Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "No wrinkles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expendable pattern casting (EPC) molding shell paint for casting steel and preparation method thereof

InactiveCN102407275AHigh strengthImprove breathabilityFoundry mouldsFoundry coresFiberPolyvinyl alcohol

The invention relates to an expendable pattern casting (EPC) molding shell paint for casting steel, and the EPC molding shell paint comprises surface a layer fireproof paint and a back layer reinforcing paint, wherein the surface layer fireproof paint comprises the following components in parts by weight: 80-90 parts of high-chromium alundum powder, 10-20 parts of calcined kaolinite, 6-8 parts ofcalcium rectorite powder, 1-3 parts of sodium tripolyphosphate, 3-5 parts of polyvinyl formal solution, 0.3-0.5 part of ethoxylated alkyl sodium sulfate, 0.6-1.0 part of polyether type modified polydimethylsiloxane and 60-75 parts of water; and the back layer reinforcing paint comprises the following components in parts by weight: 75-85 parts of coal gangue sand, 15-25 parts of kaolinite, 3-6 parts of feldspar powder, 8-13 parts of calcium rectorite powder, 8-10 parts of sodium tripolyphosphate, 1.5-2.0 parts of wood fiber and 30-45 parts of water. A molding shell manufactured by the surface layer fireproof paint and the back layer reinforcing paint has the characteristics of high strength and refractoriness, good air permeability and the like.

Owner:HUBEI UNIV OF TECH

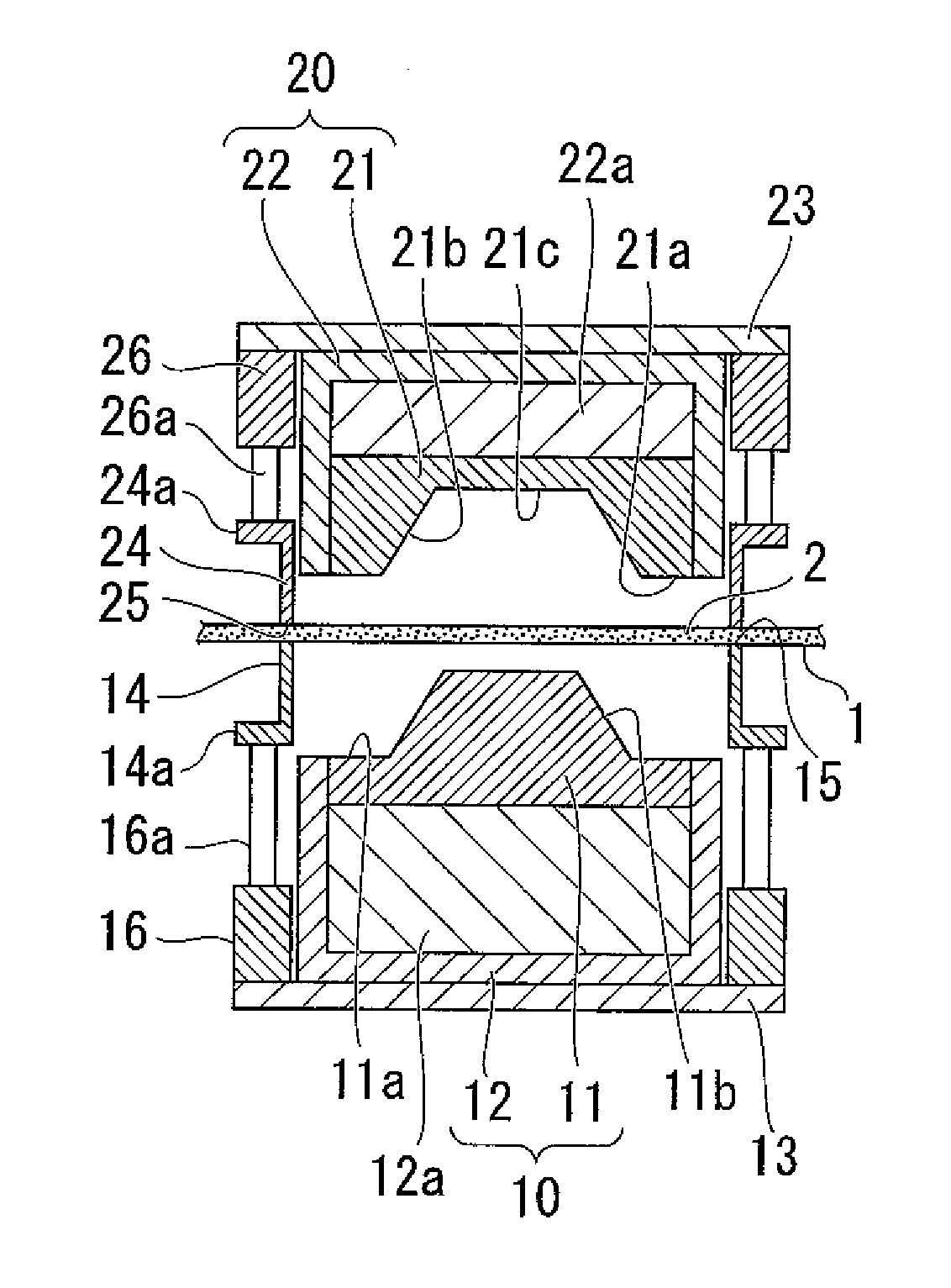

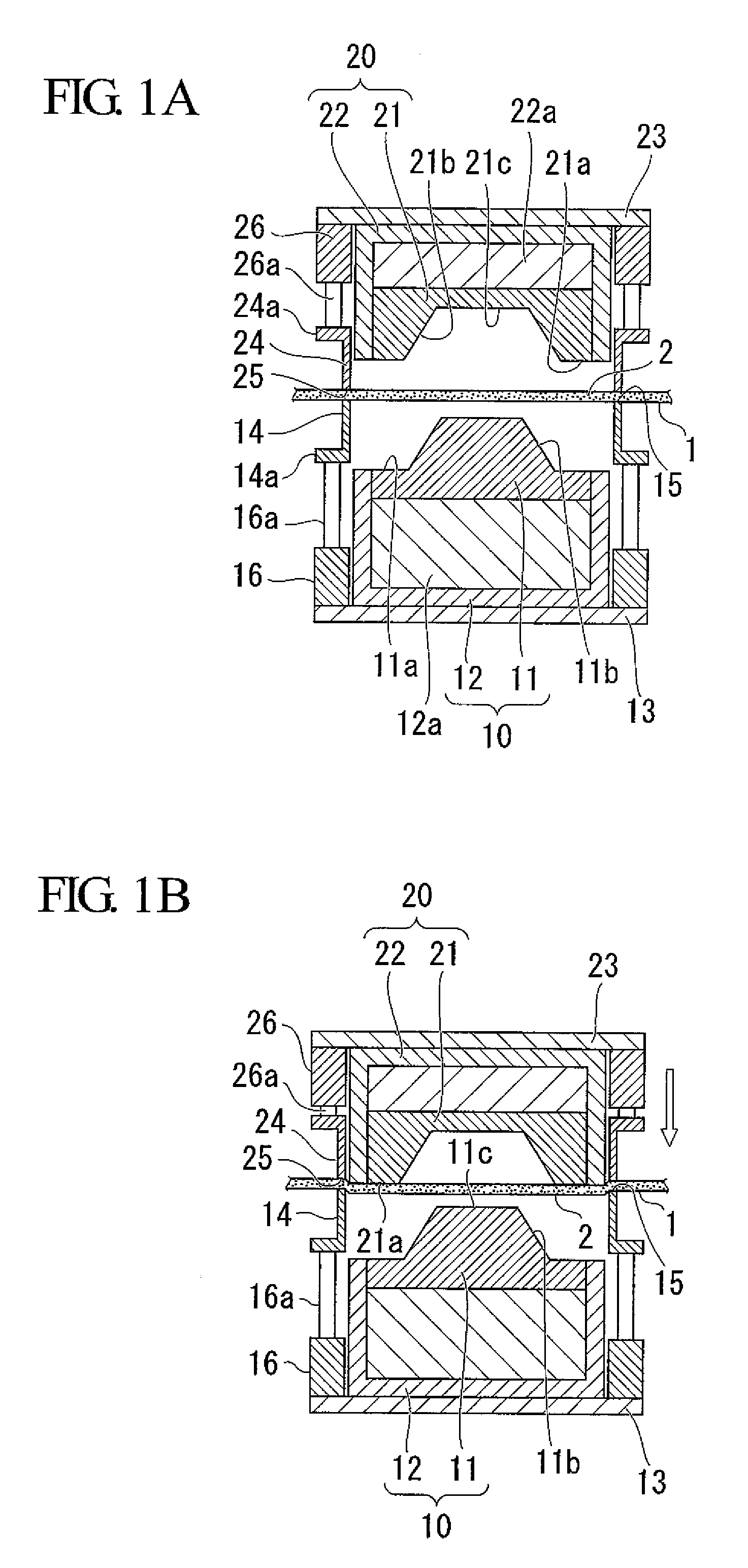

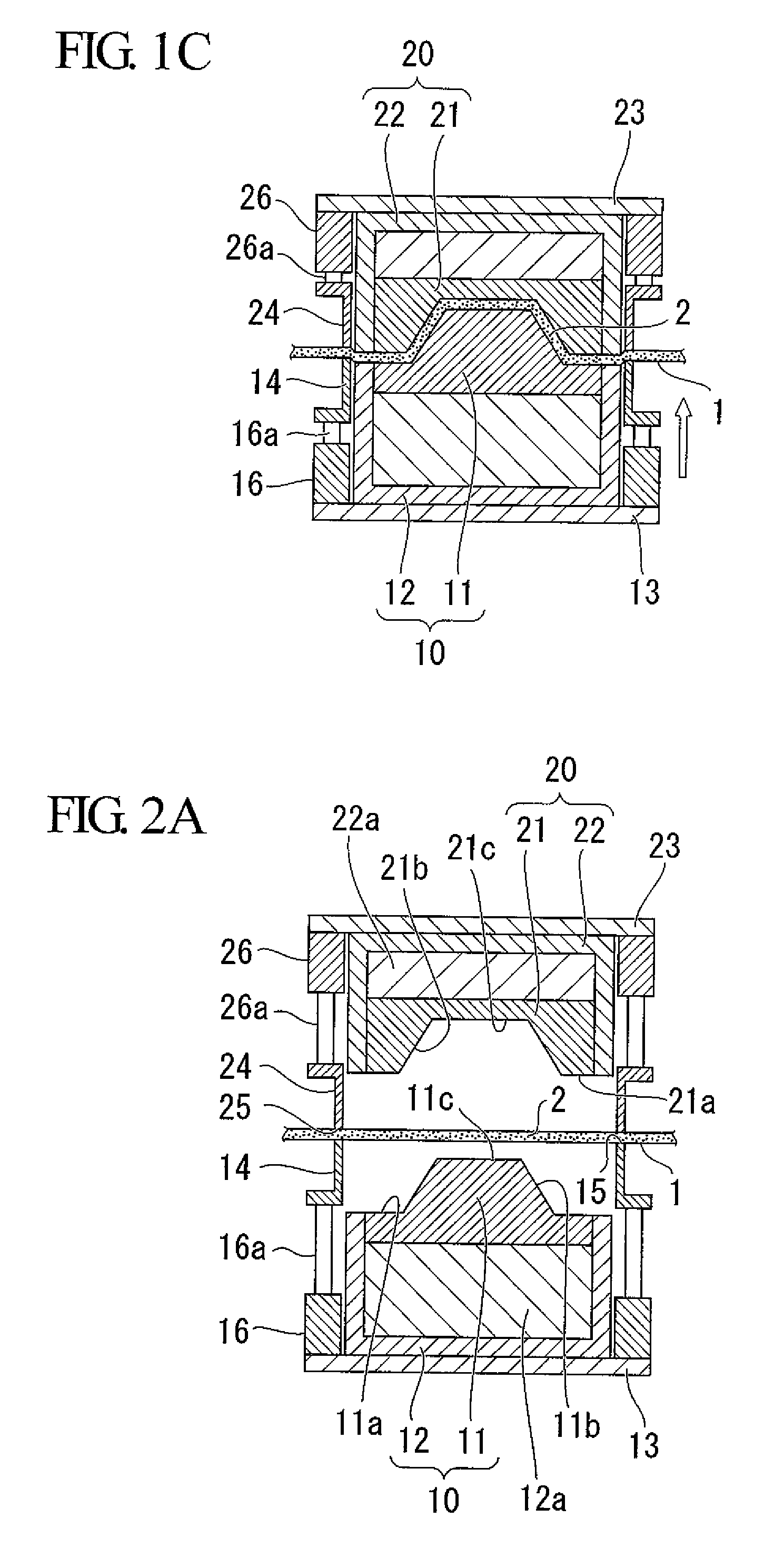

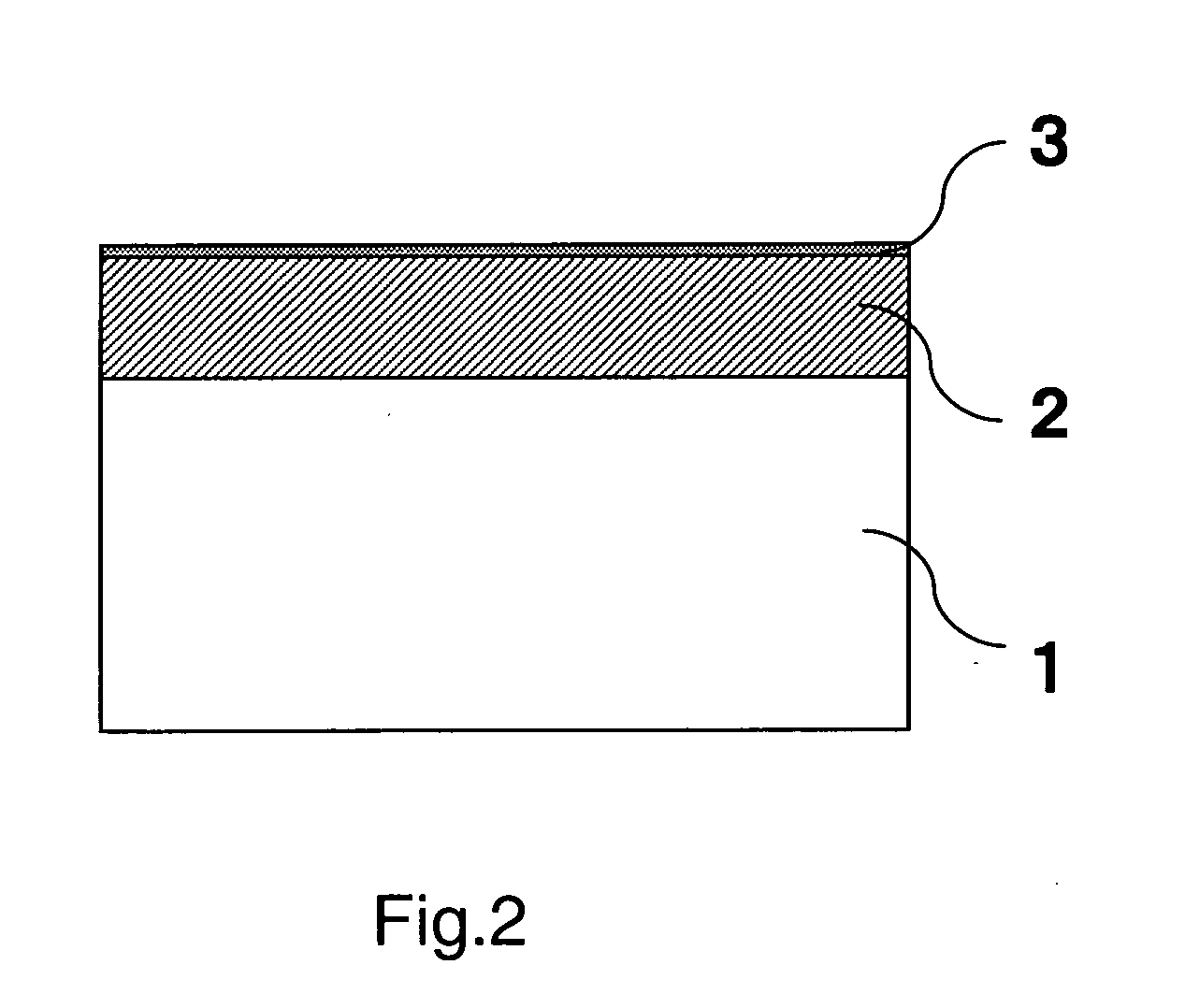

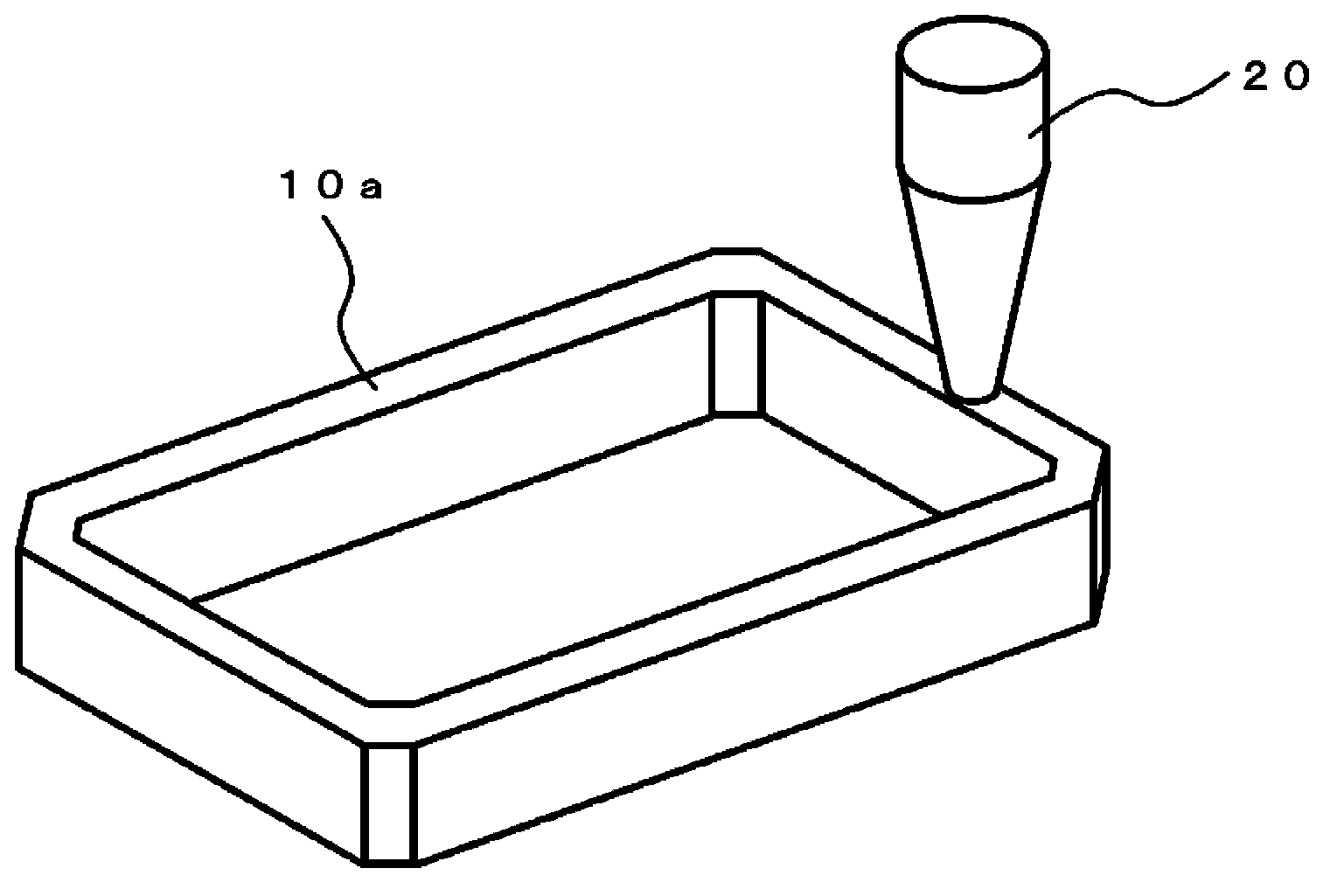

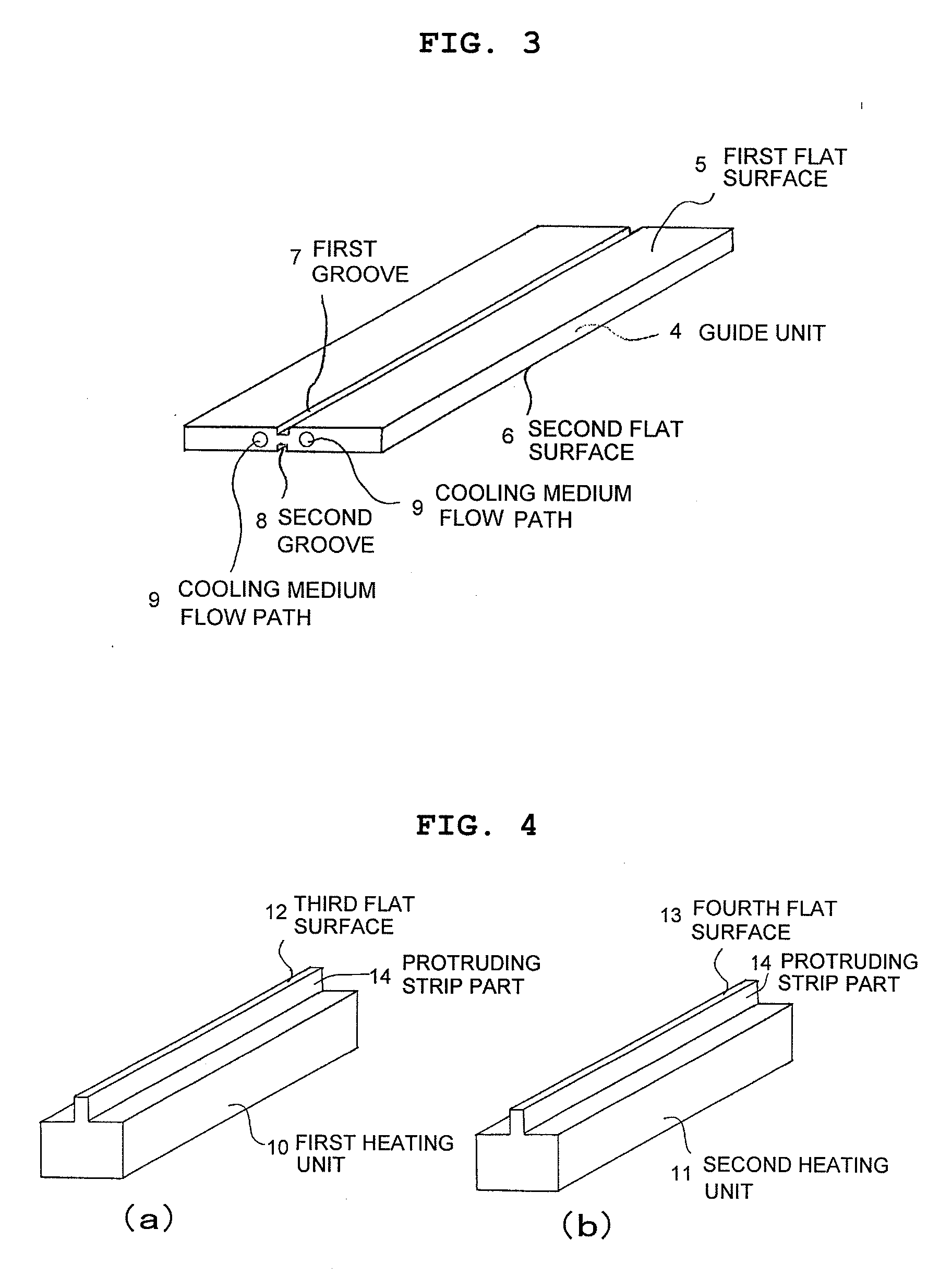

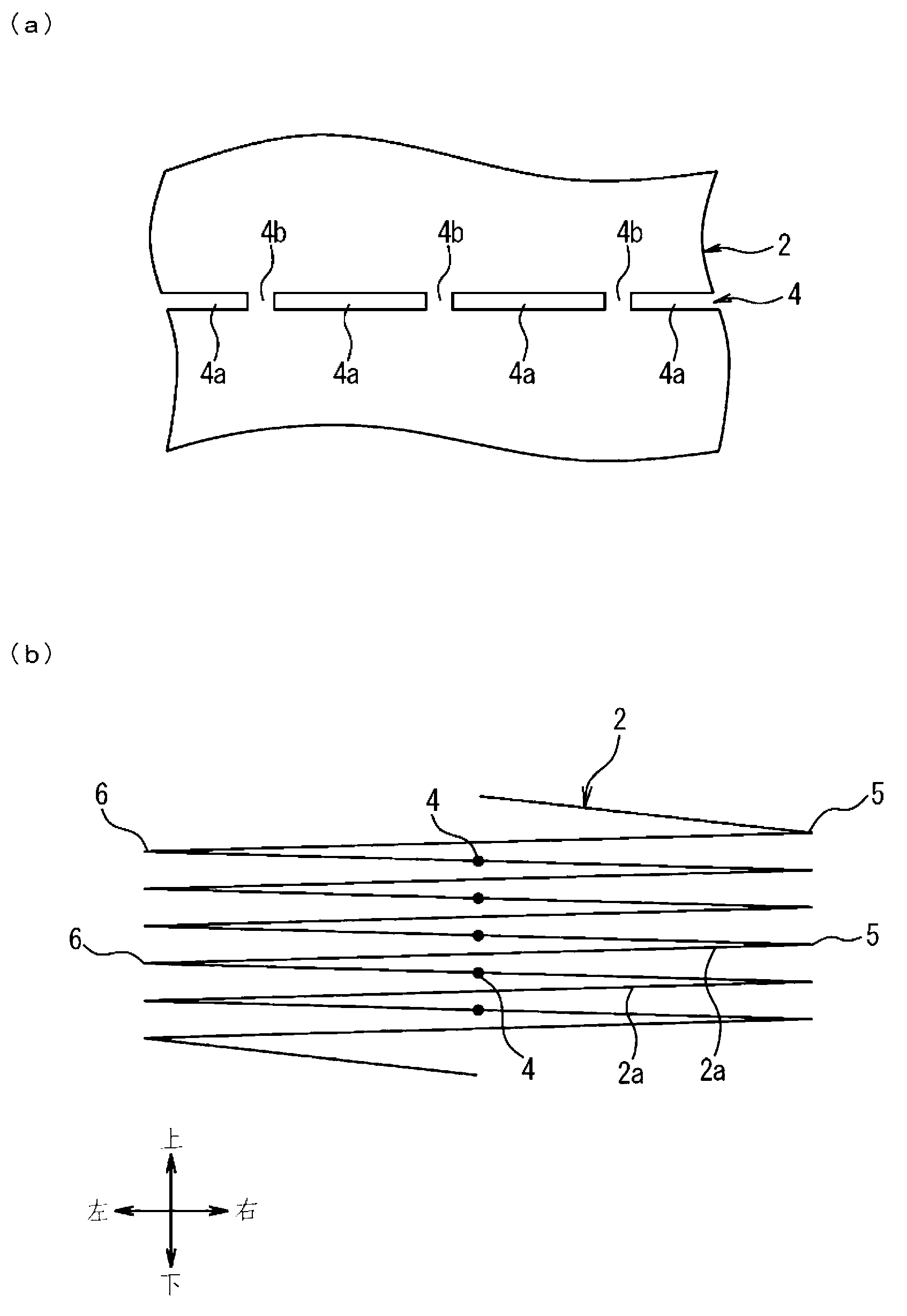

Thermoforming method for thermoforming sheet and thermoforming apparatus

InactiveUS20090039556A1Design property is not deterioratedNo wrinklesConfectioneryWood working apparatusThermoformingShell molding

The thermoforming method of the present invention is a method that includes thermoplasticizing a portion, including a part 2 which is molded with molds, of a thermoforming sheet 1 in which at least one or more thermoplastic resin layers (A) and a decorative layer (B) were laminated, at a temperature range of (Tg (A)−30)° C. to (Tg (A)+10)° C. with respect to the glass transition temperature (Tg (A)) of the thermoplastic resin layer (A); subsequently clamping by using a pair of frame clamps 14 and 24 both sides of a perimeter around the portion 2, which is molded with the molds, of the sheet 1; expanding the thermoplasticized portion between one mold and the frame clamps by pressing a portion of the one mold 20 onto one surface of the thermoplasticized portion; subsequently bringing the other mold 10 into contact with the thermoplasticized portion from the side opposite to the surface of the thermoplasticized portion that the one mold is in contact with; and mold-clamping the thermoplasticized portion with the one mold 10 and the other mold 20 to mold the thermoforming sheet. According to the present invention, forming at a low temperature in which the design properties can not be adversely affected can be achieved, and formed articles in which wrinkles or the like are not generated can be obtained.

