearingsGearing detailsGear wheelSurface tooth

The invention provides a single-input double-output transmission device. The single-input double-output transmission device comprises a base, and further comprises planet wheels, an input shaft, a fixed gear, a rotary supporting frame and transmission shafts rotationally connected with the rotary supporting frame. The input shaft is provided with a central gear. The transmission shaft is provided with eccentric bearings and a transmission gear engaged with the central gear. The planet wheels are provided with inner gear rings and bearing holes, the tooth number of the inner gear rings is 1-4 larger than that of the fixed gear, and the fixed gear is fixedly connected with the base. The eccentric bearings are installed in the bearing holes. The rotary supporting frame is provided with an outer gear ring and a first end surface tooth, the outer gear ring is coaxial with the input shaft, and the plane where the first end surface tooth is located is perpendicular to the input shaft. The two ends of each transmission shaft are rotationally connected with the rotary supporting frame, the rotary supporting frame is used for supporting the transmission shafts, other supporting parts are not needed, and thus the size of the whole transmission device is relatively small.

Owner:安徽邮谷快递智能科技有限公司

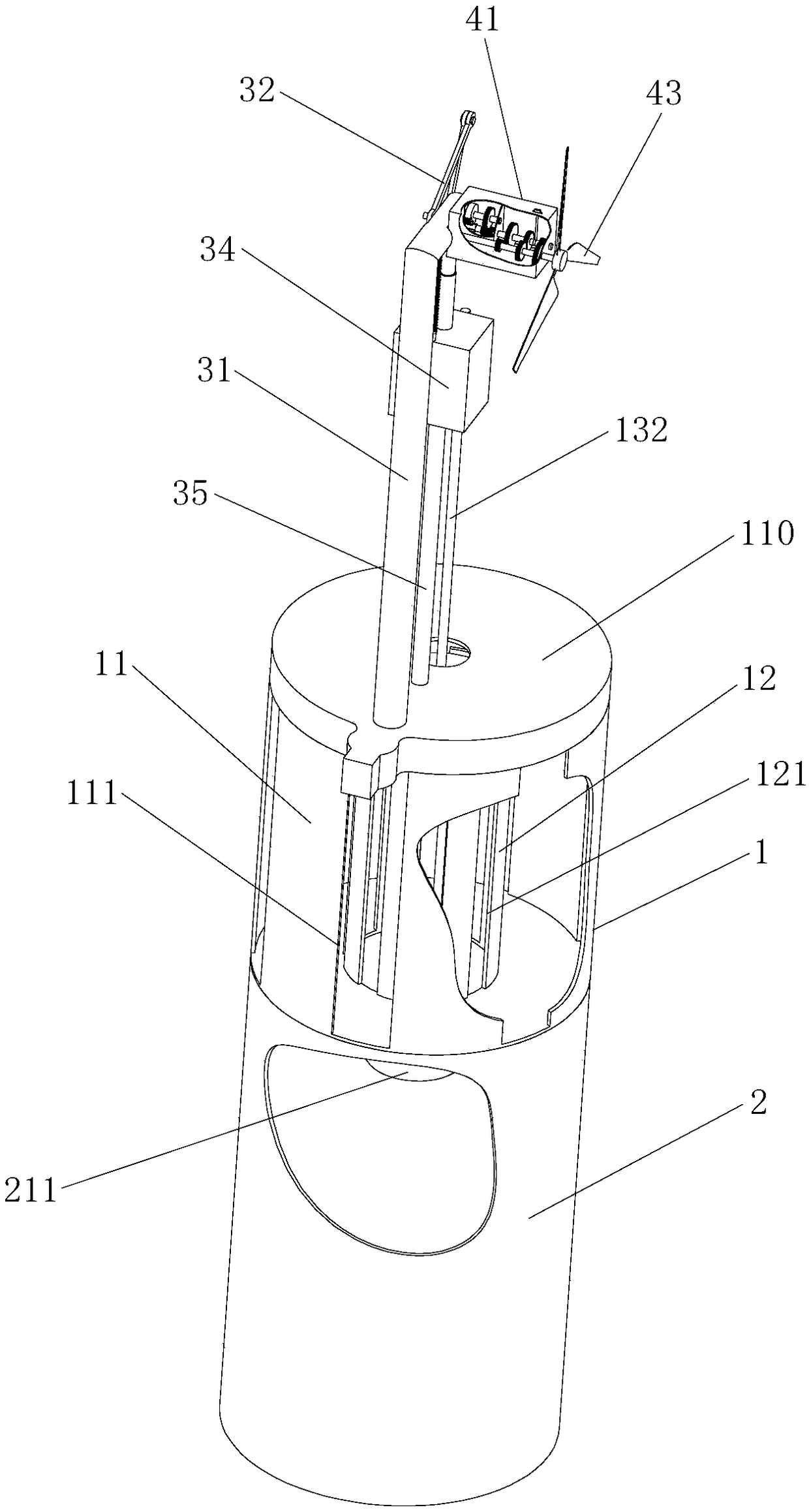

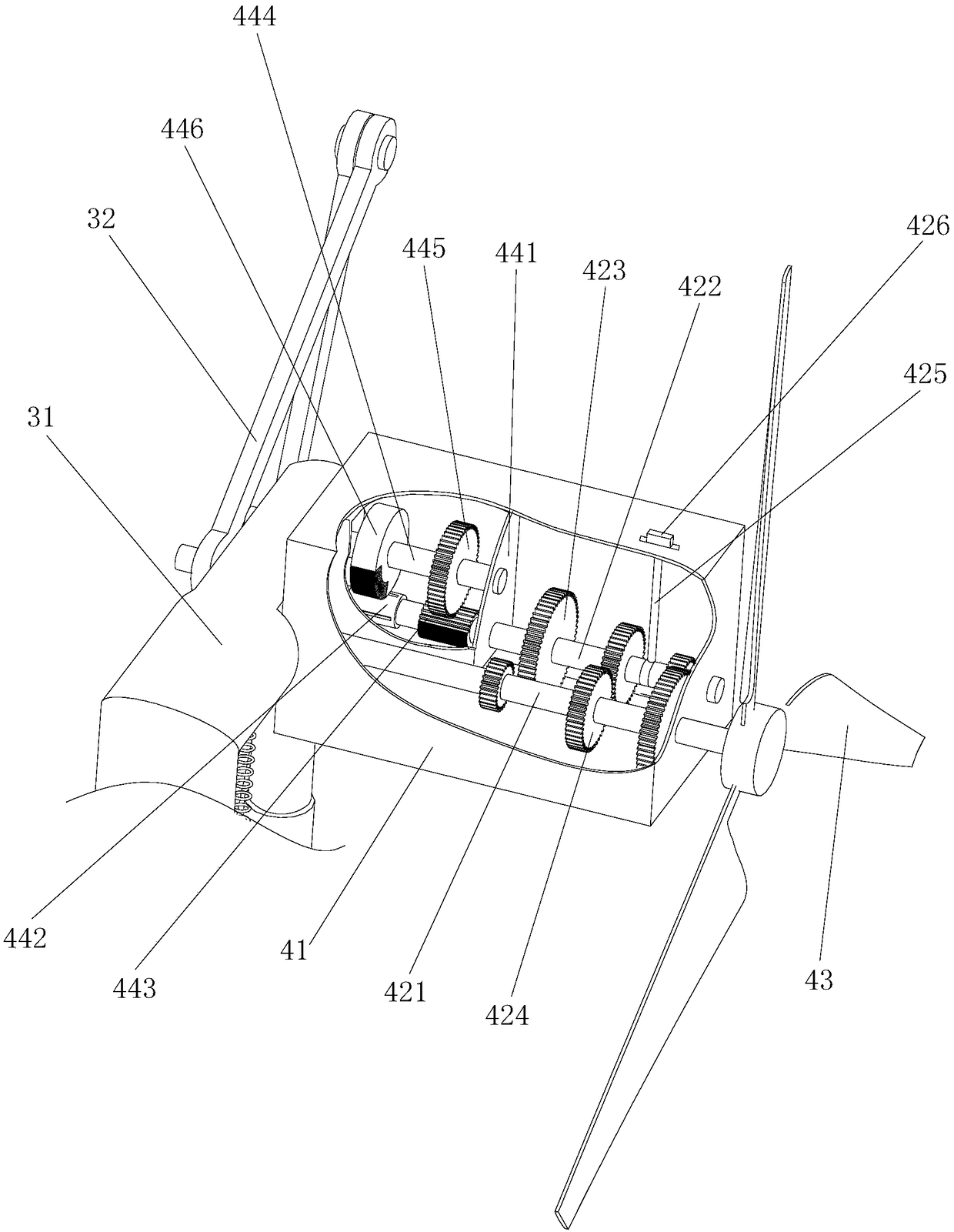

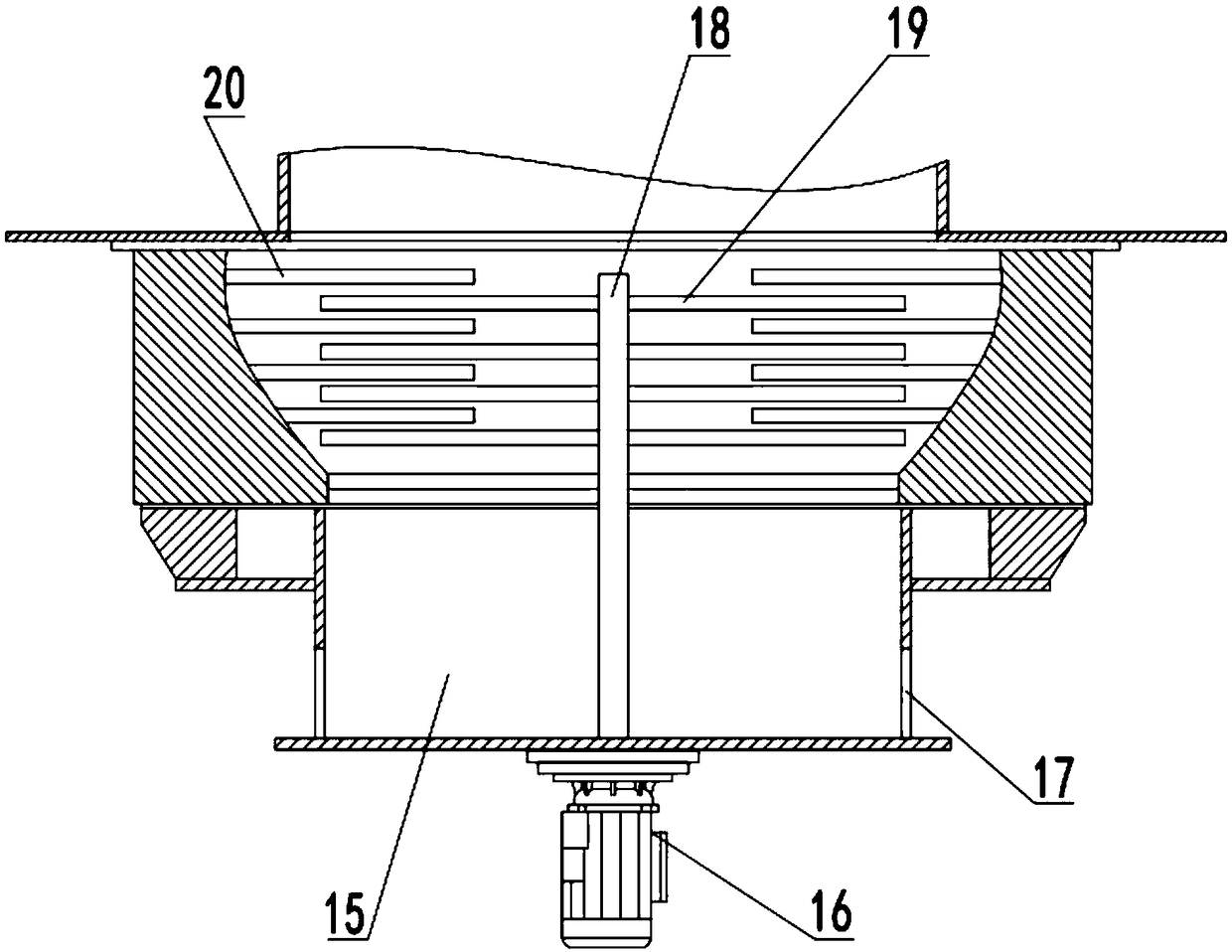

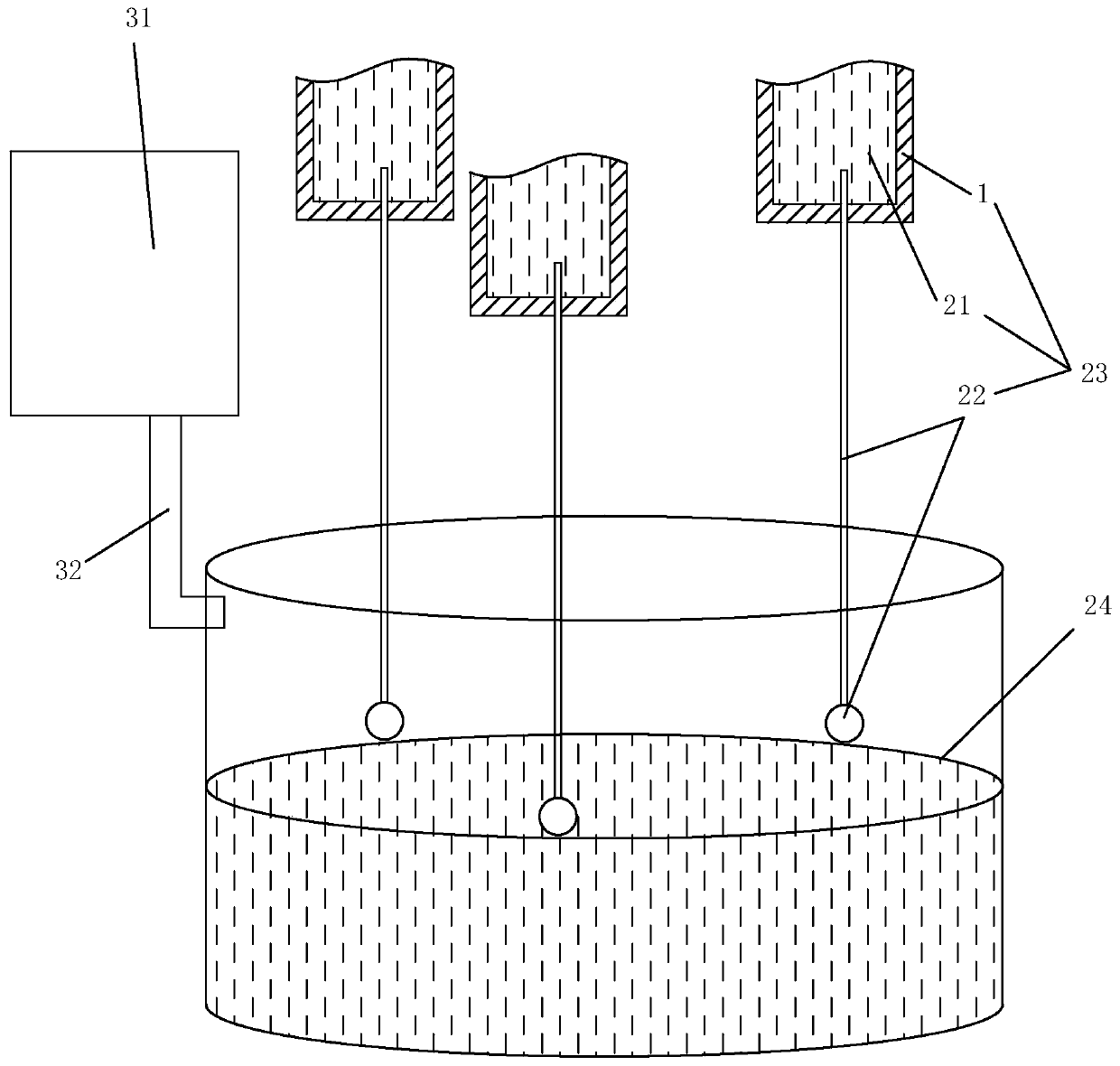

Flea beetle trapping device using wind energy

PendingCN109042575ASimple structural designReasonable structural designInsect catchers and killersTrappingEngineering

The invention relates to a flea beetle trapping device using wind energy. The device includes a trapping mechanism, a storage mechanism, an alignment crank slider mechanism and an wind energy mechanism, wherein the storage mechanism is installed on the lower portion of the trapping mechanism, and the alignment crank slider mechanism and the wind energy mechanism are installed on the upper portionof the trapping mechanism. The whole trapping mechanism is yellow and includes a trapping outer cover, a trapping inner cover and a brush, wherein the trapping inner cover is installed on the inner side of the trapping outer cover, and the brush is installed on the upper portion of the trapping inner cover; an insect accommodating external chamber is formed between the trapping outer cover and thetrapping inner cover to serve as an intermittent area for insects; the inside space of the trapping inner cover refers to an insect accommodating internal chamber; the trapping outer cover is provided with an outer-cover insect inlet along the side wall, and the trapping inner cover is provided with an inner-cover insect inlet along the side wall; the upper end in the storage mechanism is provided with a tapered escaped insect funnel, and a cruciferous vegetable extract solution is placed at the inside bottom of the storage mechanism to induce beetles. The structure is simple, and the devicehas the function of preventing the insects from escaping, meets field application needs, has high trapping efficiency, is good in effect, saves energy and is environmentally friendly.

Owner:贵州省植保植检站 +1

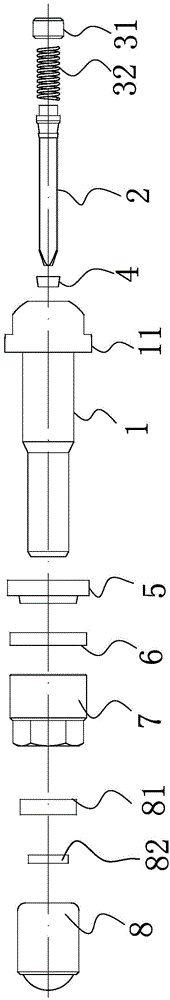

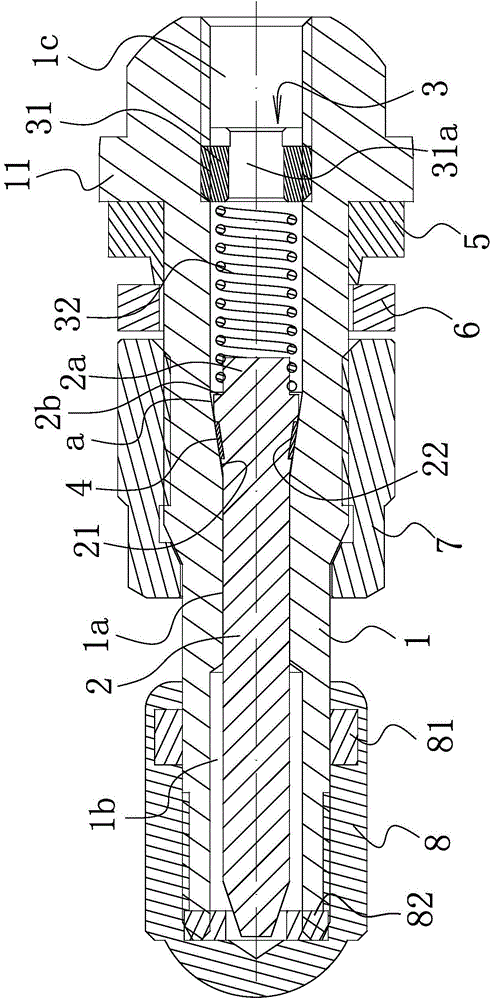

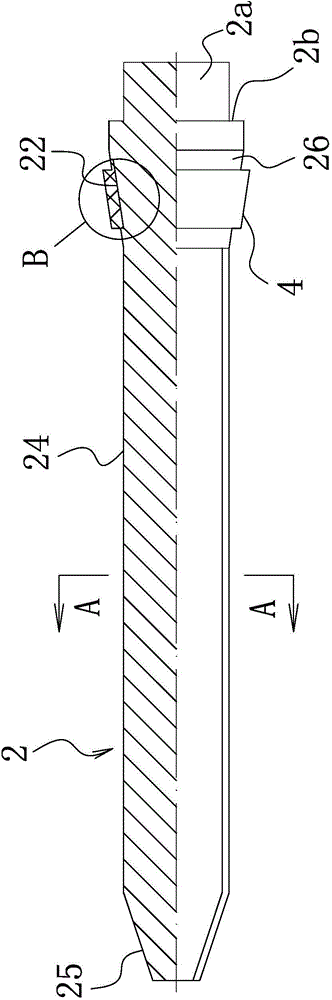

Safe and energy-saving inflating valve

InactiveCN104019256AImprove inflation efficiencyImprove sealingCheck valvesLift valveInlet channelEngineering

The invention belongs to the technical field of inflating valves, and particularly relates to a safe and energy-saving inflating valve solving the technical problem that in the prior art, sealing performance is poor. The safe and energy-saving inflating valve comprises a valve body with an air inlet channel, the air inlet end of the air inlet channel is provided with an air inlet cavity chamber, the air outlet end of the air inlet channel is provided with an air outlet cavity chamber, an inner annular sealing cone is formed between the air inlet cavity chamber and the air inlet channel, the valve body is internally provided with a valve element with the two ends inserted into the air inlet cavity chamber and the air outlet cavity chamber respectively, the valve element is provided with an outer annular sealing cone matched with the inner annular sealing cone, an elastic control assembly is arranged between the valve body and the end, provided with the outer annular sealing cone, of the valve element, the valve element is further provided with a sealing structure capable of being located between the inner annular sealing cone and the outer annular sealing cone through the elastic control assembly when the air inlet cavity chamber of the air inlet channel stops supplying air to the air outlet cavity chamber, and the valve element is fixedly connected with the sealing structure through a circumferential structure. The safe and energy-saving inflating valve has the advantages of being good in sealing performance and high in practicality.

