Tile cutting device for urban construction

A cutting device and ceramic tile technology, applied in work accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of easy hands, reduced work efficiency, low safety factor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

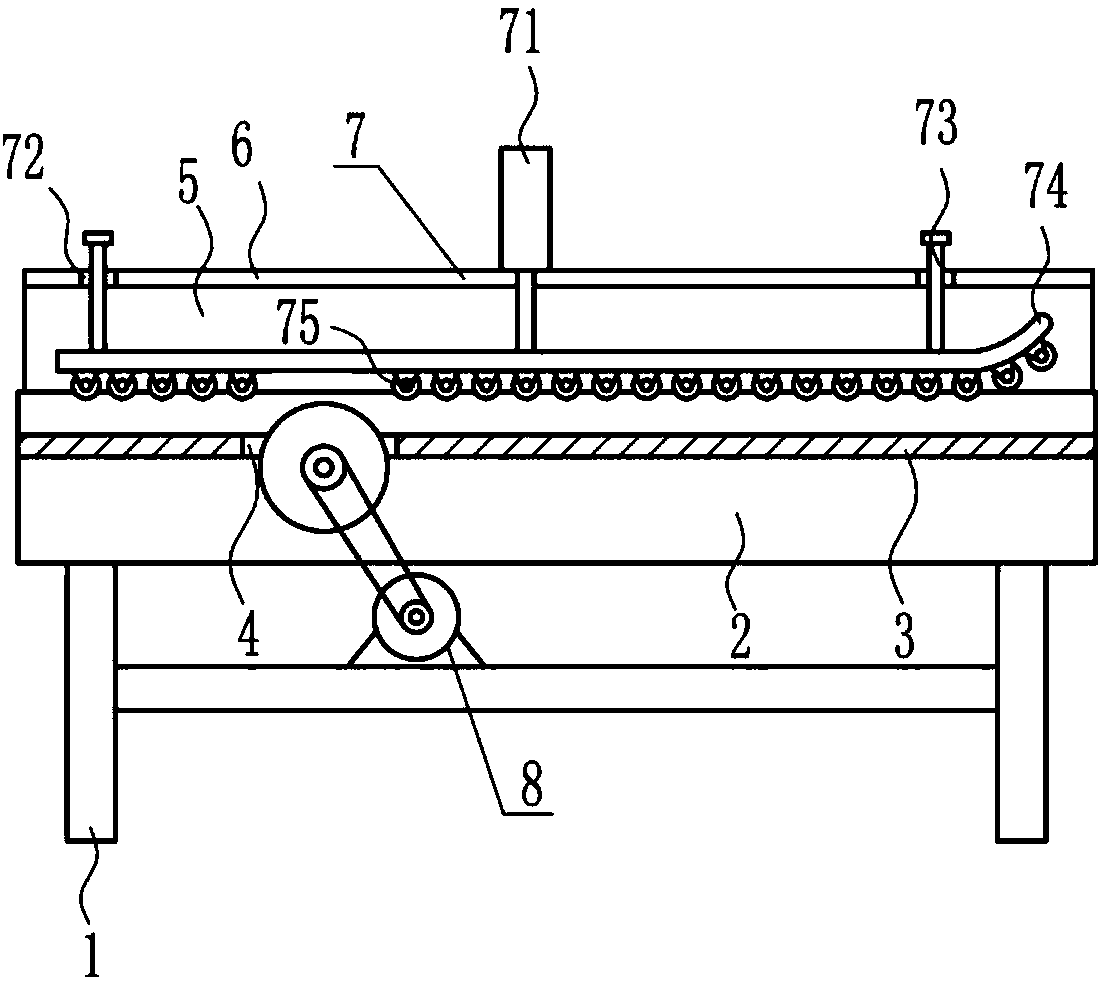

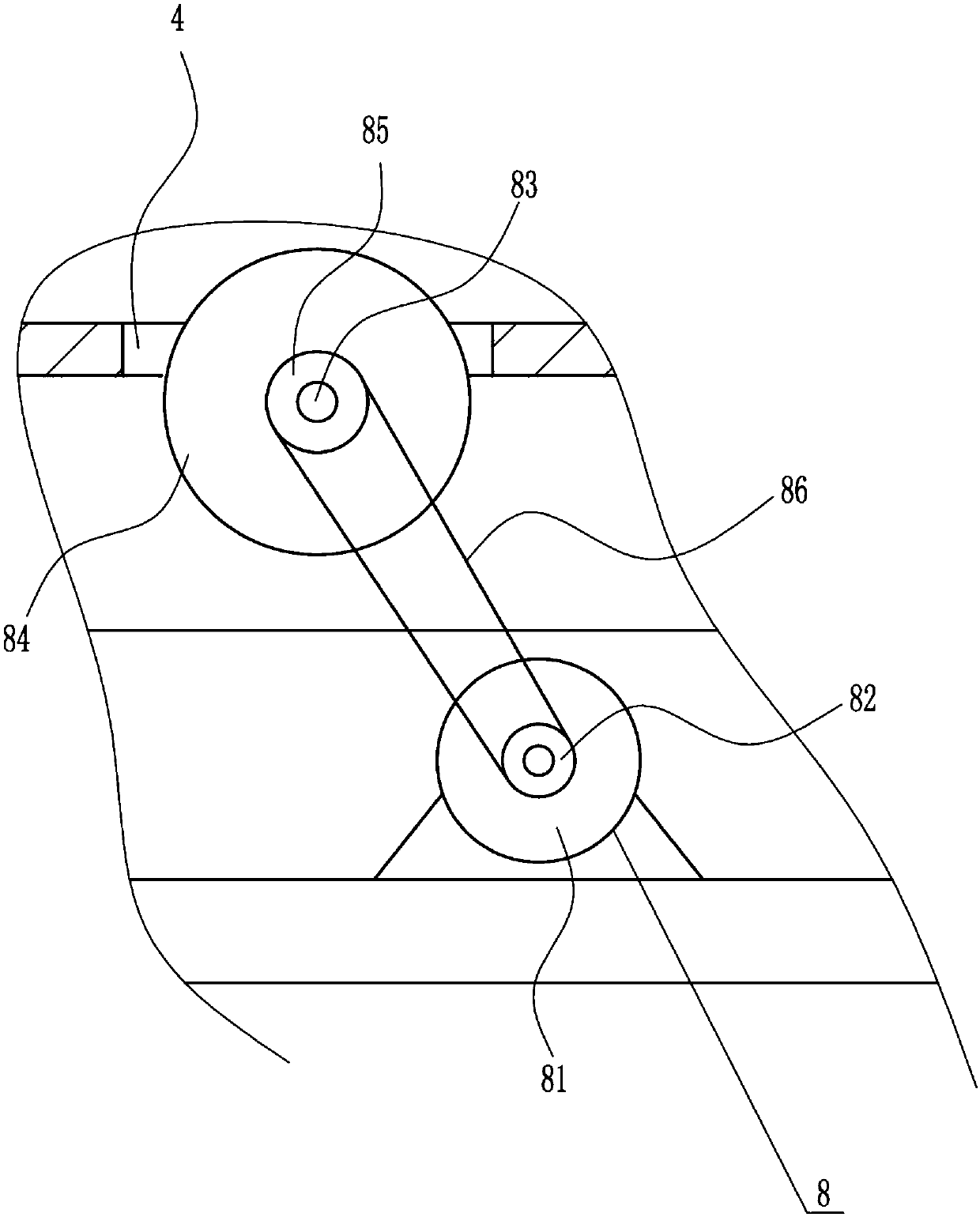

[0036] A tile cutting device for urban construction, such as Figure 1-8 As shown, it includes a frame 1, a cutting table 2, a placement plate 3, a rear side plate 5, a top plate 6, a pressing device 7 and a cutting device 8, the top of the frame 1 is provided with a cutting table 2, and the middle of the cutting table 2 A placement plate 3 is arranged horizontally, and a through groove 4 is opened on the inner side of the left position of the placement plate 3. A rear side plate 5 is provided on the top rear side of the cutting table 2, and a top plate 6 is horizontally connected to the front side of the top of the rear side plate 5. The top plate 6 A pressing device 7 is arranged on the top, and a cutting device 8 is arranged on the left side of the frame 1 and the cutting table 2 .

Embodiment 2

[0038] A tile cutting device for urban construction, such as Figure 1-8As shown, it includes a frame 1, a cutting table 2, a placement plate 3, a rear side plate 5, a top plate 6, a pressing device 7 and a cutting device 8, the top of the frame 1 is provided with a cutting table 2, and the middle of the cutting table 2 A placement plate 3 is arranged horizontally, and a through groove 4 is opened on the inner side of the left position of the placement plate 3. A rear side plate 5 is provided on the top rear side of the cutting table 2, and a top plate 6 is horizontally connected to the front side of the top of the rear side plate 5. The top plate 6 A pressing device 7 is arranged on the top, and a cutting device 8 is arranged on the left side of the frame 1 and the cutting table 2 .