Owner:DAINIPPON INK & CHEM INC

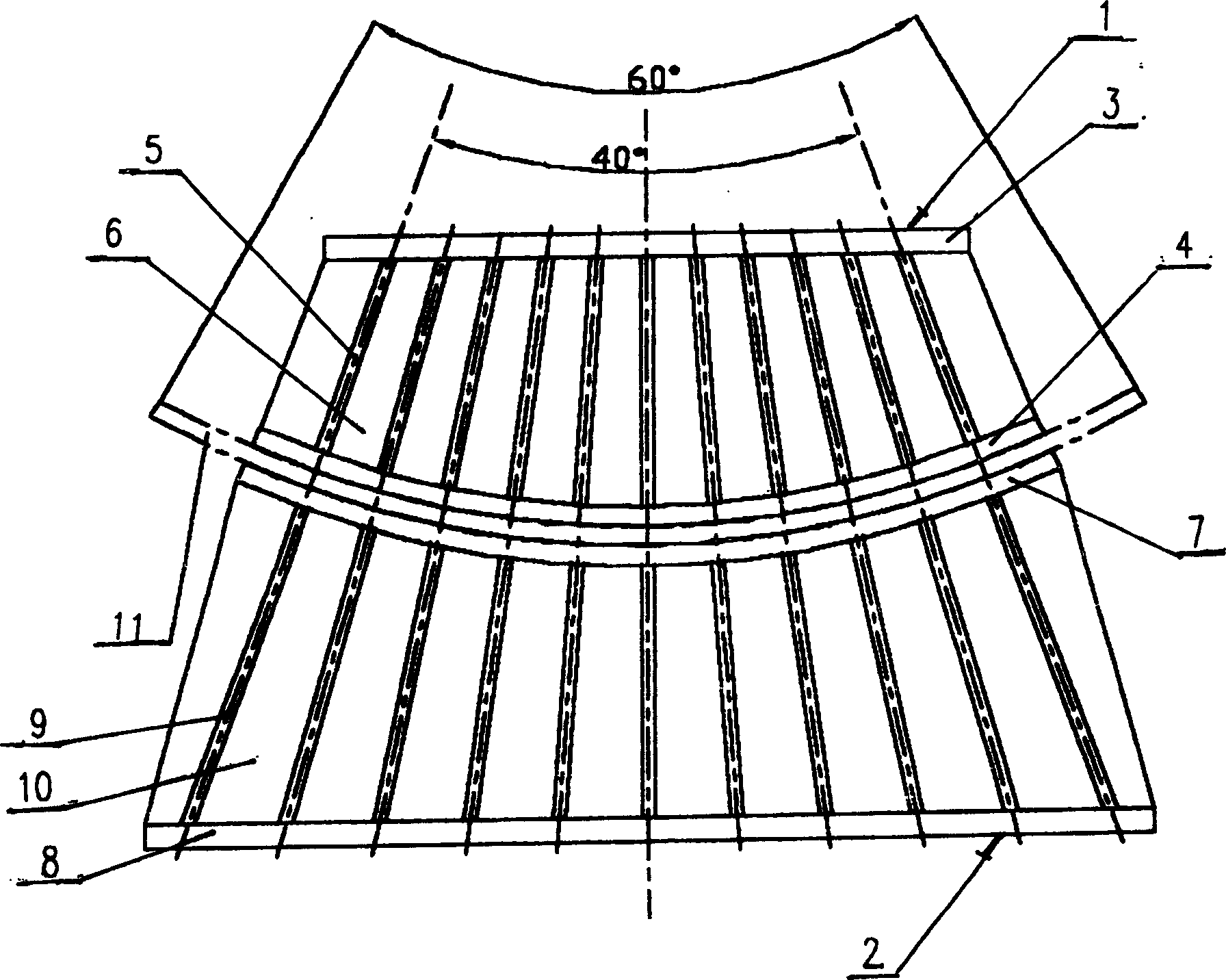

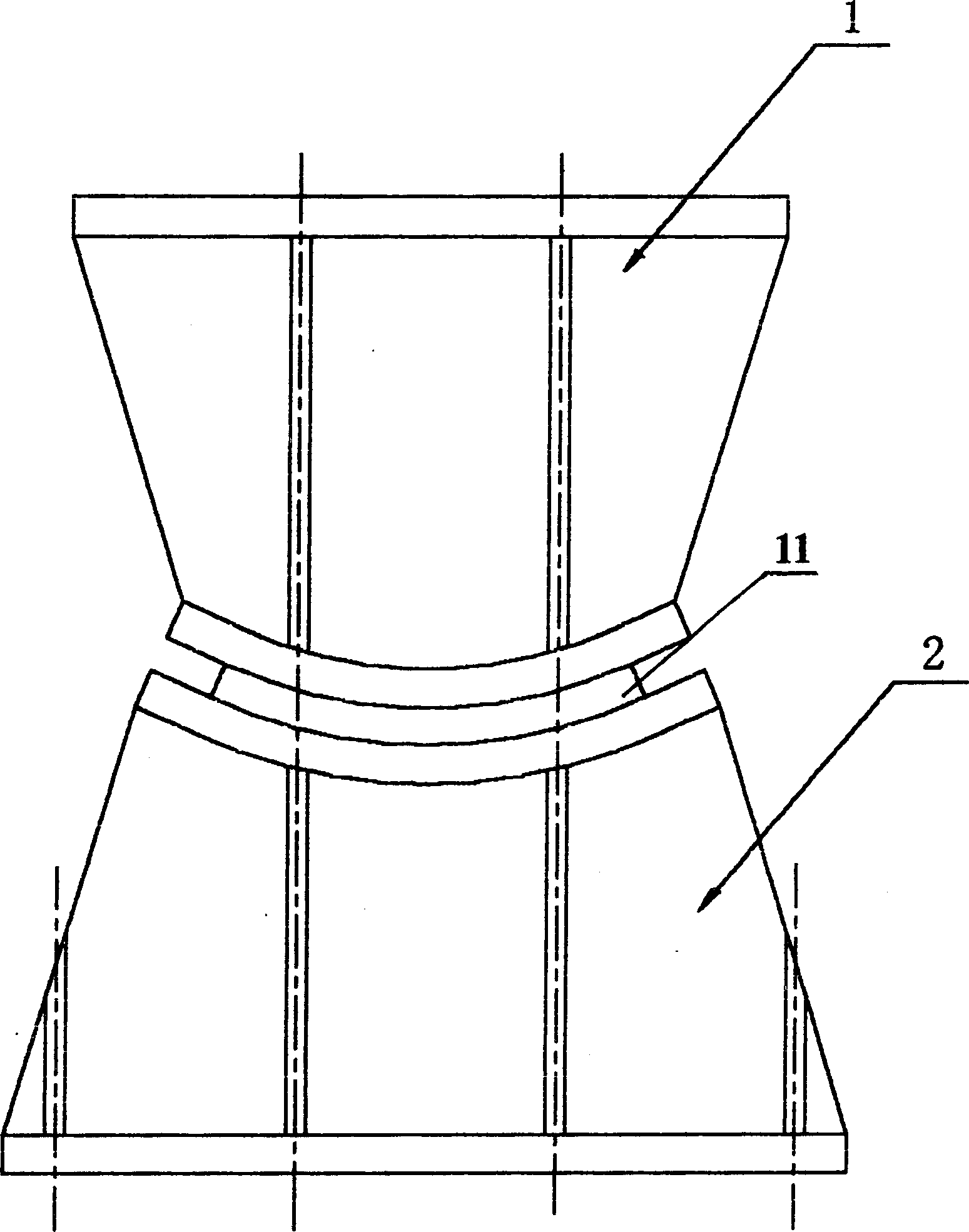

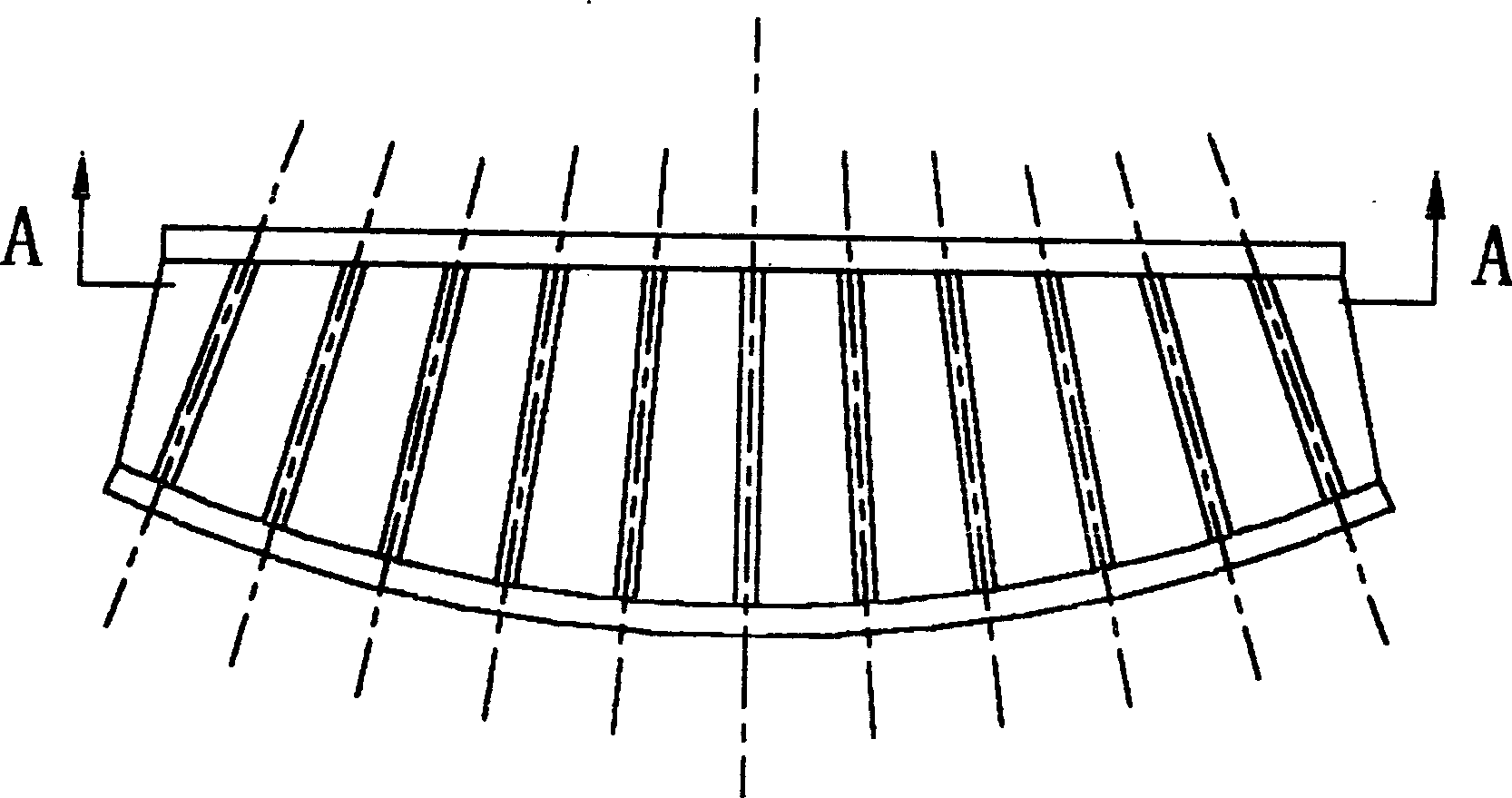

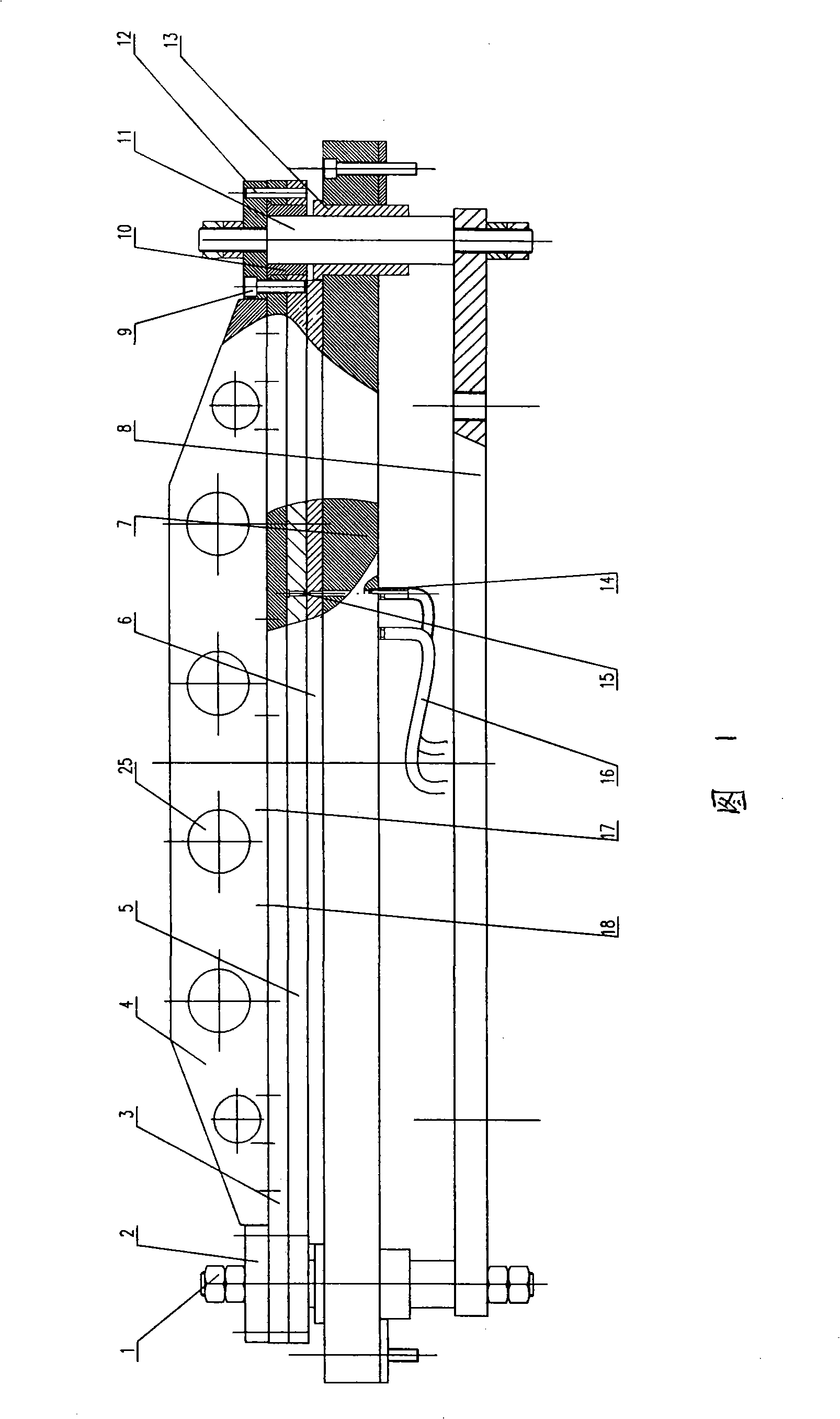

Double curvature plate cold press forming method and equipment thereof

The present invention relates to double curvature plate cold pressing formation method and apparatus. The formation process includes the following steps: determining the rebound elasticity of cold pressed steel plate, determining the curvature radius and size of upper and lower working plates, setting plate material, cutting, pressing, etc. The formation apparatus includes upper pressing mold, lower pressing mold, reinforcing ribbed plates welded onto the top plate, upper working plate, lower working plate and bottom plate, and oil press. The present invention makes it possible to produce high quality double curvature plate with smooth surface.

