Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Increased adhesion area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

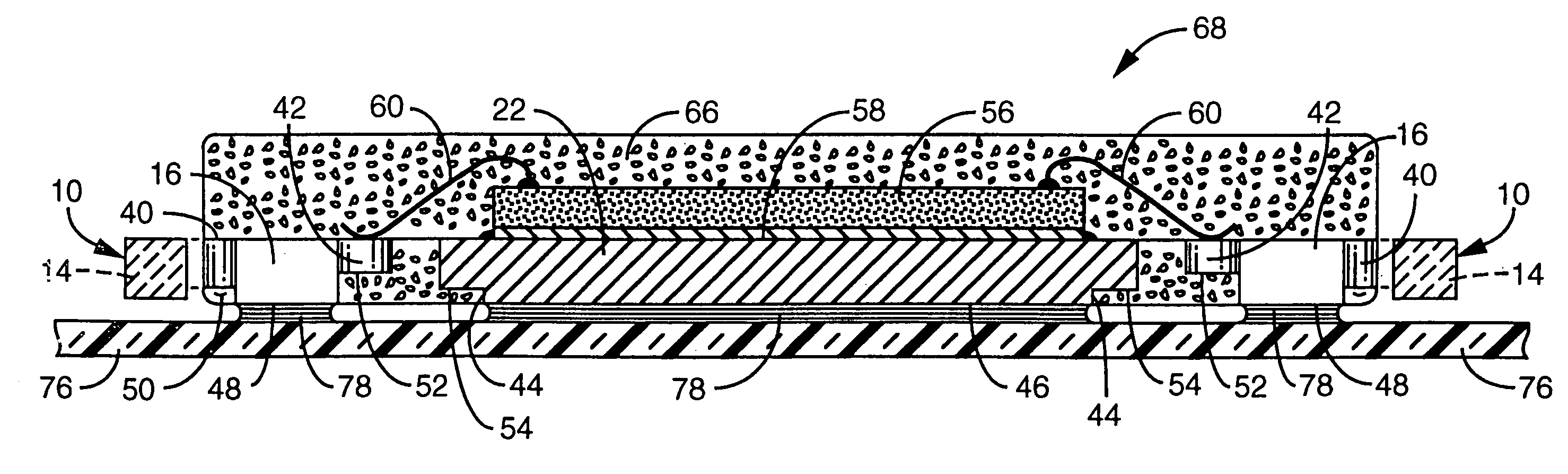

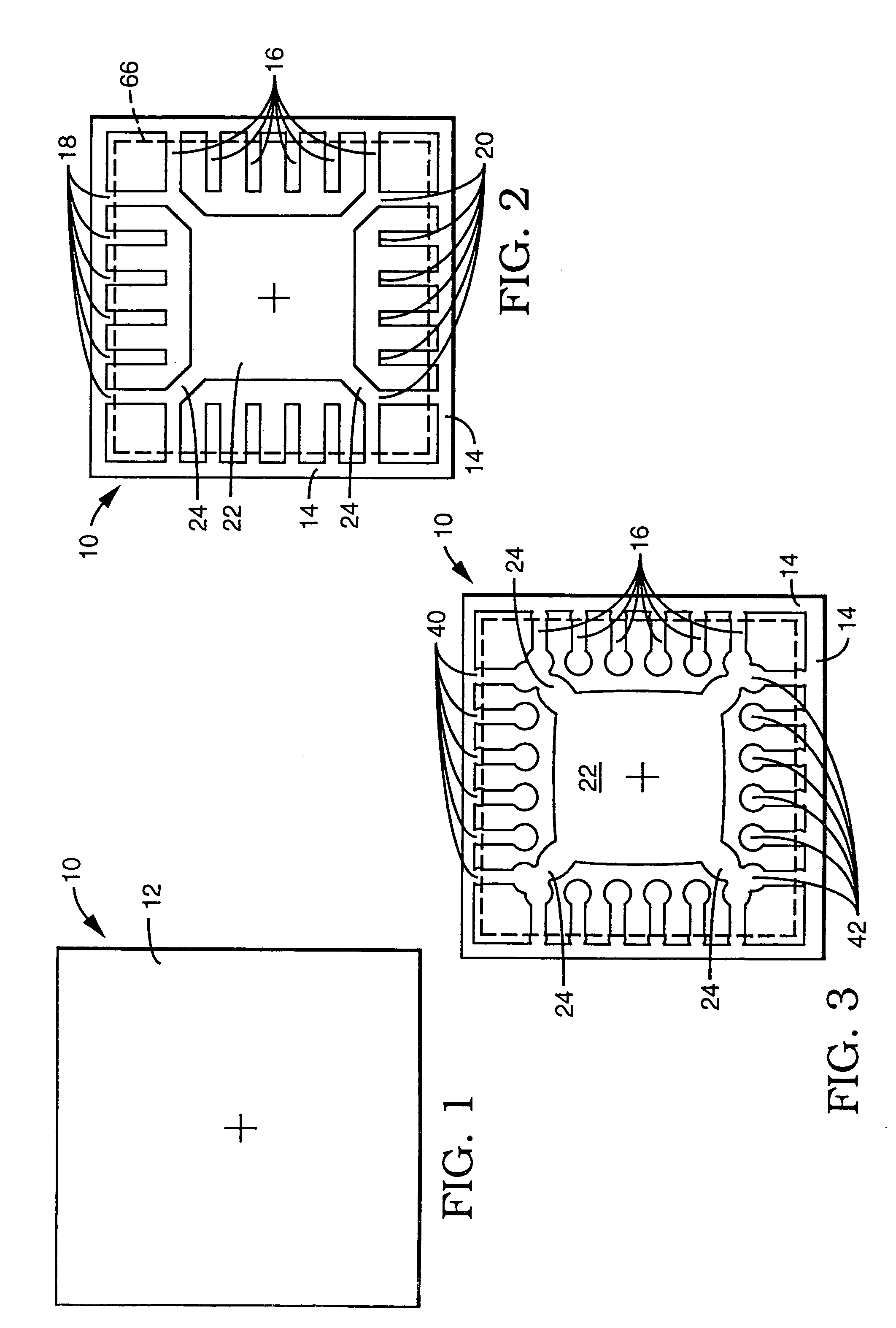

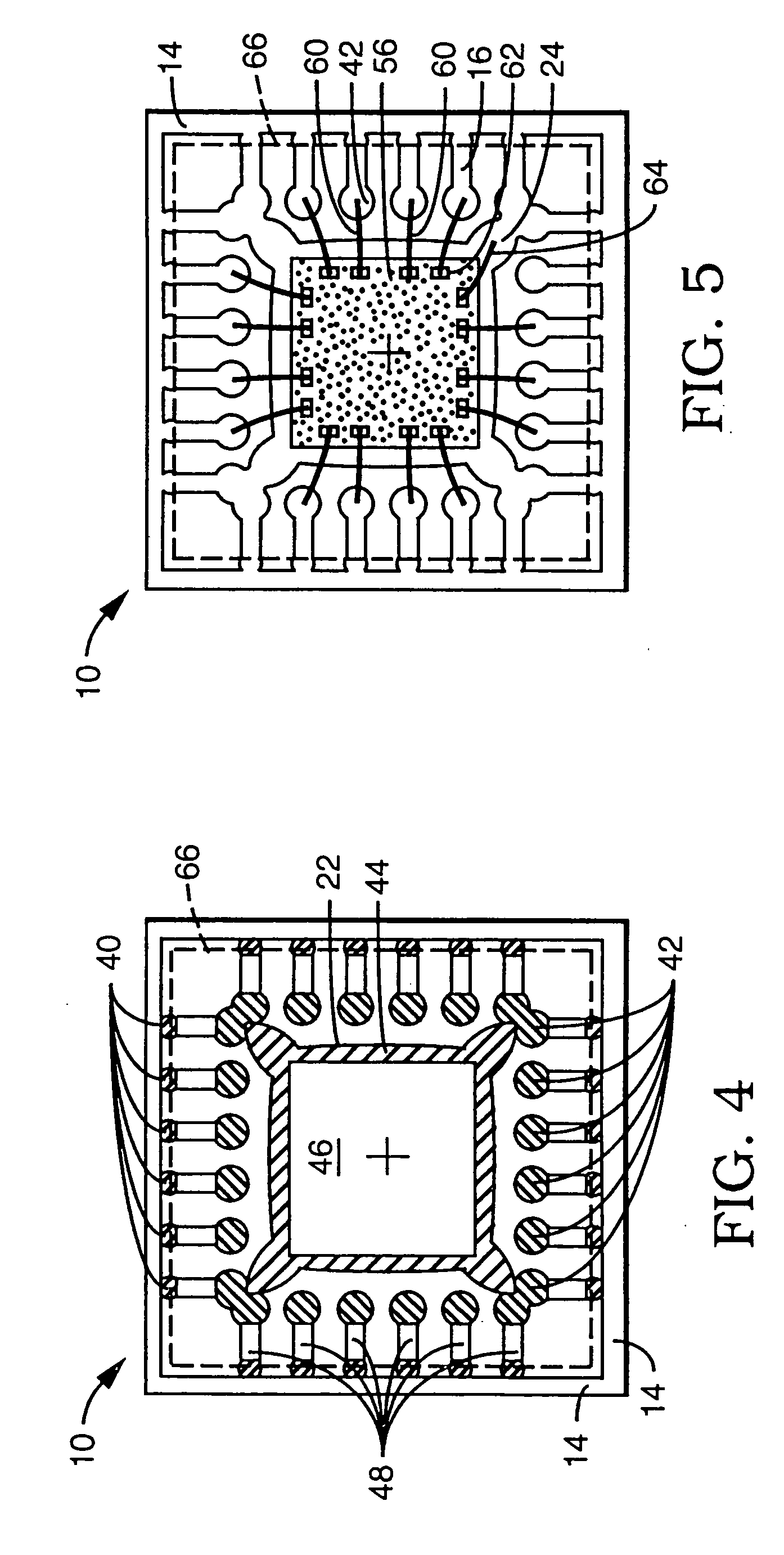

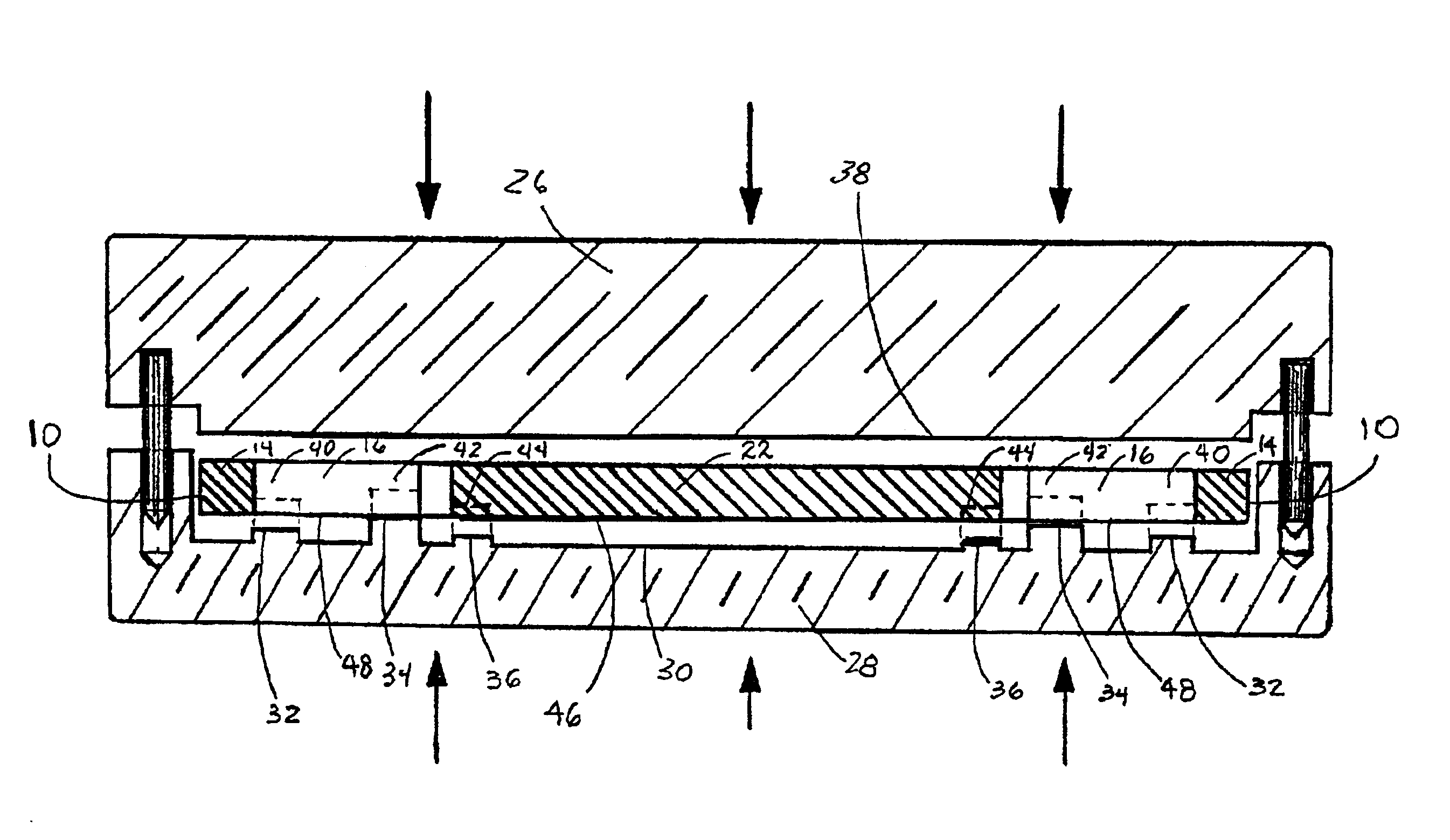

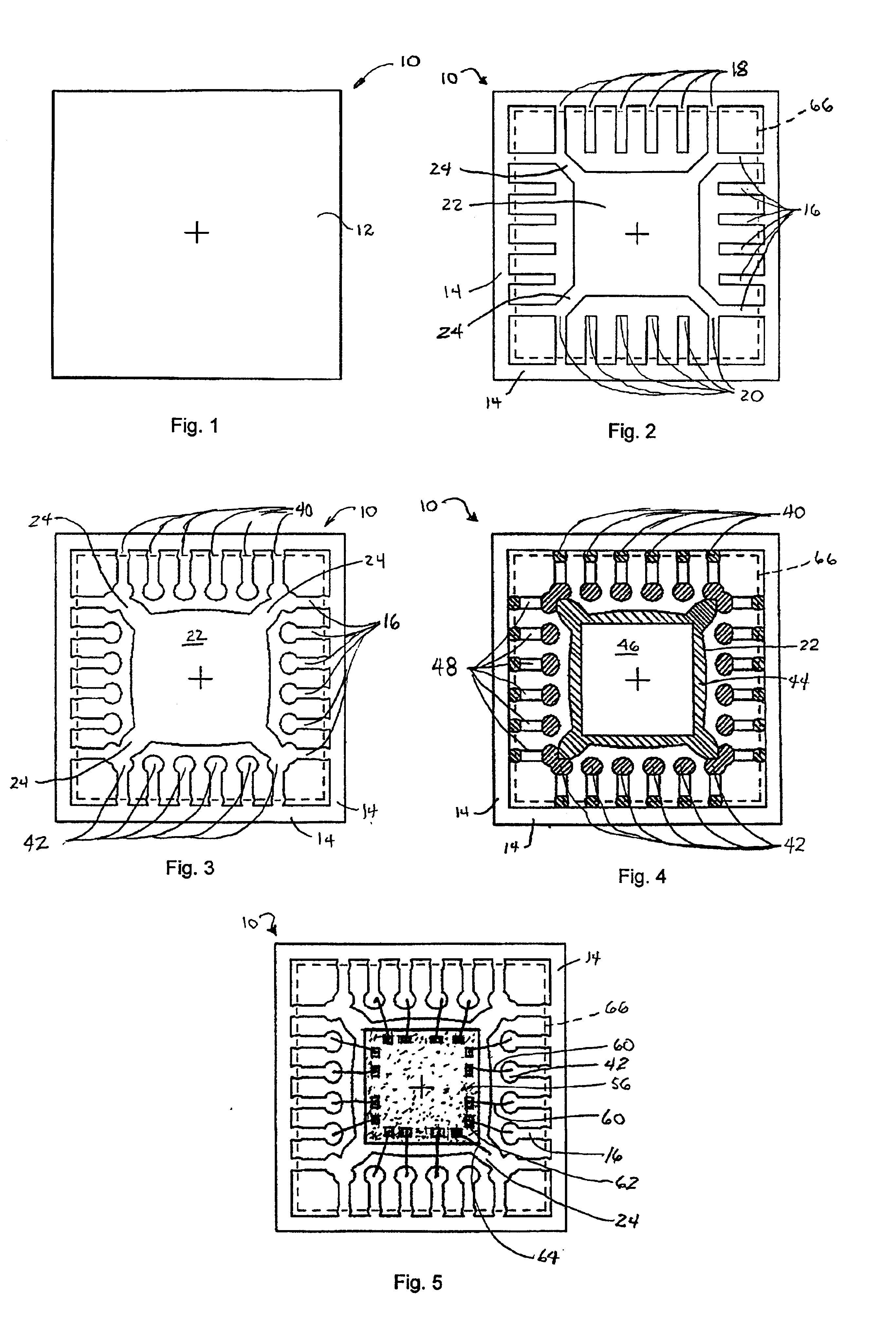

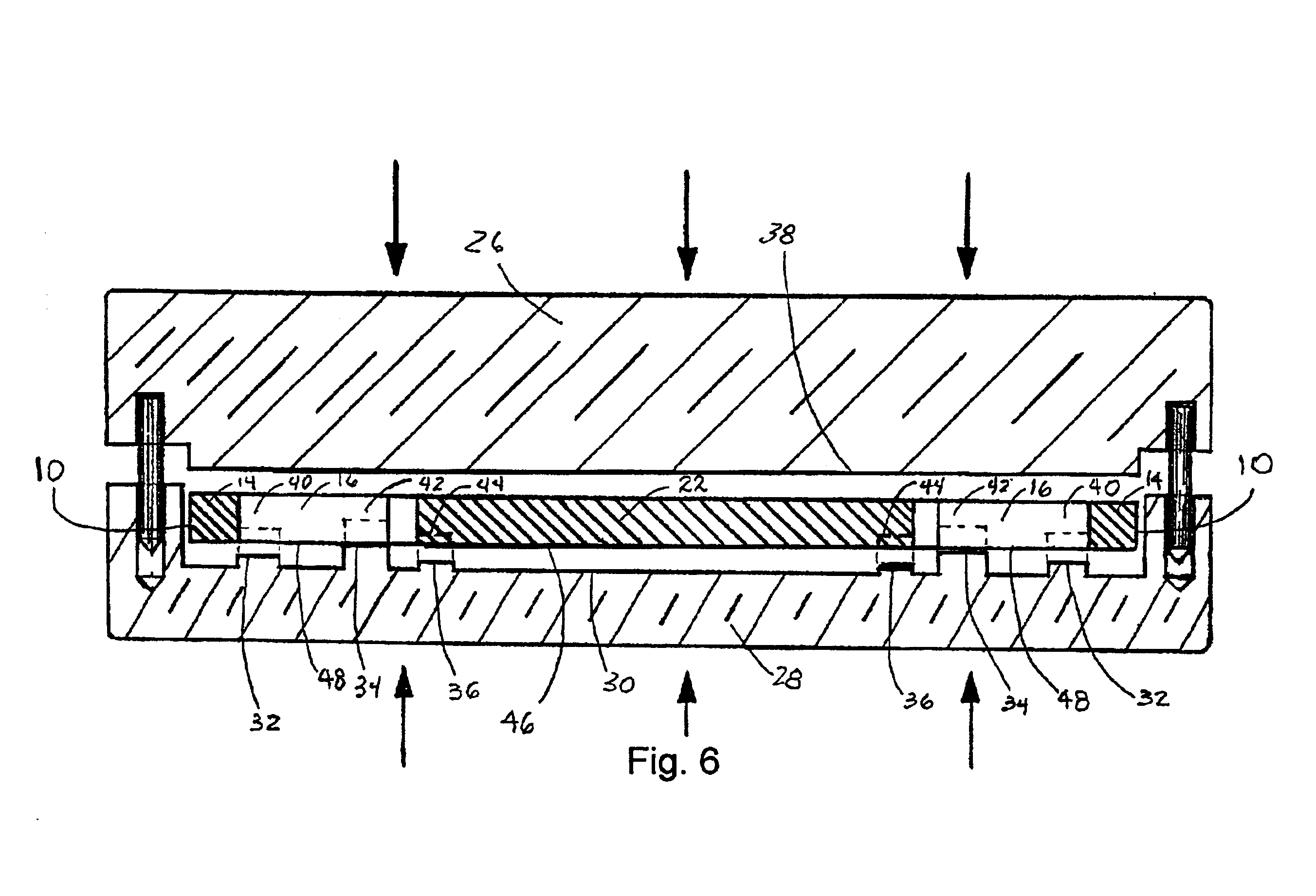

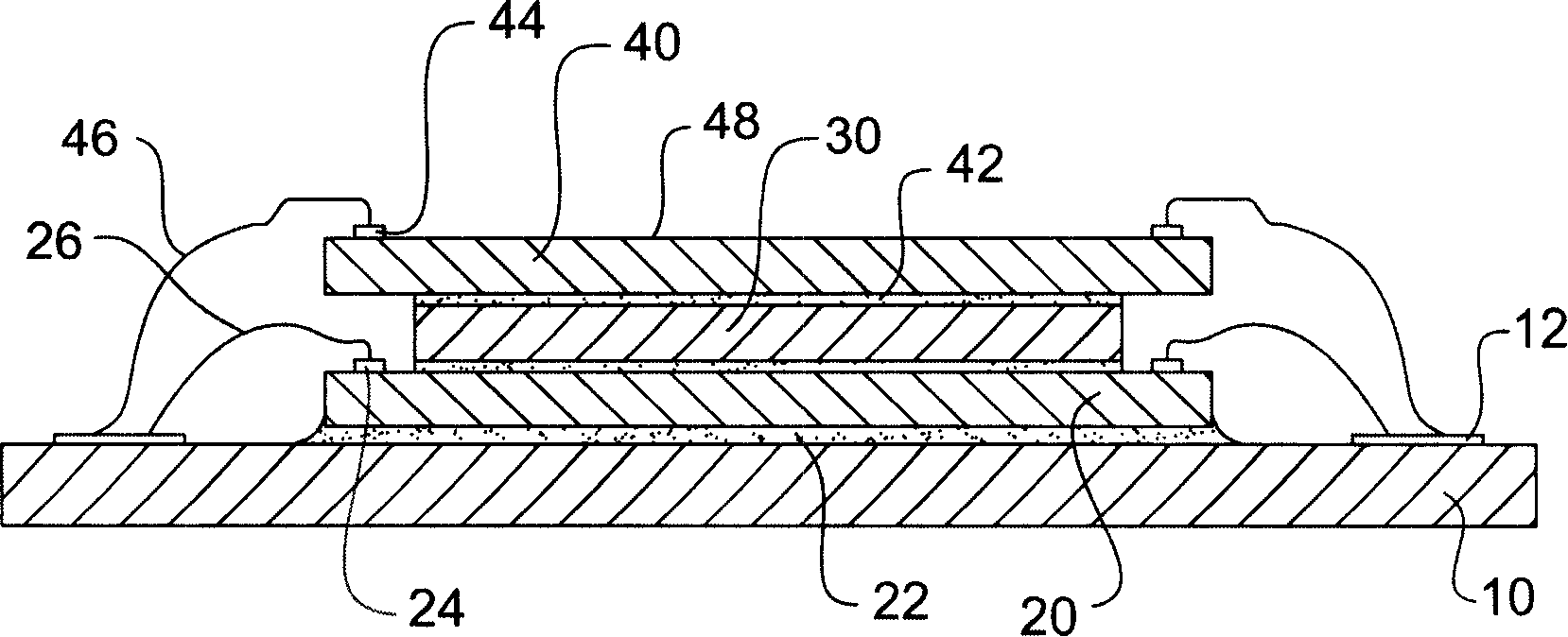

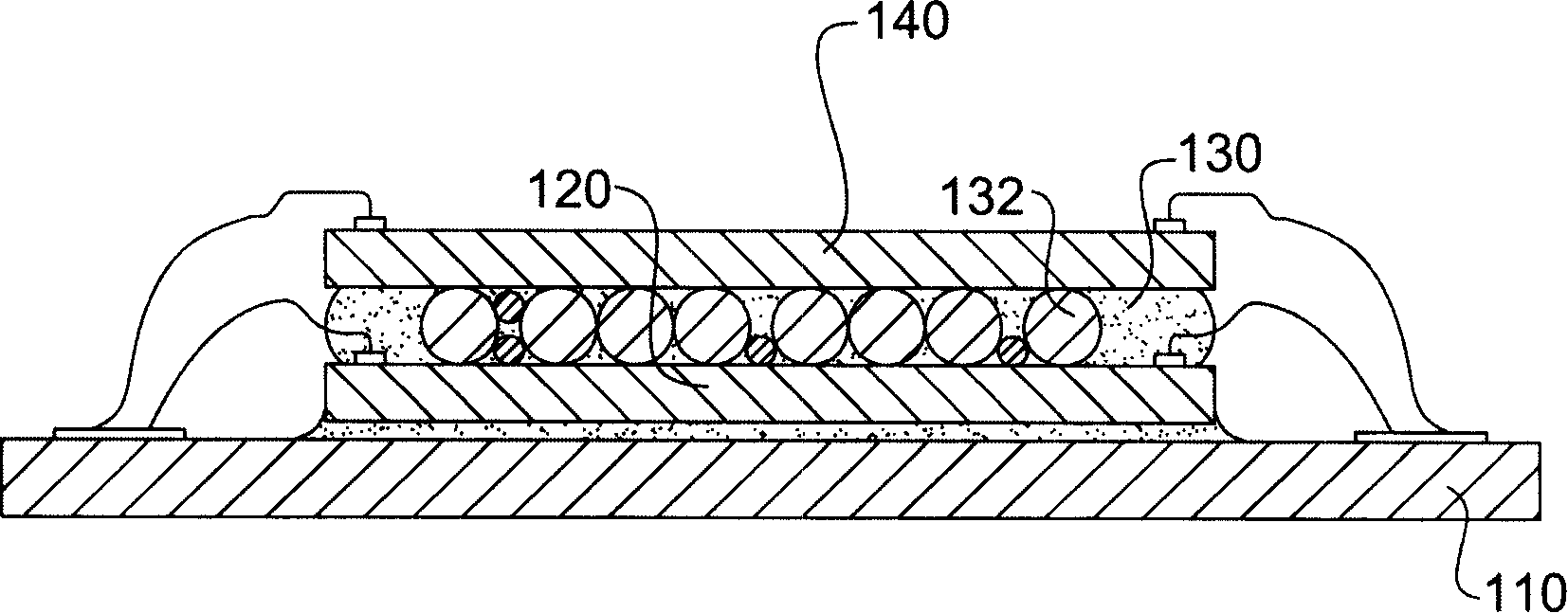

Semiconductor package with exposed die pad and body-locking leadframe

InactiveUS6965157B1Improve mechanical lockingReduce morbiditySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A very thin, small outline, thermally enhanced semiconductor package includes a leadframe that is coined to form locking features on an exposed die pad and on a plurality of extremely narrow, closely spaced leads. The coined features improve the mechanical locking between the leadframe and the plastic body of the package to increase their resistance to delamination and subsequent penetration by moisture, and enable reliable wire bonds to be made to the otherwise extremely narrow leads.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Semiconductor package with exposed die pad and body-locking leadframe

InactiveUS6847103B1Reduce incidenceIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A very thin, small outline, thermally enhanced semiconductor package includes a leadframe that is coined to form locking features on an exposed die pad and on a plurality of extremely narrow, closely spaced leads. The coined features improve the mechanical locking between the leadframe and the plastic body of the package to increase their resistance to delamination and subsequent penetration by moisture, and enable reliable wire bonds to be made to the otherwise extremely narrow leads.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

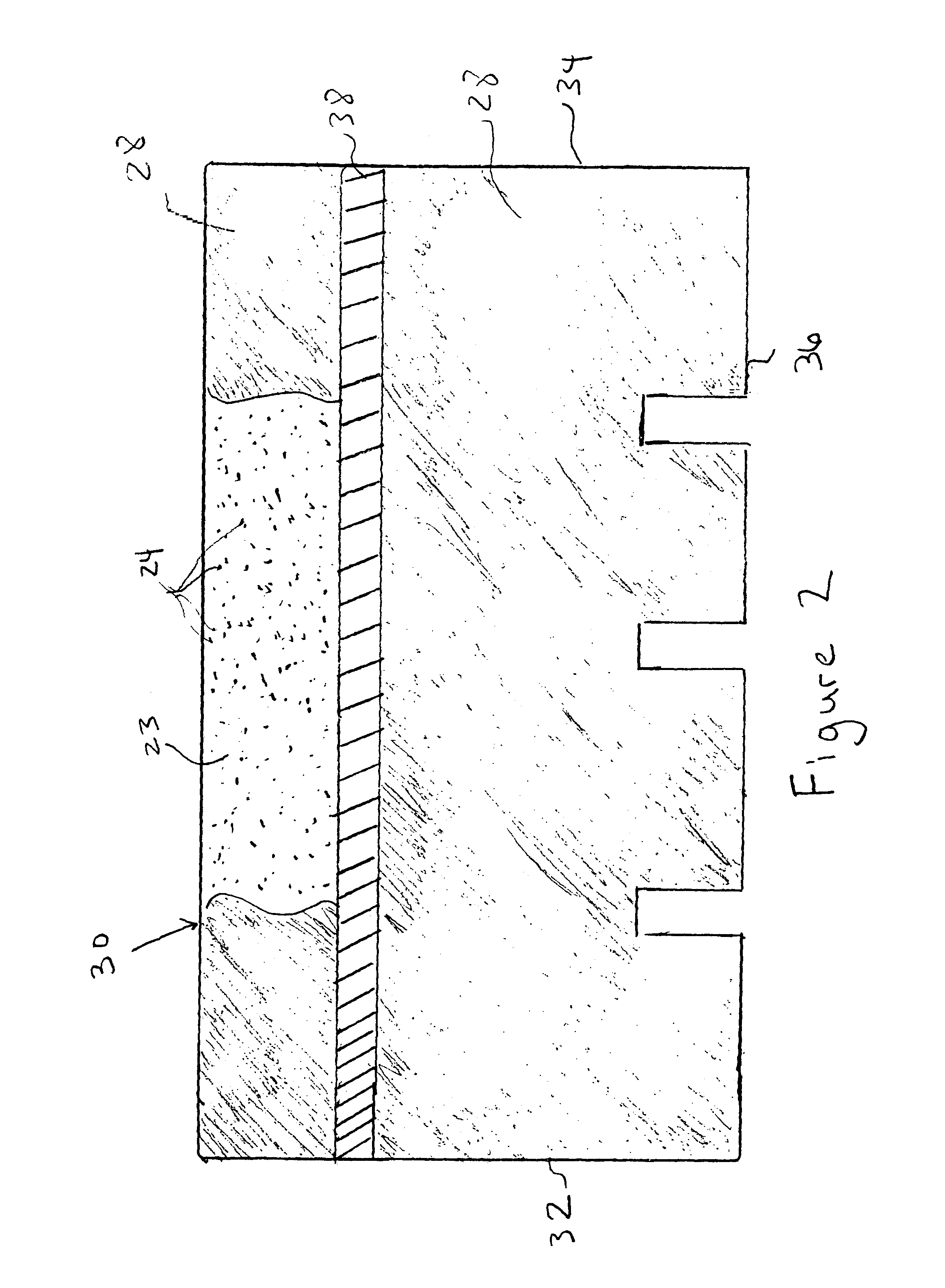

Composition and method of sealing and protecting asphalt shingles or other porous roofing and construction materials

Sealing compositions and application methods for sealing and protecting asphalt roof shingles or other porous roofing and construction materials are described for eliminating algae, mold and mildew, increasing granular adhesion, providing additional UV protection and significantly increasing the wind resistance of the roof or other construction material. The sealing composition includes an acrylic polymer that has been modified by a silicone surfactant to alter its wetting properties so as to promote wicking of the sealer under asphalt shingles and at open edges to prevent curling and water infiltration. The method of applying the sealing composition promotes uniform distribution of the product on the surface of installed roofs as well as enhances bonding between individual shingles by improved penetration on and between shingle layers to increase adhesion area.