Owner:NINGBO ORIENT HISUN ENERGY SAVING TECH

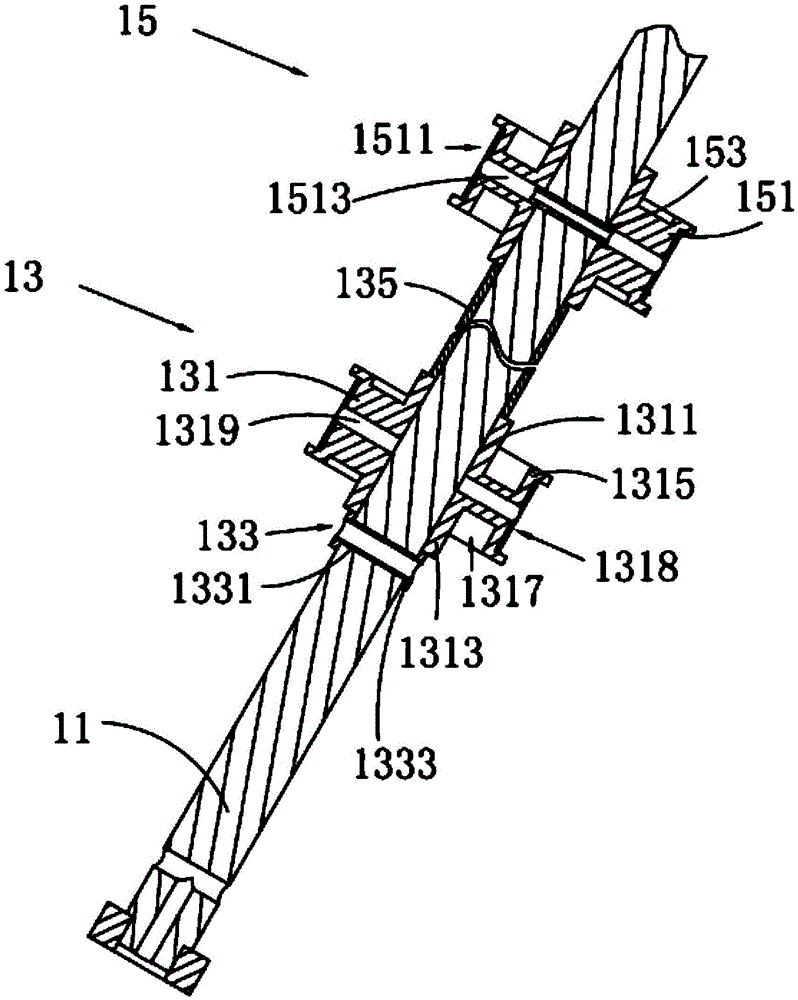

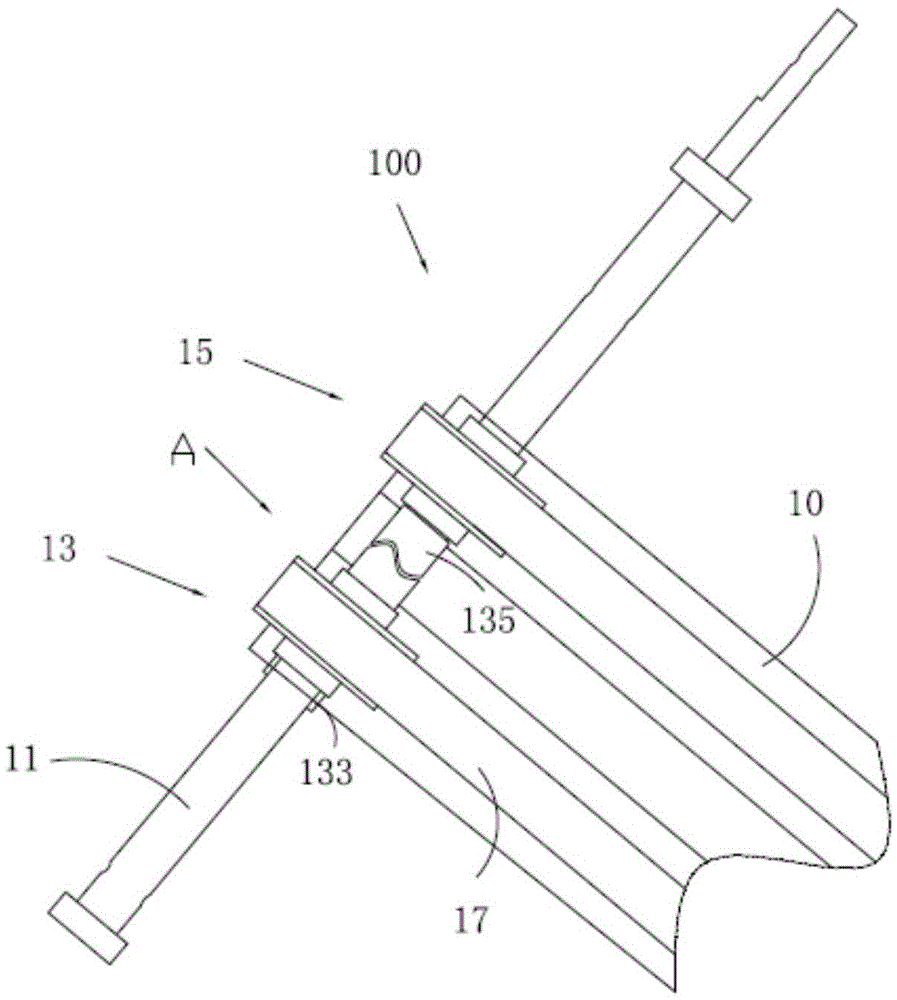

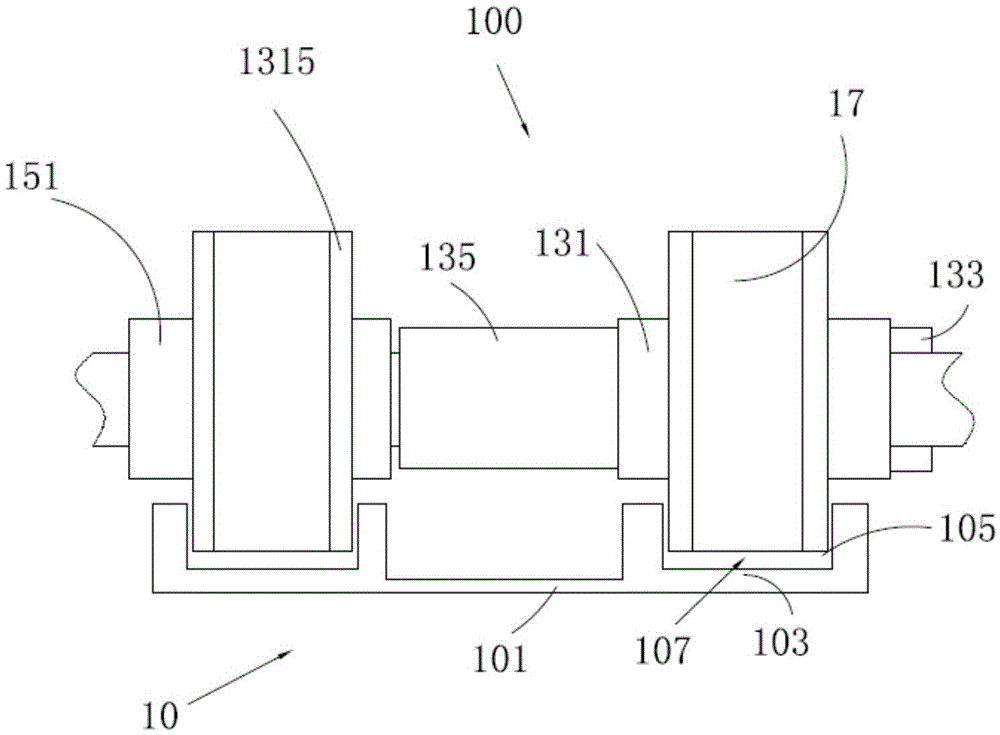

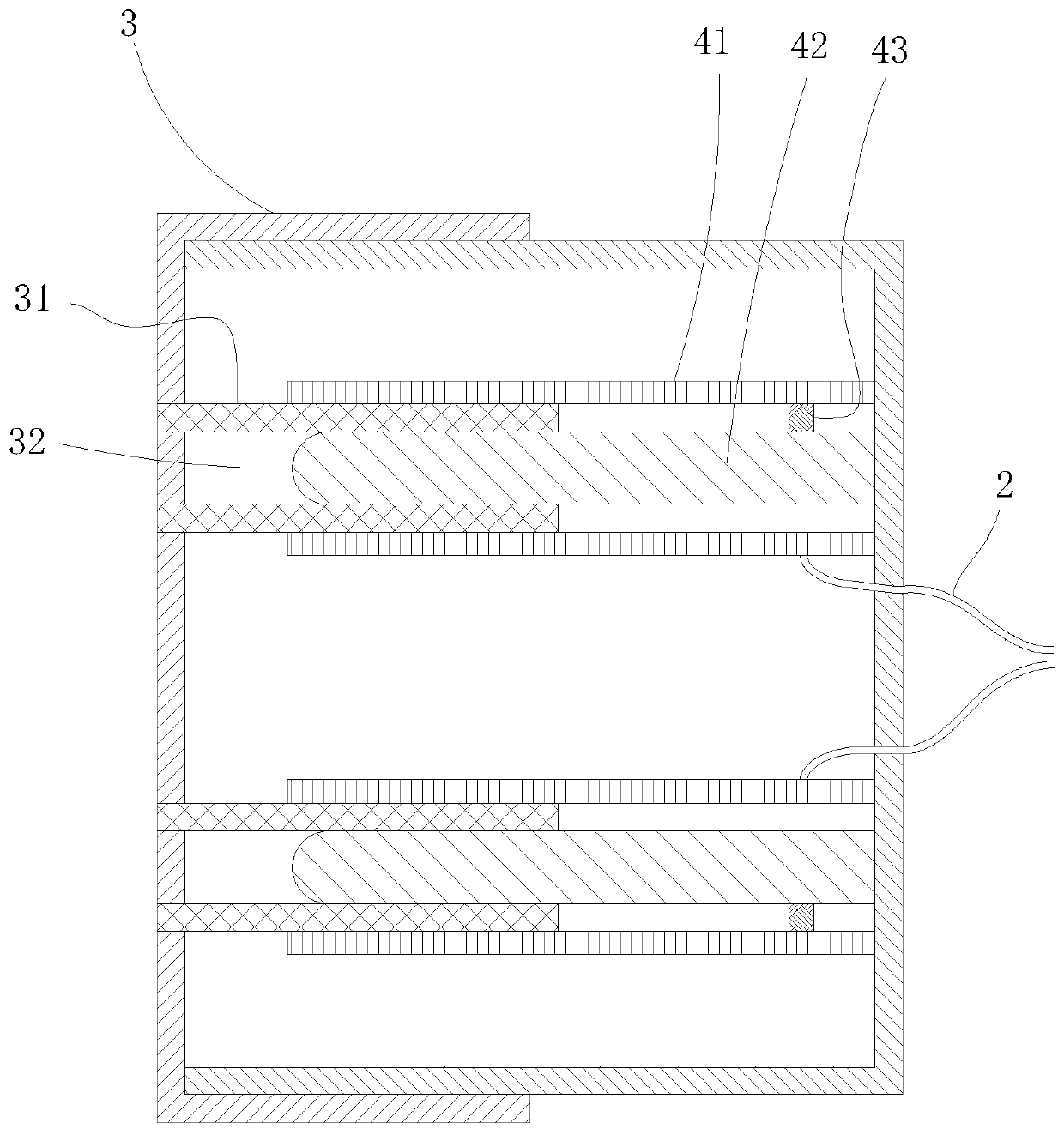

isochronous transfer structure

ActiveCN103910254BReduce tension differencesNot easy to jumpArticle feedersArticle deliveryDrive wheelTransmission belt

A synchronous conveying structure comprises a driven shaft, a first transmission wheel, a second transmission wheel, two transmission belts, a conveying seat, a retaining piece and a retaining ring, wherein the first transmission wheel and the second transmission wheel sleeve the driven shaft at interval, the second transmission wheel fixedly sleeves the driven shaft, and the first transmission wheel rotatably sleeves the driven shaft; the conveying seat is provided with at least two conveying units at interval and in parallel; the driven shaft is arranged on the conveying seat at interval; the retaining piece and the retaining ring are mounted on the driven shaft and abuts against both sides of the first transmission wheel to clamp the first driven wheel, so that the axial position of the first transmission wheel relative to the driven shaft can maintain constant; one sides of the transmission belts are accommodated inside the corresponding conveying units to form a conveying passage between the conveying units and the transmission belts. According to the synchronous conveying structure, the two transmission belts can maintain the relative identity in position relatively easily, have small tension difference and avoid fluctuation. Meanwhile, the synchronous conveying structure is simpler in structure.

Owner:SHENZHEN YIHUA COMP +2

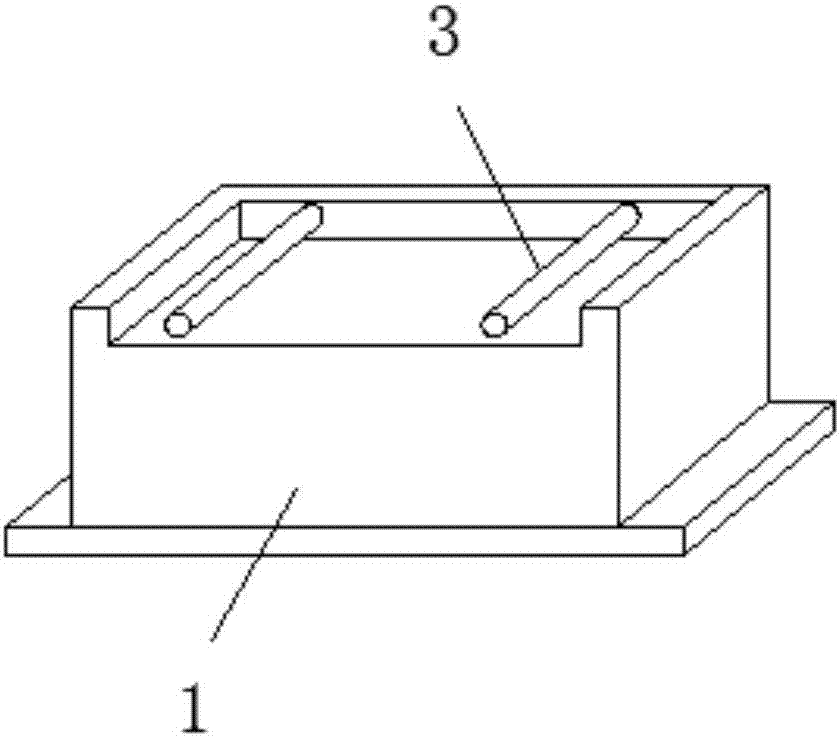

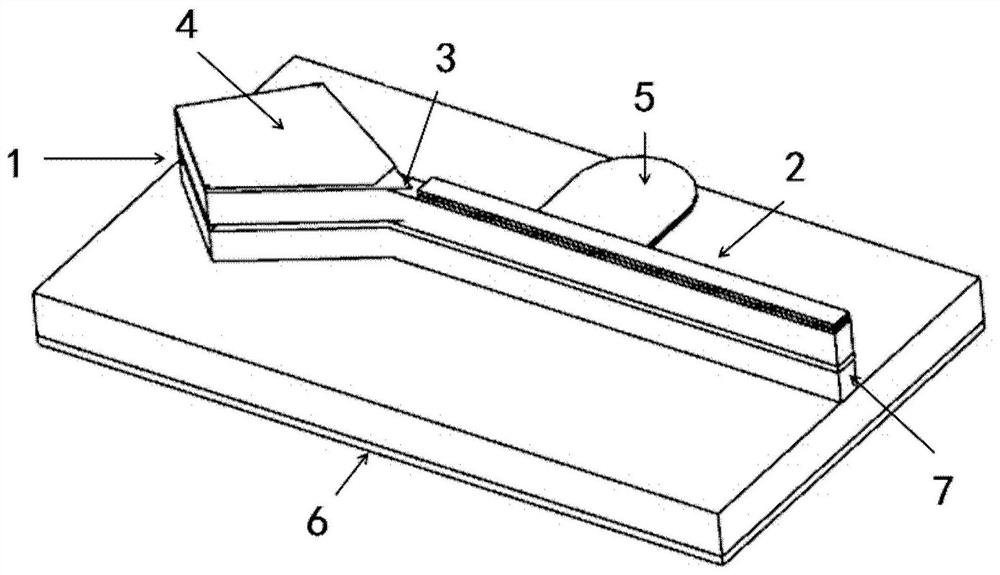

Single-crack manufacturing mold for composite structure body and using method thereof

ActiveCN111044339AImprove sealingNot easy to jumpPreparing sample for investigationMechanical engineeringWall plate

The invention aims to solve the problem of pouring leakage and solve the problems of prefabricated crack length and inclination angle of a single-crack test piece of a complex. A single-crack manufacturing mold comprises four parts including a trapezoidal groove positioning bottom plate, side wall plates, clamping plates and a crack size controllable assembly, wherein trapezoidal bosses are arranged at the bottom ends of the clamping plates and are self-locked in the trapezoidal groove positioning bottom plate, U-shaped grooves are formed in the side wall plates, the four clamping plates are embedded into the corresponding positions, the clamping plates and the side wall plates are positioned by means of large screws and large butterfly nuts in the horizontal direction, and the trapezoidalgroove positioning bottom plate and the side wall plates are positioned by means of small screws and small butterfly nuts in the vertical direction, so that the mold sealing performance is good, andthe leakage problem is solved. The inclination angle and length of the crack can be precisely adjusted by rotating a crack rotating device and adjusting the length of a T-shaped thin steel sheet. Thelarge screws on the two sides of a mold serve as lifting handles and bring convenience to test piece carrying. The mold has the advantages of good overall sealing performance, leakage prevention, simple disassembly and assembly, precisely controllable and adjustable inclination angle and length of the prefabricated crack, stable and reliable performance in pouring, and convenient carrying.