Owner:中国船舶集团渤海造船有限公司

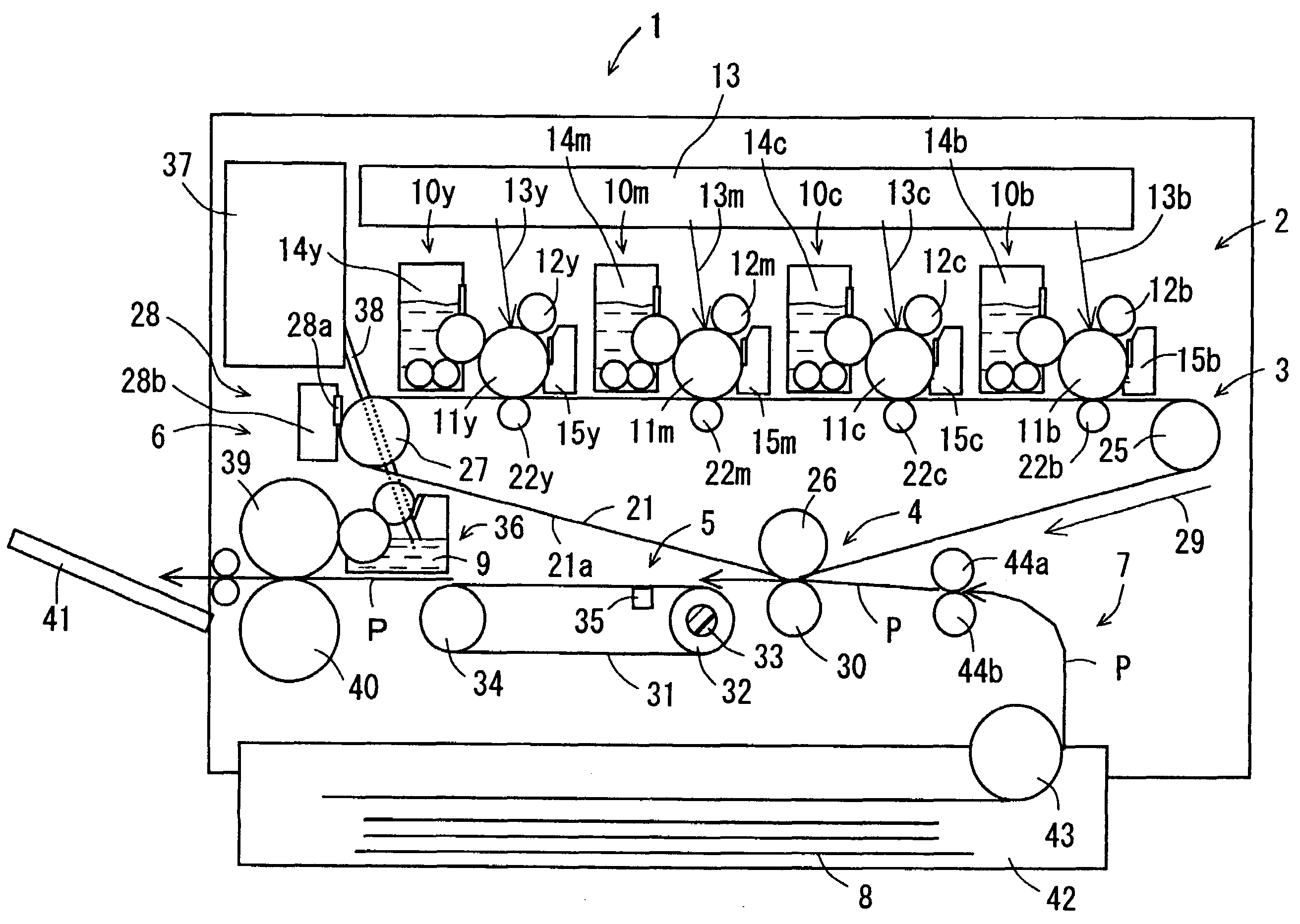

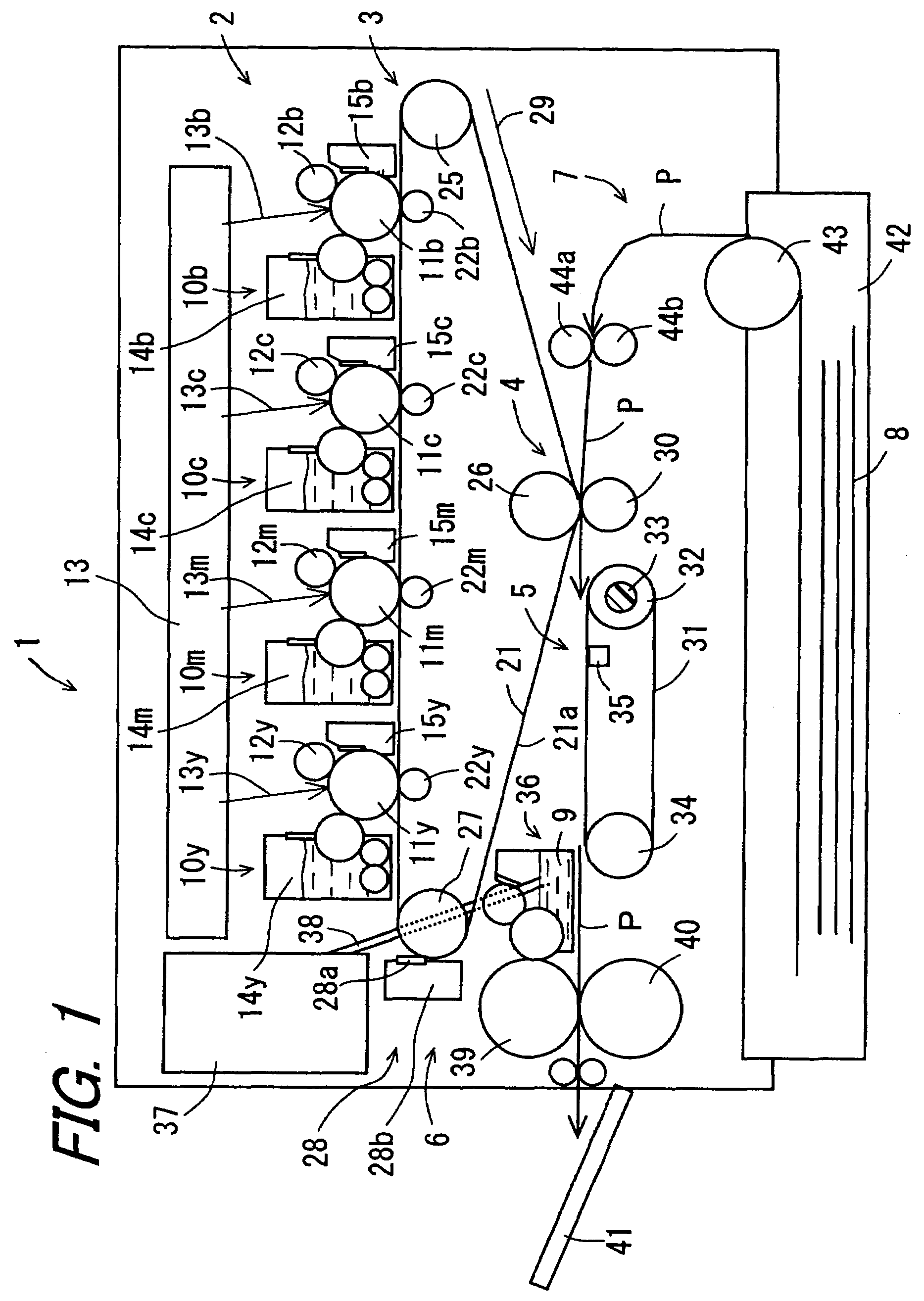

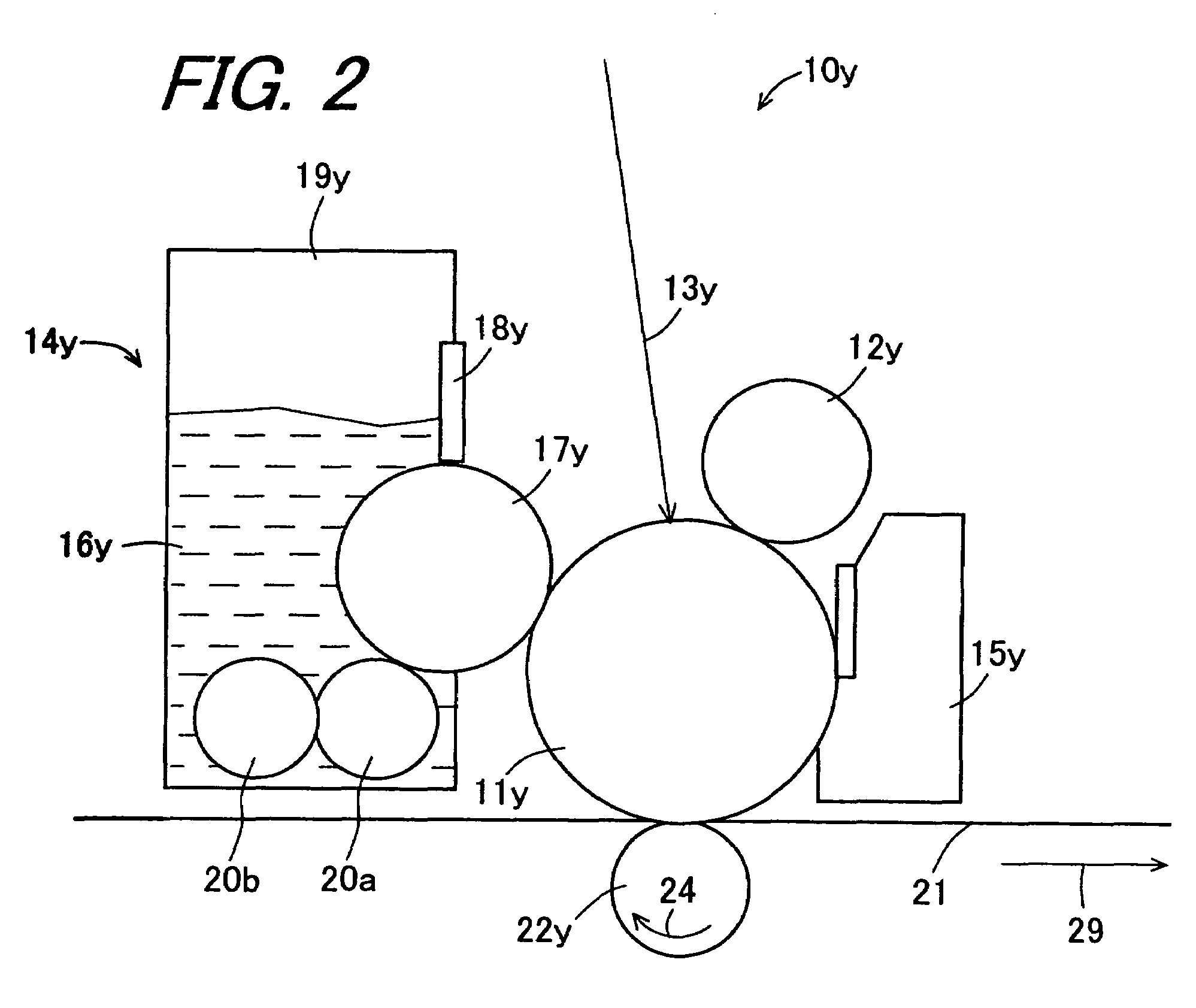

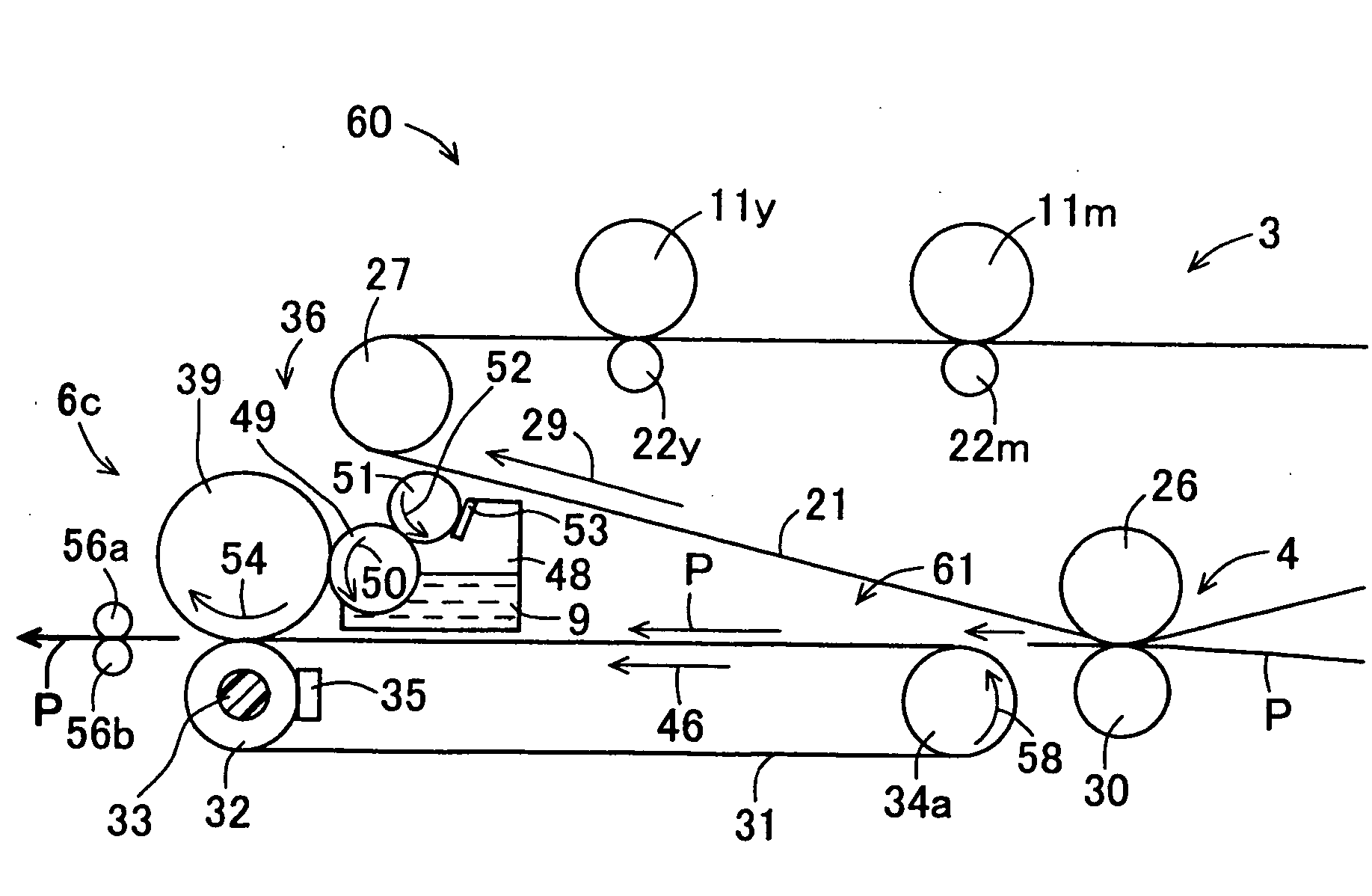

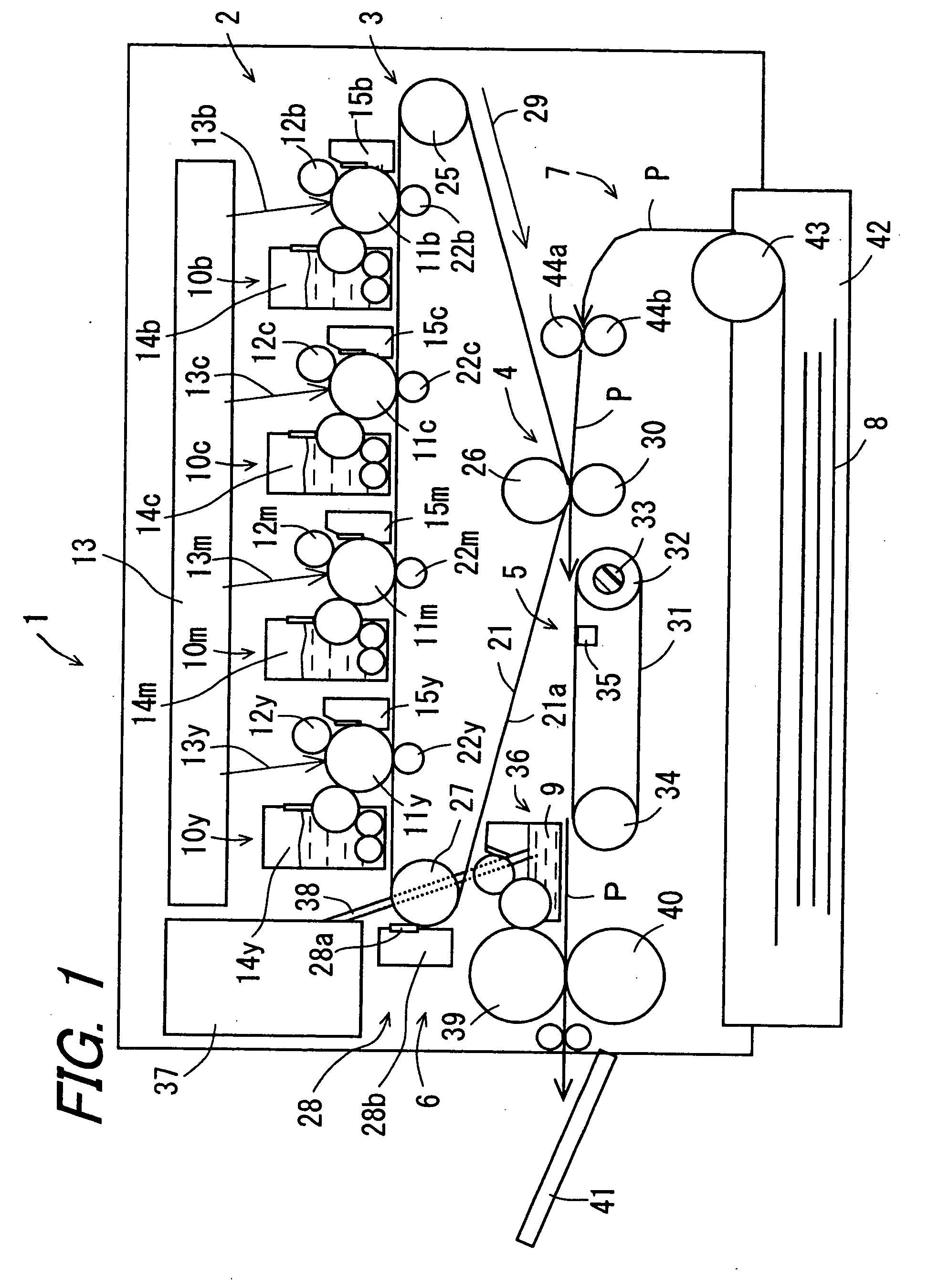

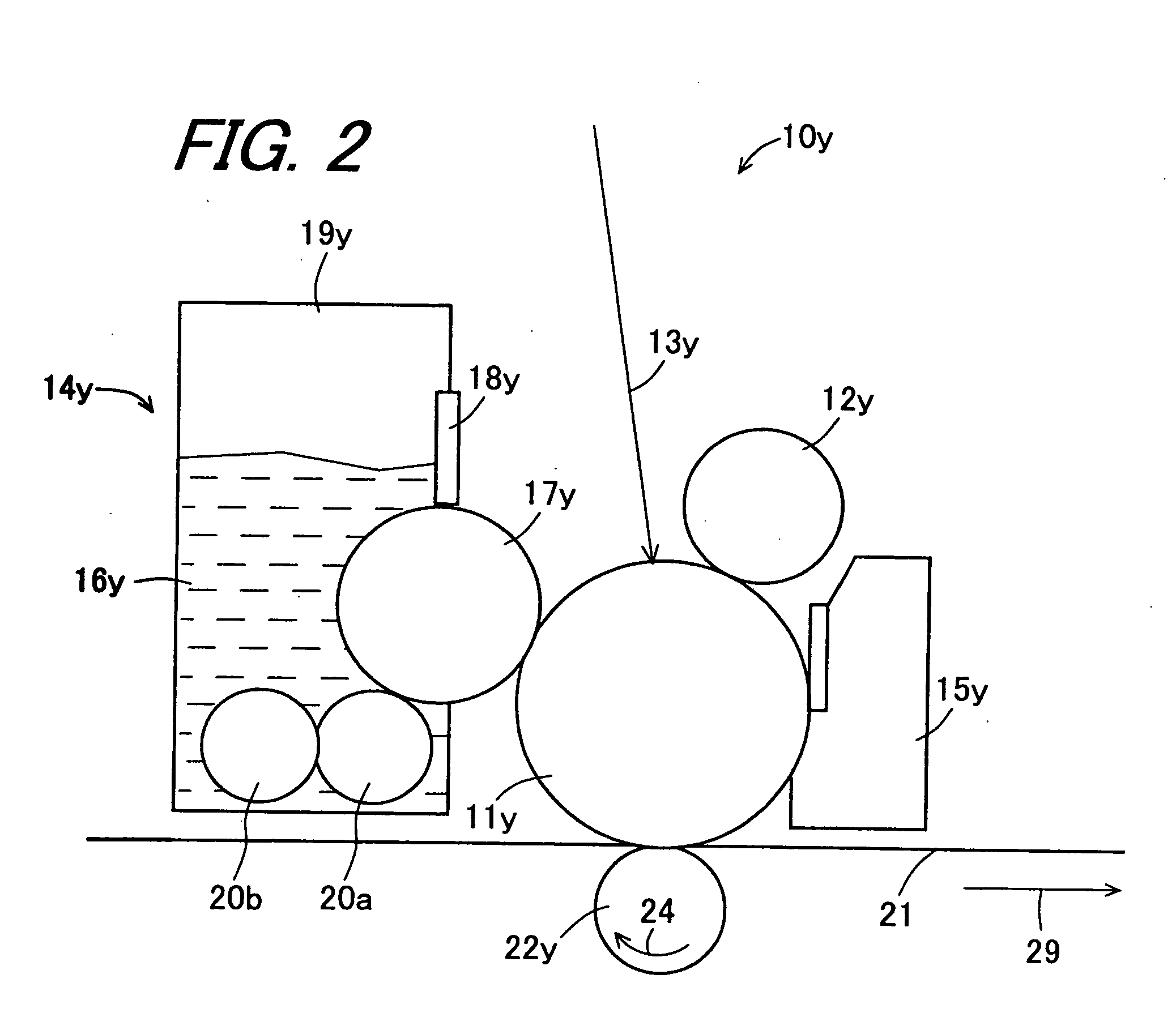

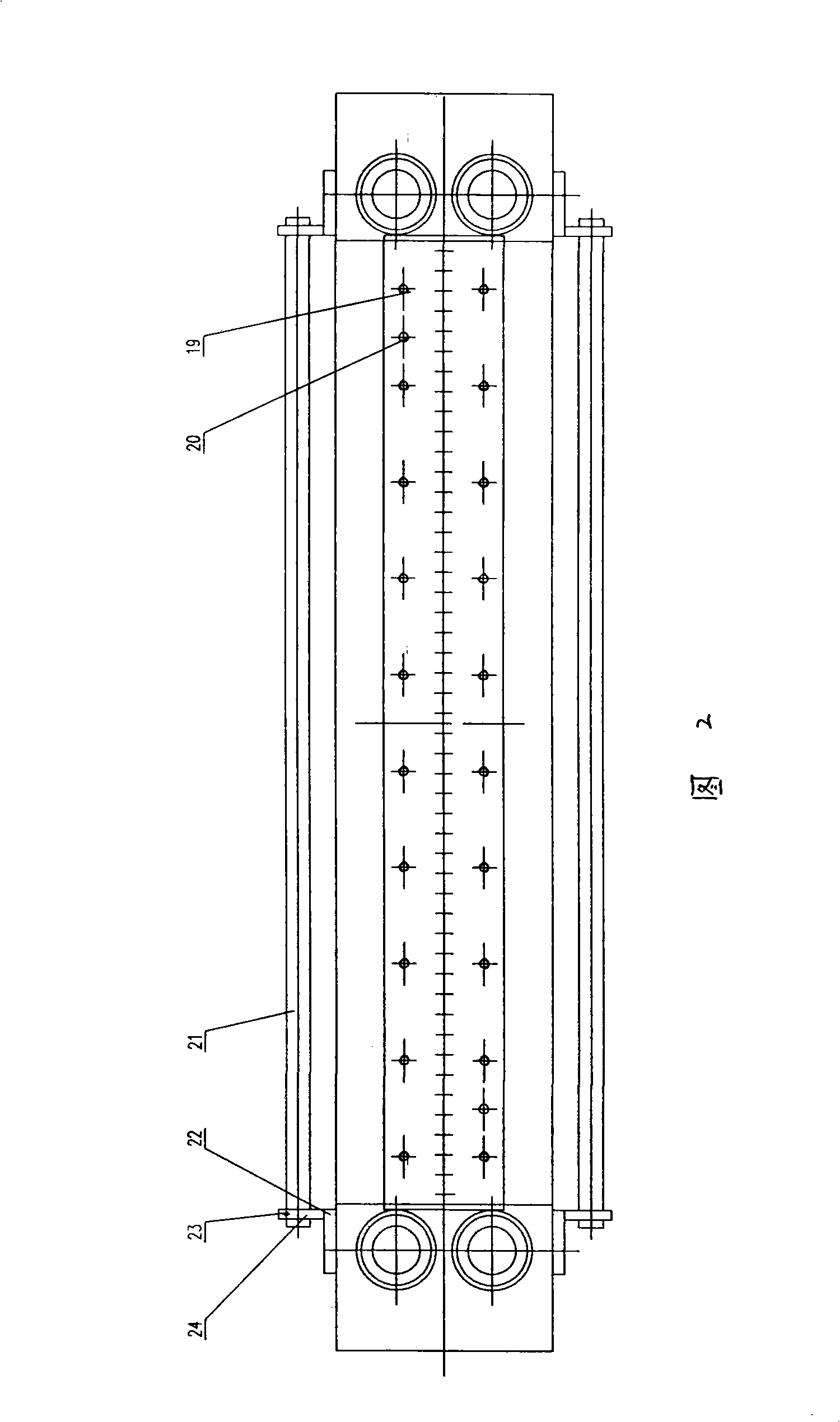

Image forming apparatus employing heating and fixer fluid applying sections

InactiveUS7697877B2Reduce consumptionNo curlsElectrographic process apparatusElectricityImage formation

An image forming apparatus is provided in which a toner is prevented from flowing and being agglomerated, at the time of application of a fixer fluid to a toner image so as to fix the toner image to a recording medium, and the recording medium is prevented from generating curl and wrinkle, and consumption of the fixer fluid and electricity can be reduced, and even a multicolored toner image can be fixed for a relatively short time. An image forming apparatus includes a toner image forming section, an intermediate transfer section, a secondary transfer section, a heating section, a fixer fluid applying section, and a recording medium supplying section. A recording medium carrying the toner image on a surface thereof is heated by the heating section and then, a fixer fluid is applied to the toner image by the fixer fluid applying section so that the toner image is fixed.