Owner:ENVIROSEAL LLC

Ceramic substrate

InactiveUS20030104186A1Stress toleranceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesMetallurgySemiconductor

The present invention provides a ceramic substrate for use in an apparatus for manufacturing and inspecting semiconductors. The ceramic substrate comprises a through-hole having excellent tolerance performance against a drawing stress applied to an external terminal pin. The through-hole is provided with a projection which protrudes into the ceramic substrate made of aluminum nitride as primary component.

Owner:IBIDEN CO LTD

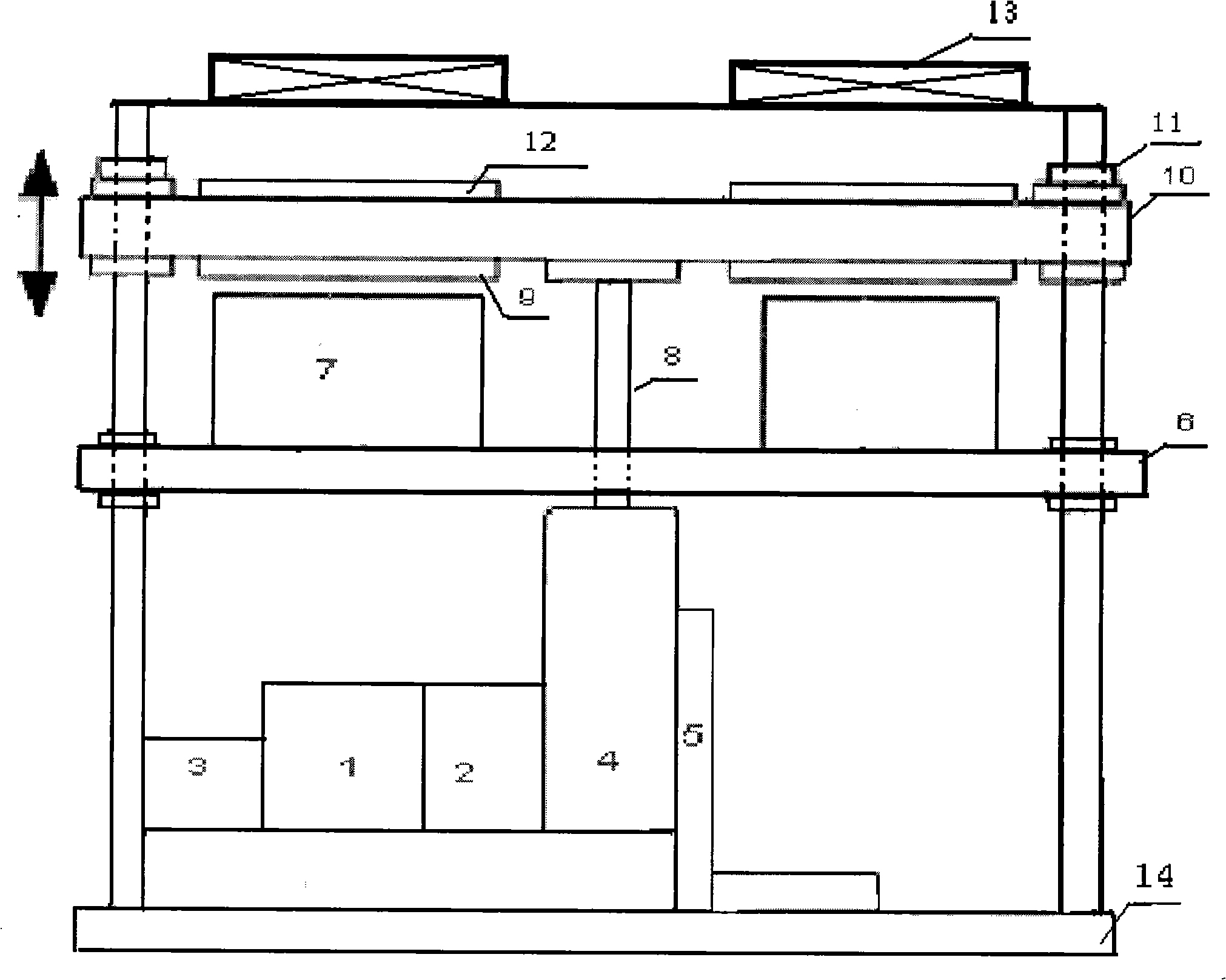

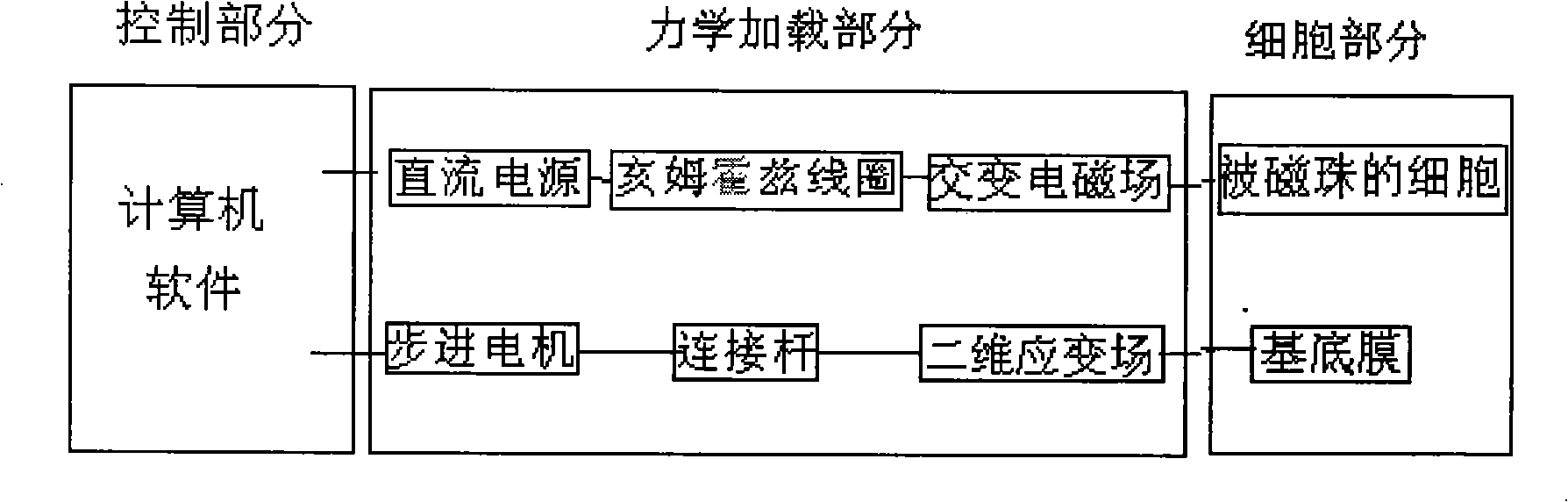

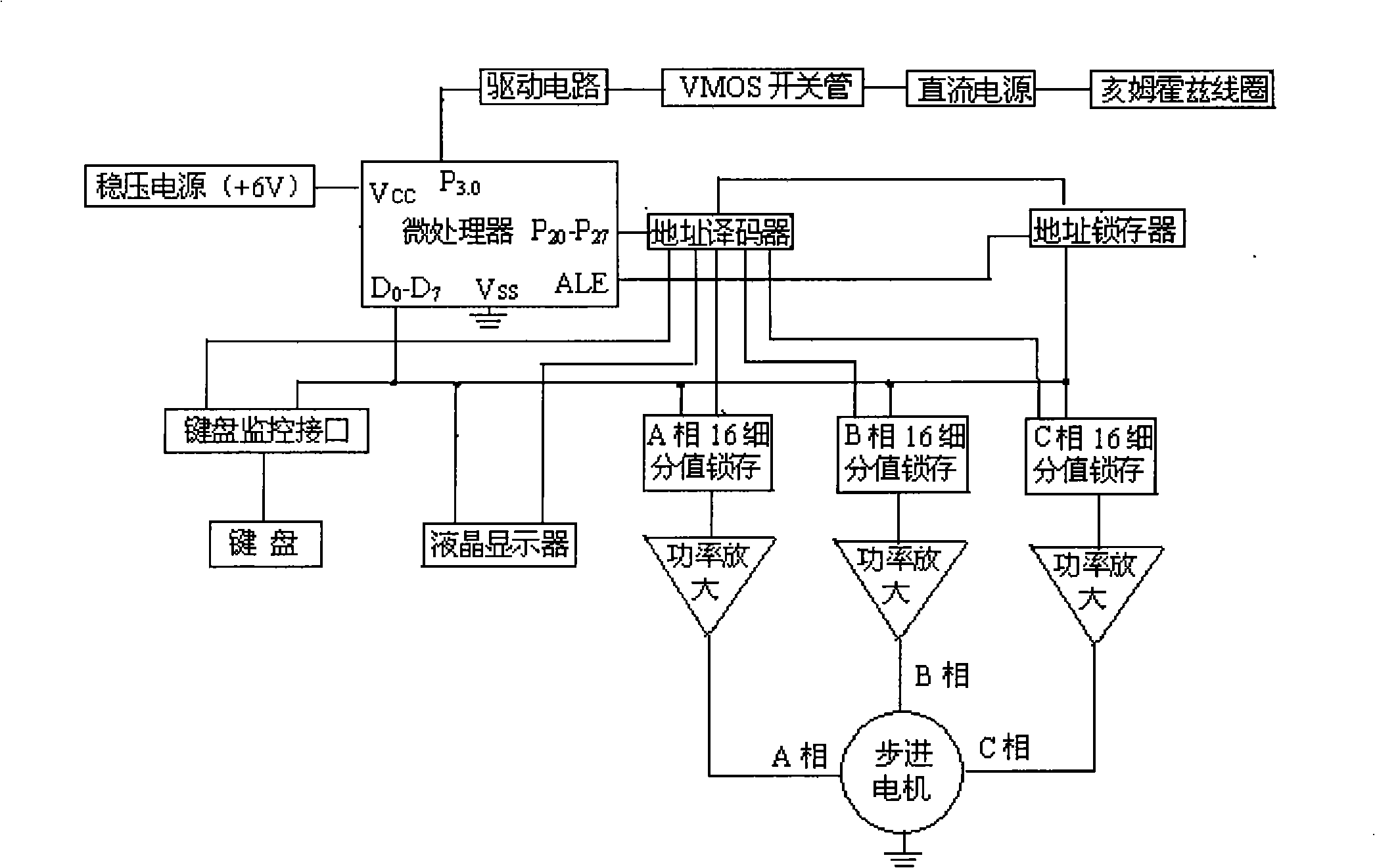

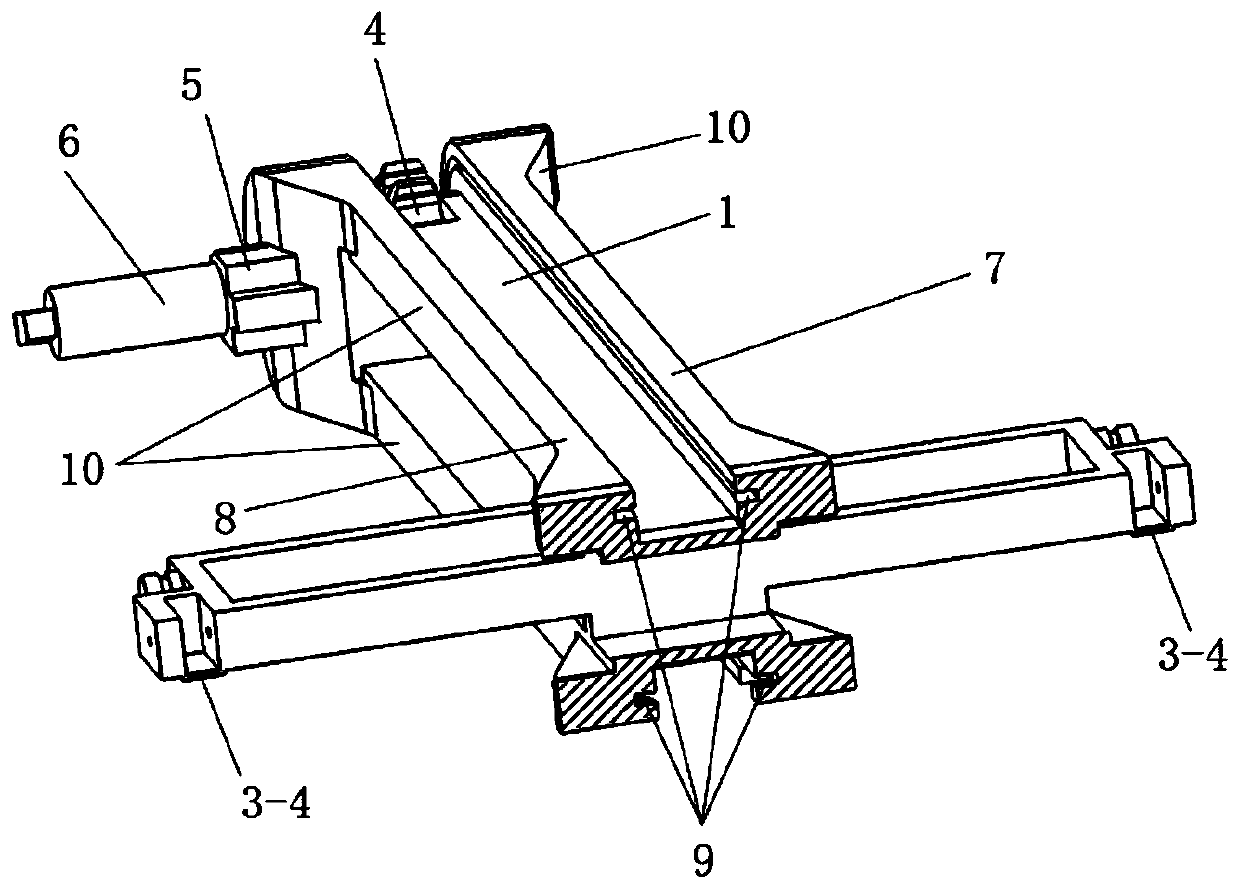

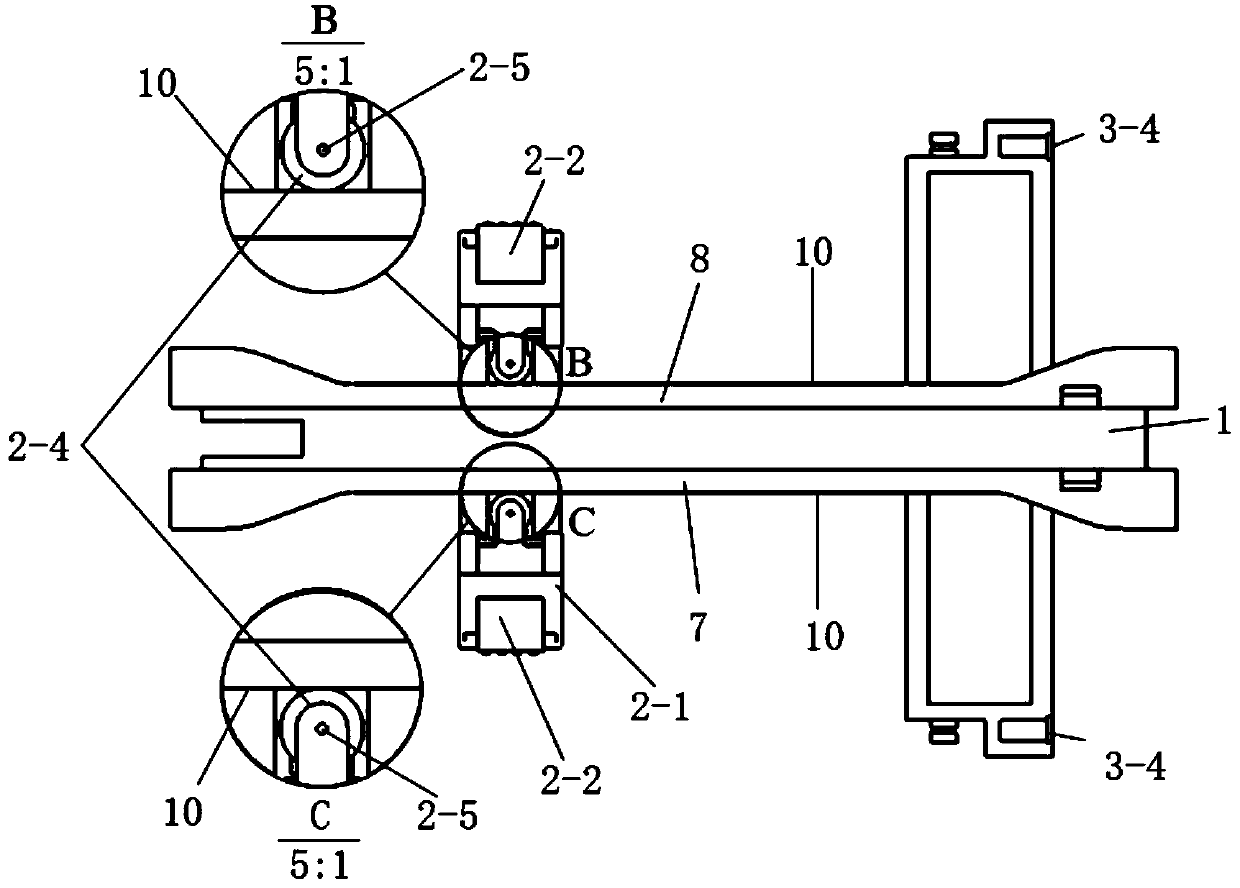

Cell three-dimensional mechanical loading unit

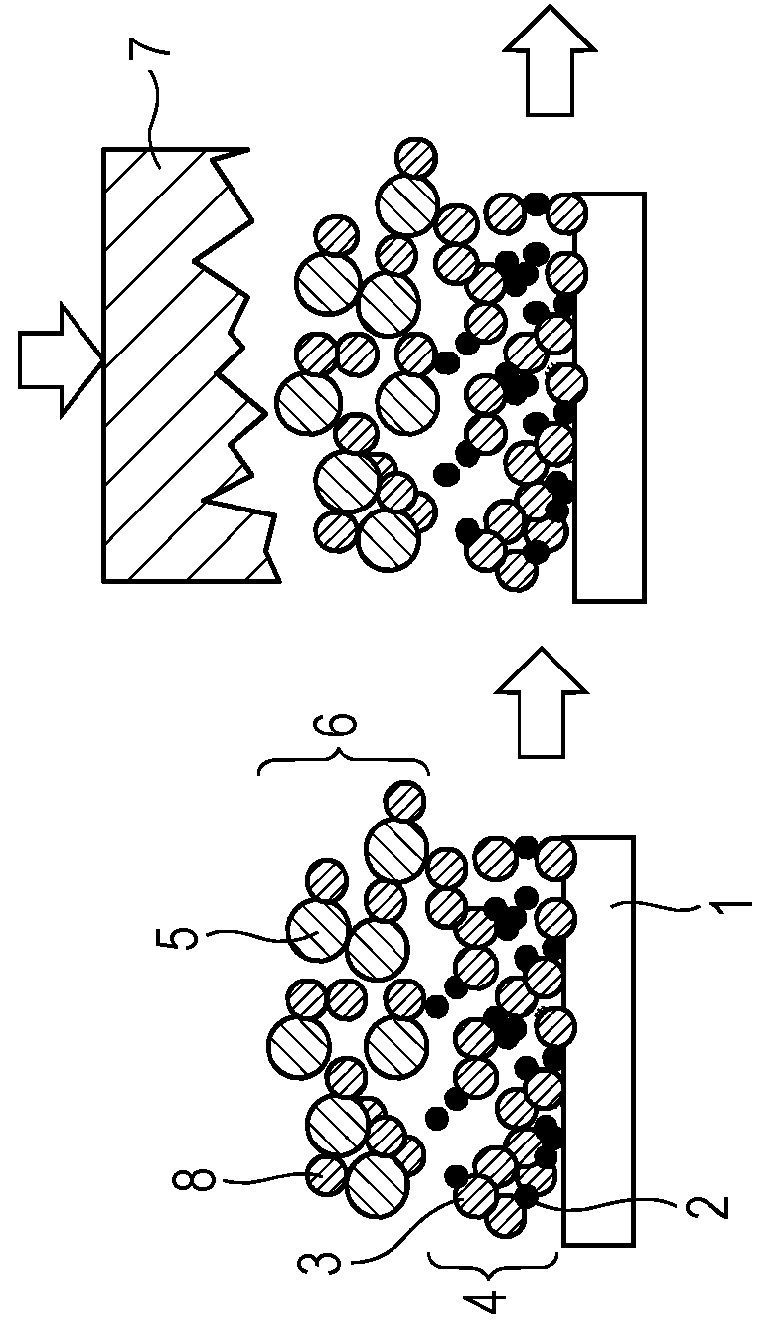

InactiveCN101298592AIncrease stretch areaIncreased adhesion areaTissue cultureElectrical/wave energy microorganism treatmentSilicone membraneMagnetic bead

The invention discloses a drawing and loading device for cells, which relates to a cellular mechanics loading device that belongs to the medical instrument. The drawing and loading device for cells consists of a control part, a mechanical part and an electromagnetic part, which is characterized in that: the cells are cultivated on an elastic silicon membrane, and circumferential-direction drawing and compressive loading are carried out for the cells through a dynamic system, meanwhile, magnetic bead collagen with ferroferric oxide enveloped is attached to the surfaces of the cells through integrin family, then alternating magnetic field is respectively loaded at an upper and a lower bottoms of a cell cultivating box, rendering the cells to be drawn under the magnetic force while being under the circumferential stress in a base strain field, so as to control the transformation of the cells along the axis Z and control the cell morphology. By simulating the borne mechanical stress of cells under physiological conditions, the drawing and loading device for cells can realize mechanical loading with different dimensions under different mechanical forces, and has the advantages of simple structure, convenient use, wide application and excellent reproducibility, etc.

