Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "No production impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

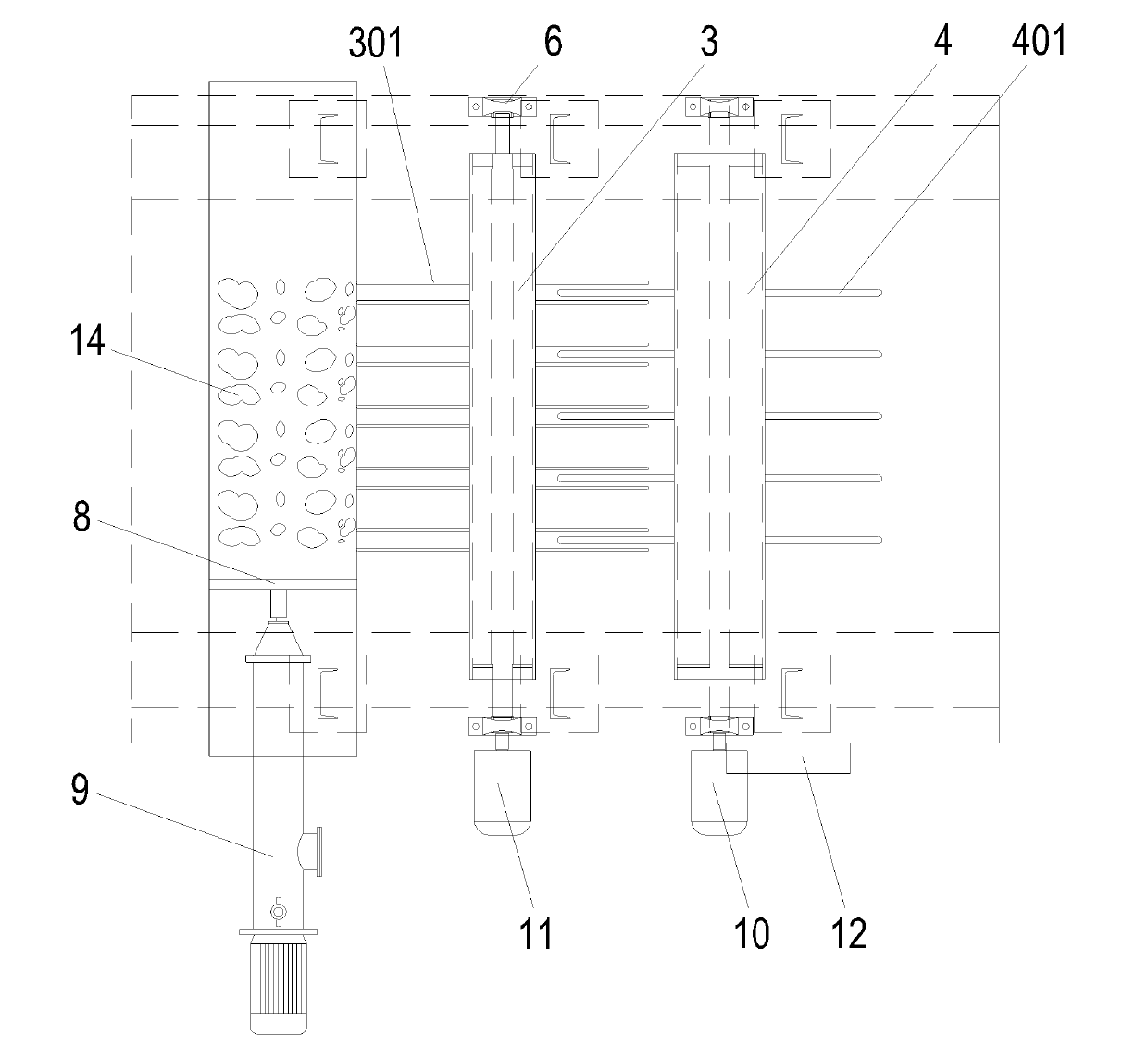

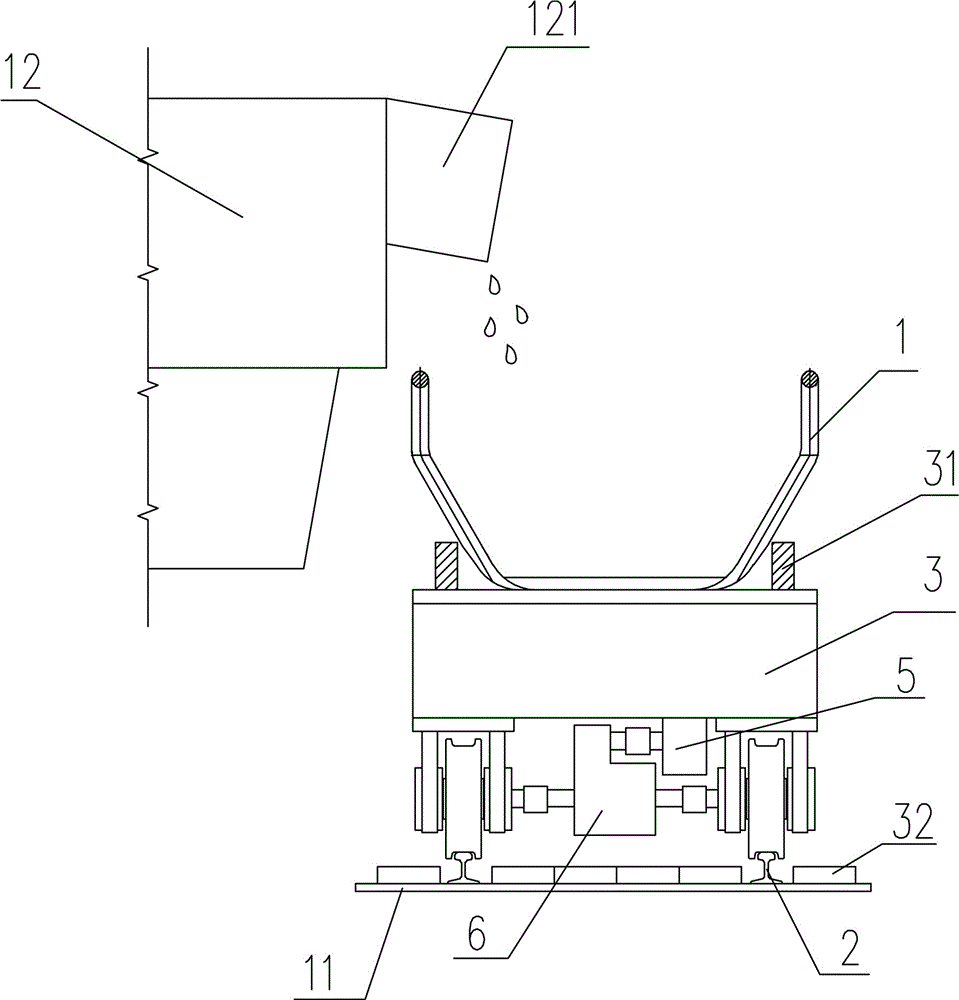

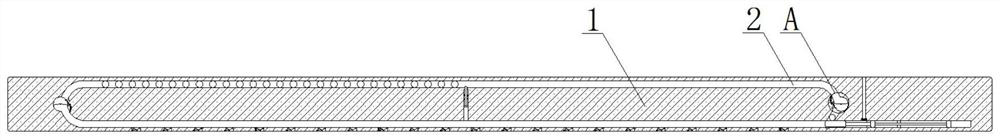

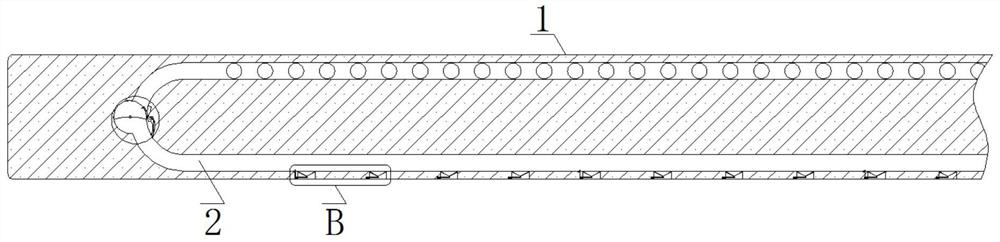

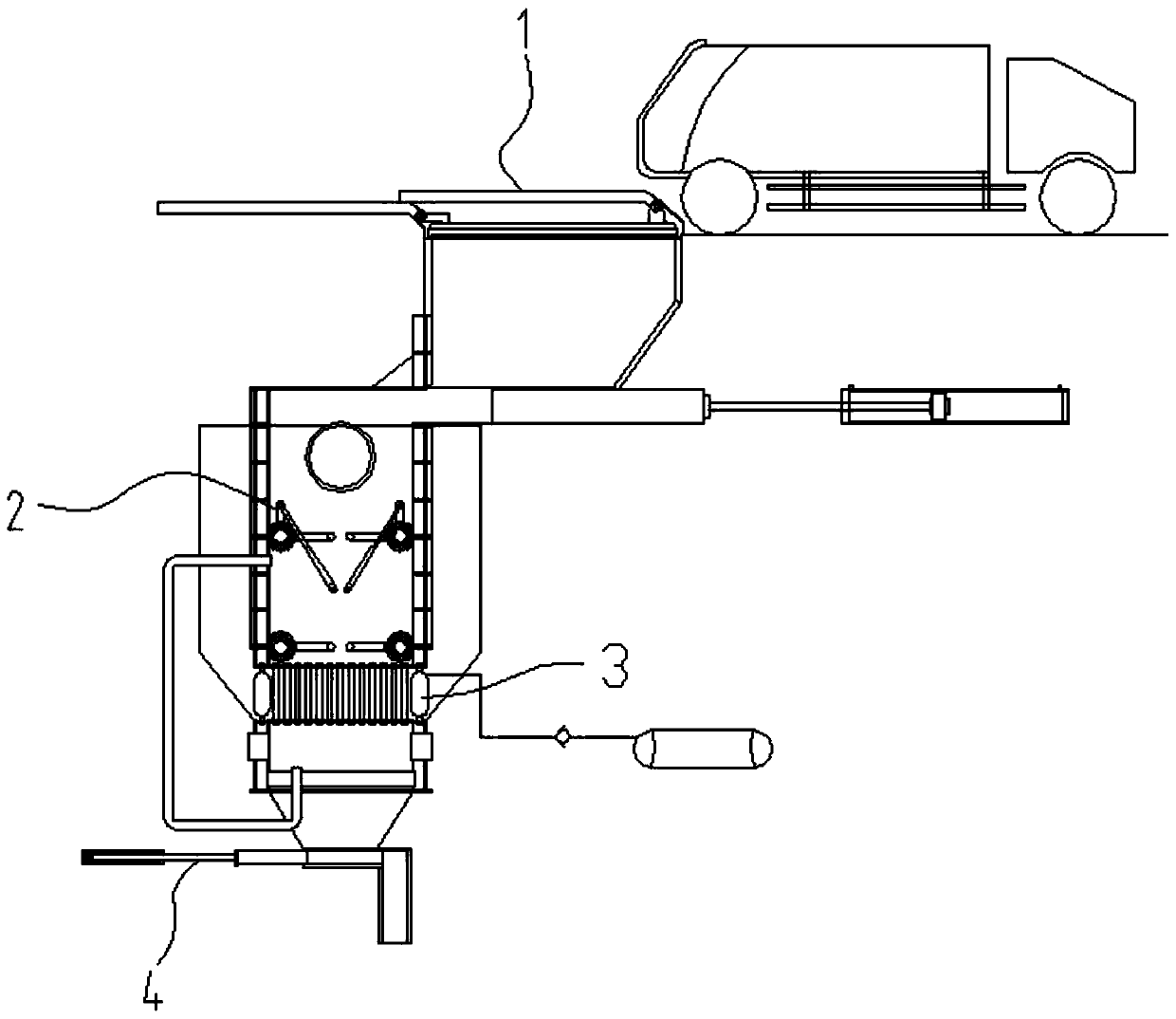

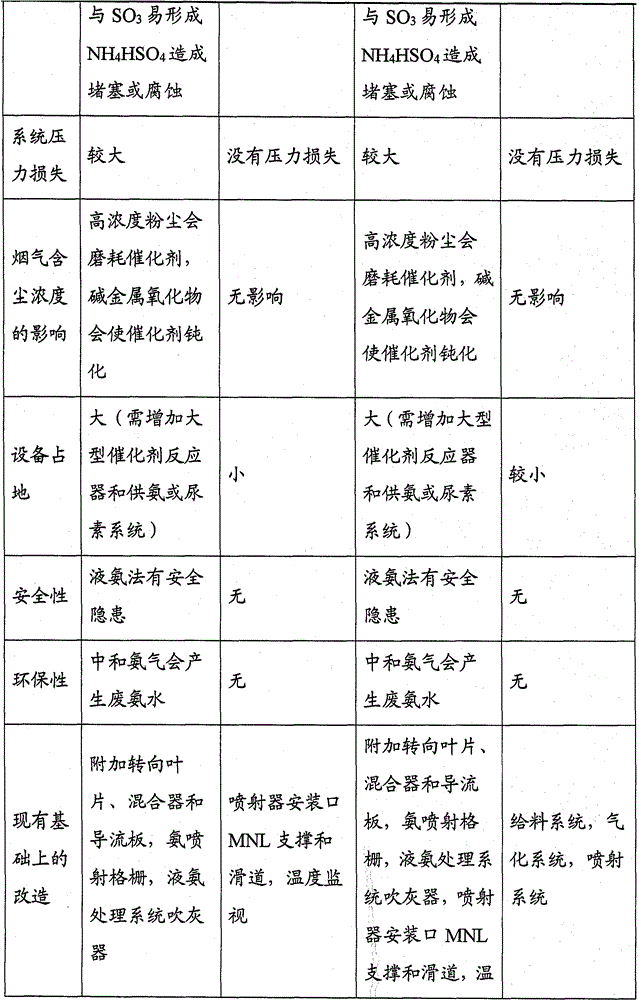

Oil-gas mixed transportation pipeline device and method for simulating formation, blocking and melting of hydrates

ActiveCN105510529ANo production impactEasy to control temperatureMaterial analysisData processing systemTemperature control

