Perforating die of flexible heat controlled thin film

A thermal control film and punching technology, applied in metal processing and other directions, can solve the problems of slow processing speed, low ignition point, toxic stability, etc., and achieve the effect of high positioning accuracy, appropriate tension and stable stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

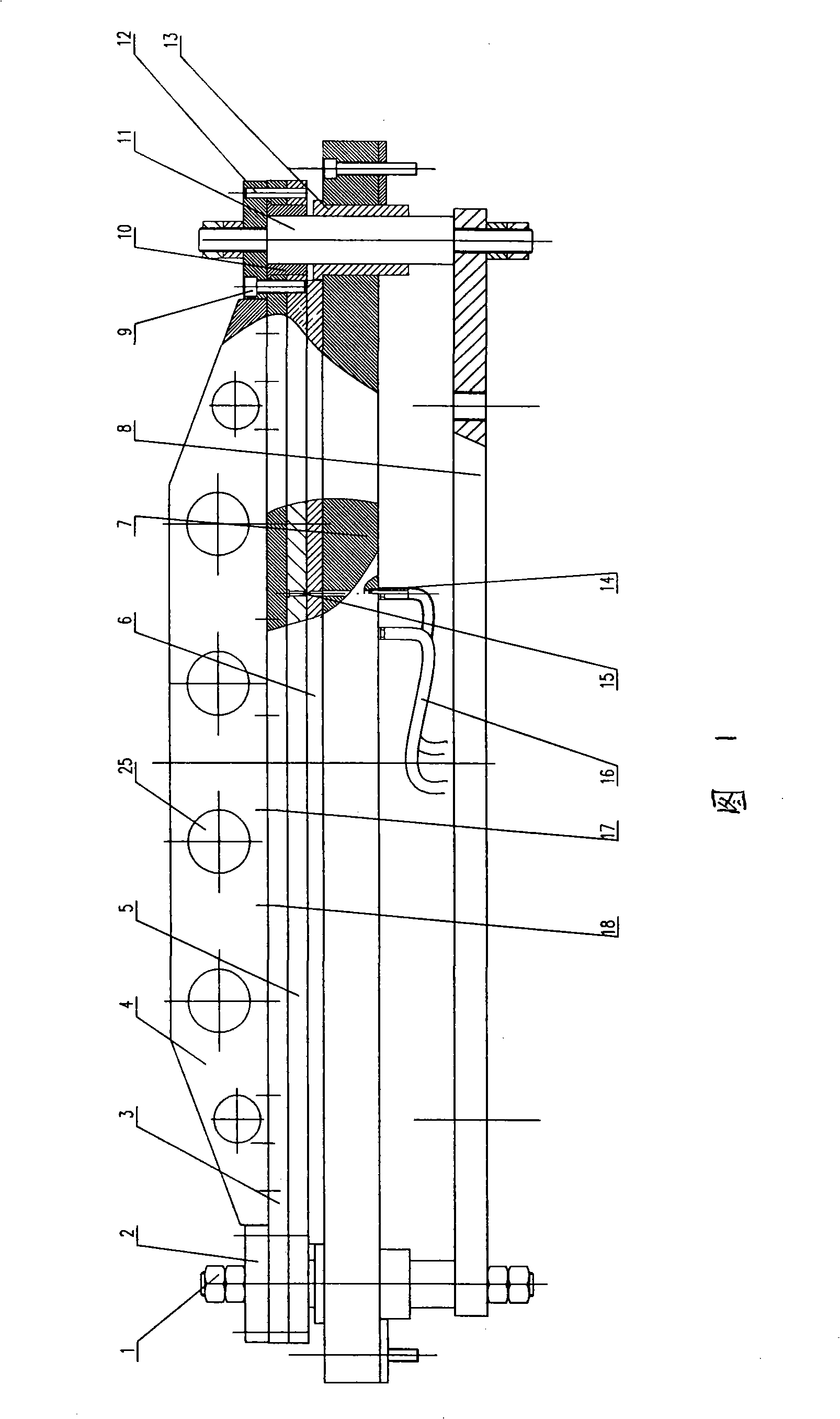

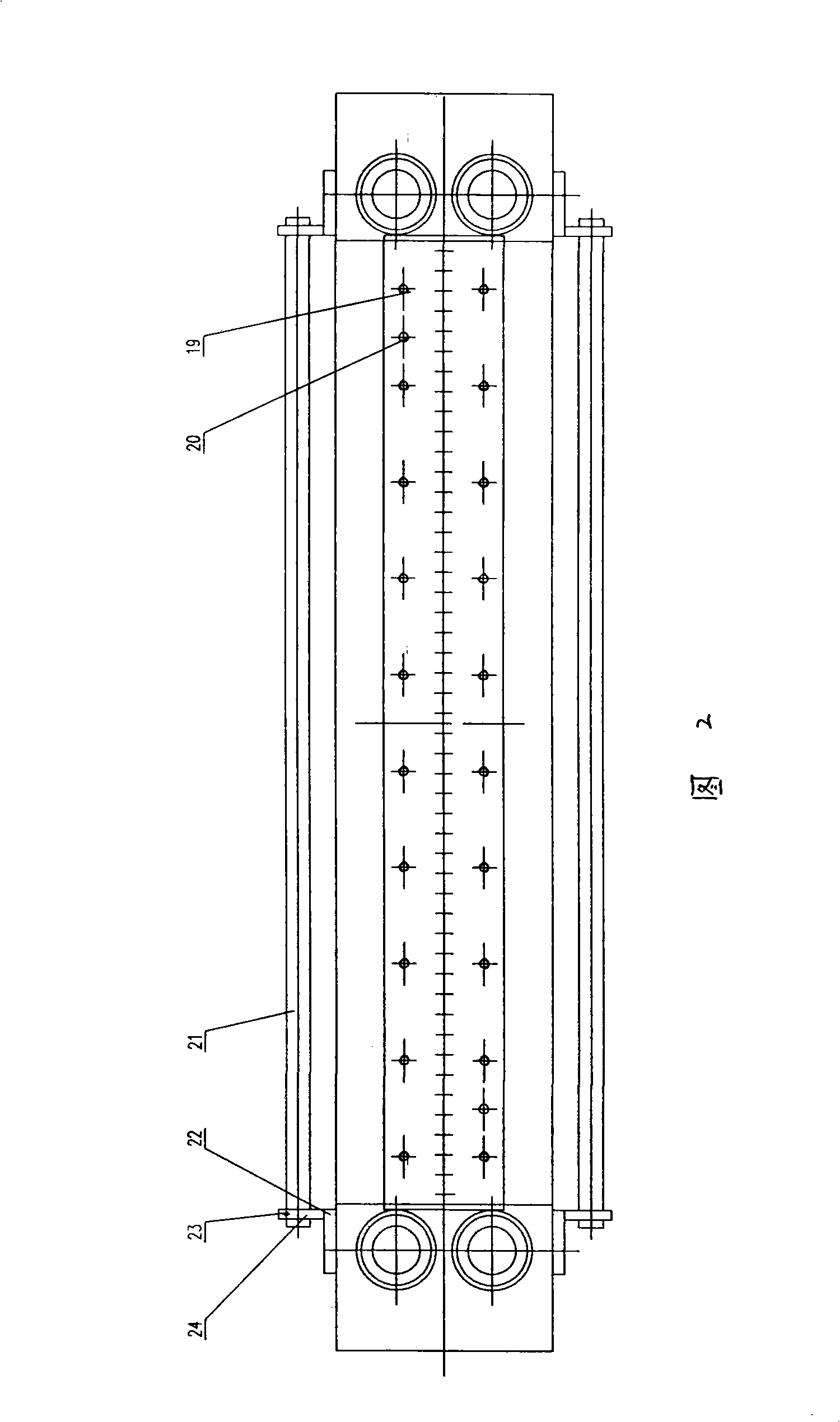

[0008] As shown in Figures 1 and 2, the described flexible thermal control film punching die includes a die 6 and a punch 15, and is characterized in that the die 6 and the punch 15 are double-row cutting edges , the die 6 is fixedly mounted on the lower plate 7 by the first positioning pin 20 and the first hexagon socket head cap screw 19, the lower plate 7 is provided with a support plate 22, and the bottom plate 24 is fixed on the support plate 22 by the first screw 23, the support plate 22 is provided with a tension roller 21, and the guide post 11 is arranged on the lower plate 7 through the guide sleeve 13. The lower end of the guide post 11 is provided with a connecting plate 8, and the lower plate 7 and the die 6 are correspondingly provided with through holes, and the punch 15 and The die 6 is correspondingly arranged on the fixing plate 5 , the gland 2 , the pressing plate 3 and the fixing plate 5 are arranged on the guide post 11 through the pressing sleeve 10 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com