Owner:CHONGQING UNIV

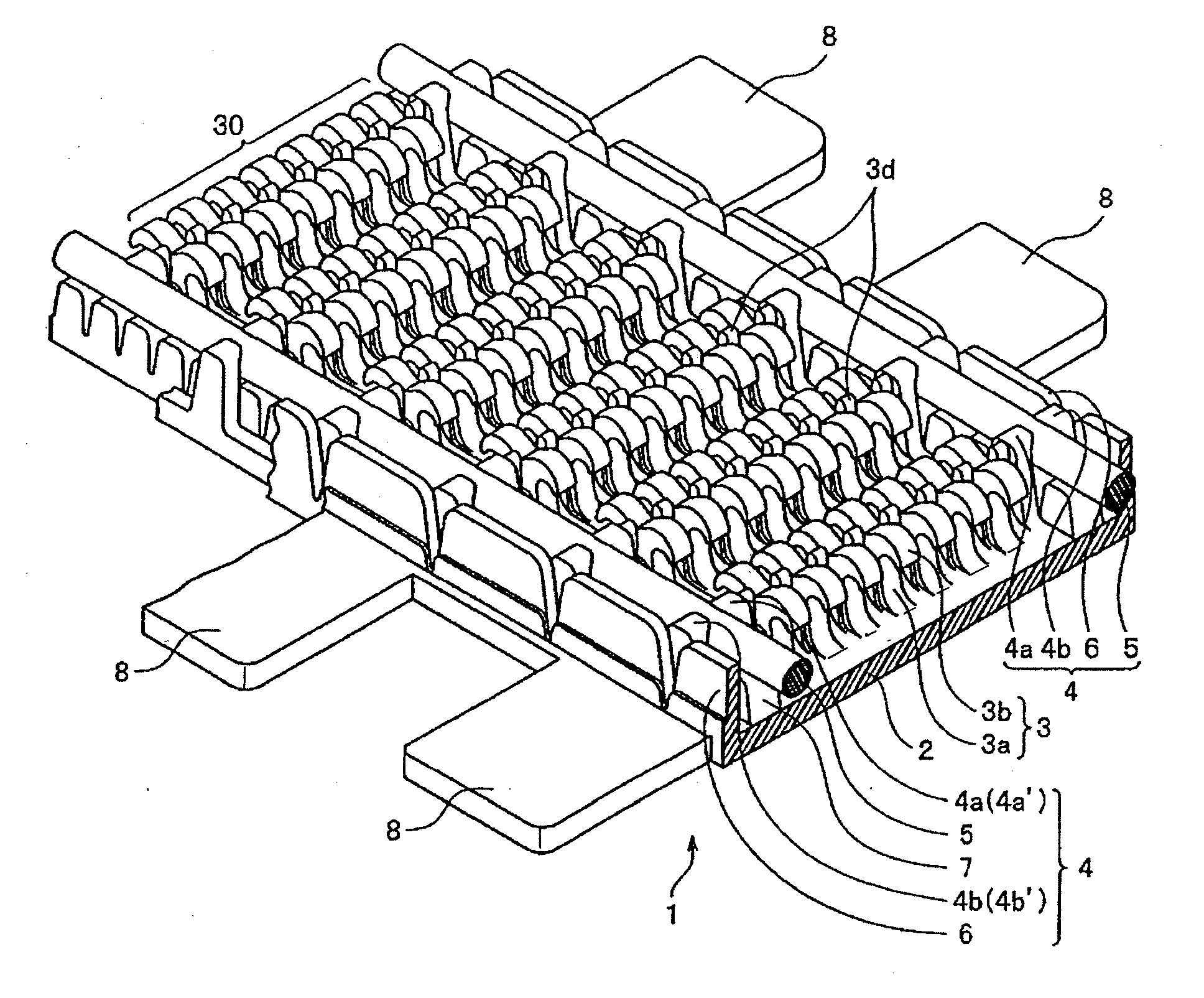

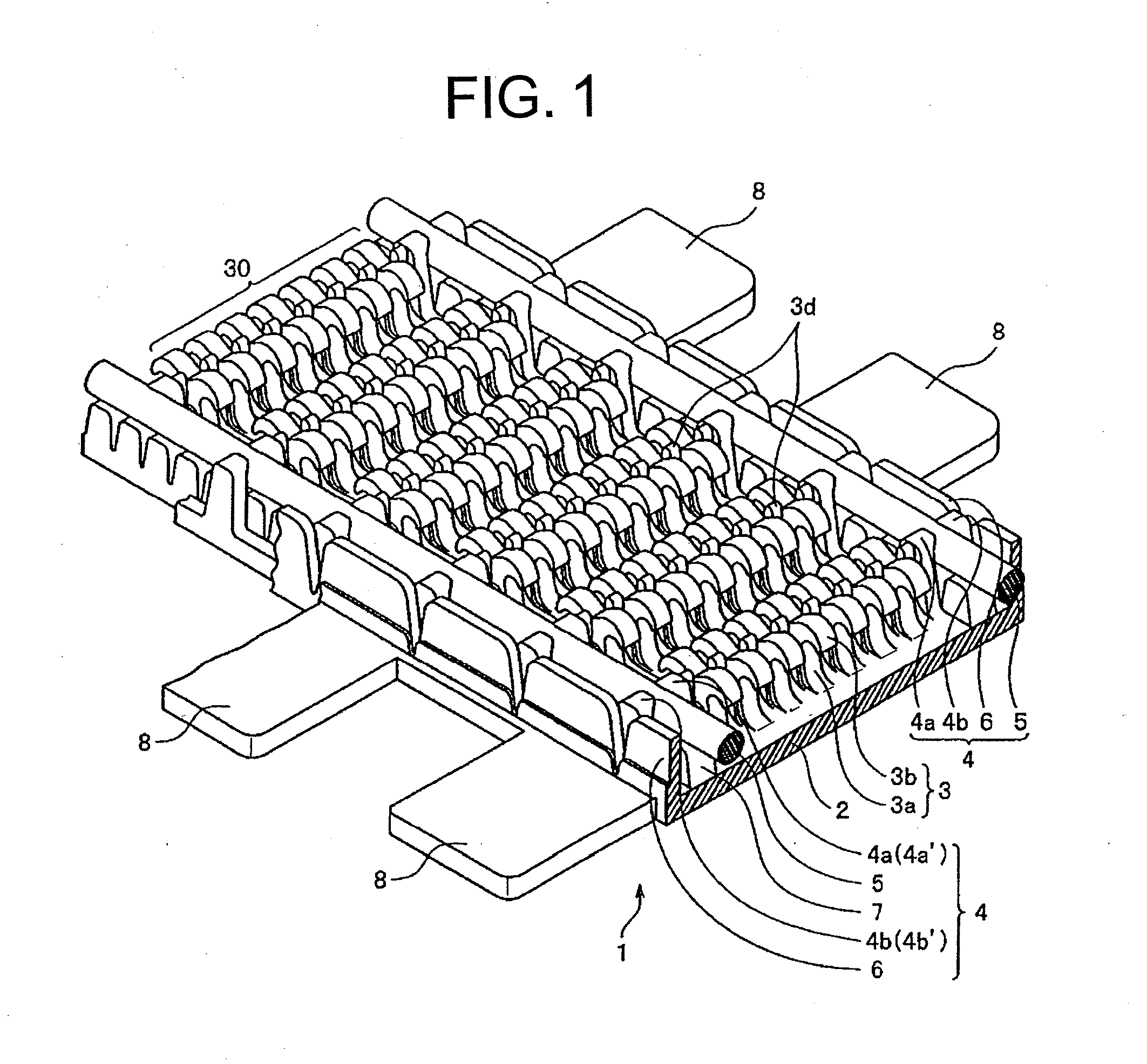

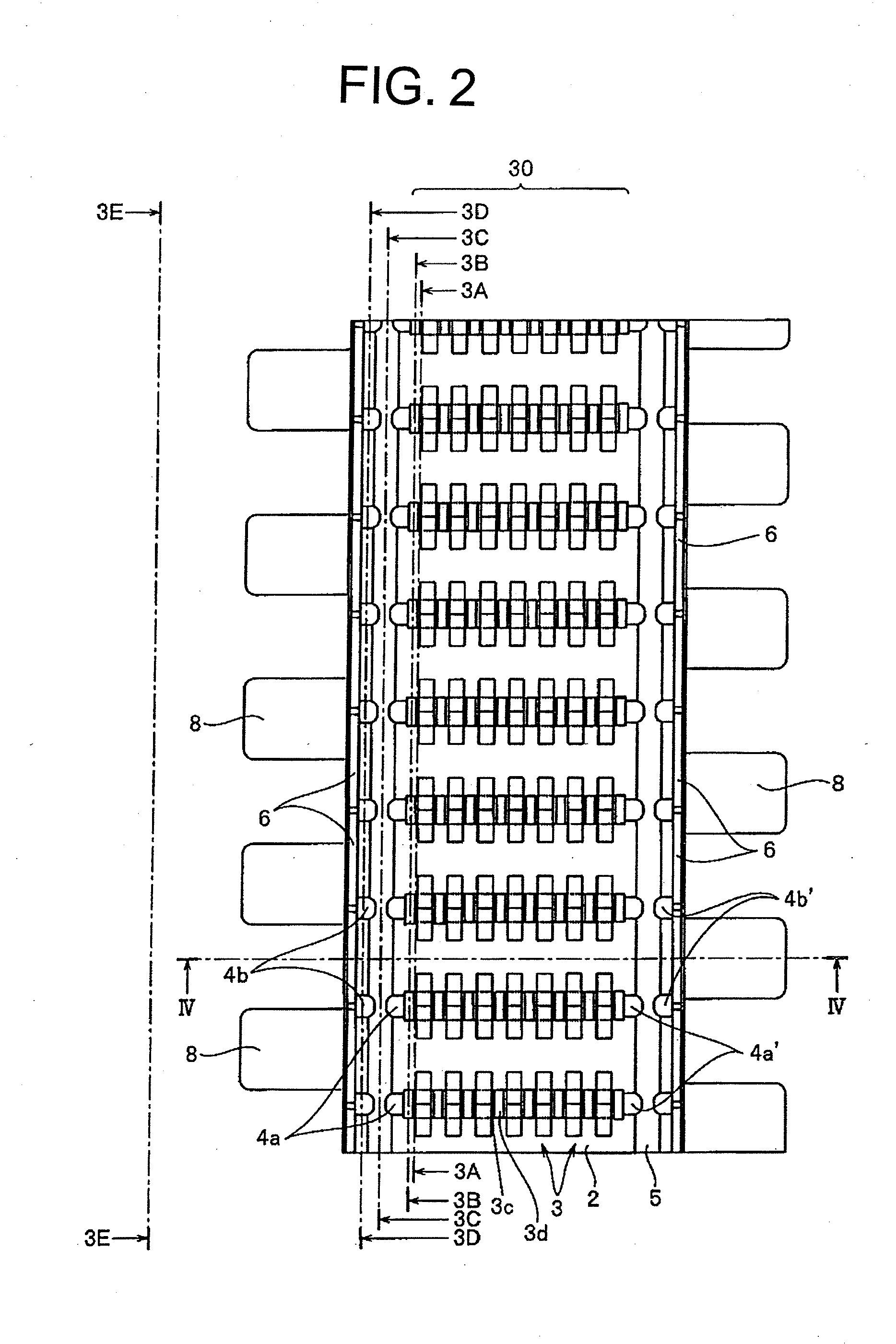

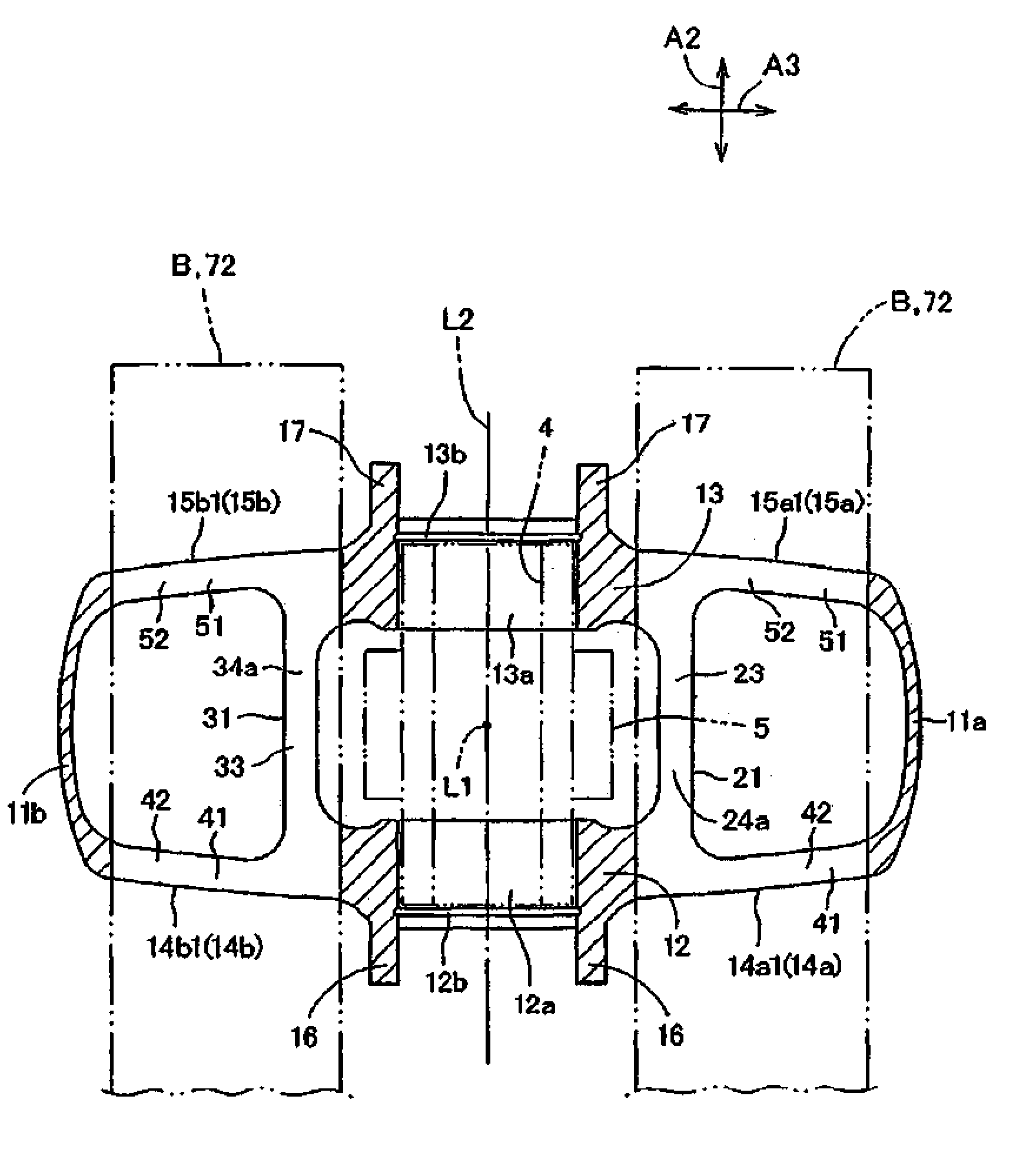

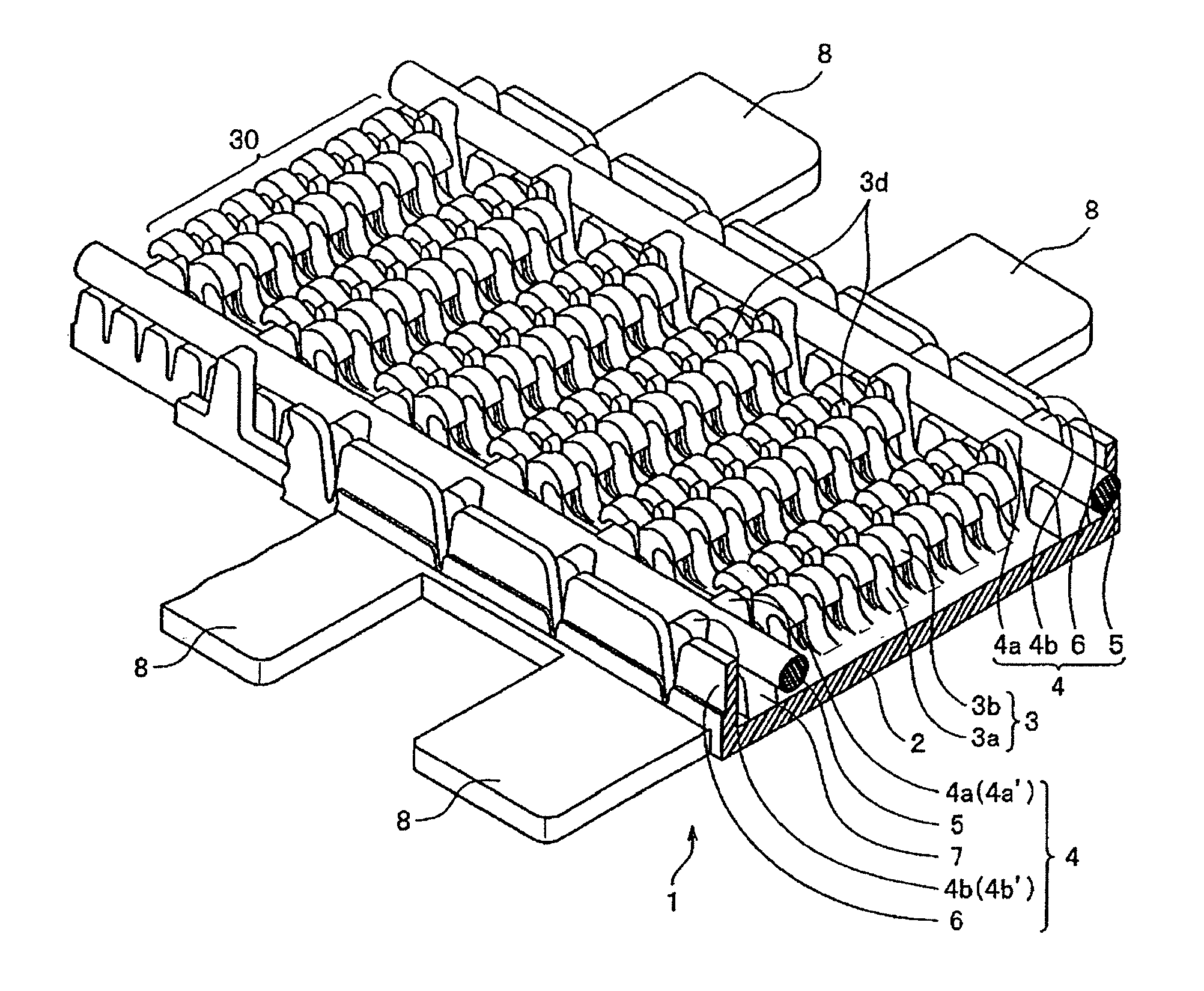

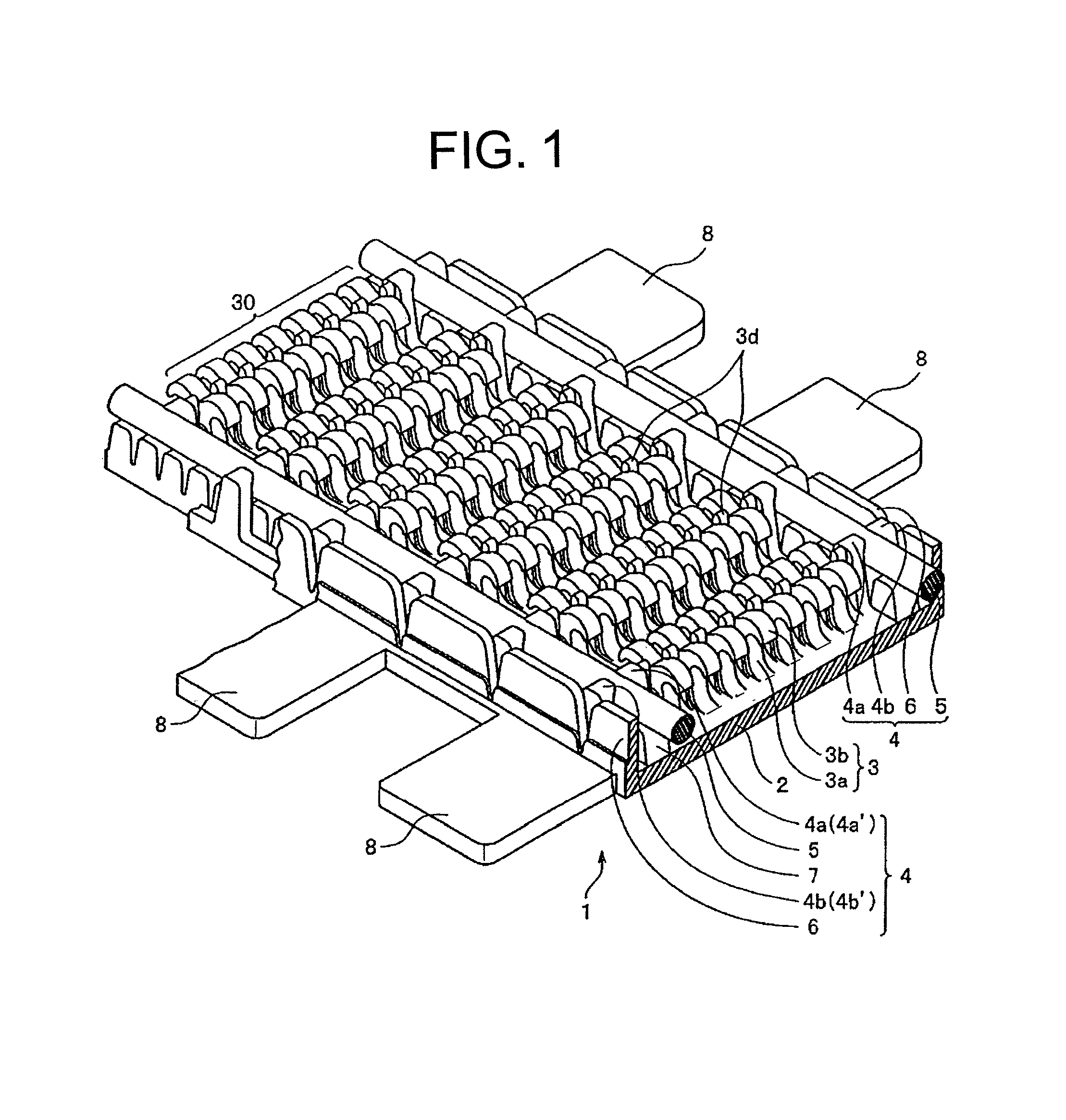

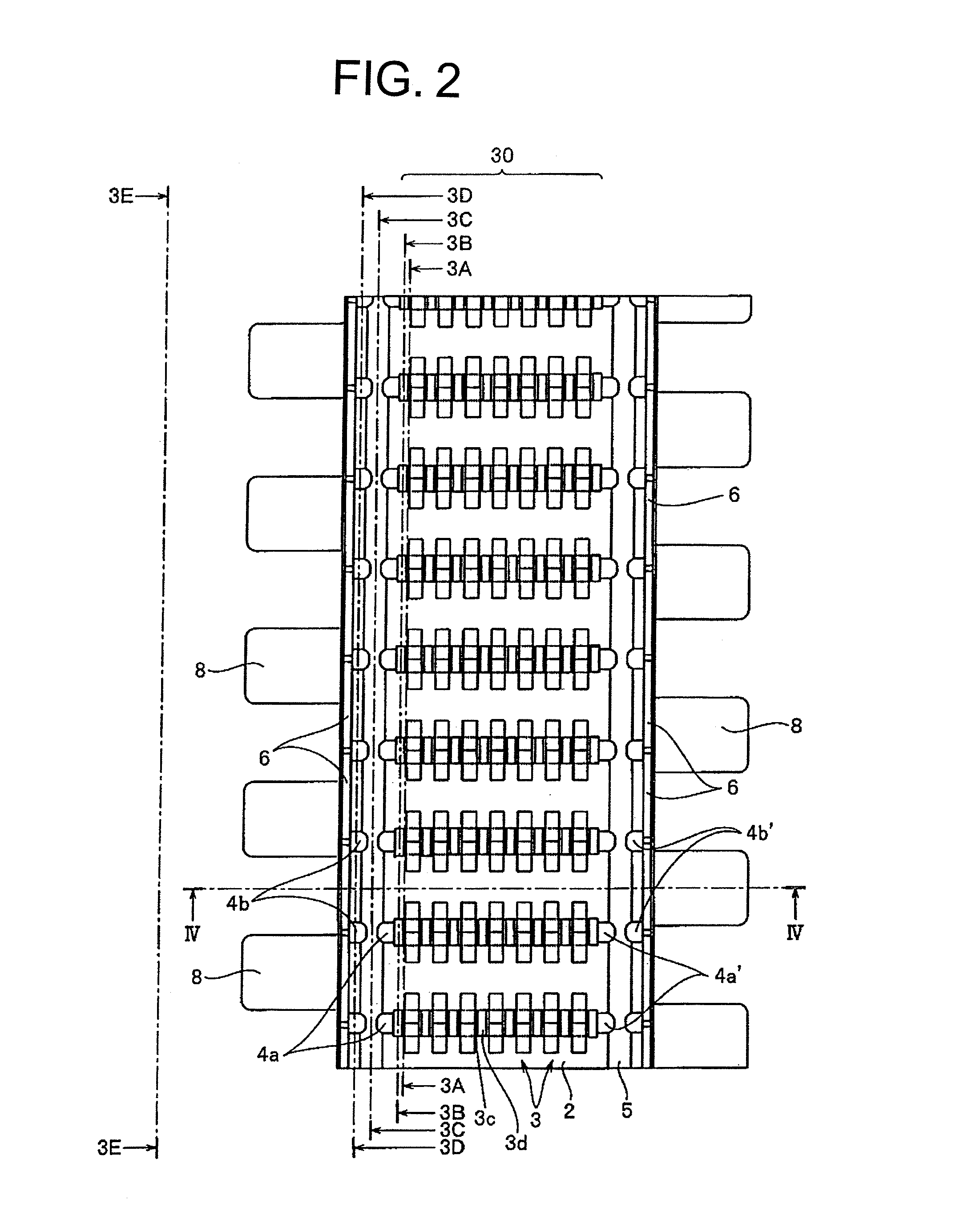

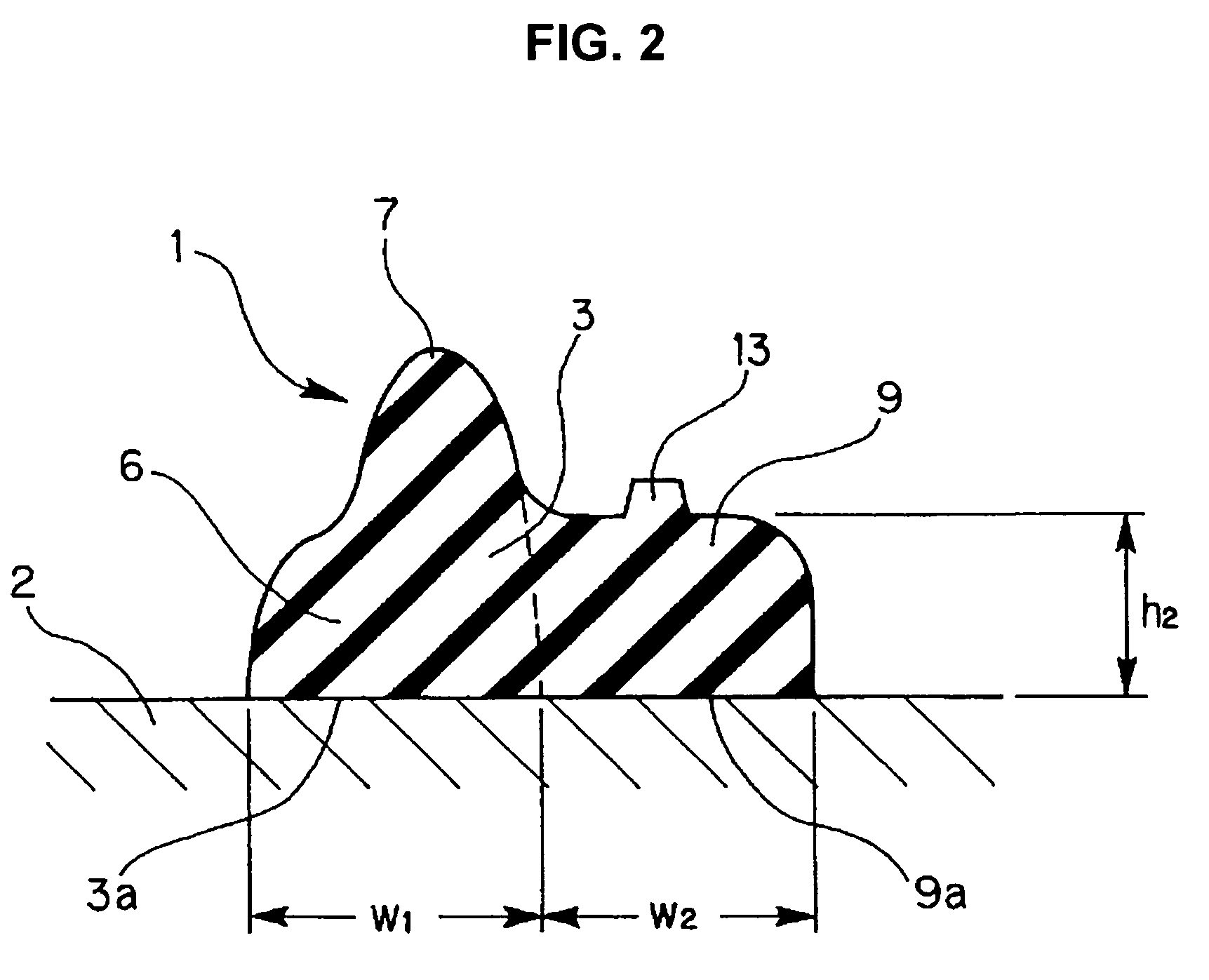

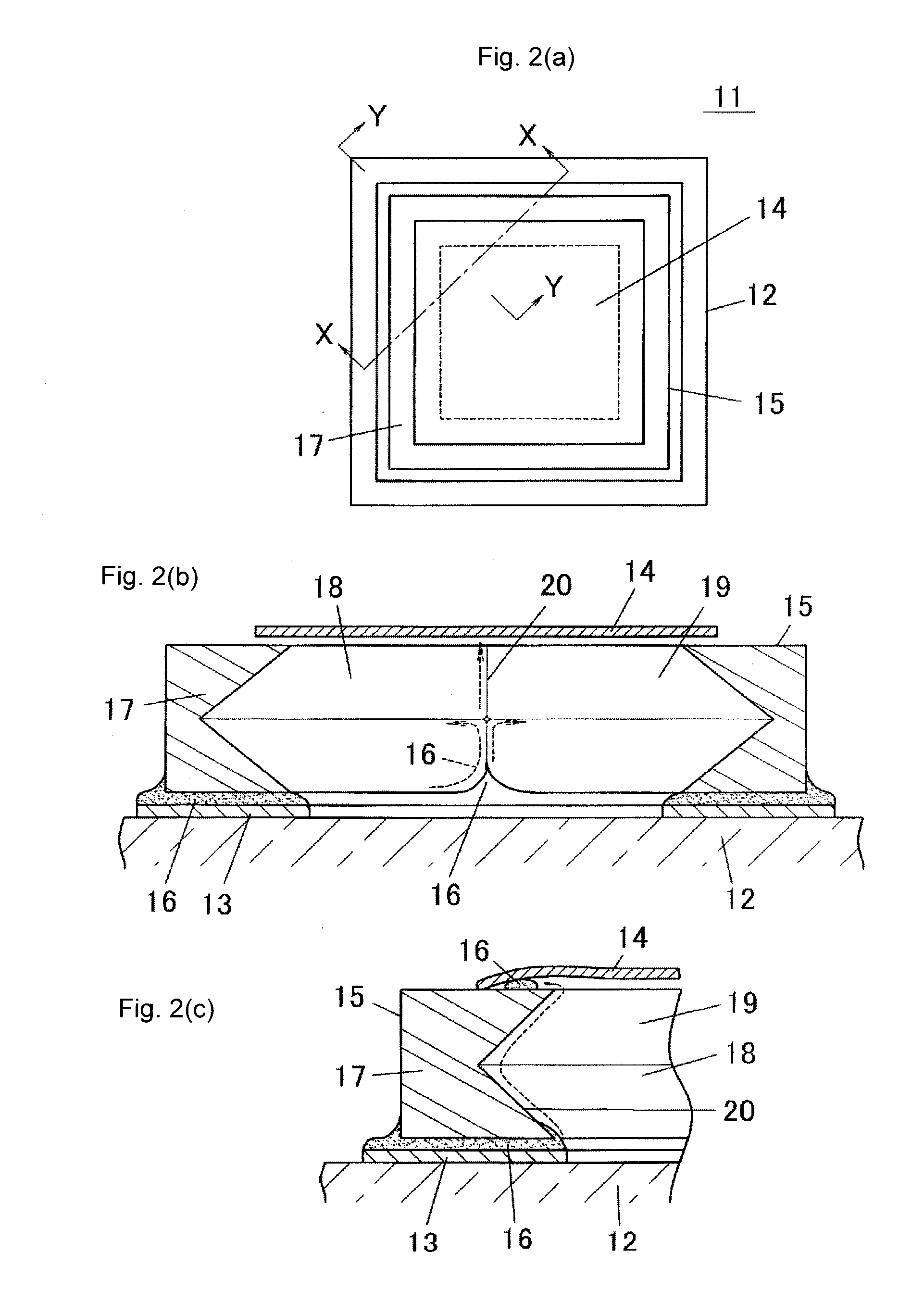

Molded Male Surface Fastener

A molded male surface fastener (1) comprises resin invasion preventing walls (4), which prevent an invasion of a molding foamable resin material of a cushion body, on right and left edge portions along a longitudinal direction of a surface of a flat base member (2) made of a thermoplastic resin, a plurality of engaging elements (3) provided between left and right resin invasion preventing walls (4), and a linear sealing body (5) that is continuously disposed in the longitudinal direction of the base member (2) along a peripheral portion of a top portion of each resin invasion preventing wall (4). When an engaging element forming surface of the surface fastener (1) is placed on a concavo-convex surface of foaming body molding cavities of a foaming mold (100), if the mold has the same magnetic force as that in the related art, the linear sealing body (5) is well adhered along the concavo-convex surface. Therefore, sealing performance between the mold and the resin invasion preventing walls (4) can be greatly improved. As a result, even when foam molding is performed, a foamable resin material (200) is not invaded into an engaging element forming region, and the molded male surface fastener (1) can be accurately molded and integrated at a predetermined position of a foaming body.

