Molding extruder of PFA plastic products

A plastic product and extruder technology, applied in the field of fluoroplastic product processing, can solve the problems of uneven surface, high processing efficiency and complex structure of finished products, and achieve the effect of compact structure design, high processing efficiency and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

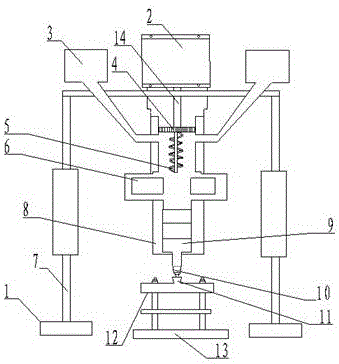

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0018] see figure 1 , the embodiment of the present invention includes:

[0019] A PFA plastic product forming extruder includes: two supporting feet, each supporting foot adopts a supporting base structure, and a supporting column is connected to the supporting foot, and the supporting column adopts a vertical rectangular column structure. The top of the two supporting columns is connected with a horizontal beam structure, and the extruder body is set on the horizontal beam. At the same time, a hydraulic cylinder is set on the upper end of the extruder body, and the hydraulic cylinder provides extrusion power for the extruder body. An optimal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com