Method for manufacturing goalkeeper's stick

A production method and technology of a goalkeeper, which is applied in the field of production of goalkeeper clubs, can solve the problems of the goalkeeper's straight rods, such as high scrapping rate, waste of materials and labor costs, lack of materials or air bubbles, etc., and improve the quality of the roughs, layer The effect of good bonding and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for making a goalkeeper club described in this embodiment includes the following steps:

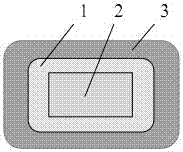

[0043] (1) Send the silicone inflatable bead forming mold 3 to the heating furnace, heat the silicone inflatable bead forming mold 3 to the temperature T, clean the inner surface of the mold, and apply a release agent;

[0044] (2) Put the raw silica gel material into the upper and lower molds of the silica gel inflatable bead molding mold 3; the density of the silica gel particles is 0.88g / cm 3

[0045] (3) Put the steel core tool 2 into the silicone inflatable bead forming mold 3, close the silicone inflatable bead forming mold 3 and send it to the stove for molding. The molding temperature is 160°C and the molding time is 70 minutes;

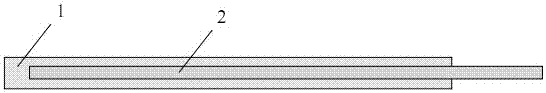

[0046] (4) After the molding time is up, take out the goalkeeper silicone bead formed by the silicone material and the steel core tool 2, and then pull out the steel core tool 2 to obtain the silicone inflatable bead 1, such as figure 1...

Embodiment 2

[0061] A method for making a goalkeeper club described in this embodiment includes the following steps:

[0062] (1) Send the silicone inflatable bead forming mold 3 to the heating furnace, heat the silicone inflatable bead forming mold 3 to the temperature T, clean the inner surface of the mold, and apply a release agent;

[0063] (2) Put the raw silica gel material into the upper and lower molds of the silica gel inflatable bead molding mold 3; the density of the silica gel particles is 1.18g / cm 3

[0064] (3) Put the steel core tool 2 into the silicone inflatable bead forming mold 3, close the silicone inflatable bead forming mold 3 and send it to the stove for molding. The molding temperature is 180°C and the molding time is 60 minutes;

[0065] (4) After the molding time is up, take out the goalkeeper silicone bead formed by the silicone material and the steel core tool 2, and then pull out the steel core tool 2 to obtain the silicone inflatable bead 1, such as figure 1...

Embodiment 3

[0080] A method for making a goalkeeper club described in this embodiment includes the following steps:

[0081] (1) Send the silicone inflatable bead forming mold 3 to the heating furnace, heat the silicone inflatable bead forming mold 3 to the temperature T, clean the inner surface of the mold, and apply a release agent;

[0082] (2) Put the raw silica gel material into the upper and lower molds of the silica gel inflatable bead molding mold 3; the density of the silica gel particles is 1.58 / cm 3

[0083] (3) Put the steel core tool 2 into the silicone inflatable bead forming mold 3, close the silicone inflatable bead forming mold 3 and send it to the furnace table for molding. The molding temperature is 200°C and the molding time is 50 minutes;

[0084] (4) After the molding time is up, take out the goalkeeper silicone bead formed by the silicone material and the steel core tool 2, and then pull out the steel core tool 2 to obtain the silicone inflatable bead 1, such as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com