Owner:YKK CORP

Easy-adhesion copolyester fiber and fabric thereof

InactiveCN103184572AIncreased adhesion areaHigh bonding strengthMonocomponent copolyesters artificial filamentFiberAlcohol

The invention discloses easy-adhesion copolyester fiber. An acid component forming the copolyester fiber mainly has terephthalic acid structural units. In a dihydric alcohol component forming the copolyester fiber, the content of aliphatic diol structural units comprising side chain and carbon atom number under 6 is 20-90mol%. The fiber has no melting point or low melting point. When the fiber is prepared into fabric and when the fabric is heated by using a common iron or other heating devices, a partial fusion phenomenon occurs to the fabric, and an adhesion effect is provided. The fabric can be used in side locking of positions such as cuffs and trouser bottoms, and can be used in shaping of collars and the like, such that clothes can be provided with certain stiffness.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

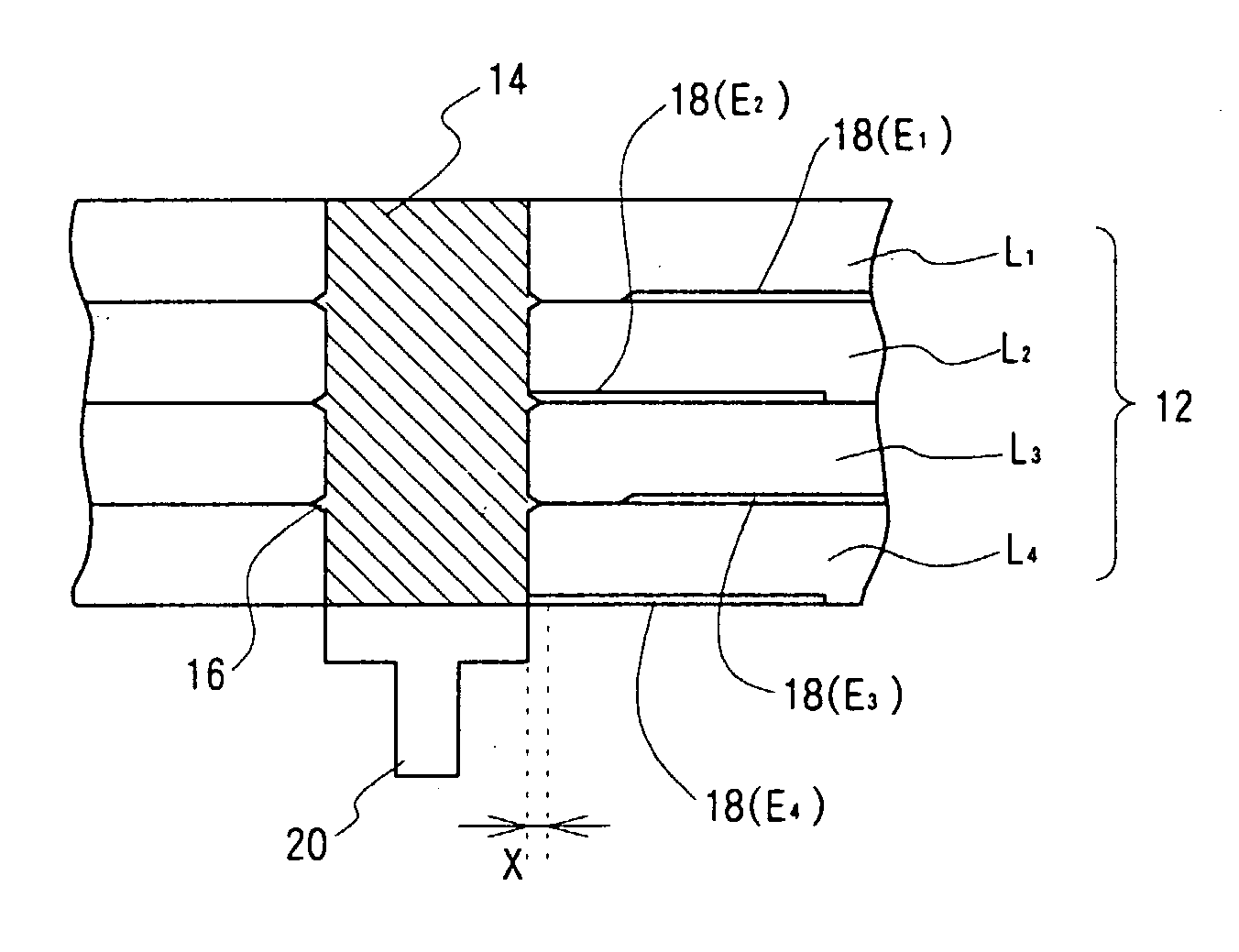

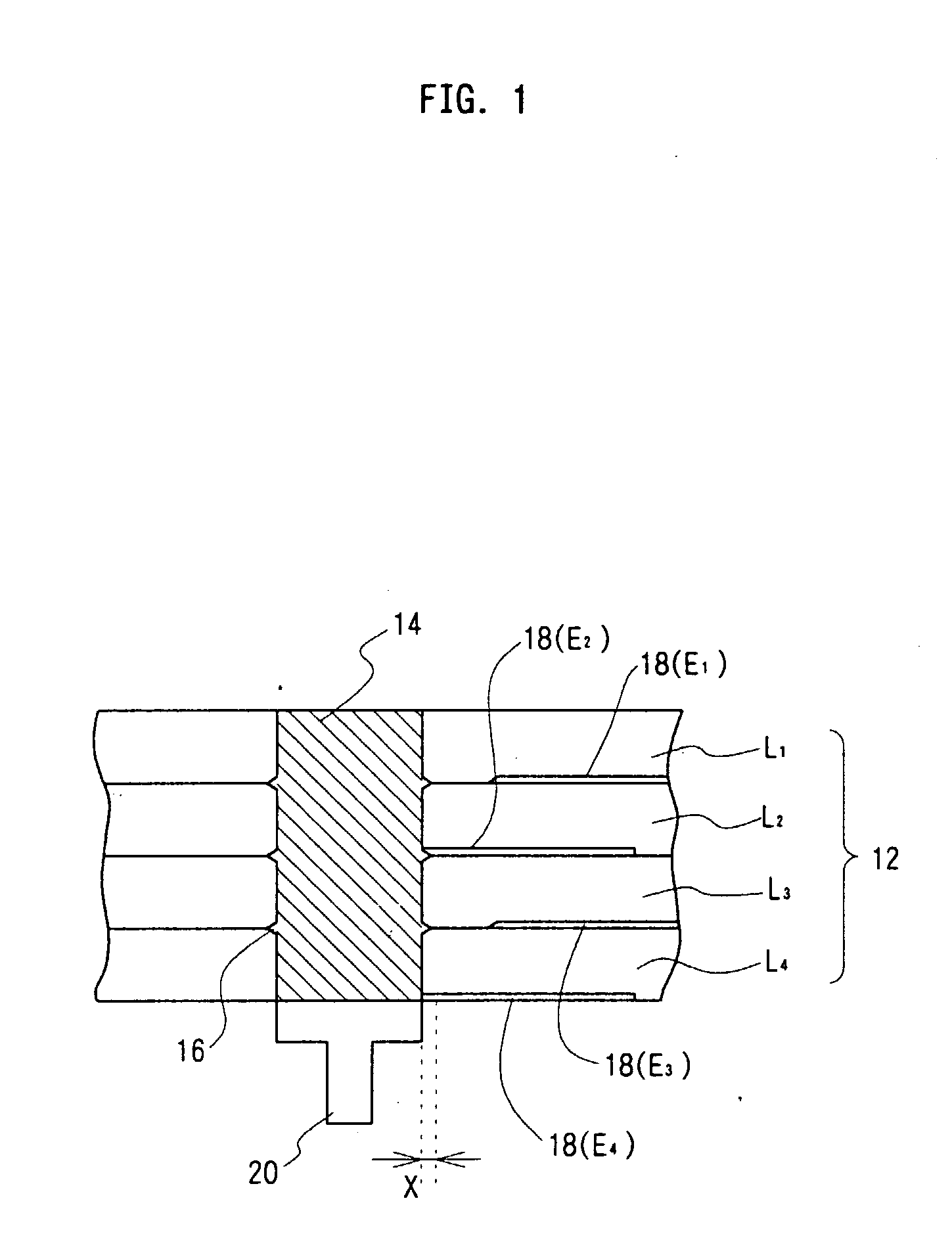

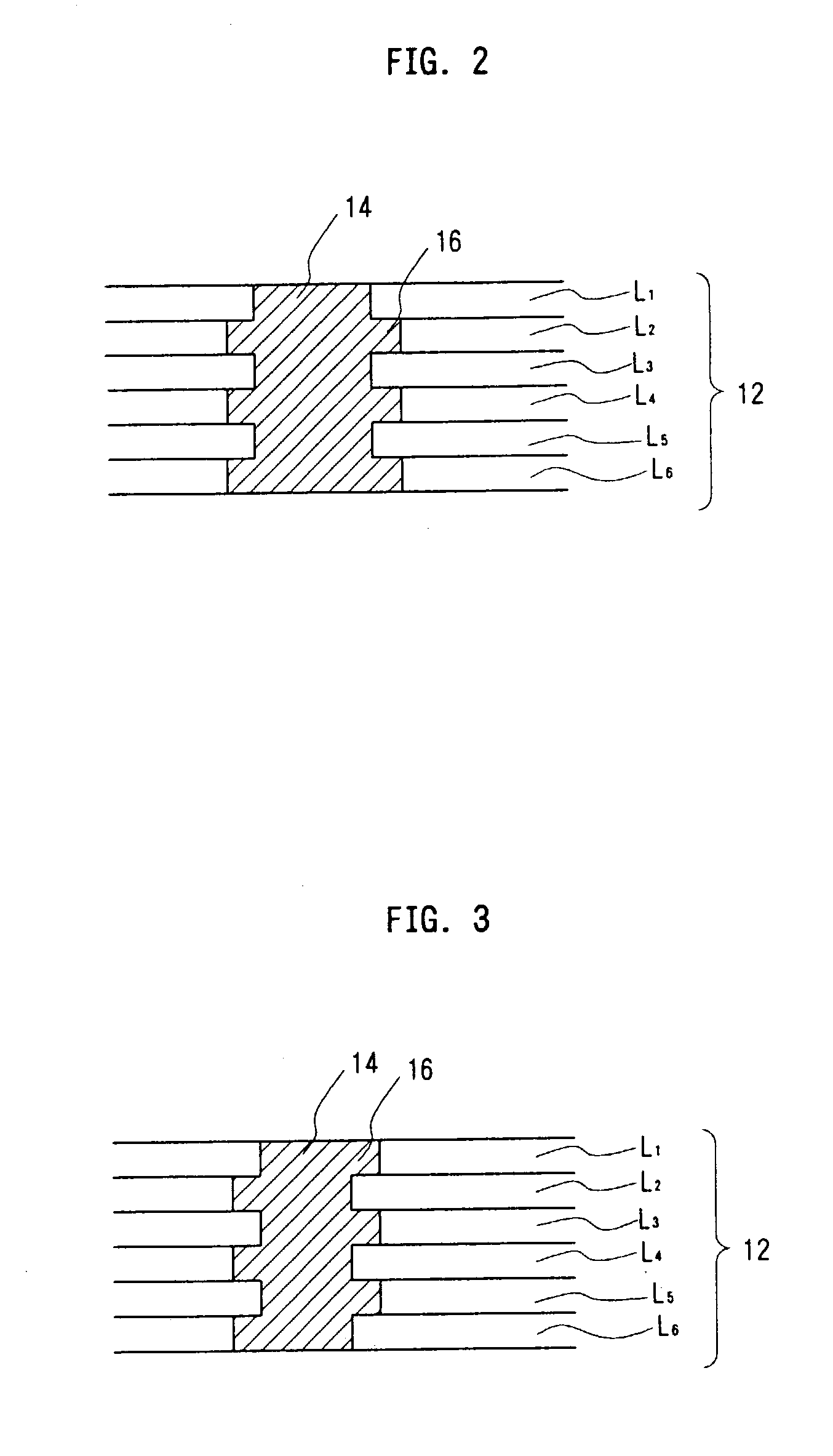

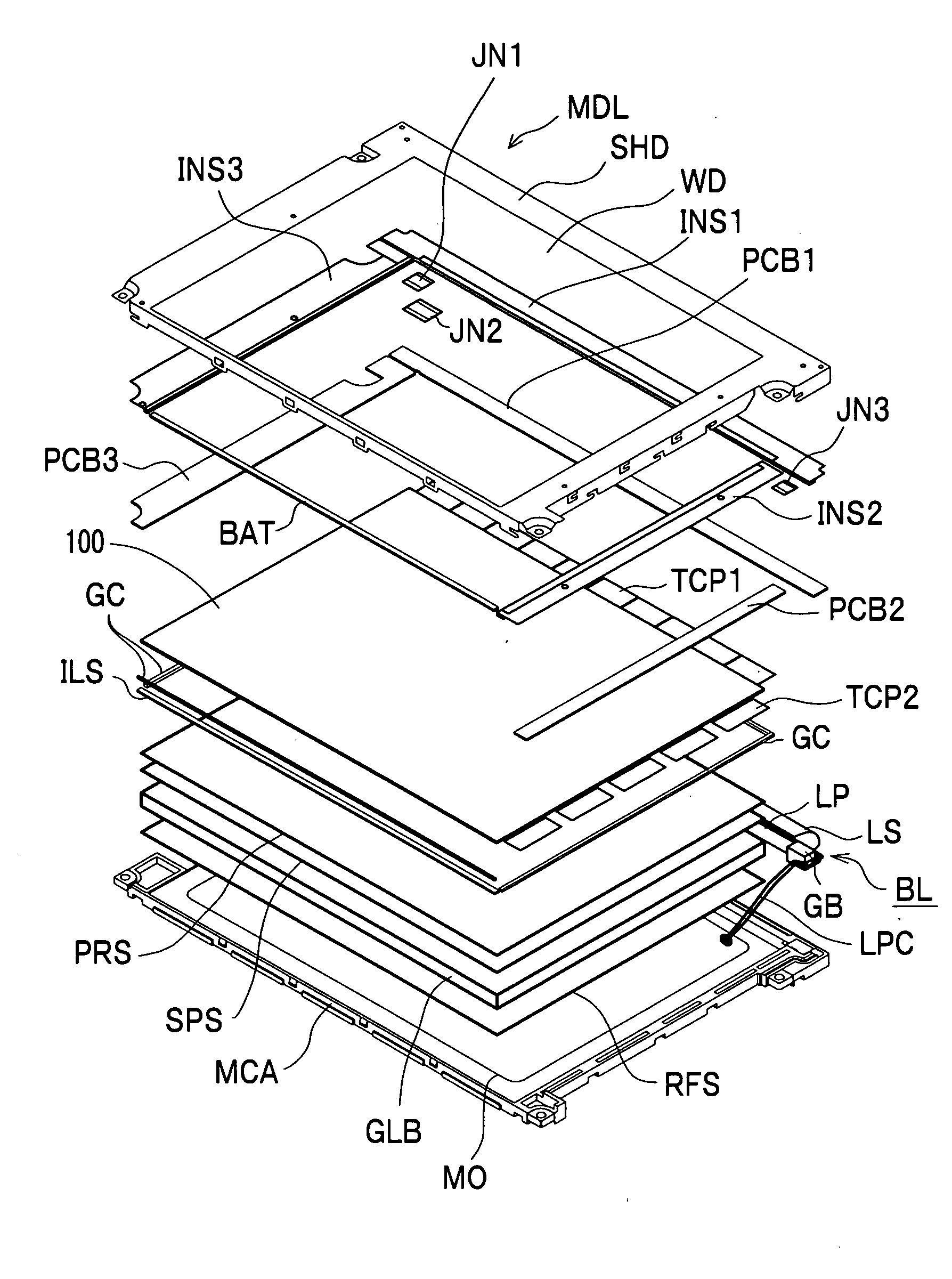

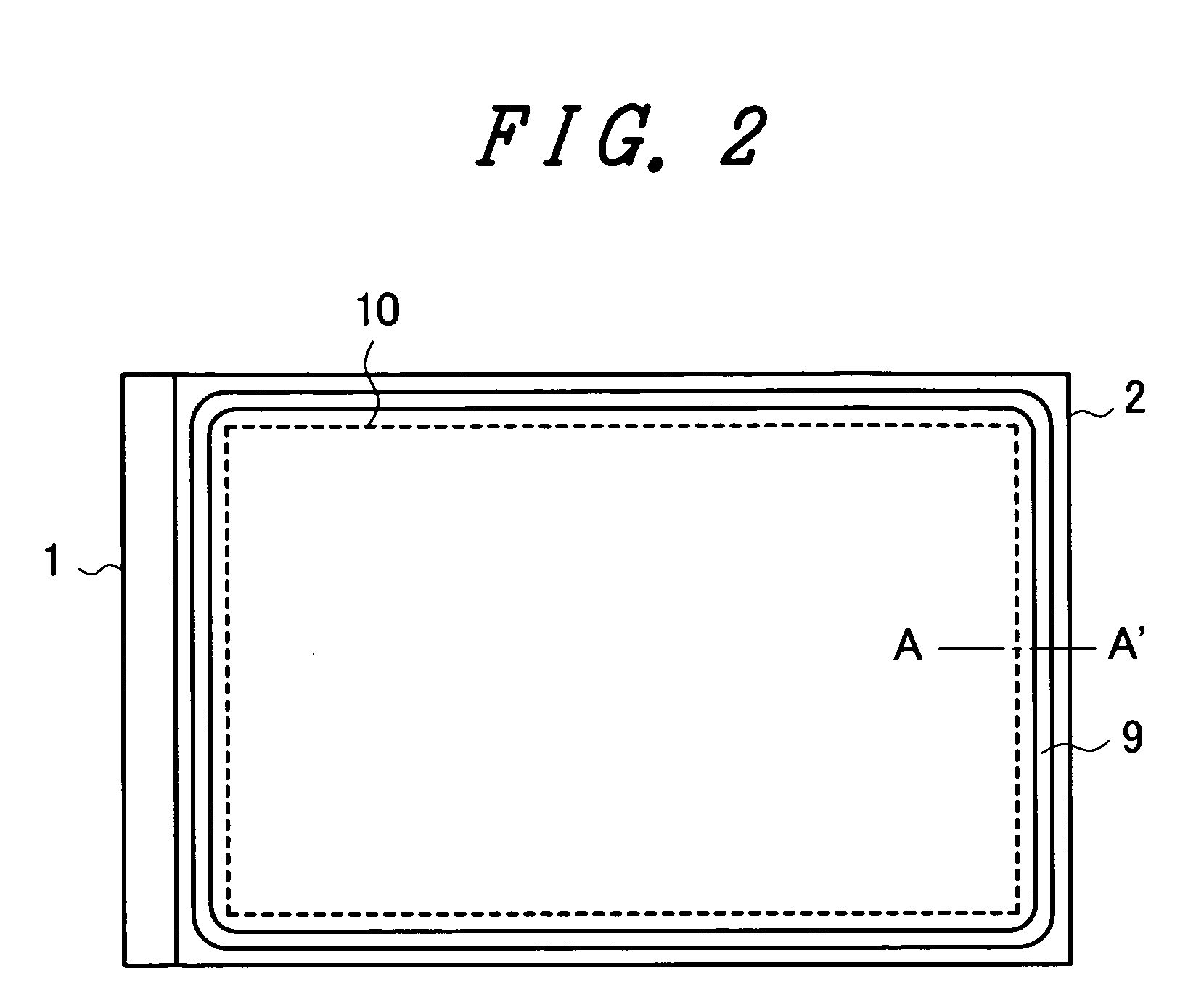

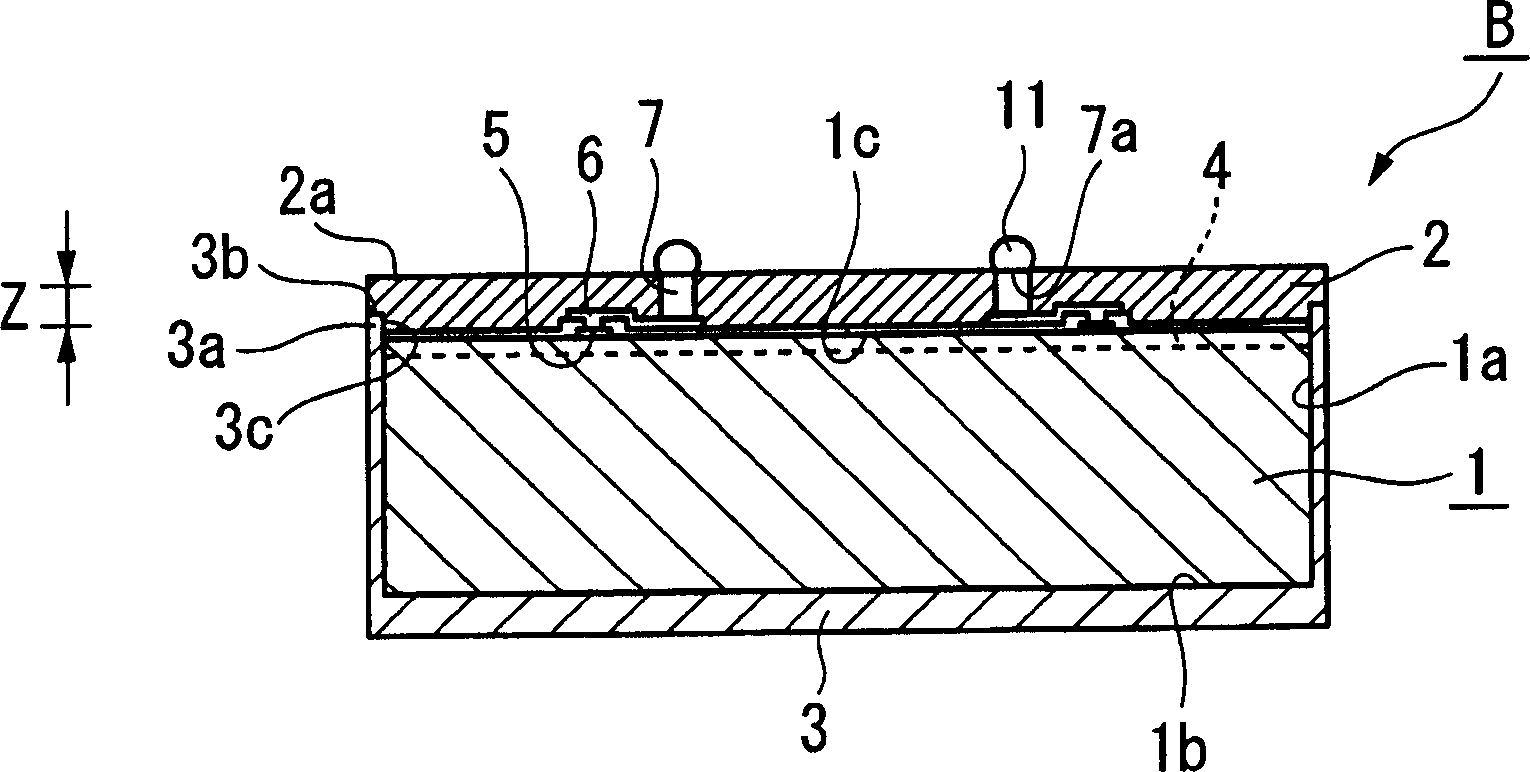

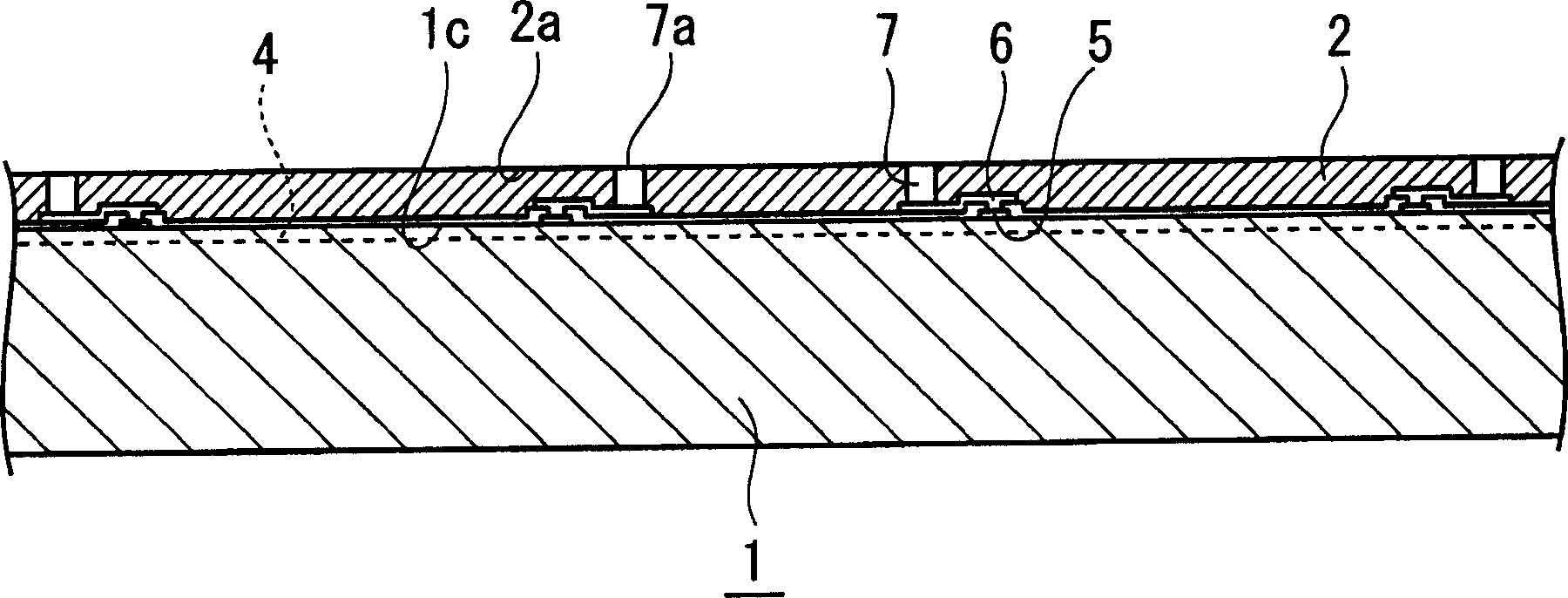

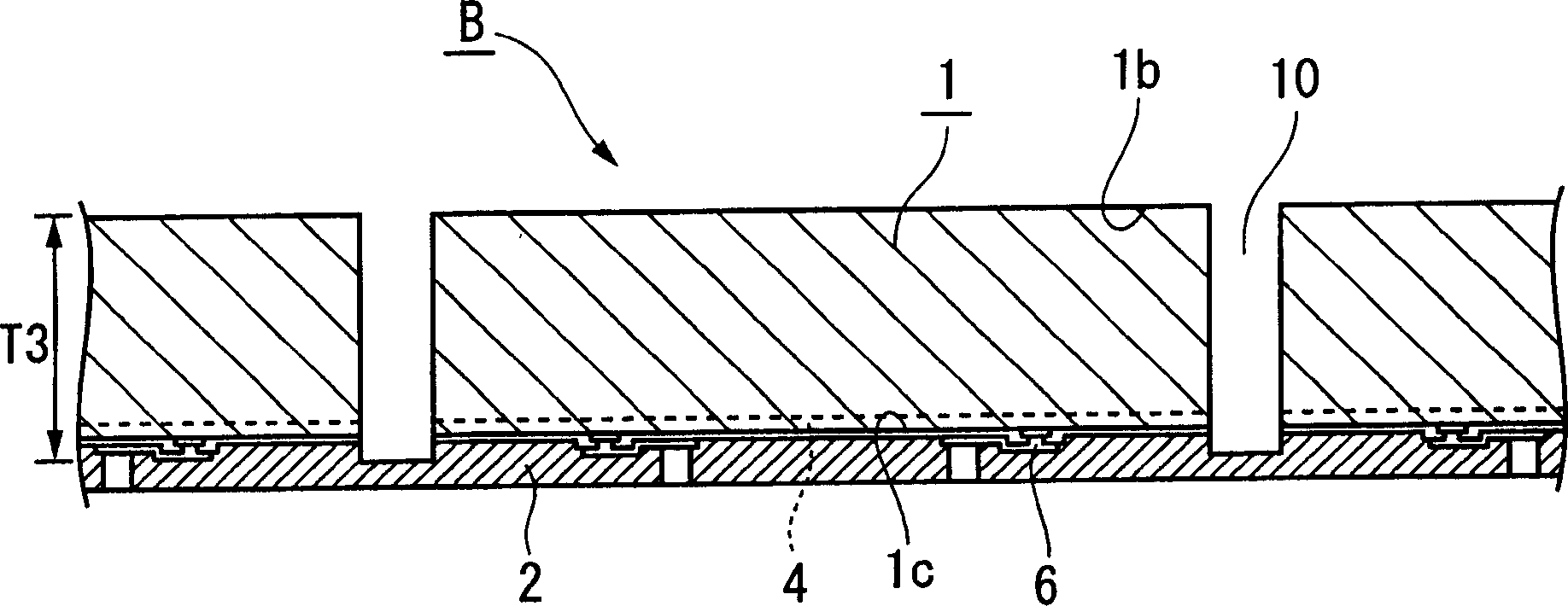

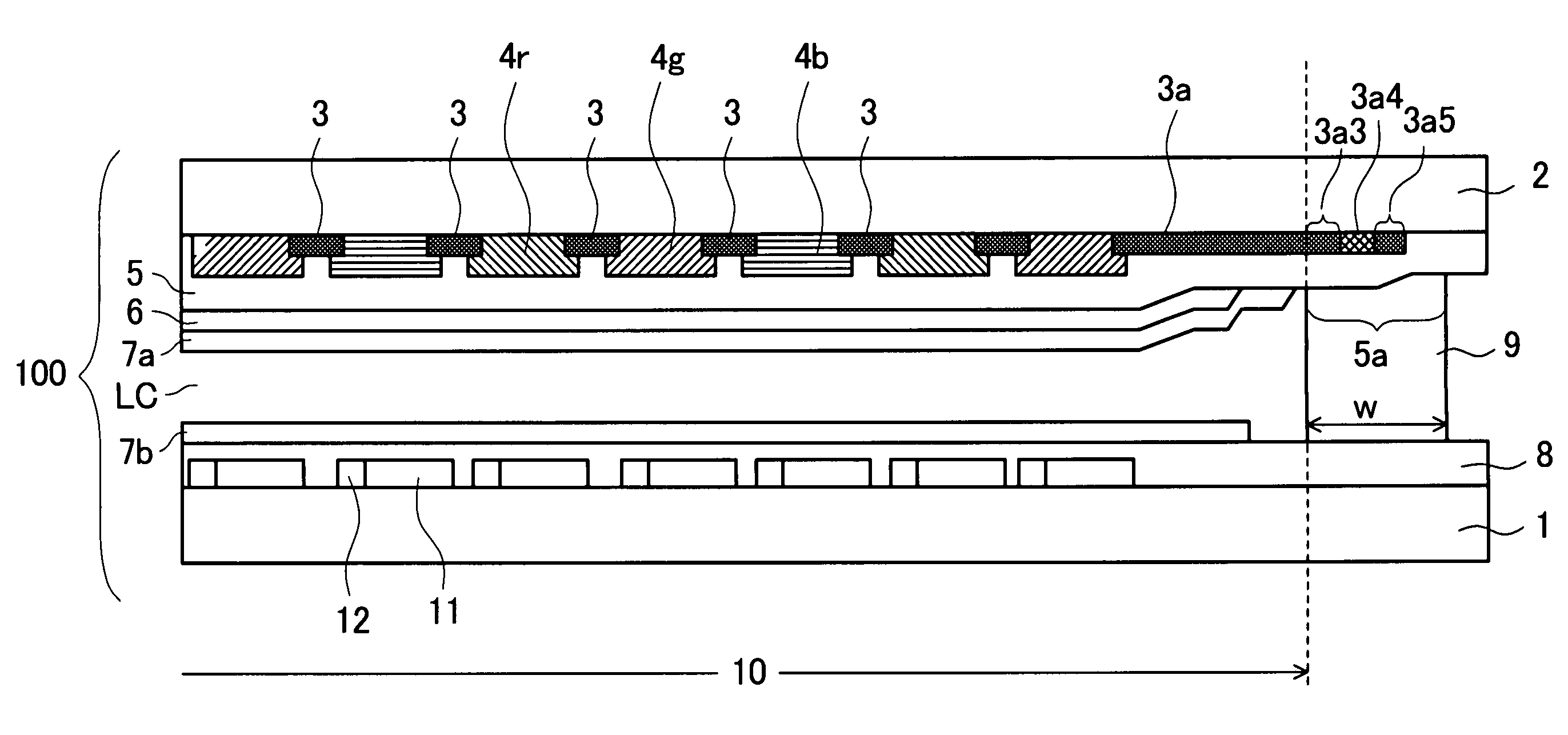

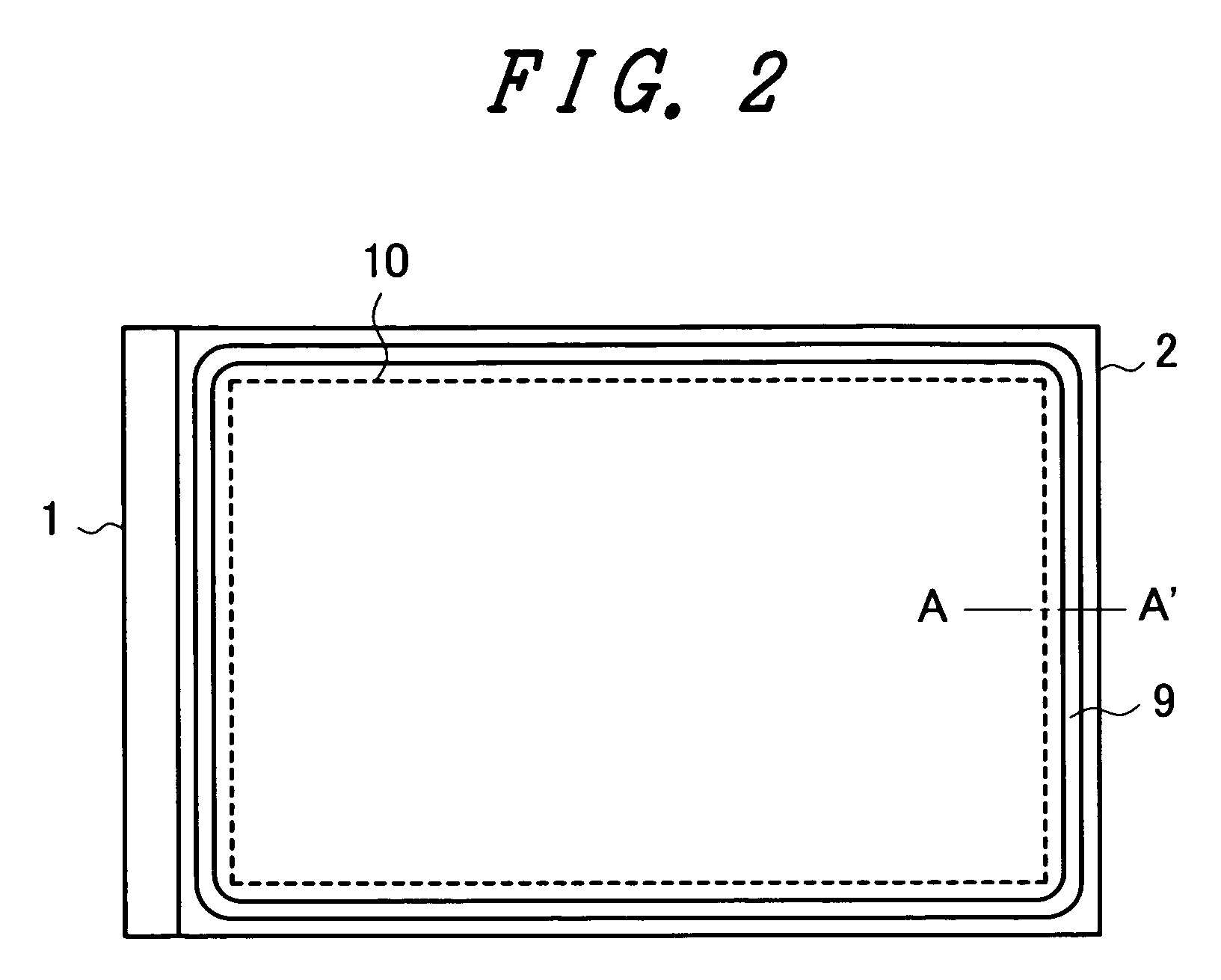

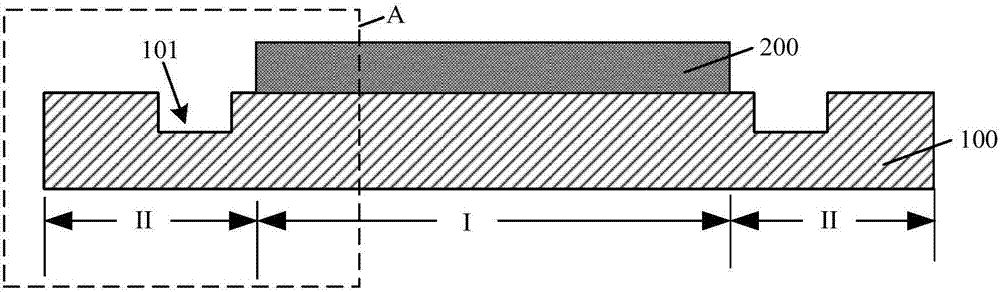

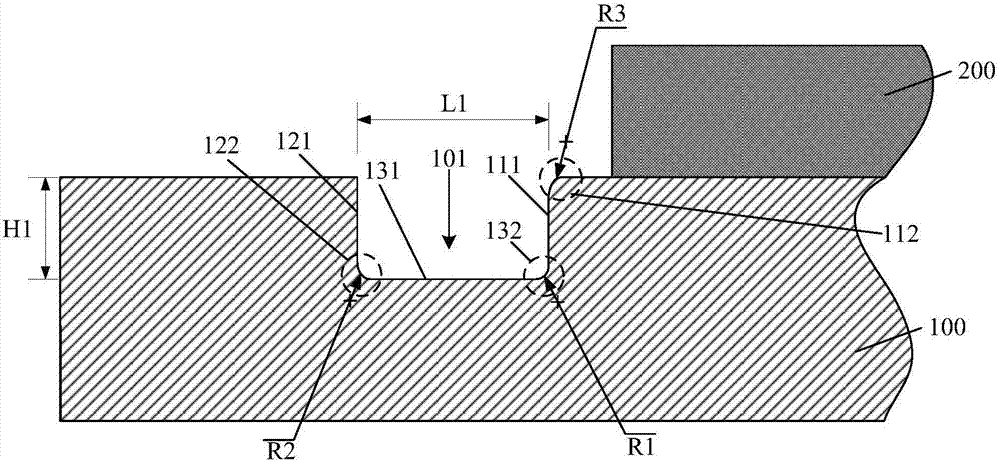

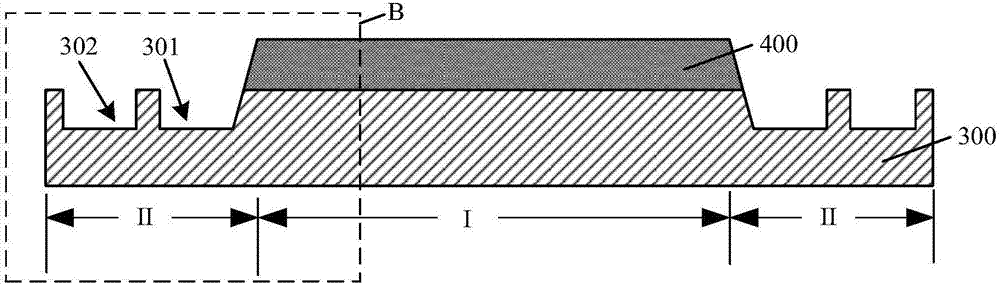

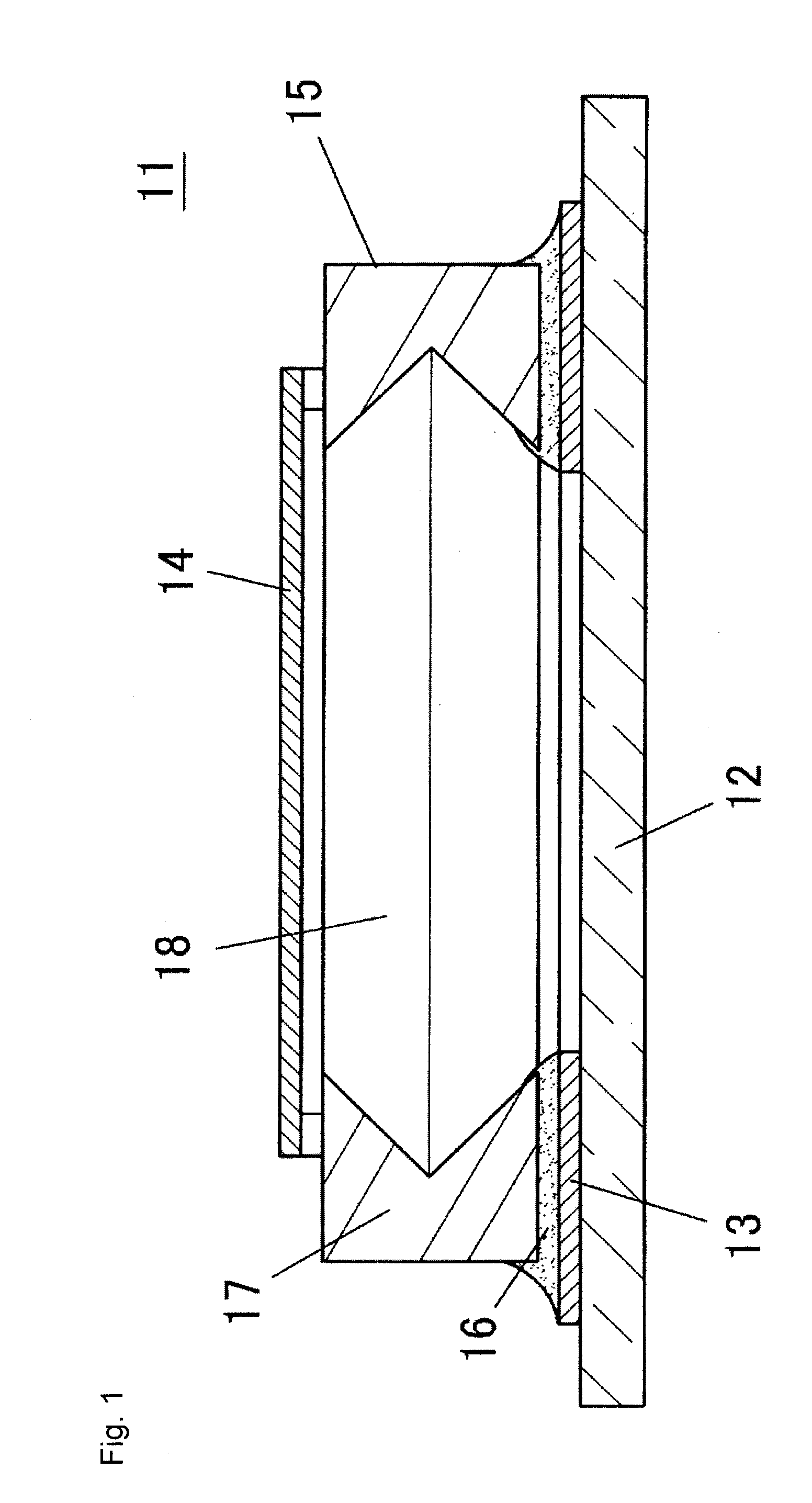

Liquid crystal display device

ActiveUS20080192186A1High bonding strengthQuality improvementNon-linear opticsLiquid-crystal displayEngineering

The present invention provides a liquid crystal display device which can enhance quality and reliability of image display by preventing the generation of bubbles in the inside of a liquid crystal display panel and, at the same time, by suppressing leaking of light from an end of a black matrix film. In the liquid crystal display panel which sandwiches a liquid crystal layer between two glass substrates, the liquid crystal layer is surrounded by a sealing material having a predetermined width. On one glass substrate, a black matrix film and an overcoat film are arranged from one-glass-substrate side such that the black matrix film and the overcoat film overlap the sealing material. The black matrix film is, in the widthwise direction of the sealing material, formed into a planar flat black matrix film until a middle position of the sealing material from a side on which the liquid crystal layer is arranged, and is formed into a slit-shaped slit black matrix film from the middle position. Due to such a constitution, an adhesion area between the glass substrate and the overcoat film under an applied region of the sealing material is enlarged and hence, an adhesion strength is increased thus largely enhancing an adhesion strength.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

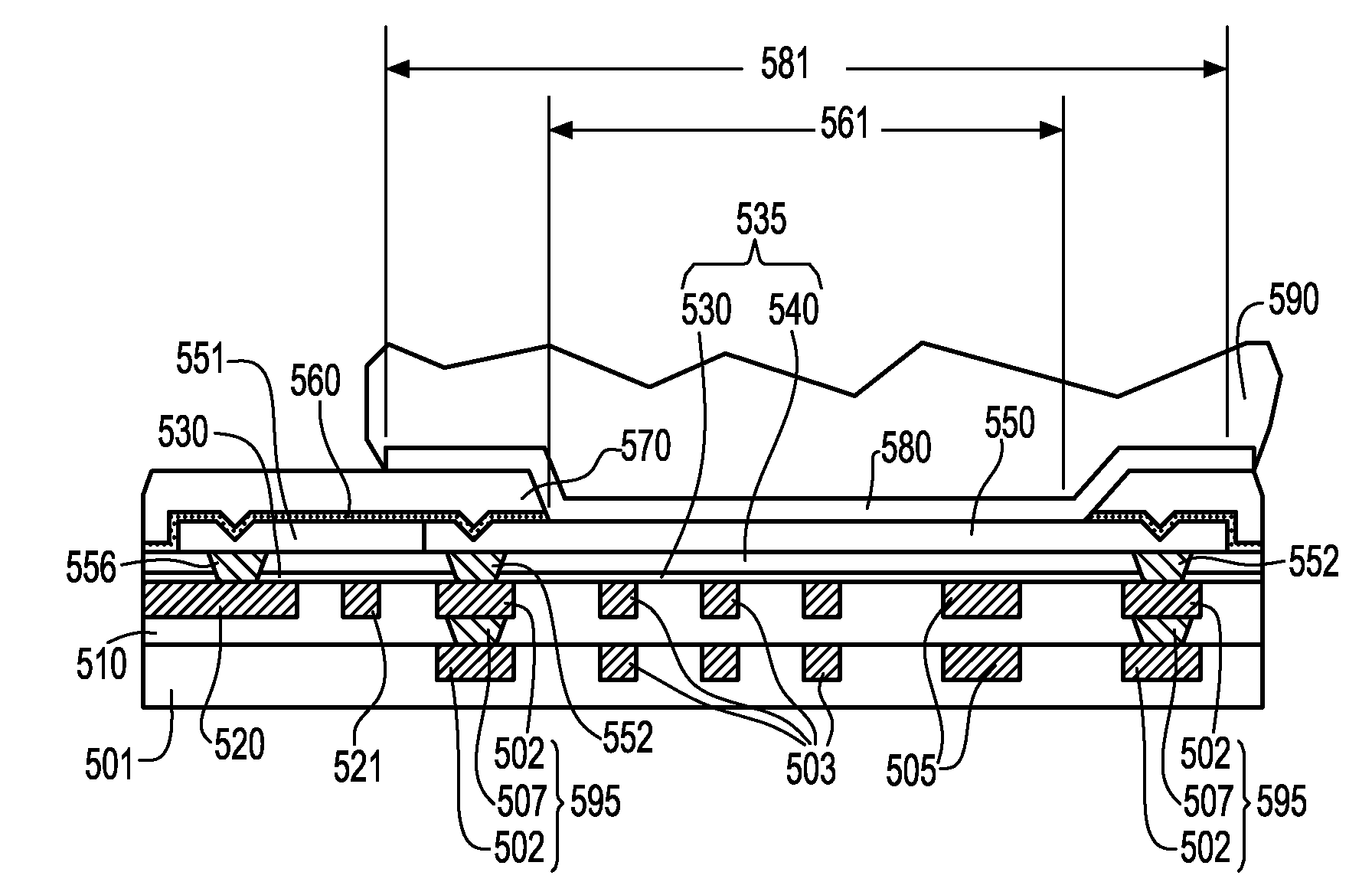