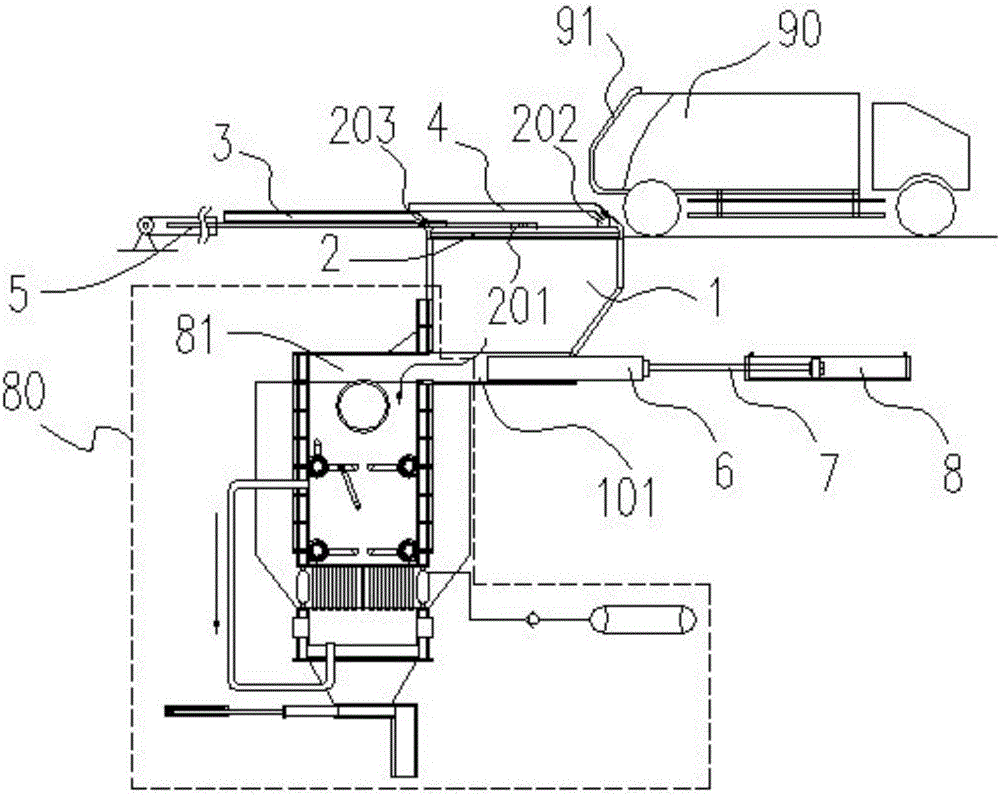

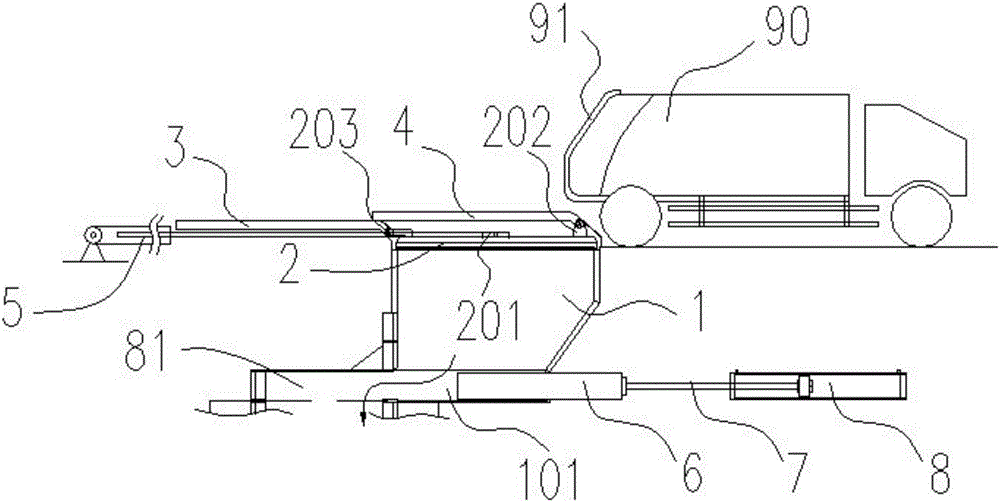

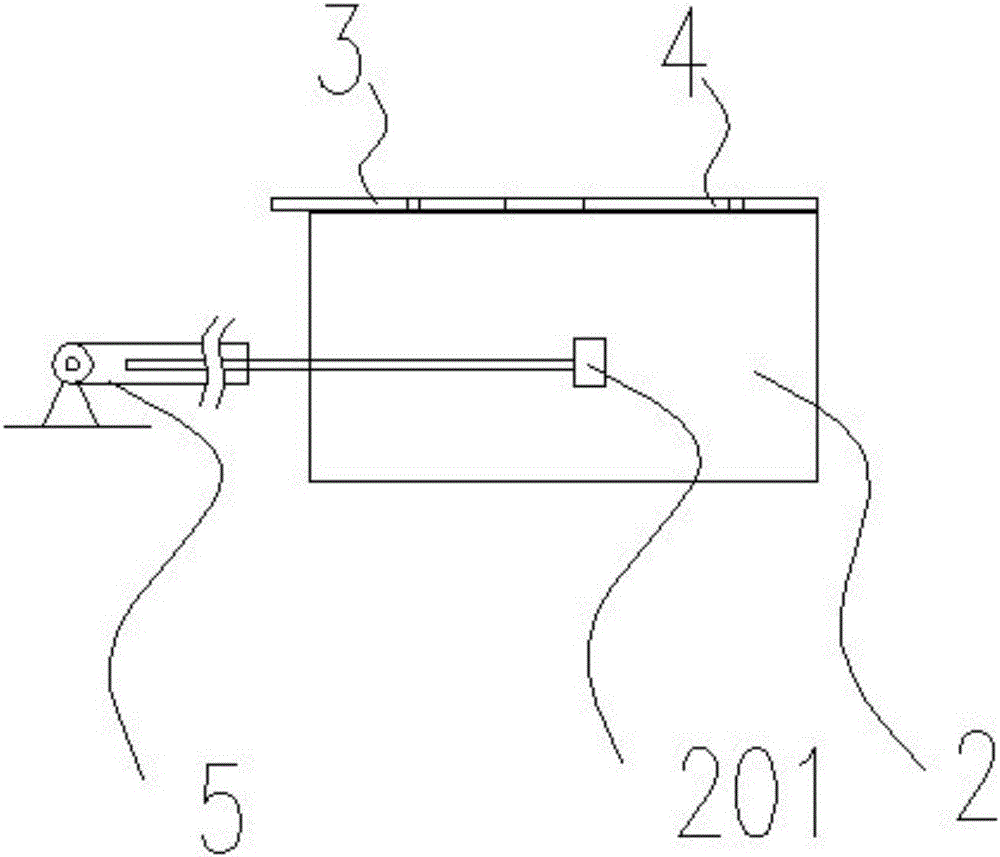

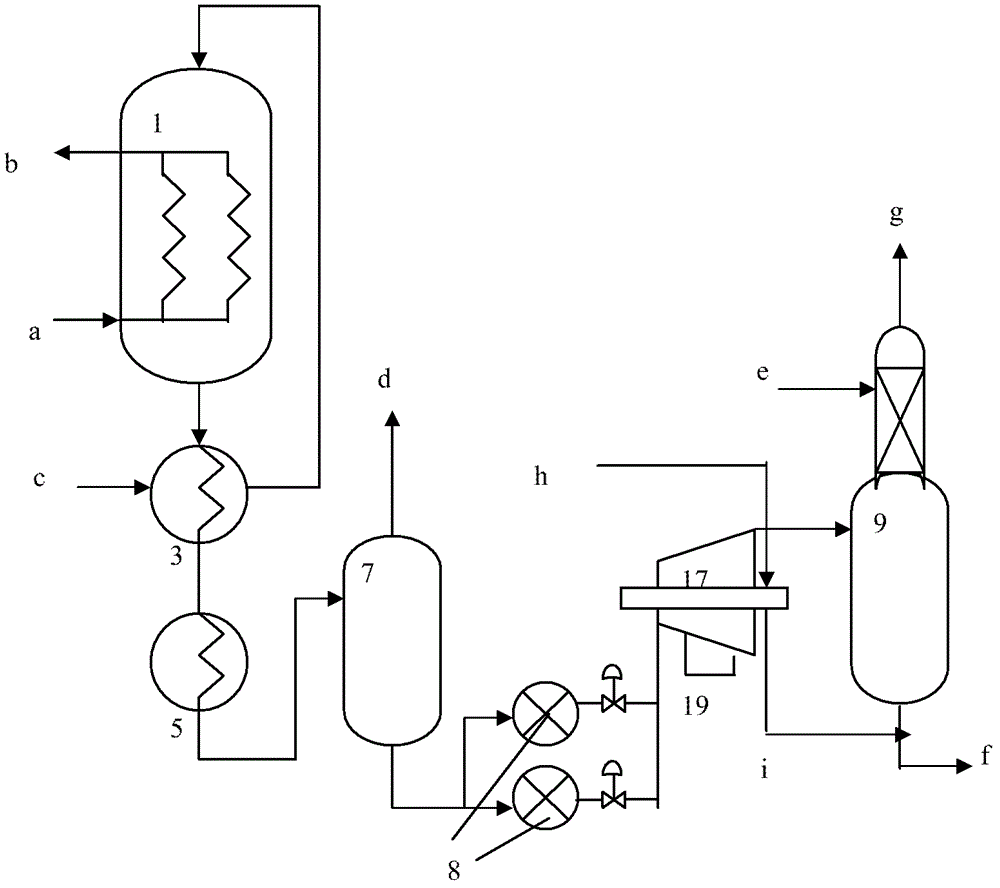

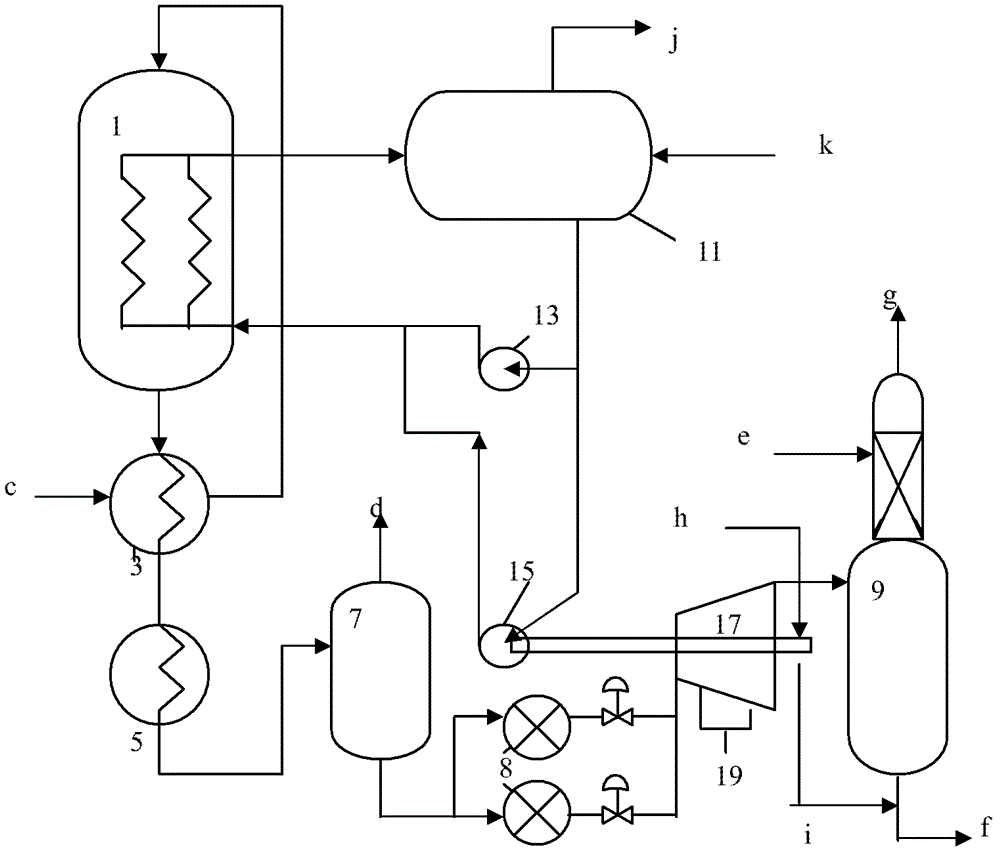

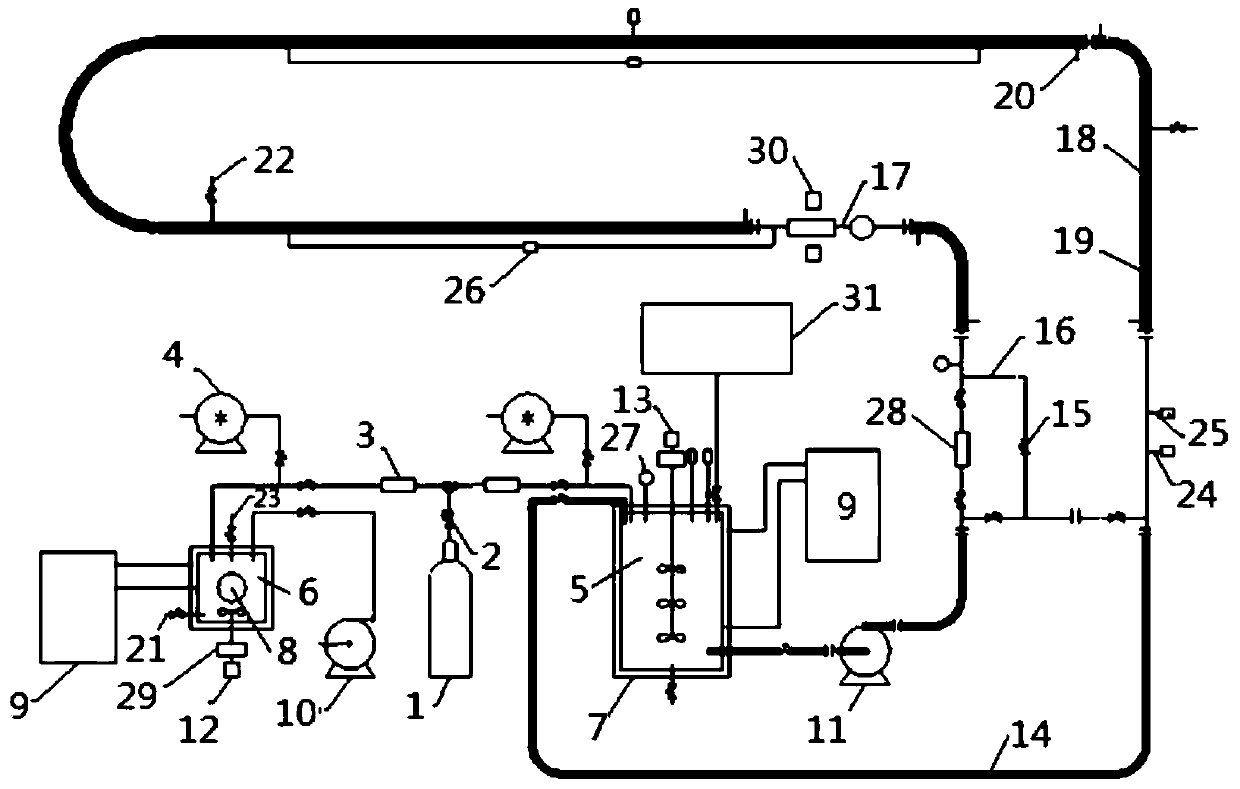

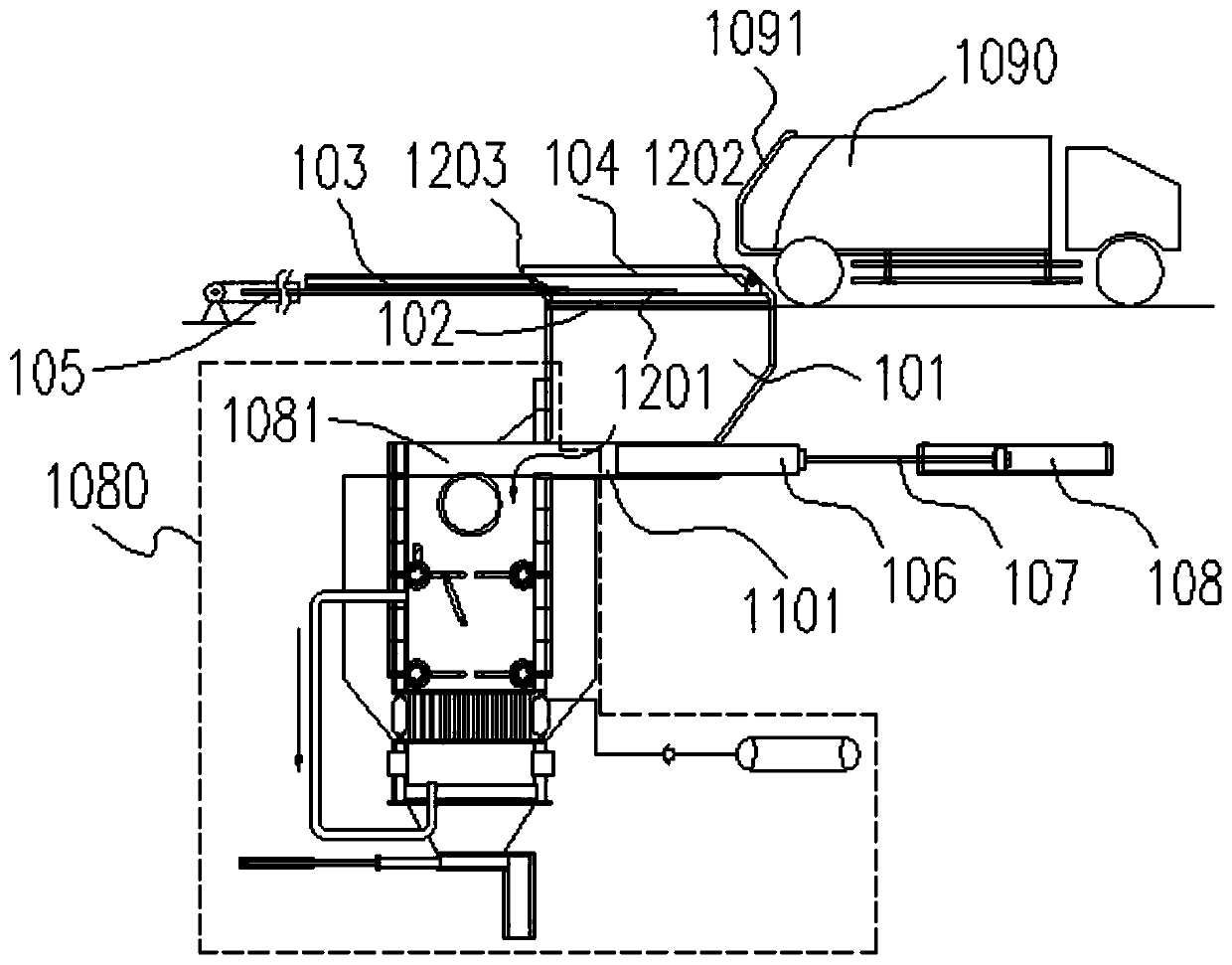

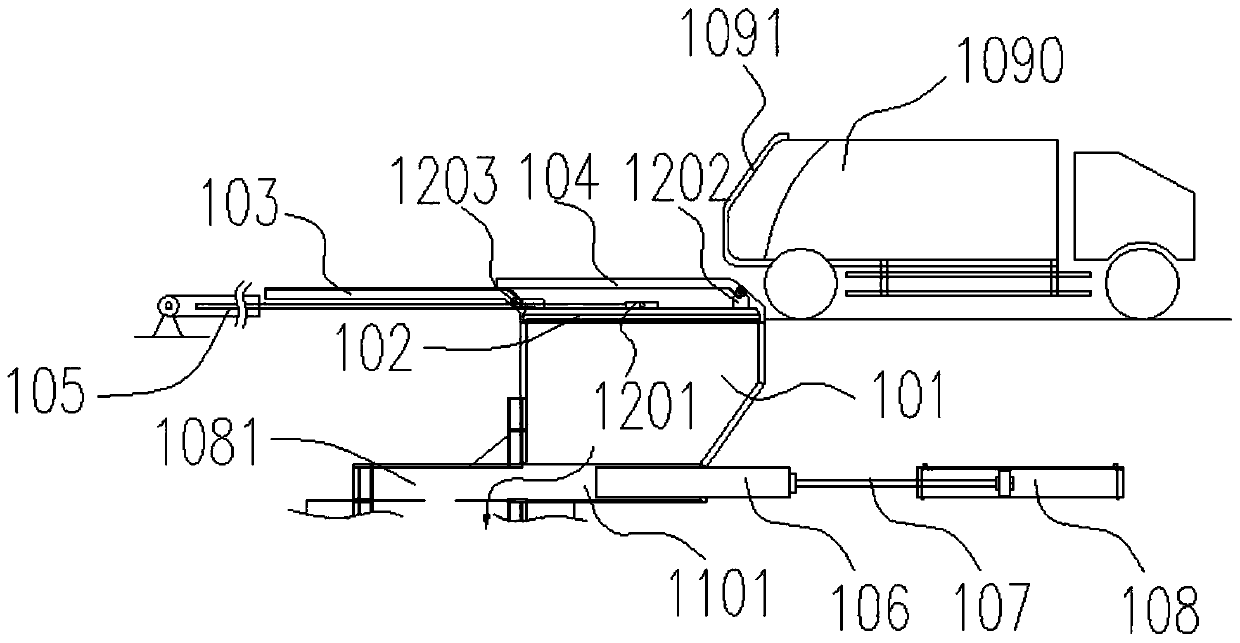

The invention discloses an oil-gas mixed transportation pipeline device and a method for simulating formation, blocking and melting of hydrates. The device comprises a reaction kettle I and a reaction kettle II, wherein the reaction kettle I and the reaction kettle II are connected with the same gas supplying system; a grouting port is formed in the reaction kettle I; the top of the reaction kettle II is communicated with the bottom of the reaction kettle II through a circulation pipeline, and a liquid injection port is formed in the circulation pipeline; each of the reaction kettle I and the reaction kettle II is provided with a temperature control device for adjusting the temperature; a detection device for detecting the reaction state of the natural gas hydrates in a pipeline is further mounted on the circulation pipeline and connected with a data processing system. The oil-gas mixed transportation pipeline device and the method for simulating formation, blocking and melting of the hydrates have a very good effect on controlling loss caused by long-time production suspension as a result of blocking of the pipeline in a high-risk blocking state.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Display gray scale binding point voltage adjusting method, display and medium

PendingCN113674710ANo crosstalkImprove crosstalk phenomenonStatic indicating devicesDisplay deviceEngineering

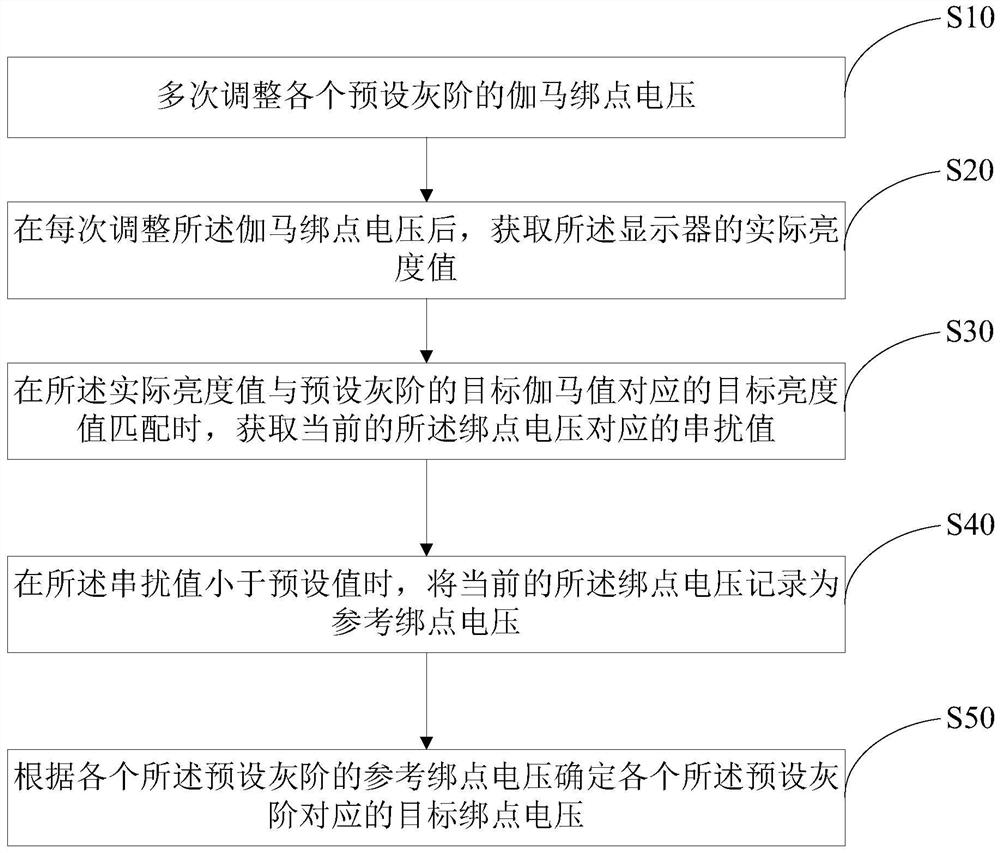

The invention discloses a display gray scale binding point voltage adjusting method, a display and a medium. The method comprises the following steps: adjusting gamma binding point voltage of each preset gray scale for multiple times; after the voltage of the gamma binding point is adjusted each time, obtaining the actual brightness value of the display; when the actual brightness value is matched with a target brightness value corresponding to a target gamma value of a preset gray scale, acquiring a crosstalk value corresponding to the current binding point voltage; when the crosstalk value is smaller than a preset value, recording the current binding point voltage as a reference binding point voltage; and determining a target binding point voltage corresponding to each preset gray scale according to the reference binding point voltage of each preset gray scale. The technical problem of image crosstalk of the display is solved, and the image crosstalk phenomenon of the display is improved.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD +1