Owner:WUHAN UNIV OF SCI & TECH

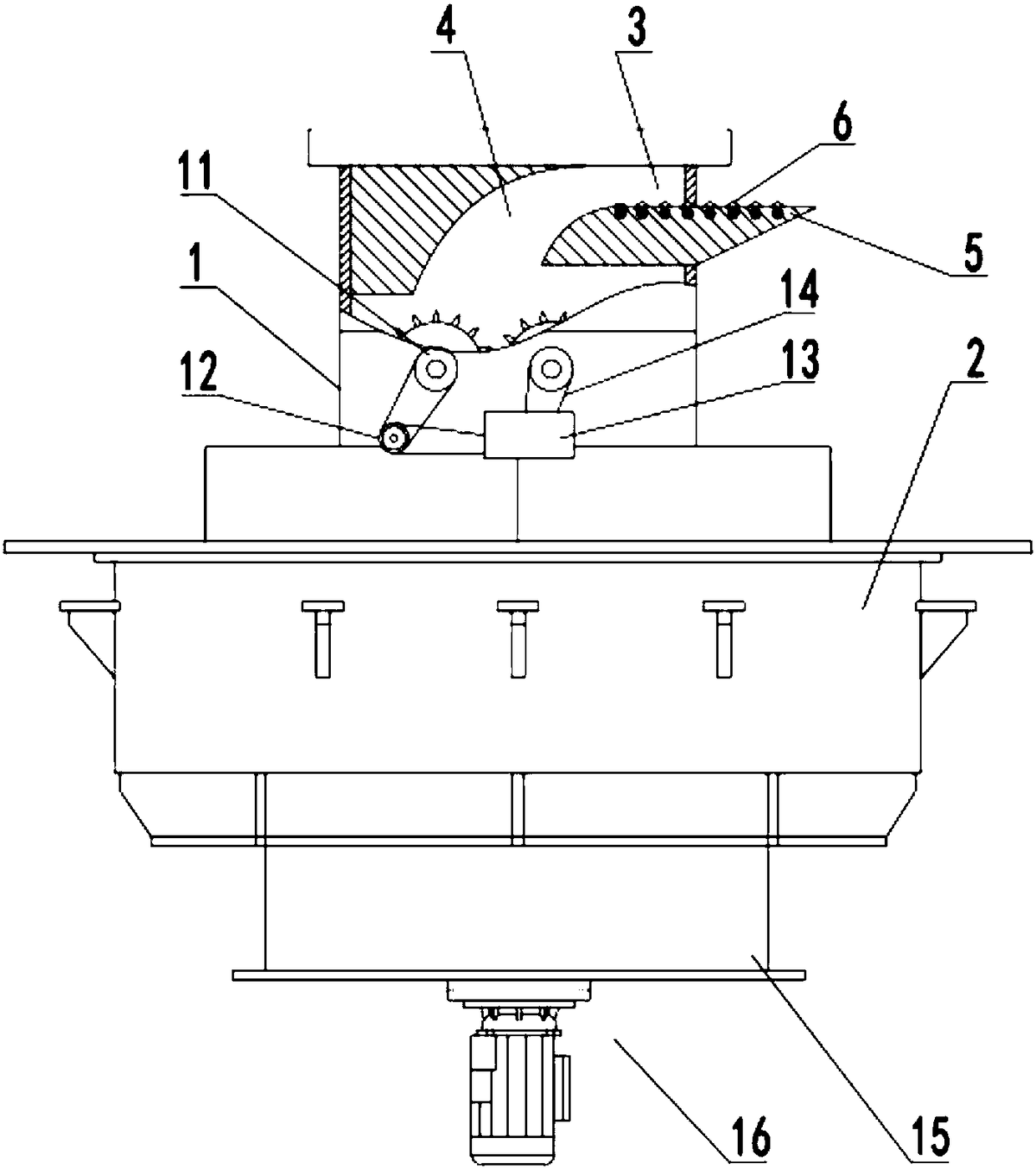

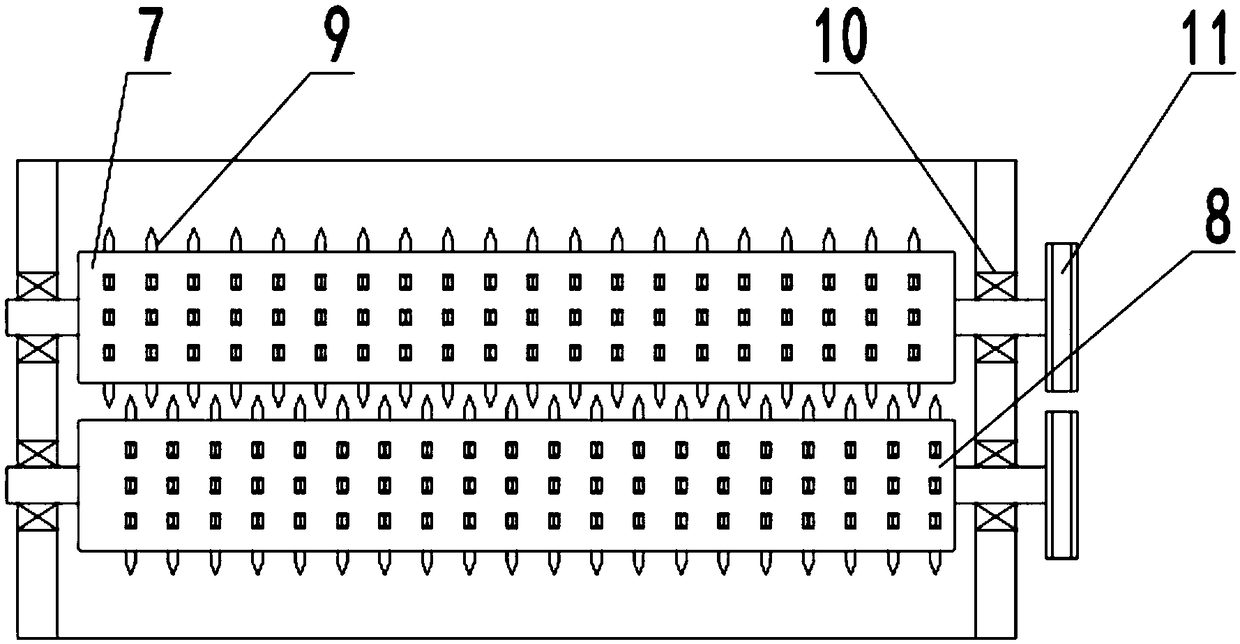

Two-level breaking recovery device for corrugated cases

The invention discloses a two-level breaking recovery device for corrugated cases. The device comprises a shell body provided with an inner cavity and fixedly spliced by an upper shell and a lower shell, a first smashing mechanism and a second smashing mechanism are installed in the cavity of the shell body from top to bottom, and the first smashing mechanism comprises a first breaking roller anda second breaking roller which are installed in the shell body through bearings; a plurality of breaking cutters are fixed to the surfaces of the first breaking roller and the second breaking roller,the positions of the breaking cutters on the first breaking roller and the second breaking roller are staggered, the rotating directions of the first breaking roller and the second breaking roller areopposite, and the rotating speeds of the first breaking roller and the second breaking roller are different. The device has the advantages that the differential speed design of the first breaking roller and the second breaking roller can make the corrugated cases or corrugated paperboards more easily torn and broken, the corrugated cases and the corrugated paperboards cannot easily jump from thebreaking cutters on the first breaking roller and the second breaking roller, through the two smashing mechanisms, the smashing effect can be greatly improved, and the corrugated cases and the corrugated paperboards can be conveniently recycled.