Owner:SHARP KK

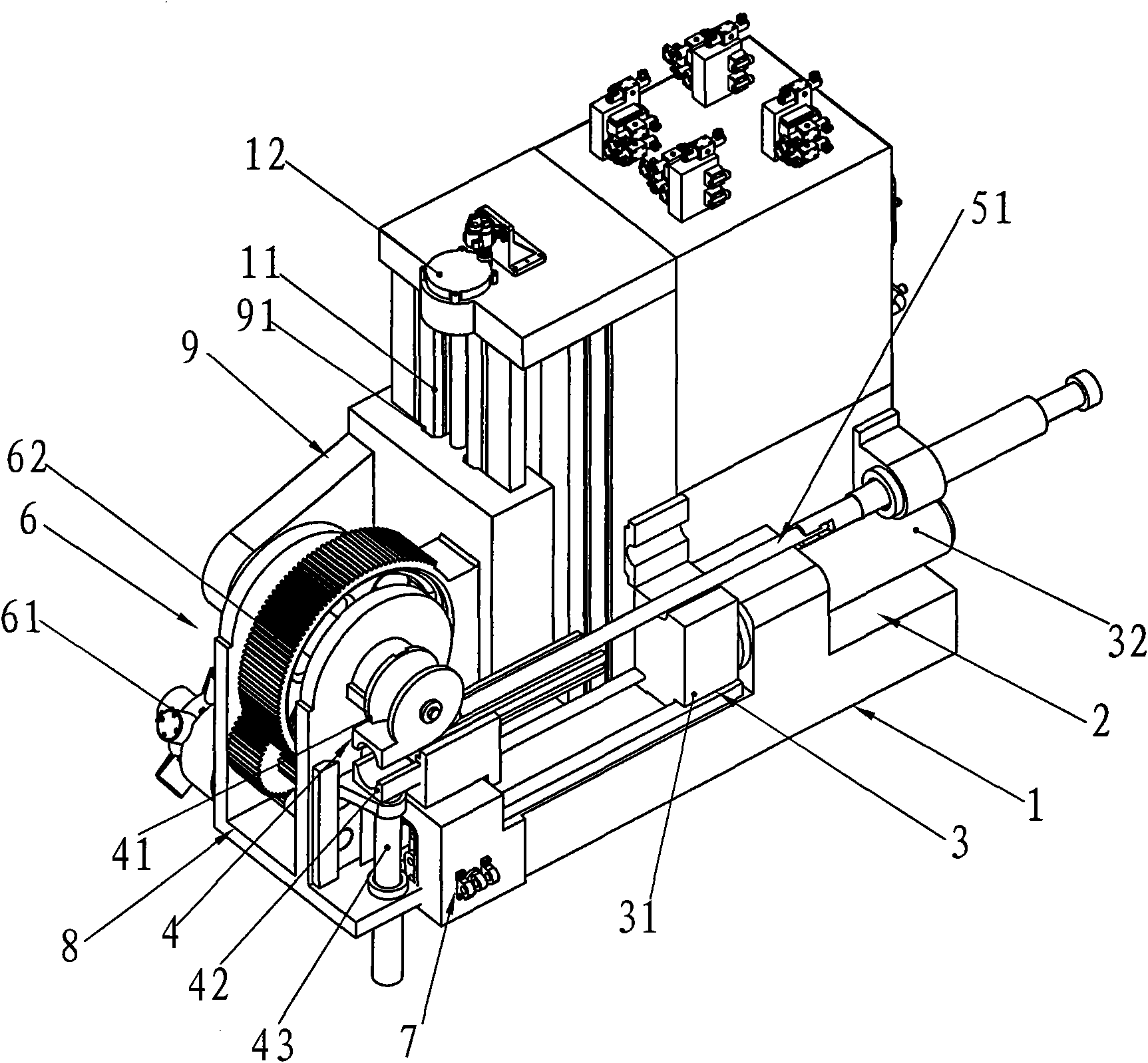

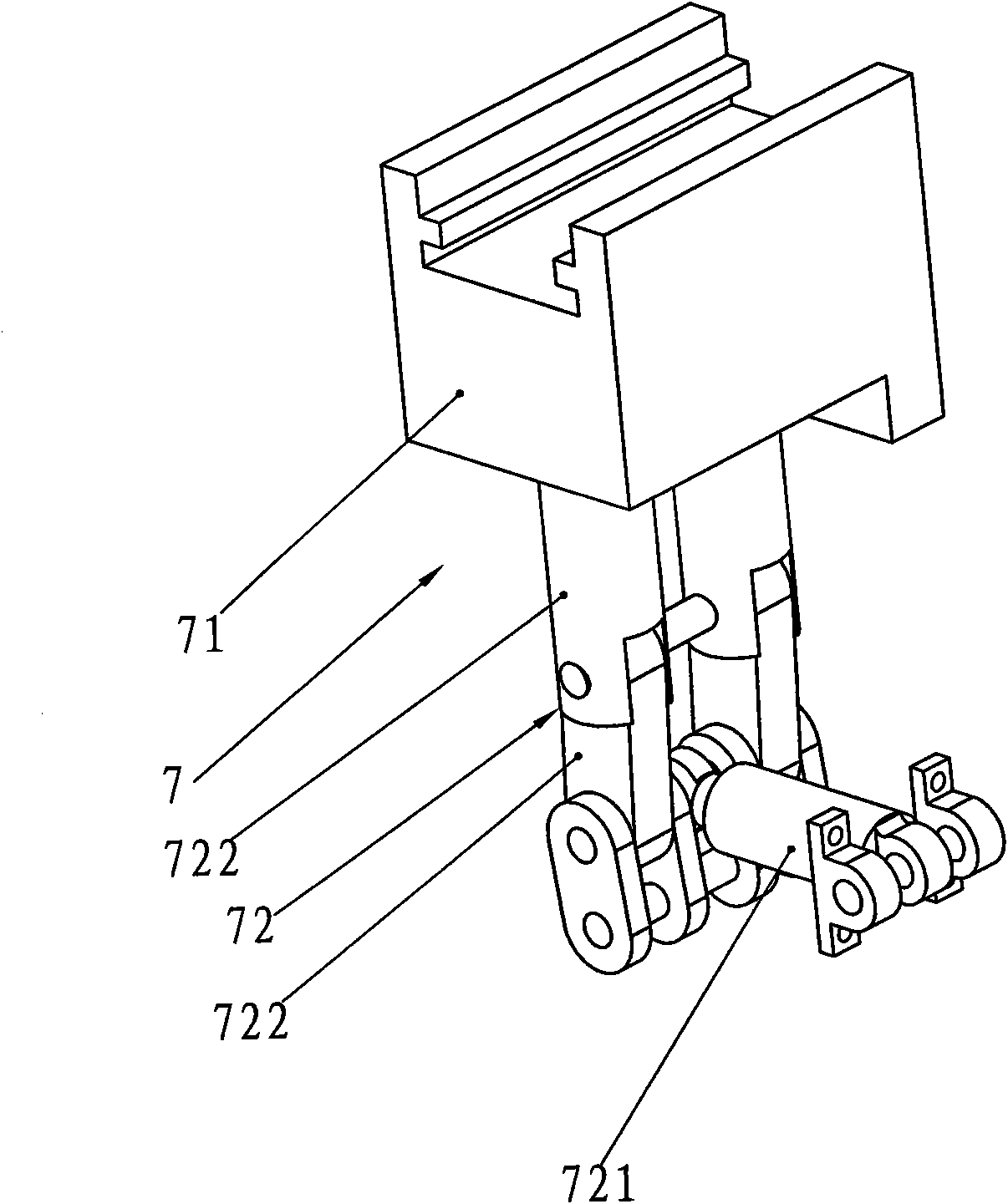

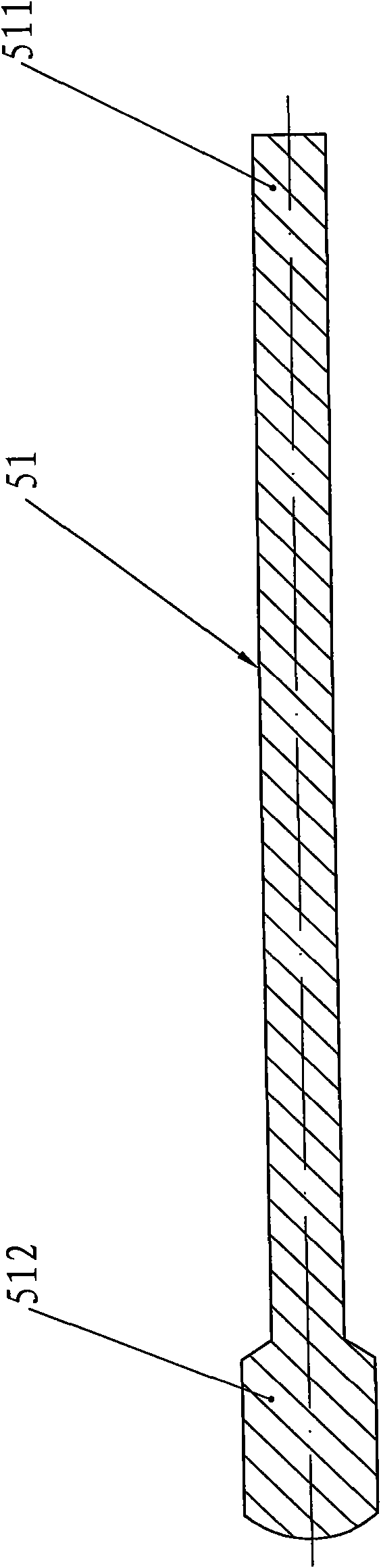

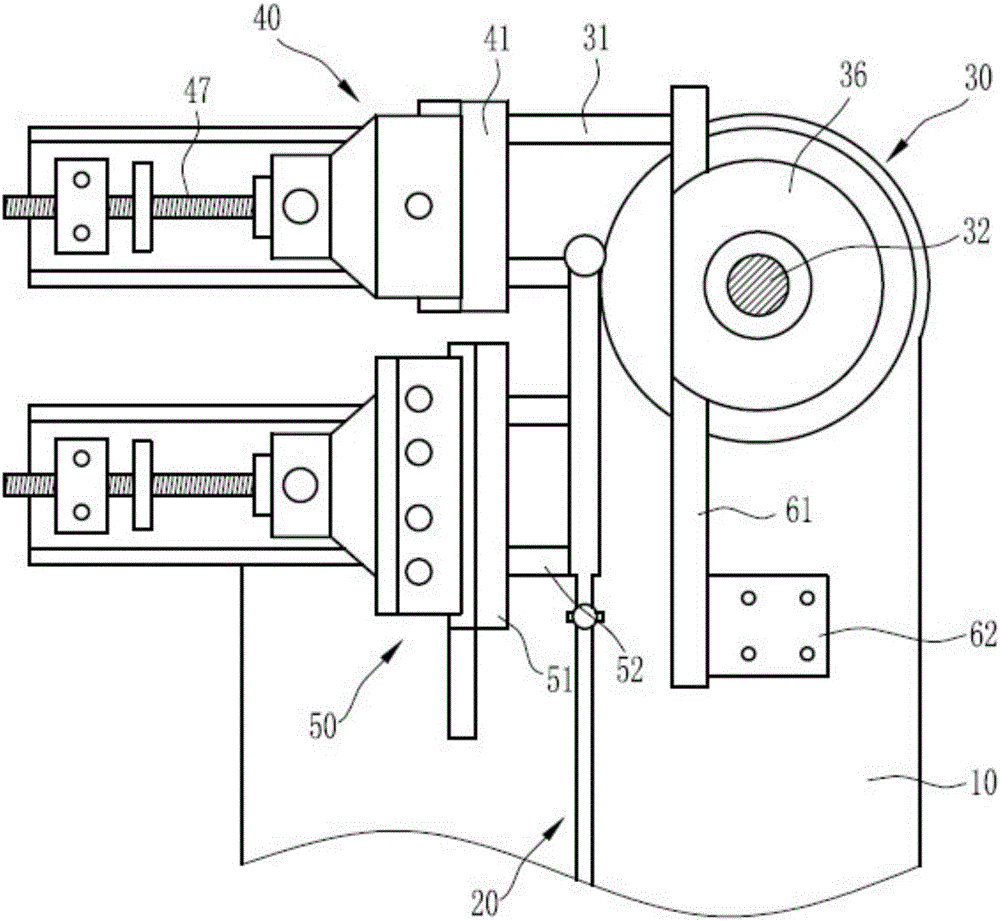

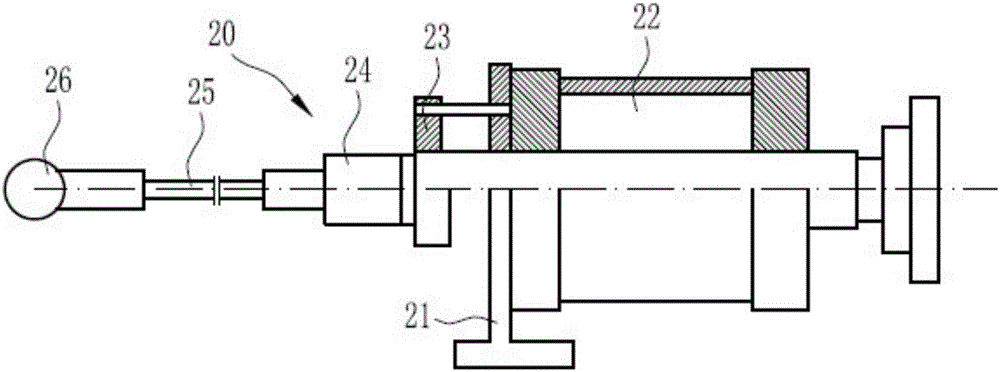

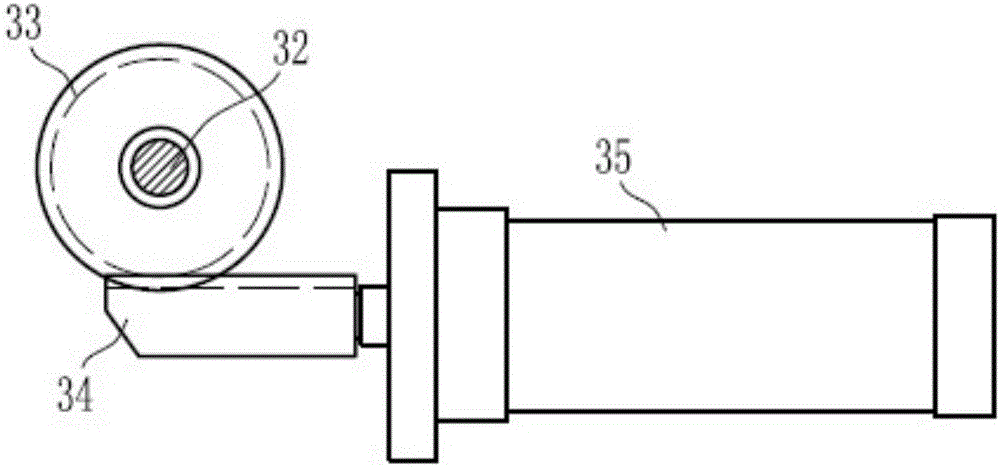

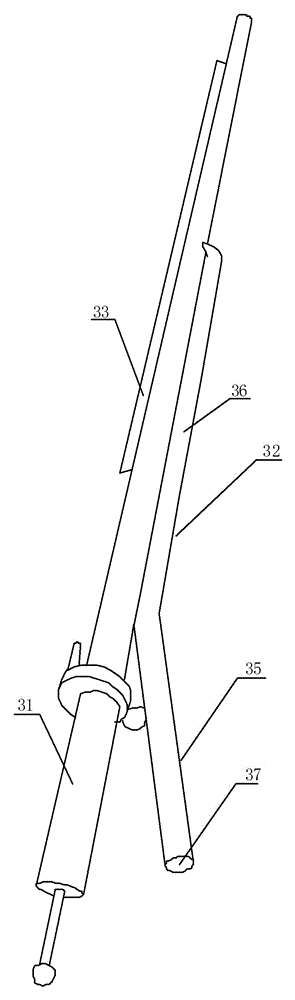

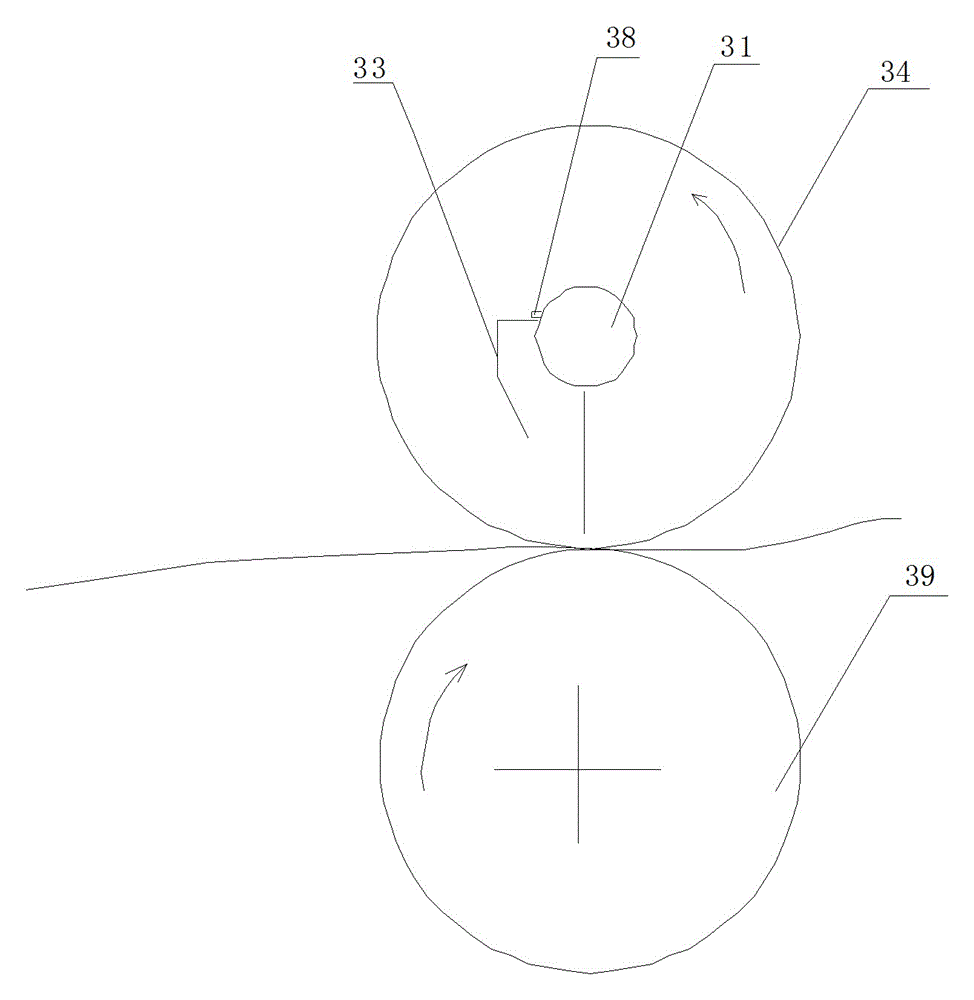

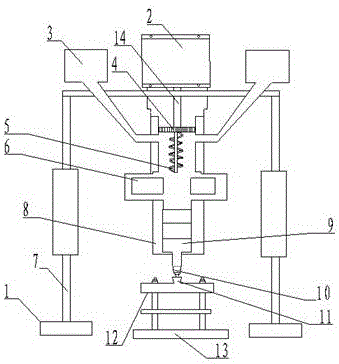

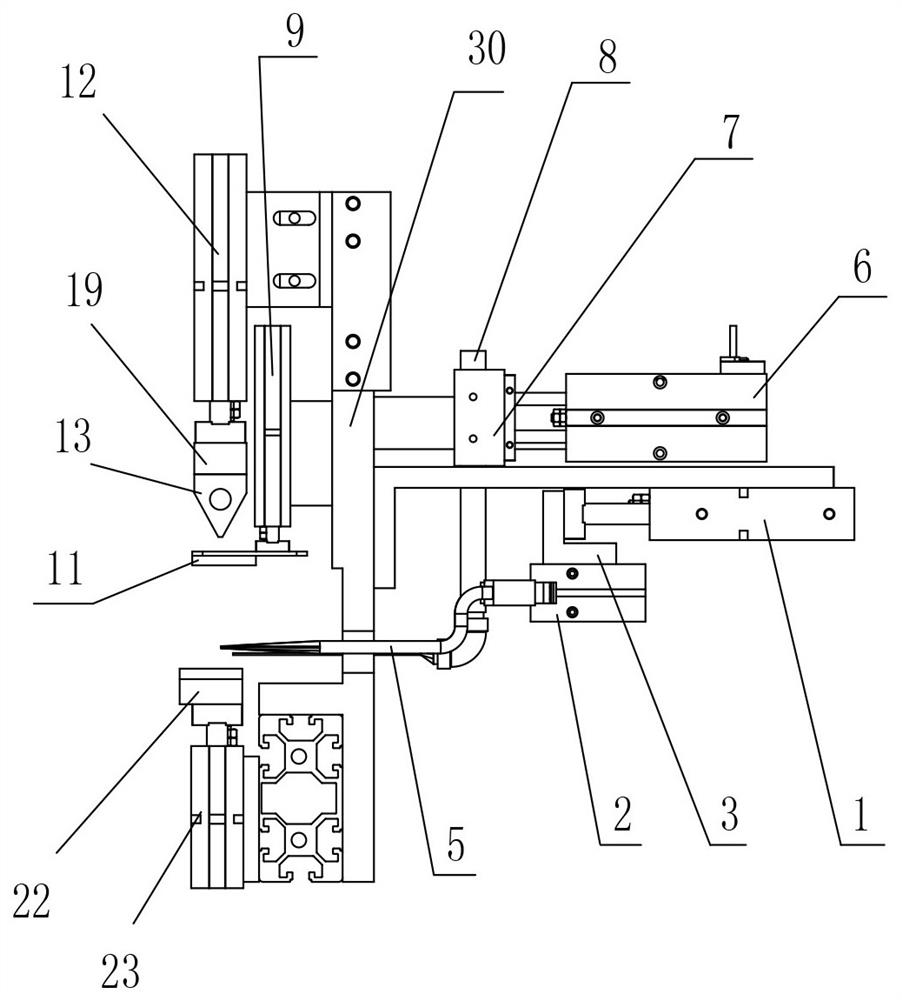

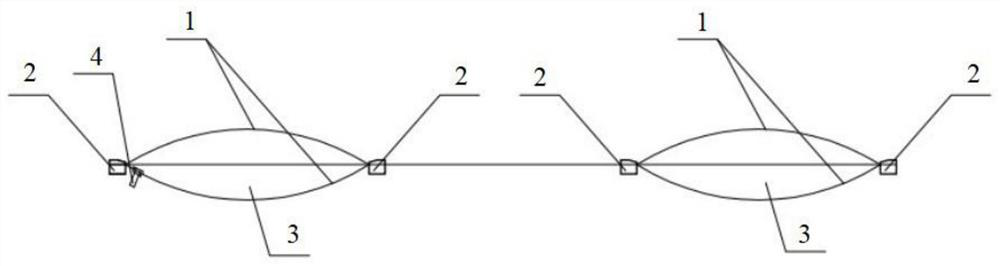

Elbow pipe piece forming machine

The invention relates to a forming machine, in particular to an elbow pipe piece forming machine. The technical scheme provided by the invention is as follows: the elbow pipe piece forming machine comprises a machine body, a working platform, a pipe-pushing mechanism, a bending mechanism, a core rod, a core rod positioning mechanism and a drive mechanism, wherein the bending mechanism comprises a bending mold and a mold clamping block arranged correspondingly to the bending mold; the end surface of the bending mold, which is opposite to the mold clamping block, is an arc-shaped clamping groove which is matched with the peripheral surface of a pipe piece; the mold clamping block and the bending mold rotate synchronously; the core rod comprises a sheathing end and an expanding end; the diameter of the expanding end of the core rod is larger than that of the sheathing end which is the end butted with the core rod positioning mechanism; the expanding end is the end between the bending mold and the mold clamping block; and the mold clamping block position is provided with a mold locking mechanism which achieves mold combination or separation of the mold clamping block and the bending mold. By adopting the technical scheme, the invention provides the elbow pipe piece forming machine which has convenient operation and can not lead the bent pipe piece to generate wrinkles.

Owner:何崇翔

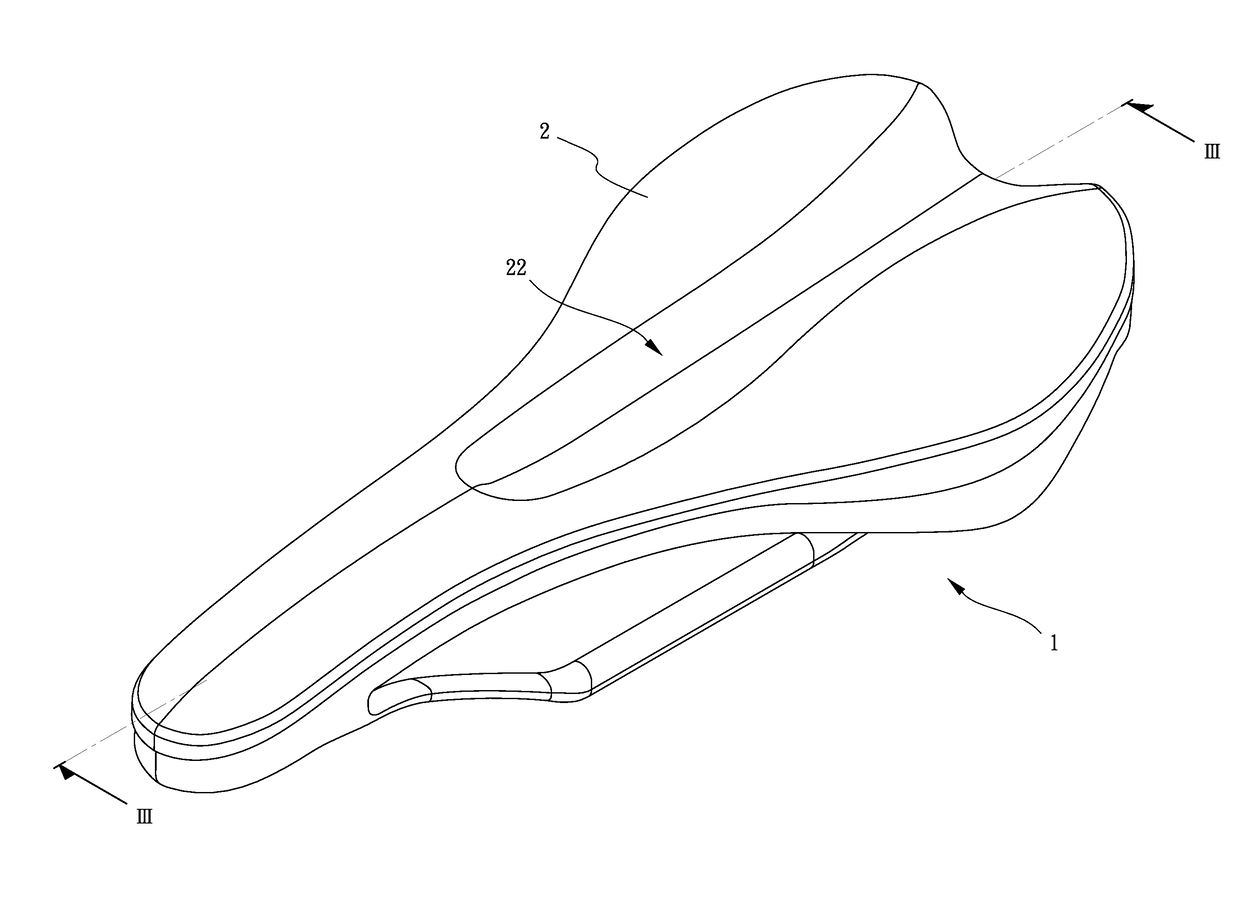

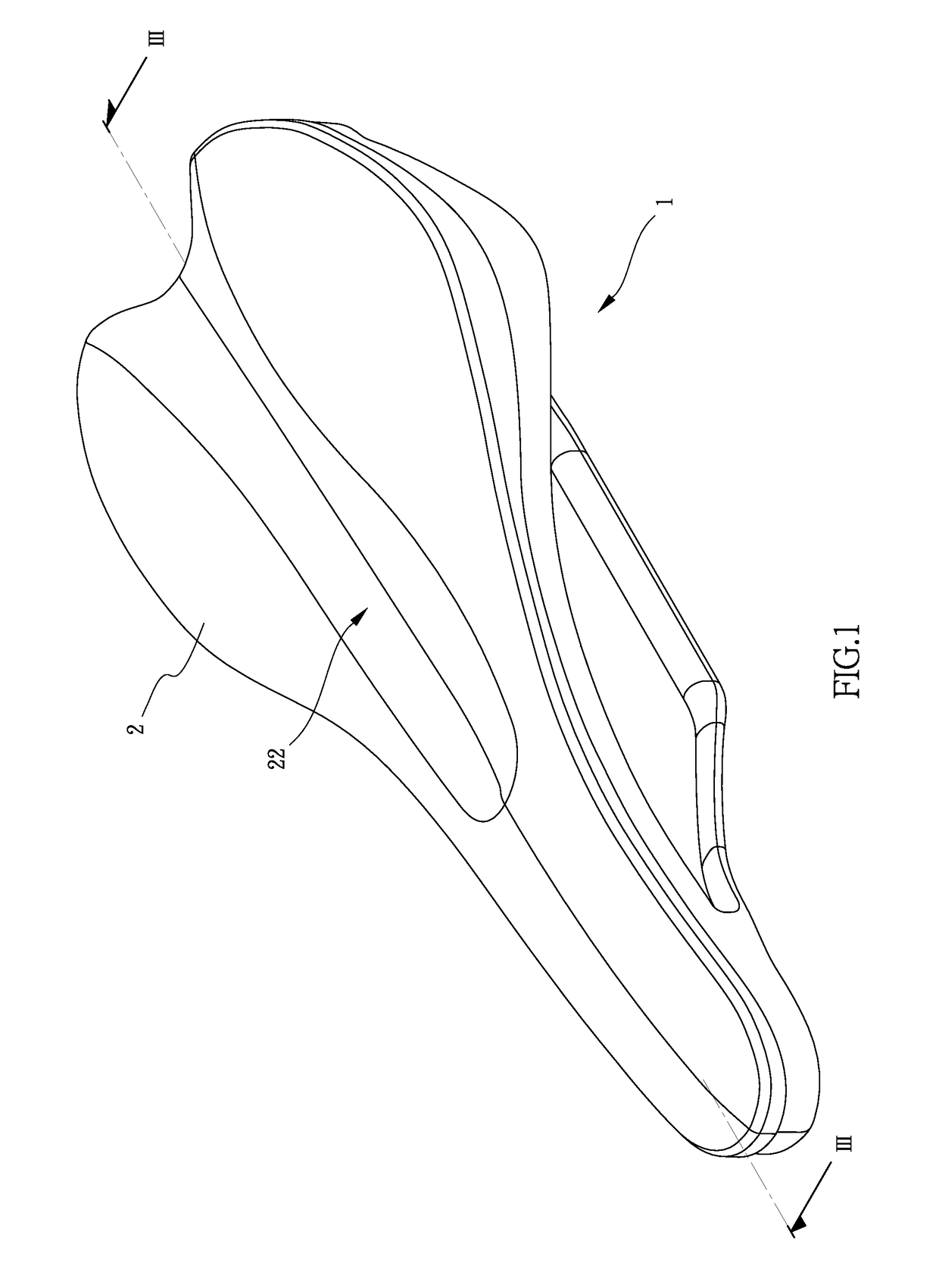

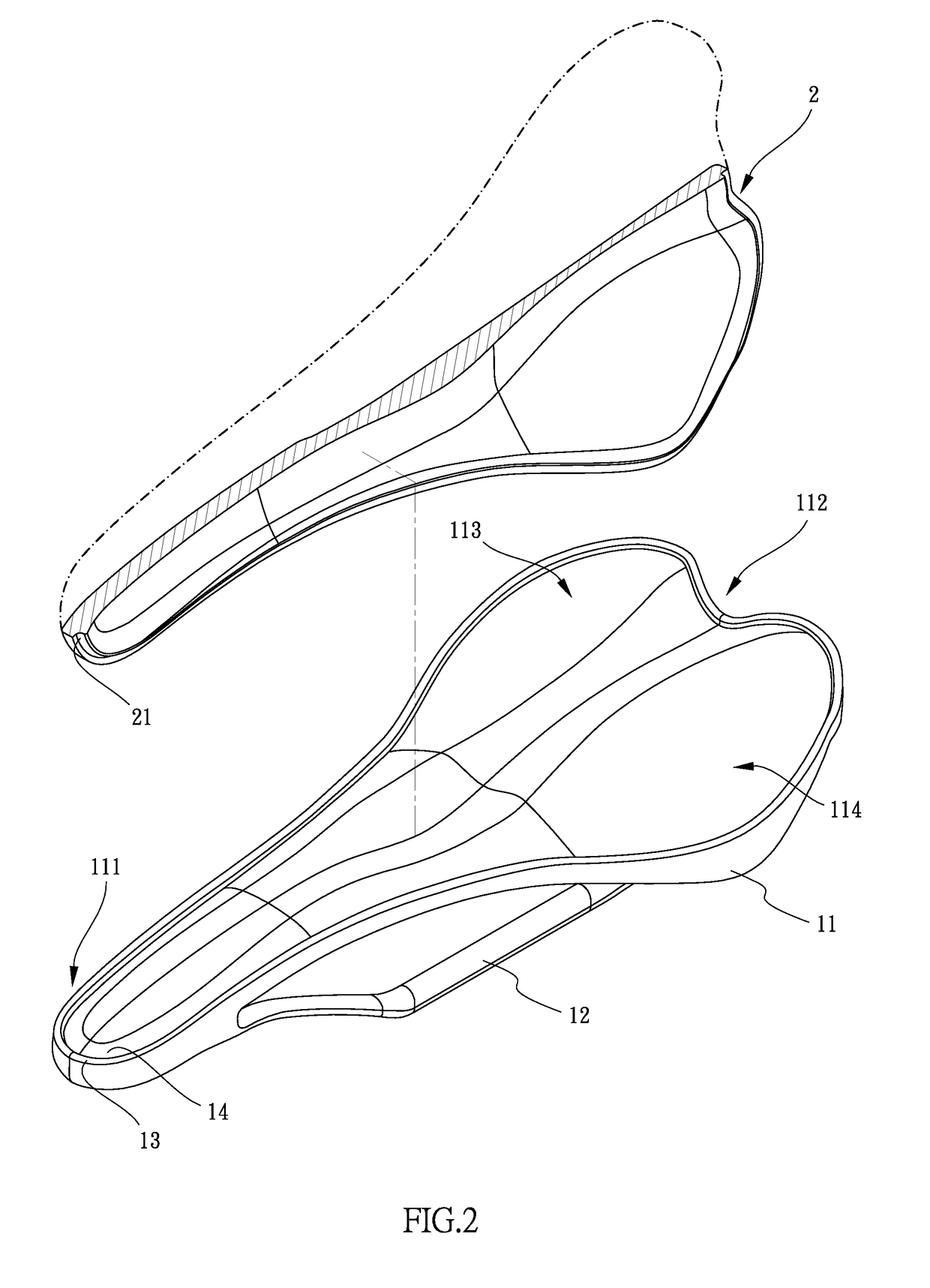

Seat for bicycles

InactiveUS20180290703A1Easy to assembleNo wrinklesCycle saddlesStructural engineeringMechanical engineering

A bicycle seat includes a support having a base and two rails. A ridge is formed along the periphery of the top of the base so as to define an installation recess between the ridge and the top of the base. The two rails are connected to the underside of the base and spaced apart from each other. A pad is engaged with the installation recess and has a groove defined along the periphery of the underside thereof. The ridge is engaged with the groove to directly connect the pad to the base. A recessed area is defined in the top of the pad to provide comfort to the users.

Image forming apparatus

InactiveUS20060133863A1Reduce consumptionShort timeElectrographic process apparatusElectricityImage formation

An image forming apparatus is provided in which a toner is prevented from flowing and being agglomerated, at the time of application of a fixer fluid to a toner image so as to fix the toner image to a recording medium, and the recording medium is prevented from generating curl and wrinkle, and consumption of the fixer fluid and electricity can be reduced, and even a multicolored toner image can be fixed for a relatively short time. An image forming apparatus includes a toner image forming section, an intermediate transfer section, a secondary transfer section, a heating section, a fixer fluid applying section, and a recording medium supplying section. A recording medium carrying the toner image on a surface thereof is heated by the heating section and then, a fixer fluid is applied to the toner image by the fixer fluid applying section so that the toner image is fixed.