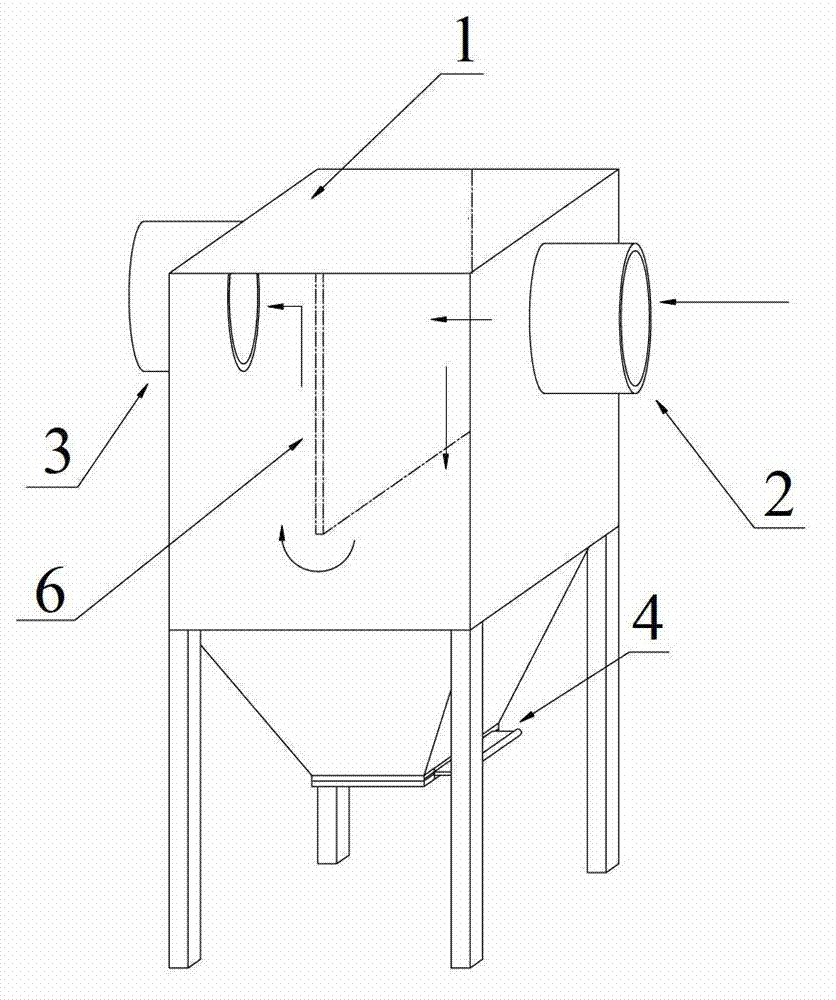

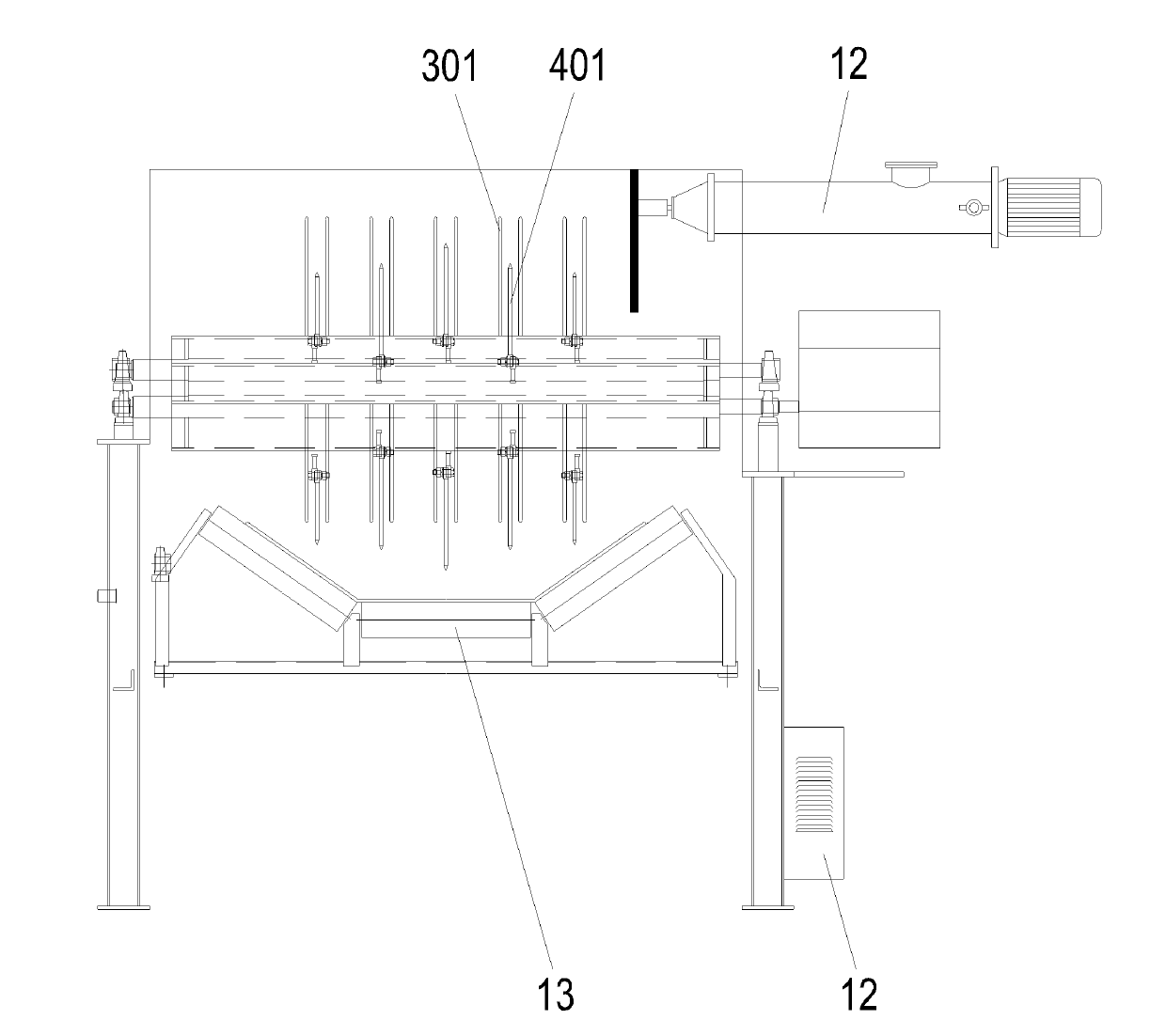

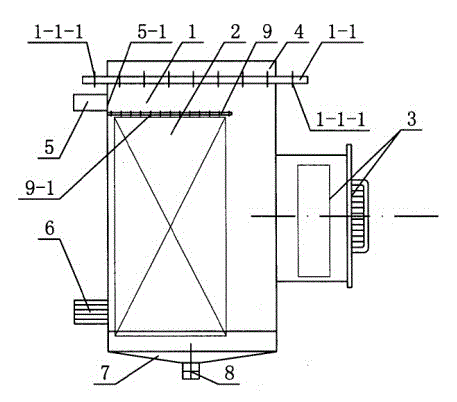

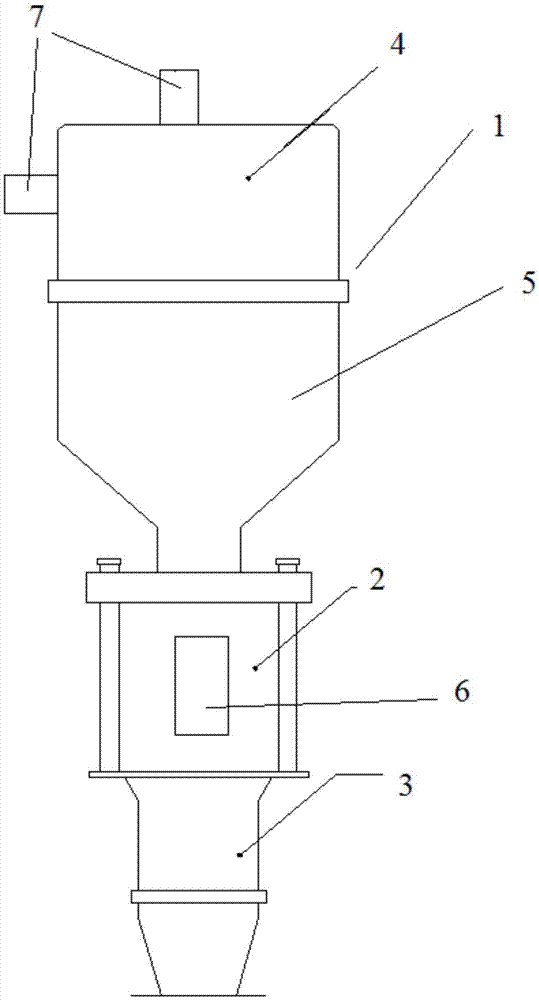

Dust removing system and auxiliary dust removing device

InactiveCN103071659AAlleviate sediment agglomerationGuaranteed emission concentrationDirt cleaningEngineering

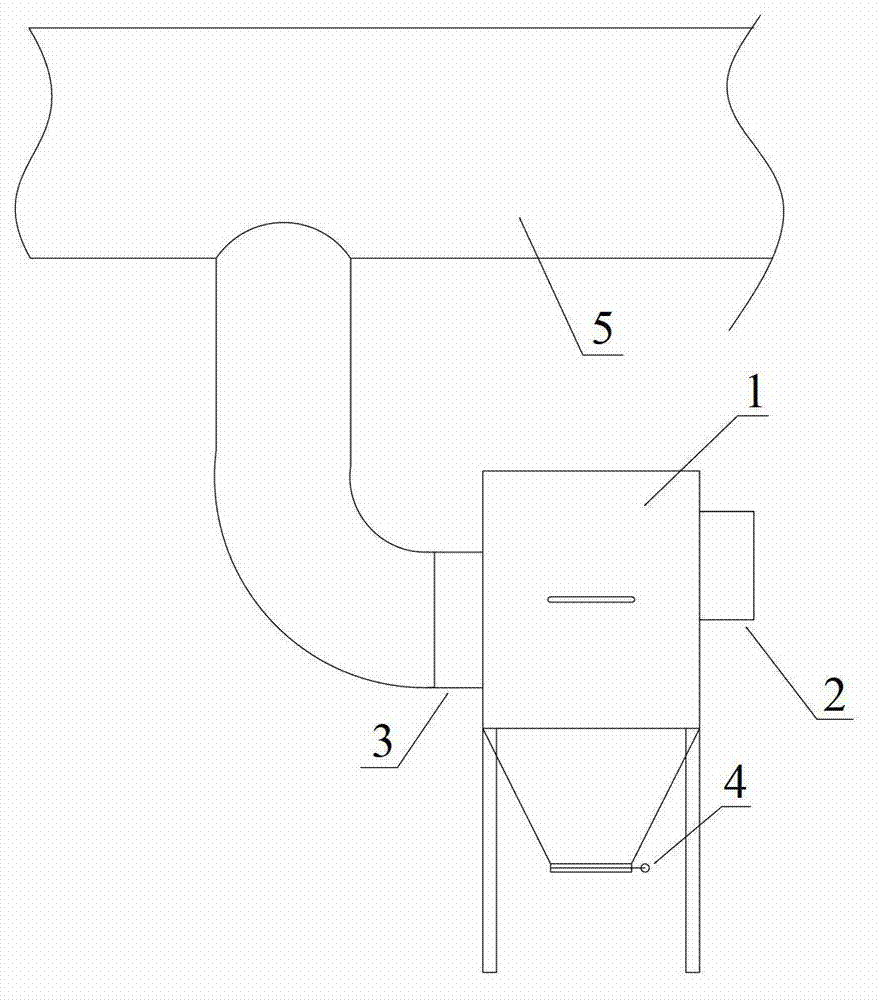

The invention relates to a dust removing system and an auxiliary dust removing device. The dust removing system comprises a dust remover, a dust removing pipeline and the auxiliary dust removing device, wherein the dust remover is connected with the tail end of the dust removing pipeline, a dust suction hole is arranged in the dust removing pipeline, the auxiliary dust removing device comprises a box body, a dust suction opening is arranged in one side wall of the box body, a dust discharge opening is arranged in the side wall opposite to the side wall provided with the dust suction opening, and the dust discharge opening of the auxiliary dust removing device is communicated with the dust suction hole of the dust removing pipeline. The dust removing system provided by the invention has the advantages that the auxiliary dust removing device is additionally arranged at the dust suction hole end of the dust removing pipeline, the hydromechanics principle is utilized, and a large amount of dust is accumulated into the box body of the auxiliary dust removing device, so the quantity of dust entering the dust removing pipeline and the dust remover can be reduced, the dust deposition agglomeration in the dust removing pipeline and the dust remover can be relieved, the discharge concentration of the dust remover is ensured, and the influence on the service life of the dust remover caused by the deposition agglomeration of a large amount of dust is also relieved.

Owner:ZHAOQING LEOCH BATTERY TECH

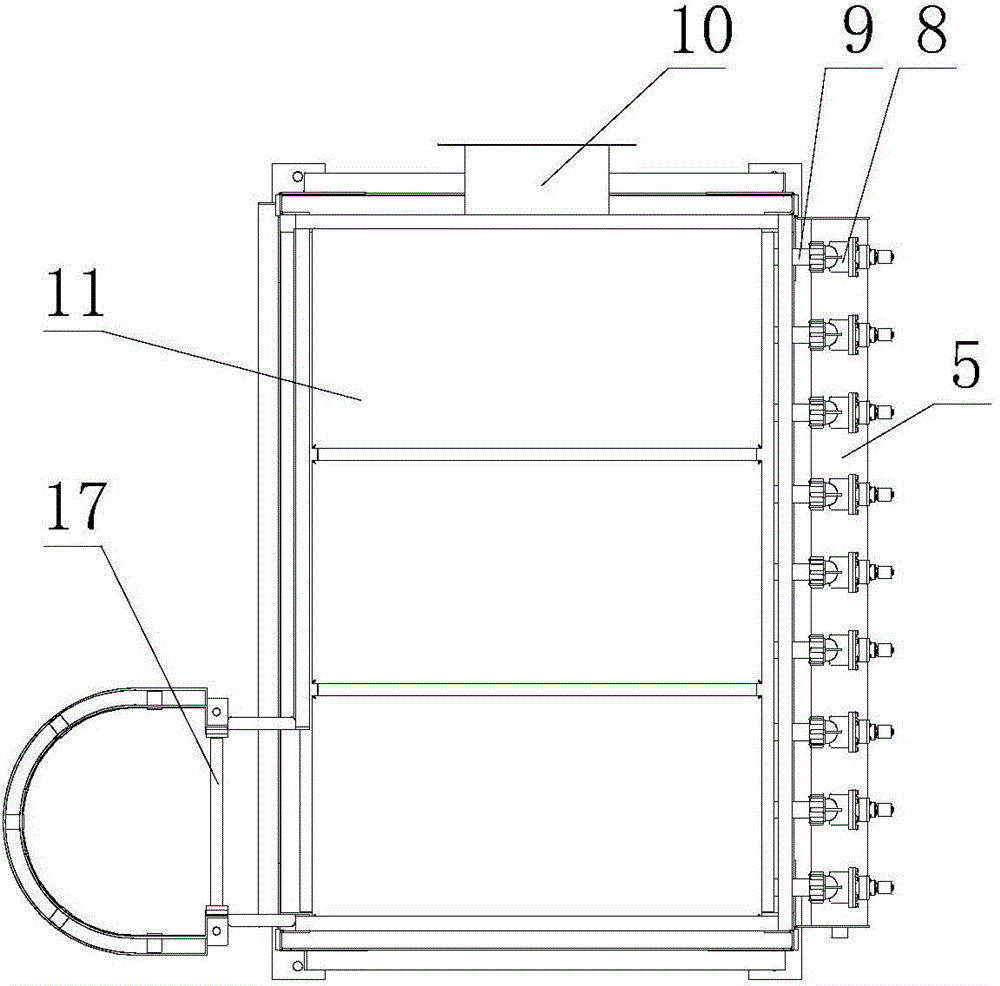

Combined type cloth bag dust remover

InactiveCN104353302ASolution to short lifeEasy maintenanceCombination devicesDispersed particle filtrationKeelBaghouse

The invention discloses a combined type cloth bag dust remover which comprises a plurality of cloth bag dust remover units, wherein each cloth bag dust remover unit comprises a barrel body; an overhaul platform is mounted at the top end of each barrel body; the bottom of each barrel body is connected with an ash bucket; pattern plates are arranged in the barrel bodies and divide the inner cavities of the barrel bodies into clean chambers and filtering chambers, which are distributed up and down; the clean chambers are communicated with purified air outlets; the pattern plates are provided with cage keels in a hanging manner; filtering bags sleeve the cage keels; pulse ash cleaning devices are mounted on the outer walls of the barrel bodies. The combined type cloth bag dust remover is simple in structure, and the cloth bag dust remover units can be combined according to a production requirement, so that the type selection is convenient; once one of the cloth bag dust remover units is faulted and needs to be maintained, the unit only needs to be stopped, and other units continuously work; therefore, influence on the production is avoided, and the faulted unit is convenient to maintain.

