Spinning machine for textile fabric producing and processing and technology of spinning machine

A technology for textile fabrics and textile machines, which is used in spray/jet textile material processing, textile, textile and papermaking, etc., can solve the problems of easy wrinkles and cannot eliminate static electricity on the surface of fabrics, and achieves improved surface quality, excellent dust removal effect, Structured novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

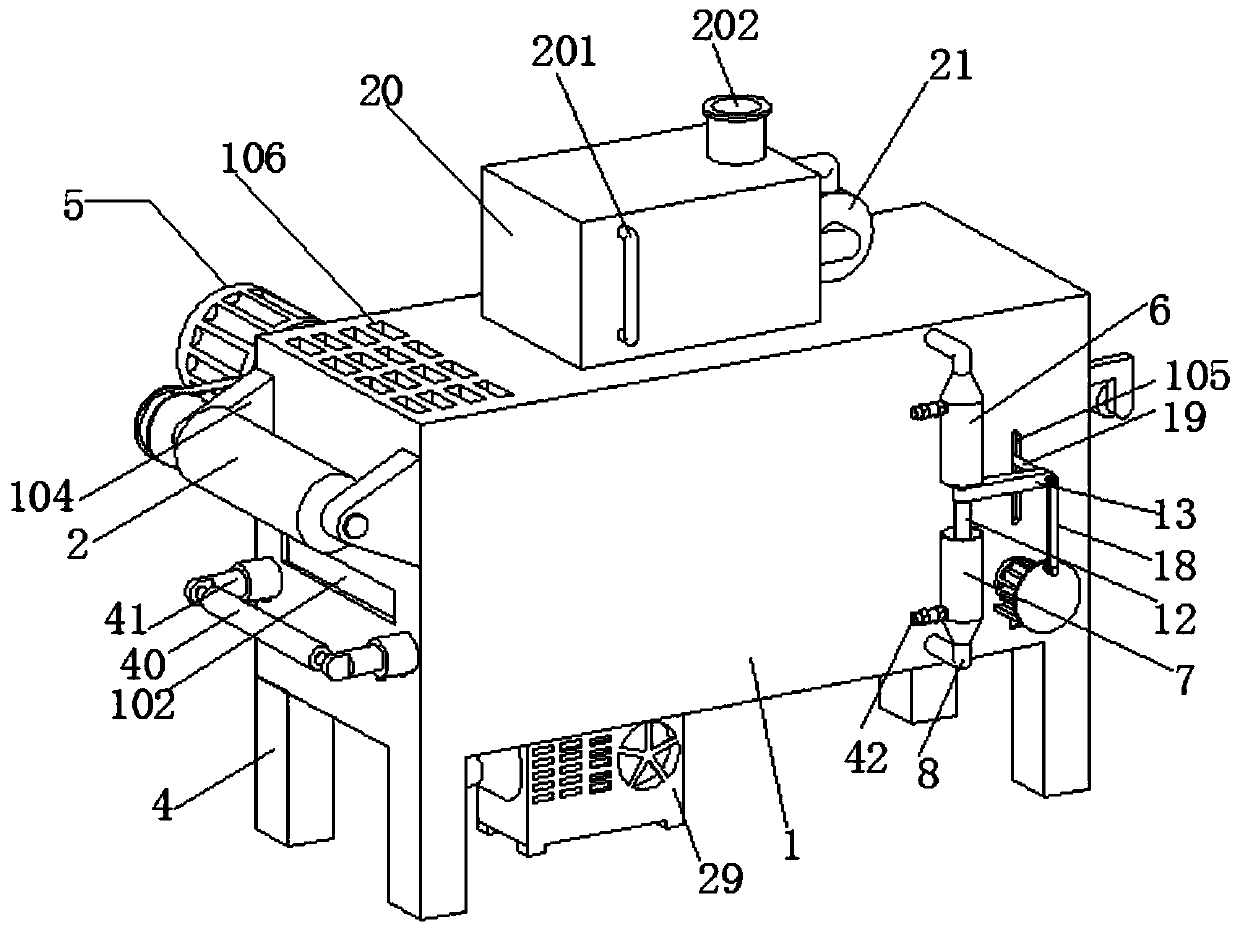

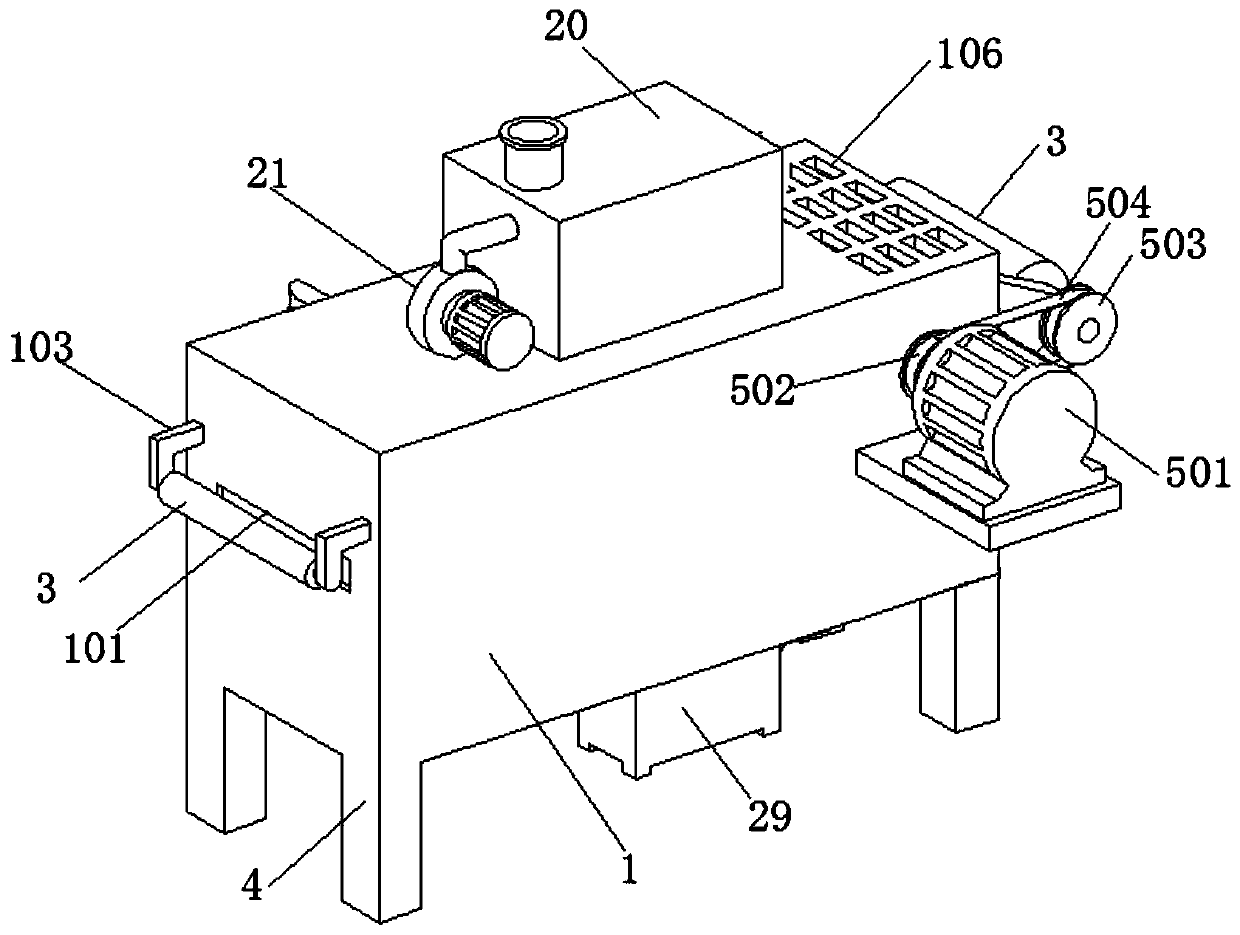

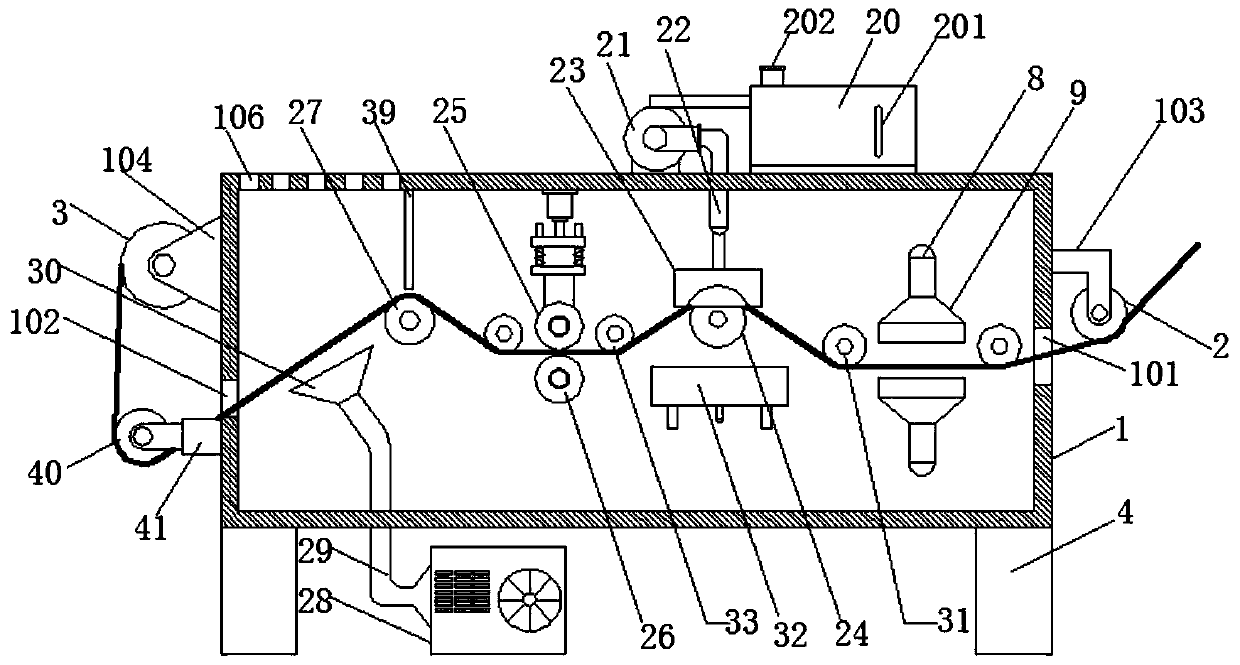

[0041] Embodiment 1 has introduced a kind of textile machine for fabric production and processing, with reference to the attached Figure 1~3 , its main structure includes a cabinet 1, a winding roller 2 and a guide roller 3, four corners of the lower surface of the cabinet 1 are provided with feet 4, the right side of the cabinet 1 is provided with a fabric inlet 101, and the left side of the cabinet 1 is provided with There is a fabric outlet 102, the first rotating bracket 103 is arranged on the right side of the cabinet 1 above the fabric inlet 101, the introduction roller 3 is rotated and arranged