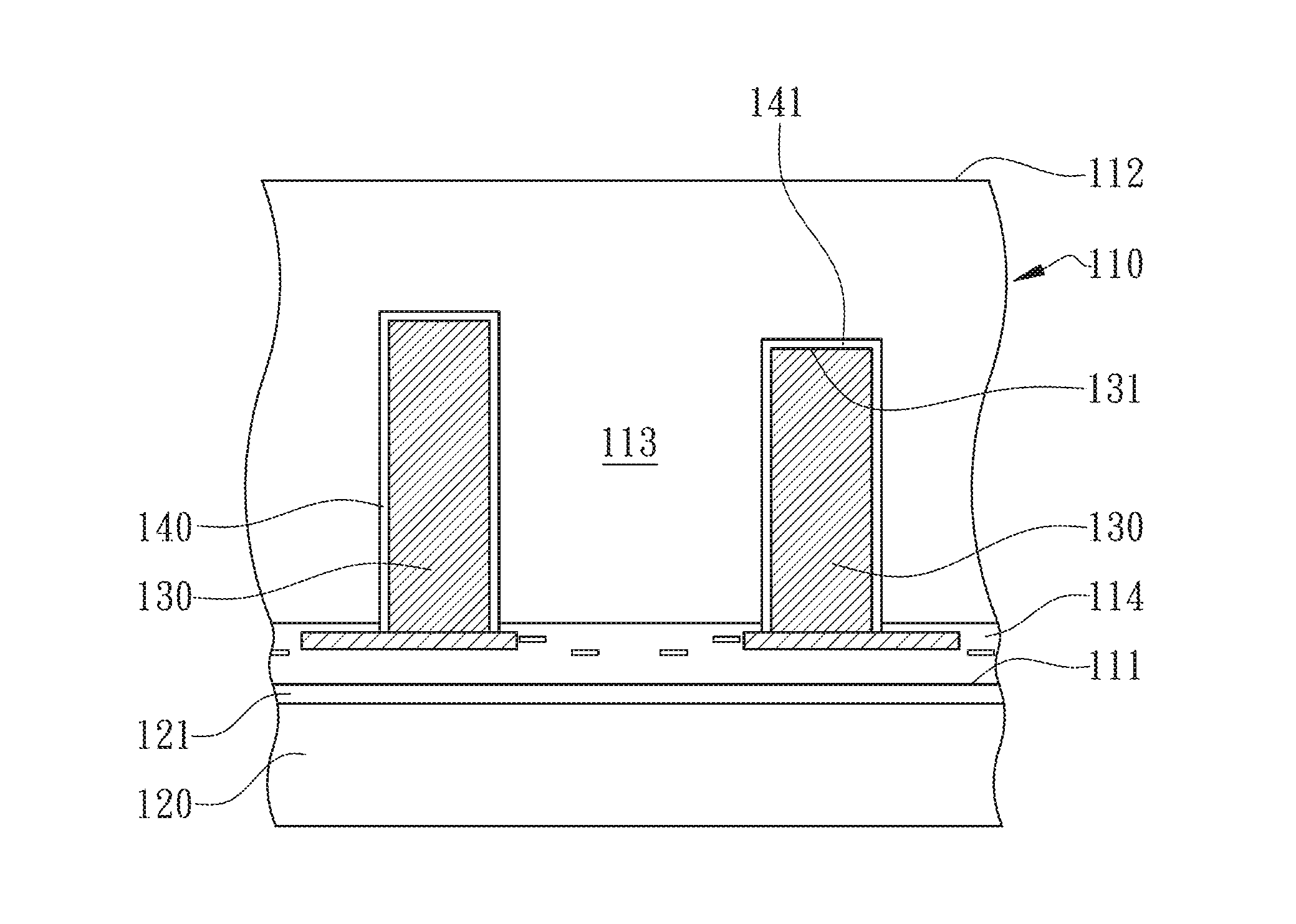

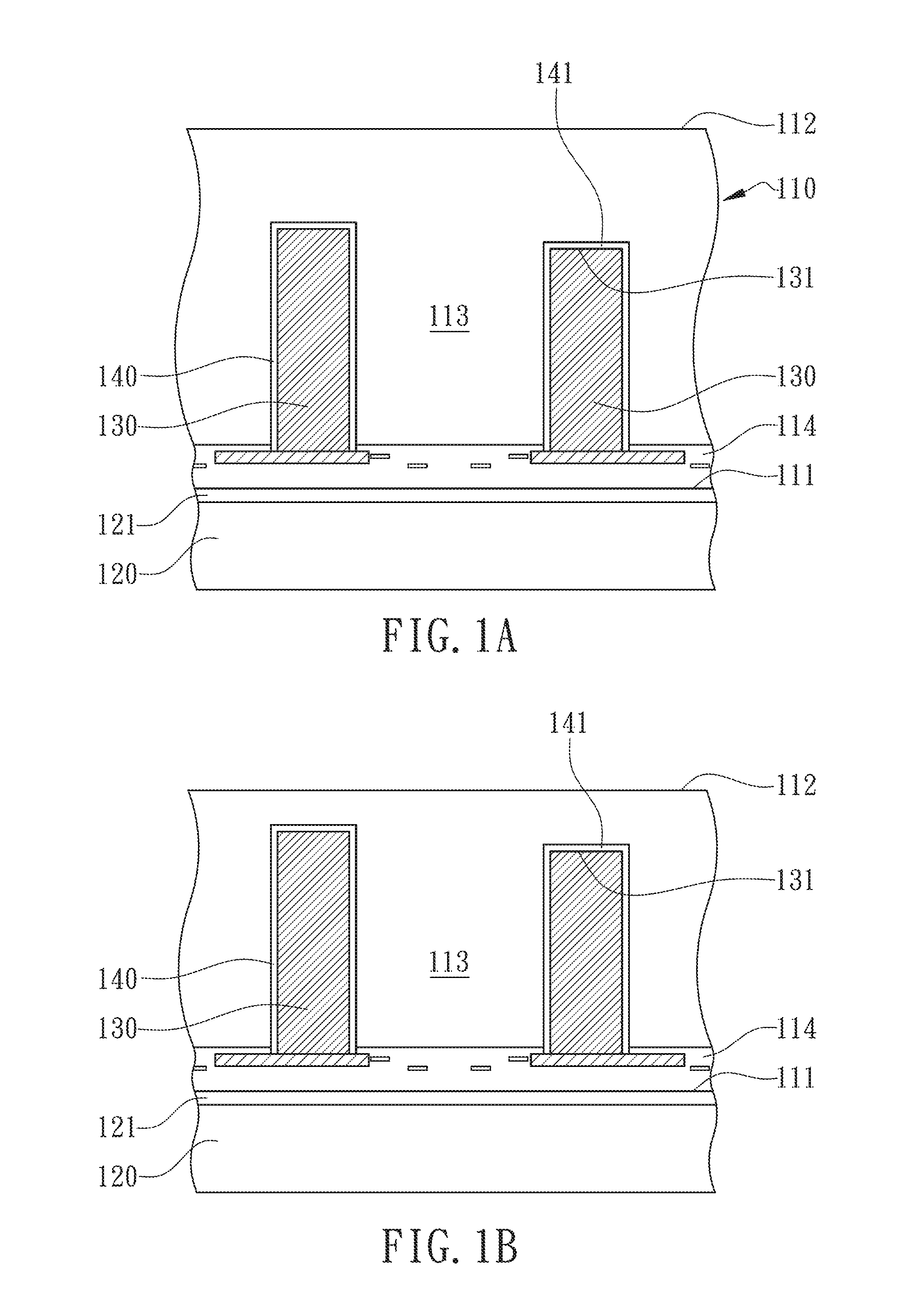

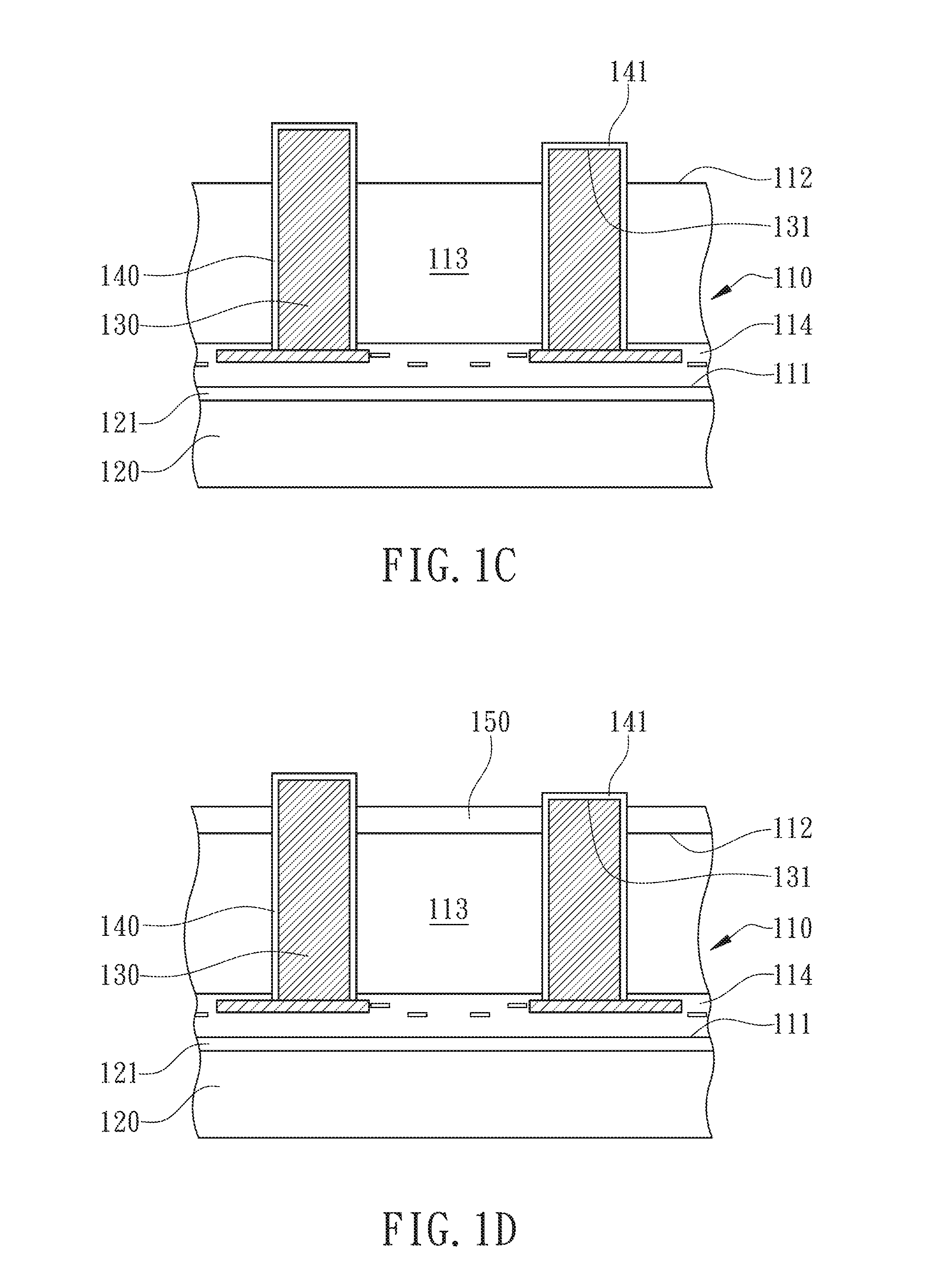

Structure and method for enhancing resistance to fracture of bonding pads

InactiveUS20080111250A1Increased adhesion areaIncrease flexibilitySemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor

The present invention provides bond pads structures between semiconductor integrated circuits and the chip package with enhanced resistance to fracture and improved reliability. Mismatch in the coefficient of temperature expansion (CTE) among the materials used in bond structures induces stress and shear on them that may result in fractures within the back end dielectric stacks and cause reliability problems of the packaging. By placing multiple metal pads which are connected to the bond pad through multiple metal via, the adhesion between the bond pads and the back end dielectric stacks is enhanced.

Owner:MARVELL ASIA PTE LTD

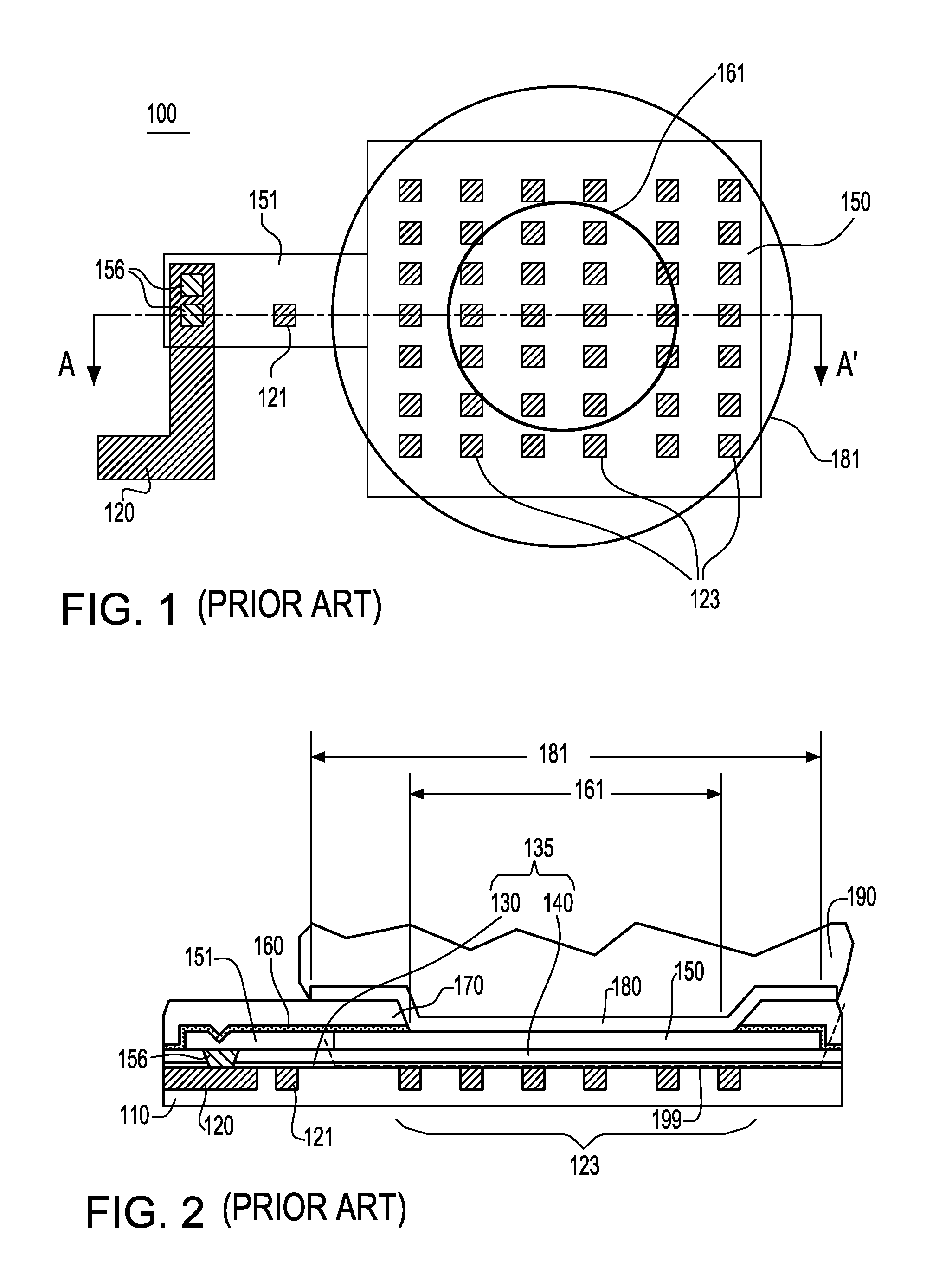

Fabrication process and structure to form bumps aligned on TSV on chip backside

InactiveUS20150048496A1Increase the areaHigh strengthSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyEngineering

Disclosed is a fabrication process of fabricating bumps aligned on TSVs on chip backside. A plurality of TSV pillars are embedded inside the semiconductor layer of an IC substrate where the sidewalls the bottom of the TSV pillars toward the chip backside are covered by a dielectric liner. Then, the thickness of the semiconductor layer is reduced from the chip backside to make the bottom portion of the dielectric liner to be exposed from the chip backside by including a first selectively etching. Then, a backside passivation is disposed on the chip backside without disposing on the bottoms of the TSV pillars. Then, the bottom portion of the dielectric liner is removed by a second selectively etching. An UBM layer is disposed on the backside passivation. A plurality of bumps are disposed on the UBM layer where the interface between each bump and each TSV pillar is a central protrusion lumped toward the corresponding bump. Accordingly, the interfaces between the bumps and the TSV pillars offer an increased bonding area to increase adhesion anchoring effects for the bumps bonded on the UBM layer through the central protrusions.

Owner:POWERTECH TECHNOLOGY +1

Piston and method for manufacturing the same

The present invention reduces weight while assuring required rigidity of a piston reduces cost of the piston. A piston includes first and second pin bosses supporting a piston pins, a first side wall coupling the first pin boss and a piston skirt, a second side wall coupling the second pin boss and the piston skirt, and a pair of bridges coupling the first and second side walls and forming upward spaces just above. First and second through holes are formed in the first and second side walls. The first and second through holes and the upper spaces are formed by a single punching process using a punch and, simultaneously, the bridges are formed.