Owner:ZHANGJIAGANG AIER ENVIRONMENTAL PROTECTION ENG CO LTD

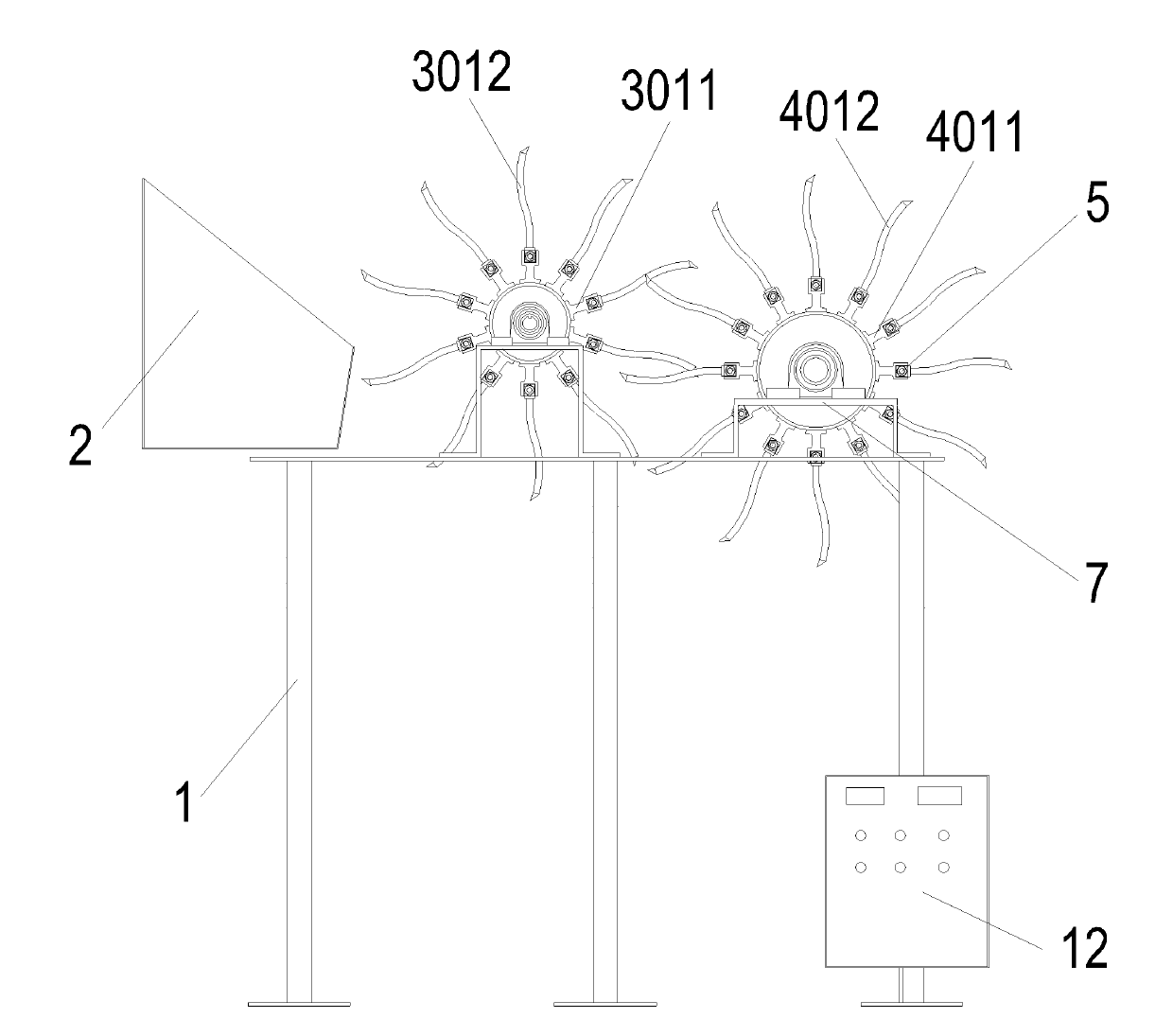

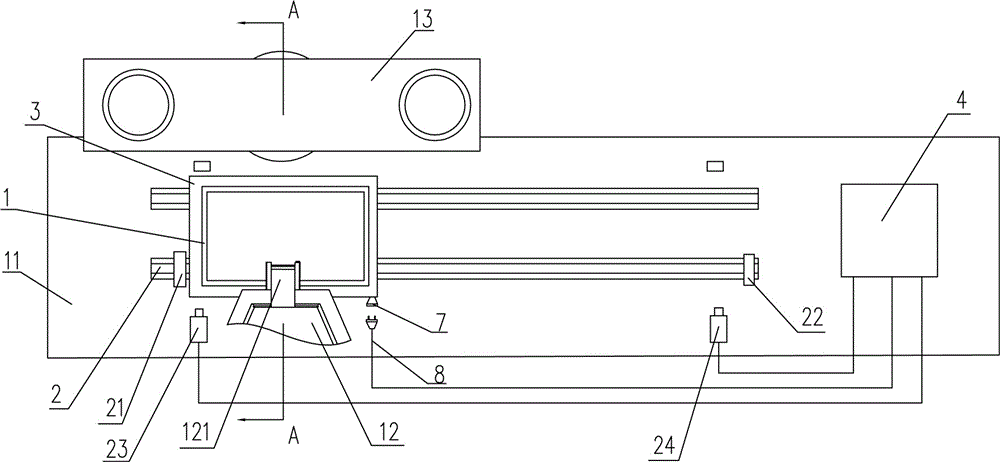

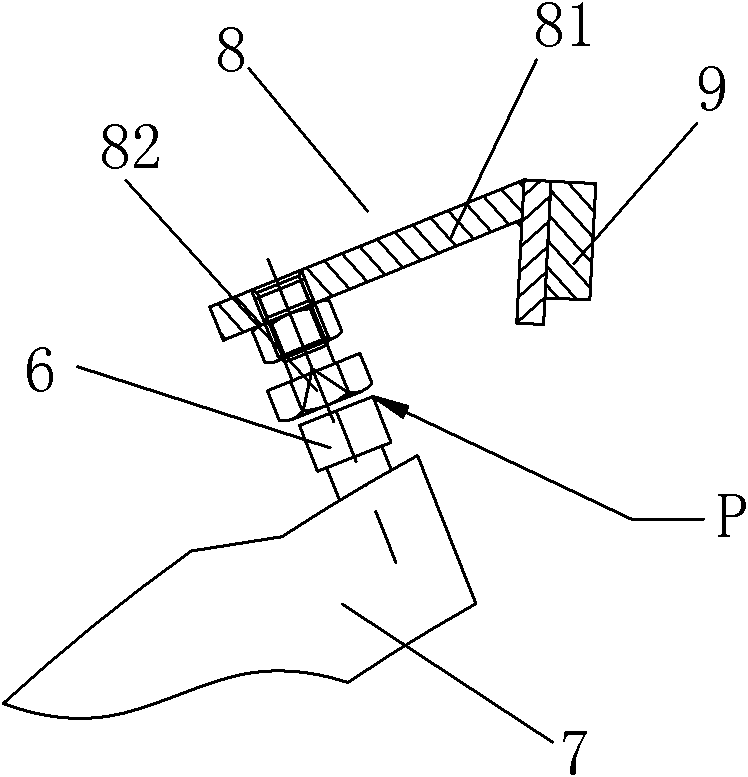

Sundries removing machine used for belt conveyer

InactiveCN102602685ANot easy to damageNo production impactConveyorsConveyor partsCouplingEngineering

The invention relates to a sundries removing machine used for a belt conveyer. The sundries removing machine comprises a rack, wherein a sundries box, a sundries stirring device and a sundries taking device are arranged at the top of the rack from the left to the right, the sundries stirring device and the sundries taking device are staggered from each other and are respectively connected with a driving system; the sundries taking device is provided with a plurality of hook teeth and is arranged on the rack by a mounted bearing and a bearing seat plate, and the sundries taking device is connected with a first motor reducing gear in the driving system by a coupling; a plurality of stirring teeth are arranged on the sundries stirring device, one hook tooth is staggered between each pair of stirring teeth; and the sundries stirring device is arranged on the rack by the mounted bearing and the bearing seat plate and is connected with a second motor reducing gear in the driving system by a coupling. The sundries removing machine has the beneficial effects that the structure is simple, the installation, the use and the maintenance are convenient, the investment is low, and the degree of automation is high.

Owner:BEIJING HAOHUA YUANHANG ENG TECH

Sugarcane soil-piercing slashing method

The invention relates to a sugarcane soil-piercing slashing method and belongs to the technical field of sugar crop harvesting.Based on innovation on a traditional slashing harvest method, the sugarcane soil-piercing slashing method is characterized in that in a sugarcane maturation stage from November to May next year, a sharp hoe is used for soil-piercing slashing, an included angle between the hoe and the ground is between 10 degrees and 80 degrees, and underground 3-5 cm of sugarcane stubs are retained.The sugarcane soil-piercing slashing method has the advantages that sugarcanes are slashed and harvested reasonably, germination of sugarcane buds of sugarcane stub roots is promoted while yield and sugar content of the sugarcanes are increased, perennial root emergence rate is increased, perennial root performance of the sugarcanes is enhanced, perennial root life is prolonged, production cost is reduced and sugarcane grower earnings and enterprise benefit are increased.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI +1

Regulating method of gap between blade and knife door of filament cutter

ActiveCN102058151AIncrease productivityNo production impactTobacco treatmentScrew positionStandard distance

Owner:SHANGHAI TOBACCO GRP CO LTD

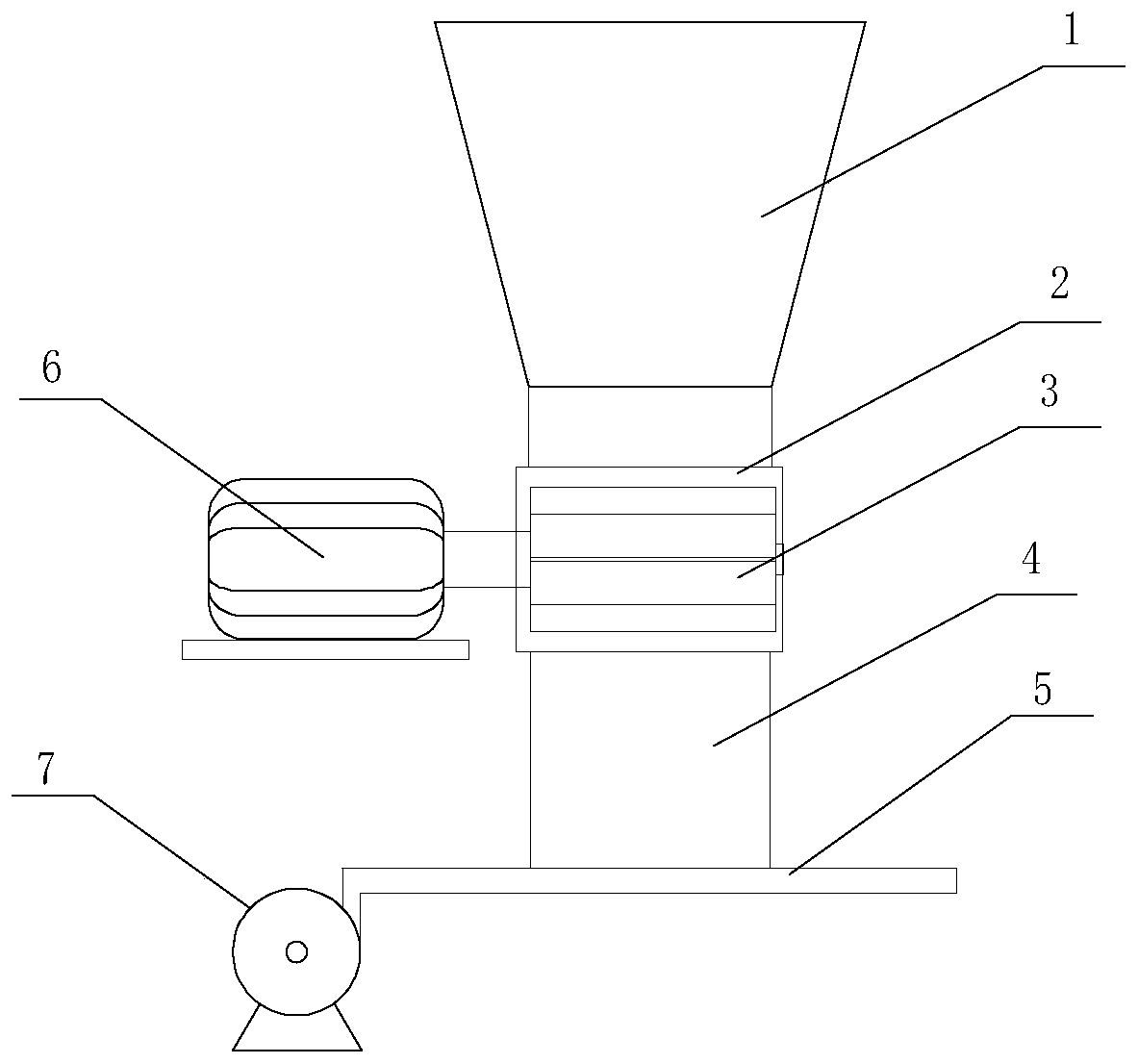

Automatic quantitative feeding system of household garbage high-temperature cracking furnace

InactiveCN106697980AEasy to stackEasy to transportIncinerator apparatusLoading/unloadingWastewaterCaking

The invention discloses an automatic quantitative feeding system of a household garbage high-temperature cracking furnace. The automatic quantitative feeding system comprises a garbage storage bin which is arranged over the cracking furnace and communicates with a cracking furnace charge opening of the cracking furnace; the lower portion of the garbage storage bin is provided with a garbage pushing opening, and the garbage pushing opening communicates with the cracking furnace charge opening in a staggered mode; a material pushing partition plate is horizontally arranged on the garbage pushing opening, the bottom side of the garbage storage bin is movably sealed by the material pushing partition plate, and the outer side of the material pushing partition plate is connected with a piston rod and an air cylinder; a movable cover plate is arranged on the garbage storage bin; and the upper portion of the cover plate is connected with a telescopic pull rod. By means of the automatic quantitative feeding system of the household garbage high-temperature cracking furnace, garbage can be conveniently stacked and transported into the cracking furnace, waste water and other secondary pollution can be avoided, the garbage is sufficiently cracked without caking, production is not influenced, and the thermal efficiency is high.

Owner:怀化市西南创业机械制造有限公司

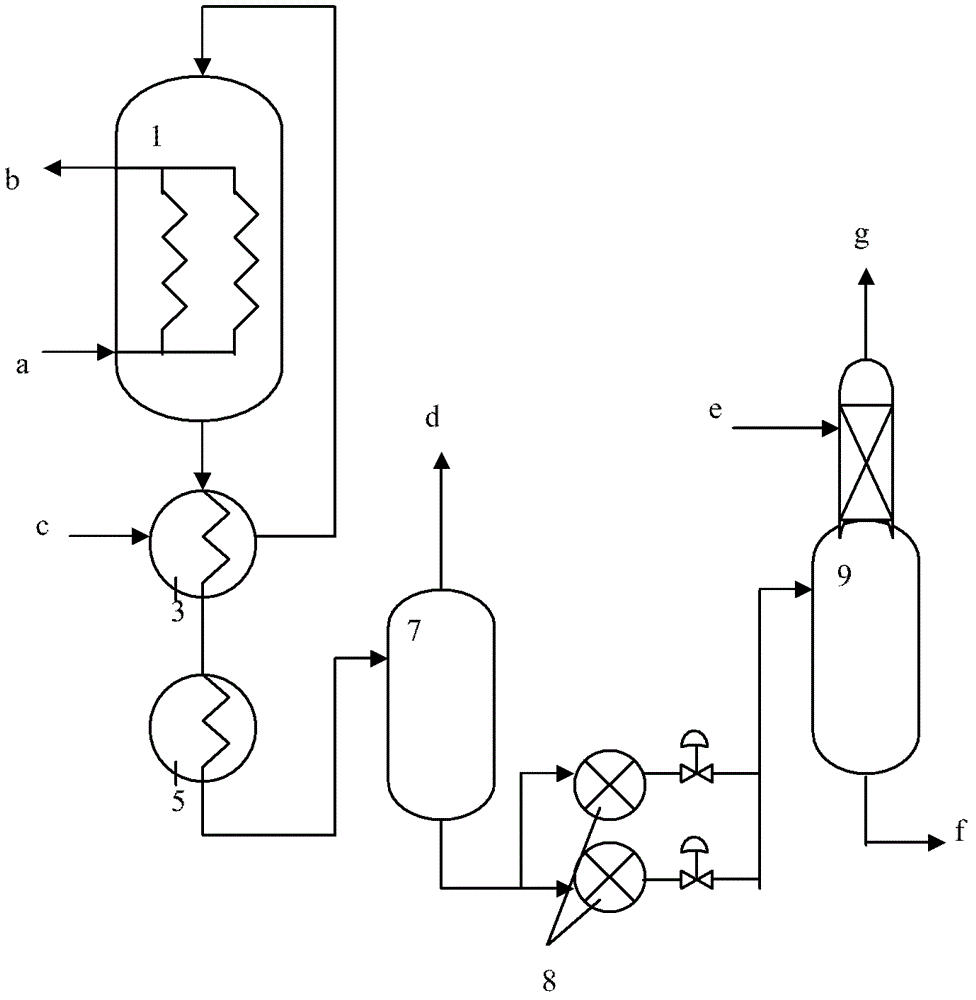

Methanol synthesis process, methanol synthesis system

ActiveCN103373898BThe same process effectEfficient use ofOrganic compound preparationChemical industryHigh pressureEnergy loss

The invention provides a methanol synthesis process. The process comprises the following steps of: recycling the pressure energy of the methanol separated from a methanol high-pressure separator; and carrying out flash evaporation on the methanol, from which the pressure energy is recycled. The invention also provides a methanol synthesis system applied to any methanol synthesis process provided by the invention. The methanol synthesis system comprises the methanol high-pressure separator, a flash evaporation tank, and a hydraulic turbomachine, wherein the working medium inlet of the hydraulic turbomachine is communicated with the methanol outlet of the methanol high-pressure separator, and the working medium outlet of the hydraulic turbomachine is communicated with the inlet of the flash evaporation tank. By adopting the methanol synthesis system provided by the invention, the pressure energy contained in the methanol generated by the methanol high-pressure separator can be recycled so as to prevent unnecessary energy loss.

Owner:ENN SCI & TECH DEV

Magnesium-calcium-zirconium slag non-sticking spraying coating

The present invention relates to a calcium magnesium zirconium spray paint not adhesive to the dregs, effectively solving the problem of the high energy consumption and environmental pollution caused by the use of the paint. The present invention consists of the following weight percentage: 20 to 80 percent of dolomite, 2 to 10 percent of zirconium sand, 5 to 15 percent of corundum powder, 2 to 10 percent of microsilica powder, 2 to 5 percent of bentonite, 5 to 15 percent of soft clay, 2 to 6 percent of phosphate, 0.1 to 1 percent of calcium lignosulfonate, and 0.2 to 2 percent of boric acid;the total content is 100 percent. The tests in the steel converter show that the spray paint of the present invention has the good fluidity and can finish the spraying and compensating operation in three minutes; the present invention can effectively isolate the dregs and the deposited dregs are easy to deal with; the operational time is reduced. The main raw material used in the present invention is the non-burning dolomite containing no water; the source of the raw materials is wide and convenient; moreover, the use of the non-burning raw material can save a large amount of energy; the present invention can effectively reduce the cost and save the energy consumption.