on the first rotating bracket 103, and the left side of the cabinet 1 above the fabric outlet 102 is arranged There is a second rotating bracket 104, and the winding roller 2 is rotatably arranged on the second rotating bracket 104, and the rear side of the winding roller 2 is provided with a driving device 5, wherein the driving device 5 includes a winding motor 501, a driving p...

Embodiment 2

[0045] Embodiment 2 has introduced a kind of textile machine based on the improved textile fabric production and processing of embodiment 1, with reference to the attached Figure 1~3 , its main structure includes a cabinet 1, a winding roller 2 and a guide roller 3, four corners of the lower surface of the cabinet 1 are provided with feet 4, the right side of the cabinet 1 is provided with a fabric inlet 101, and the left side of the cabinet 1 is provided with There is a fabric outlet 102, the first rotating bracket 103 is arranged on the right side of the cabinet 1 above the fabric inlet 101, the introduction roller 3 is rotated and arranged on the first rotating bracket 103, and the left side of the cabinet 1 above the fabric outlet 102 is arranged There is a second rotating bracket 104, and the winding roller 2 is rotatably arranged on the second rotating bracket 104, and the rear side of the winding roller 2 is provided with a driving device 5, wherein the driving device 5...

Embodiment 3

[0050] Embodiment 3 has introduced a kind of textile machine based on the improved textile fabric production and processing of embodiment 2, with reference to the attached Figure 1~3, its main structure includes a cabinet 1, a winding roller 2 and a guide roller 3, four corners of the lower surface of the cabinet 1 are provided with feet 4, the right side of the cabinet 1 is provided with a fabric inlet 101, and the left side of the cabinet 1 is provided with There is a fabric outlet 102, the first rotating bracket 103 is arranged on the right side of the cabinet 1 above the fabric inlet 101, the introduction roller 3 is rotated and arranged on the first rotating bracket 103, and the left side of the cabinet 1 above the fabric outlet 102 is arranged There is a second rotating bracket 104, and the winding roller 2 is rotatably arranged on the second rotating bracket 104, and the rear side of the winding roller 2 is provided with a driving device 5, wherein the driving device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com