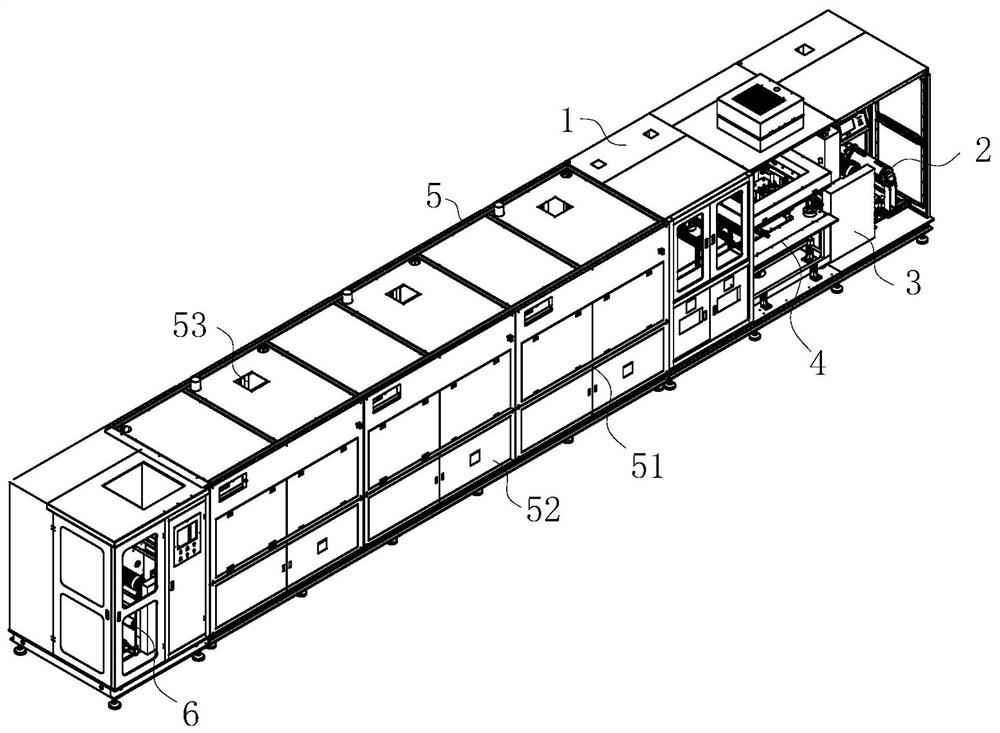

Precision electronic ceramic film silk-screen printing machine

A technology of ceramic thin film and precision electronics, applied in the field of precision electronic ceramic thin film screen printing machine, can solve the problems of difficulty in realizing 4 combined large-scale thin film screen printing, affecting the efficient and fast production of ceramic thin film screen printing, difficult ceramic thin film metal screen printing operation, etc. High consistency, improved efficiency, improved quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