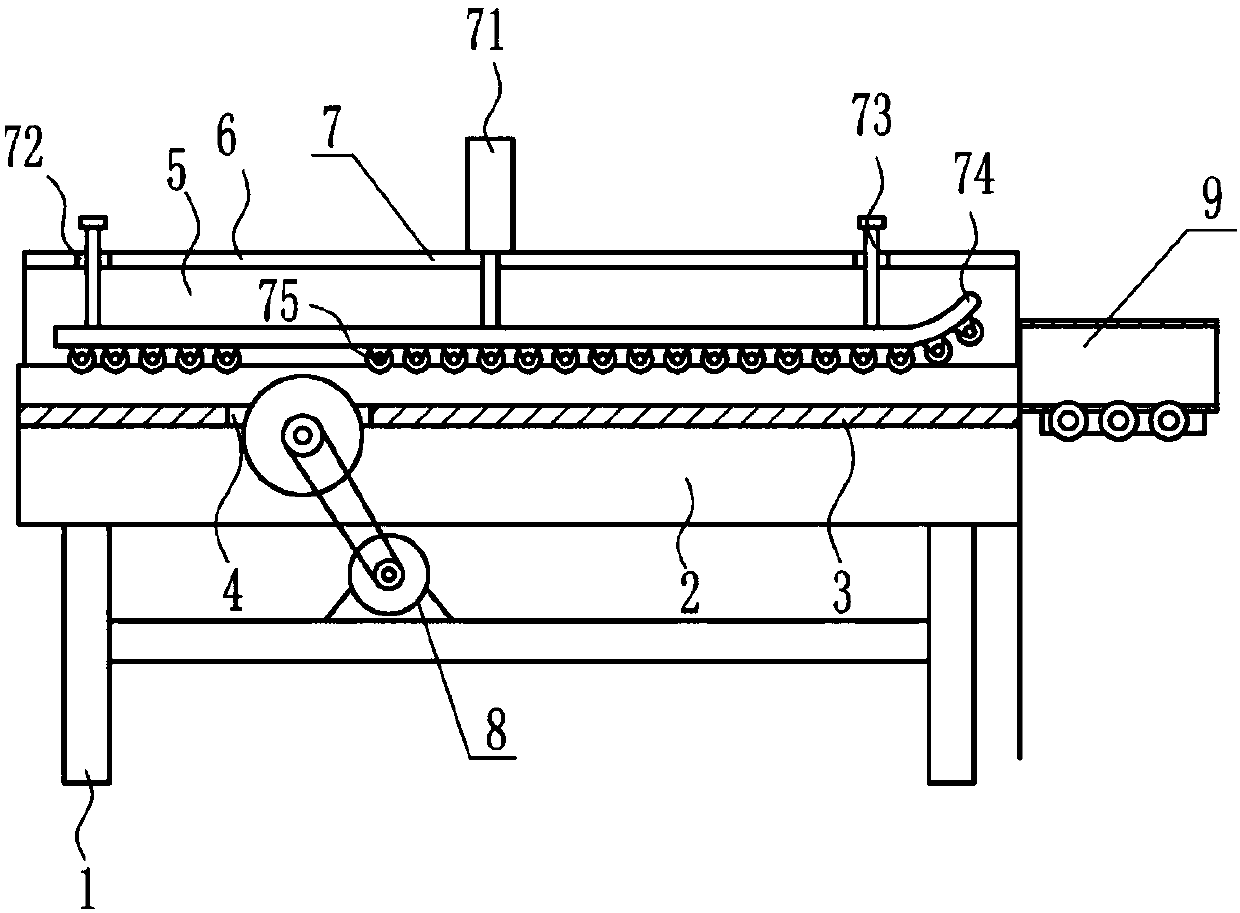

[0039] The pressing device 7 includes a first cylinder 71, a guide rod 73, a pressing plate 74 and a pressing wheel 75. The top of the top plate 6 is provided with a first cylinder 71, and the l...

Embodiment 3

[0041] A tile cutting device for urban construction, such as Figure 1-8 As shown, it includes a frame 1, a cutting table 2, a placement plate 3, a rear side plate 5, a top plate 6, a pressing device 7 and a cutting device 8, the top of the frame 1 is provided with a cutting table 2, and the middle of the cutting table 2 A placement plate 3 is arranged horizontally, and a through groove 4 is opened on the inner side of the left position of the placement plate 3. A rear side plate 5 is provided on the top rear side of the cutting table 2, and a top plate 6 is horizontally connected to the front side of the top of the rear side plate 5. The top plate 6 A pressing device 7 is arranged on the top, and a cutting device 8 is arranged on the left side of the frame 1 and the cutting table 2 .

[0042] The pressing device 7 includes a first cylinder 71, a guide rod 73, a pressing plate 74 and a pressing wheel 75. The top of the top plate 6 is provided with a first cylinder 71, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com