Owner:郑州荣达工矿集团有限公司

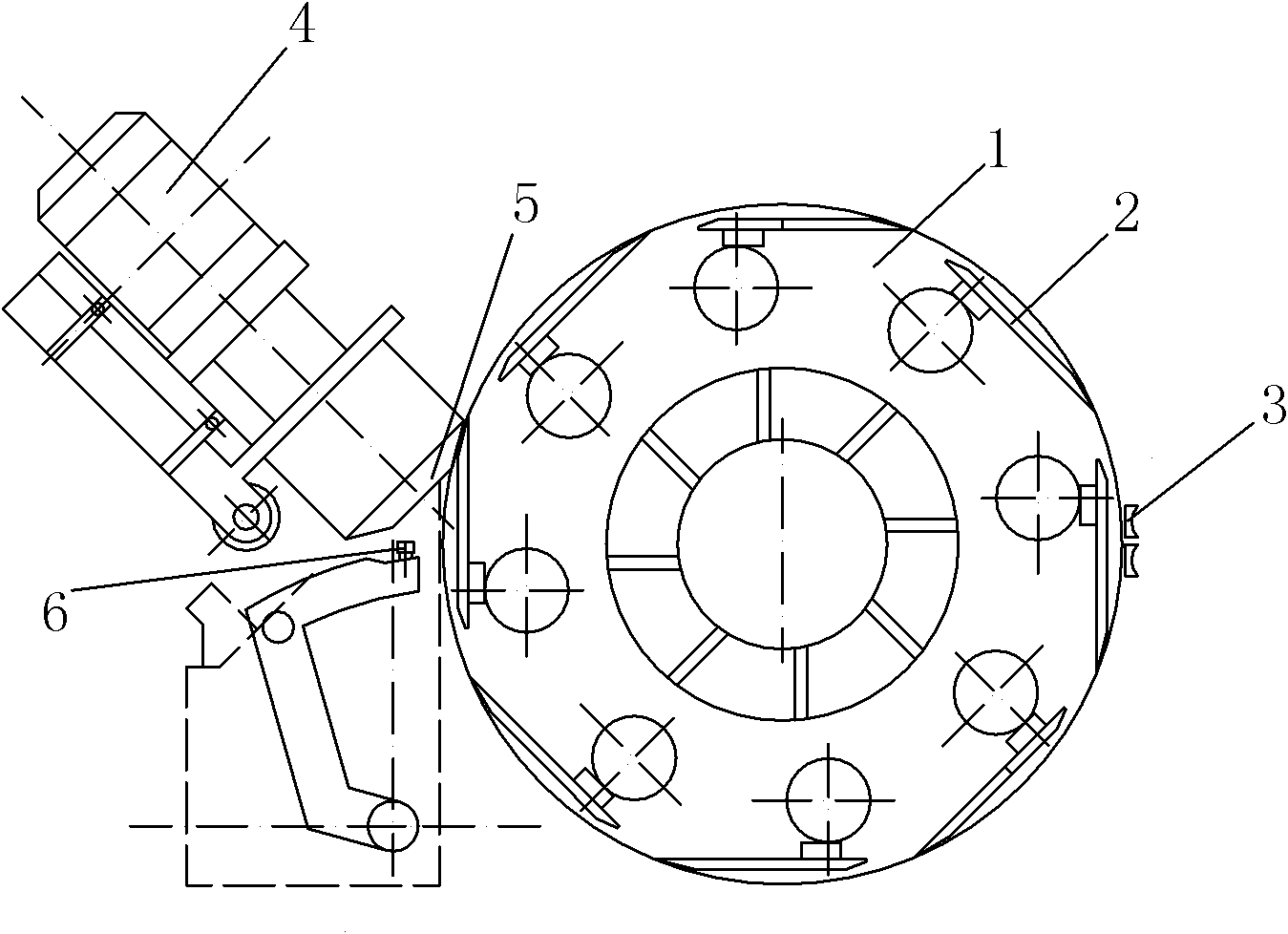

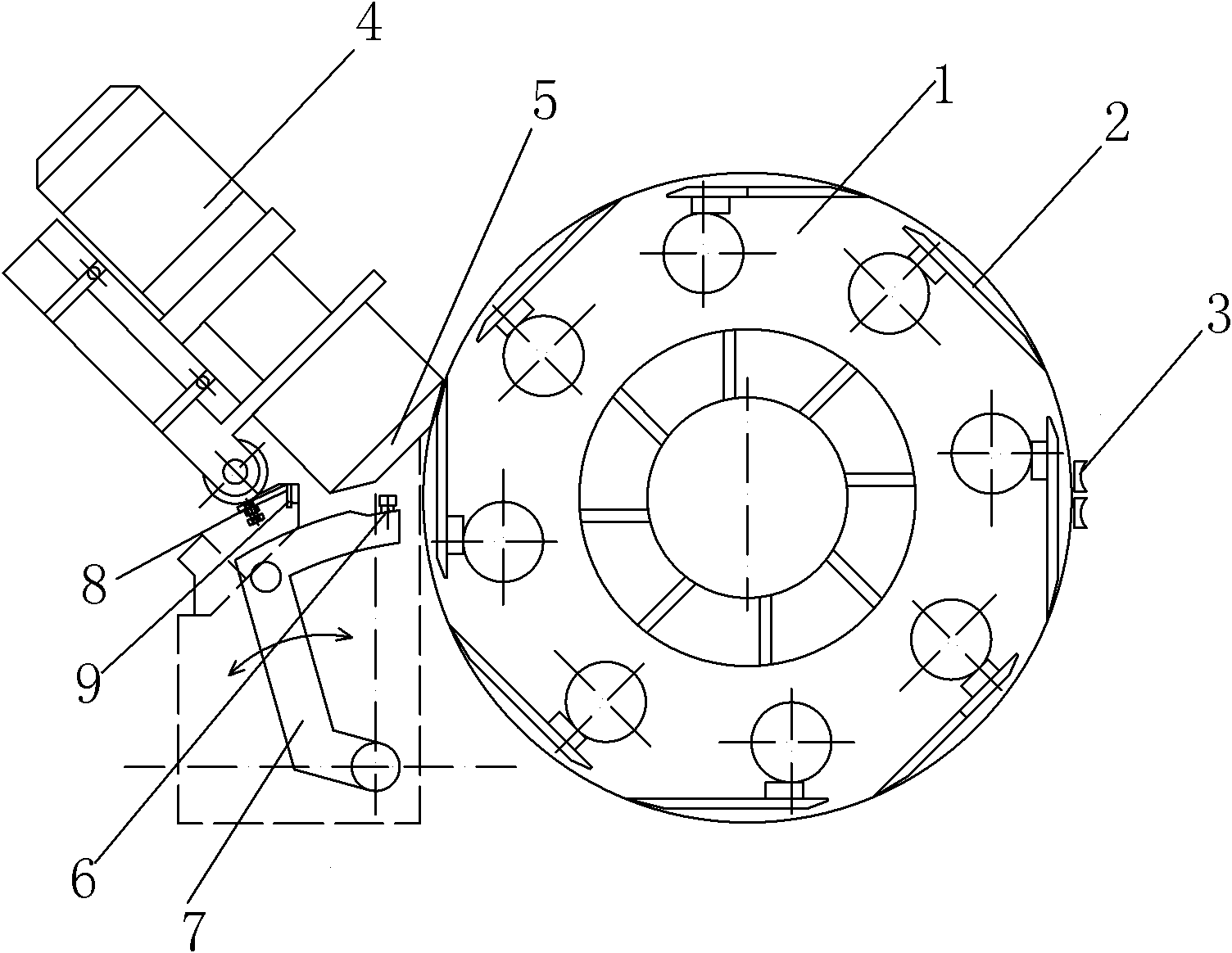

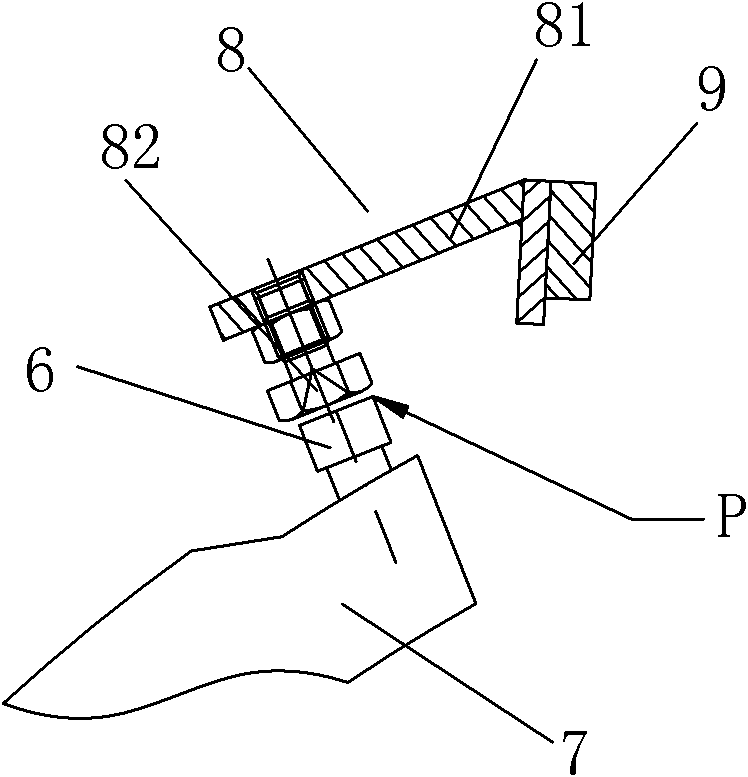

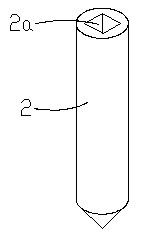

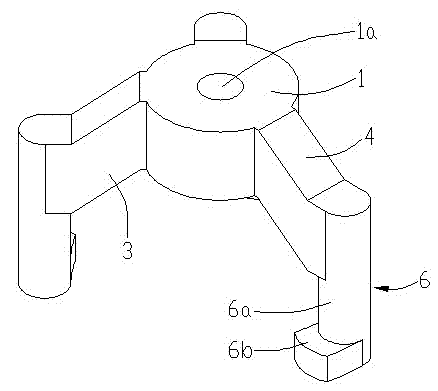

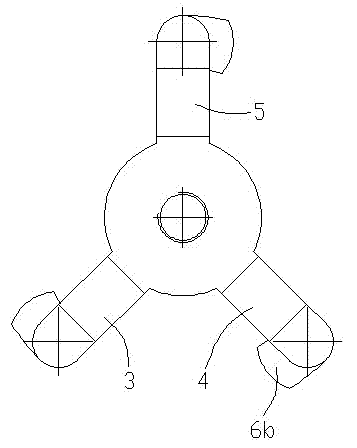

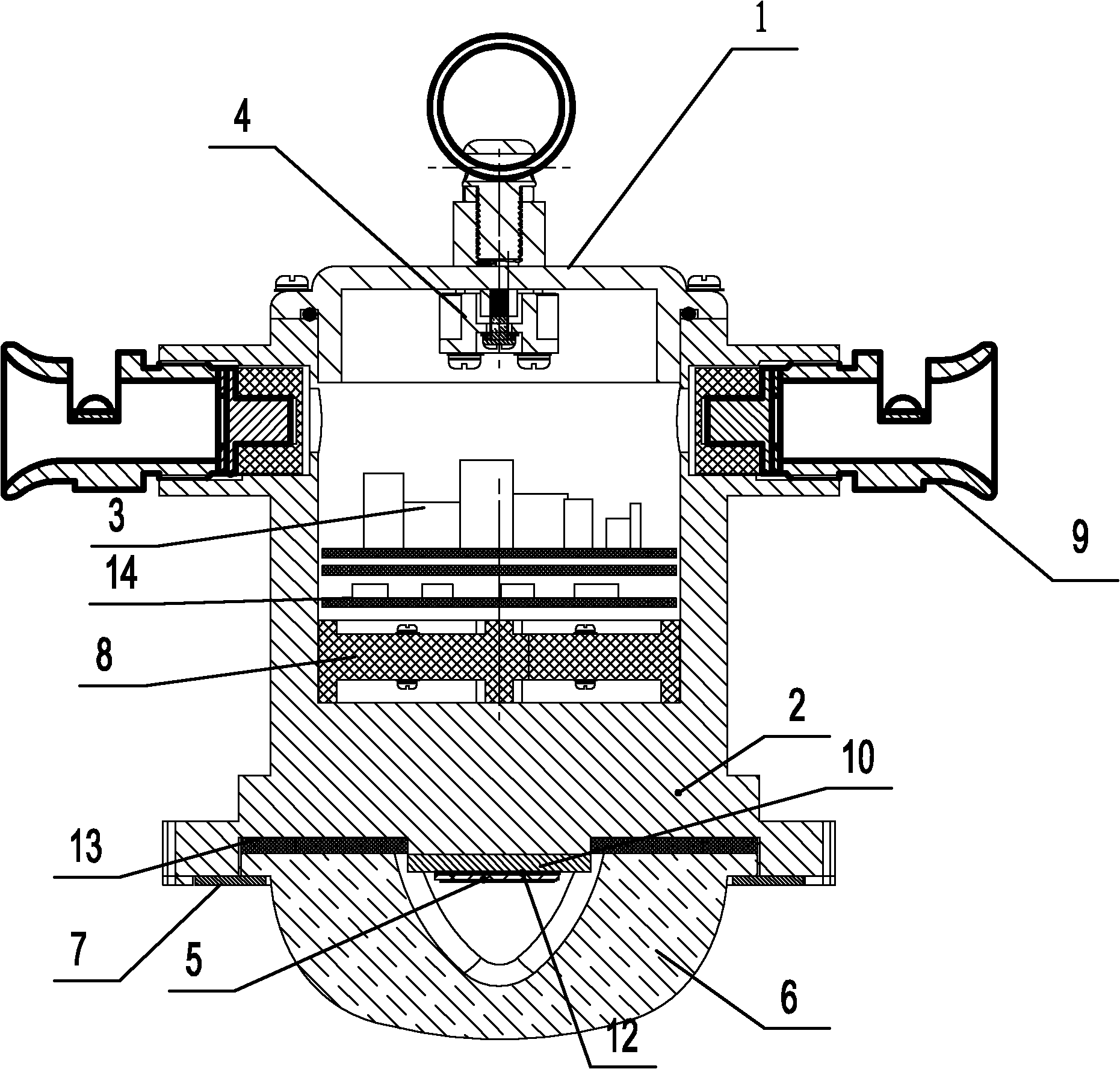

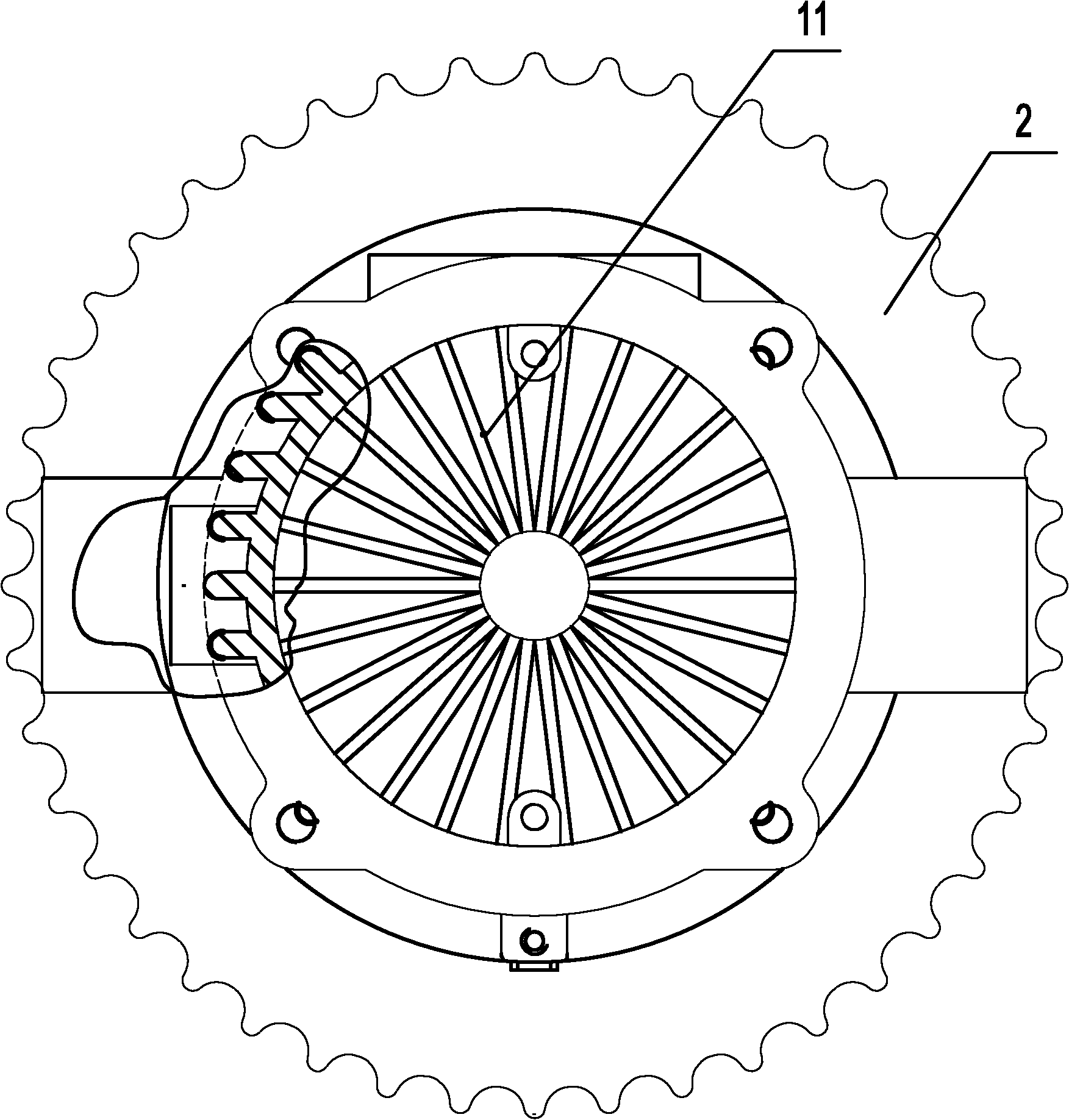

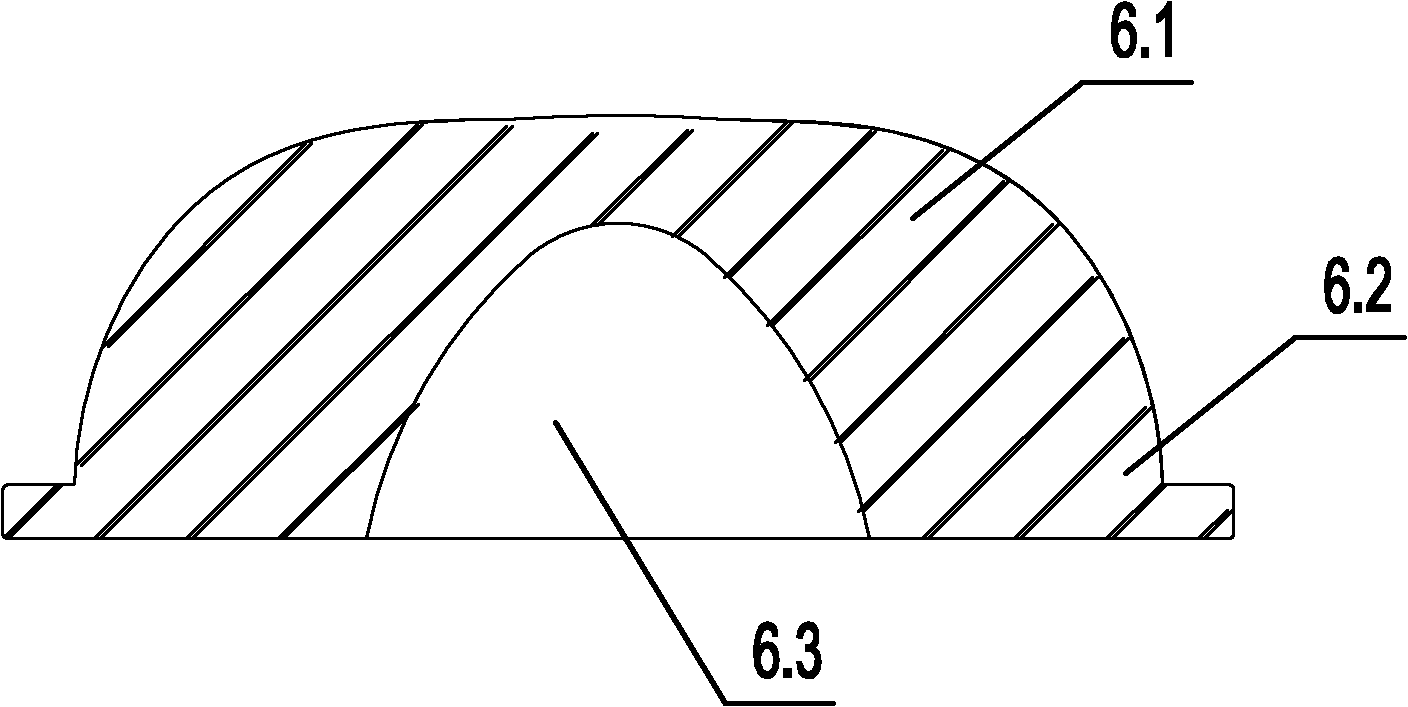

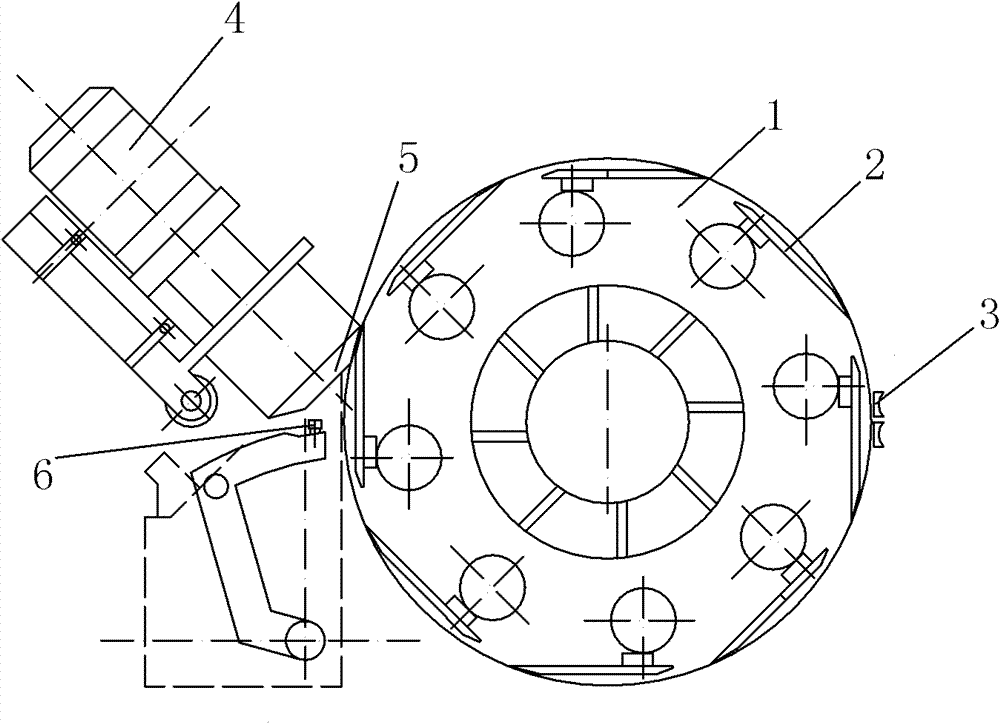

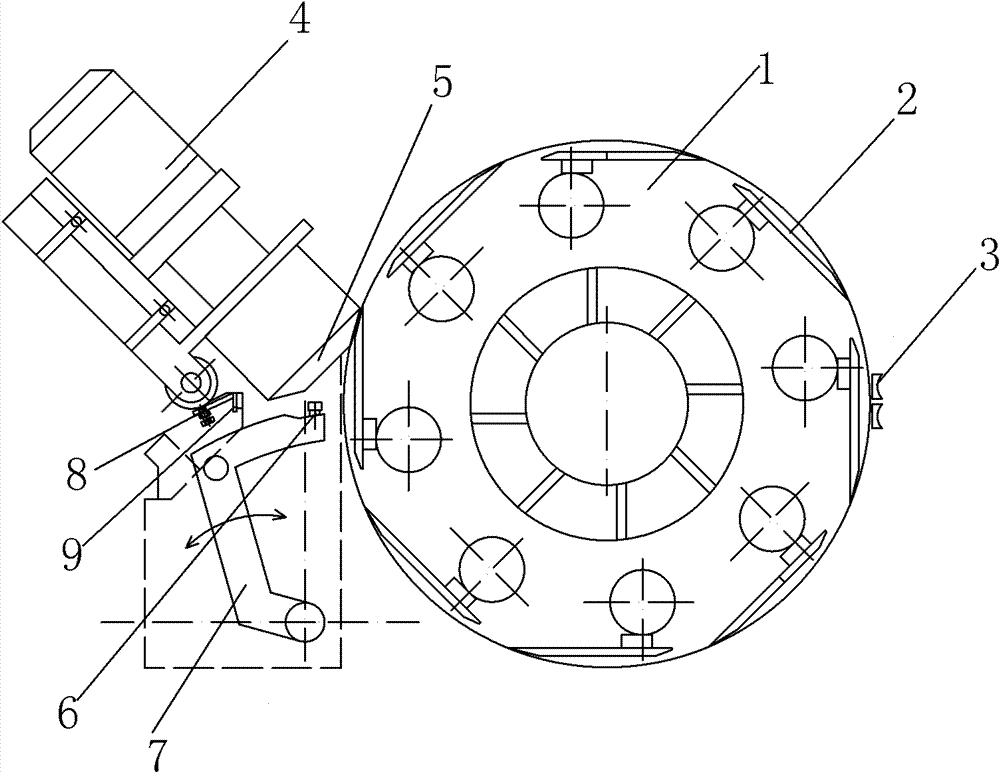

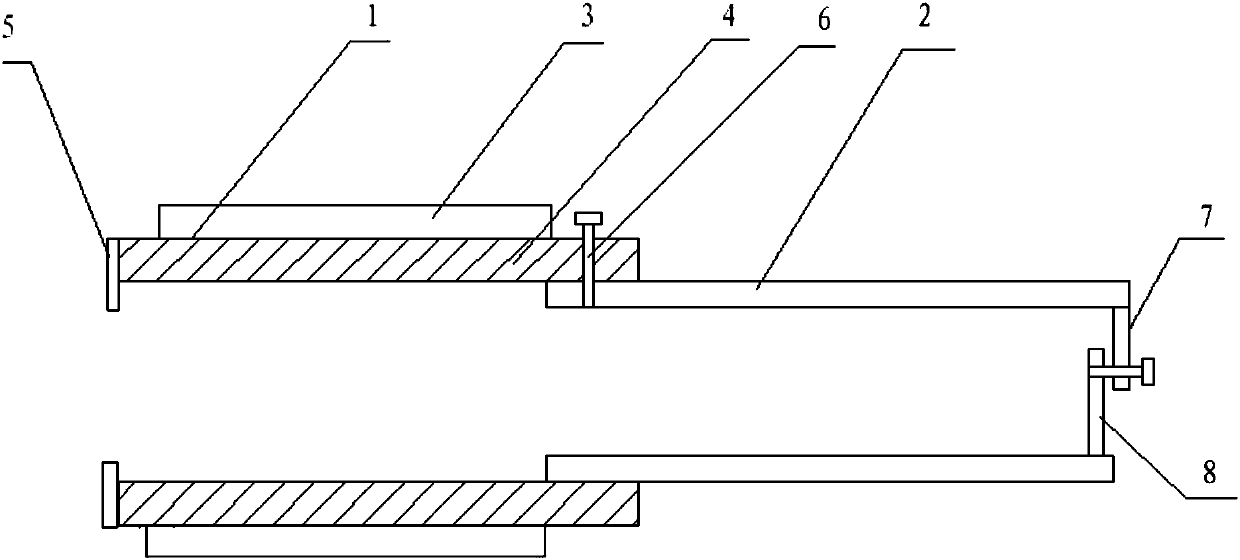

Device for quickly dismounting skid driving wheel of automobile production line

InactiveCN102152101ASimple structureEasy to processMetal working apparatusProduction lineDrive wheel