Owner:张荷友

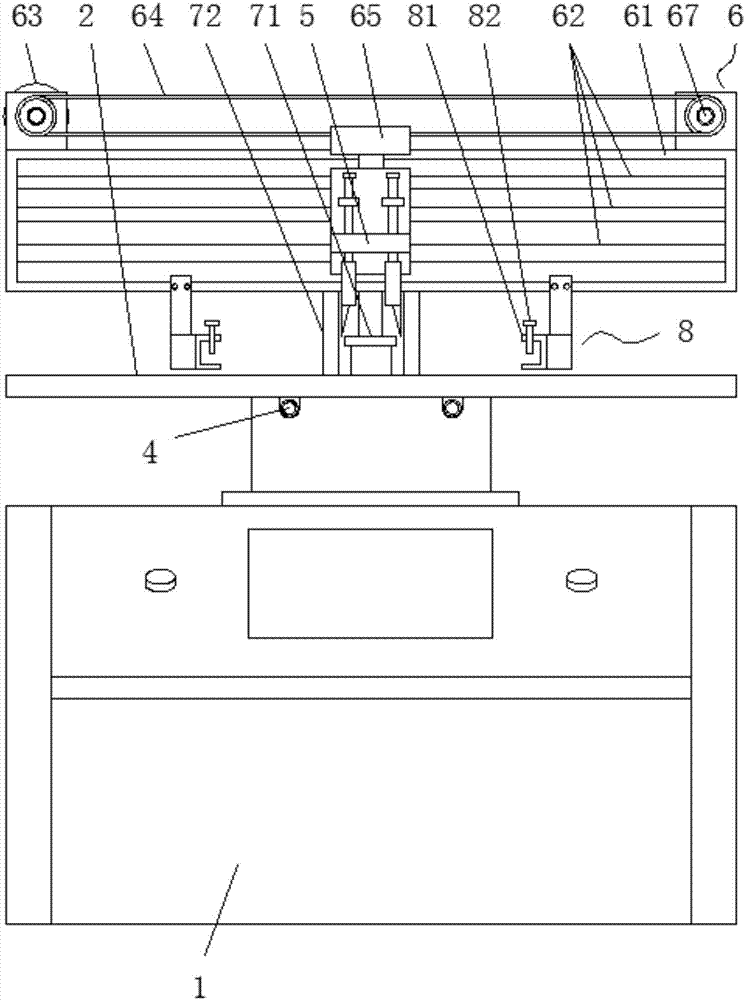

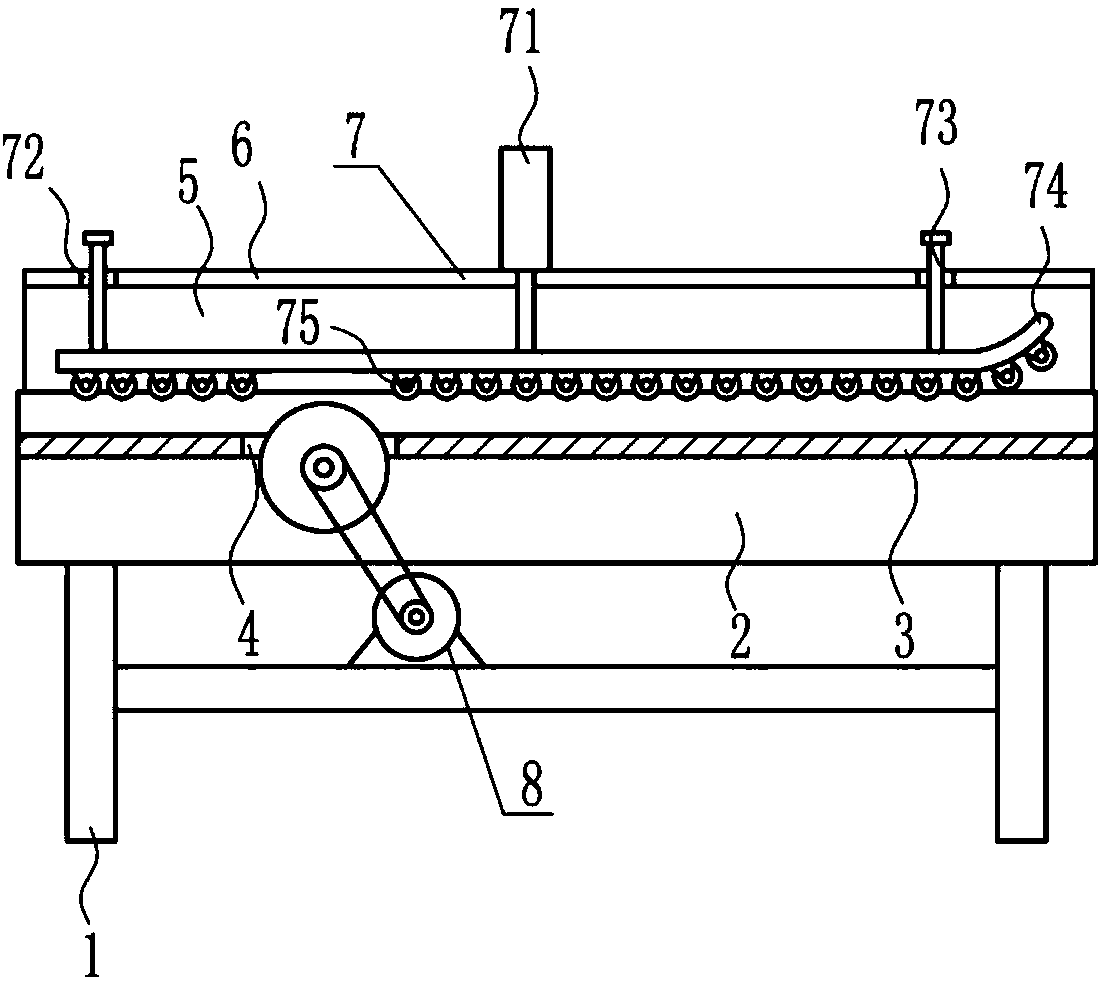

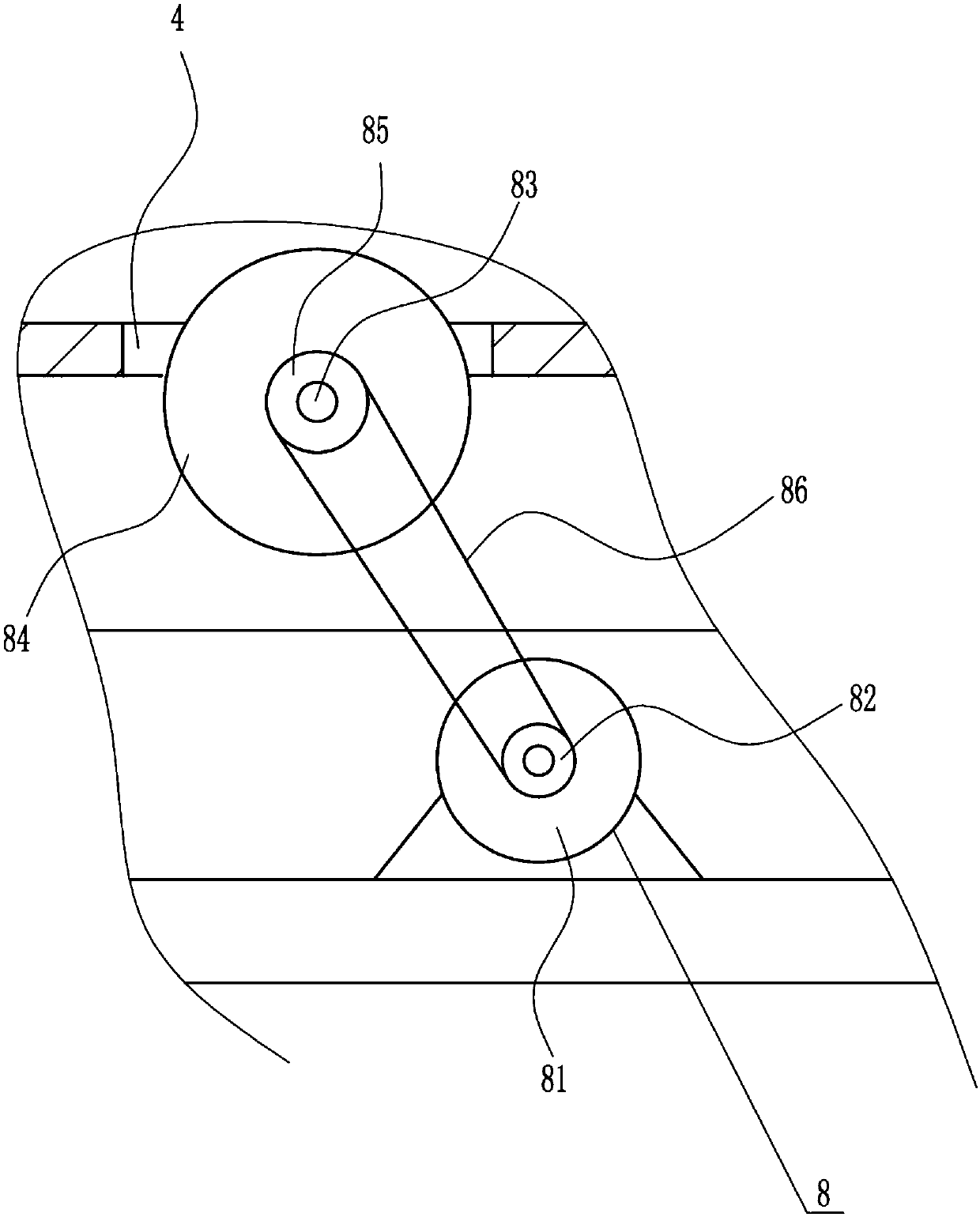

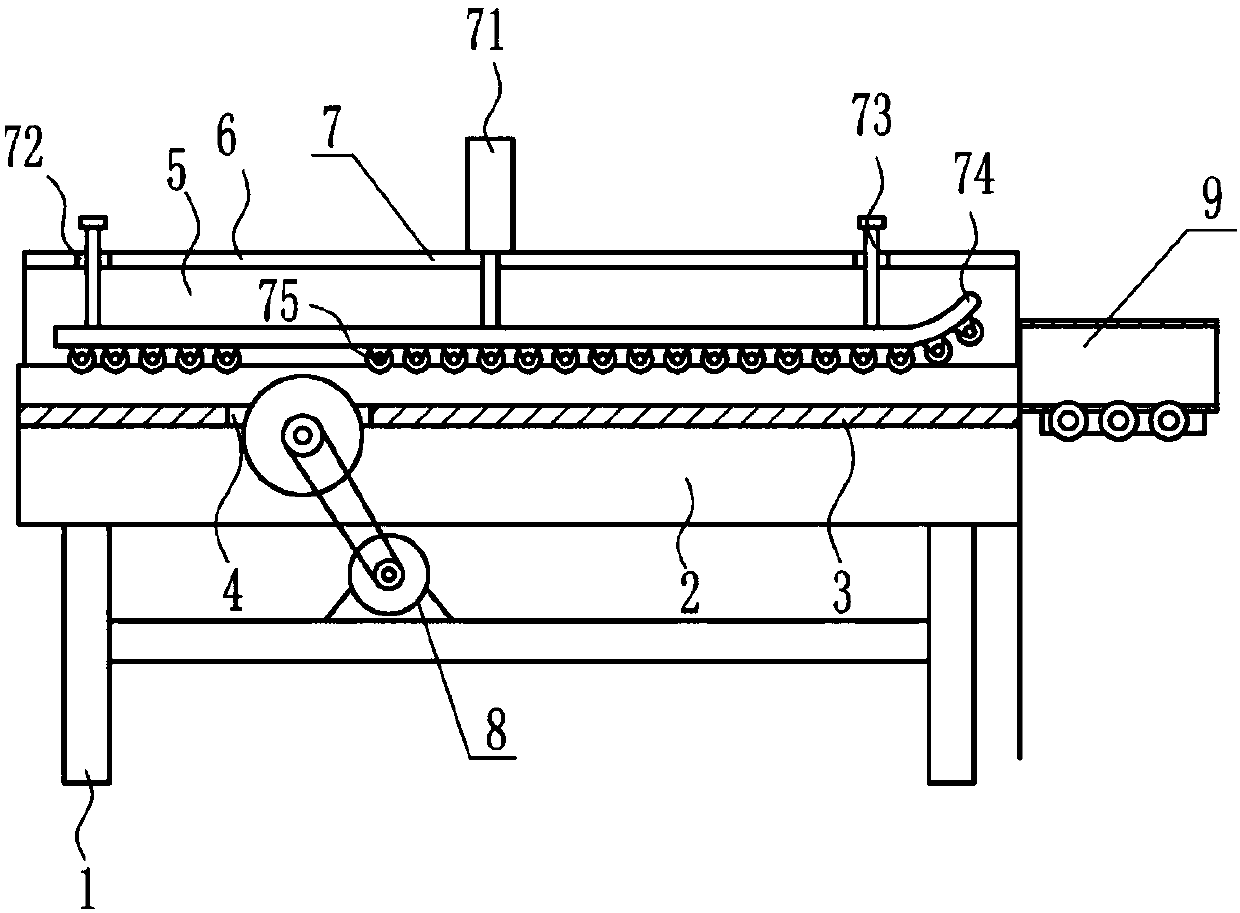

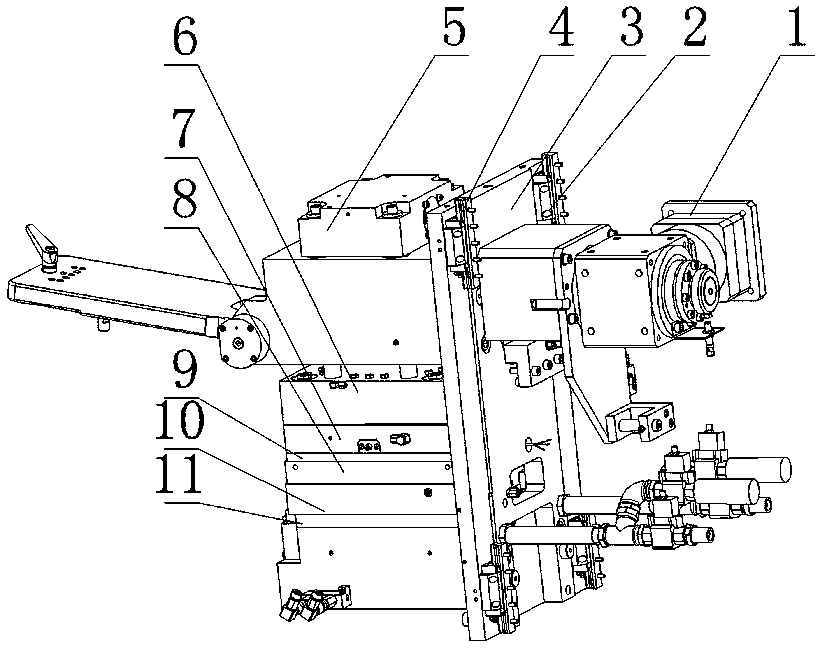

Printing device of LED aluminum substrate assembly

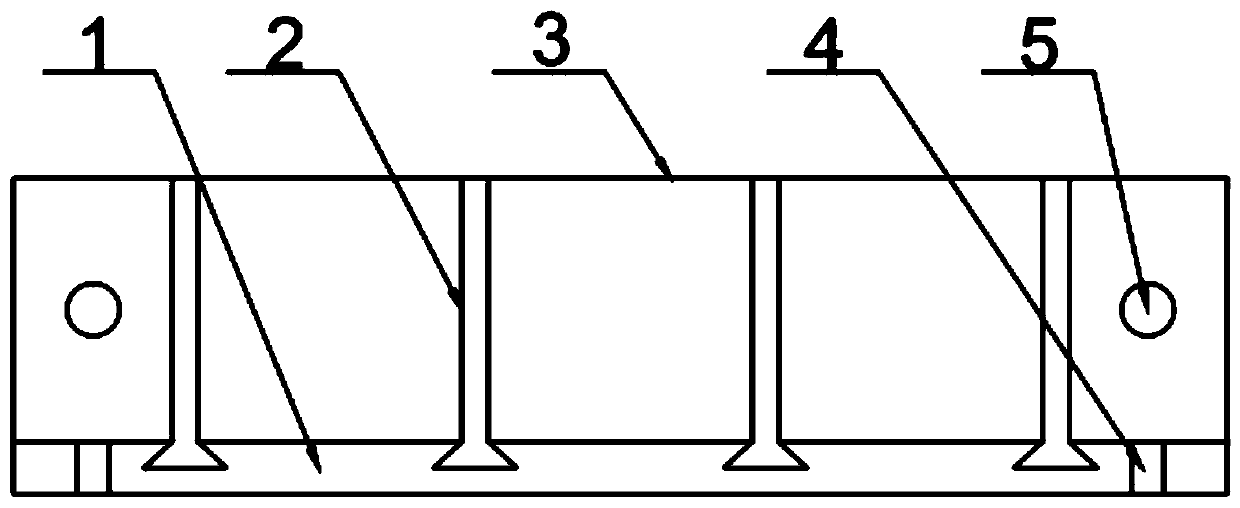

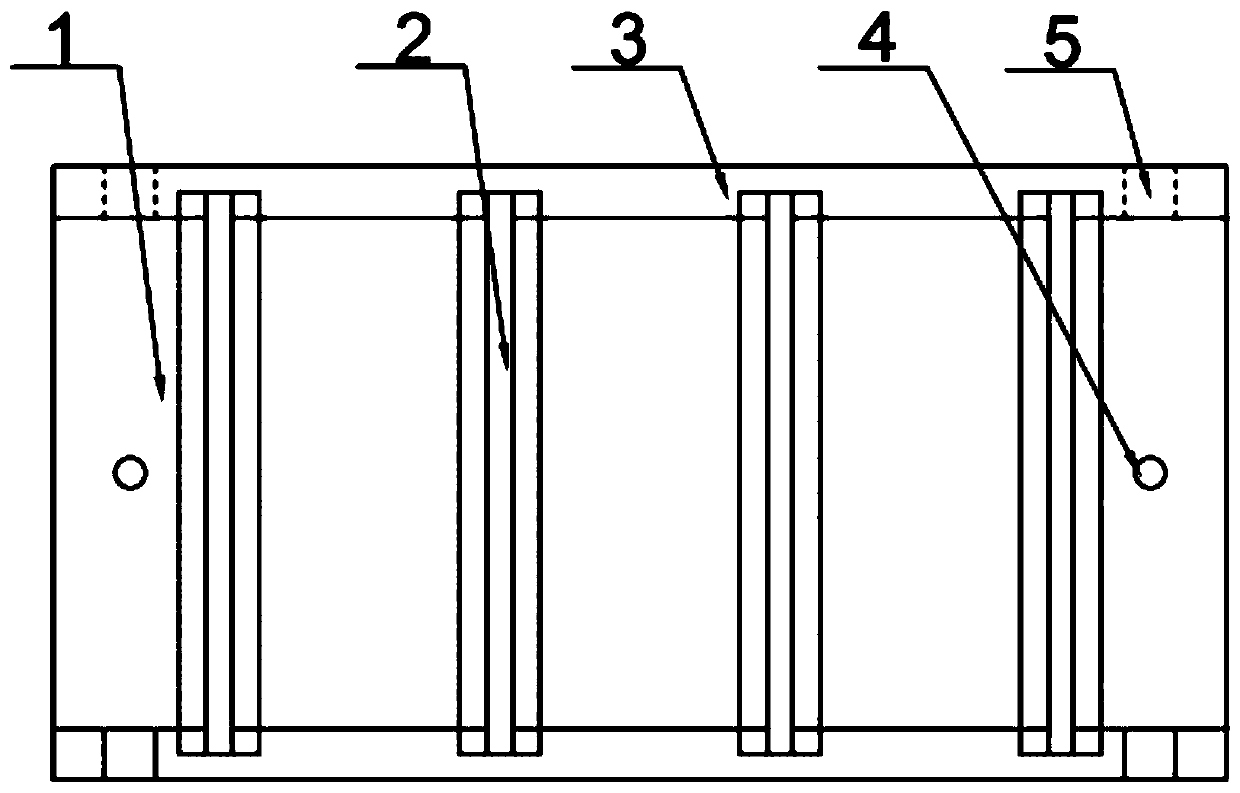

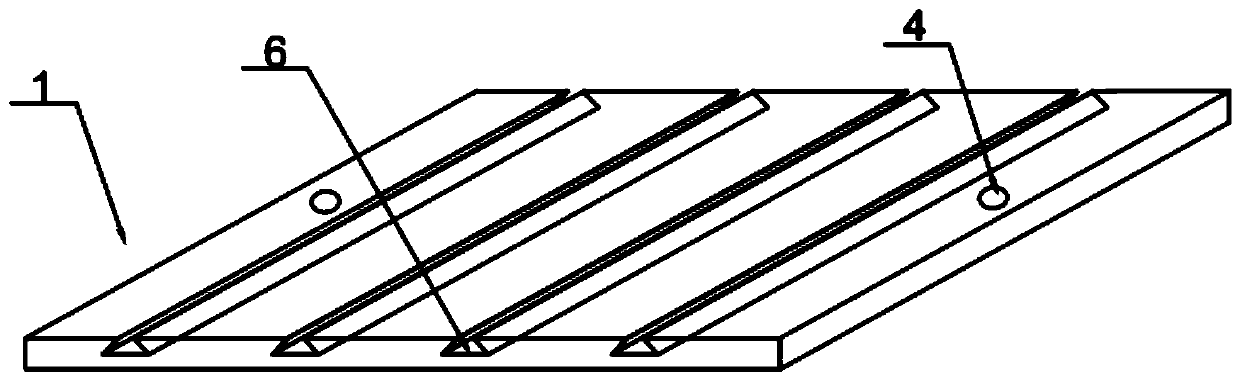

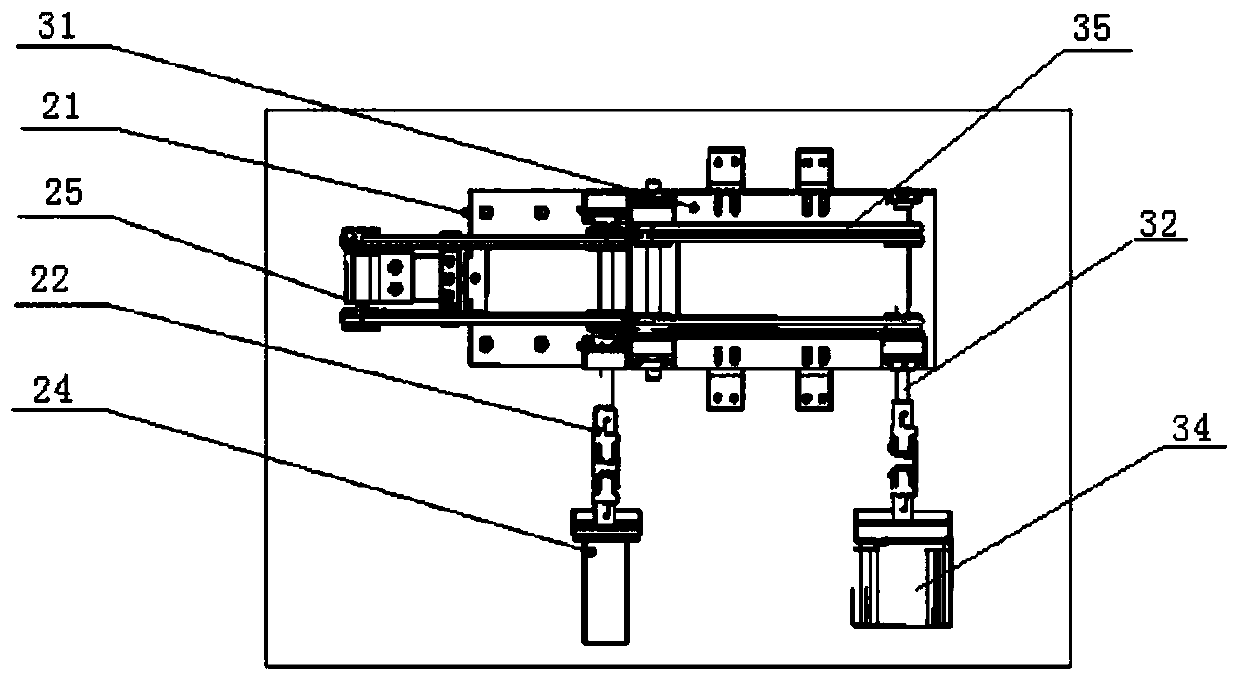

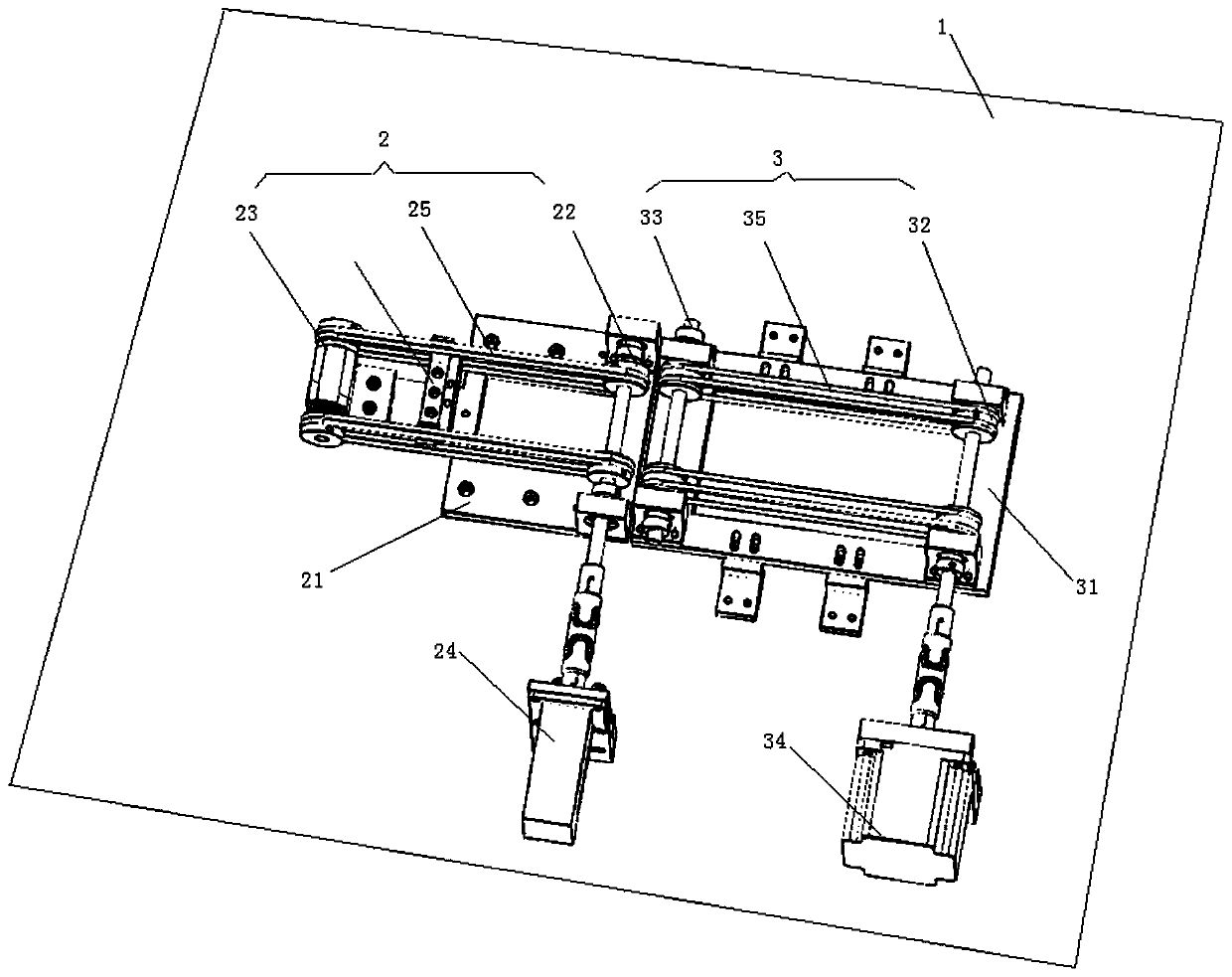

PendingCN107379739ASmooth horizontal movementNot easy to jumpScreen printersElectric machineryStructural engineering

The invention discloses a printing device of an LED aluminum substrate assembly, and relates to the field of LED aluminum substrate production equipment. The printing device of the LED aluminum substrate assembly comprises a seat, a printing platform, a traveling mechanism, a scraper blade device and a lifting mechanism, wherein a rod-shaped sliding track is arranged on a base; the printing platform is slidably connected to the inside of the rod-shaped sliding track and is fixed by a locking nut; the traveling mechanism is mounted on the lifting mechanism; a scraper is mounted in the traveling mechanism and can move horizontally; a positioning device is arranged on the front surface of the traveling mechanism. The traveling mechanism is adopted, at least three sliding rods are used and are driven by a driving motor, the scraper blade device moves horizontally and stably, and cannot jump easily, the printing effect is good, meanwhile, the printing platform is in detachable connection with the device, therefore, different printing platforms can be changed according to demands of products, and later maintenance is also facilitated.

Owner:芜湖谱瑞电子科技有限公司

Tile cutting device for urban construction

InactiveCN107932750ANot easy to jumpGuaranteed stabilityWorking accessoriesStone-like material working toolsEngineeringUrban construction

The invention relates to a tile cutting device, in particular to a tile cutting device for urban construction. The tile cutting device for urban construction is high in safety coefficient, saves timeand labor and is high in efficiency. In order to achieve the aims, the tile cutting device for urban construction comprises a rack and the like; a cutting table is arranged on the top of the rack, a containing plate is horizontally arranged in the middle of the cutting table, a through groove is formed in the left position of the containing plate, a rear side plate is arranged on the rear side ofthe top of the cutting table, a top plate is horizontally connected to the front side of the top of the rear side plate, a compressing device is arranged on the top plate, and a cutting device body is arranged on the rack and the left side of the cutting table. Tiles can be pressed through the pressing device, when the tiles are cut, cutting stability is ensured, the tiles are not prone to moving, cutting precision is improved, through a loading device, people can pick the tiles for feeding without bowing, and work efficiency is improved.