Owner:SHARP KK

Method for manufacturing coating film

InactiveUS20080233305A1Sufficient surface hardnessLittle curlPretreated surfacesOptical/shielding coatings applicationUltraviolet radiationUltraviolet

A method for manufacturing a coating film having a coating layer on a transparent base material. The method includes a step of forming a coated film by coating a coating liquid having a material for forming a coating layer that is curable by ultraviolet radiation on the transparent base material, and a step of irradiating the coated film composed by the coating liquid and formed on the transparent base material with pulsed ultraviolet radiation to form the coating layer.

Owner:TOPPAN PRINTING CO LTD

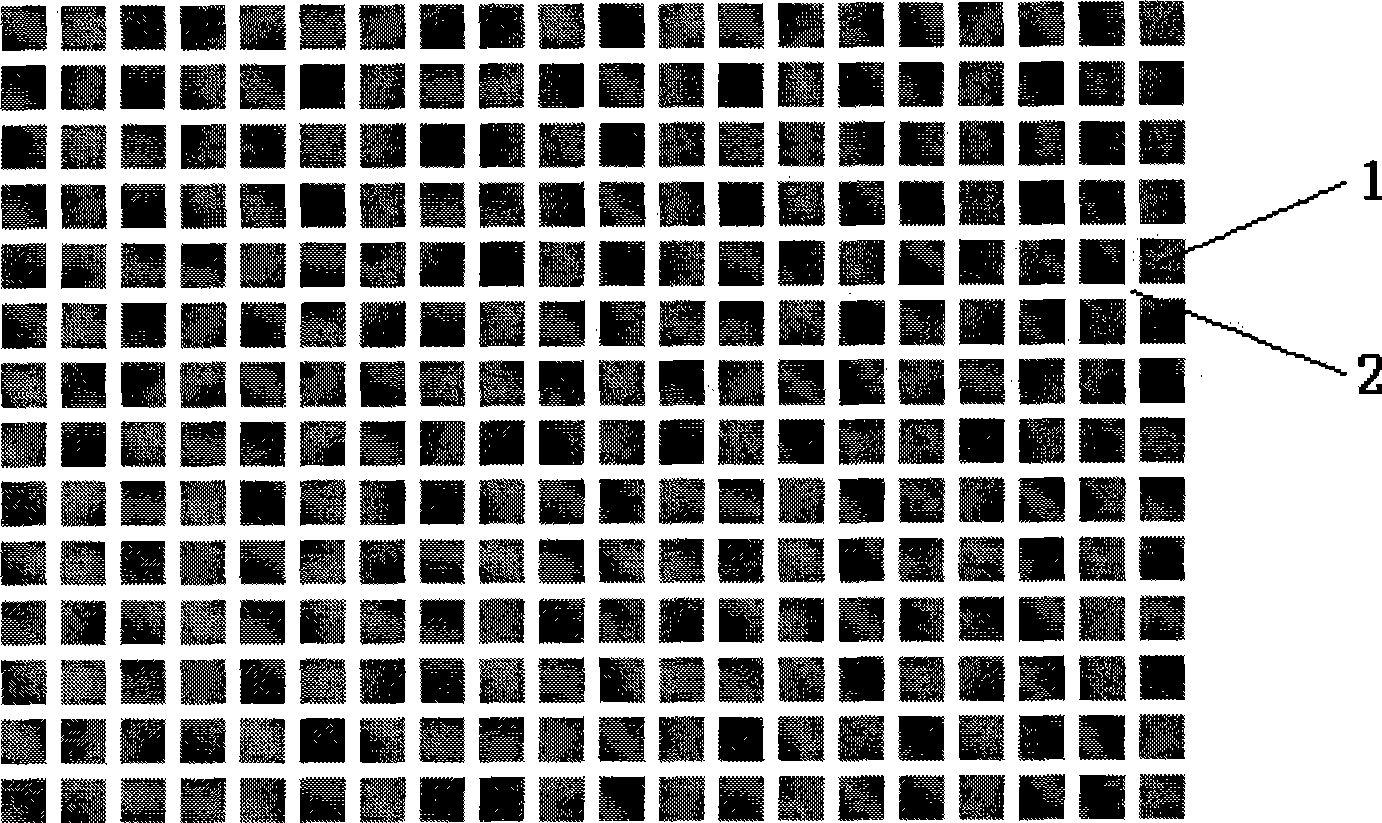

Lithium ion battery cathode sheet and preparation method thereof, and lithium ion battery

InactiveCN101378112AFlat surfaceIncreasing the thicknessElectrode manufacturing processesActive material electrodesEngineeringLithium intercalation

The invention provides a negative electrode piece of a lithium battery, which comprises a negative current collector and negative active materials coated on the negative current collector; wherein, the surface of the negative current collector consists of a plurality of coated parts and uncoated parts; and the coated parts are separated by the uncoated parts. The invention also provides a method for preparing negative electrodes as well as the lithium battery with the negative electrode piece. The negative electrode piece is well contacted with the electrolyte and the negative active materials are unlikely to drop or get broken during the lithium intercalation and de-intercalation, thus greatly improving the cyclic performance and specific capacity of the lithium batteries with the negative electrode pieces.

Owner:BYD CO LTD

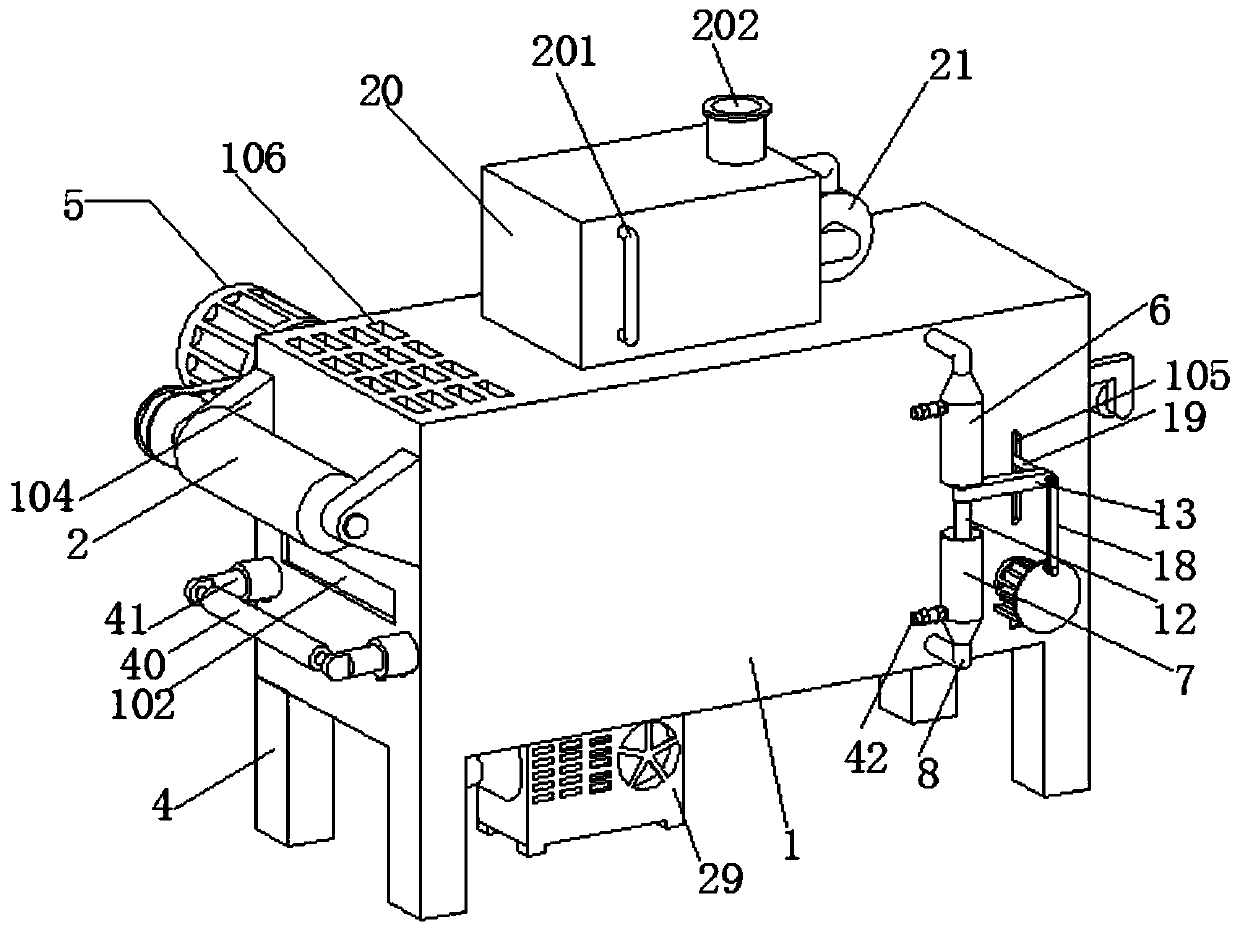

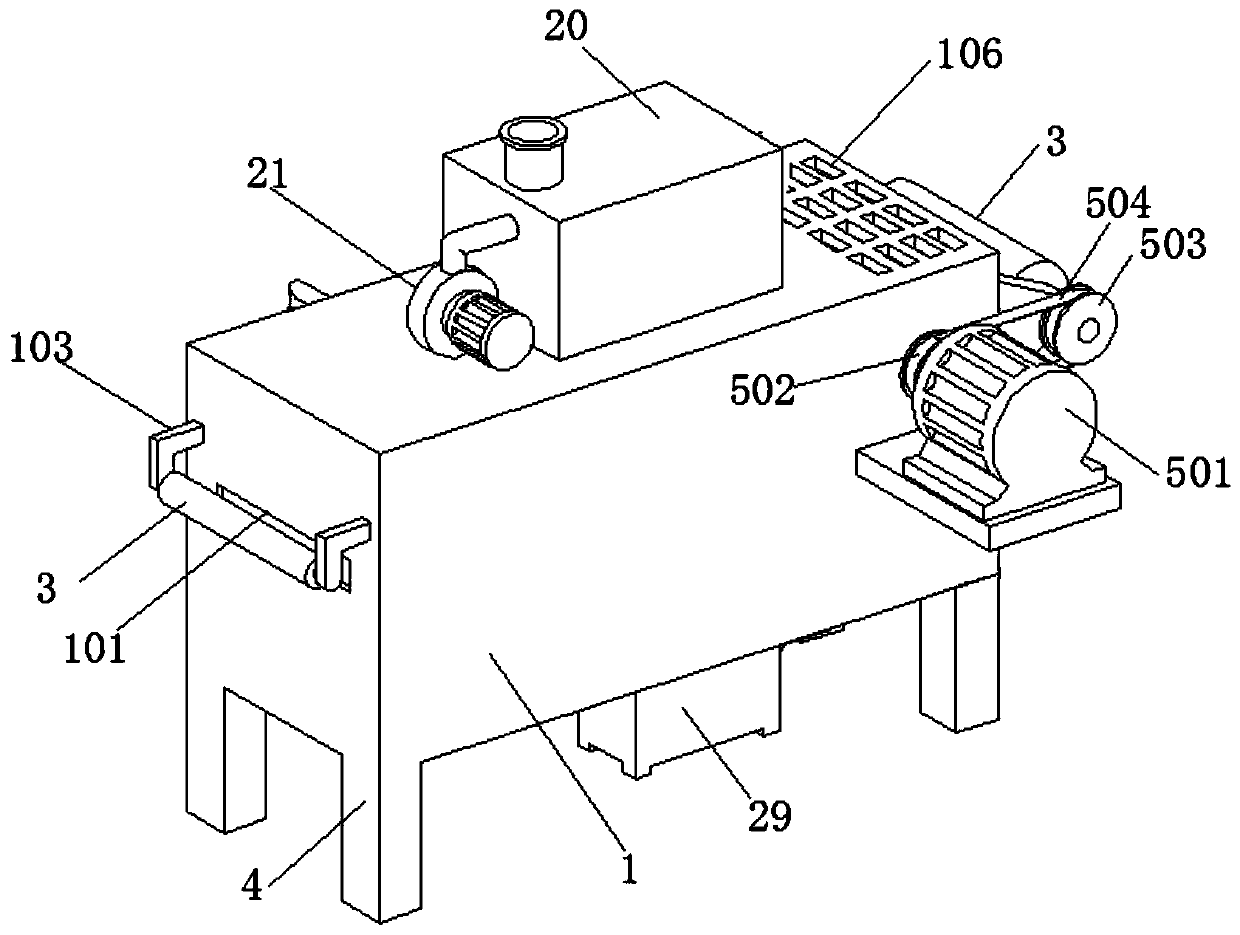

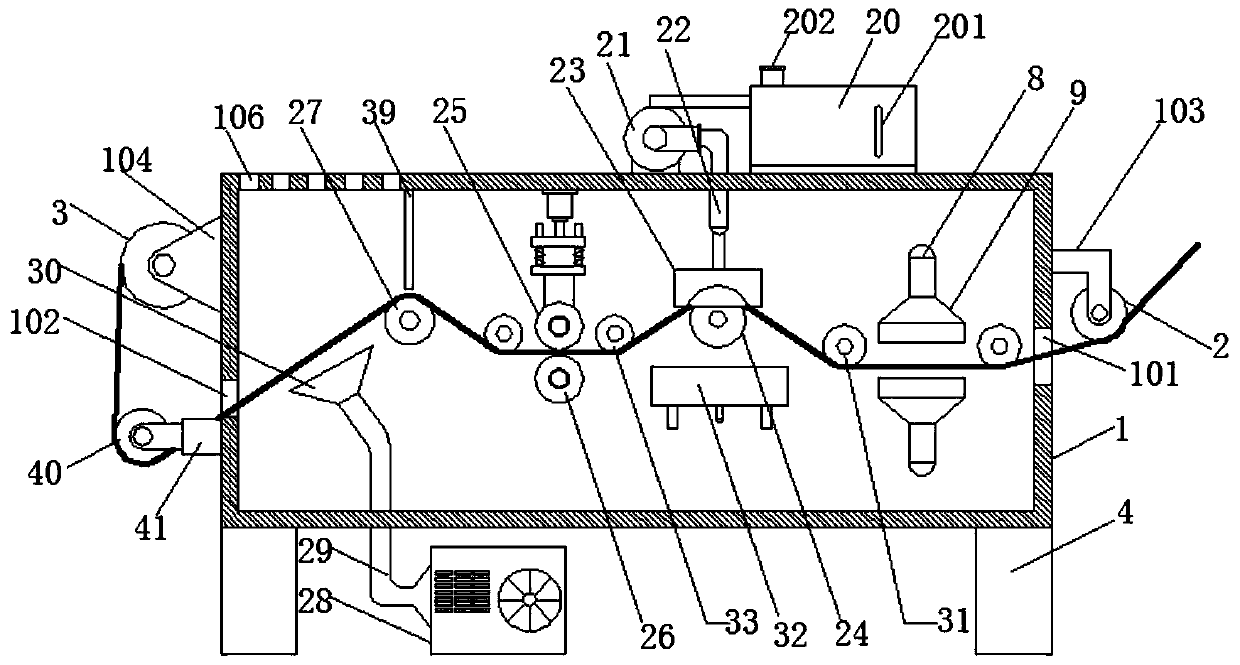

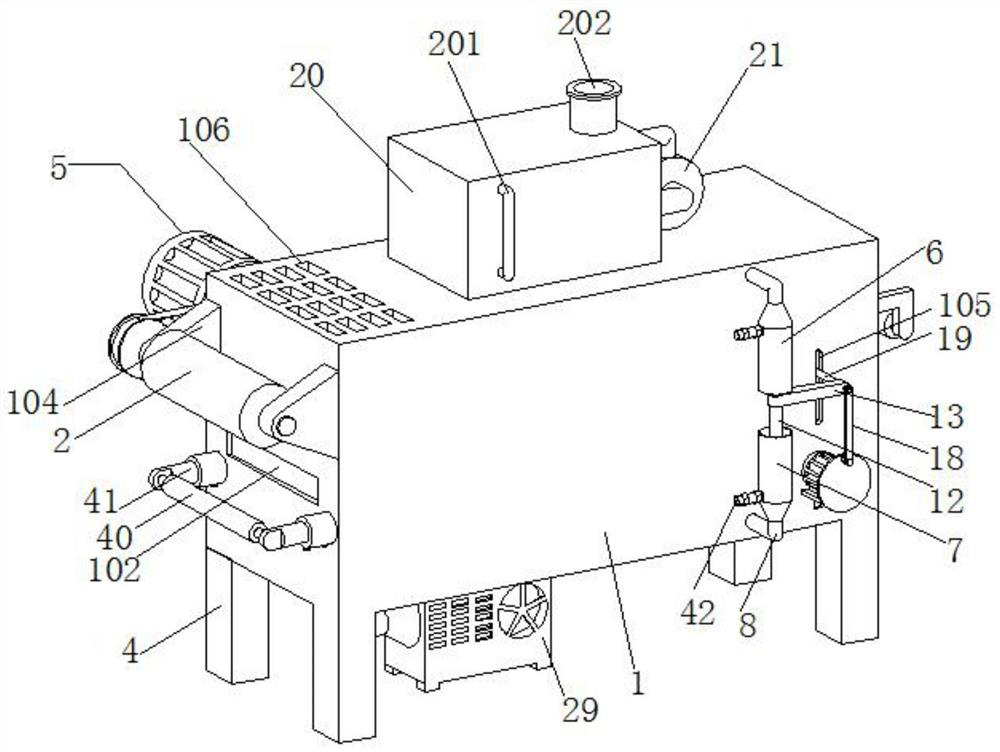

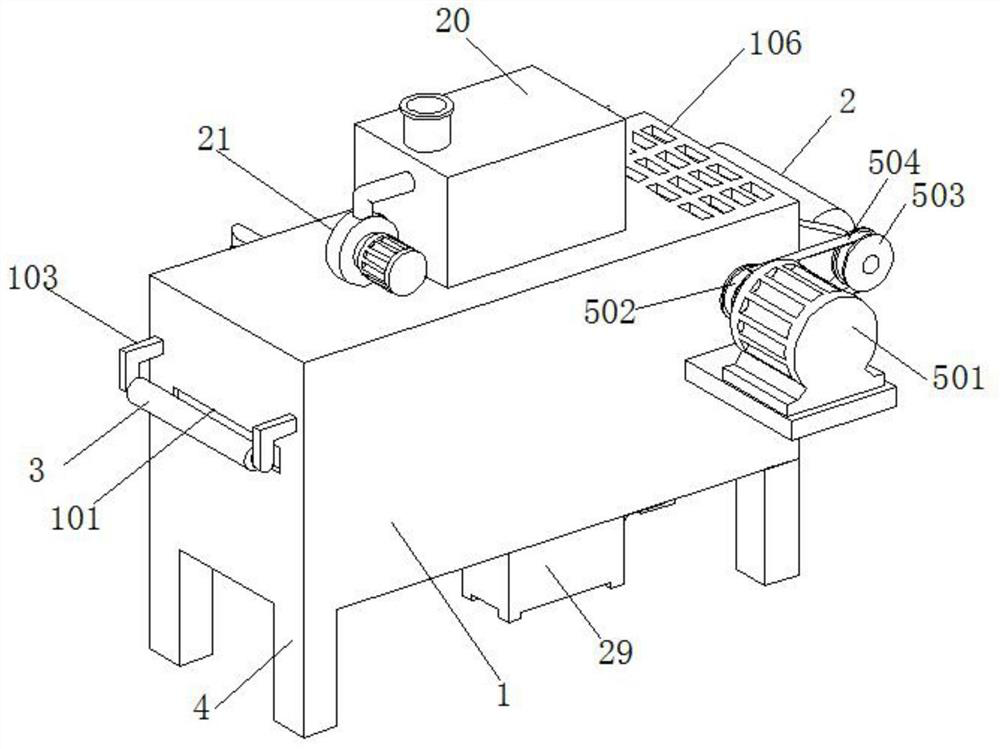

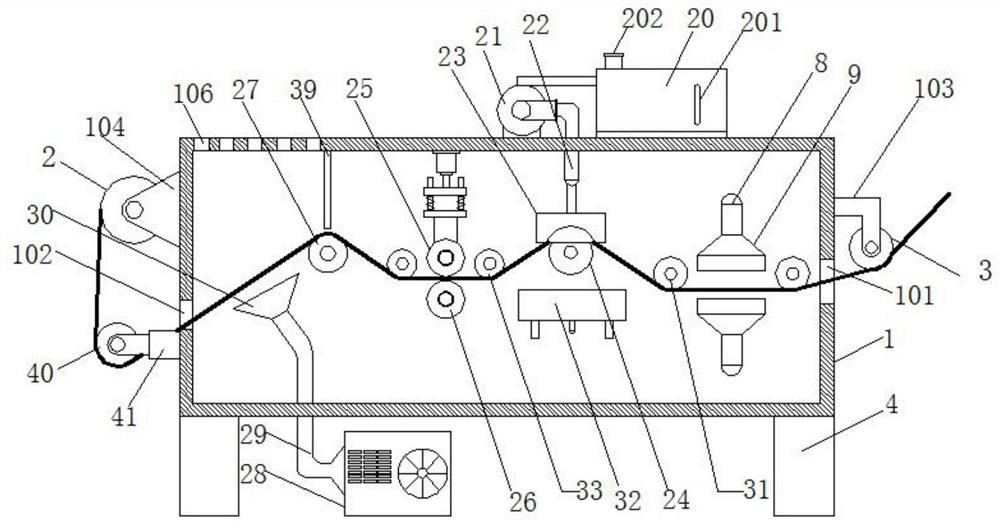

Spinning machine for textile fabric producing and processing and technology of spinning machine

ActiveCN111501169AImprove surface qualityNo wrinklesMechanical cleaningPressure cleaningSpinningDust control

The invention relates to the technical field of textile fabric processing equipment, and particularly discloses a spinning machine for textile fabric producing and processing and a technology of the spinning machine. A machine case, a winding roller and a guiding-in roller are included. Stand bars are arranged at the four corner positions of the lower surface of the machine case. A fabric inlet isformed in the right side face of the machine case. A fabric outlet is formed in the left side face of the machine case. The right side face of the part, located above the fabric inlet, of the machinecase is provided with a first rotation support, and the guiding-in roller is rotationally arranged on the first rotation support. Wind power combined electrostatic precipitation is conducted on the spun formed fabric firstly, then, anti-static liquid is sprayed to the fabric, the fabric obtained after anti-static liquid spraying is subjected to ironing treatment, finally, after an air heater is used for drying the fabric at the front treatment end, rolling is conducted, accordingly, static electricity does not exist on the surface of the prepared textile fabric, meanwhile, the dust on the surface of the textile fabric is effectively removed, wrinkles do not exist on the surface of the ironed textile fabric, the fabric surface quality is greatly improved, and the product market competitiveness is improved.

Owner:浙江兰溪银丰纺织有限公司

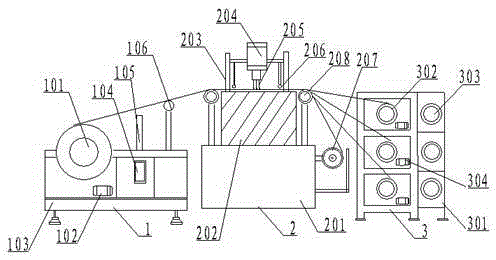

Transparent tape slitting machine

InactiveCN105383989AImprove cutting efficiencyUniform qualityArticle deliveryEngineeringUltimate tensile strength

The invention discloses a transparent tape slitting machine. The transparent tape slitting machine comprises a pay-off device, a cutting device and a take-up device. The pay-off device comprises a pay-off base, and a pay-off rotary shaft is fixedly disposed on the pay-off base. The cutting device comprises a cutting base; a supporting plate is disposed at the upper end of the cutting base; two supporting stand columns in the vertical direction are disposed at the upper end of the supporting plate; the upper ends of the supporting stand columns are connected with a supporting transverse beam structure; a cutting air cylinder is disposed in the middle of the supporting transverse beam; a cutting air cylinder spindle mechanism is disposed at the lower end of the cutting air cylinder; cutters are disposed on the spindle mechanism. By means of the transparent tape slitting machine, the tape slitting efficiency is improved, the labor intensity of slitting work is relieved, and the tape slitting quality is uniform.