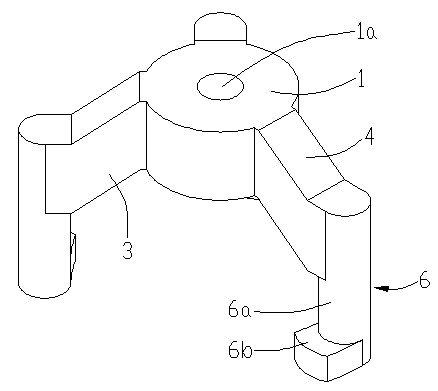

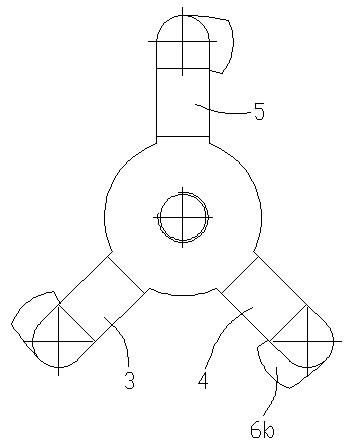

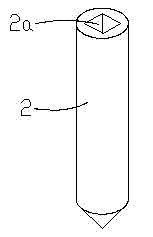

The invention discloses a device for quickly dismounting a skid driving wheel of an automobile production line. An axis of a pedestal (1) is provided with a threaded hole (1a) penetrating upper and lower end surfaces of the pedestal; a thimble (2) is inserted into the threaded hole (1a), and is in threaded fit with the pedestal (1); three cantilevers are arranged at the outer periphery of the pedestal (1), and are a first cantilever (3), a second cantilever (4) and a third cantilever (5) respectively, wherein the first cantilever (3) is vertical to the second cantilever (4); an included angle between the first cantilever (3) and the third cantilever (5) is equal to an included angle between the second cantilever (4) and the third cantilever (5); and inner ends of the three cantilevers are fixed on the pedestal (1), and claw hooks (6) are fixed at outer ends of the three cantilevers. The device is not restricted to a narrow on-site space, and the skid driving wheel can be dismounted under the condition of not dismounting a motor in advance; the operation is simple and fast, the time and labor are saved, the production is not influenced, and the production efficiency is guaranteed.

Owner:力帆科技(集团)股份有限公司

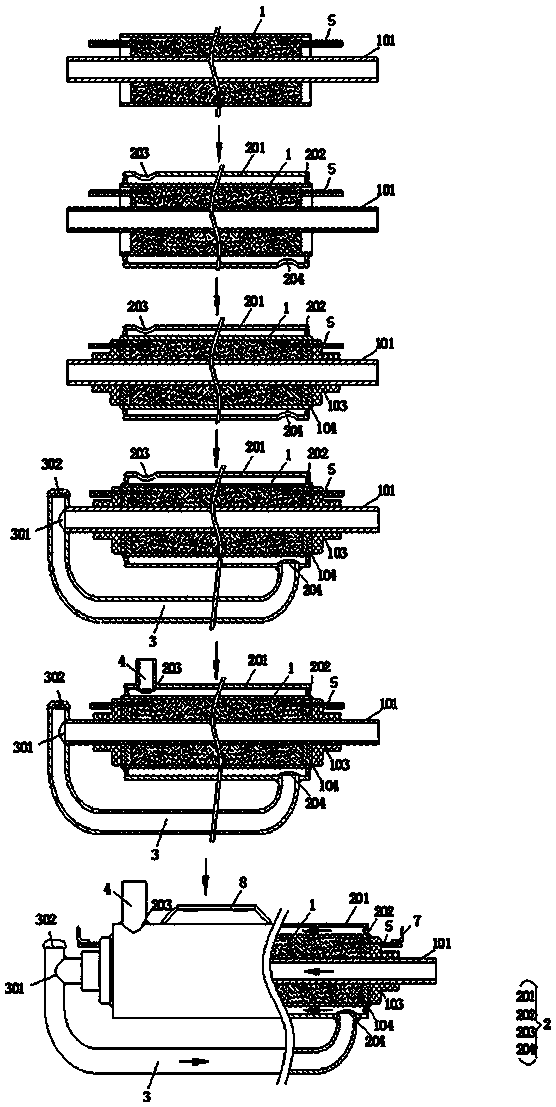

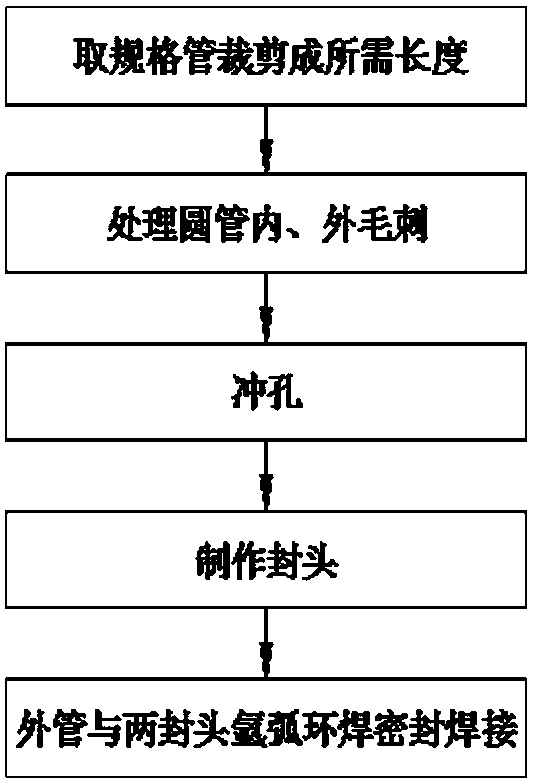

Manufacturing method of two-way heat exchange heater

The invention discloses a manufacturing method of a two-way heat exchange heater. The manufacturing method of the two-way heat exchange heater comprises the following steps that the step 1, an outer pipe assembly is manufactured; the step 2, a connecting pipe assembly is manufactured; the step 3, a two-way heat exchange heater body is manufactured; the step 4, the humidity is removed, and a ceramic insulation head is installed; the step 5, a connecting assembly is installed; the step 6, a pipe head and a temperature controller support are welded; the step 7, leakage detection of a product is conducted; the step 8, a terminal sheet is welded and fixed; and the step 9, laser marking of the required technical parameters is conducted. The manufacturing method of the two-way heat exchange heater has the advantages that the product quality is improved, the production cost is reduced, various working procedures are independent and have no interference with each other, and the manufacturing technology is simple.

Owner:肇庆市庆林电热电器有限公司

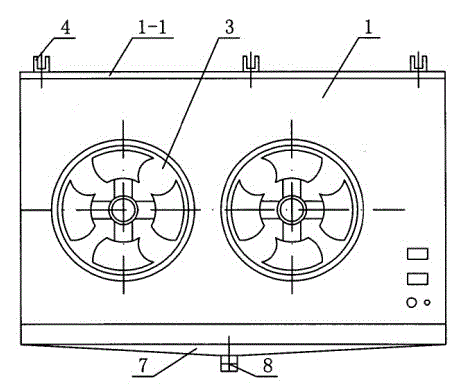

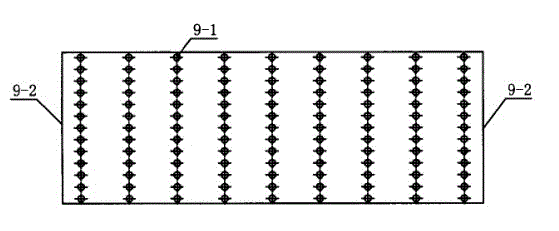

Modified air cooler

InactiveCN103062966ATo achieve the effect of defrostingSimple structureCorrosion preventionRefrigeration componentsWater diversionEngineering

The invention relates to an air cooling device, in particular to a modified air cooler which comprises a box body (1), an evaporator (2), a fan (3) and a water diversion disc (9). The box body (1) is connected with the fan (3), and the evaporator (2) is arranged in the box body (1). The box body (1) is provided with a water inlet pipe (5) and a water outlet pipe (6), and a water receiving disc (7) is arranged on the lower portion of the box body (1). A water drain opening (8) is arranged on the water receiving disc (7), and the water diversion disc (9) is arranged on the upper portion of the evaporator (2) in the box body (1). An outlet end (5-1) of the water inlet pipe (5) is accessed to the upper portion of the water diversion disc (9), and a plurality of water diversion holes (9-1) are formed in the water diversion disc (9). The modified air cooler is simple in structure, good in defrosting effect, and convenient to defrost. The water diversion disc is adopted to spray water and defrost without stopping a machine, and production efficiency is high. The water diversion disc is long in service life, and quite convenient and quick to maintain and replace after being damaged.

Owner:CHANGZHOU JINGLENG IND REFRIGERATION EQUIP

Breeding method for cold-resistant okra

InactiveCN107466847AHigh activityKeep alivePlant genotype modificationSeed immunisationUltraviolet lightsGamma ray

The invention discloses a breeding method of cold-resistant okra, which is characterized in that it includes the following aspects: (1) seed storage, treating the okra seeds with a gibberellin solution, mixing them with a culture medium for storage, and storing them in 2 Heating the colchicine solution at ‑4°C for storage; (2) Mutagenesis breeding, first spraying the seeds with active selenium solution, then irradiating them with ultraviolet light at varying temperatures, and finally irradiating them with gamma rays; (3) Pregermination, immerse the mutagenized seeds in gibberellin solution for constant temperature germination; (4) Breeding, breed and cultivate at a temperature of 3-5°C, and screen cold-resistant seeds; (5) Cross-breeding, mutagenized seeds The okra seeds, the third-generation seeds, and the fourth-generation seeds were crossed three times to obtain the fifth-generation seeds for large-scale planting.

Owner:宁国市绿缘蔬菜种植专业合作社

Device for quickly dismounting skid driving wheel of automobile production line

InactiveCN102152101BSimple structureEasy to processMetal working apparatusProduction lineDrive wheel

The invention discloses a device for quickly dismounting a skid driving wheel of an automobile production line. An axis of a pedestal (1) is provided with a threaded hole (1a) penetrating upper and lower end surfaces of the pedestal; a thimble (2) is inserted into the threaded hole (1a), and is in threaded fit with the pedestal (1); three cantilevers are arranged at the outer periphery of the pedestal (1), and are a first cantilever (3), a second cantilever (4) and a third cantilever (5) respectively, wherein the first cantilever (3) is vertical to the second cantilever (4); an included anglebetween the first cantilever (3) and the third cantilever (5) is equal to an included angle between the second cantilever (4) and the third cantilever (5); and inner ends of the three cantilevers arefixed on the pedestal (1), and claw hooks (6) are fixed at outer ends of the three cantilevers. The device is not restricted to a narrow on-site space, and the skid driving wheel can be dismounted under the condition of not dismounting a motor in advance; the operation is simple and fast, the time and labor are saved, the production is not influenced, and the production efficiency is guaranteed.

Owner:力帆科技(集团)股份有限公司

Simulation method of oil and gas mixed transportation pipeline installation and hydrate formation, blockage and ablation

ActiveCN105510529BEasy to control temperaturePressure is easy to controlMaterial analysisData processing systemTemperature control

The invention discloses an oil-gas mixed transportation pipeline device and a simulating method for hydrate formation, blockage and ablation, comprising a reactor I and a reactor II, both of which are connected to the same gas supply system, and react There is a grouting port on the kettle I, and the top and bottom of the reactor II are connected through a circulation pipeline, and a liquid injection port is provided on the circulation pipeline; both the reactor I and the reactor II are equipped with temperature regulators to adjust their temperature. A control device, and a detection device for detecting the reaction state of natural gas hydrate in the pipeline is installed on the circulation pipeline, the detection device is connected with the data processing system, and the detection device is connected with the data processing system. The measure of the present invention for the high-risk blockage state has a very good effect on controlling the loss of long-term stoppage of pipeline due to blockage.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

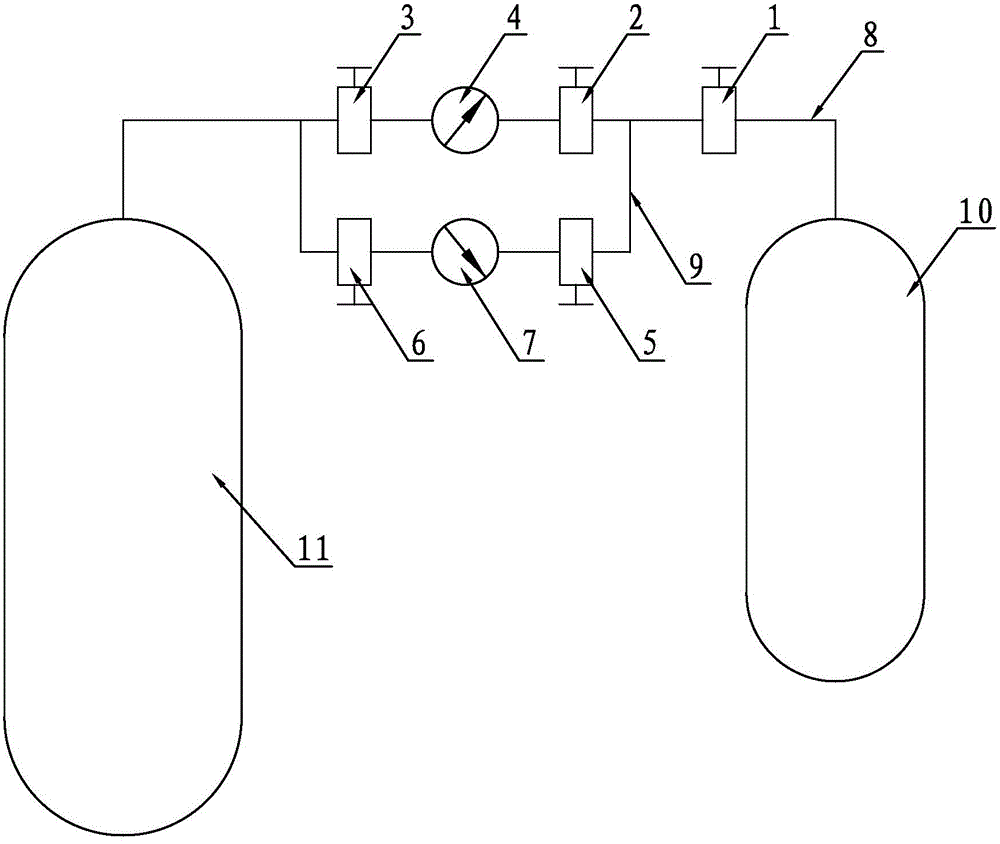

Dual-pipeline switching gas-filling device of polycrystalline ingot furnace and control method thereof

InactiveCN104611767AGuaranteed stable air supplyEnsure normal crystal growthPolycrystalline material growthSingle crystal growth detailsEngineeringElectrical and Electronics engineering

The invention provides a dual-pipeline switching gas-filling device of a polycrystalline ingot furnace and a control method thereof. The dual-pipeline switching gas-filling device comprises a first hand valve, a first hand valve, a third hand valve, a first flowmeter, a fourth hand valve, a fifth hand valve, a second flowmeter, a main gas channel and an auxiliary gas channel; the first hand valve, the second hand valve and the third hand valve as well as the first flowmeter are connected in series and mounted on the main gas channel; one end of the main gas channel is communicated with an argon tank, while the other end of the main gas channel is communicated with the ingot furnace; the fourth hand valve, the fifth hand valve and the second flowmeter are connected in series and mounted on the auxiliary gas channel; one end of the auxiliary gas channel is connected to the main gas channel between the first hand valve and the second hand valve, while the other end of the auxiliary gas channel is connected to the main gas channel between the third hand valve and the ingot furnace. The dual-pipeline intake switching pressure-maintaining device is adopted, and capable of automatically switching the auxiliary gas channel to supply gas into the ingot furnace, and no influence is caused on the production.

Owner:JIANGSU ZHAOJING PHOTOELECTRIC TECH DEV

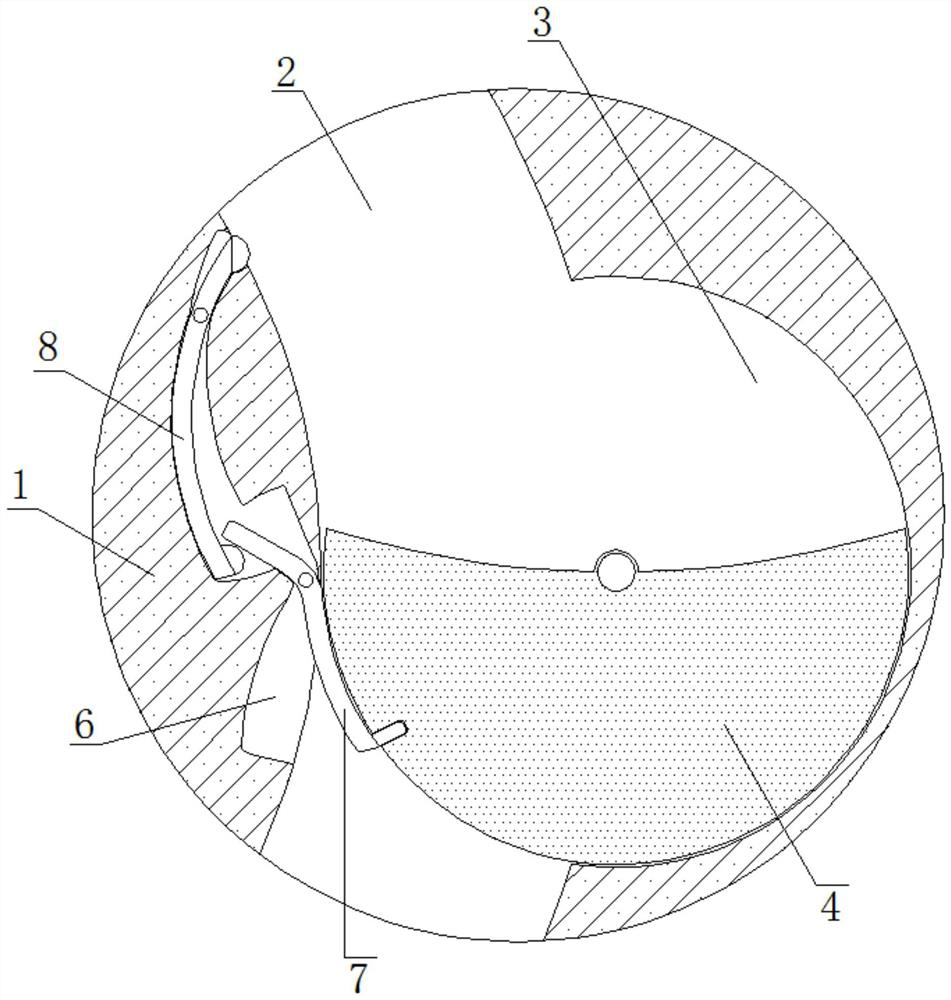

Collection device for overflow steel slag for continuous casting tundish

ActiveCN105945272AImprove reliabilityImprove securityMelt-holding vesselsCasting cleaning apparatusSlagContinuous casting

The invention discloses a collection device for overflow steel slag for a continuous casting tundish. The collection device comprises a slag basin; a supporting platform is arranged between a tundish and a rotary table; tracks which penetrate through the tundish and the rotary table are arranged on the supporting platform; a track trolley which can move along the tracks are arranged on the tracks; and the slag basin is placed on the track trolley. According to the collection device, the track trolley can drive the slag basin to move to the underneath of an overflow hole of the tundish driven by a drive mechanism, so that the slag basin can bear and receive the steel slag which overflows out of the overflow hole of the tundish; in addition, the track trolley can also drive the slag basin to leave the underneath of the overflow hole of the tundish and move out of the space between the tundish and the rotary table, so that the travelling trolley can hoist the slag basin without being influenced by the rotary table; a controller which can control the drive mechanism so as to control the movement of the track trolley is also arranged on the supporting platform; and the collection device for the overflow steel slag for the continuous casting tundish can also safely and reliably collect the steel slag which overflows out of the overflow hole of the tundish without influencing the production.