Owner:戚展鹏

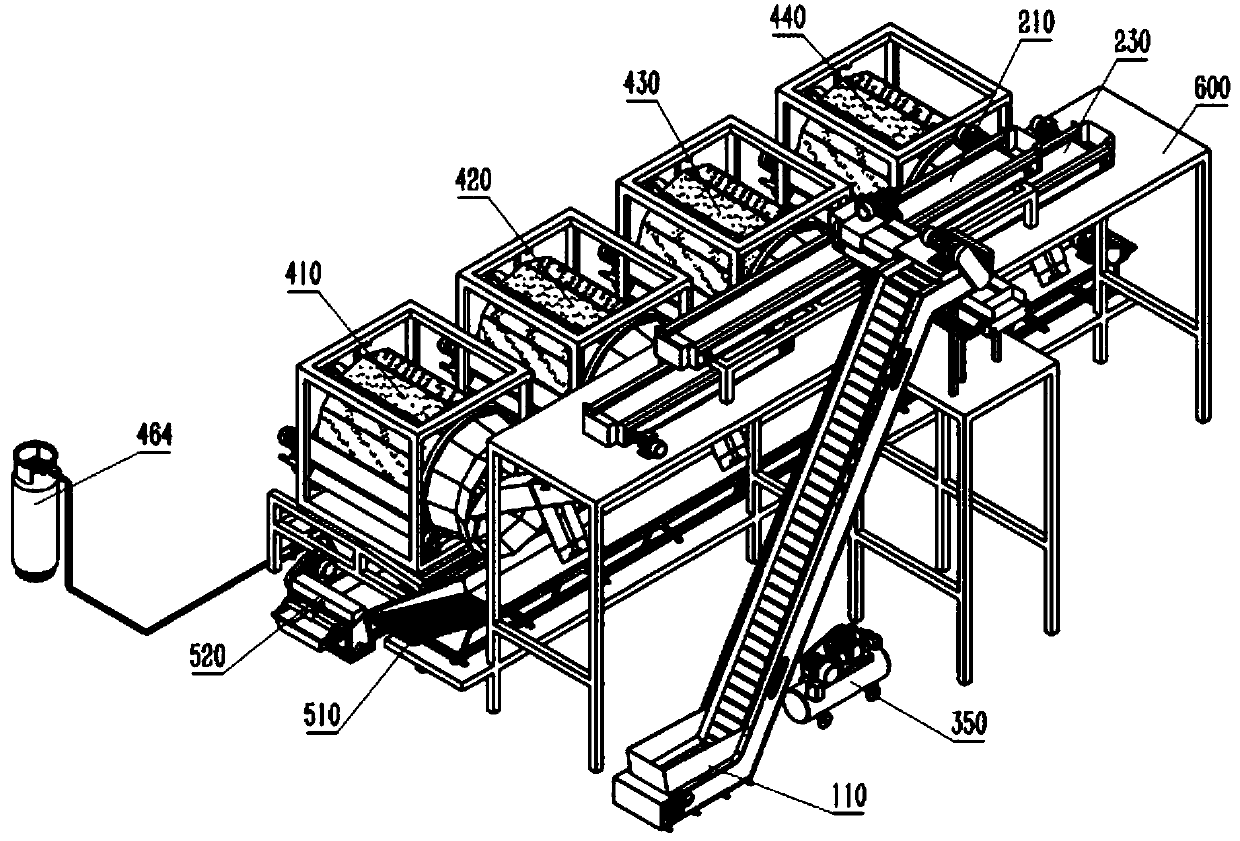

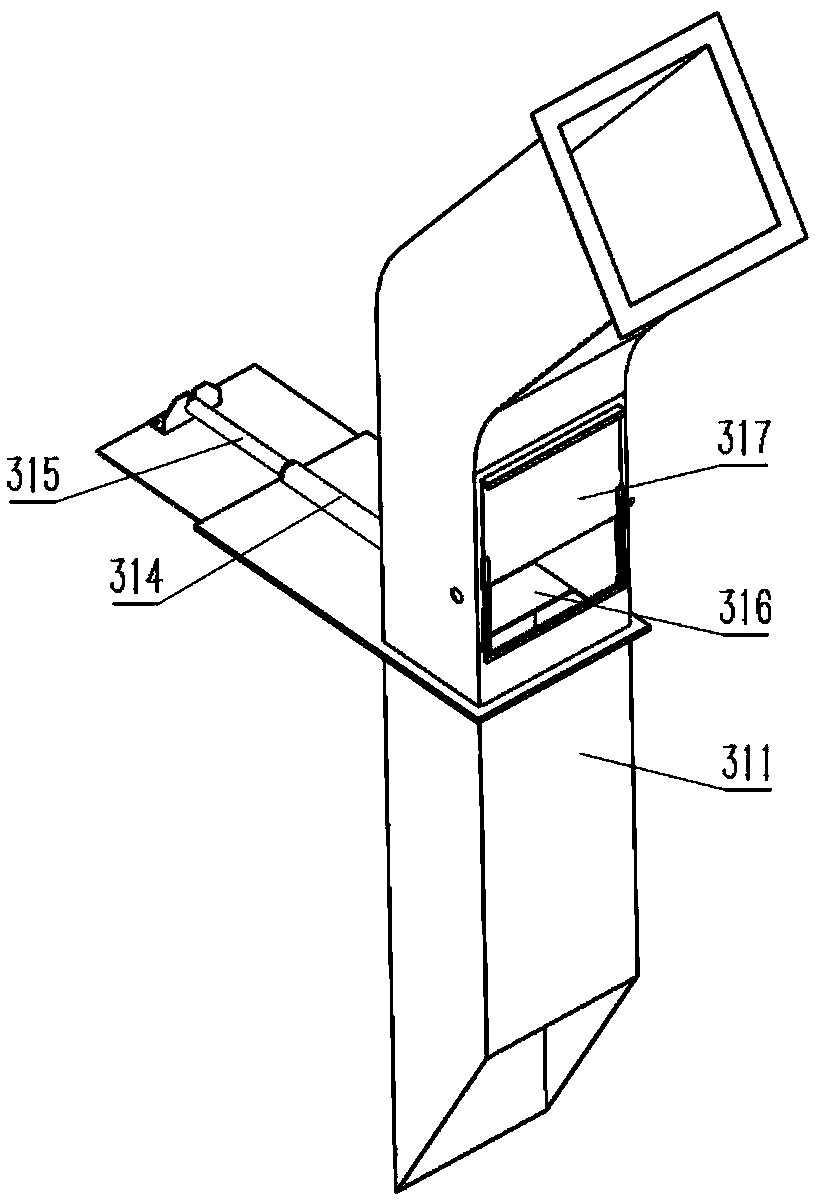

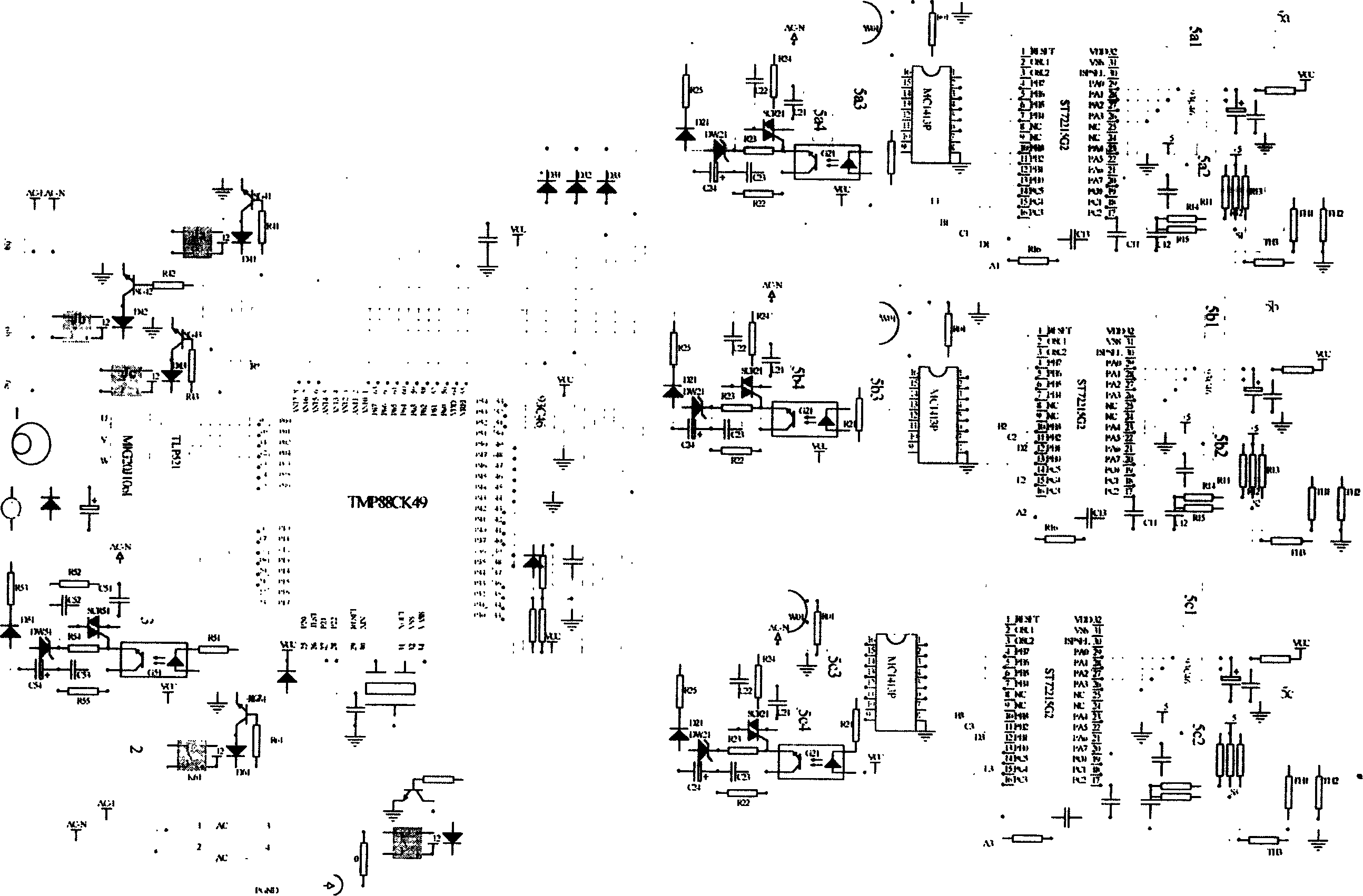

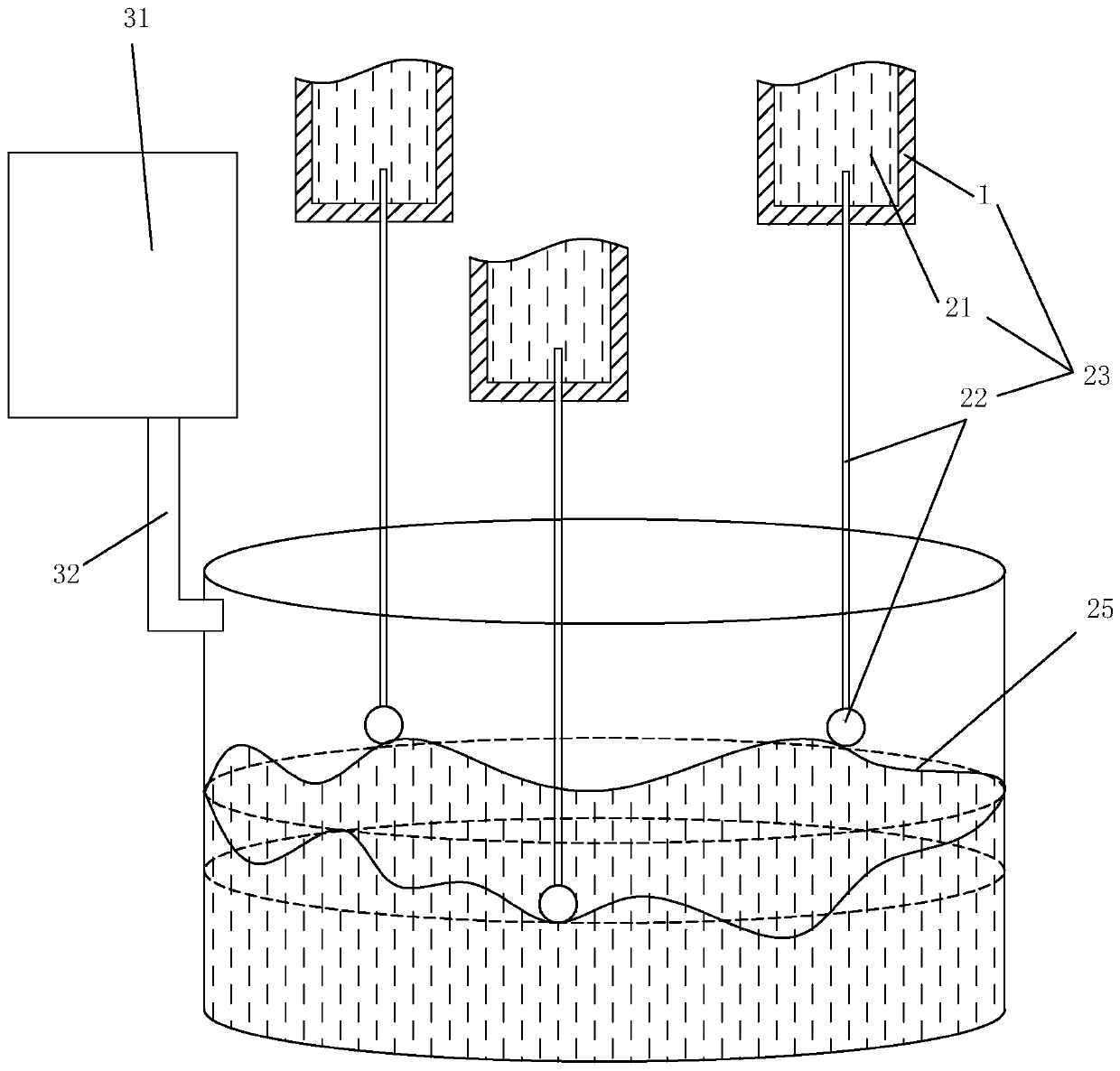

Automatic continuous gas-fueled tea leaf baking machine and control method

ActiveCN109662162AGuaranteed qualityFully automatedPre-extraction tea treatmentProduction lineCooking & baking

The invention relates to an automatic continuous gas-fueled tea leaf baking machine and a control method. The automatic continuous gas-fueled tea leaf baking machine comprises a PLC control unit, a baking unit, a feeding unit for automatically and quantitatively supplying tea leaves to the baking unit, and a discharging unit for automatically conveying the baked tea leaves of the baking unit to anext process. The automatic continuous gas-fueled tea leaf baking machine can execute automatic and quantitative feeding and automatic discharging, safety measures such as flame extinguishing alarming, gas leakage alarming and automatic gas supply stop in the baking process are achieved by adding a flame detector and a gas sensor, automatic and continuous tea leaf baking is achieved, the production efficiency and the continuity and safety of a production line are greatly improved, and safe production is ensured. In addition, the baking unit adopts an upper and lower heating combined gas heating way, and the tea leaf baking efficiency and the quality of tea are greatly improved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

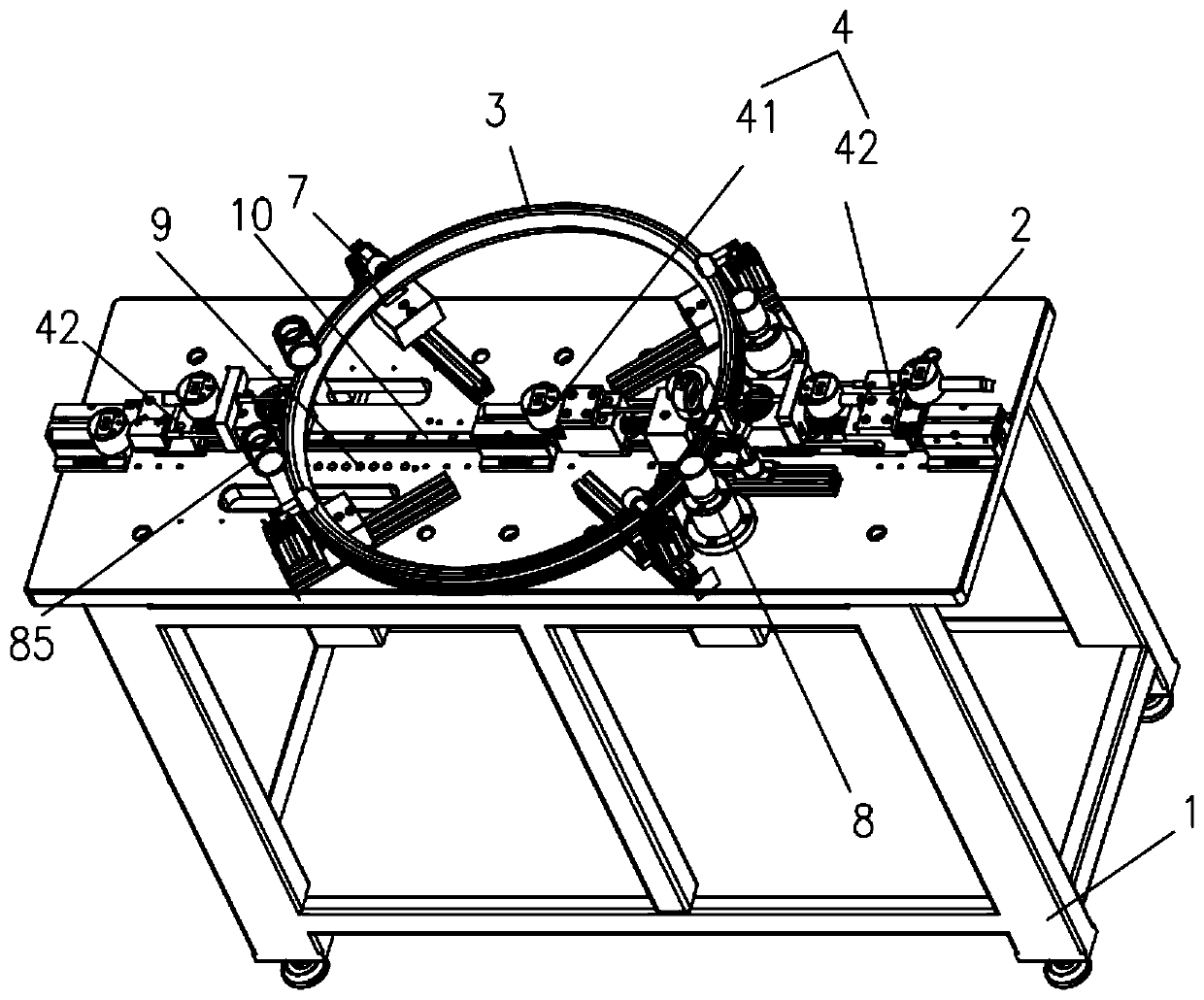

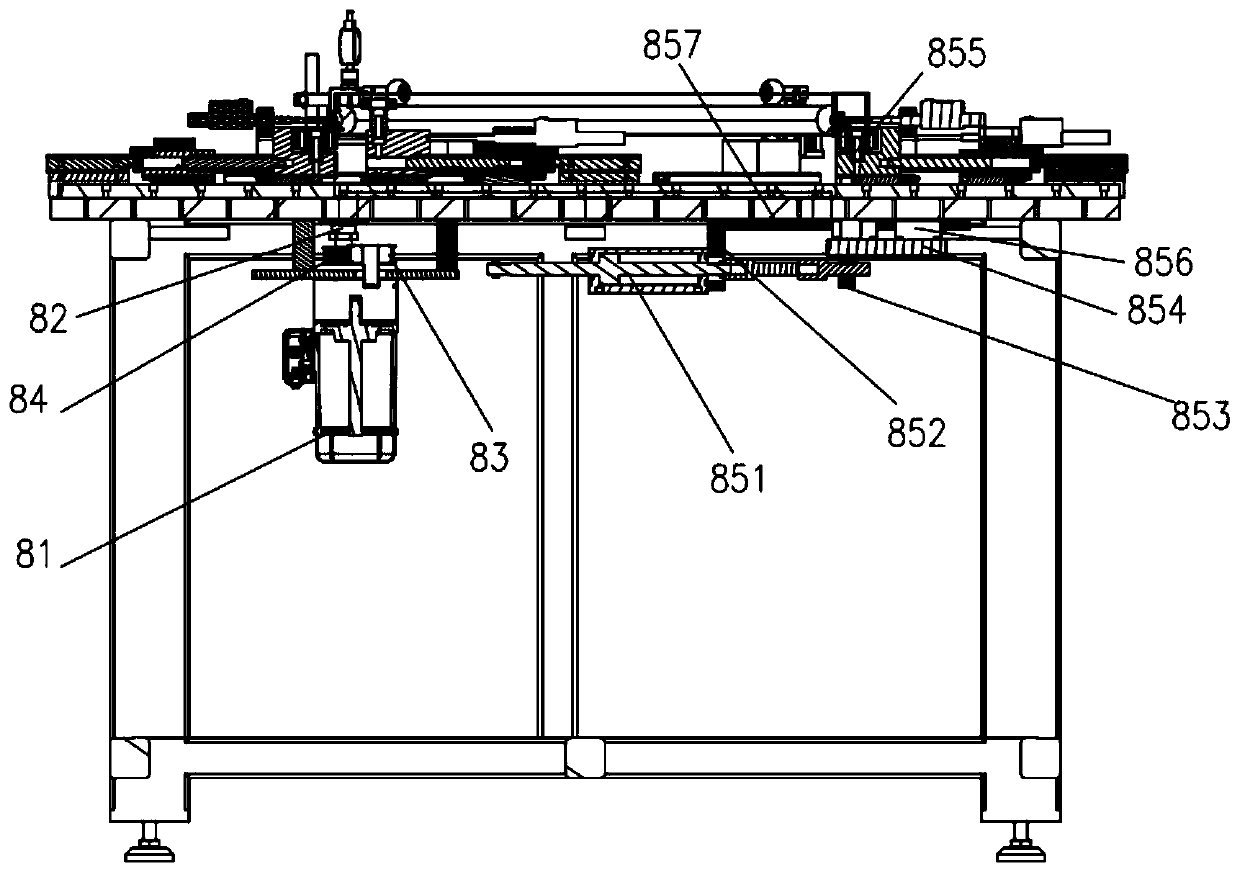

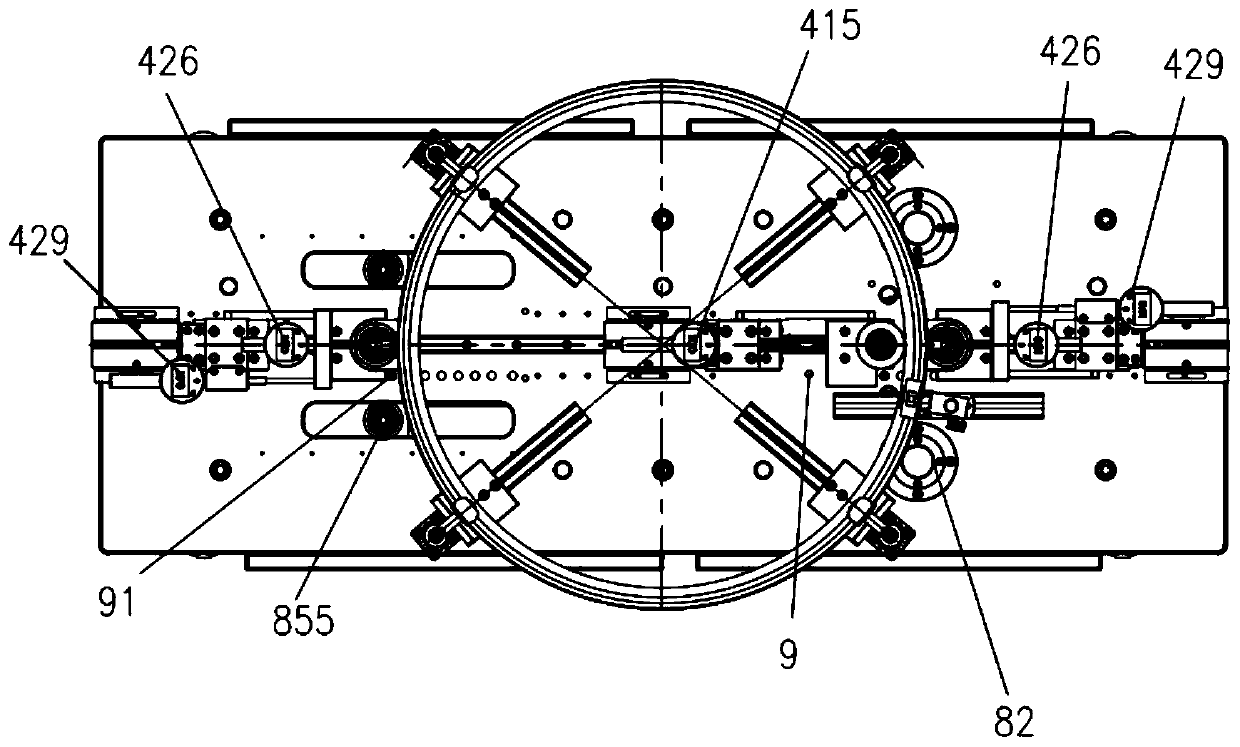

Measuring instrument suitable for measuring roundness and diameter of annular product

PendingCN111521099ANot easy to jumpNot easy to damageMechanical counters/curvatures measurementsMechanical diameter measurementsTire beadControl system

The invention relates to the technical field of measurement, and discloses a measuring instrument suitable for measuring the roundness and the diameter of an annular product. The measuring instrumentcomprises a rack, a working table, a measuring assembly, a driving device and a control system. The driving device is used for driving the to-be-tested annular product to rotate. The control system isused for controlling the operation of the driving device and receiving and processing measurement data of the measurement assembly, and an inner diameter measurement assembly and an outer diameter groove measurement assembly in the measurement assembly are located inside and outside an inner ring of the annular product to be measured respectively. The inner diameter measuring assembly is attachedto the inner ring wall; and the outer diameter groove measuring assembly is respectively attached to the outer ring wall and the tire bead. The diameter and roundness related parameters of the to-be-measured annular product can be accurately measured through reasonable distribution of the measuring assemblies on the working table and corresponding structures, data operation processing is conducted through the control system, and the bounce value, the error, the roundness, the height value between the diameters and other data of the to-be-measured annular product can be obtained. The measuringinstrument is high in automation degree and accurate in detection result, and manpower is greatly saved.