Owner:TAICANG ZHONGHOU MECHANICS CO LTD

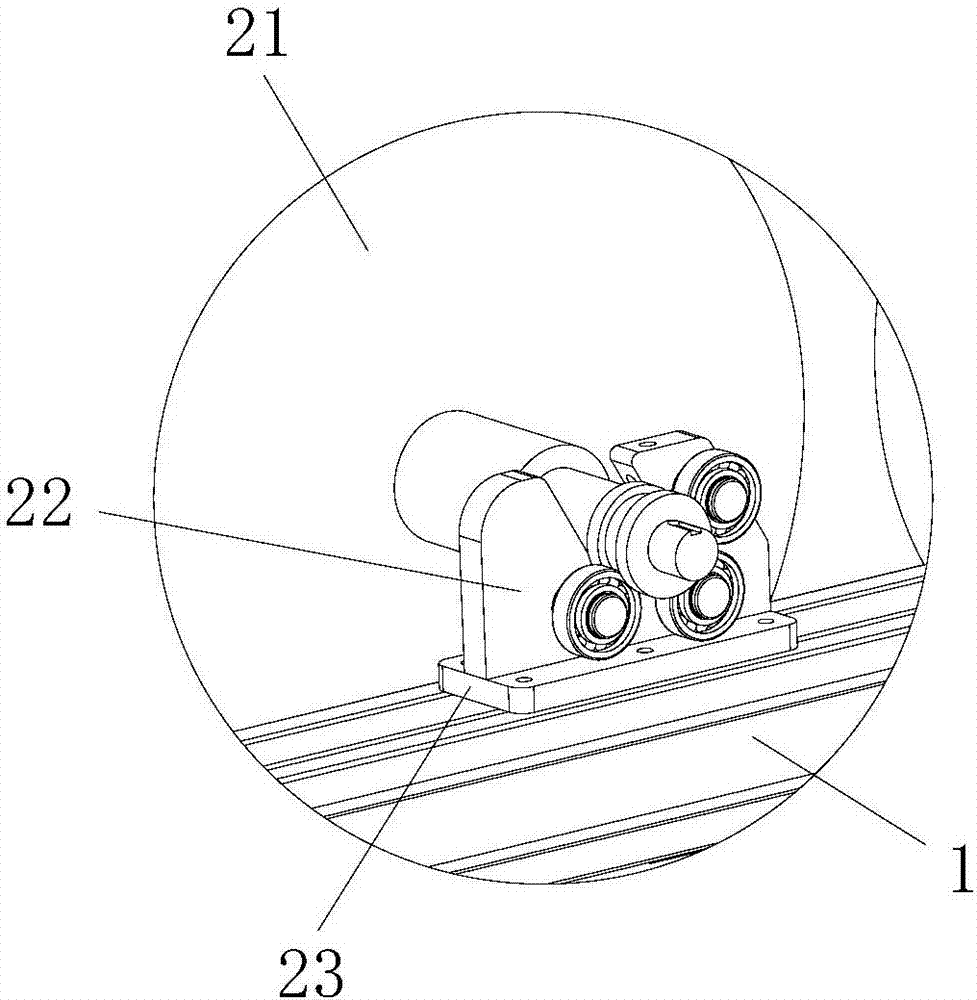

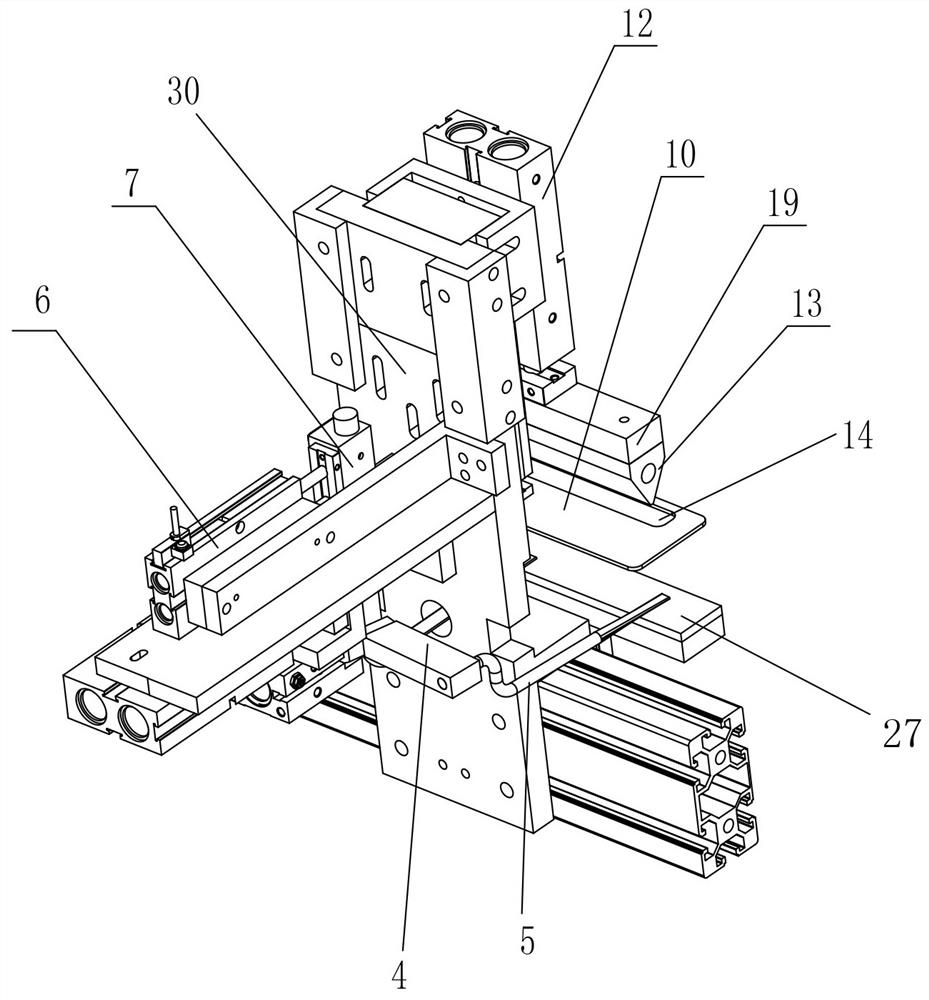

Tube-bending machine

InactiveCN106825152AWork reliablyNot easy to damageMetal-working feeding devicesPositioning devicesTube bendingEngineering

The invention belongs to the technical field of pipe bending processing equipment, and in particular relates to a pipe bending device. It includes a machine frame, a mandrel feeding and shaping mechanism, a pipe bending mechanism, a pipe clamping mechanism, a guiding and pressing mechanism, etc.; The mechanism includes a main shaft rotatably mounted on the frame, on which a transmission gear is fixedly set, and the transmission gear meshes with a drive rack, and the drive rack is connected to an elbow to drive the oil cylinder; the top end of the main shaft A pipe bending die is installed; the clamping mechanism includes a clamping die, and the clamping die is connected with a clamping die driving mechanism. The whole machine of the invention has a compact and reasonable structural design, can realize bending of various specifications of elbows, works stably and reliably, and is convenient for forming the elbows, which is beneficial to improving work efficiency.

Owner:NANJING GAODA STAINLESS STEEL

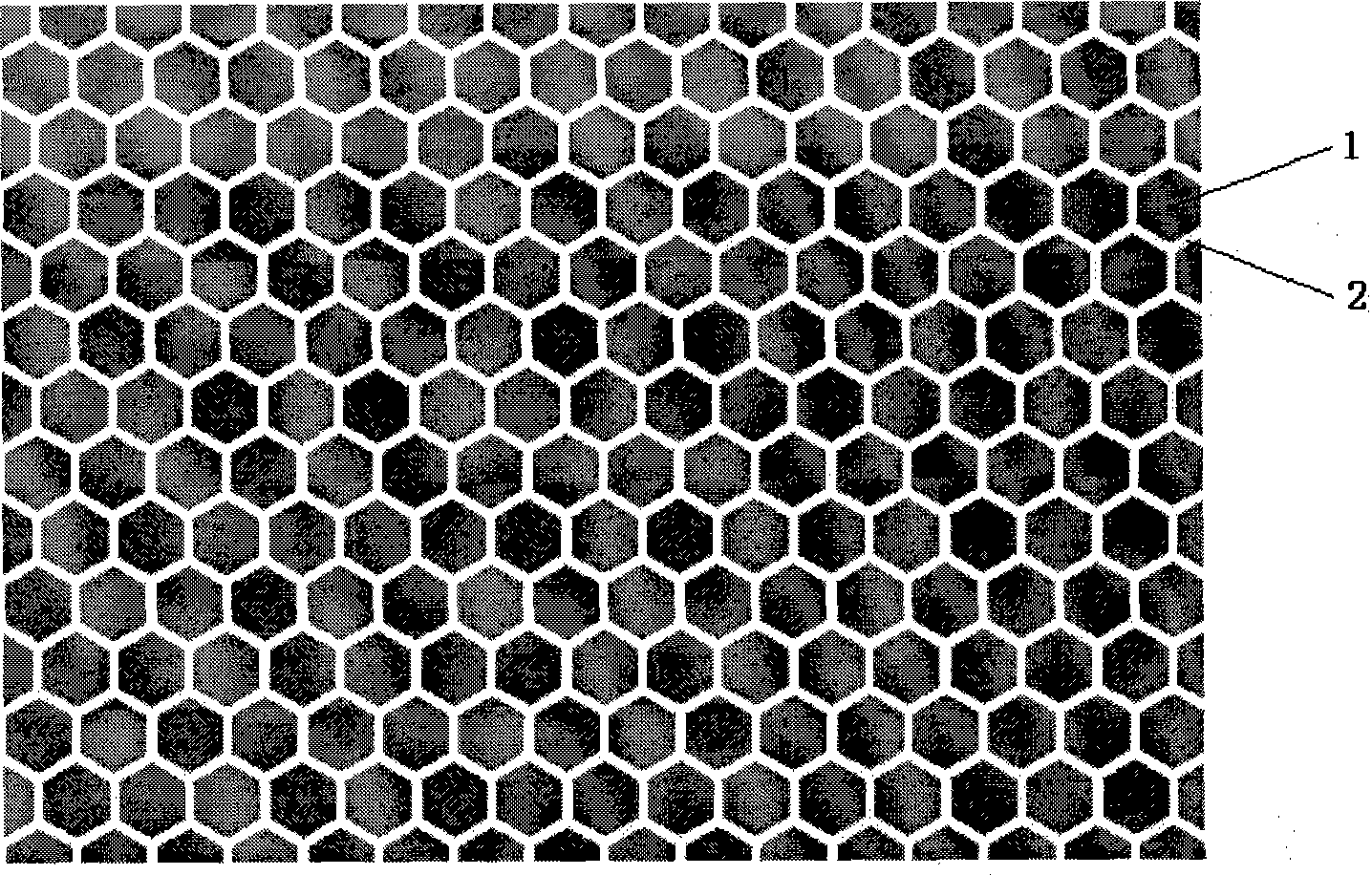

Production technology for water ripple resistant lining

InactiveCN105019106AFeel softImprove bulkWoven fabricsLiquid/gas/vapor textile treatmentEngineeringHot-melt adhesive

The invention discloses a production technology for water ripple resistant lining comprising following steps: nylon grey cloth weaving: nylon wire is employed as grey cloth material, 2 / 2 twill weave structure is employed, and the grey cloth from a cloth unloading device is sent to a starching machine by a cloth guiding rack; starching and coating with hot melt adhesive: the grey cloth is coated by the starching machine with a microporous round net and a base coating sizing agent with high viscosity; powder spreading: adhesive powder is spread onto the clot with a powder spreading machine wherein PA nylon powder with diameter range from 80 microns to 140 microns is used as the adhesive powder; powder absorbing, infrared sintering and drying; cooling and coiling: the stentered and sized grey cloth is naturally cooled and the grey cloth is coiled with a cloth coiling rack. At last the water ripple resistant lining undergoes factory testing. The peeling strength, reverse osmosis strength and levelness after washing of the water ripple resistant lining reach 7 to 8 newtons per 2.5 centimeters, 0.4 newtons per 5 centimeters and the fourth class respectively. There is no water ripple or creases with the use of the water ripple resistant lining and additional value of high-end clothing is increased.

Owner:维柏思特衬布(南通)有限公司

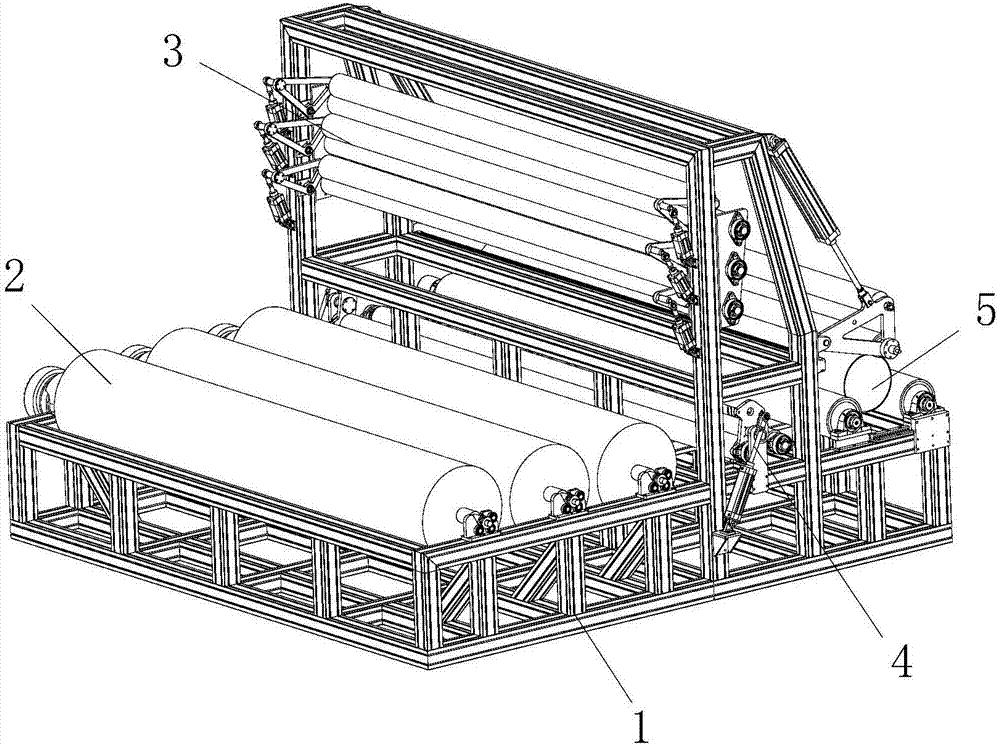

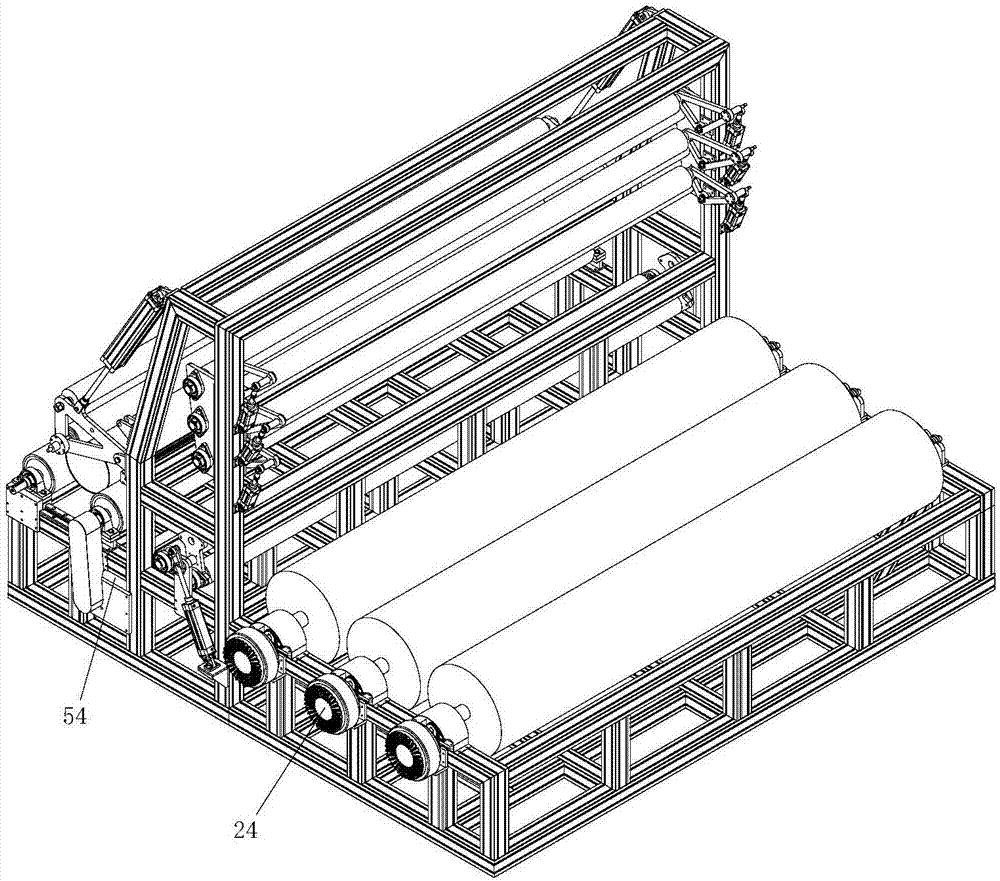

Composite weaving cotton cloth winding machine

PendingCN107285106ANo wrinklesImprove product qualityArticle deliveryWebs handlingCotton clothWinding machine

The invention discloses a composite weaving cotton cloth winding machine. The winding machine comprises an aluminum profile rack, a fabric roll mechanism, a glue coating mechanism, a tensioning mechanism and a rolling mechanism; three layers of weaving cotton cloth penetrates the position, corresponding to the glue coating mechanism, between a glue coating and cloth clamping roller and a smooth roller, a stretchable driving device drives a creel compression roller swing arm to move to enable the glue coating and cloth clamping roller to abut against the smooth roller, the upper layers and the lower layers of two layers of weaving cotton cloth are coated with glue through glue coating and cloth clamping roller, and therefore the three layers of weaving cotton cloth can be bonded together to form composite weaving cotton cloth; the three layers of weaving cotton cloth obtained after glue coating penetrates a tensioning mechanism, a tensioning cylinder drives a tensioning roller to move in the direction getting close to or being far away from a fixing roller, and the three layers of weaving cotton cloth obtained after glue coating are tensioned and bonded to form the composite weaving cotton cloth; and finally, a driving roller assembly of the rolling mechanism enables the composite weaving cotton cloth to be wound on a mold mandril, the composite weaving cotton cloth is compressed on the mold mandril through a compression roller assembly, and bonding and rolling of the three layers of weaving cotton cloth are completed. By means of the composite weaving cotton cloth winding machine, the three layers of weaving cotton cloth can be bonded together to form the composite weaving cotton cloth, the folding phenomenon is avoided, and rolling and winding are achieved.

Owner:黄松檀

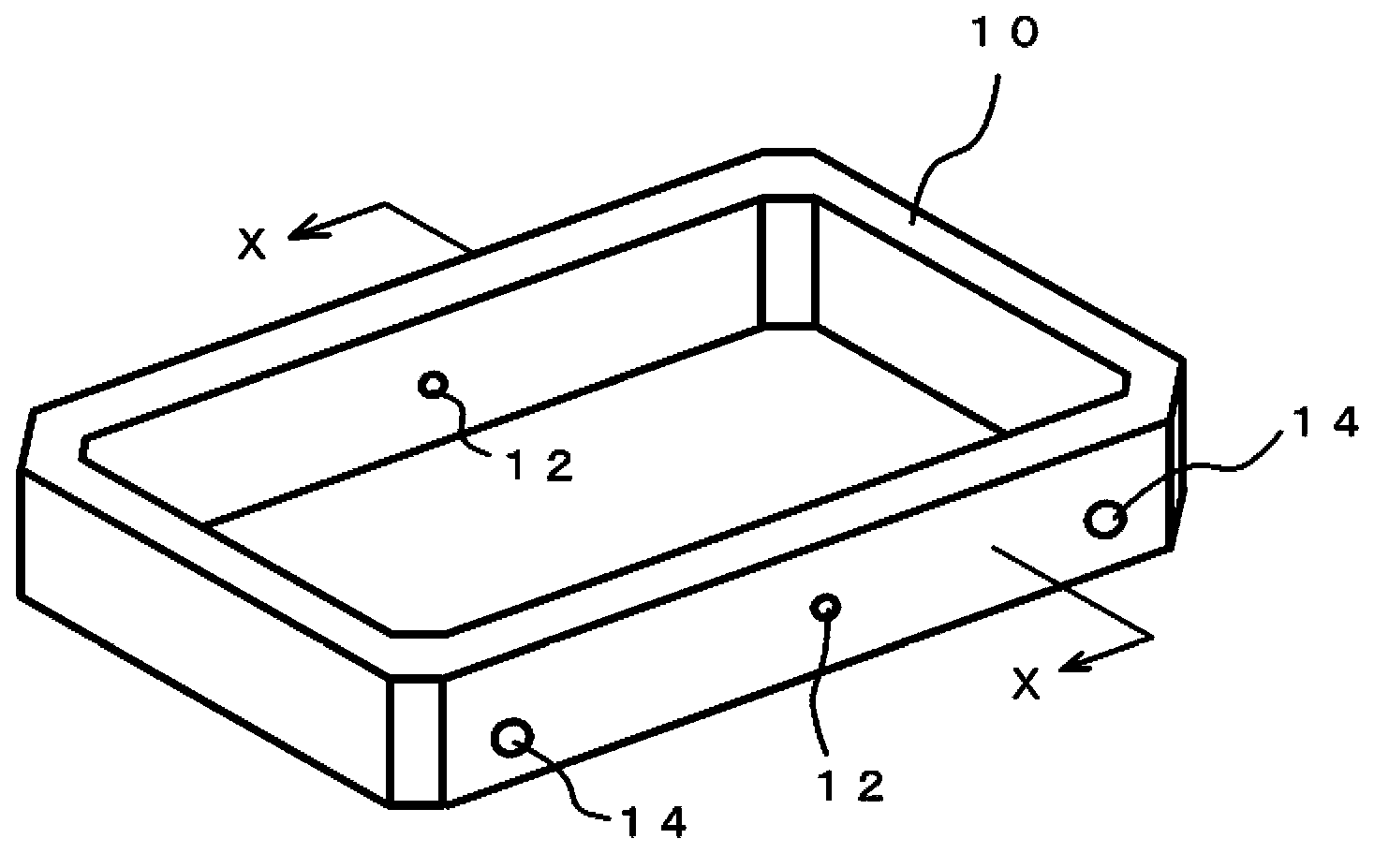

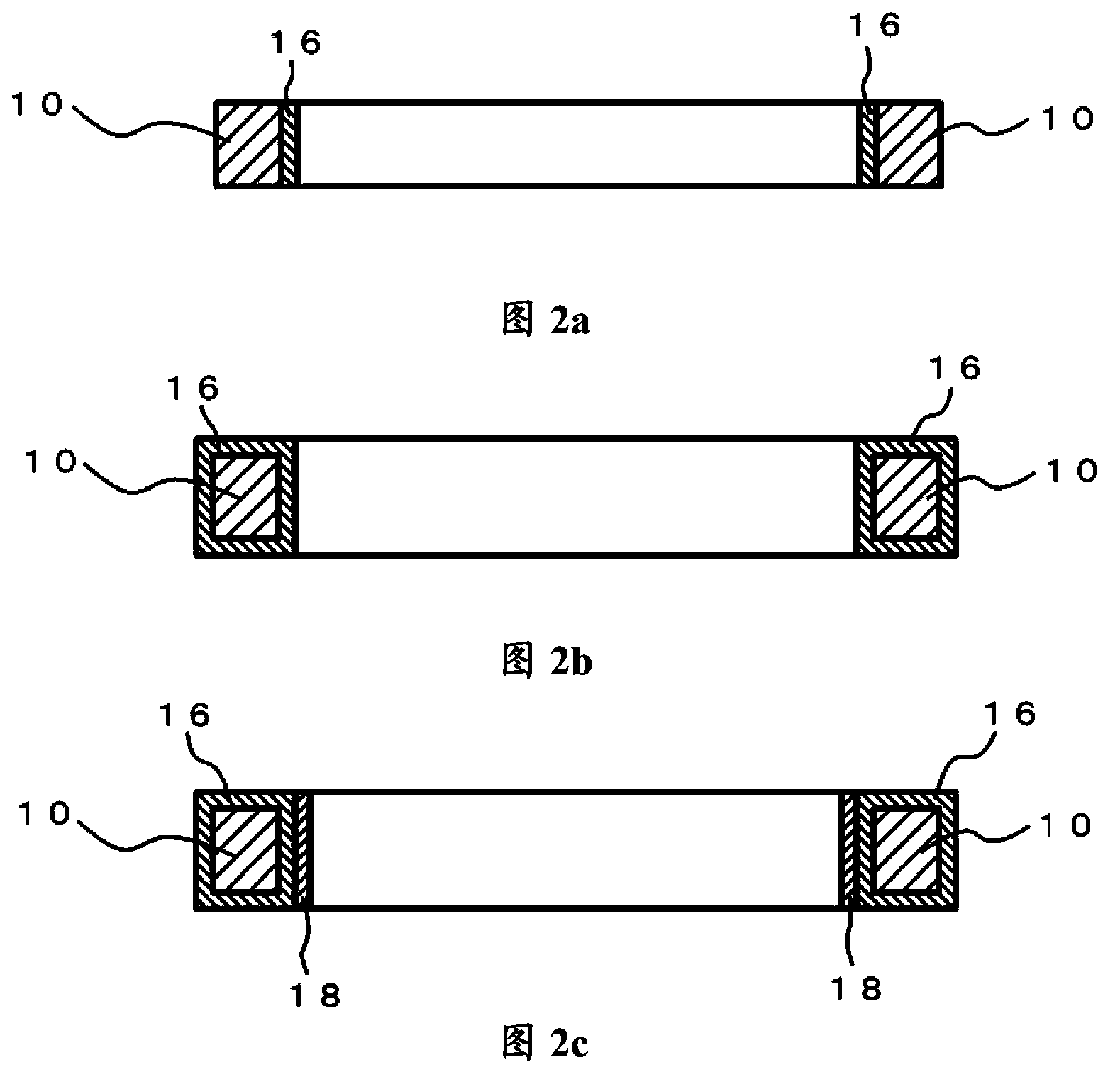

A dustproof thin film assembly frame and a dustproof thin film assembly

InactiveCN103365074ANo warpingRigid enoughPhotomechanical apparatusOriginals for photomechanical treatmentUltraviolet lightsEngineering

The invention provides a resin-produced dustproof thin film assembly frame with increased rigidity. The dustproof thin film assembly frame (10) is formed by melt pressure and is formed by thermoplastic resin mixing intensity enhancer in a fiber shape. Preferably, at least the inner side surface of the dustproof thin film assembly frame (10) is covered with a resin covering film (16) with light resistance to ultraviolet light.