Owner:HONDA MOTOR CO LTD

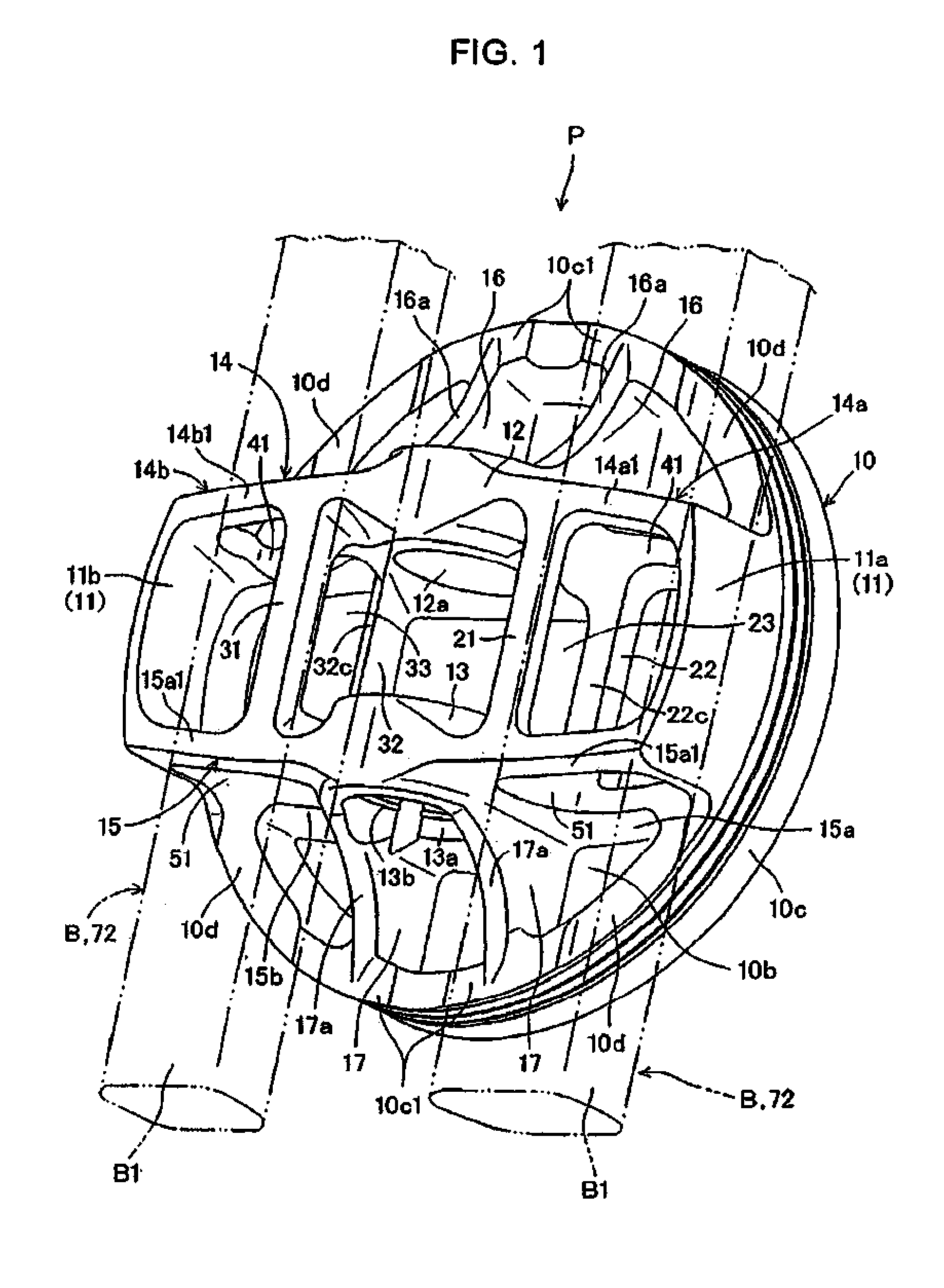

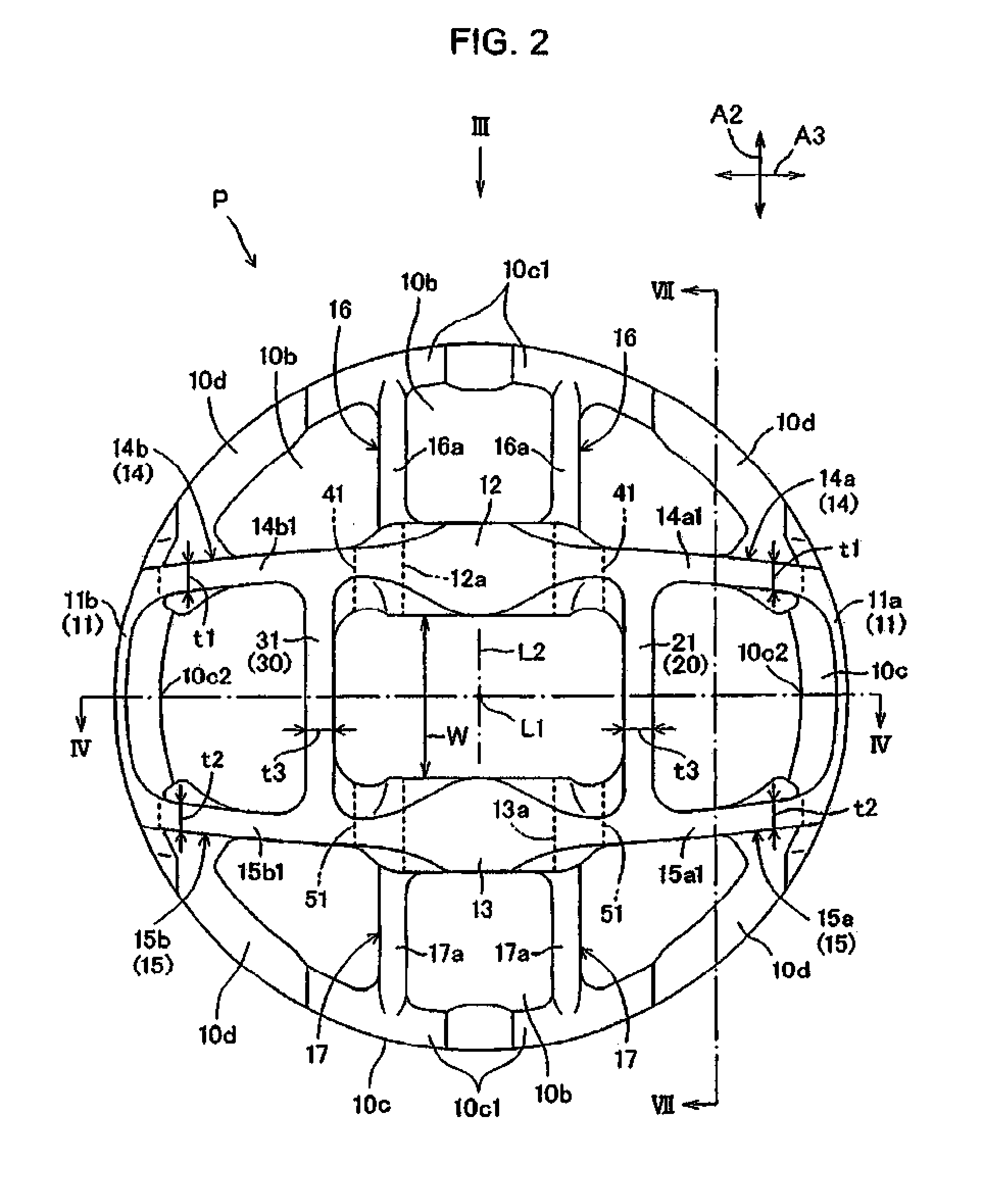

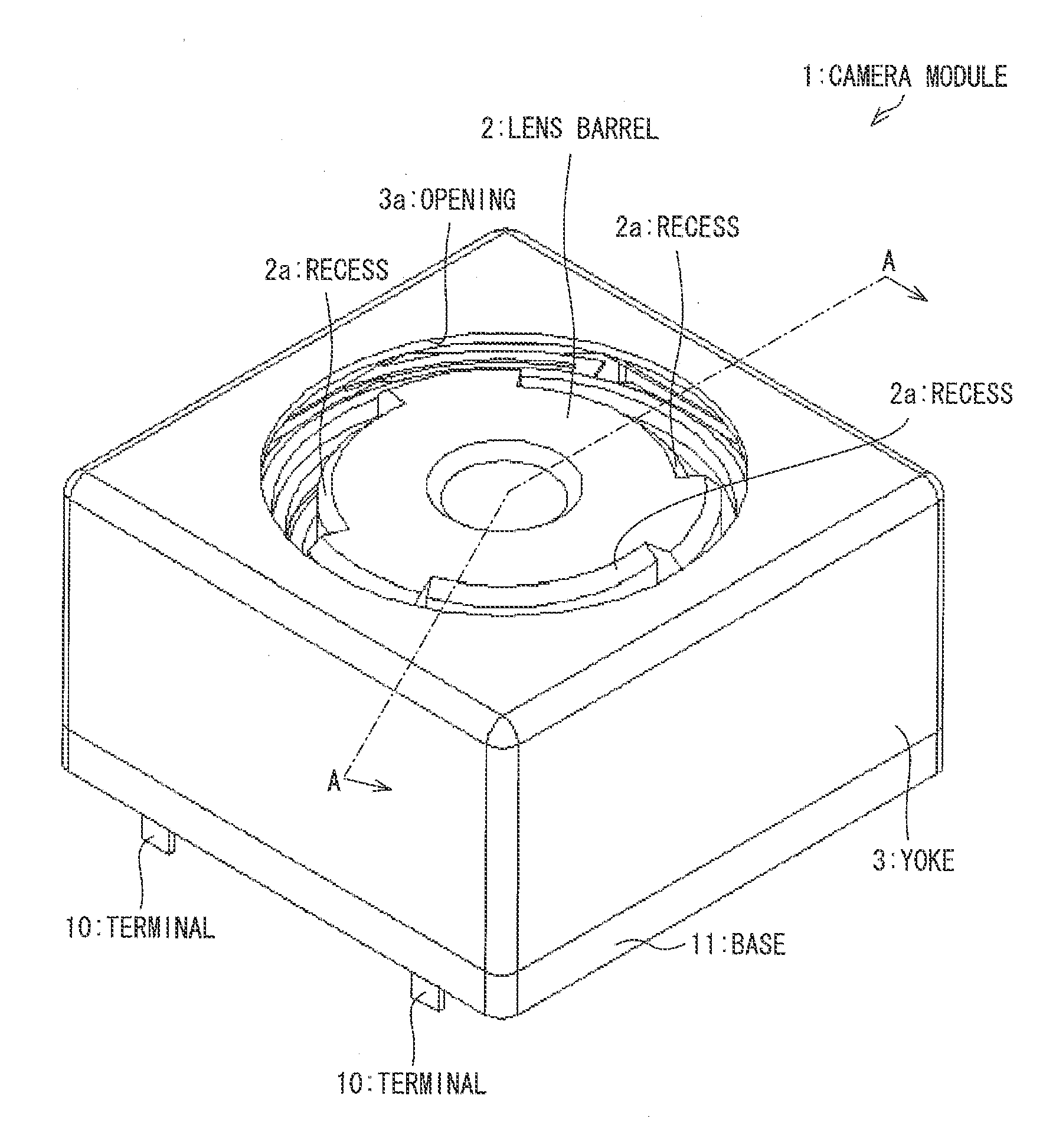

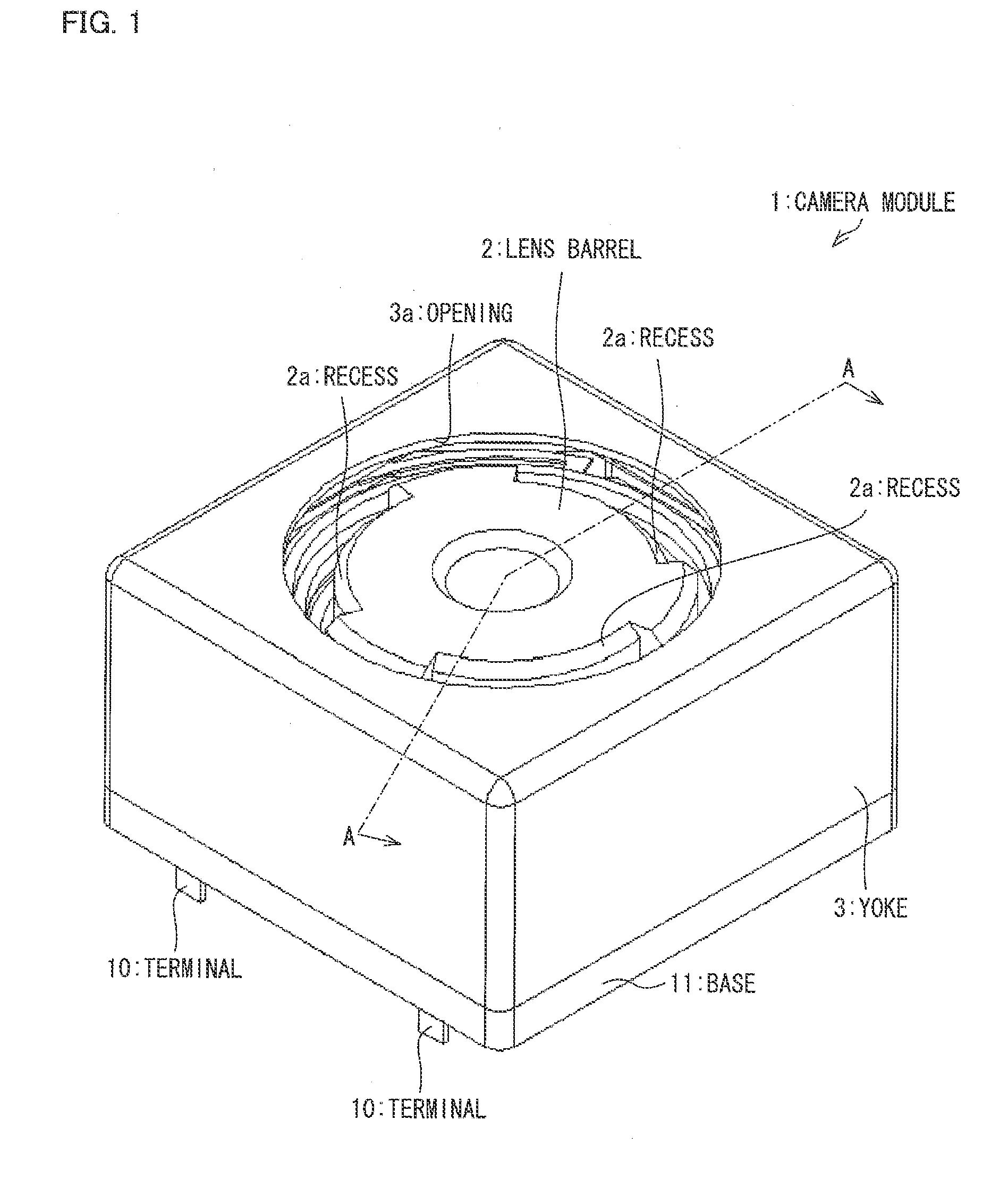

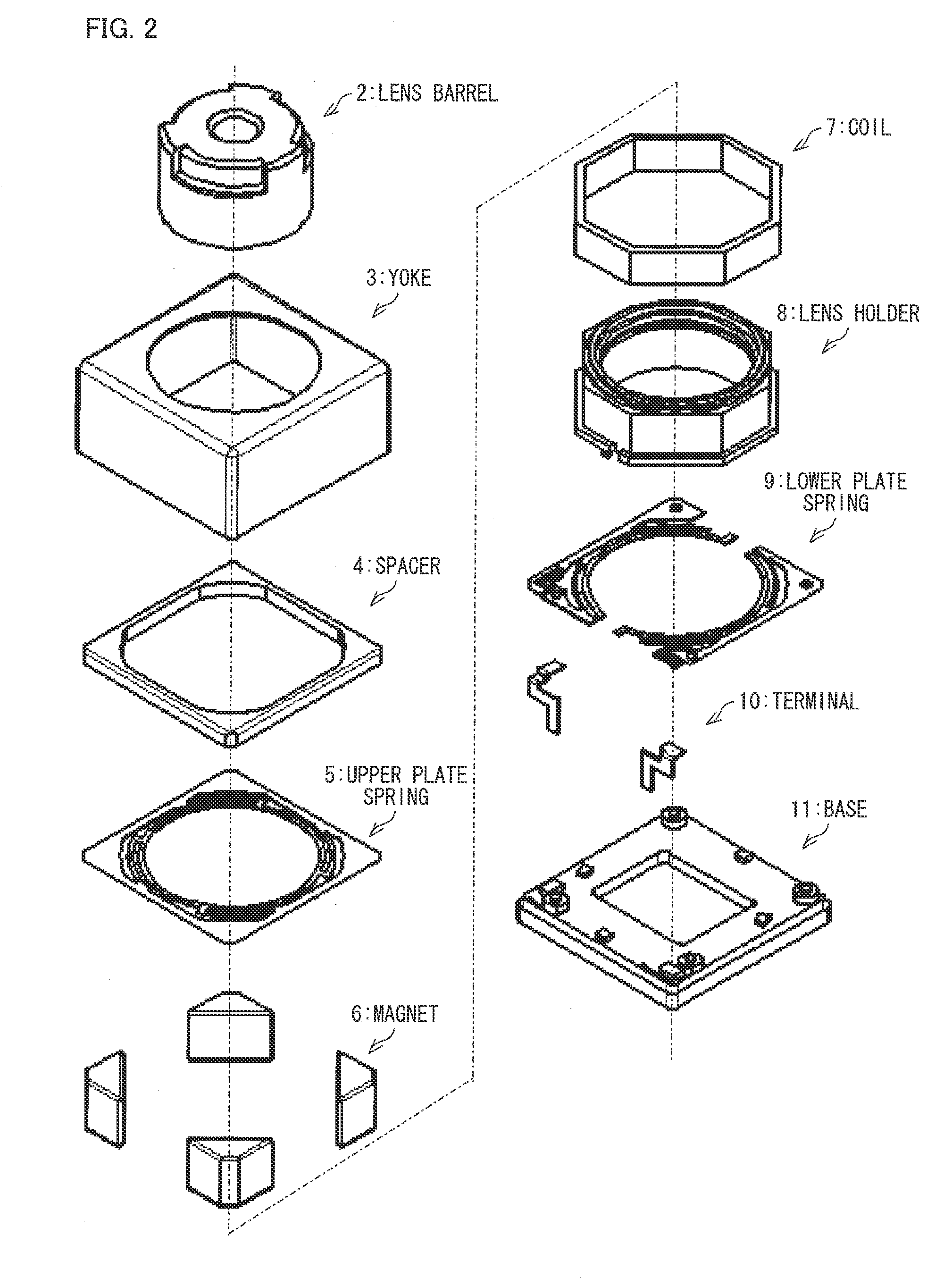

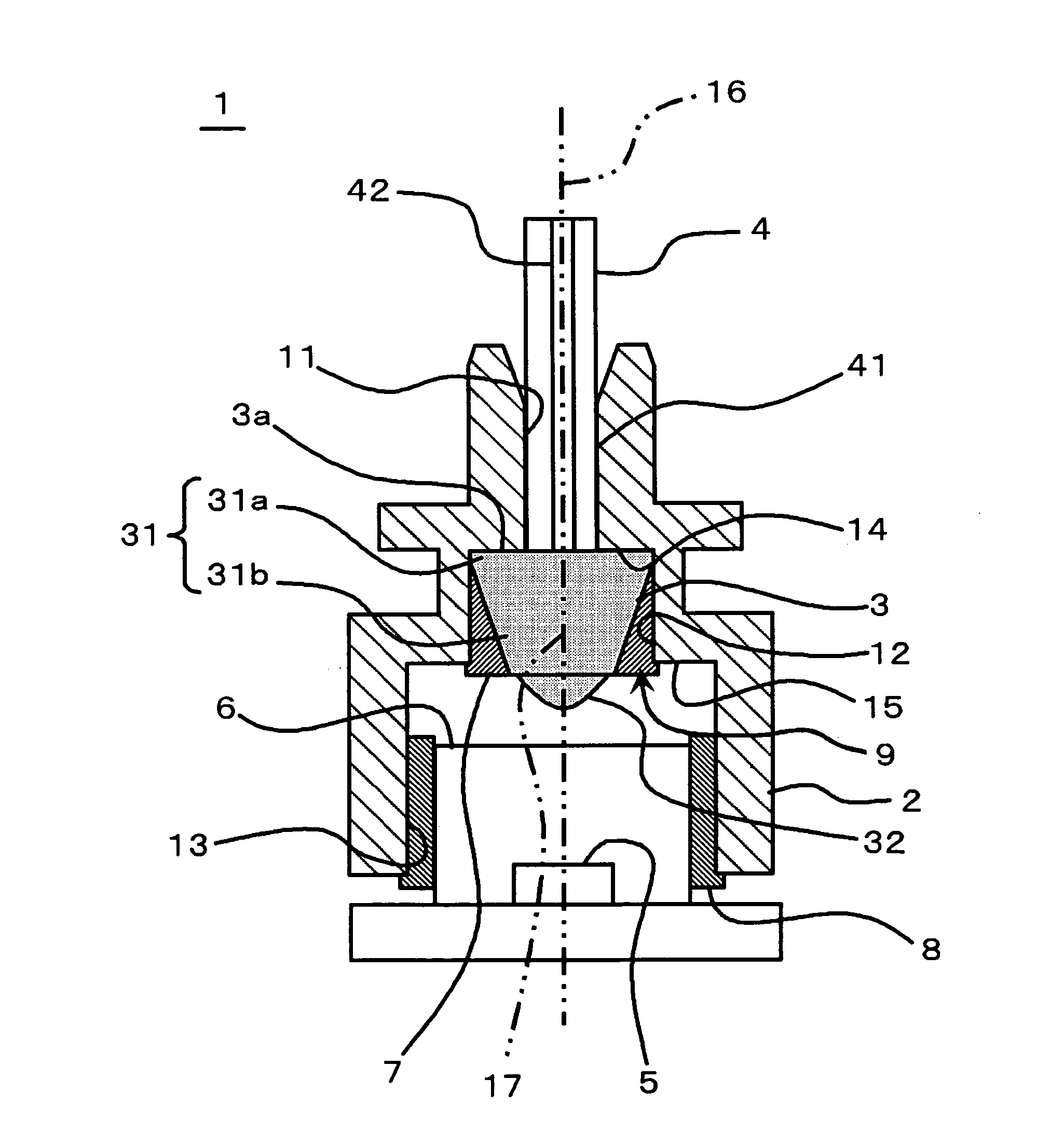

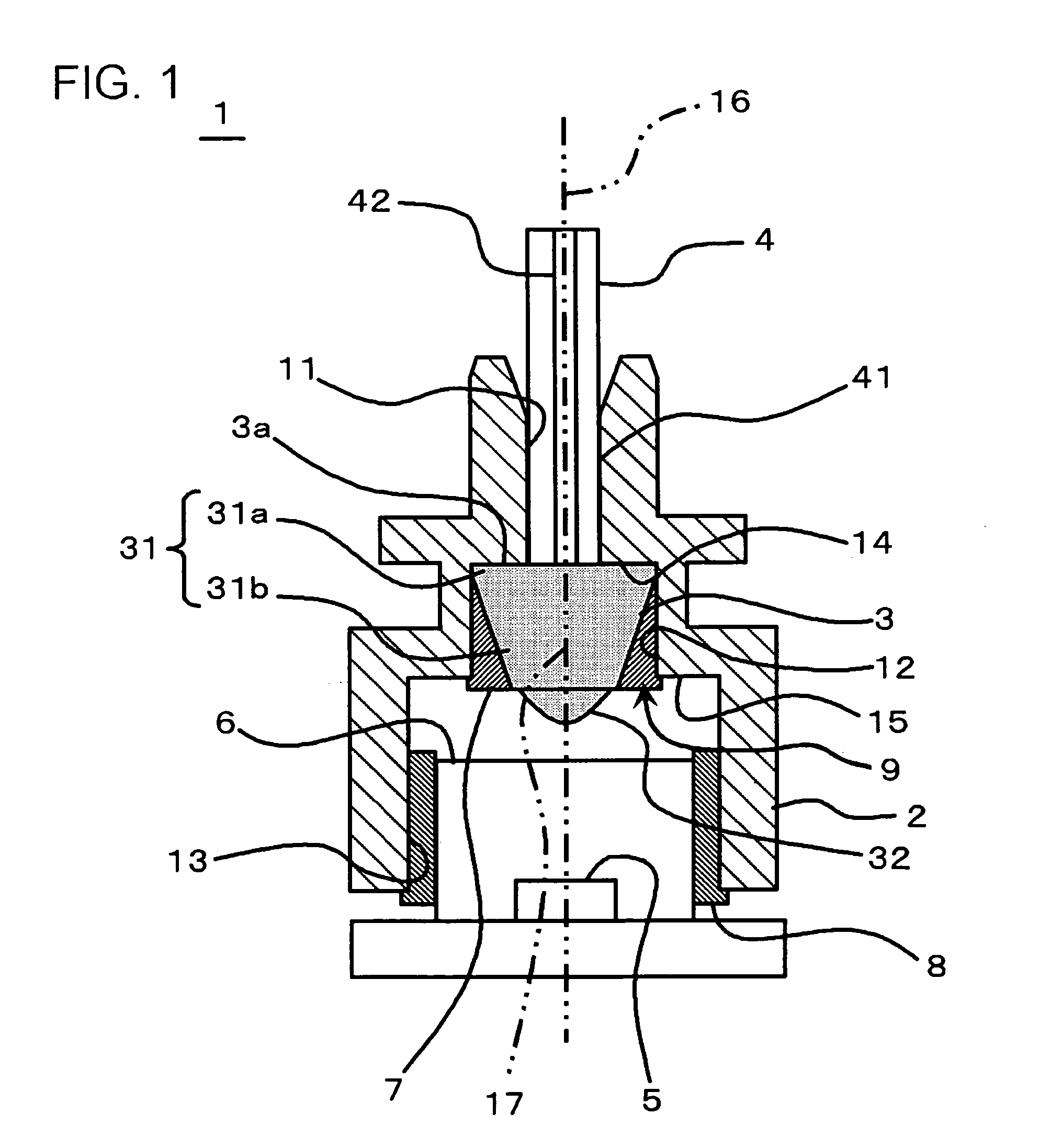

Camera module

ActiveUS20150370034A1High bonding strengthSimple configuration without causing a deterioration in assembly accuracyMountingsCamera lensEngineering

According to a camera module (1), a lens barrel (2) and a lens holder (8) adhere to each other via an adhesive layer (12), and the lens barrel (2) has a recess (2a) having a bottom surface (2a3) that is located between an upper side surface (8a1) and a lower side surface (8a2) of a groove (8a).

Owner:SHARP KK

Molded male surface fastener

ActiveUS8512845B2Surface of surface of of surface severeUnevenness of of of of severeSnap fastenersLayered productsCushionFastener