Owner:XIAMEN HONGJI WEIYE INDAL

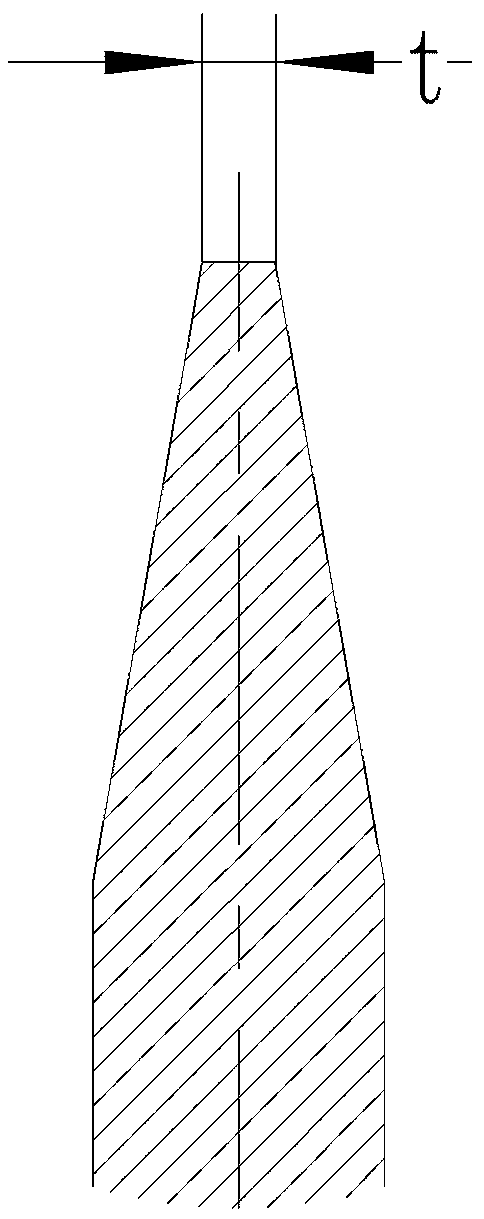

Quenching strengthening process of thin blade cutting edge

InactiveCN111286596AHigh hardnessImprove toughnessFurnace typesOther manufacturing equipments/toolsLaser quenchingEngineering

The invention discloses a quenching strengthening process of a thin blade cutting edge. The process is characterized in that after a thin blade is integrally quenched by a traditional quenching process, the integrally-quenched thin blade is subjected to rough sharpening; the roughly-sharpened thin blade is moved at a high speed, the relative moving speed is 100-400 mm / s, when the thin blade moves,a high-power-density laser light spot is adopted to irradiate the cutting edge, the power density is larger than or equal to 150 W / mm<2>, the cutting edge forms a laser quenching layer, and finally fine sharpening is carried out, so that the thin blade with the quenched-strengthened cutting edge is obtained. A high-power-density laser device is matched with the fast-moving thin blade, so that thecutting edge of the thin blade is protected from being melted, the quenching effect is achieved, the sharpness, the wear resistance and the service life of the thin blade are improved, and the best performance of the material of the thin blade is played.

Owner:浙江久恒光电科技有限公司

Forming mechanism of bubble cap forming machine

The invention discloses a forming mechanism of a bubble cap forming machine. The forming mechanism of the bubble cap forming machine comprises an upper forming die and a lower forming die. The lower forming die is installed on a forming frame. The forming mechanism of the bubble cap forming machine is characterized in that a rotatable transmission shaft is installed on the forming frame, a crankshaft is arranged on the transmission shaft, and an eccentric wheel is installed on the transmission shaft; the eccentric wheel is in contact with a roller fixed to a machine frame of the bubble cap forming machine, and the crankshaft is connected with a moving frame through a shaft sleeve.; and the moving frame is connected with a capsule box, the capsule box is composed of a fixed upper box body and a slidable lower box body, and an air bag is arranged in the capsule box, and the lower box body is connected with the upper forming die. According to the forming mechanism of the bubble cap forming machine, the structure of the crankshaft and the eccentric wheel are adopted, so that a packaging die is stable in state and not prone to jumping during die opening-and-closing, the structure of theair bag can be used for stable forming of a bubble cap, and the forming mechanism of the bubble cap forming machine is high in reliability and is very suitable for bubble cap molding.

Owner:RUIAN HUAPU MACHINERY +1

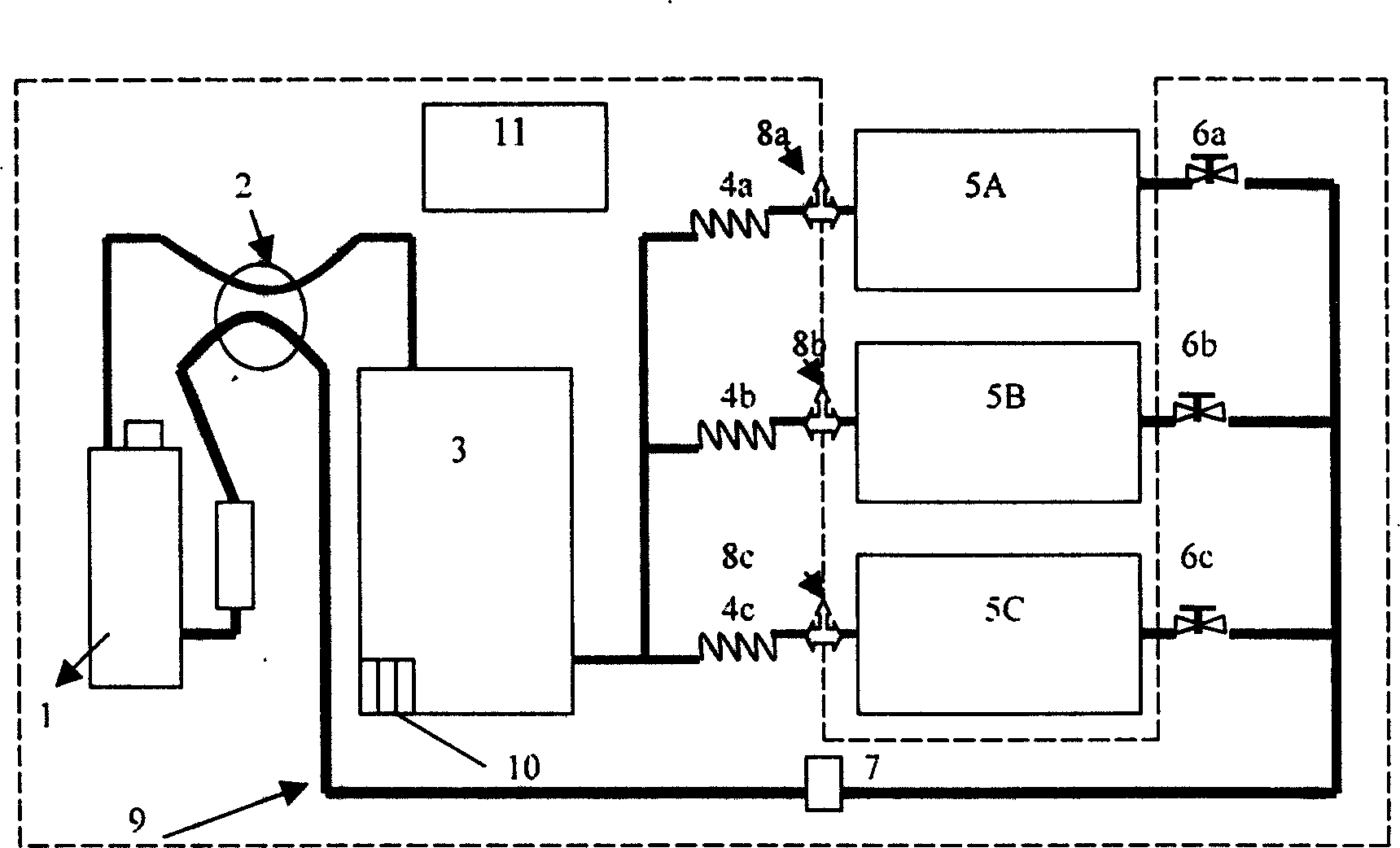

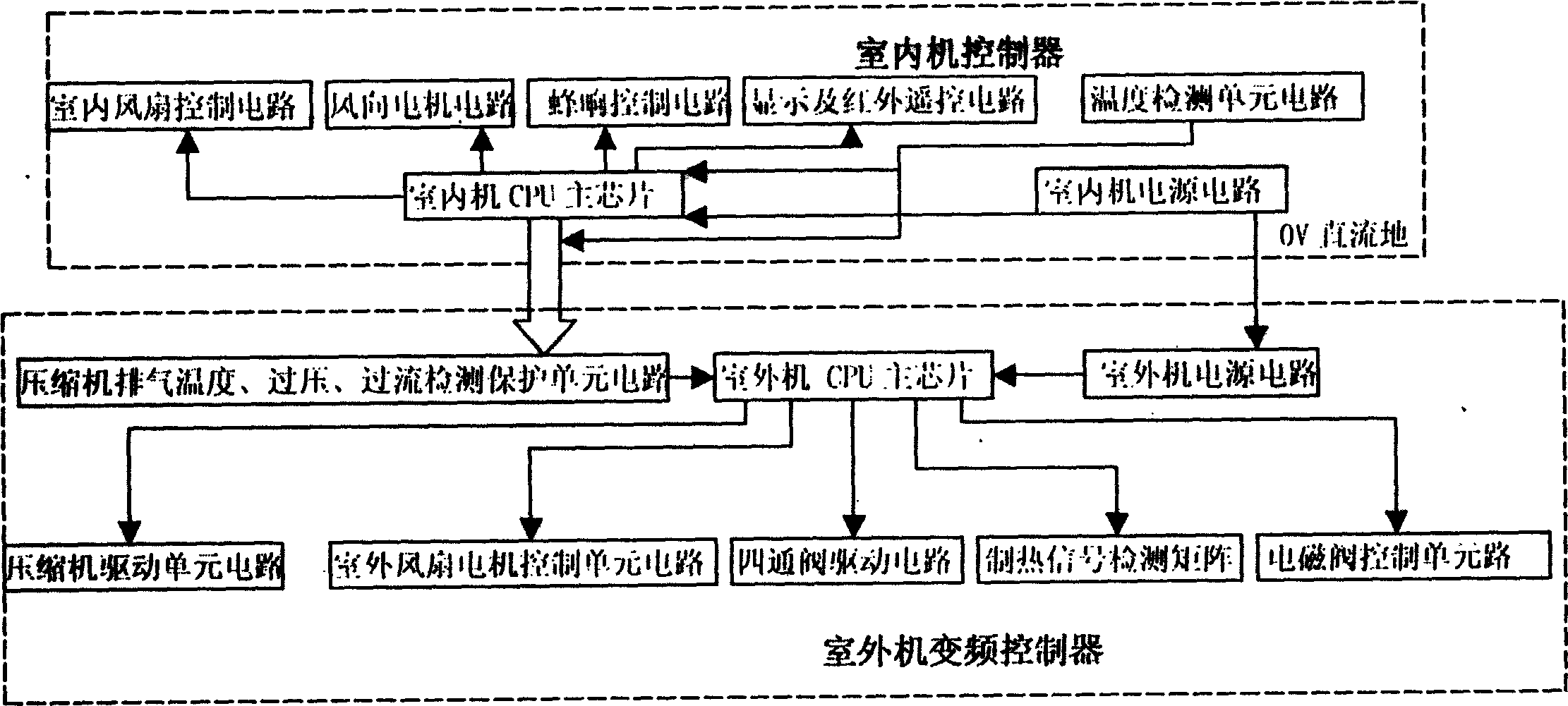

Triple-evaporator air conditioner and variable frequency control method

InactiveCN1202387CSignificant power saving effectSimple controlSpace heating and ventilation safety systemsSpace heating and ventilation control systemsControl mannerSystem pressure

The present invention relates to a one-to-three air conditioner and its frequency conversion control method. The air conditioner includes an indoor unit and an outdoor unit, wherein the frequency conversion compressor of the outdoor unit and the controller of the indoor unit are connected with output 30Hz-60Hz, 60Hz ~90Hz, 90Hz~120Hz frequency conversion controller; the control method is that when one indoor unit is running, the frequency conversion controller output frequency is 30Hz~60Hz; when two indoor units are running, the output frequency is 60Hz~90Hz; When three indoor units are running, the output frequency is 90Hz~120Hz. The present invention is more energy-saving than ordinary industrial frequency one-drag multiple air conditioners; the control method is simple, reliable, and has fewer problems; no matter when a single indoor unit is working, or when two indoor units or three indoor units are working at the same time, the pressure of the compressor system is basically the same. The same, it is not easy to trip, and the operation reliability is high. The invention has low production and improvement cost; the outdoor unit is small in size and easy to install.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

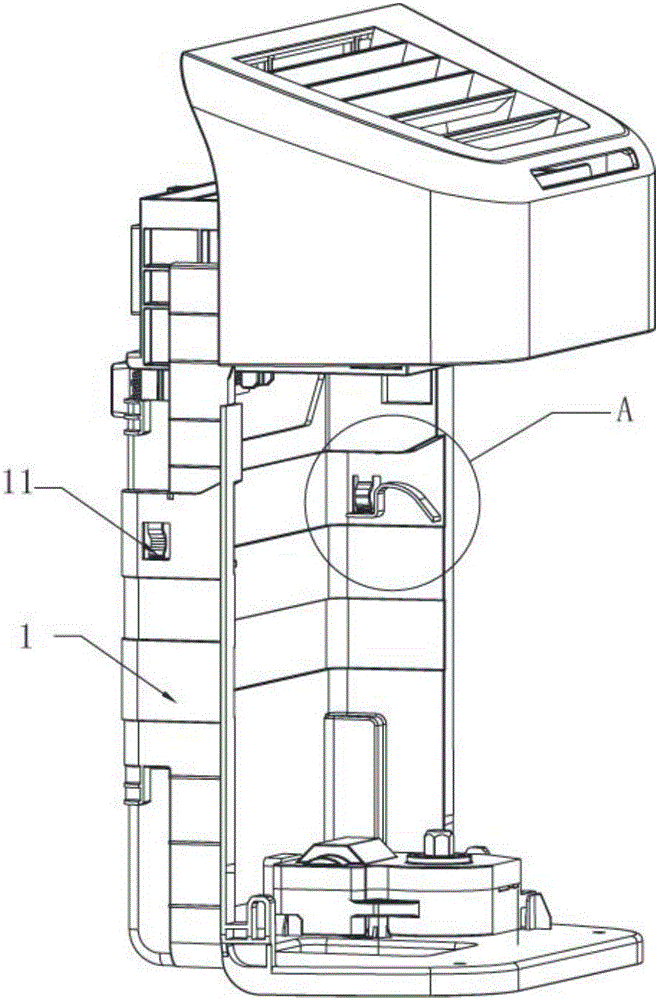

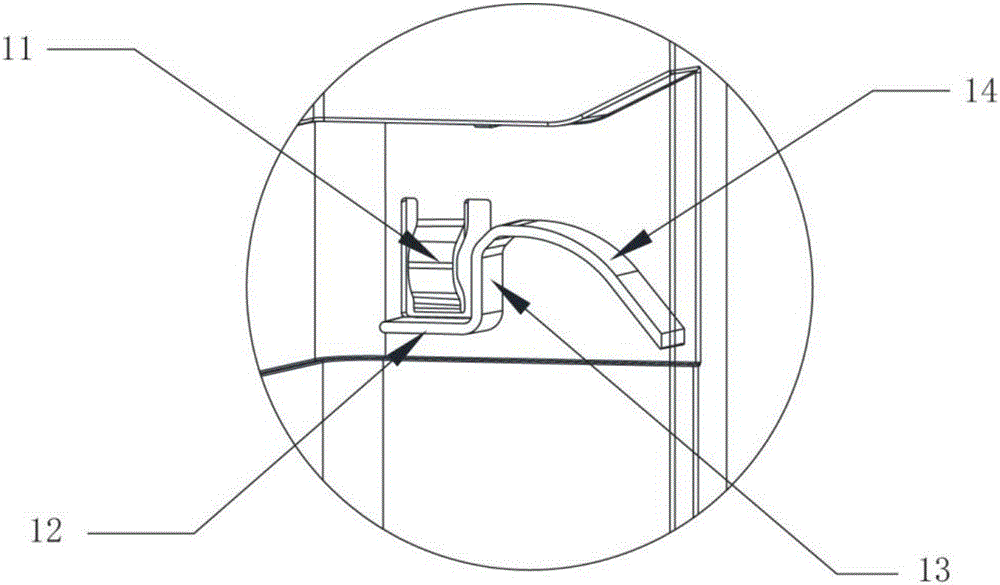

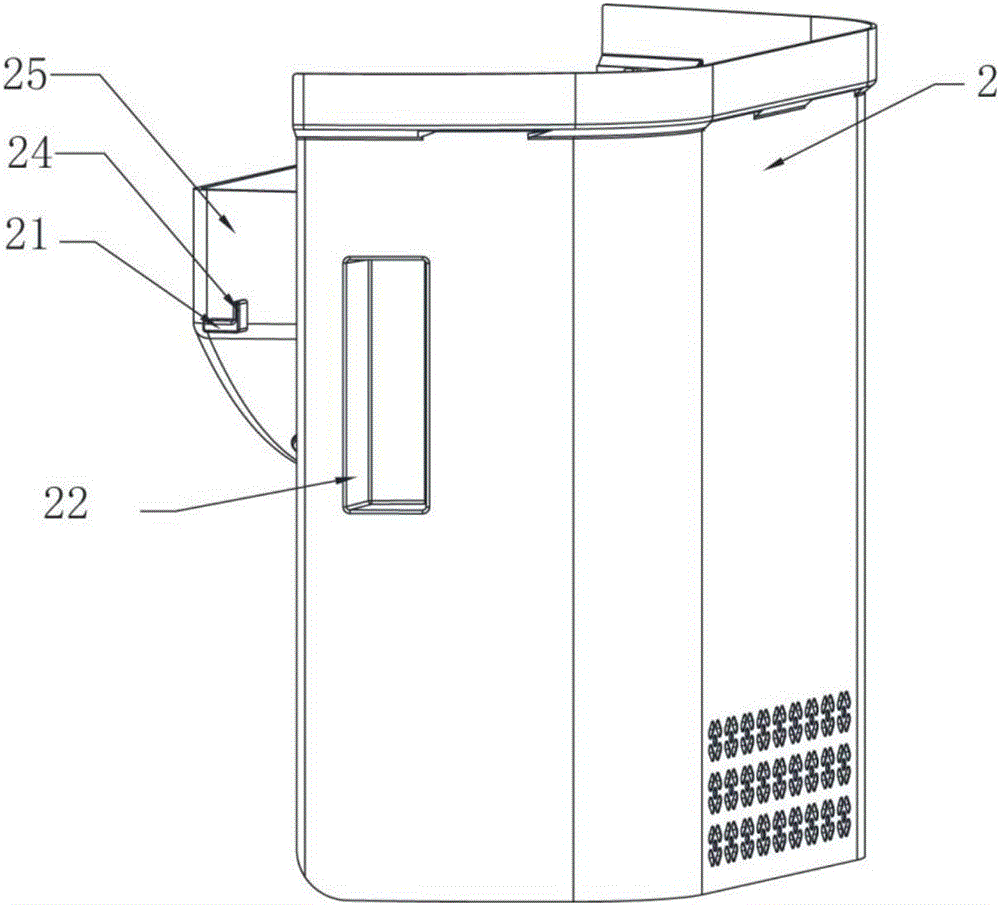

Refrigerator and ice machine assembly thereof

InactiveCN106247716AReduce crash noiseNot easy to jumpDomestic cooling apparatusLighting and heating apparatusIce storageEngineering

The invention relates to the technical field of refrigerator ice making, and provides a refrigerator and an ice maker assembly thereof. The ice machine assembly includes a base and an ice storage box, the base includes two opposite side walls, at least part of the ice storage box is movably inserted between the two side walls; at least one side wall is provided with a first The protrusion and the first limiting part and the second limiting part located on the adjacent two sides of the first protrusion, the first protrusion has elasticity; the ice storage box is provided with a second protrusion and a third protrusion, The second protrusion is movably locked between the first protrusion and the first limiting portion, and the third protrusion is movably locked between the first protrusion and the second limiting portion. The elastic limit of the first limiting part and the second limiting part by the first elastic protrusion makes it difficult for the ice storage box to jump relative to the base when it is plugged into the base, thereby reducing the risk of falling. Collision noise between the ice storage bin and the base and between the ice cubes and the ice storage bin body when freezing.

