A temperature-measuring resistor that is not prone to temperature jumps

A technology for measuring temperature resistance and temperature value, which is applied to thermometers, thermometers using directly heat-sensitive electric/magnetic elements, and measuring heat, etc. It can solve problems such as poor contact, signal line stealing electricity, and signal line copper core exposure. , to achieve the effects of reducing inspection and maintenance workers, avoiding accelerated aging, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

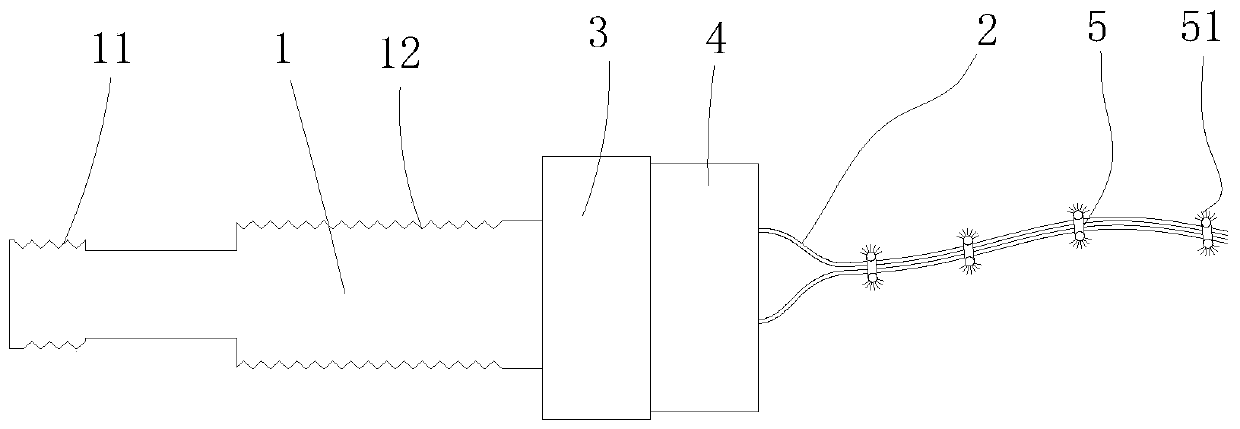

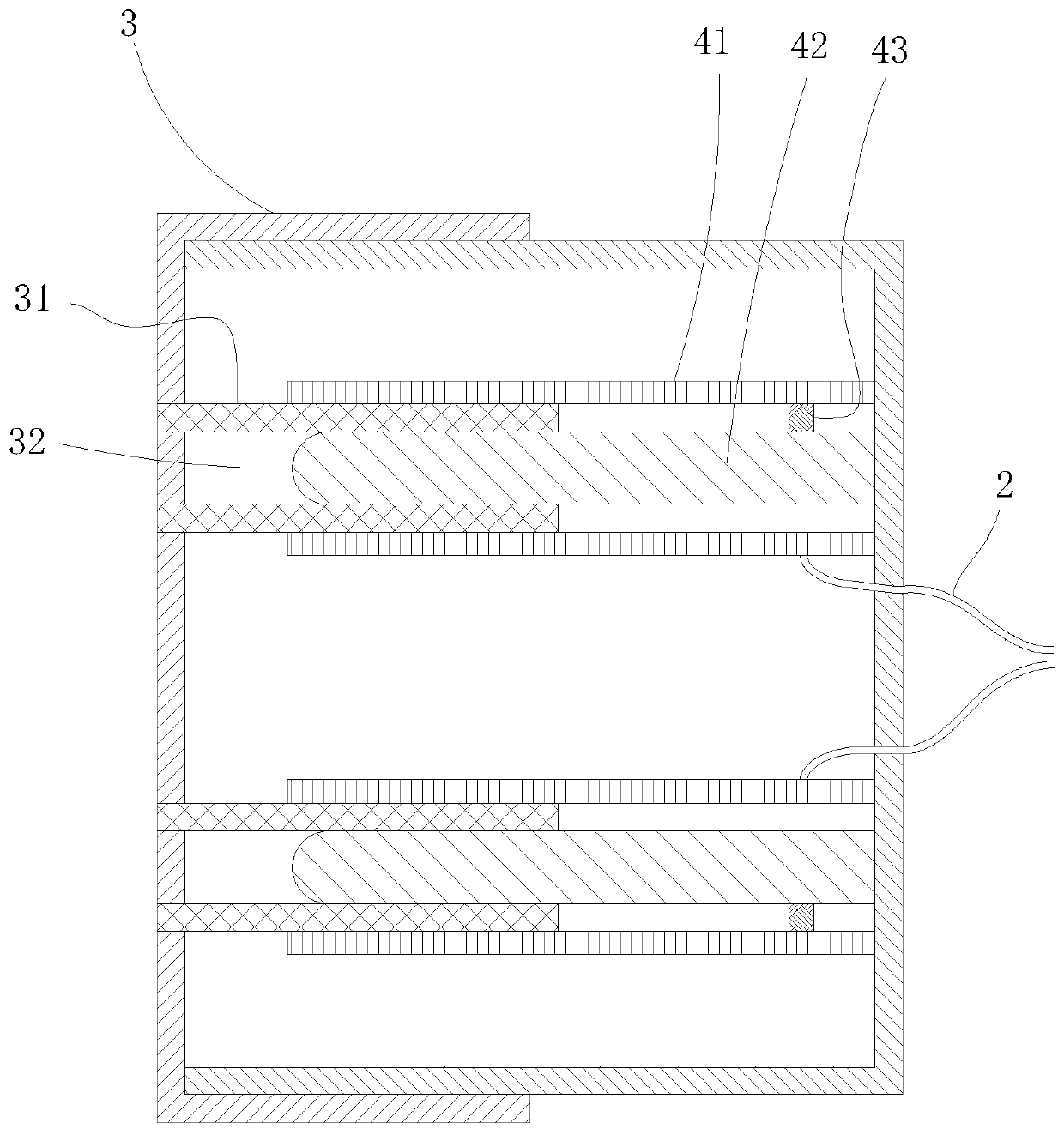

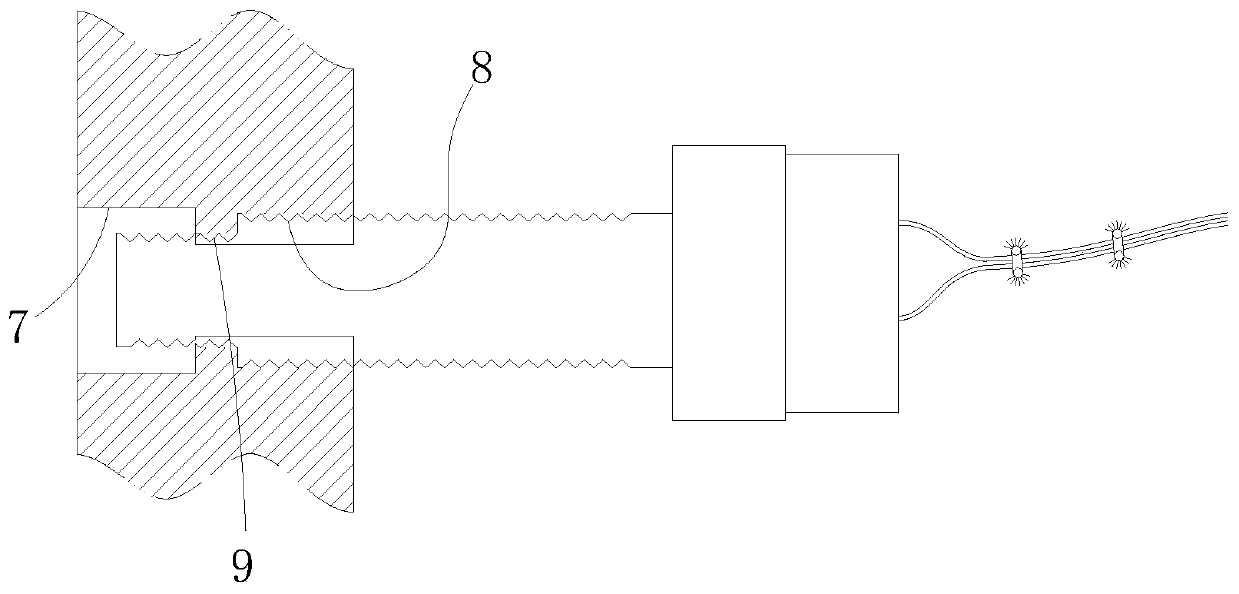

[0021] Example. A temperature measuring resistor that is not prone to temperature jumps, such as figure 1 As shown, including the temperature measuring probe 1, the front end of the temperature measuring probe 1 is provided with a positive screw thread 11 on the peripheral surface, and the peripheral surface of the temperature measuring probe 1 rear end is provided with a reverse screw thread 12 whose thread diameter is larger than the forward screw thread 11. An annular groove 13 is provided between the spiral thread 11 and the reverse spiral thread 12, the pitch of the forward spiral thread 11 is equal to that of the reverse spiral thread 12, the width of the annular groove 13 is greater than the length of the forward spiral thread 11, and the temperature measuring probe 1 It is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com