Owner:JIANGSU YONGGANG GROUP CO LTD

A kind of postoperative rehabilitation nursing training device of cardiology department

ActiveCN110898402BPromote blood circulationPromote recoveryMuscle exercising devicesNursing careEngineering

The invention discloses a postoperative rehabilitation nursing training device for the department of cardiology. The postoperative rehabilitation nursing training device for the department of cardiology comprises a sleeve gasket, the sleeve gasket is made of hard rubber and cannot generate too much deformation under pressure, a cavity channel is formed in the sleeve gasket and is annular, a grooveis formed in the right side of the inner bottom of the outer annular wall of the cavity channel, rotating grooves are formed in the left side and the right side of the outer annular wall of the cavity channel, and rotating wheels are movably connected into the rotating grooves. According to the postoperative rehabilitation nursing training device for the department of cardiology, the annular cavity channel is formed in the sleeve gasket; when the device is used, a patient lies on a bed, the sleeve gasket wraps the outer side of the arm of the patient, a finger ring of the pull rope annularlysleeves the five fingers of the patient, the patient starts to open and close the five fingers after all preparatory work is completed, the piston rod is continuously pulled and controlled to compressand push the reset spring, the fingers of the patient are exercised, and blood circulation is promoted to a certain extent.

Owner:JILIN UNIV

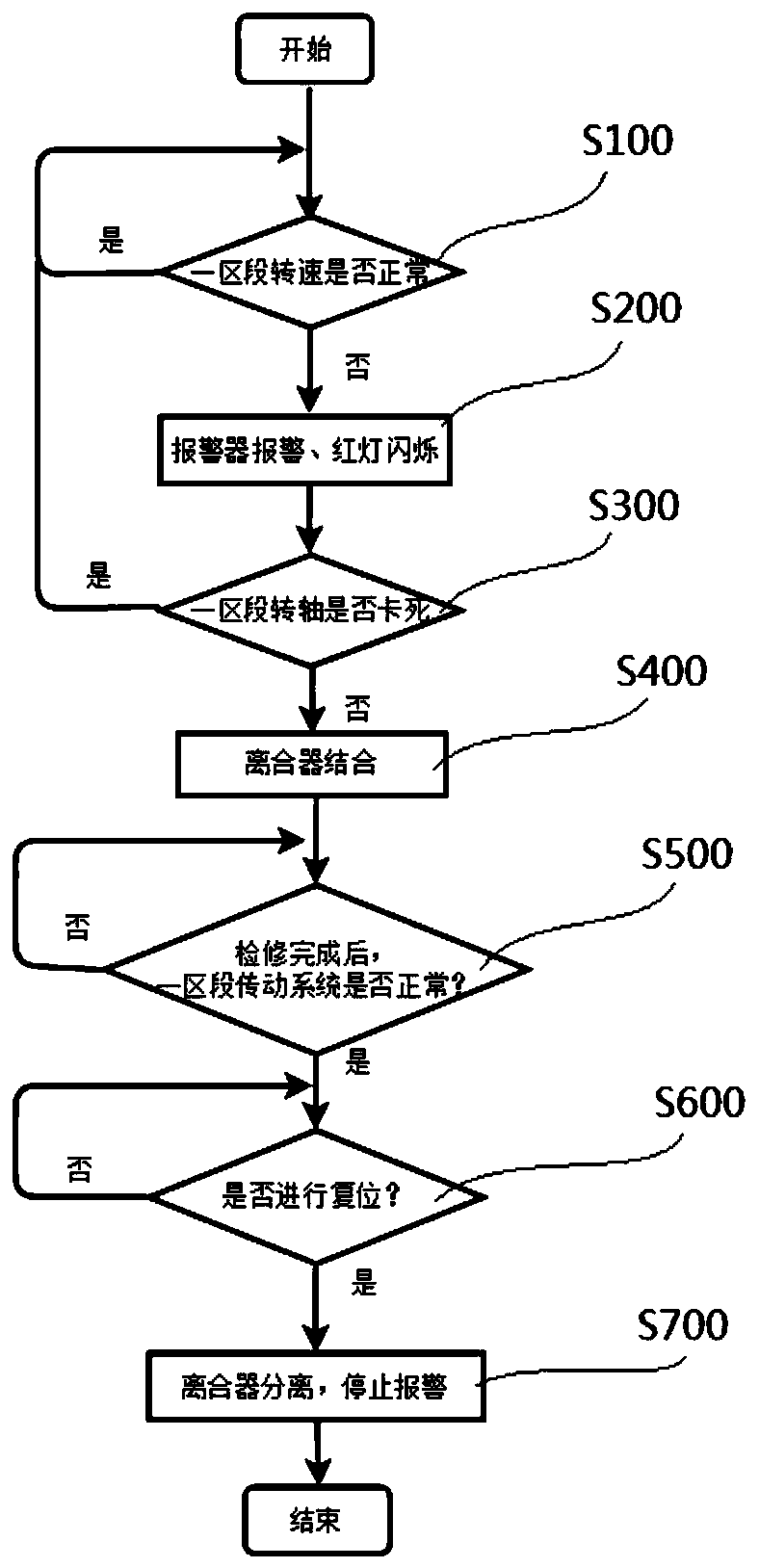

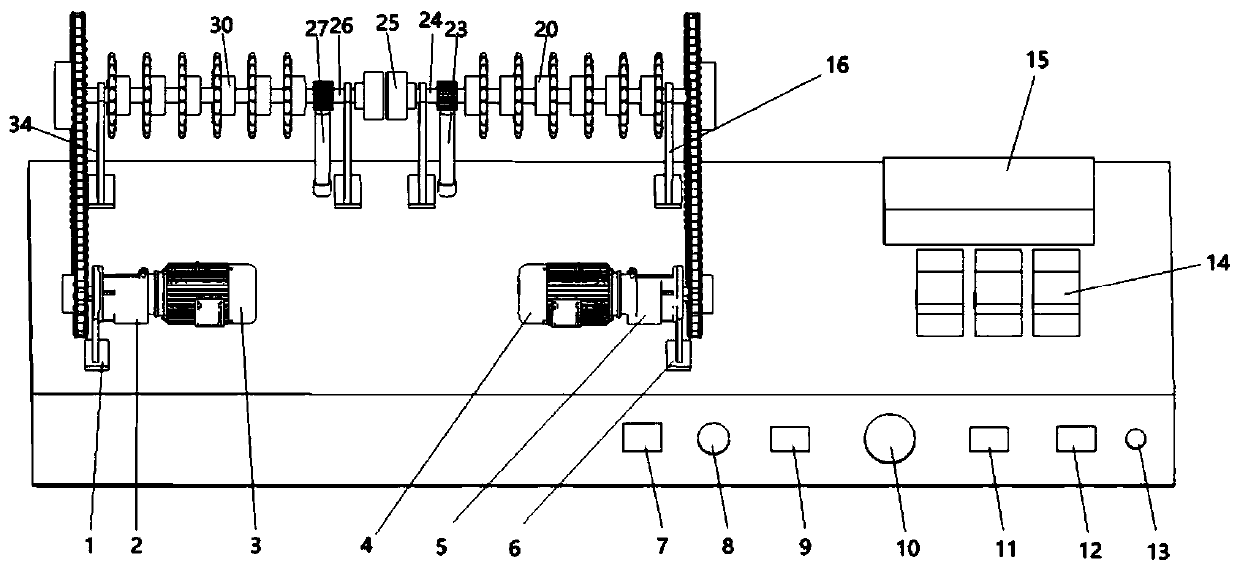

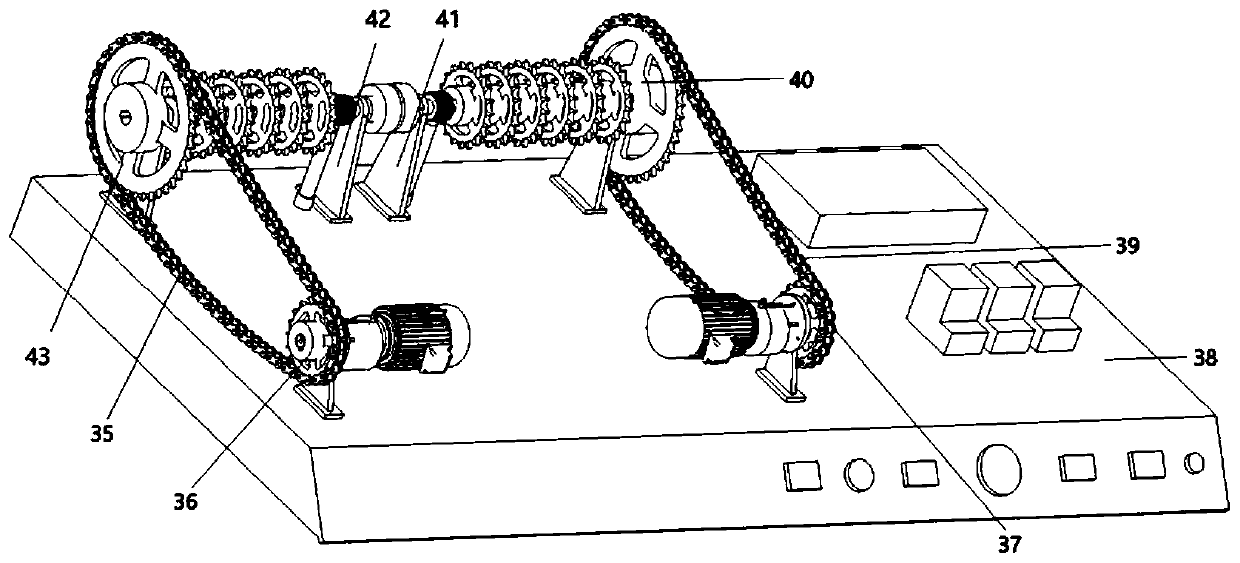

Automatic fault switching system and automatic fault switching system and method in tanker section

PendingCN110093671ANo production impactEasy to removeFilament manufactureFilament/thread formingManufacturing technologyPower switching

The invention belongs to the technical field of spinning manufacture, and provides an automatic fault switching system and an automatic fault switching system and method in a tanker section. The automatic fault switching system is used for fault determination and power switching of a first rotating shaft and second rotating shaft, and comprises a clutch and a control module, wherein the clutch isarranged between the first rotating shaft and the second rotating shaft and is used for connecting or disconnecting the first rotating shaft and the second rotating shaft; when the first rotating shaft or the second rotating shaft has a rotation fault, the control module controls the clutch to connect the first rotating shaft with the second rotating shaft; the automatic fault switching system andmethod in a tanker section is a system and method of the automatic fault switching system moving to the tanker section. The automatic fault switching system can prevent the rotating shafts from stopping rotating when the faults occur, thereby preventing a tanker from stopping rotating, ensuring the continuity of the production, reducing the waste silk rate, and avoiding raw material waste and decrease of the yield.

Owner:SHEN MA INDUSTRY CO LTD

Material absorbing device used for producing automobile connector

PendingCN107021357AGuaranteed tightnessNo production impactLarge containersLoading/unloadingControl systemInjection molding machine

The invention relates to a material absorbing device used for producing an automobile connector. The material absorbing device comprises a material absorber and a material containing assembly which are connected. The material absorber is further connected with a feeding tank. The discharging end of the material containing assembly is connected with a feeding port (3) in an injection molding machine, and the lower portion and the top of the material containing assembly are provided with a first sensor and a second sensor, wherein the first sensor and the second sensor are used for detecting the raw material amount in the material containing assembly and feeding back corresponding feeding and stopping signals. The material absorber, the first sensor and the second sensor are connected with a control system. Compared with the prior art, the material absorbing device has the beneficial effects that feeding is automatic, the labor cost is reduced, and losses of the quality of raw materials are low in the conveying process.

Owner:SHANGHAI CHIEF LAND ELECTRONICS CO LTD

Anti-corrosion lining of dechlorination tank

InactiveCN102489235AShort repair timeNo production impactChemical/physical/physico-chemical processesCeramic tilesEngineering

An anti-corrosion lining of a dechlorination tank relates to the repairing of leakage points of a tank body. The anti-corrosion lining comprises the dechlorination tank part; a leakage hole is arranged on the dechlorination tank; potash water glass plaster is arranged in the leakage hole and at the periphery of the leakage hole; and acid-resisting ceramic tiles are arranged on the potash water glass plaster. The anti-corrosion lining has the beneficial effects that the leaked tank body is not needed to be replaced, the repairing time is short and the production is not affected.

Owner:TIANJIN BOTIAN CHEMICAL

Sulfuric-acid-method titanium dioxide production method and cleaning method for membrane equipment in sulfuric-acid-method titanium dioxide production method

ActiveCN110813098AEasy to disassemble and operateDoes not affect product qualitySemi-permeable membranesSpecific water treatment objectivesWastewaterEngineering

The invention discloses a sulfuric-acid-method titanium dioxide production method and a cleaning method for membrane equipment in a water washing procedure of the sulfuric-acid-method titanium dioxideproduction method. The cleaning method is characterized in that a cleaning agent is added for online cleaning of a membrane on the basis of keeping an unchanged working state of the membrane equipment in a water treatment procedure. By introduction of the cleaning method into titanium dioxide production, and on the premise of no influence on the quality of a recovered titanium dioxide product, acleaning process can be greatly simplified; the utilization rate of the membrane equipment can be significantly improved; generation of wastewater can be reduced; thus, titanium dioxide production efficiency can be significantly improved, and cost can be reduced.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