Owner:HEFEI HUALING CO LTD +2

Bailey beam construction trestle expansion joint system and construction method

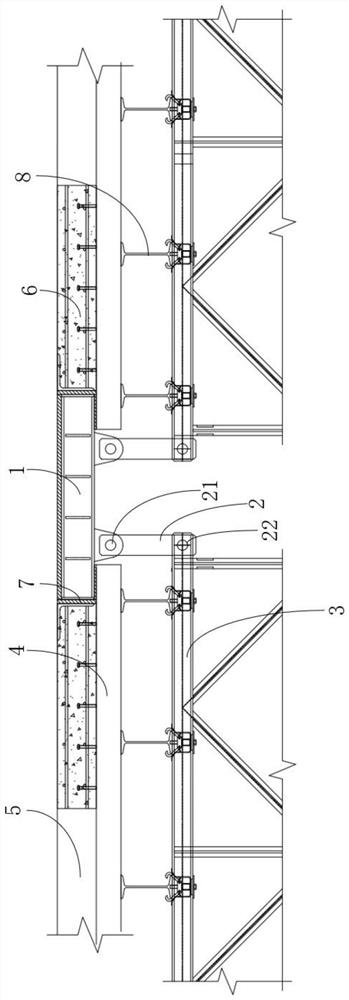

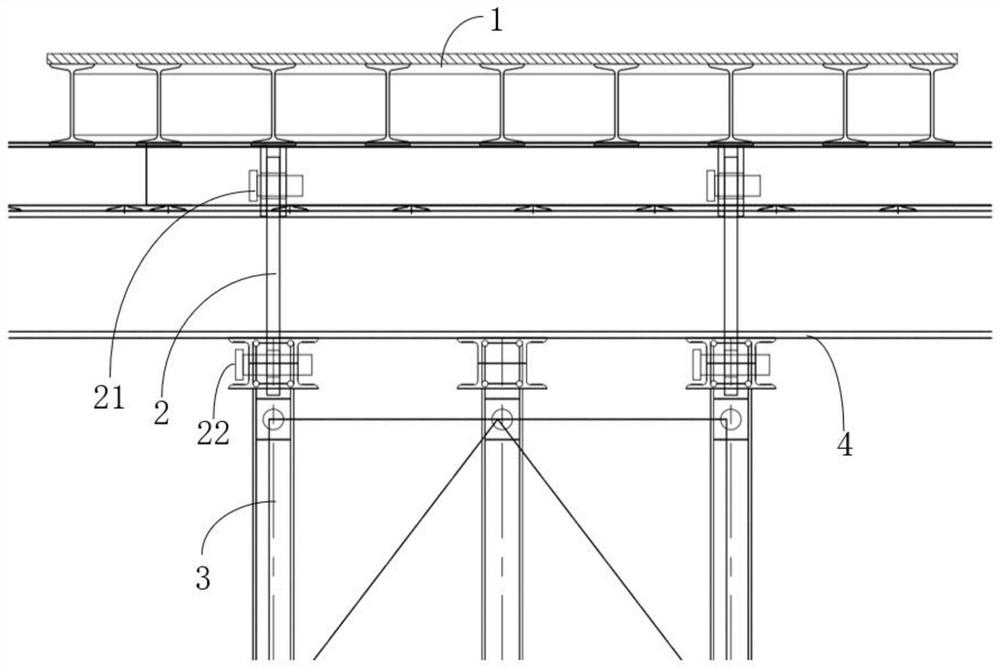

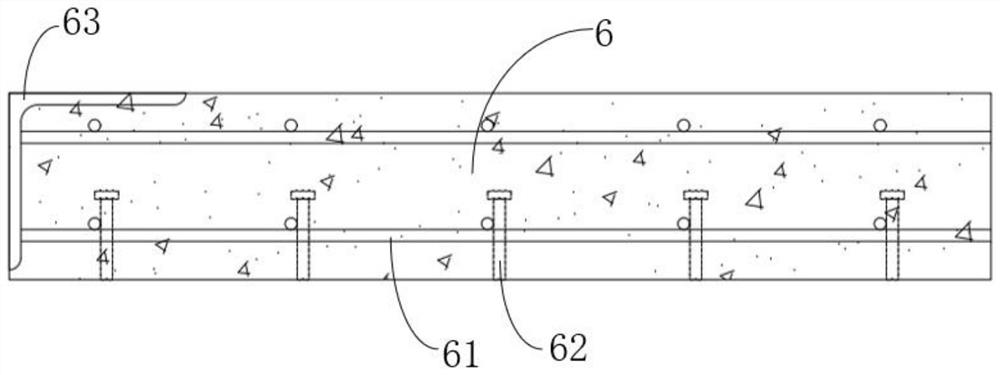

PendingCN114525726ANot easy to deform and breakAvoid breakingClimate change adaptationBridge structural detailsExpansion jointBridge deck

The invention relates to a bailey beam construction trestle expansion joint system and a construction method, and the system comprises at least two bailey beams, the two bailey beams are arranged at intervals, and a gap is formed between the two bailey beams; the two bridge deck slabs are respectively arranged on the corresponding bailey beams, and a bridge deck pavement layer is arranged on the top surface of each bridge deck slab; the cover plate is located between the two bridge deck pavement layers, and the cover plate is laid above the gap; one end parts of the two connecting rods are respectively hinged with the corresponding bailey beams, the other end parts of the two connecting rods are respectively hinged with the cover plate, and the top surface of the cover plate is flush with the top surface of the bridge deck pavement layer, so that when a vehicle passes, the vehicle is not easy to jump, and when the vehicle jumps, the cover plate is not easy to fall off. The cover plate can slightly move left and right in the horizontal direction, and the cover plate is not prone to damage or deformation, so that the structure is not prone to bumping, and the cover plate is not prone to damage or deformation.

Owner:中铁大桥局第七工程有限公司

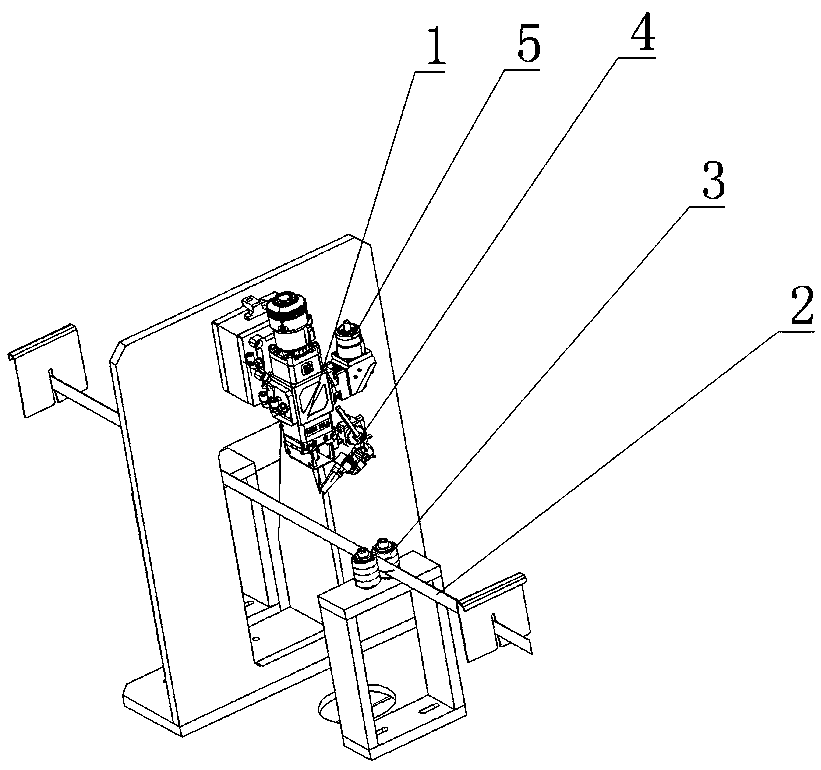

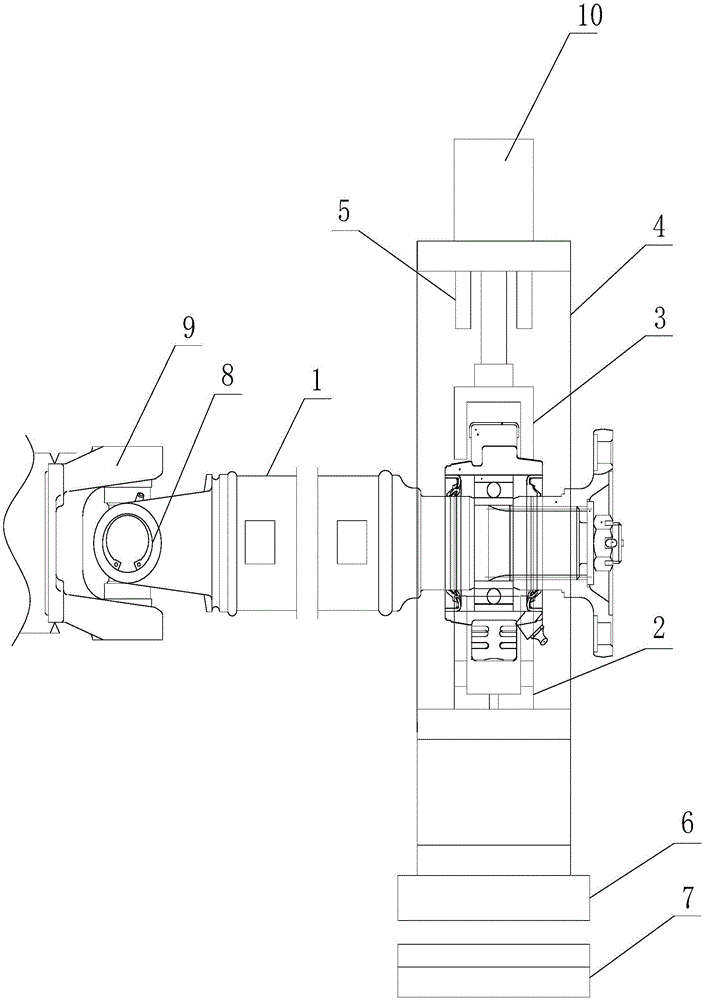

Fixing and machining device of before-car transmission shaft

InactiveCN106563961AExtended service lifeNot easy to jumpPositioning apparatusMetal-working holdersDrive shaftMachine tool

The invention discloses a fixing and machining device of a before-car transmission shaft. The fixing and machining device mainly solves the problems that when an existing before-car transmission shaft is used, transmission failures and machining error generation are easily caused by flange end faces and seam allowance bouncing, and assembly errors are easily caused by noncoincidence of axis directions of the flange end faces and the before-car transmission shaft after assembly is carried out. The fixing and machining device of the before-car transmission shaft comprises the transmission shaft, a support, at least one supporting clamp and at least one pressing clamp; one end of a rotating shaft is connected with a flange yoke, and the flange yoke is connected with a three-claw chuck of a machine tool; the transmission shaft is located between the supporting clamps and the pressing clamps; the pressing clamps are connected with a driving mechanism for controlling the pressing clamps to press or release the transmission shaft. By means of the above scheme, the aims that the transmission shaft is not likely to shake, and power transmission and part machining are not influenced are achieved, and the high practical value and promotional value are achieved.

Owner:CHONGQINGS FAR EAST TRANSMISSION SHAFT

Rapid detector for line maintenance of wire

InactiveCN109283420AImprove functionalityTo offer comfortCurrent/voltage measurementElectrical testingPower flowElectrical and Electronics engineering

The invention discloses a rapid detector for line maintenance of a wire. The detector comprises a frame, a clamp meter and first rollers, a connection rack is arranged in the outer side of the frame,movable wheels are arranged in the inner side of the connection rack, the movable wheels are connected to the connection frame rack via movable shafts respectively, the connection rack is fixedly connected to the frame, a pipe is arranged in the outer side of the frame, the bottom of the frame is connected with second support bars, the first rollers arranged in the bottom ends of the second support bars respectively, and connected to the second support bars via connecting shafts respectively, and first support bars are arranged in the top of the frame. The rapid detector is provided with the frame, the clamp meter and the frame form a detachable structure via screws, when a line of the bare wire needs current detection, the clamp meter can be disengaged from the frame by dismounting the screws, a worker can take the wire by hand, and implements current detection on the bare wire.

Owner:冯爱明

Resonant tuning fork liquid density sensor with piezoelectric actuation and piezoelectric detection

ActiveCN102353612BHigh measurement accuracyImprove reliabilitySpecific gravity measurementLiquid densityPiezoelectric actuators

The invention discloses a resonant tuning fork liquid density sensor with piezoelectric actuation and piezoelectric detection, comprising a tuning fork body, a clamped body, a piezoelectric actuator, a piezoelectric vibration pickup, and a temperature sensor, wherein, the piezoelectric actuator and the piezoelectric vibration pickup are arranged on the clamped body, the generated alternating force is transmitted to the tuning fork body by the piezoelectric actuator to let the tuning fork body produce simple harmonic vibration with intrinsic frequency itself; when immersing the tuning fork body in a liquid under test, the additional mass of the tuning fork body changes so as to let the vibration frequency of the tuning fork body change; by picking up the vibration signal with the piezoelectric vibration pickup, the detection of the vibration frequency of the tuning fork body is realized; because the vibration frequency of the tuning fork body is a monotone function of the liquid density, thus the real-time on-line detection of the liquid density is realized; and the temperature sensor is arranged on the clamped body for real-time detection of the temperature of the liquid under test, and is used for compensating the variation of the elastic modulus of the tuning fork body. According to the invention, the high precision on-line detection of densities of various liquids at different temperature can be realized.

Owner:BEIHANG UNIV

Wood barking machine for wood processing

The invention relates to the related technical field of wood processing machinery, and discloses a wood barking machine for wood processing. The wood barking machine comprises a rack, a driving motoris fixedly mounted on the surface of the rack, a barking knife is fixedly mounted on an output shaft of the driving motor, a speed change gear box located on one side of the surface of the rack is fixedly mounted on the output shaft of the driving motor, a barking auger located in an inner cavity of the rack is fixedly mounted on a speed change shaft of the speed change gear box, and a cutting knife is fixedly mounted on the side wall of the barking auger. The cutting knife is arranged on the side wall of the barking auger, and therefore in the rotating process of the barking auger, the outerbark of wood is scratched by the cutting knife through extrusion between the barking auger and the barking knife, meanwhile, the scratched bark is torn out through the barking knife, and therefore thewood is not prone to jumping through extrusion between the barking auger and the barking knife; and meanwhile, the phenomenon that wood is not barked completely due to tree filaments is avoided, andfinally the aim of efficient barking is achieved.

Owner:日照益尔居木业股份有限公司

Transmission mechanism of sheet inserting machine

The invention discloses a transmission mechanism of a sheet inserting machine. The transmission mechanism comprises an integral bottom plate, a second-stage transmission module and a third-stage transmission module, wherein the second-stage transmission module and the third-stage transmission module are sequentially arranged on the integral bottom plate, and the second-stage transmission module and the third-stage transmission module are used for providing different transmission speeds; the second-stage transmission module comprises a second-stage transmission module supporting plate; a second-stage transmission main shaft, a second-stage driven shaft, a second-stage transmission motor and a second-stage transmission belt are integrated on the second-stage transmission module supporting plate; the third-stage transmission module comprises a third-stage transmission module supporting plate, and a third-stage transmission main shaft, a third-stage driven shaft, a third-stage transmissionmotor and a third-stage transmission belt are integrated on the third-stage transmission module supporting plate; and the second-stage transmission module supporting plate and the third-stage transmission module supporting plate are detachably arranged on the integral bottom plate. The transmission mechanism of the sheet inserting machine is stable in operation, the belts are not prone to jumping, disassembly and assembly are convenient, and later maintenance is facilitated.