Owner:YKK CORP

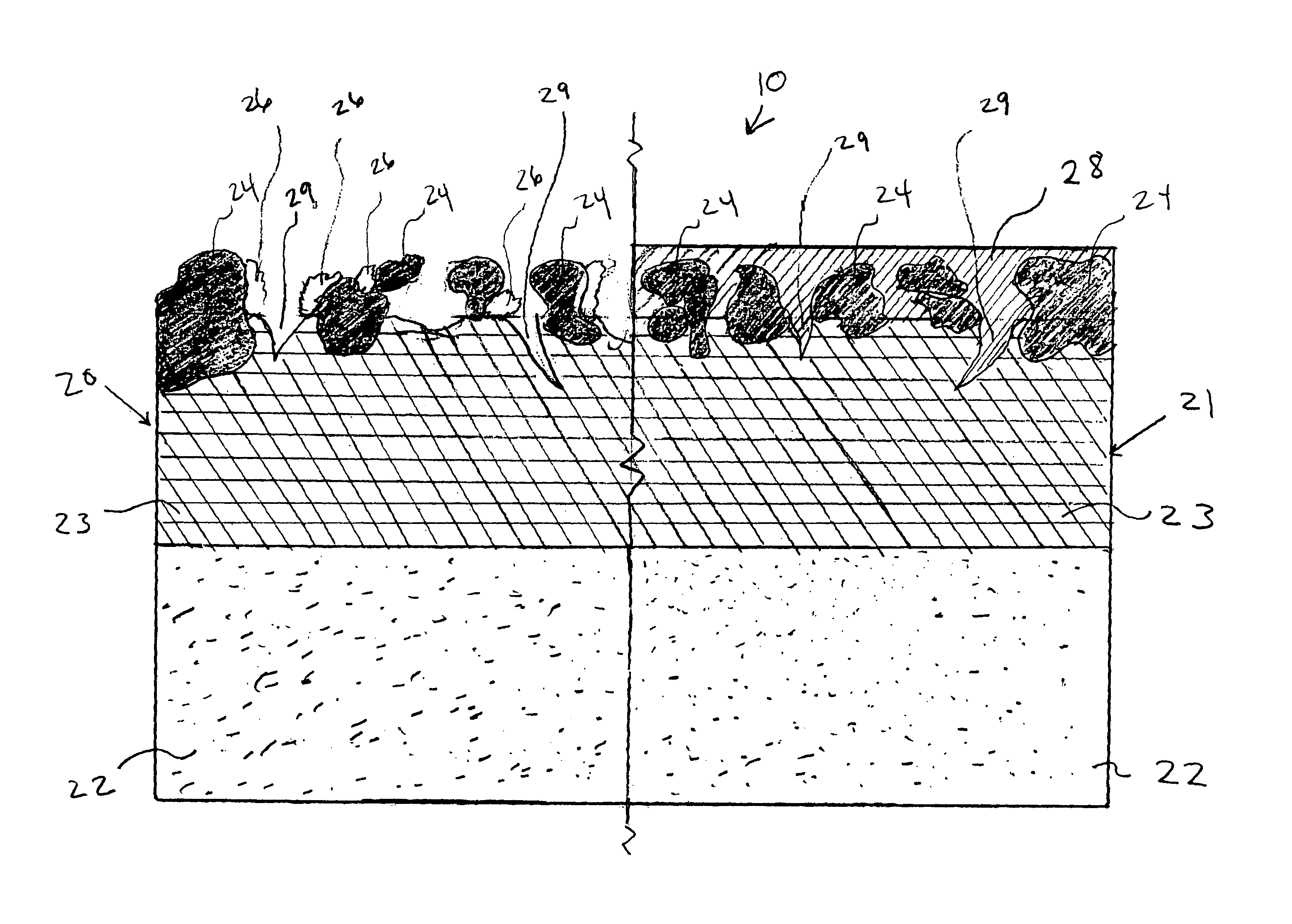

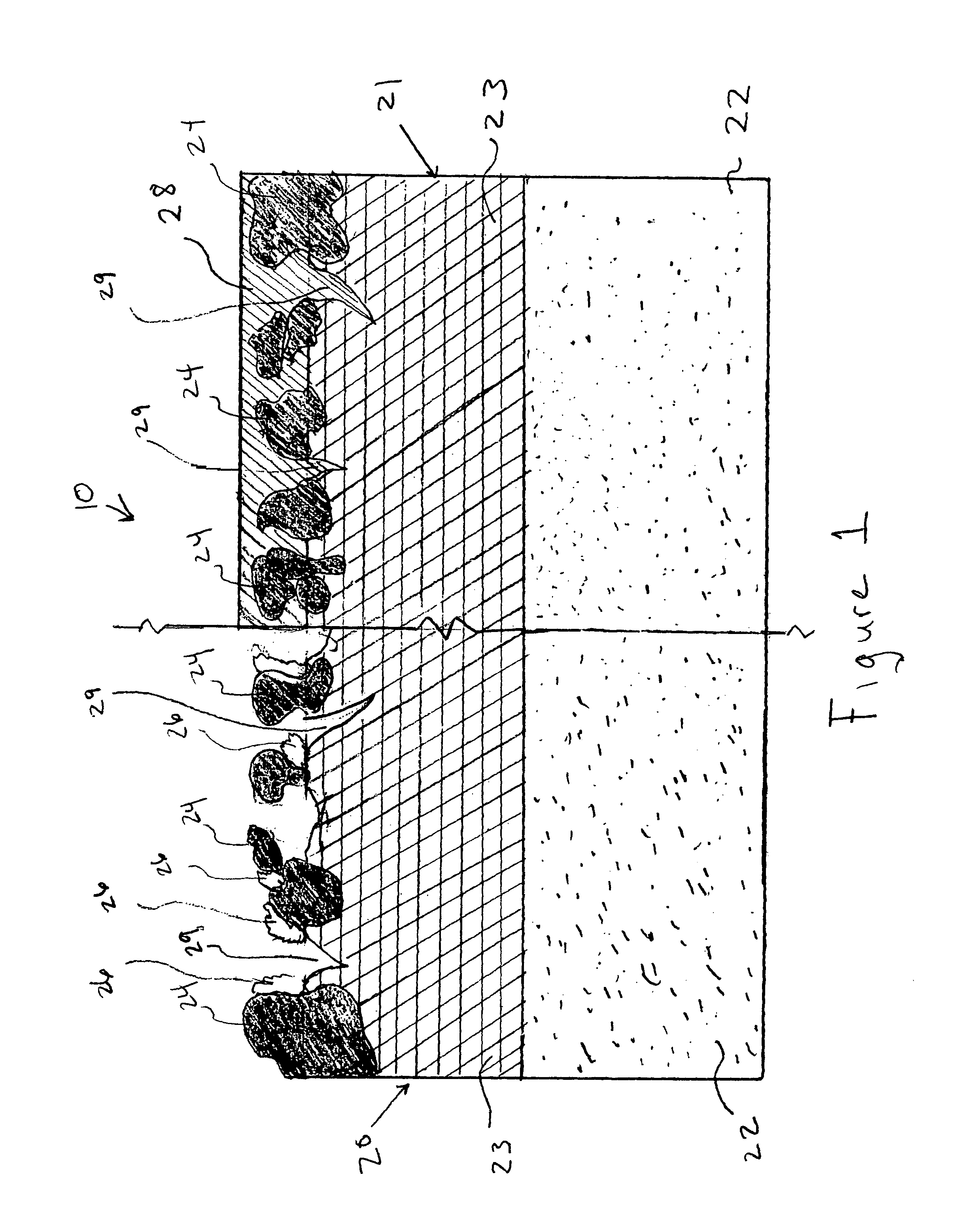

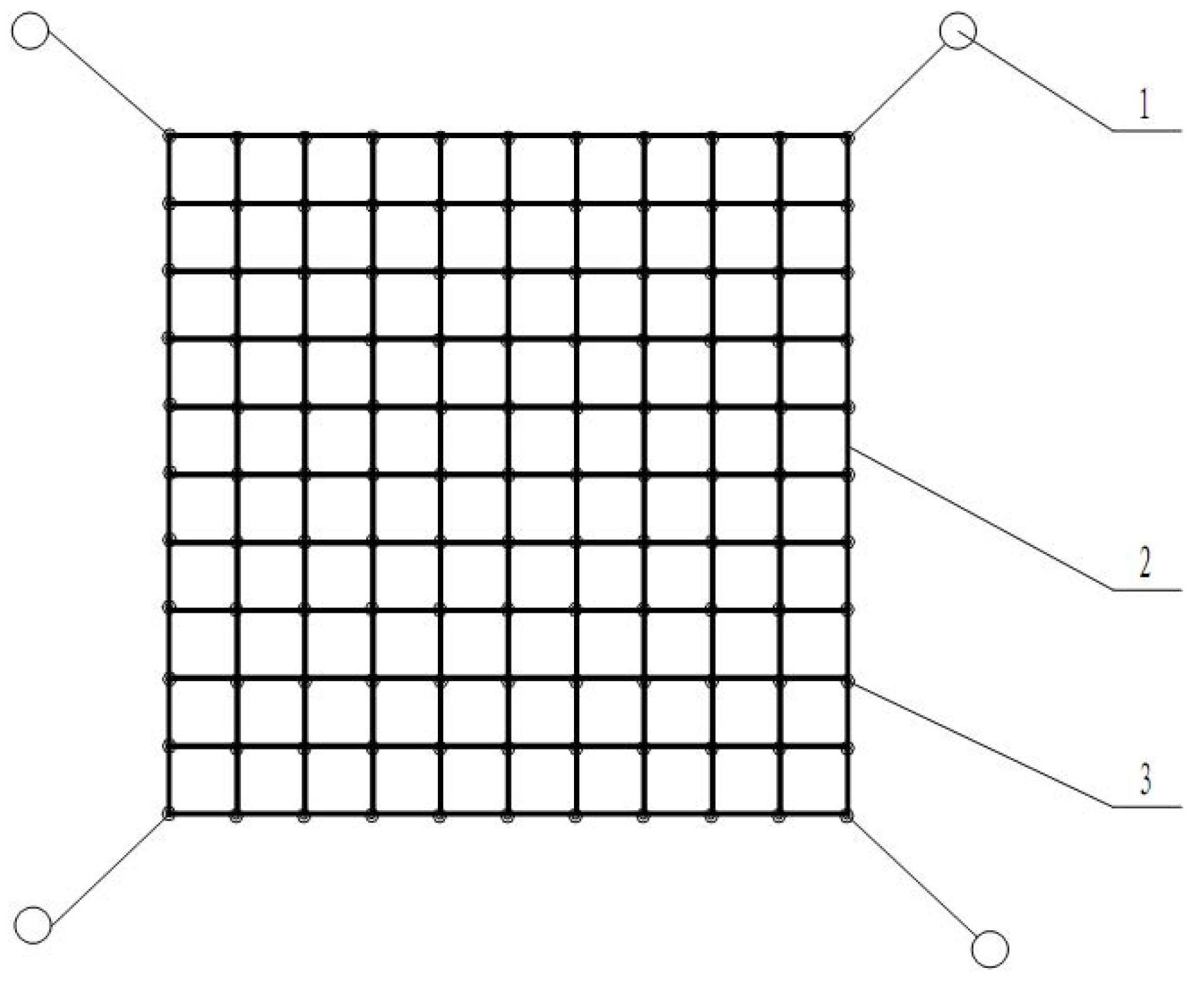

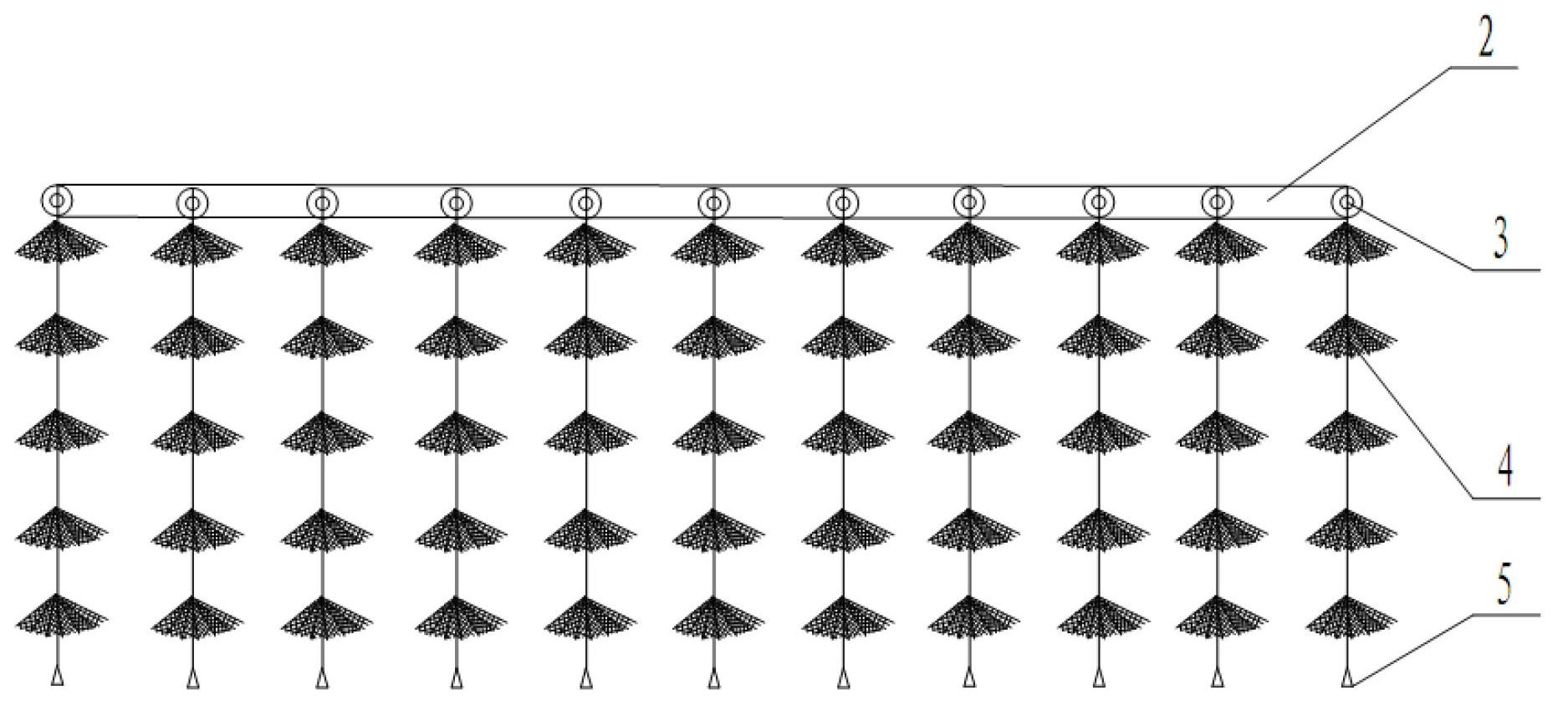

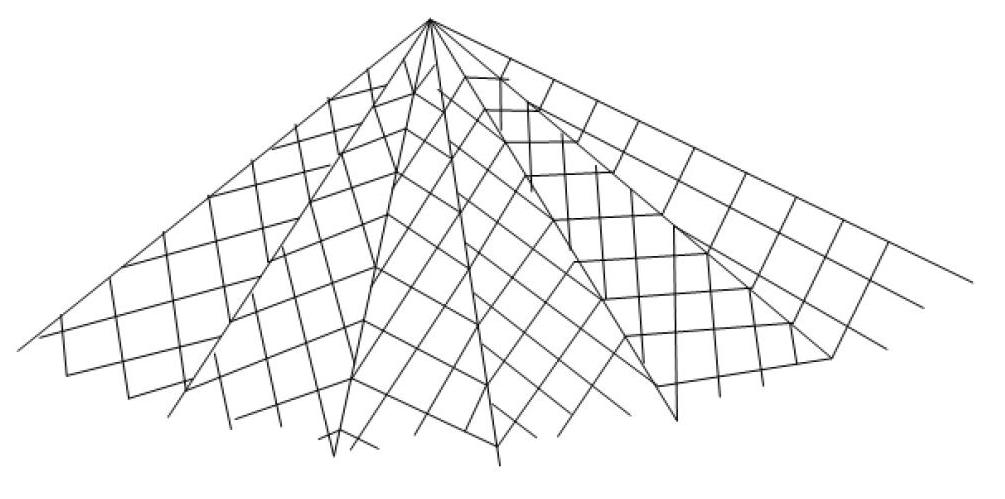

Three-dimensional artificial fish nest with floating frame for adhesive eggs

InactiveCN102657124AIncreased adhesion areaSuitable for artificial breedingClimate change adaptationPisciculture and aquariaThree-dimensional spaceEngineering

The invention discloses a three-dimensional artificial fish nest with a floating frame for adhesive eggs. The three-dimensional artificial fish nest is characterized by comprising fixed piles and the floating frame, wherein the floating frame is fixed on the fixed piles via fixing cables, a plurality of cables suspended with sinkers are arranged below the floating frame, and a plurality of adhesion matrixes are uniformly bound on each cable. The three-dimensional artificial fish nest disclosed by the invention can imitate the roots of aquatic plants or trees needing to be well adhered by fertilized eggs, and provide an omni-directional and three-dimensional type batch development place for the fertilized eggs of fishes laying adhesive eggs. The three-dimensional artificial fish nest is simple in structure, as well as convenient to throw and detach; a floating-type structure is not easy to be influenced by the change of a water surface; the adhesion area of the fish eggs is larger, and the three-dimensional space of a water body is adequately utilized; and large-scale propagation conditions can be provided for artificial breeding for fishes laying adhesive eggs living in different water layers and resource enhancement for natural populations. The three-dimensional artificial fish nest is especially suitable for artificial breeding for fishes living in the middle layer and the low layer of the water body.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Method for manufacturing semiconductor device and semiconductor device

InactiveCN1835196ASimple designSolve the removal problemSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device fabrication

A semiconductor device production method which includes steps of: preparing a wafer on which multiple integrated circuits are formed on a principal face; forming a rewiring which is electrically connected to the integrated circuits via a pad electrode; and dicing the wafer after forming an electrode terminal on the rewiring, including steps of: forming a first resin layer by sealing at least the rewiring and the electrode terminal formed on the principal face of the wafer with a first resin; processing a first dicing from a back face of the wafer to the principal face of the wafer or halfway to the first resin layer when the first resin layer is formed; forming a second resin layer by sealing a cut line outlined upon the first dicing and the back face of the wafer continuously with a first resin; and processing a second dicing while leaving the second resin layer which covers a side face outlined upon the first dicing.

Owner:YAMAHA CORP

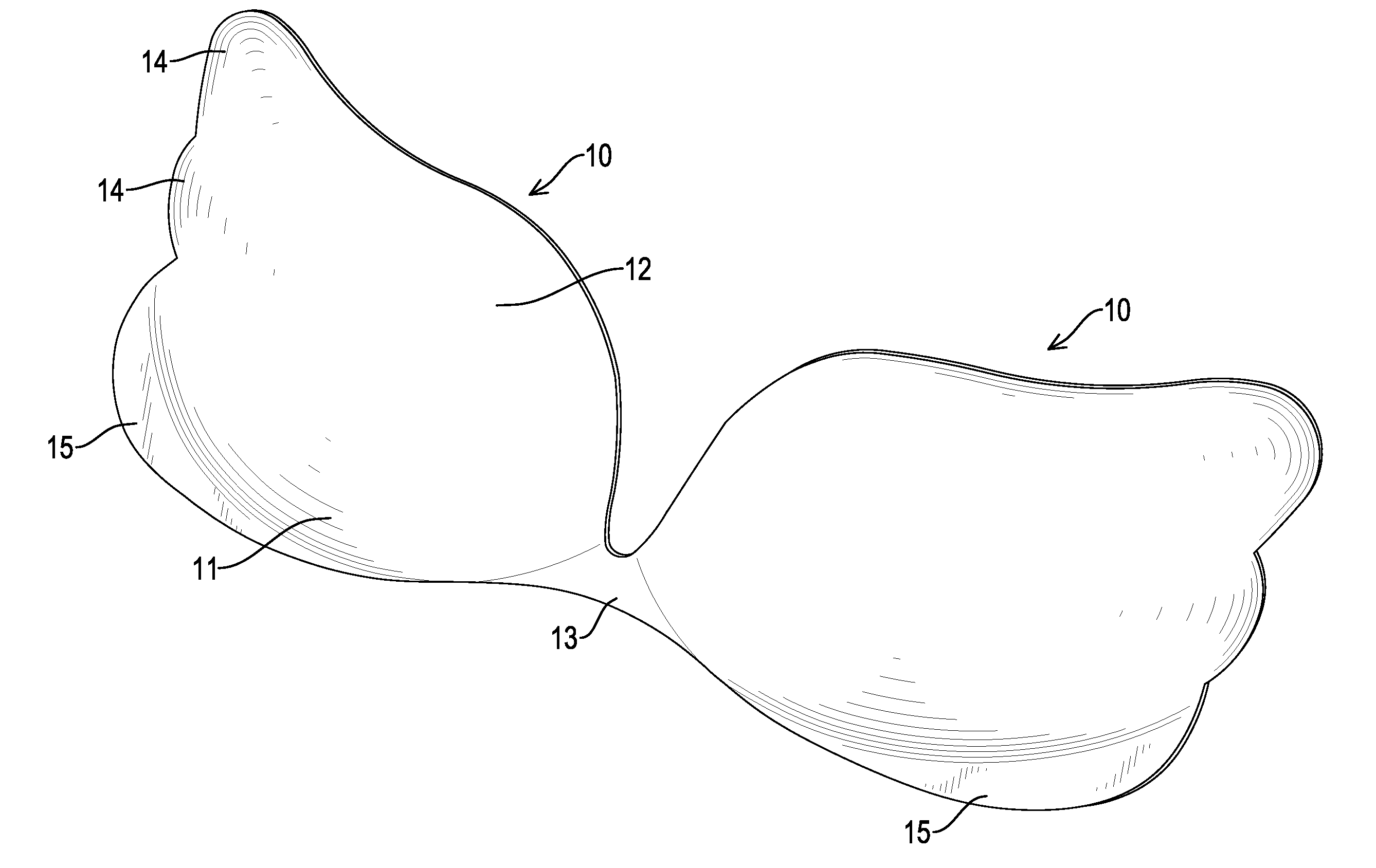

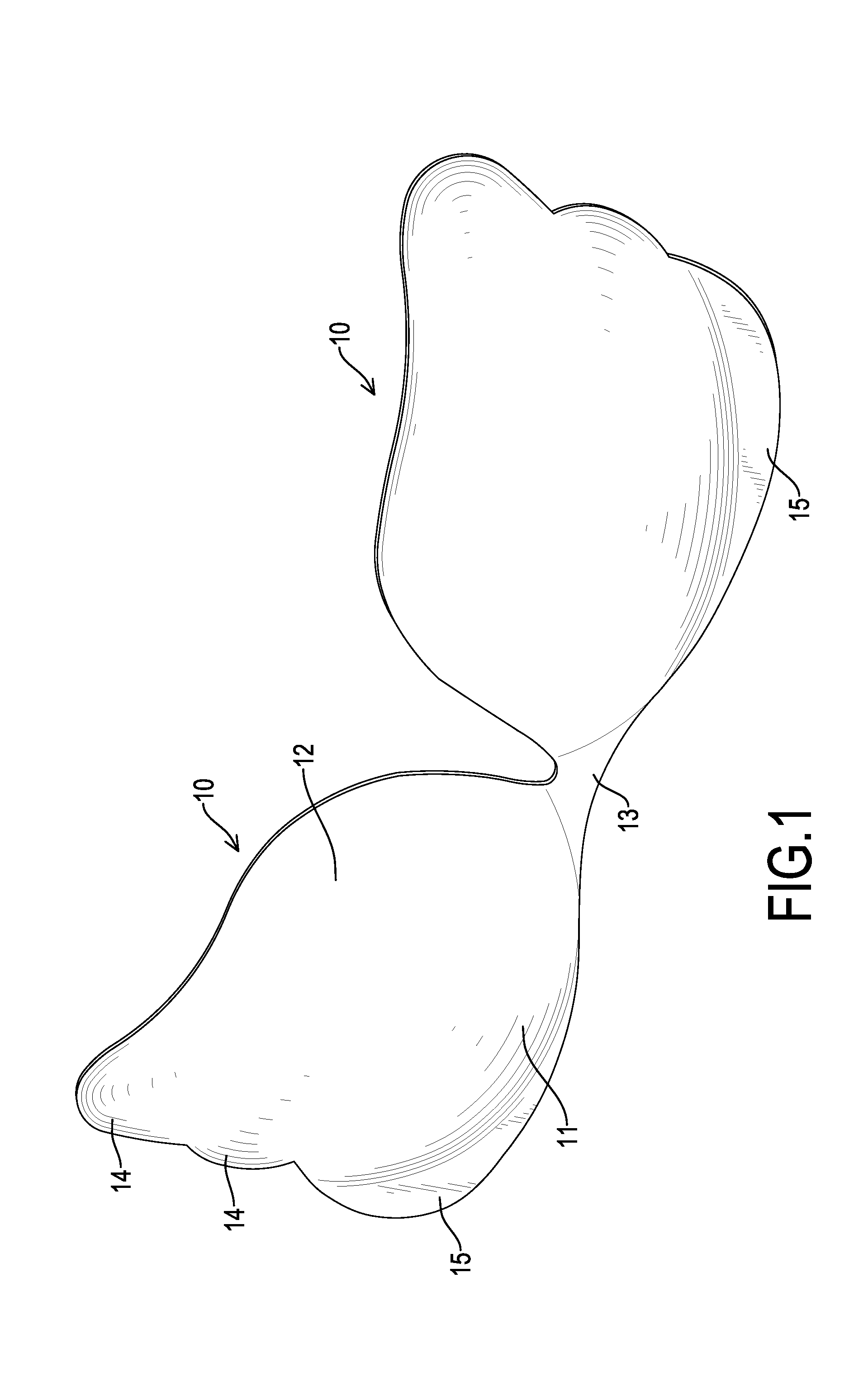

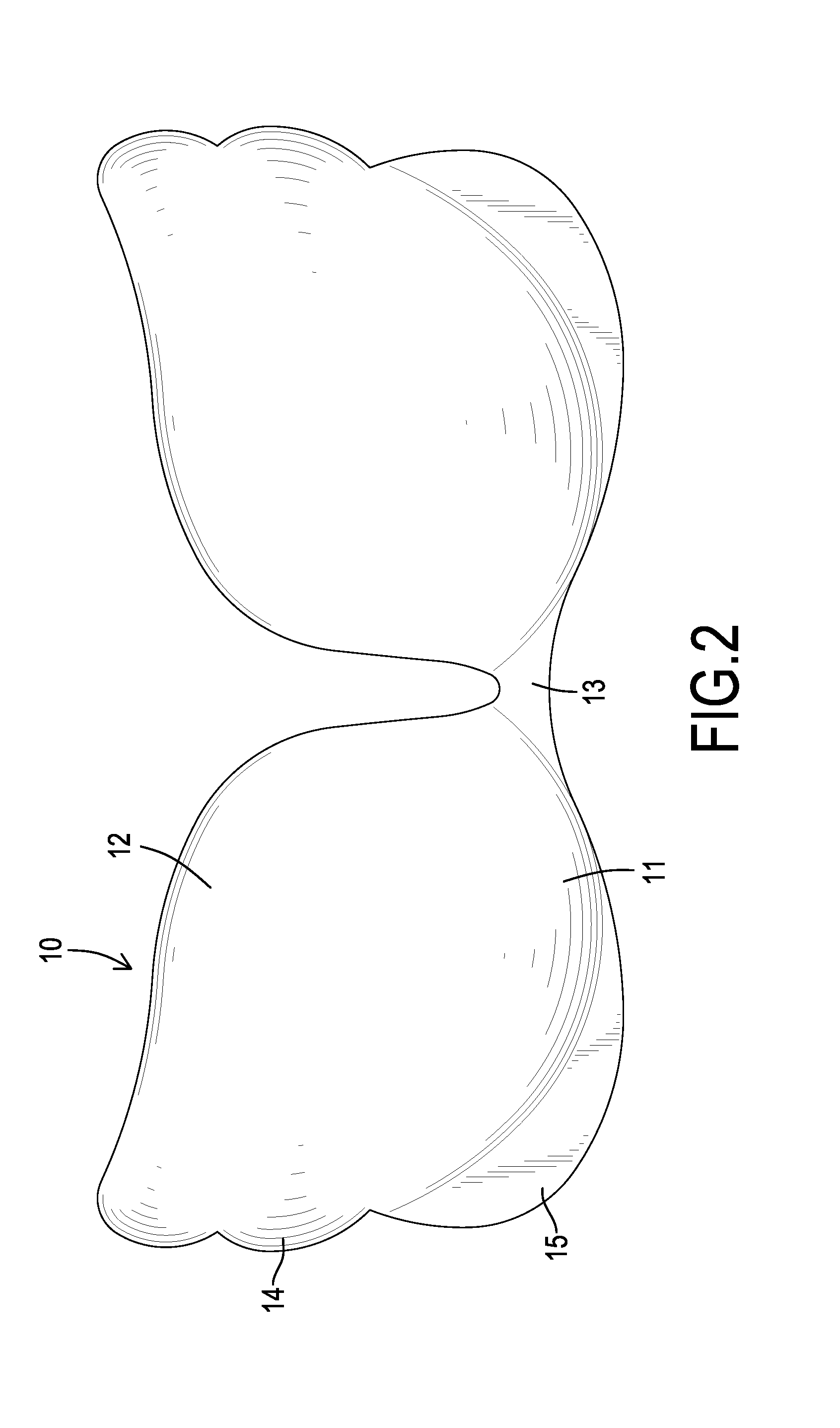

Backless strapless bra

InactiveUS20140273739A1Shorten the timeIncreased adhesion areaBrassieresMechanical engineeringEngineering

Owner:CHANG JU CHUNG

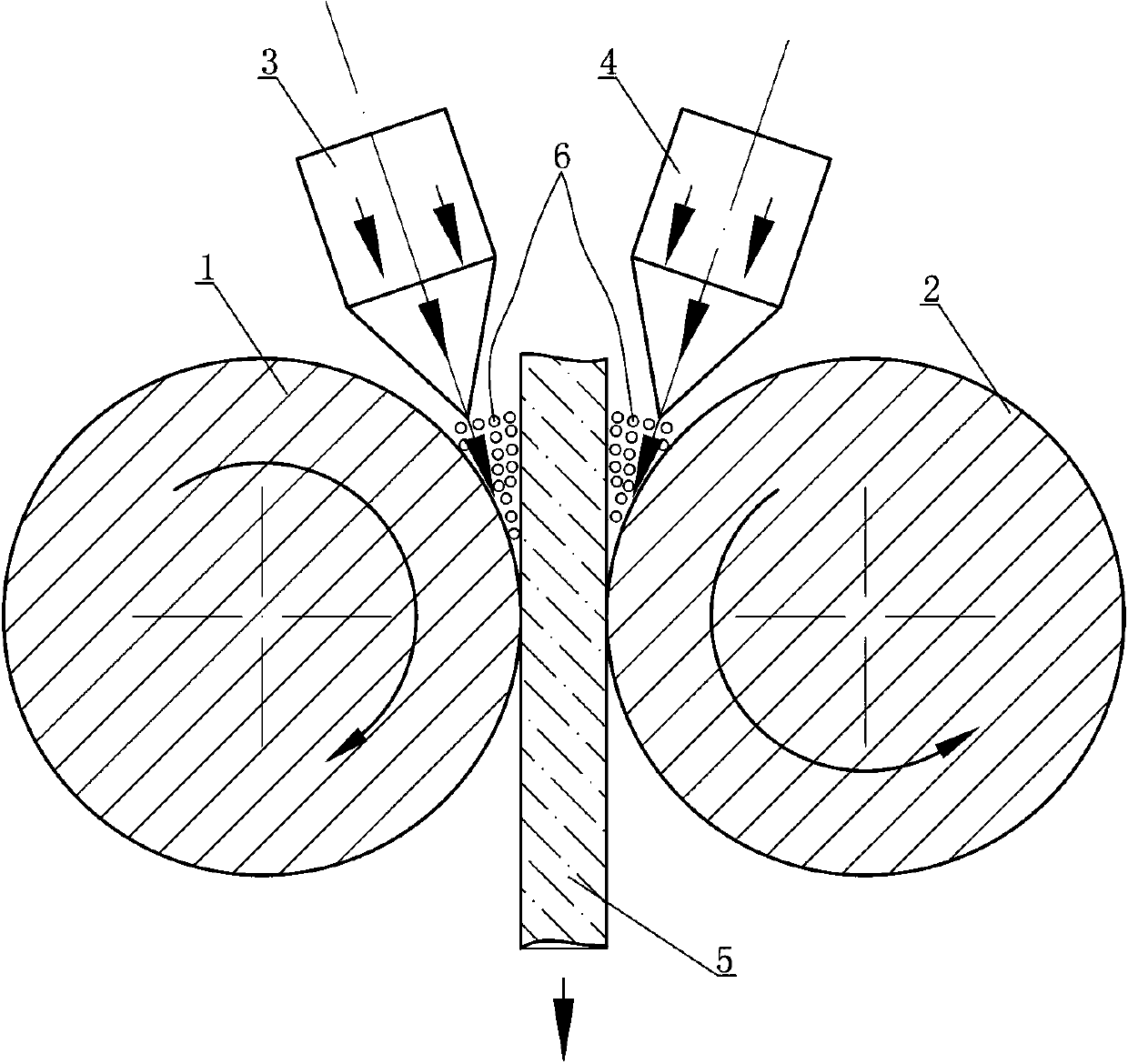

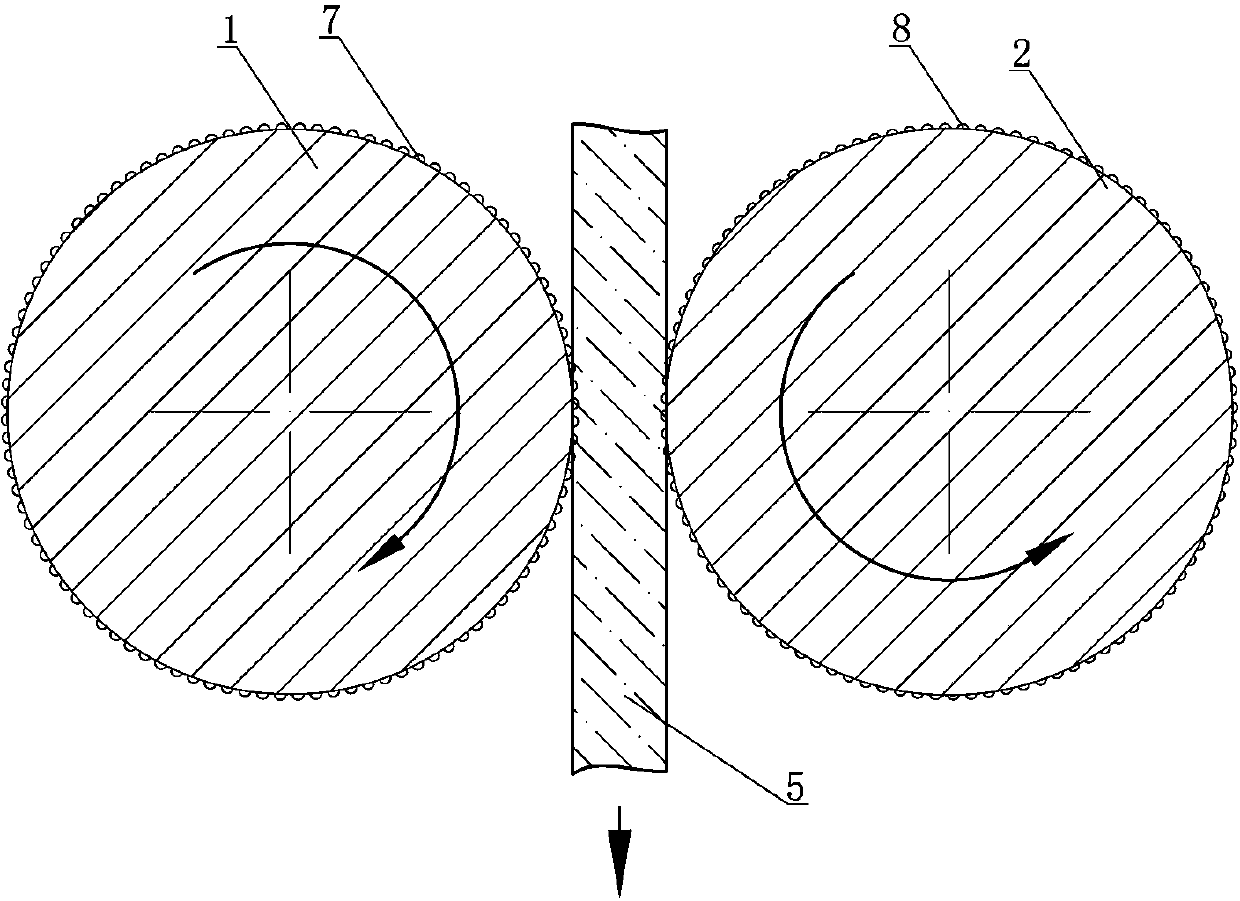

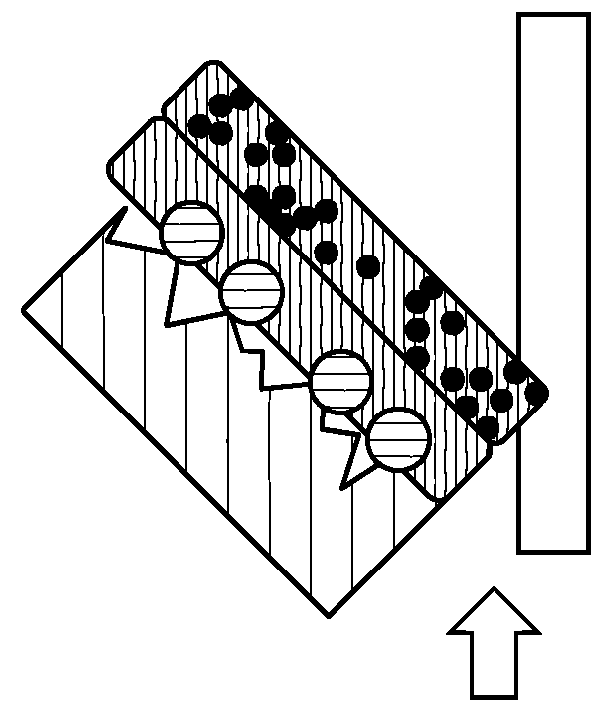

Concave pit lithium ion battery current collector as well as manufacturing method and equipment of concave pit lithium ion battery current collector

ActiveCN103811768AIncreased adhesion areaNo pollution in the processElectrode carriers/collectorsCurrent collectorEngineering

The invention provides a concave pit lithium ion battery current collector as well as a manufacturing method and equipment of concave pit lithium ion battery current collector. The manufacturing method comprises the following steps: filling the part between the current collector and a leftward roller with grains with the rigidity which is greater than that of a current collector material by a leftward sand filling hopper above the leftward roller when the current collector passes through a rolling station between the leftward roller and a rightward roller; extruding by the leftward roller to form a left concave pit in one side of the current collector by the grains; or / and filling the part between the current collector and the rightward roller with the grains with the rigidity which is greater than that of the current collector material by a rightward sand filling hopper above the rightward roller; and extruding by the rightward roller to form a right concave pit in one side of the current collector by the grains. According to the concave pit lithium ion battery current collector as well as the manufacturing method and equipment of of the current collector, the contact face between an active material of the concave pit lithium ion battery current collector and the surface of the current collector is enlarged and the surface sticking area between the active material and the current collector is enlarged, so that the adhesion strength is easy to enhance and the contact conductivity is improved; a process for manufacturing the concave pit lithium ion battery current collector by using a sand filling and rolling method is simple and is suitable for large-scale industrial production.