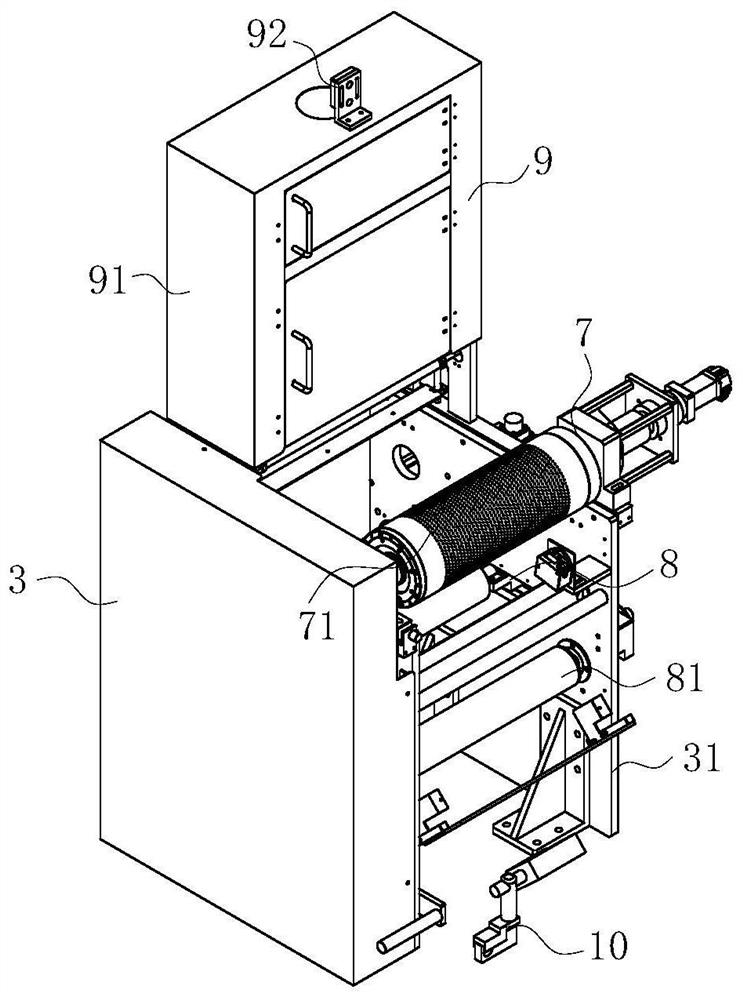

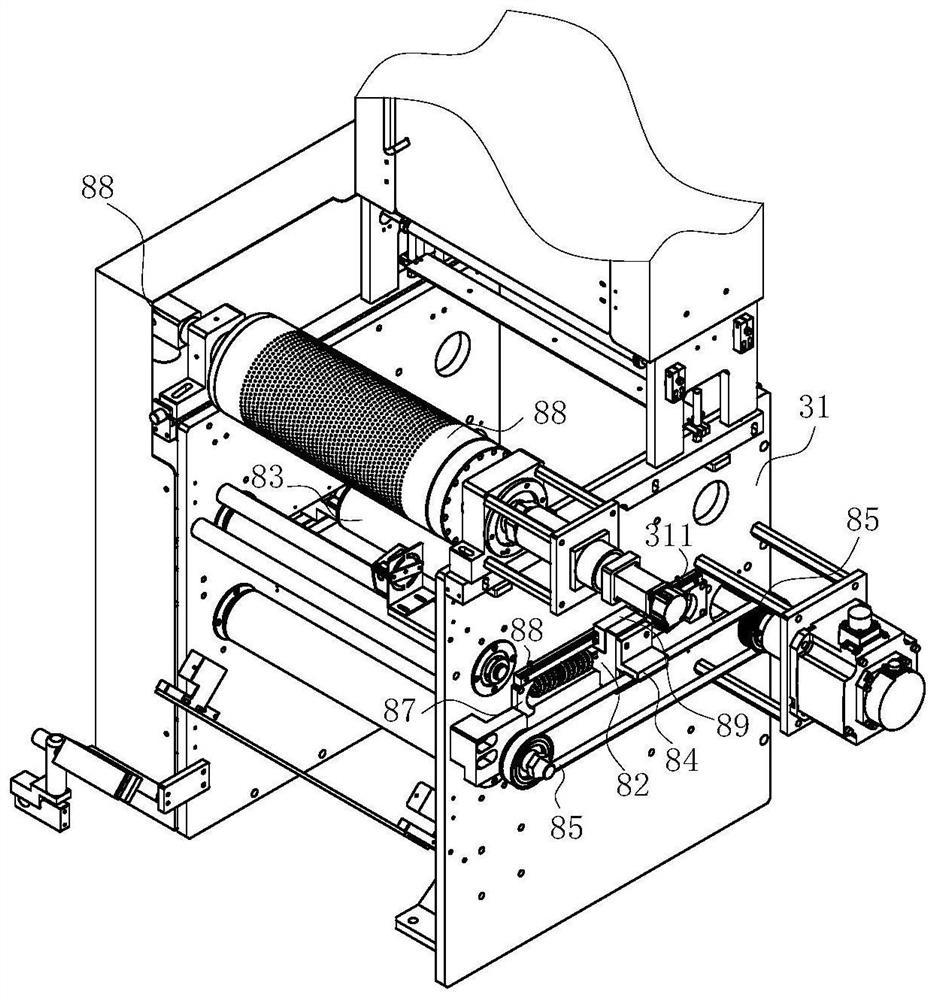

[0039]As an embodiment of the present invention, the tension conveying mechanism 3 is composed of a fixed base 31, a vacuum adsorption roller mechanism 7, a tension adjustment mechanism 8 and an image detection assembly 9; the upper end of the fixed base 31 is provided with a vacuum adsorption roller mechanism 7, and the vacuum adsorption roller mechanism 7 includes a vacuum roller 71, a rotating tube 72, a rotating column 73 and a vacuum pump 74; the circumferential wall of the vacuum roller 71 is provided with air holes; one end of the vacuum roller 71 rotates through a bearing A rotating tube 72 is connected, and the rotating tube 72 is installed on the upper end surface of one side of the fixed base 31 through a support frame; the other end of the vacuum roller 71 is connected to the upper end surface of the other side of the fixed base 31 through a rotating column 73, and The end of the rotating column 73 is connected to the output end of the driving motor, and the driving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com