Owner:晶海洋半导体材料(东海)有限公司

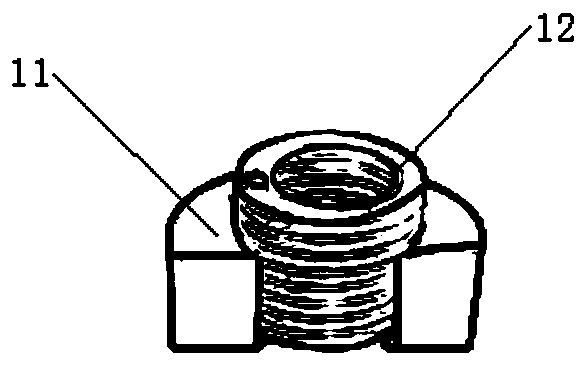

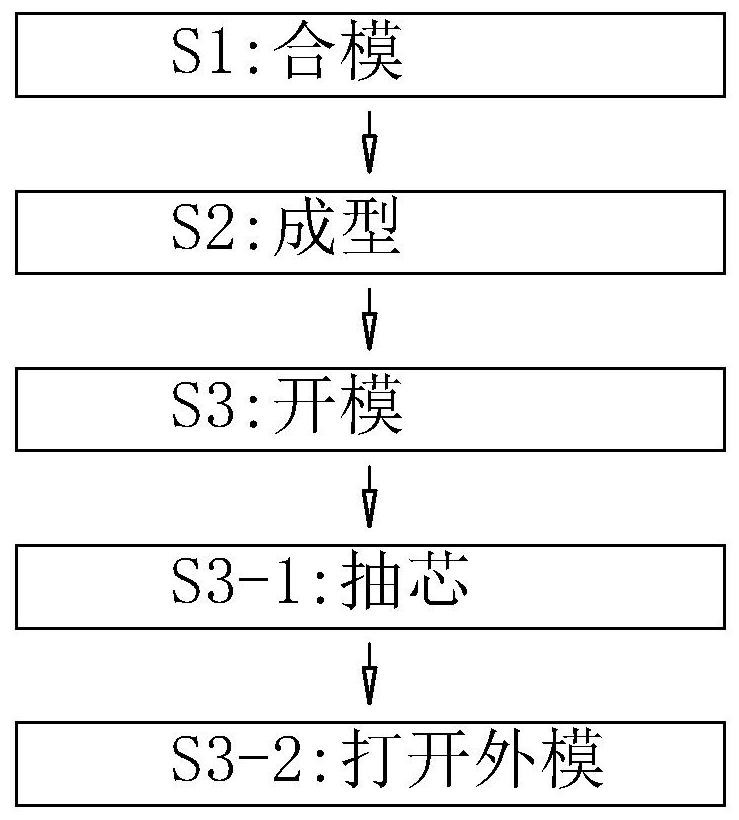

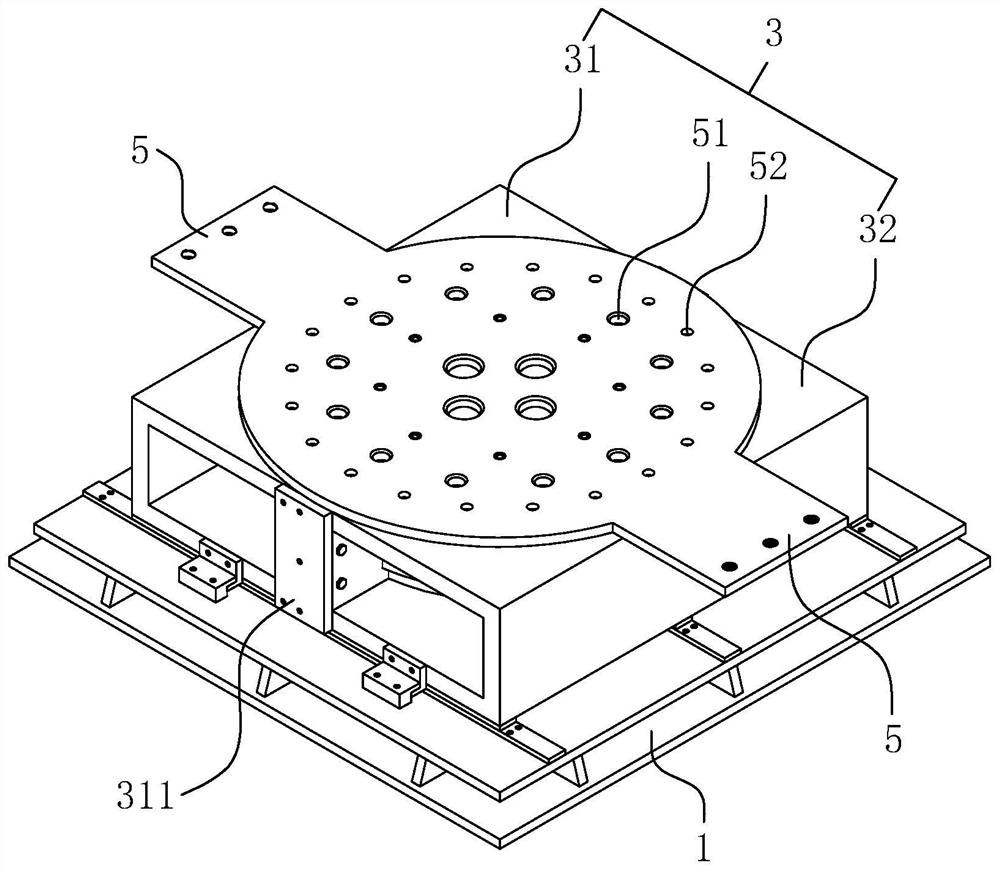

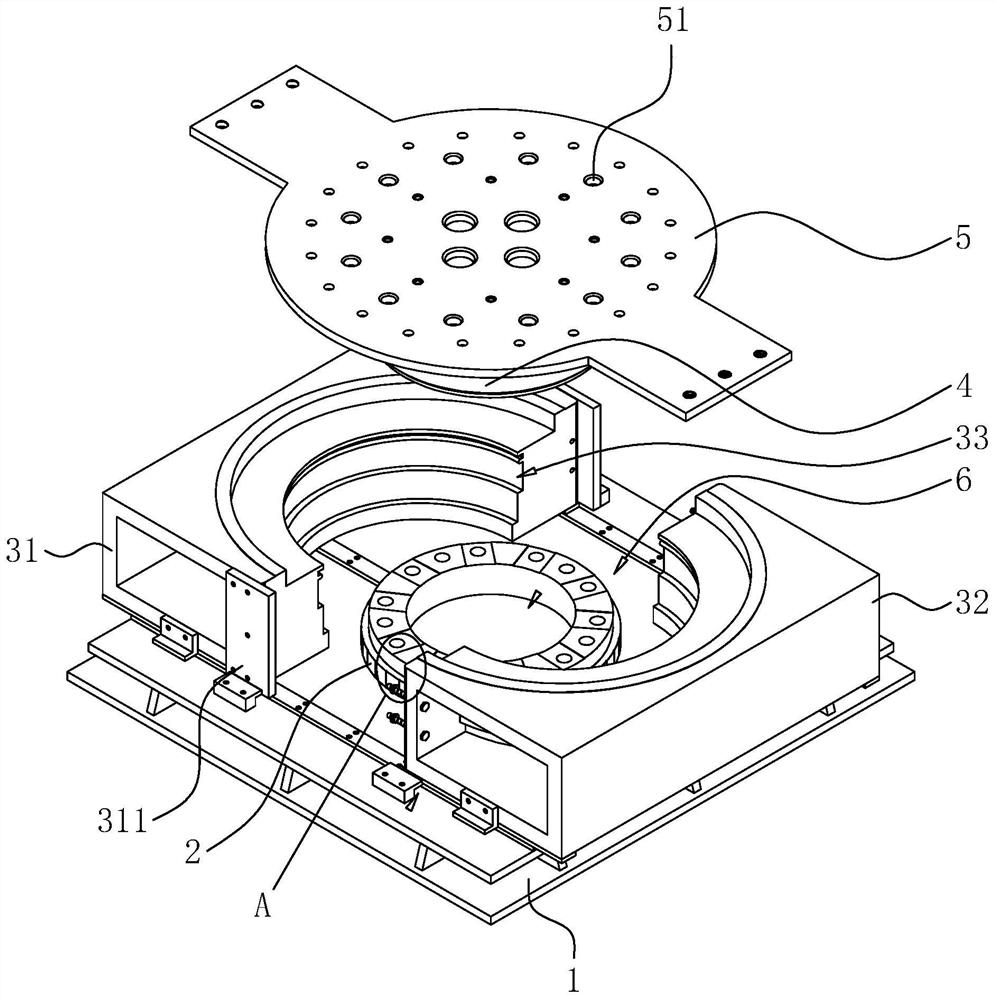

Die opening method of core shooter

The invention relates to a die opening method of a core shooter, and relates to the technical field of spheroidal graphite cast iron pipe core making. The die opening method of the core shooter comprises the steps of S1, carrying out die closing; S2, forming; and S3, carrying out die opening, wherein the step S3 further comprises the steps of S3-1, carrying out core-pulling: moving an upper die away, and pulling a core die out from a sand core along the axial direction of a lower die; and S3-2, opening an outer die: separating the outer die from the sand core. According to the die opening method of the core shooter provided by the invention, after core sand produces strength and forms the sand core, the upper die is firstly moved away, then the core die is pulled out from the sand core along the axial direction of the lower die, the peripheral face of the sand core is protected by the outer die at the moment, the sand core is not easy to damage when the core die is pulled out from thesand core, then the outer die is opened, and the sand core is not needed to be moved in the die opening process, so that the probability of sand core damage is reduced, the sand core precision is improved, and the precision of a female end of a spheroidal graphite cast iron pipe is further improved.

Owner:济南柳玉鑫机械设备有限公司

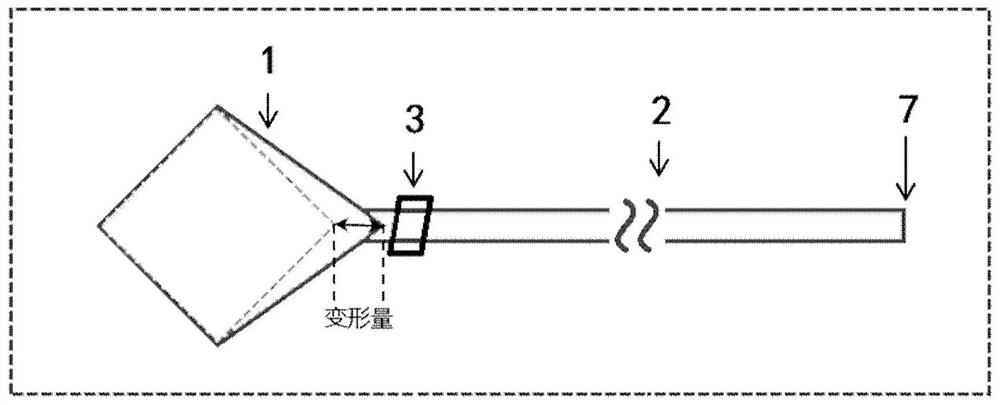

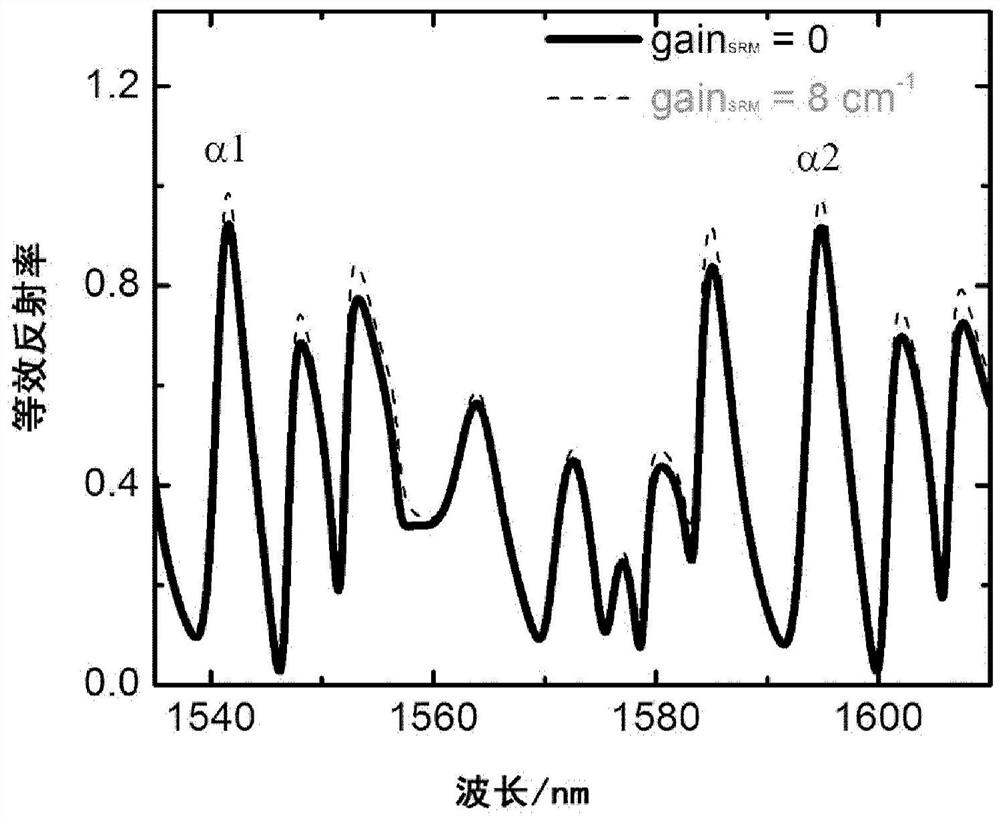

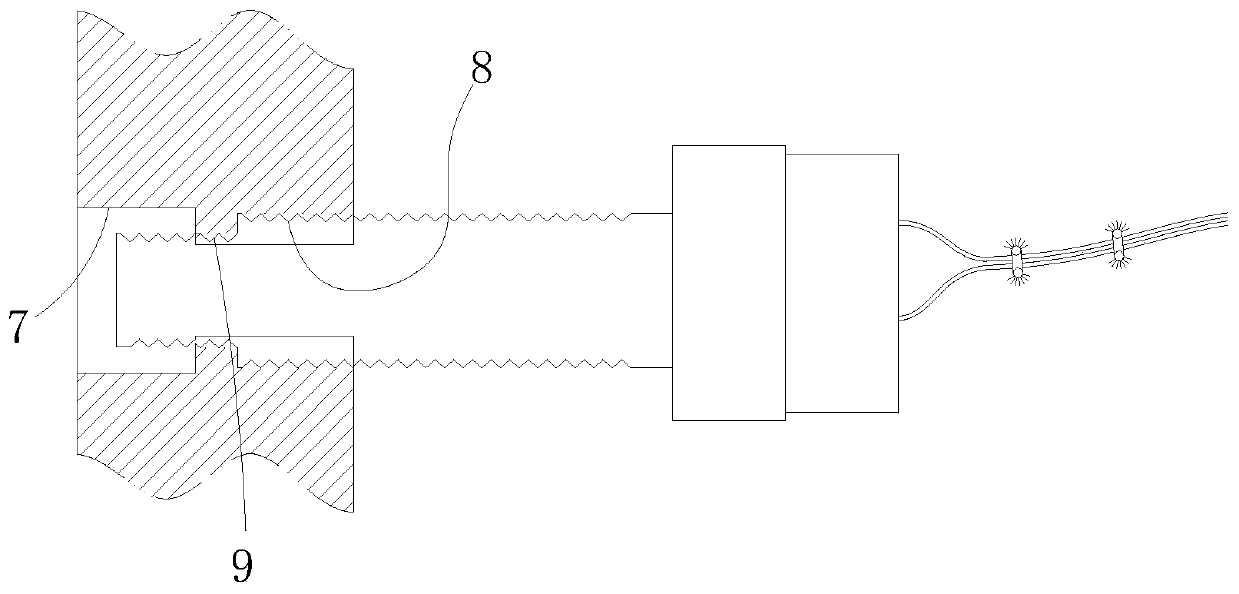

Tunable coupled cavity semiconductor laser

ActiveCN109638645BIncrease output powerLarge wavelength tuning rangeLaser optical resonator constructionLight reflectionEngineering

A tunable coupled cavity semiconductor laser, comprising: an FP cavity; a modified whispering gallery microcavity connected to the first end of the FP cavity as a reflective end face of the FP cavity, the modified whispering gallery microcavity is formed with the FP cavity A coupling cavity structure; and an electrical isolation groove, which is arranged between the FP cavity and the modified whispering gallery microcavity; wherein, light can enter the modified whispering gallery microcavity from the FP cavity, and pass through several times in the modified whispering gallery microcavity. After the secondary reflection, the light of a specific wavelength is reflected back into the FP cavity. The coupled mode of the tunable coupled cavity laser accounts for a high proportion of the fundamental mode of the FP intracavity mode, thereby reducing the loss of light in the FP cavity, and at the same time making the coupled cavity lasing mode more stable and the output power higher; at the same time , the equivalent reflectivity spectrum of the modified whispering gallery microcavity is insensitive to the gain change in the cavity, and the lasing mode is not easy to jump to the adjacent longitudinal mode, so that the tunable coupled cavity laser can obtain a large wavelength tuning range.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Boiler feedwater sequential control logic optimization system and control method

PendingCN109799846ANot easy to jumpEasy to check on-site management and remote monitoring managementLevel controlLogic optimizationEngineering

The invention discloses a boiler feedwater sequential control logic optimization system and a control method and belongs to the technical field of removal of measured value jumping of boiler feedwaterlevel meters. By the system, the measured value about water level acquired by the boiler feedwater level meter bodies is not easy to jump, and currently actual water level information of the boiler is acquired according to information of the water line scales where lifting water in water level display tubes reaches and is checked when water levels of three points in the boiler are at the equal altitude. The system comprises three boiler water level meter bodies, and further comprises a light shield and three light guide posts; the boiler water level meter body comprises the water level display tubes containing the lifting water; the water level display tubes are provided with water line scales; the light shield is hermetically closely fixedly connected to three water level display tubes through three shield bottom holes at the bottom surface of the light shield.

Owner:CHINA ENERGY ENG EASTERN ELECTRIC POWER TESTING RES INST CO LTD

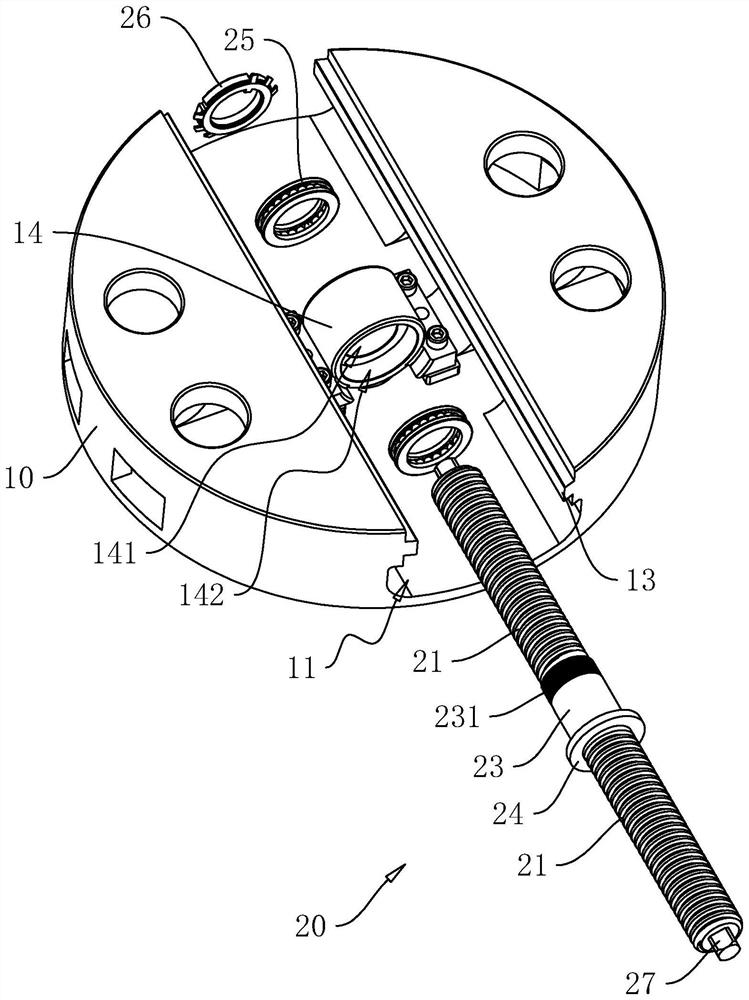

Fixture for machining submersible pump shell blank

The invention relates to a clamp for machining a submersible pump shell blank, and relates to the field of clamps. The clamp comprises a chuck body provided with a sliding groove formed in the radial direction of the chuck body; the two-way lead screw is rotationally connected into the sliding groove, the two-way lead screw is fixed relative to the chuck body in the axial direction of the two-way lead screw, and the two-way lead screw is provided with two transmission thread parts with opposite rotating directions; the sliding blocks are connected into the sliding grooves in a sliding mode in the axial direction of the two-way lead screw, and the two sliding blocks are in threaded connection with the two transmission threaded parts of the two-way lead screw correspondingly; the supporting plate is arranged on the sliding block and slides in the axial direction of the bidirectional lead screw along with the sliding block. The clamping jaws are arranged on the supporting plate, the two clamping jaws are oppositely arranged, the supporting plate provides a supporting area for the clamping jaws, the supporting area is located in the middle of the clamping jaws, each clamping jaw is provided with two sets of clamping points arranged at intervals in the axial direction of the chuck body, the supporting area is located between the two sets of clamping points, and each set of clamping points comprises two clamping points; and each group of clamping points can swing relative to the supporting area. The blank clamping device has the effect of reliably clamping the blank.

Owner:慈溪汇丽机电股份有限公司

A temperature-measuring resistor that is not prone to temperature jumps

ActiveCN109141666BEasy to shapePrevent twistingThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceAviation

The invention discloses a temperature measuring resistor with low possibility of temperature value jump. The temperature measuring resistor comprises a temperature measurement probe, the circumferenceof the front end of the temperature measurement probe is provided with forward threads, the circumference of the back end of the temperature measurement probe is provided with counter threads whose diameter is greater than that of the forward threads, an annular groove is arranged between the forward threads and the counter threads, the pitch of the forward threads equals that of the counter threads, the width of the annular groove is greater than the length of the forward threads, the temperature measurement probe is connected with a signal cable via a cable connector, the signal cable is composed of two signal lines, and the cable connector comprises an aviation plug connected with the temperature measurement probe and an aviation socket connected with the signal cable. The temperaturemeasuring resistor has the advantages that the detected temperature value tends not to jump, shutdown due to misoperation of a hydropower station set tends not to occur, a lot of detection and maintenance can be omitted, and the economic benefit of a hydropower station is increased.

Owner:STATE GRID CORP OF CHINA +2

Forming mechanism of blister packaging machine

The invention discloses a forming mechanism of a blister packaging machine, which comprises an upper forming die and a lower forming die. The lower forming die is installed on a forming frame, and is characterized in that a rotatable transmission shaft , the crankshaft is arranged on the transmission shaft, and the eccentric wheel installed on the transmission shaft, the eccentric wheel is in contact with the roller fixed on the frame of the forming mechanism of the blister packaging machine, and the crankshaft passes through the shaft sleeve It is connected with the mobile frame, and the mobile frame is connected with the bag box, and the bag box is composed of a fixed upper box body and a slidable lower box body, and an air bag is arranged in the bag box, and the lower box body and the upper box body Mold connection. The structure of the present invention utilizes the structure of the crankshaft and the eccentric wheel to make the state of the packaging mold stable and not easy to jump when the mold is opened and closed, and the structure of the airbag can be used to form the blister stably, and its reliability is high , ideal for blister molding.

Owner:RUIAN HUAPU MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com