Epilating wax for living stock and preparation method of epilating wax

A technology for depilation wax and poultry, which is applied in the field of depilation wax for poultry and poultry and its preparation. It can solve the problems that the depilation can not continue to be used normally, the use effect cannot be achieved, and the wax depilation effect is poor, so as to achieve a good depilation effect. , Facilitate large-scale production and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

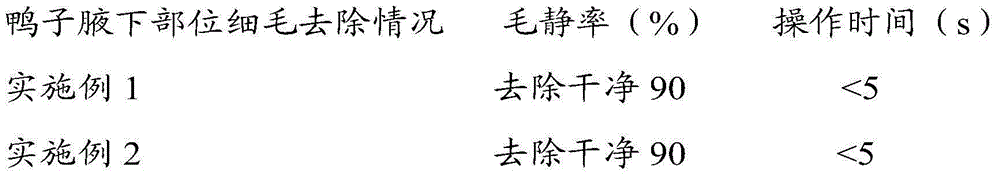

Examples

Embodiment 1

[0043] A depilatory wax for poultry and livestock, prepared from the following raw materials in mass fraction:

[0044] 10% of tackifier, 1% of plasticizer, 0.1% of toughening agent, 0.2% of film forming agent, 1% of stabilizer, and the balance is waxy substances.

[0045] The tackifier is atactic polystyrene;

[0046] Described plasticizer is polybutadiene;

[0047] Described toughening agent is butyl rubber;

[0048] Described film forming agent is polyethylene;

[0049] The stabilizer is 2,6-di-tert-butyl p-cresol;

[0050] The waxy substance is paraffin;

[0051] The preparation method is as follows:

[0052] First heat and melt the waxy substance, then add tackifier, plasticizer, toughening agent, film-forming agent and stabilizer to it, raise the temperature to 180°C, stir at a speed of 10 rpm, and wait until the raw materials are completely After melting, mix and stir at a speed of 30 rpm for 4 hours until uniformly mixed to obtain the depilation wax for poultry a...

Embodiment 2

[0054] A depilatory wax for poultry and livestock, prepared from the following raw materials in mass fraction:

[0055] 40% of tackifier, 10% of plasticizer, 5% of toughening agent, 10% of film forming agent, 5% of stabilizer, and the balance is waxy substances.

[0056] The tackifier is polyisobutylene;

[0057] Described plasticizer is methyl phthalate;

[0058] Described toughening agent is ethylene-propylene copolymer;

[0059] Described film forming agent is polypropylene;

[0060] The stabilizer is 2,6-tertiary butyl-4-methylphenol;

[0061] The waxy substance is microcrystalline wax;

[0062] The preparation method is as follows:

[0063] First heat and melt the waxy substance, then add tackifier, plasticizer, toughening agent, film-forming agent and stabilizer to it, raise the temperature to 250°C, stir at a speed of 30 rpm, and wait until the raw materials are completely After melting, mix and stir at a speed of 60 rpm for 2 hours until uniformly mixed to obtain...

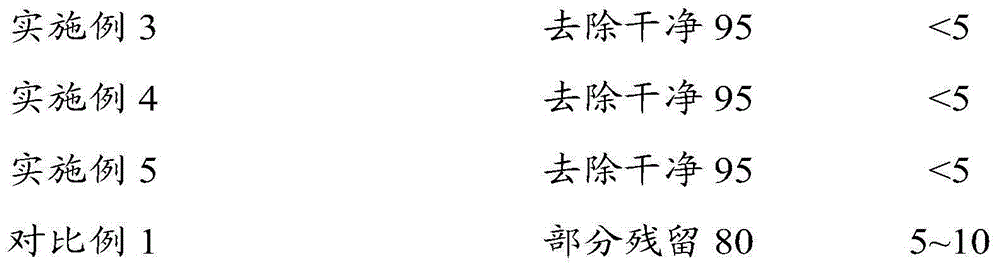

Embodiment 3

[0065] A depilatory wax for poultry and livestock, prepared from the following raw materials in mass fraction:

[0066] 20% of tackifier, 3% of plasticizer, 2% of toughening agent, 3% of film forming agent, 2% of stabilizer, and the balance is waxy substances.

[0067] The tackifier is random polypropylene;

[0068] Described plasticizer is mineral oil;

[0069] Described toughening agent is propylene-butene copolymer;

[0070] The film forming agent is ethylene-acrylic acid copolymer;

[0071] The stabilizer is two (3,5-tertiary butyl-4-hydroxyphenyl) sulfide;

[0072] Described wax substance is Fischer-Tropsch synthetic wax;

[0073] The preparation method is as follows:

[0074] (1) Put the film-forming agent, plasticizer, and toughening agent into the reaction kettle A to heat, raise the temperature to 190°C, and stir at a speed of 30 rpm until the materials are completely melted, and stir evenly for later use;

[0075] (2) Put waxy substances, tackifiers and stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com