Owner:SHIN ETSU CHEM IND CO LTD

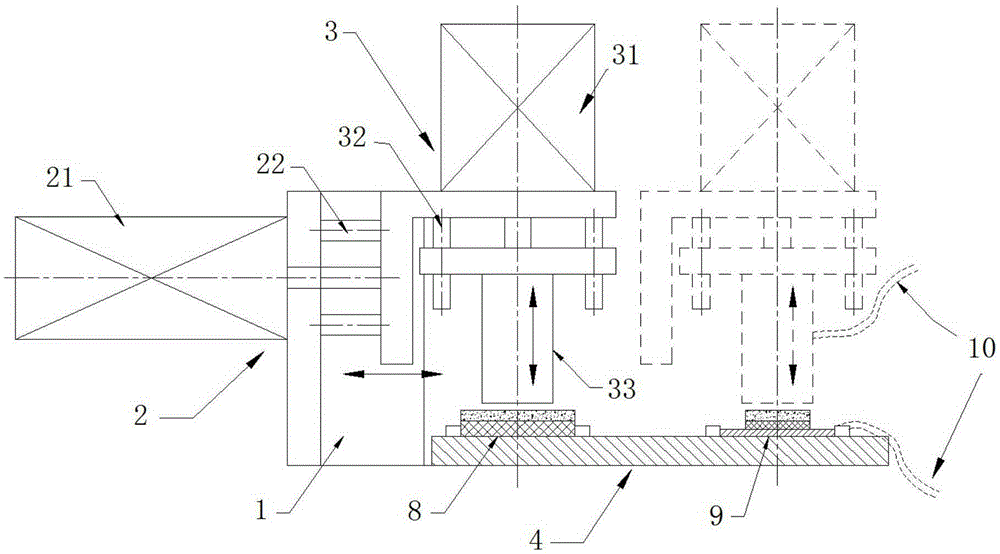

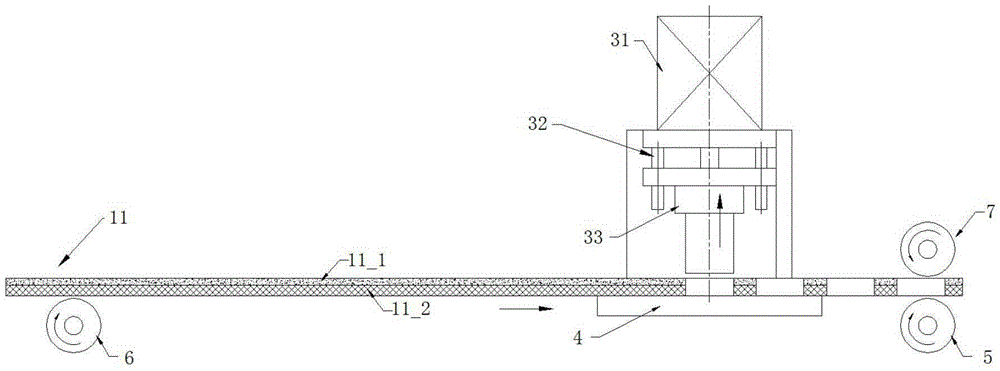

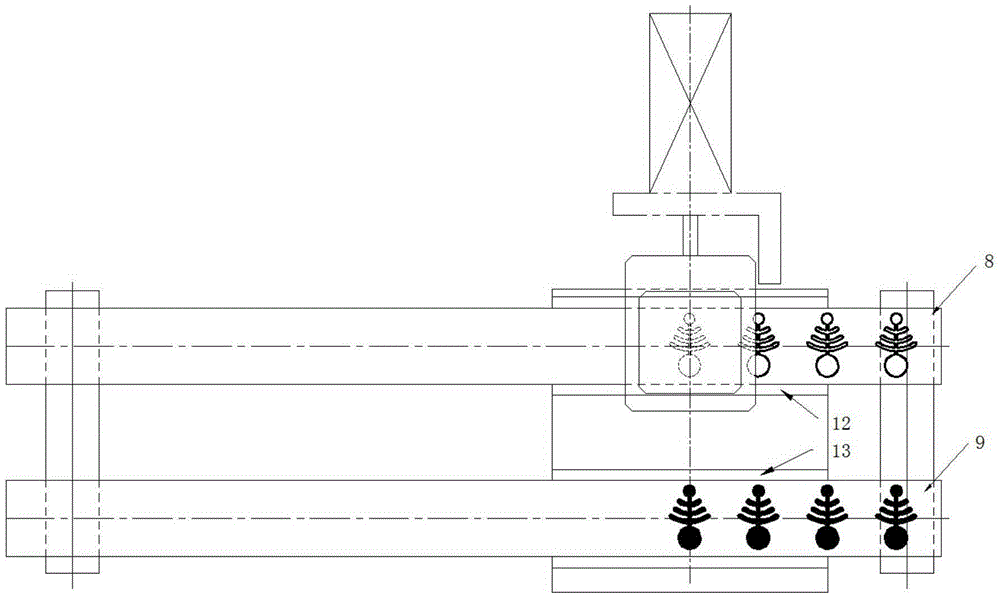

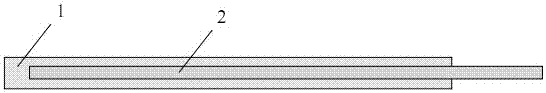

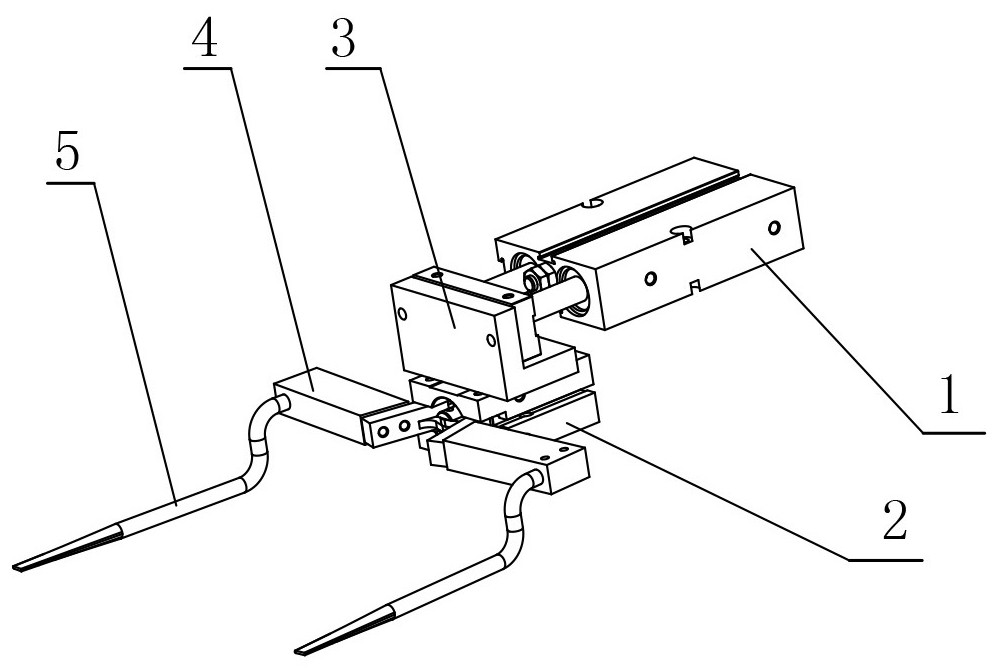

Belt metal layer film punching device and method thereof

The invention discloses a belt metal layer film punching device and a method thereof. The device comprises a base, a vacuum pump, a moving assembly, a punching assembly, a vacuum hole supporting plate, a power wheel disc, a rotating wheel disc and a pressure wheel disc. The punching assembly comprises a punching power source, punching guiding rods and a vacuum hole male die. A cutting die is arranged on the vacuum hole male die, and first adsorption holes are formed in the inner surface of a sealed area of the vacuum hole male die. The surface of the vacuum hole supporting plate is provided with female dies, positioning sliding grooves and second adsorption holes. The punching method of the device comprises the steps that a belt metal layer film is punched through the vacuum hole male die; a cut metal pattern product is adsorbed on the surface of the vacuum hole male die, and waste materials after punching are adsorbed through the vacuum hole supporting plate; and the product is stuck onto a new film through adsorptive transfer. According to the belt metal layer film punching device and the method thereof, the cut metal pattern product is subjected to adsorptive control and transferring, and it can be guaranteed that the cut product is prevented from jumping out of a punch, so that the production operation of an assembly line is achieved, and the flatness of the product surface is guaranteed.

Owner:柔电芯云(珠海)科技有限公司

Method for manufacturing goalkeeper's stick

The invention relates to the technical field of sporting goods, in particular to a method for manufacturing a goalkeeper's stick. The method comprises steps as follows: manufacturing an inflatable silica gel batten; manufacturing a straight-bar preform; obtaining a straight-bar rough blank after molding of the preform; manufacturing middle-section and front-section filling plates; manufacturing a preform of a goalkeeper's plate; obtaining a rough blank of the goalkeeper's plate after molding of the preform; obtaining a rough blank of the goalkeeper's stick through finishing. The method has the beneficial effects as follows: 1, the quality of the rough blank of the goalkeeper's straight bar is improved; 2, strength of the goalkeeper's straight bar is improved; 3, production benefit is increased.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

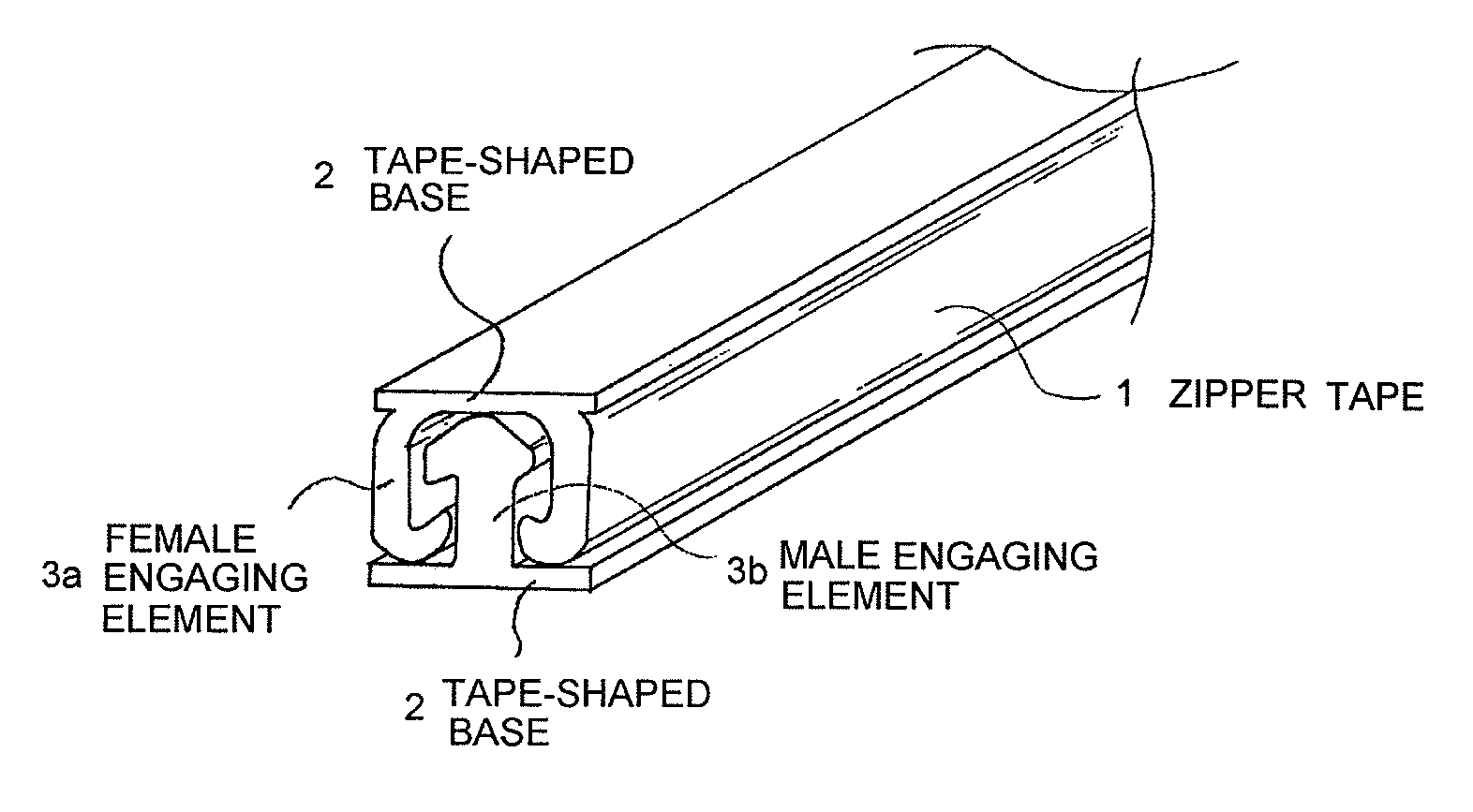

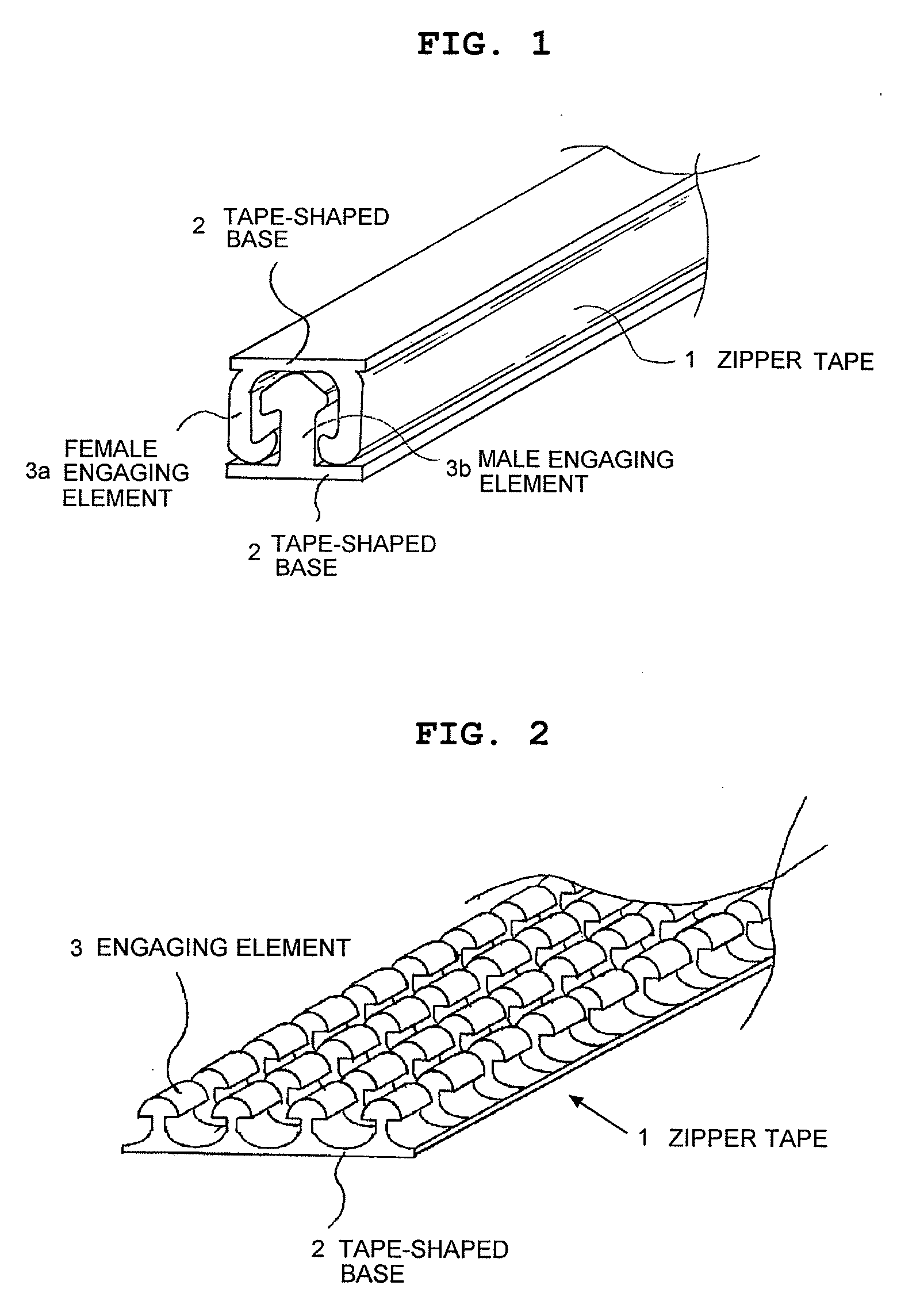

Heat bonding method and heat bonding device

InactiveUS20120314977A1Easy to engageNo wrinklesBag making operationsPaper-makingThermal bondingElectrical and Electronics engineering

Owner:CHOKOKU PLAST CORP

Perforating die of flexible heat controlled thin film

InactiveCN101347942AAppropriate tensionHigh positioning accuracyMetal working apparatusPunchingEngineering

The invention relates to a flexible thermal control film punching die which comprises a female die 6 with two rows of cutting edges, and a male die 15; wherein, the female die 6 is fixedly arranged on a lower plane plate 7 by a first positioning pin 20 and a first internal hexagonal head screw 19; a supporting plate 22 is arranged on the lower plane plate 7; a bottom plate 24 is fixed on the supporting plate 22 by a first screw 23; a tight roll 21 is arranged on the supporting plate 22; guide poles 11 are arranged on the lower plane plate 7 by guide sleeves 13; a connecting plate 8 is arranged at the lower end of each guide pole 11; the lower plane plate 7 and the female die 6 are correspondingly provided with through holes; the male die 15 and the female die 6 are correspondingly arranged on a fixing plate 5; a pressing cover 2, a pressing plate 3 and the fixing plate 5 are arranged on the guide poles 11 by pressing sleeves 10; strengthening ribs 4 are arranged on the pressing plate 3. One motion of the flexible thermal control film punching die can lead to the punching of two rows of holes without interruption. A four-guide-pole positioning structure of the four guide poles is adopted for the flexible thermal control film punching die, with high positioning precision ensured; certain side force is applied to the four guide poles, the guiding of each guide pole employs dry friction, and films can not be polluted by oil in the process of punching. The films retain smooth and have suitable tensile force without being folded in the process of punching.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

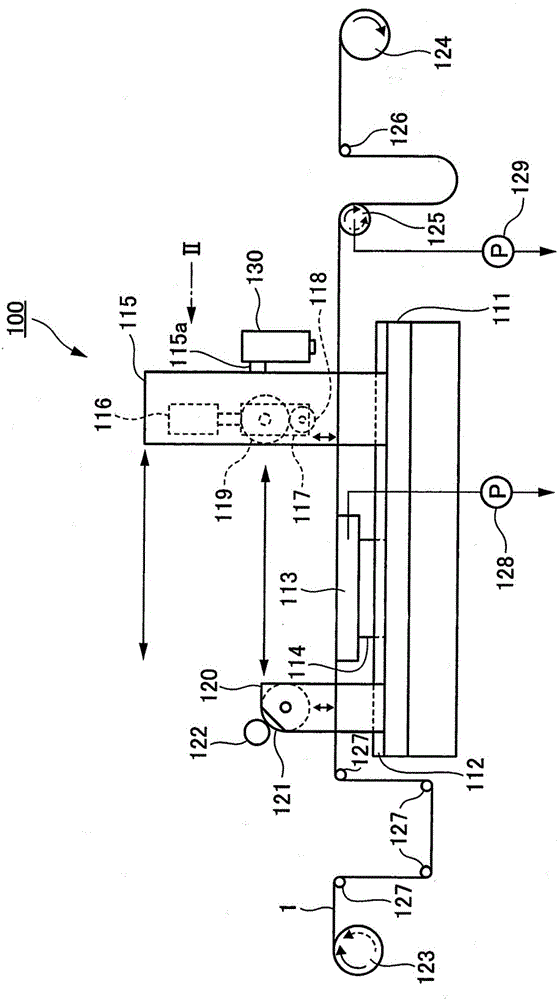

Printing press

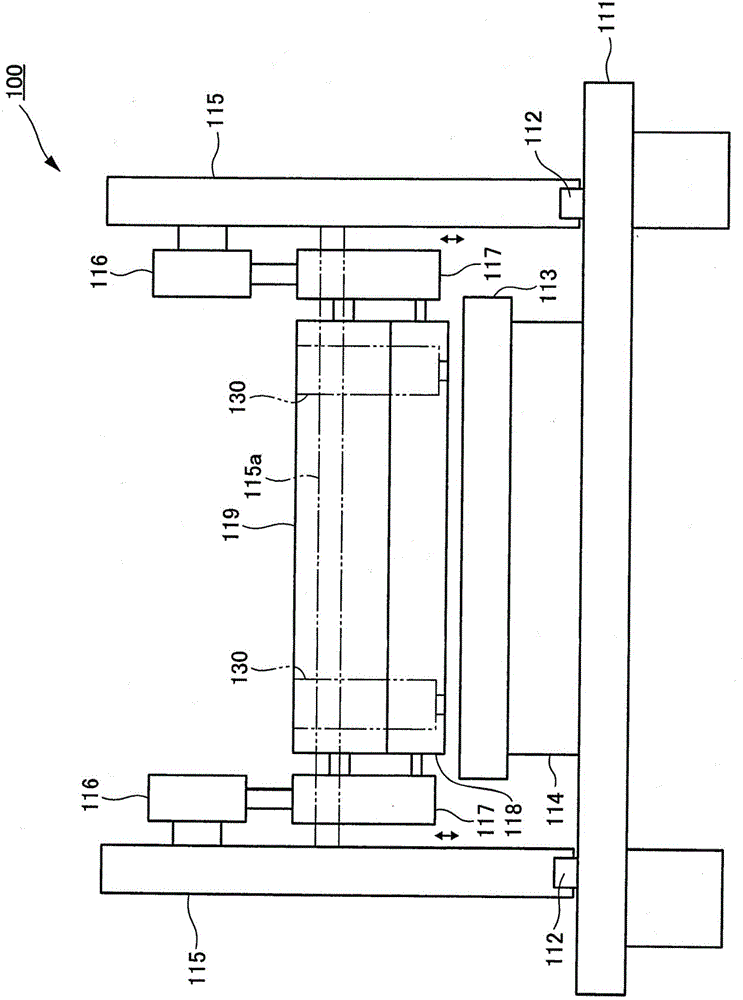

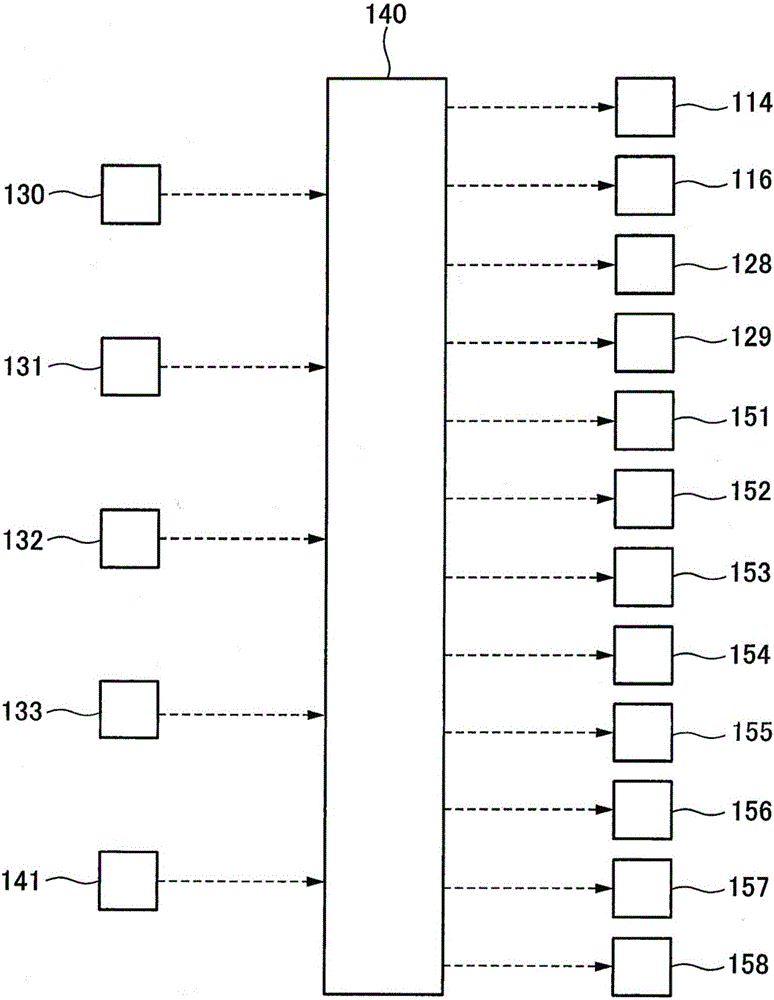

The invention provides a printing press which can forming a pattern on a tubular base material in high quality. The printing press (100) comprises: a feed roller (123) which can feed a base material (1), a suction roller (125) which can hold and convey the base material (1) fed by the feed roller (123), an objective table (113) which is configured between the feed roller (123) and the suction roller (125) and supports the base material (1) on the upper surface, a suction pump (128) which can hold the base material (1) on the upper surface of the objective table (113), and a registering adjusting device (114) which can adjust the position of the objective table (113); wherein the control device (140) controls the suction pump (128) in a way of holding the base material (1) on the objective table (113), the control device (140) controls the feed roller (123) and the suction roller (125) in a tension release way of objective table (113) separately, and the the control device (140) controls the registering adjusting device (114) in a way of adjusting the position of the objective table (113).

Owner:KOMORI CORP

Manufacture method of ham sausage type silkworm feed

InactiveCN102640865ASolve shelf life issuesSolve long-distance transportation problemsAnimal feeding stuffVitamin CCholine chloride

The invention relates to a manufacture method of ham sausage type silkworm feed. The method comprises the following steps that: 1) soybean flour, mulberry green branch powder, starch, vitamin C, compound vitamin B, inorganic salt, citric acid, crotonic acid, choline chloride and the like are placed into mulberry leaf powder to be stirred to the uniformly mixed state, and dry powdery feed is obtained; 2) water is added into the dry powdery feed obtained in the first step, the materials are continuously stirred until the materials are uniformly mixed, and mixed feed is obtained; and 3) the mixed feed obtained in the second step is sequentially subjected to filling, buckling and steam boiling, then, the steamed and boiled feed is placed into cold water to be soaked, then, the feed is cleanly flushed, and the ham sausage type silkworm feed is obtained. When the manufacture method provided by the invention is adopted, the feed ham sausage type silkworm feed problem is solved, and the long-distance transportation problem is also solved.

Owner:山东省蚕业研究所

Green sheet, manufacturing method thereof and slurry composition for forming green sheet

The invention provides a raw film, the manufacturing method thereof and the slurry combination for generating the raw film. The raw file is good in binding property, plasticity, property for stripping off from the slices or film used in manufacturing and surface property with no concavo convex, no crack and no wrinkles. The raw film is prepared by coating the slurry combination containing component solvent, binding agent and power onto the slices or films and stripping off after it is dry. In which, the component solvent contains the low boiling point solvent with boiling point below 100 degrees centigrade and high boiling point solvent with boiling point above 100 degrees centigrade.

Owner:NITTETABU MINING CORP

Molding extruder of PFA plastic products

The invention discloses a molding extruder of PFA plastic products. The molding extruder comprises two support legs, wherein a support stand column is connected to each support leg; the top end of each of the two support stand columns is connected to a horizontal beam structure; an extruder body is arranged on a horizontal beam; a hydraulic cylinder is arranged at the upper end of the extruder body; the extruder body adopts a vertical structure; a housing is made of a double-layered material; a material heating chamber is formed in the extruder body; left and right symmetric material drums are connected to the housing of the extruder. The molding extruder of PFA plastic products is compact in structure design and high in processing efficiency; the surfaces of the processed fluoroplastic finished products are uniform and are free of folds.