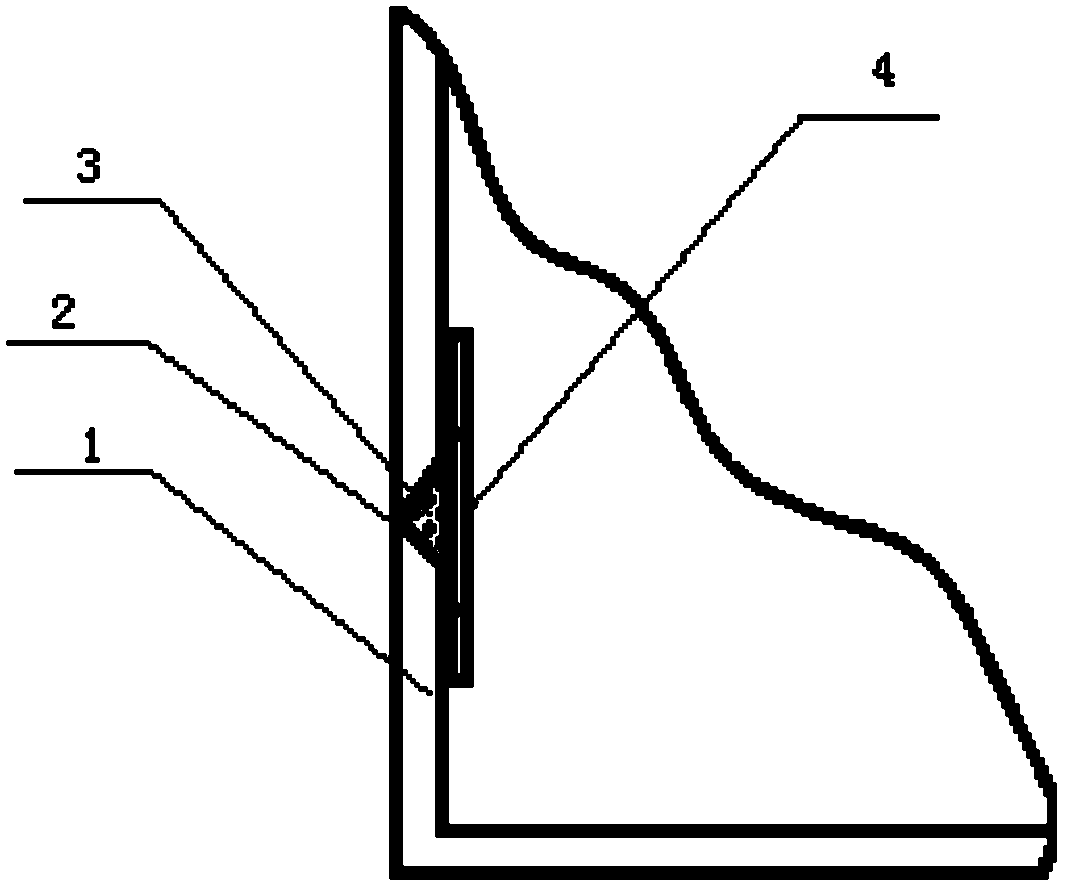

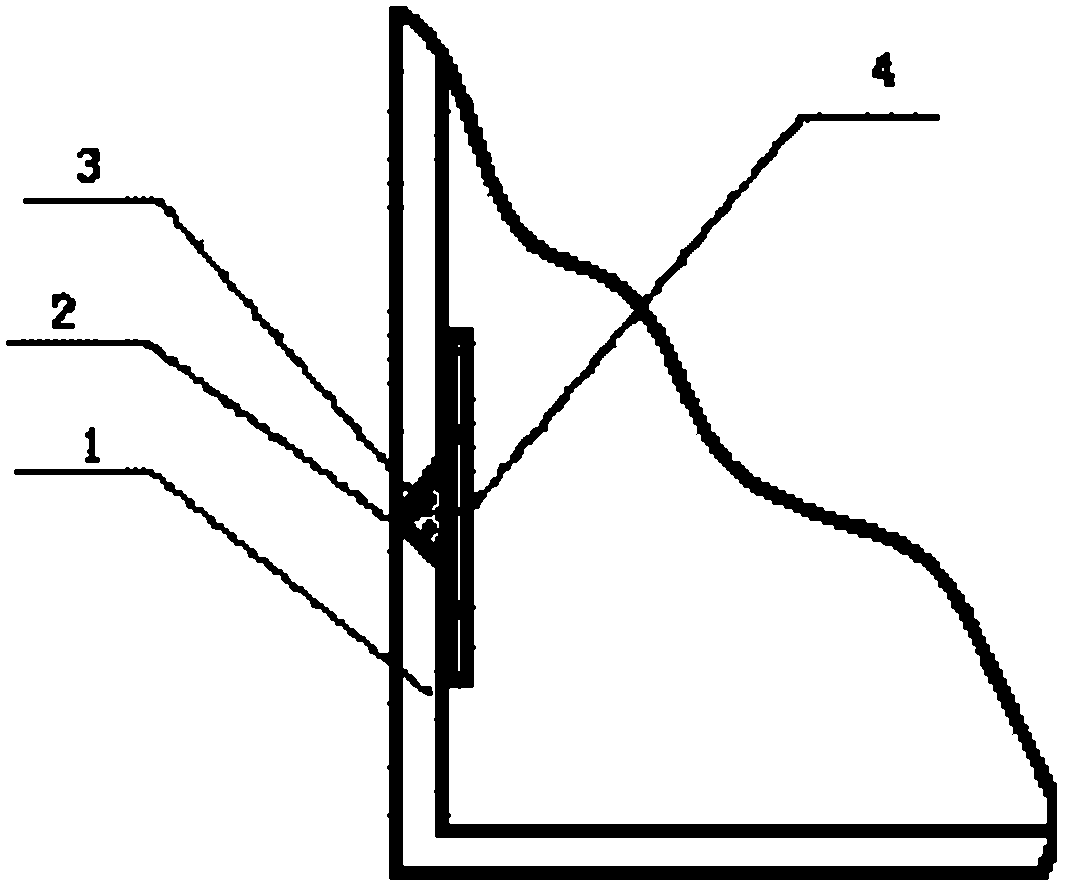

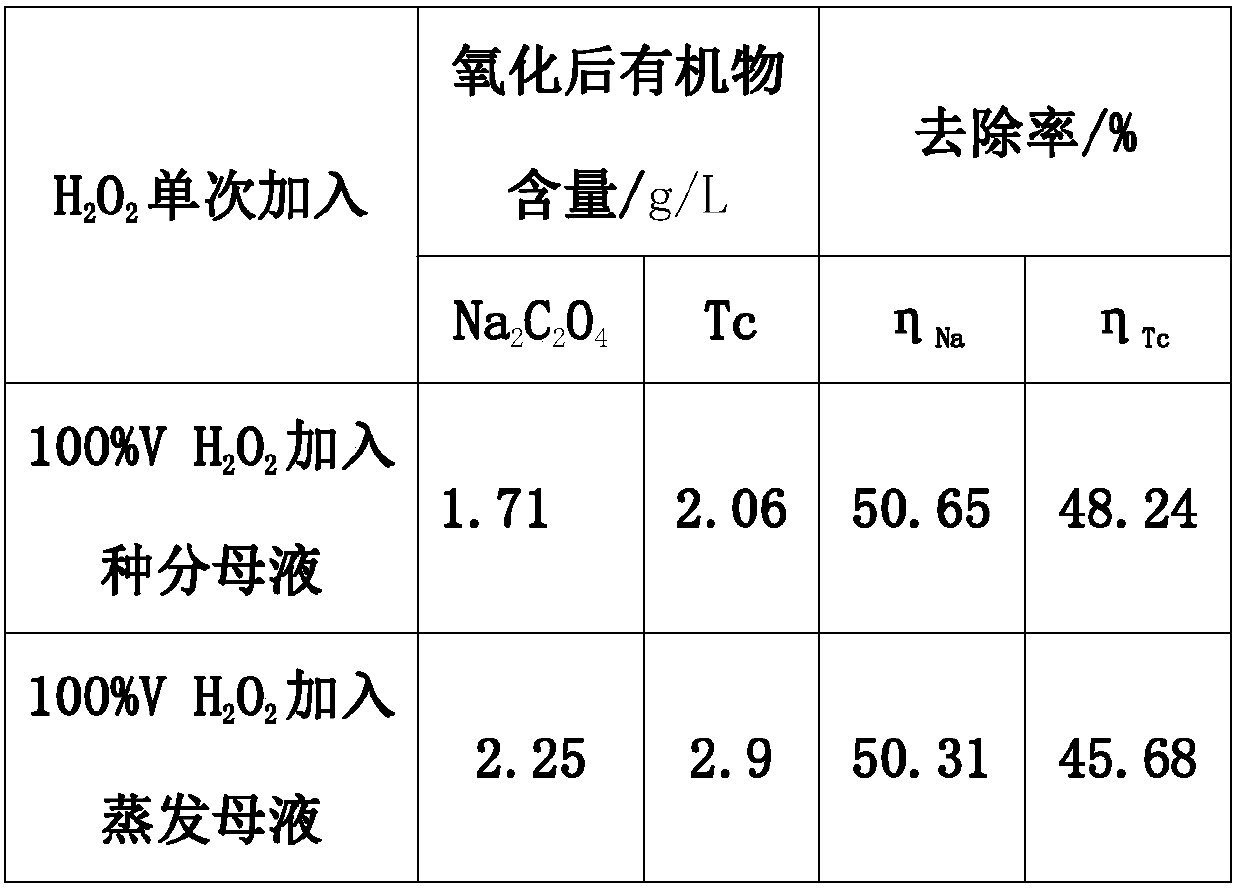

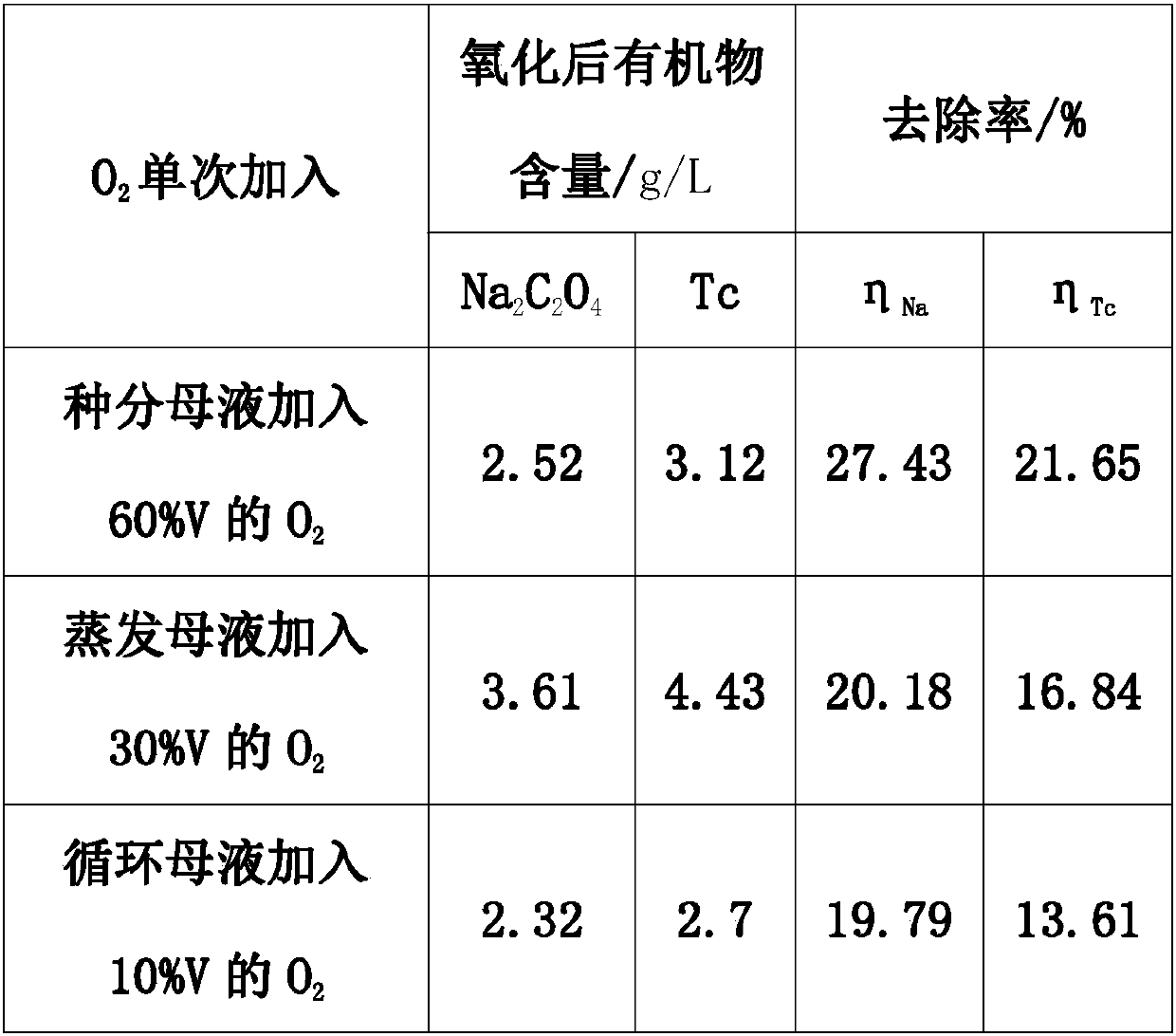

A method for multi-stage hydrogen peroxide to remove organic matter in alumina production process

ActiveCN106044811BLow costReduce energy consumptionAluminium oxides/hydroxidesPregnant leach solutionSodium aluminate

The invention discloses a method for removing organic substances in the aluminum oxide production process with hydrogen peroxide through multiple stages. The method comprises the following steps that firstly, leach liquor is injected into bauxite, aluminum oxide in the bauxite is leached, and a seed pregnant solution is obtained; secondly, the content of organic substances in the seed pregnant solution is measured, and the total volume V of hydrogen peroxide needed for a reaction is calculated; thirdly, 50-70%V of hydrogen peroxide is added into the seed pregnant solution, a reaction is carried out, and a solution obtained after the reaction enters an evaporation stage; fourthly, 20-40%V of hydrogen peroxide is added into an evaporation mother solution, a reaction is carried out for 1-60 min, and a solution obtained after evaporation of the evaporation mother solution serves as leach liquor to be recycled; fifthly, 5-15%V of hydrogen peroxide is added into the recycled leach liquor, and then the steps are repeated. According to the method, H2O2 is added into a sodium aluminate solution and can make full contact with the sodium aluminate solution; besides, H2O2 has the oxygenolysis feature and can remove organic substances under the normal pressure conditions, and the running pressure of equipment is reduced; the method has the advantages of being small in energy consumption, high in efficiency, low in cost and free of pollution.

Owner:GUIZHOU UNIV

Efficient energy-efficient environmental-friendly intrinsically safe and flameproof illuminating lamp

InactiveCN102121609AEliminate potential safety hazardsSave energyPoint-like light sourceElectric circuit arrangementsComputer moduleEngineering

The invention discloses an efficient energy-efficient environmental-friendly intrinsically safe and flameproof illuminating lamp, and relates to an efficient energy-efficient environmental-friendly flameproof illuminating lamp which can be used under a well or an environment at which various inflammable gases exist. The lamp provided by the invention is composed of an upper cover, a shell, a wiring board, an LED (light emitting diode) module and an optical lens cover, and is characterized in that the upper cover and the shell are connected through a bolt, and two sides of the shell are provided with side hole threaded plugs; the interior of the upper cover is provided with the wiring board, and the wiring board is connected with a switch power installed in the shell, an intrinsically safe module and the LED module installed on the plane of the bottom of the shell through leads, thus a loop is formed; and the optical lens cover is installed at the lower part of the shell through structural sealing and gluing, and is fixed on the shell by an optical lens pressing plate through screws. The efficient energy-efficient environmental-friendly intrinsically safe and flameproof illuminating lamp provided by the invention has the advantages of novel structure, safety, reliability, long service life, energy conservation and environmental friendliness, and is simple and convenient to process and convenient to use; and the maintenance and replacement costs are saved, so the lamp is a novel efficient energy-efficient environmental-friendly intrinsically safe and flameproof illuminating lamp integrating economical efficiency and practibility.

Owner:大连马可尼电子仪器有限公司

A high-temperature cracking furnace for odorless, anti-blocking and energy-saving domestic waste

The invention discloses an odorless anti-blocking energy-saving type household garbage high-temperature pyrolysis furnace. The odorless anti-blocking energy-saving type household garbage high-temperature pyrolysis furnace comprises a feeding system, a garbage isolation and pyrolysis system arranged at the lower end of the feeding system, a high-temperature pyrolysis and waste heat recovery system at the lower end of the garbage isolation and pyrolysis system and a deslagging system arranged at the lower end of the high-temperature pyrolysis and waste heat recovery system. The odorless anti-blocking energy-saving type household garbage high-temperature pyrolysis furnace has the beneficial effects that garage can be stacked and conveyed into the pyrolysis furnace extremely conveniently, and secondary contamination such as waste water is avoided; the garbage can be subjected to full pyrolysis during incineration, agglomeration is avoided, the production influence is avoided, and the thermal efficiency is high; and when the garbage is incinerated, incineration heat can be absorbed effectively, after the heat is absorbed, through hydraulic control, the heat energy is converted into mechanical energy and finally converted into electric energy, and energy is saved.

Owner:刘敏

Regulating method of gap between blade and knife door of filament cutter

ActiveCN102058151BNo production impactWill not be affected by production gapsTobacco treatmentScrew positionEngineering

The invention discloses a regulating method of a gap between a blade and a knife door of a filament cutter, comprising the following steps of: arranging a diamond positioning device on a grinding wheel mechanism; after the gap distance between the blade and the knife door of the filament cutter is completely regulated for the first time, determining the distance between a diamond and a positioning screw positioned on the tail part of diamond positioning device, and taking the distance as a standard distance; and when the distance between the blade and the knife door is regulated later, only regulating the height of the diamond to ensure that the distance between the diamond and the positioning screw positioned on the tail part of diamond positioning device is the standard distance so as to ensure that the gap distance between the blade and the knife door meets the requirements for filament cutting without repeatedly regulating the position relation between the blade and the knife door, the blade and a grinding wheel, the grinding wheel and the diamond. Thus less time is spent when regulating the distance between the knife door and the blade by adopting the method, no influence can be caused to production and the production efficiency is effectively improved.

Owner:SHANGHAI TOBACCO GRP CO LTD

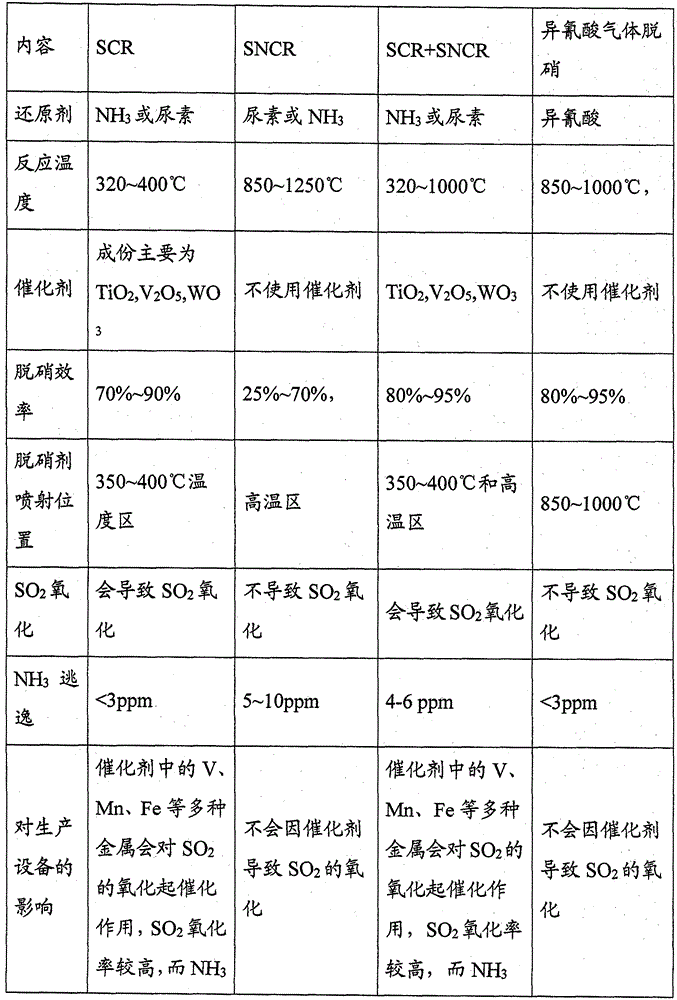

Method and system for denitrification using isocyanic acid gas

ActiveCN104874270BTo achieve the purpose of denitrificationLow costDispersed particle separationChemical reactionFlue gas

The invention discloses a method and a system for denitration by adopting isocyanic acid gas. The method and the system utilize a gasification device for preparing isocyanic acid gas which can react with an NO gas in flue gas, and the isocyanic acid gas is introduced into a high-temperature flue gas channel for chemical reaction to generate N2, CO2 and H2O gases which can be emitted. The method and the system disclosed by the invention achieve the purpose of denitration by adopting the isocyanic acid gas for reacting with the NO compound in the flue gas, after denitration of the flue gas, the NOX emission concentration is less than 50mg / Nm<3>, the denitration rate is above 90%, and the requirement that the NOX super-low emission concentration is less than 50mg / m<3> is met. For the design of an isocyanic acid gas denitration technology system, an automatic adjusting way is adopted, and by monitoring data, the feeding amount of cyanuric acid and the injection amount of the isocyanic acid gas are automatically adjusted to achieve the treatment effect required for complete reaction.

Owner:北京环科腾越环保工程有限公司 +2

Heat dissipation device for motor

InactiveCN107565739ASimple structureImprove cooling effectSupports/enclosures/casingsEngineeringContinuous operation

The invention discloses a heat dissipation device for a motor. The heat dissipation device comprises a shell assembly and a heat conduction piece. The shell assembly comprises a first shell and a second shell which are coaxially arranged. The tops and the bottoms of the two shells are in the opened state. The first shell is of a cavity structure and comprises an inner wall and an outer wall in contact with the outside. A plurality of radiating fins, which are extending along the axial direction, are arranged on the outer wall. The radiating fins are arranged at equal intervals. The length of the second shell is smaller than the length of the first shell. The second shell is of a single-layer structure. The outer wall of the second shell is attached to the inner wall of the first shell. Thesecond shell can slide along the inner wall of the first shell. The inner diameter of the second shell is matched with the outer diameter of a to-be-cooled motor. The heat conduction piece is arranged in the cavity of the first shell to fully fill the cavity of the first shell. The device is simple in structure and good in heat dissipation effect. The continuous operation of automatic products can be effectively guaranteed, and the production is not influenced by any factor at all.

Owner:SUZHOU FORCECON ELECTRIC

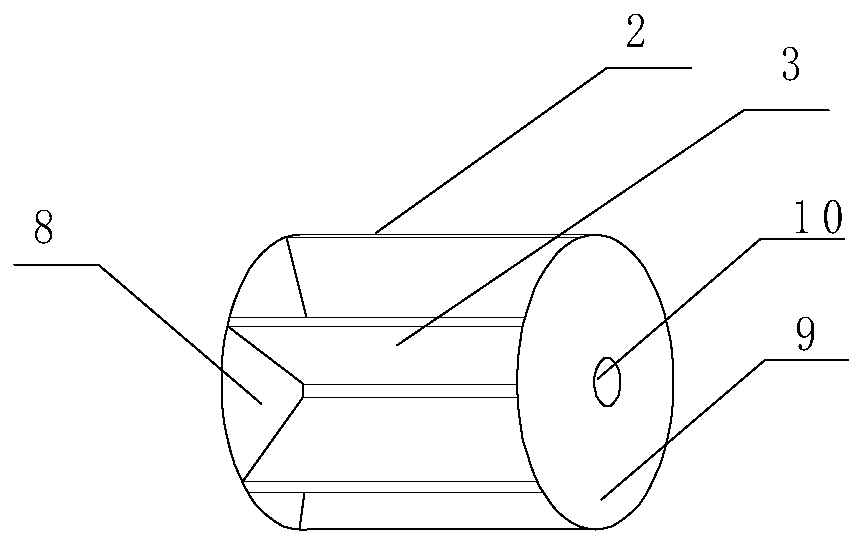

Sulfur feeding device for sulfur dioxide preparation process in air bromine-blowing production

PendingCN110921634ASimple troubleshootingGuarantee continuous and stable operationSulfur compoundsBromineElectric machinery

The invention discloses a sulfur feeding device for a sulfur dioxide preparation process in air bromine-blowing production, and relates to sulfur feeding for the sulfur dioxide preparation process inthe air bromine-blowing production. The device comprises a hopper, an outlet in the bottom of the hopper and a blanking pipe connected with the outlet; a ventilation pipe is arranged at the bottom ofthe blanking pipe and connected with a draught fan; the device further comprises a discharger, wherein the discharger is arranged on the blanking pipe and used for discharging sulfur in the hopper downwards. The discharger comprises a shell connected with the blanking pipe and a bin wheel arranged in the shell, and the bin wheel is driven by a motor to rotate. The bin wheel comprises a shaft, a first circular side plate and a second circular side plate, the first circular side plate and the second circular side plate are arranged at the two ends of the shaft, a plurality of bin partition plates are arranged between the first side plate and the second side plate and extend outwards to the outer end of the first side plate and the outer end of the second side plate from the axial direction,and partition bins are formed among each two adjacent bin partition plates, the first side plate and the second side plate. The device has the beneficial effects that a screw shaft is prevented from being locked down and halted, and stable and continuous operation of production is guaranteed.

Owner:天津长芦汉沽盐场有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com