Owner:SUZHOU CHONGEN MOLDING

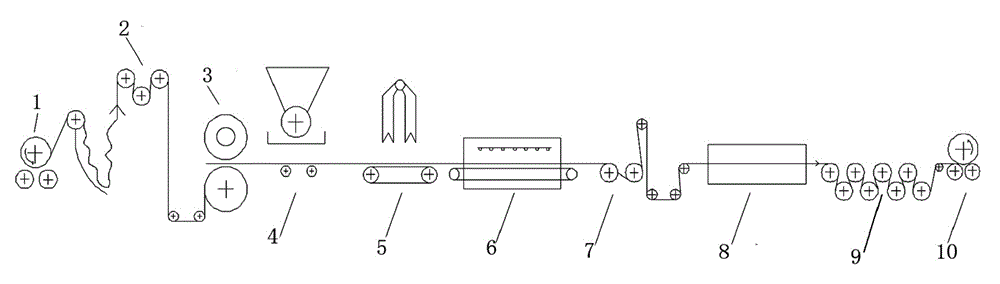

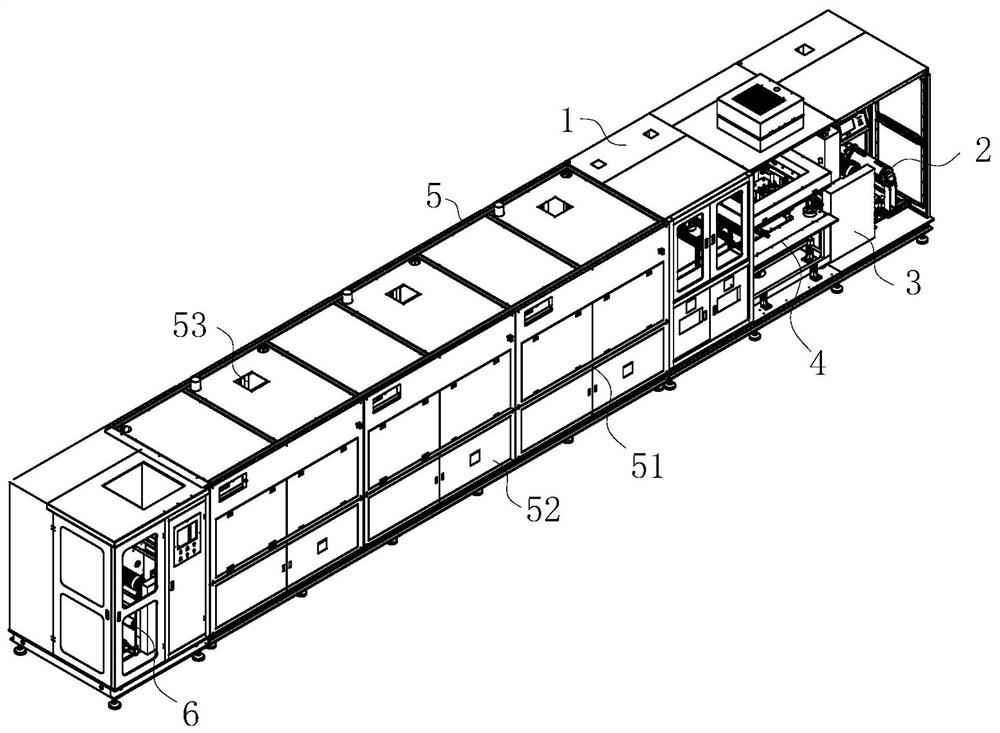

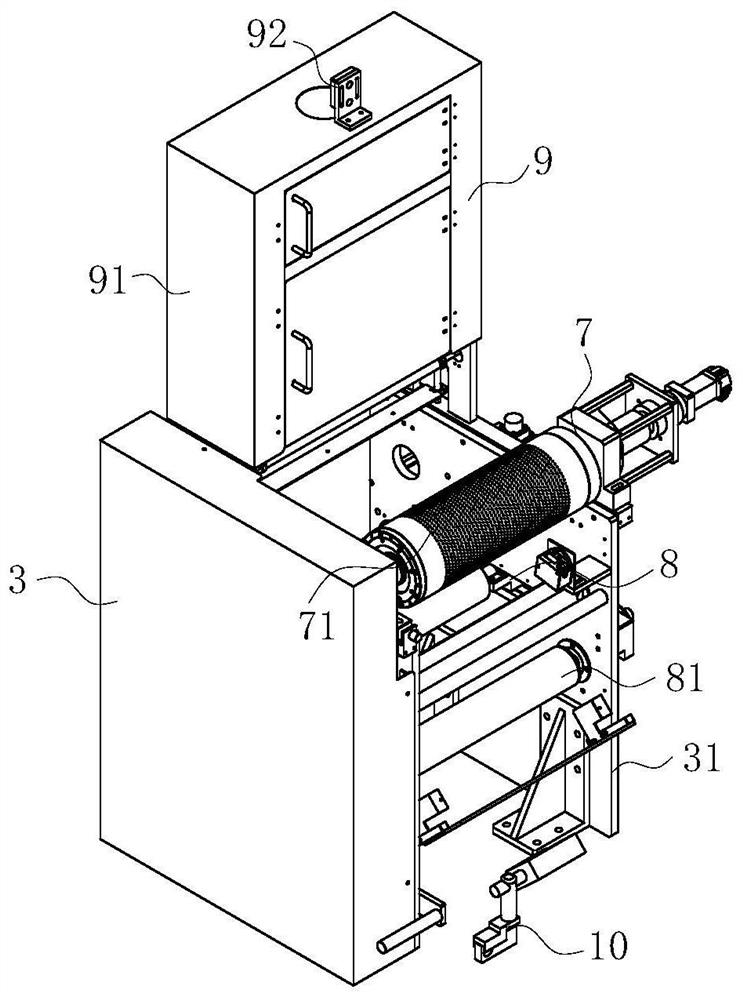

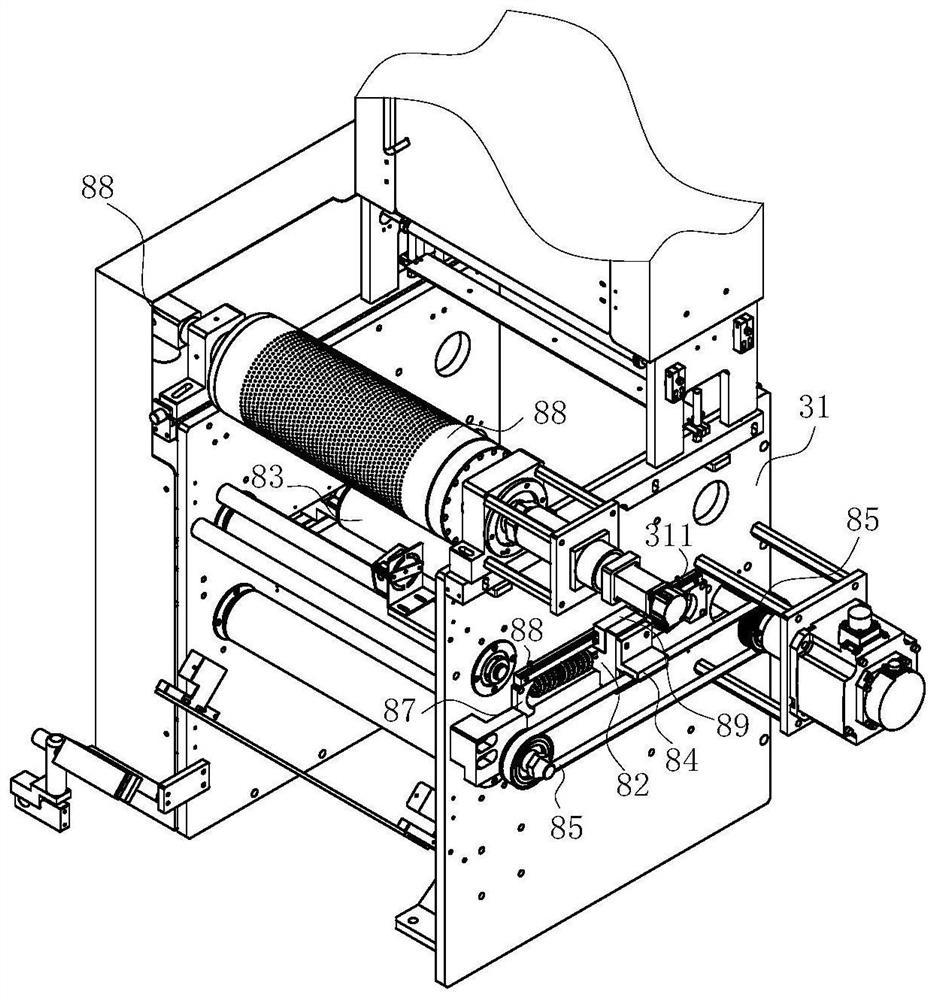

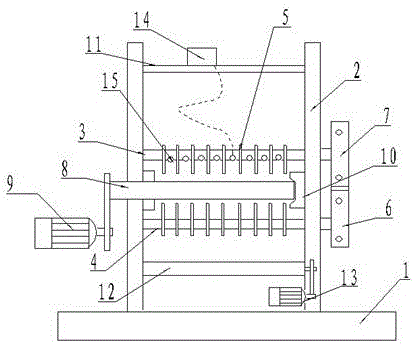

Precision electronic ceramic film silk-screen printing machine

ActiveCN112078234AImprove fluencyReasonable structural dischargeScreen printersPrinting press partsScreen printingElectric machinery

The invention belongs to the technical field of ceramic film silk-screen printing, and particularly relates to a precision electronic ceramic film silk-screen printing machine. The machine comprises arack; a conveying deviation rectifying mechanism, a tension conveying mechanism, a silk-screen printing mechanism, a drying mechanism and a winding deviation rectifying mechanism are sequentially arranged on the rack; a movable base is slidably mounted at the end of the rack through guide sliding rails, and the side wall of the movable base is connected to the driving end of a driving assembly; the output end of a deviation rectifying motor is connected with an unwinding inflatable shaft through an output shaft; the tension conveying mechanism is arranged between the unwinding deviation rectifying mechanism and the silk-screen printing mechanism, and a deviation rectifying sensor is arranged between the tension conveying mechanism and the unwinding deviation rectifying mechanism; an object carrying table is arranged on an object carrying frame through a lifting assembly, and a scraping head slurry spreading transmission assembly is arranged over the object carrying table; and a silk-screen printing head is adopted in the scraping head slurry spreading transmission assembly. By means of structural combination optimization, the equipment can adapt to silk-screen printing of productsof smaller specifications and ultra-wide film silk-screen printing, and the ceramic film silk-screen printing production efficiency is effectively improved.

Owner:肇庆市宏华电子科技有限公司

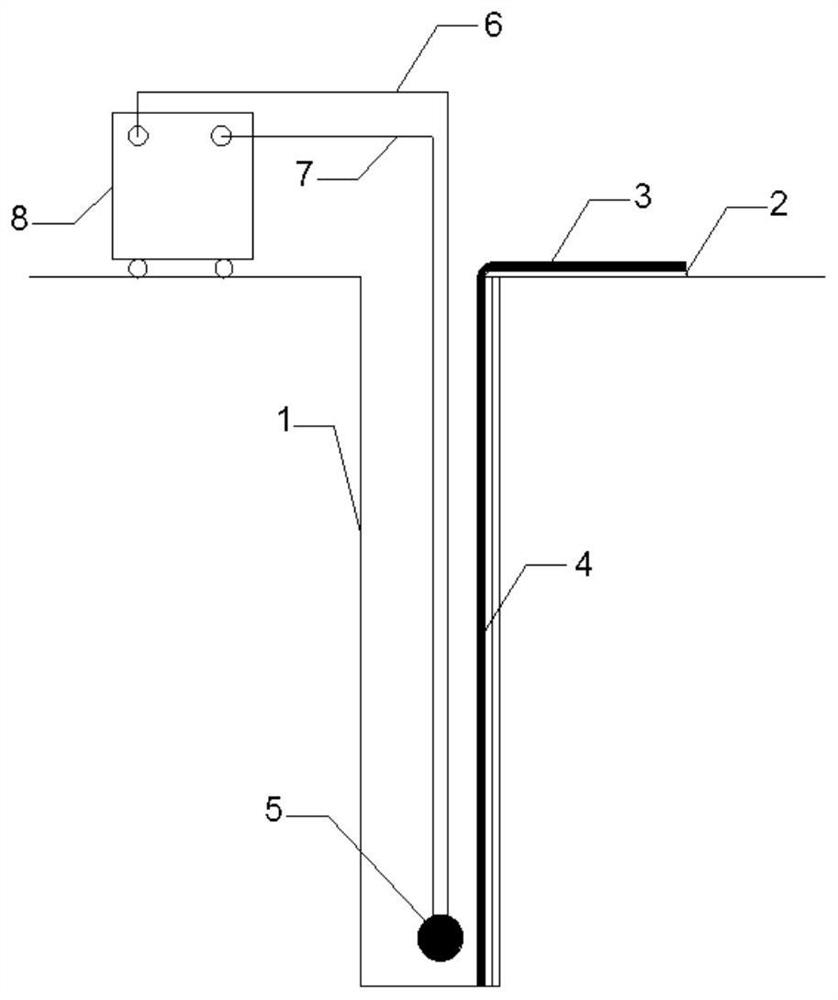

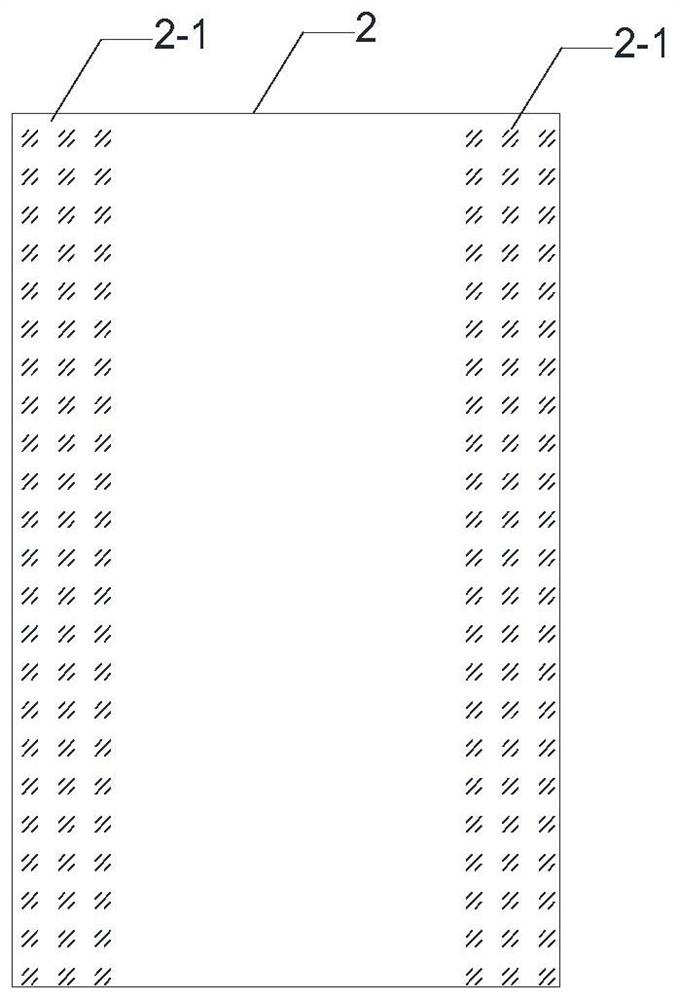

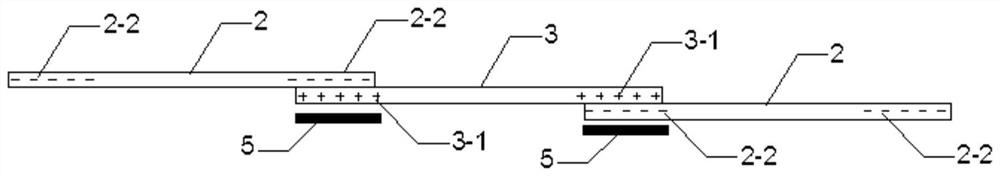

Self-adhesion device of impermeable membrane joint and self-adhesion type water interception curtain construction method thereof

ActiveCN112281885APermanent magnetizationAchieve self-adhesiveMagnetic bodiesFoundation engineeringLap jointElectric current flow

The invention relates to a self-adhesion device of an impermeable membrane joint and a self-adhesion type water interception curtain construction method thereof. The self-adhesion device comprises animpermeable membrane, a magnetizing rod or magnetizing plate, an anode cable, a cathode cable, a magnetizing and demagnetizing machine and the like, wherein the magnetizing and demagnetizing machine is connected with the magnetizing rod through the cathode cable and the anode cable, the magnetizing and demagnetizing machine enables a coil to generate a transient ultrastrong magnetic field throughinstantaneous pulse large current in the coil, magnetic materials in the coil can be permanently magnetized by the magnetic field, and the magnetizing rod or magnetizing plate is placed in the position of a to-be-activated impermeable membrane joint, so that the impermeable membrane joint is magnetized, the position of the impermeable membrane joint is activated as a cathode joint and an anode joint, and self adhesion of the impermeable membrane joint is realized. Thus, the problems that adjacent impermeable membranes are not firmly bonded, the lap joint is not tight and the impermeable effectis poor can be effectively solved, and the tightness and the impermeable performance of the lap joint of the impermeable membranes are improved while the problem that the vertical laying depth is limited is solved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Bi-directional cutting slitting equipment

InactiveCN105798969AUniform qualityNo glitchMetal working apparatusEngineeringMechanical engineering

The invention discloses bi-directional cutting slitting equipment. The bi-directional cutting slitting equipment comprises a base; two vertical supporting posts are arranged on the base; a connection cross beam, an upper cutter knife spindle, a workpiece material placing shaft, a lower cutter knife spindle and a material receiving shaft are arranged between the vertical supporting posts from top to bottom in sequence. According to the bi-directional cutting slitting equipment, cutter knives do not directly make contact with a material spindle in the using process, so that operation of the machine is smooth and steady, the cutter knife abrasion times is decreased, the service life is prolonged, the mass of the slitting equipment is uniform, and the phenomena of burrs and folds are avoided.

Owner:TAICANG ZHONGHOU MECHANICS CO LTD

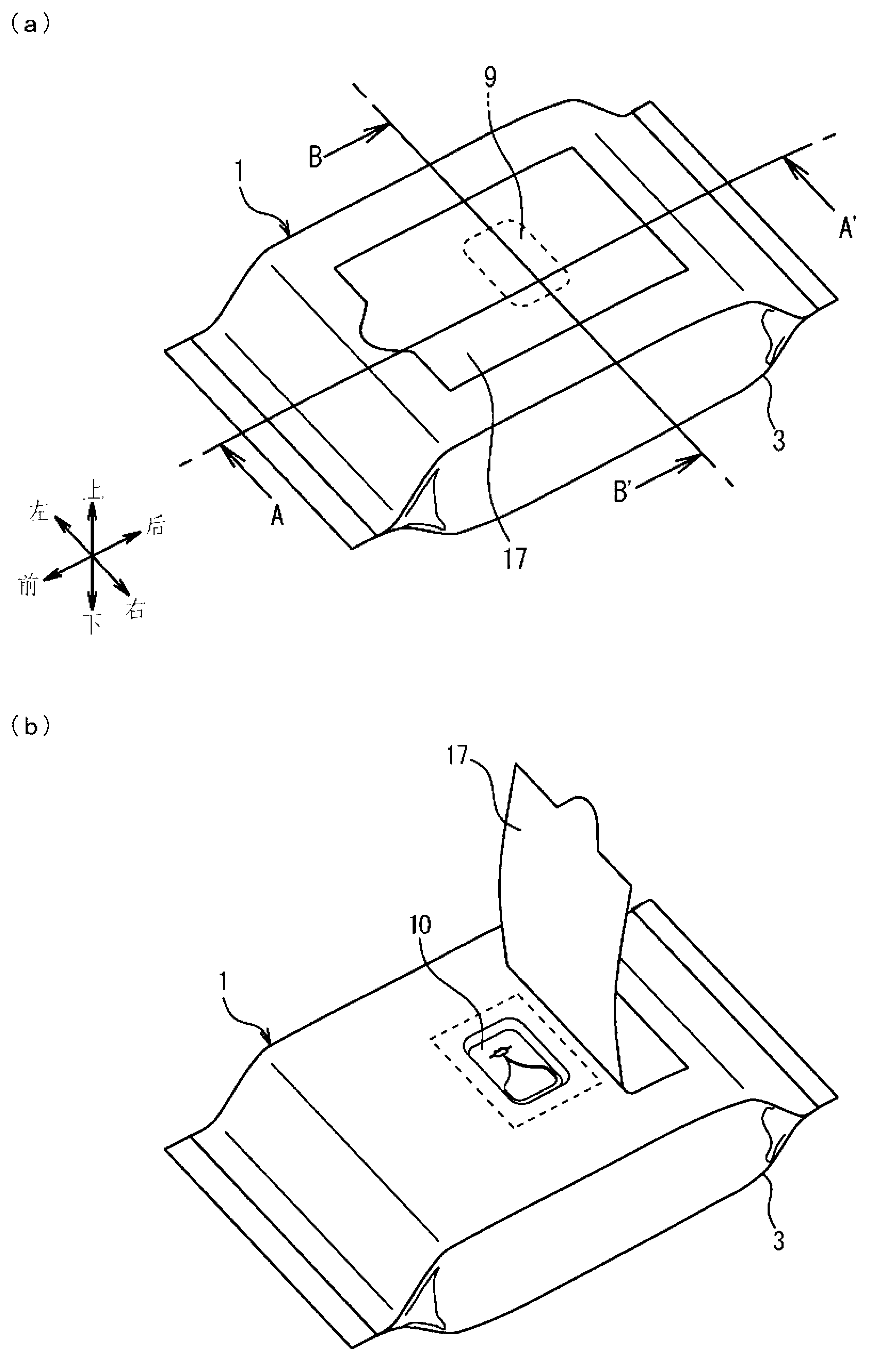

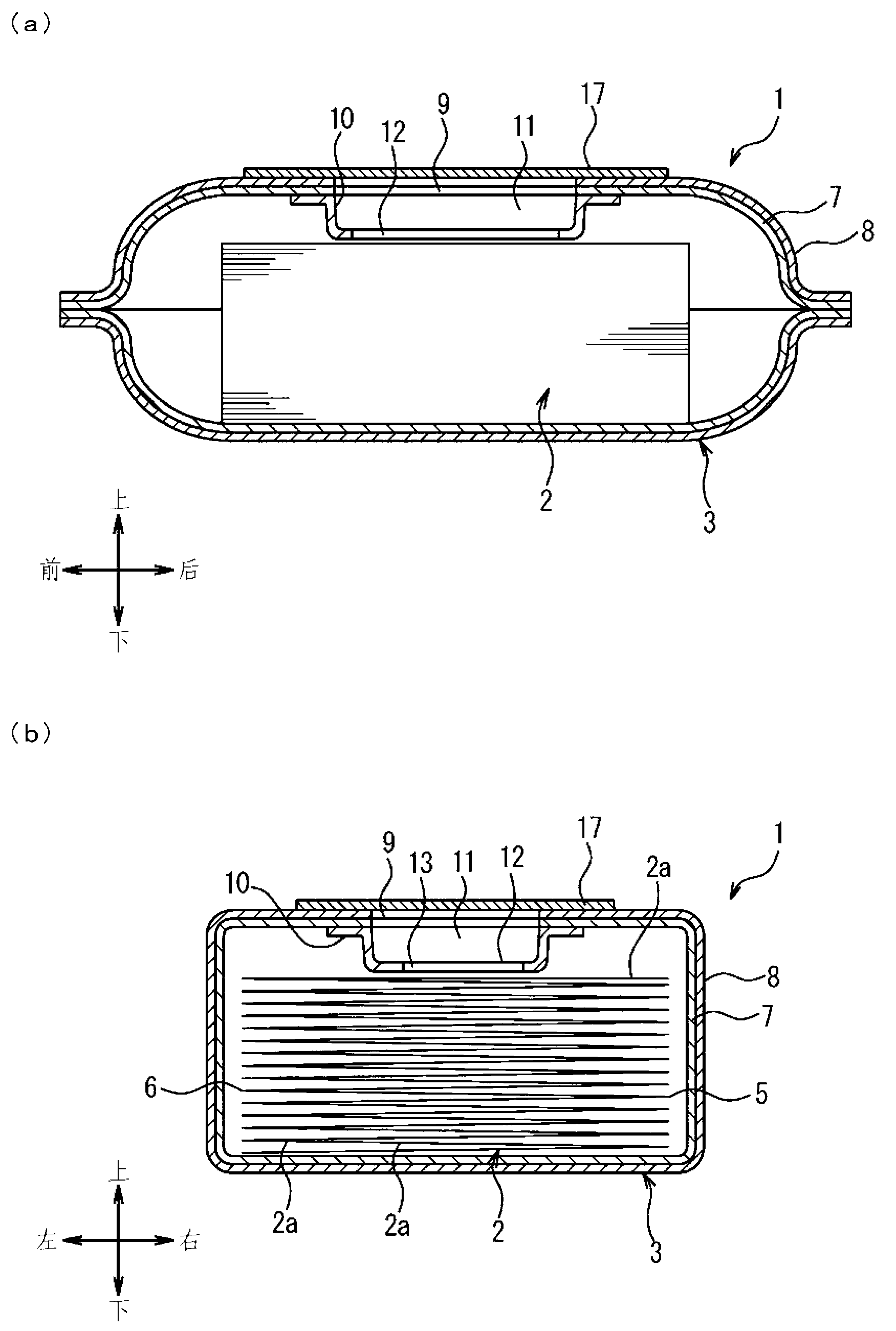

Wet wipe package

ActiveCN103228556AReduced time and operational complexityReduce effortBathroom accessoriesFlat article dispensingEngineeringWet wipe

Provided is a compact wet wipes package, wherein wet wipes can be easily drawn from a storage container, and the production cost can be kept low. This wet wipes package is provided with: a wet wipes folded body (2) which is continuously folded and stacked, and in which dividing portions (4) are formed at a predetermined interval; an airtight storage container which is formed to store the wet wipes folded body (2) and comprised an opening portion from which stored wet wipes(2a) are to be drawn outward; a base plate (10) which is attached to the opening portion and is formed with a pinching hole (12) through which the wet wipes (2a) are pinched and drawn outward; a drawing hole (13) which is linked with the pinching hole (12) and functions to divide the wet wipes (2a) at the dividing portion (4); and openable / closable lid (17) which can hermetically close the pinching hole (12) and the drawing hole (13).

Owner:山田菊夫

Box body packaging machine opening sealing mechanism and control method

PendingCN111806797AReduce volumeNo wrinklesPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringPackaging machine

The invention provides a box body packaging machine opening sealing mechanism and a control method. The box body packaging machine opening sealing mechanism includes a mounting rack and an opening sealing device, the opening sealing device includes an upper heat sealing assembly, and a lower heat sealing assembly, the mechanism further includes a pocket opening distracting device, and the pocket opening distracting device includes a first cylinder, a second cylinder, stay rod connecting boards, and stay rods. The output end of the first cylinder is connected with the second cylinder through aconnecting corner fitting, the output end of the second cylinder is provided with two stay rod connecting boards arranged horizontally and left and right, the stay rods are connected with the stay rodconnecting boards, and the output end of the second cylinder is connected with the stay rod connecting boards.

Owner:SHANGHAI SHENGDA MEDICAL HEALTH STOCK

A textile machine for producing and processing textile fabrics and its technology

ActiveCN111501169BImprove surface qualityNo wrinklesMechanical cleaningPressure cleaningDust controlAir blower

The invention relates to the technical field of textile fabric processing equipment, and specifically discloses a textile machine for textile fabric production and processing and its technology; it includes a machine case, a winding roller and a lead-in roller, four corners of the lower surface of the machine case are provided with feet, and the body of the machine case The right side is provided with a fabric inlet, the left side of the cabinet is provided with a fabric outlet, and the first rotating bracket is arranged on the right side of the cabinet above the fabric inlet, and the introduction roller is rotated and arranged on the first rotating bracket; The fabric after spinning is combined with wind force and electrostatic dust removal, and then sprayed with antistatic liquid, and then the fabric sprayed with antistatic liquid is ironed, and finally the fabric at the pre-treatment end is dried by a hot air blower and rolled up. Therefore, there is no static electricity on the surface of the prepared textile fabric, and at the same time, the dust on the surface of the textile fabric can be effectively removed, and there will be no wrinkles on the surface of the textile fabric after ironing, which greatly improves the surface quality of the fabric and improves the market competitiveness of the product .

Owner:浙江兰溪银丰纺织有限公司

Air bag type inflatable membrane structure

The invention provides an air bag type inflatable membrane structure, and belongs to the technical field of buildings. The inflatable membrane structure comprises at least two membrane materials, wherein the edges of the membrane materials are bonded and fixed through a clamp to form at least one sealed air bag with a cavity; at least one air valve is arranged on the surface of the air bag; the air valve communicates with an air supply device; the air supply device and the air valve are used for inflating the air bag; at least one hole is formed in the air bag, and the edge of the hole is fixed through the clamp to keep the air bag sealed; and a plurality of inflatable membrane structures can be spliced through clamps to construct an inflatable membrane building. The inflatable membrane structure is simple, light, easy to mount and dismount, capable of being widely applied to maintenance structures such as outer walls and roofs of building houses and structures, and particularly suitable for stadiums, exhibition houses, sunlight houses, movable houses, ecological houses, temporary houses for earthquake relief work and the like.

Owner:王建平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com