Owner:深圳市旭然电子有限公司

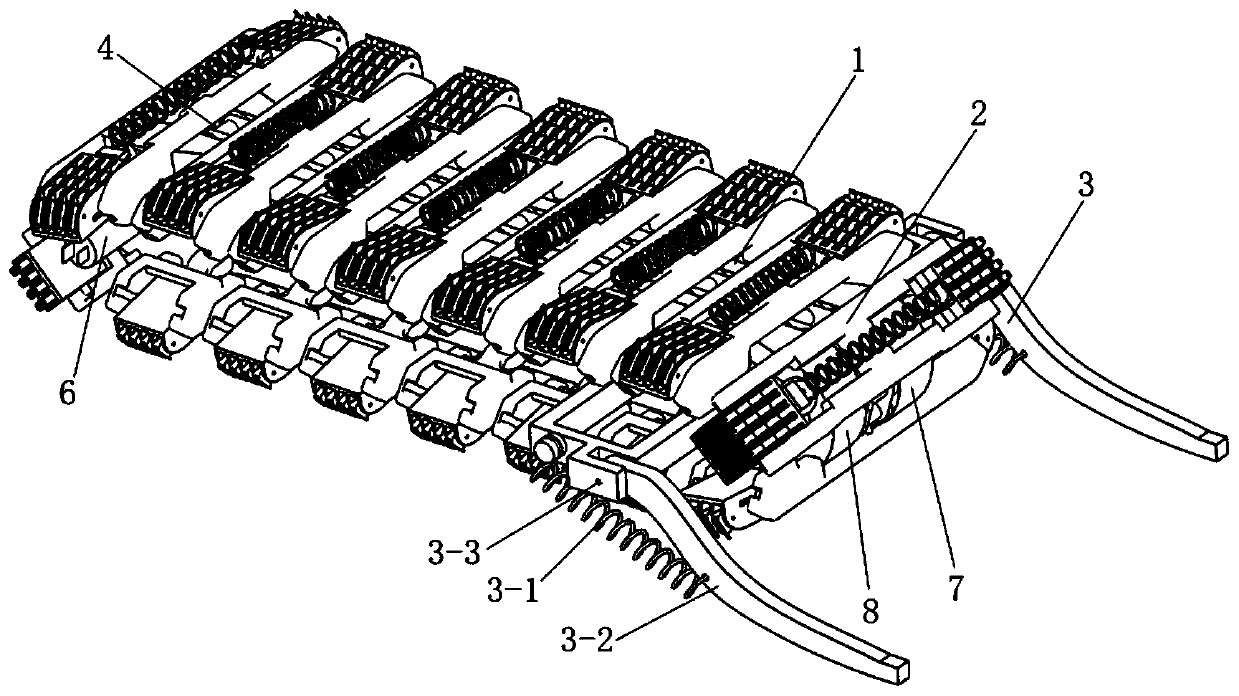

A claw-pair-grabbing type caterpillar track wall-climbing robot

The invention discloses a claw-pair-grabbing type caterpillar track wall-climbing robot which comprises a robot body. One end of the robot body is provided with a motor, and a sprocket is connected toan output shaft of the motor. The opposite sides of the other end of the robot body are respectively provided with elasticity tails. The robot body is also equipped with a claw-pair-grabbing type caterpillar track mechanism, and the claw-pair-grabbing type caterpillar track mechanism is connected to the sprocket. The robot body has cam-shaped structures on both sides which constitute cam mechanisms with claw foot adhesion mechanisms, and the cam mechanisms drive the claw foot adhesion mechanisms to perform adhesion / releasing motions. According to the invention, a claw-pair-grabbing type caterpillar track is adopted, and the loading capability is improved through a claw-pair-grabbing mode. Meanwhile, the track structure has the advantage of a large adhesion area, and can be crawl on roughceilings.

Owner:XIAN UNIV OF TECH

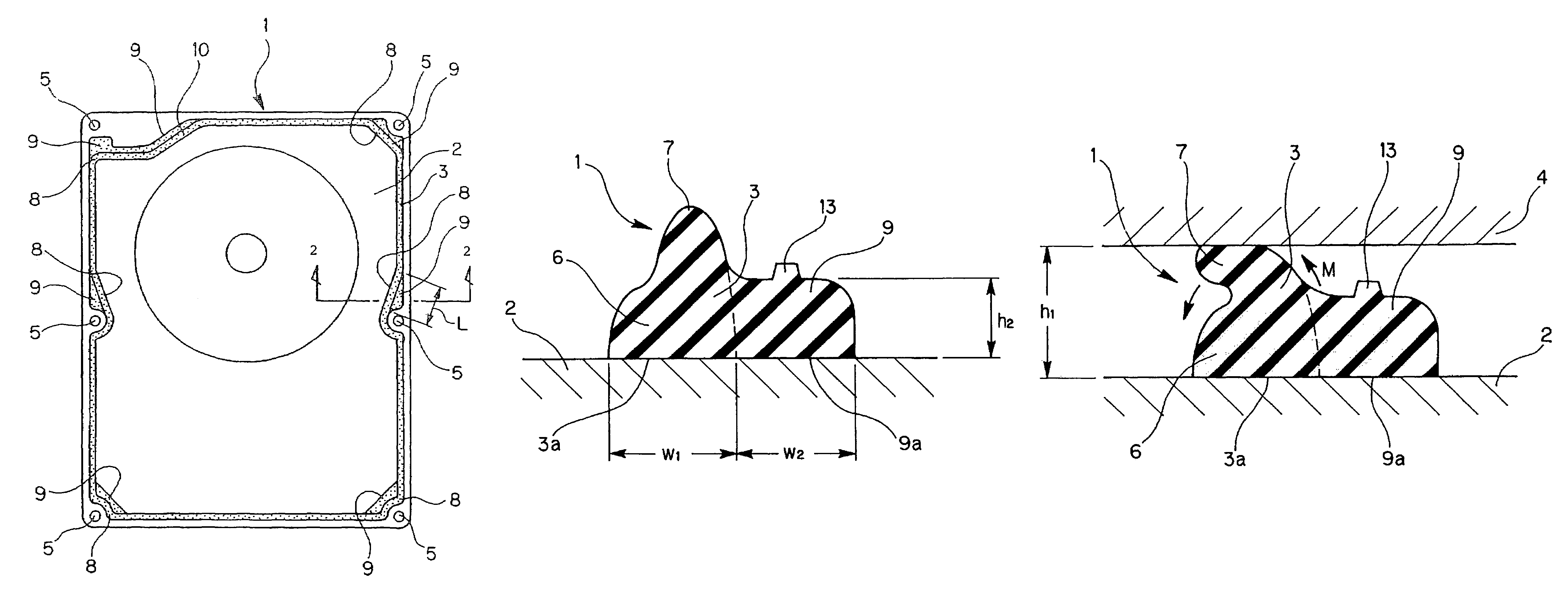

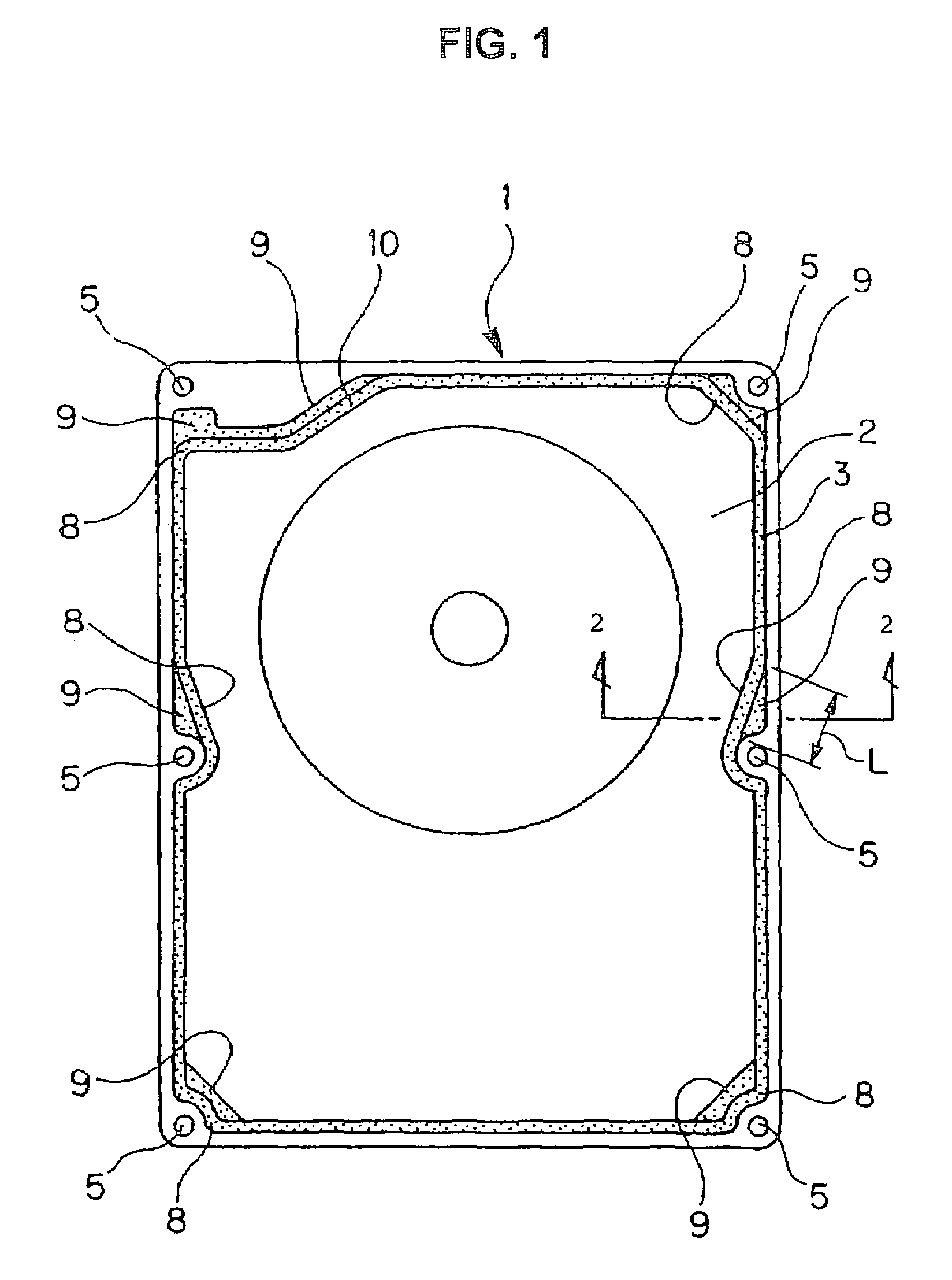

Gasket for hard disc drive having compressible lip and extension portion at screw fixing/inflection portions

InactiveUS7389992B2EffectivelyEasy to useEngine sealsApparatus for flat record carriersHard disc driveEngineering

Owner:NIPPON MEKTRON LTD

Liquid crystal display device

The present invention provides a liquid crystal display device which can enhance quality and reliability of image display by preventing the generation of bubbles in the inside of a liquid crystal display panel and, at the same time, by suppressing leaking of light from an end of a black matrix film. In the liquid crystal display panel which sandwiches a liquid crystal layer between two glass substrates, the liquid crystal layer is surrounded by a sealing material having a predetermined width. On one glass substrate, a black matrix film and an overcoat film are arranged from one-glass-substrate side such that the black matrix film and the overcoat film overlap the sealing material. The black matrix film is, in the widthwise direction of the sealing material, formed into a planar flat black matrix film until a middle position of the sealing material from a side on which the liquid crystal layer is arranged, and is formed into a slit-shaped slit black matrix film from the middle position. Due to such a constitution, an adhesion area between the glass substrate and the overcoat film under an applied region of the sealing material is enlarged and hence, an adhesion strength is increased thus largely enhancing an adhesion strength.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

Target material assembly and machining method thereof

InactiveCN107513691AIncrease capacityReduce flakingVacuum evaporation coatingSputtering coatingEngineeringMachining

The invention provides a target material assembly and a machining method thereof. The target material assembly comprises a backing plate, a target billet and an annular adsorption structure, wherein the backing plate comprises a welding area and a marginal area surrounding the welding area; the target billet is welded to the portion, located in the welding area, of the backing plate; and the annular adsorption structure is located in the portion, located in the marginal area, of the backing plate, surrounds the target billet, and comprises an annular adsorption groove, or the annular adsorption structure comprises an annular adsorption groove set, and the annular adsorption groove set comprises at least two annular adsorption grooves which are distributed in a concentric mode at intervals. The target material assembly provided by the invention comprises the annular adsorption structure which is located in the portion, located in the marginal area, of the backing plate, surrounds the target billet, and comprises one annular adsorption groove or the annular adsorption groove set, the annular adsorption groove set comprises the at least two annular adsorption grooves, in this way, in the sputtering process of a target material, re-sputtering materials can be stacked in the annular adsorption grooves, and accordingly, the situation that the re-sputtering materials are peeled off and fall onto a silicon wafer is reduced or avoided.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

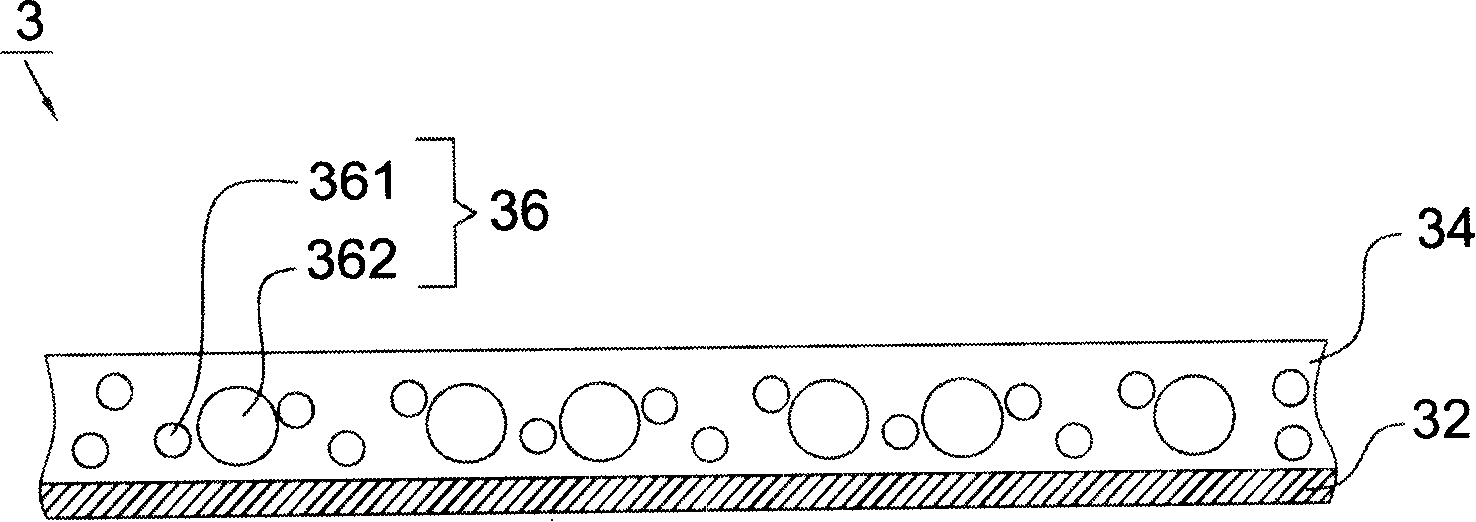

Glue film and chip encapsulation manufacture process using the glue film

ActiveCN101202252AAvoid crackingIncreased adhesion areaOther chemical processesFilm/foil adhesivesElastomerEngineering

A glue film comprises removable substrate, a resin layer and a plurality of arc elastic bodies; wherein, the resin layer which is partially curing resin is in a semi-melting status with viscosity above a first temperature and is in solid condition without viscosity under a second temperature, and the resin layer is adhesively arranged on the substrate; the arc elastic bodies are arranged in the resin layer. The invention additionally provides the packaging procedure of a chip using the glue film.

Owner:ORIENT SEMICON ELECTRONICS

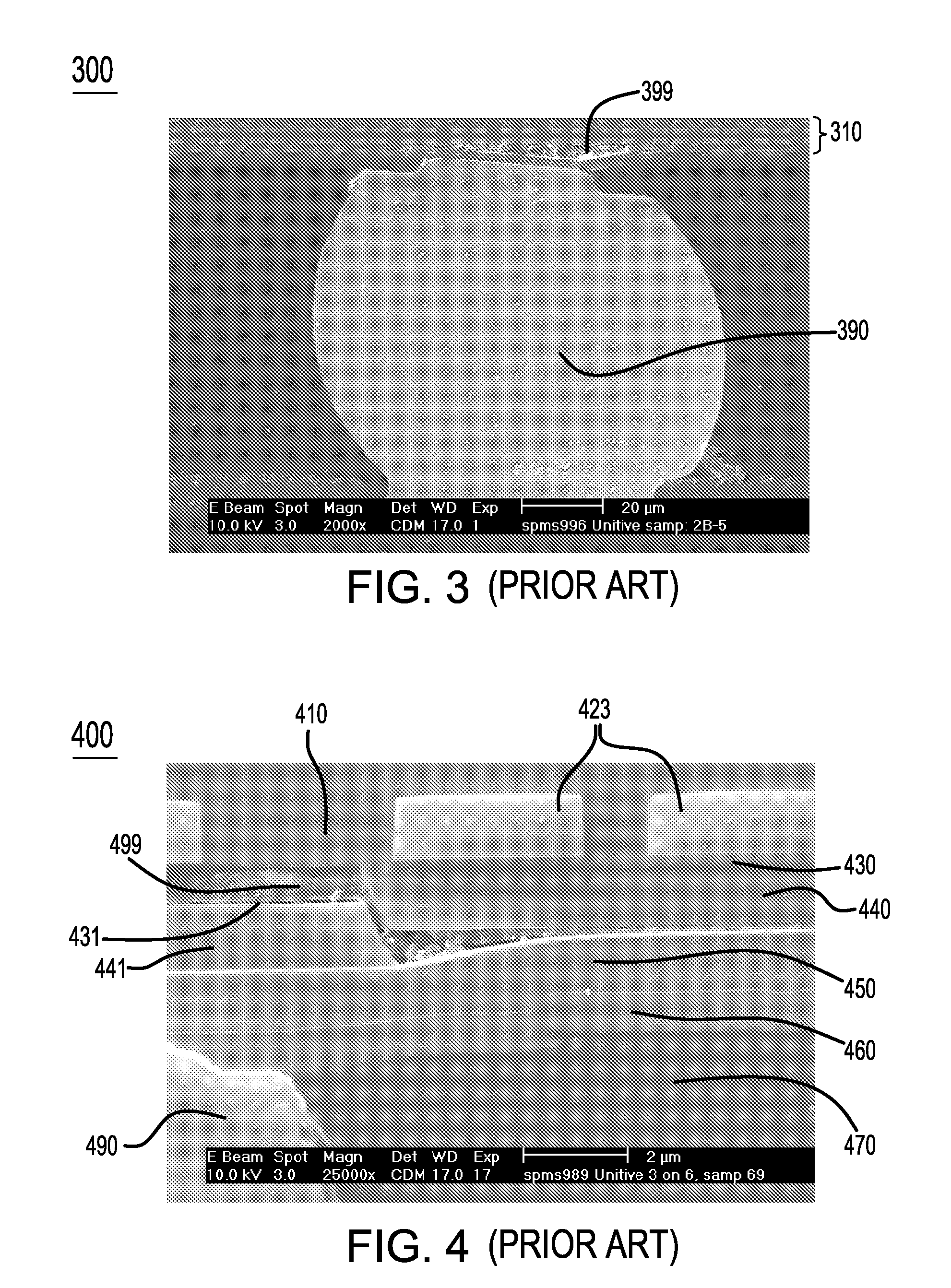

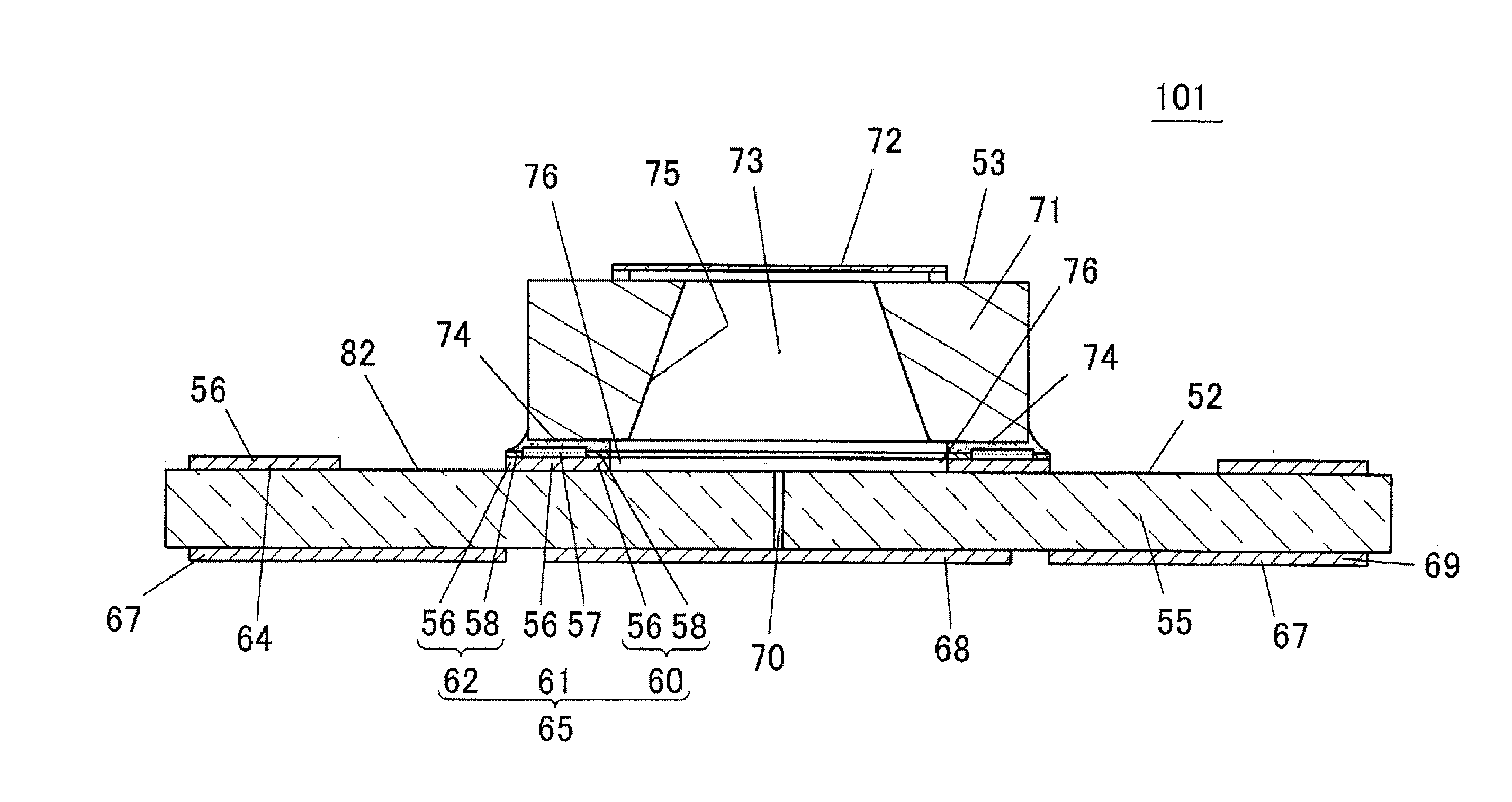

Semiconductor device

ActiveUS20110204457A1Reduce gapSpeed up the flowSemiconductor/solid-state device detailsSemiconductor electrostatic transducersEngineeringDie bonding

A semiconductor device has a semiconductor element having a base, a cavity having a polygonal horizontal cross-section penetrating vertically through the base, a diaphragm arranged on the base to cover the cavity, and a substrate formed with a die bonding pad. A lower surface of the semiconductor element is adhered on the die bonding pad with a die bonding resin. The die bonding pad is formed so as not to contact a lower end of a valley section formed by an intersection of wall surfaces of an inner peripheral surface of the cavity of the semiconductor element.

Owner:MMI SEMICON CO LTD

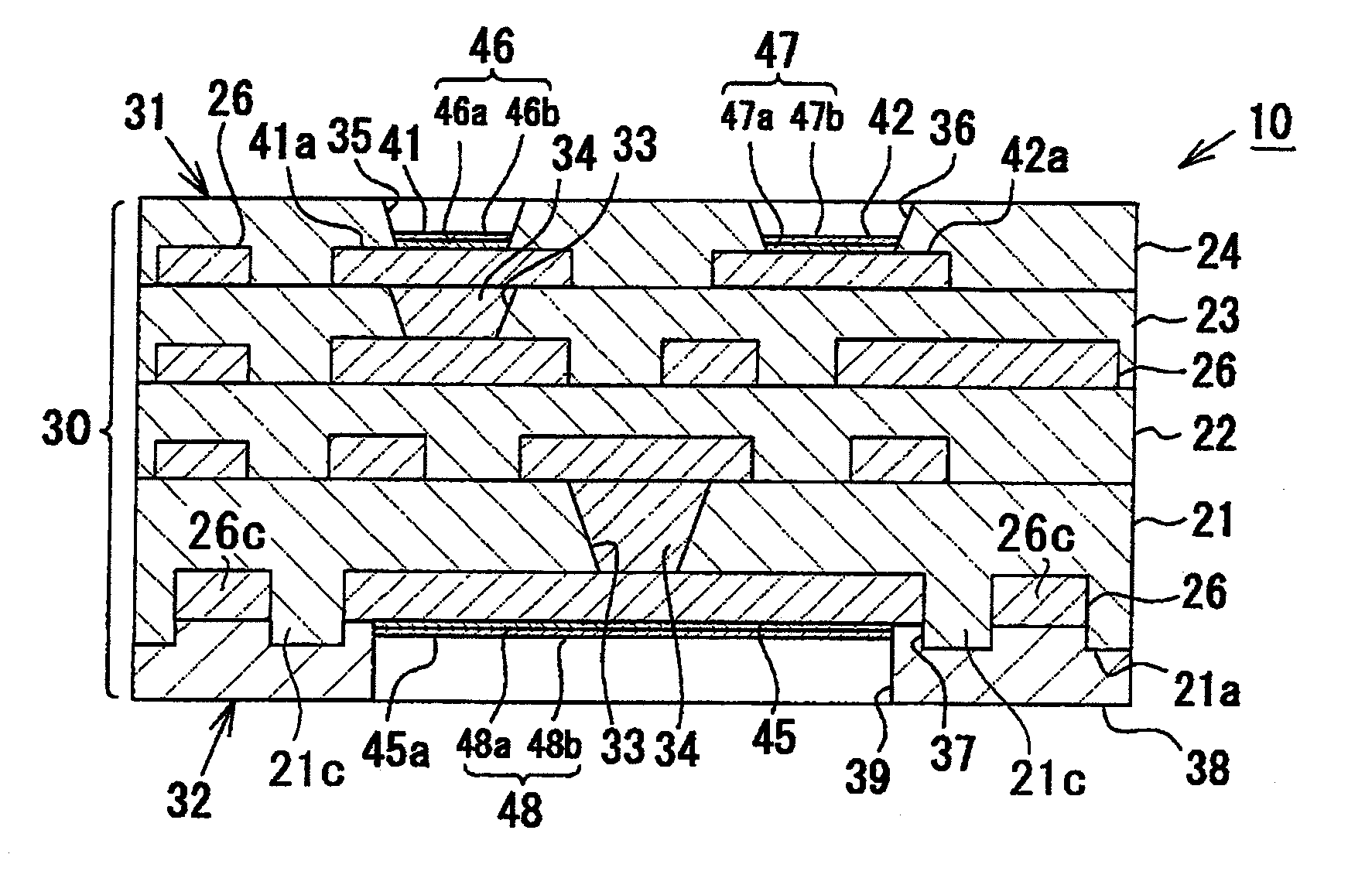

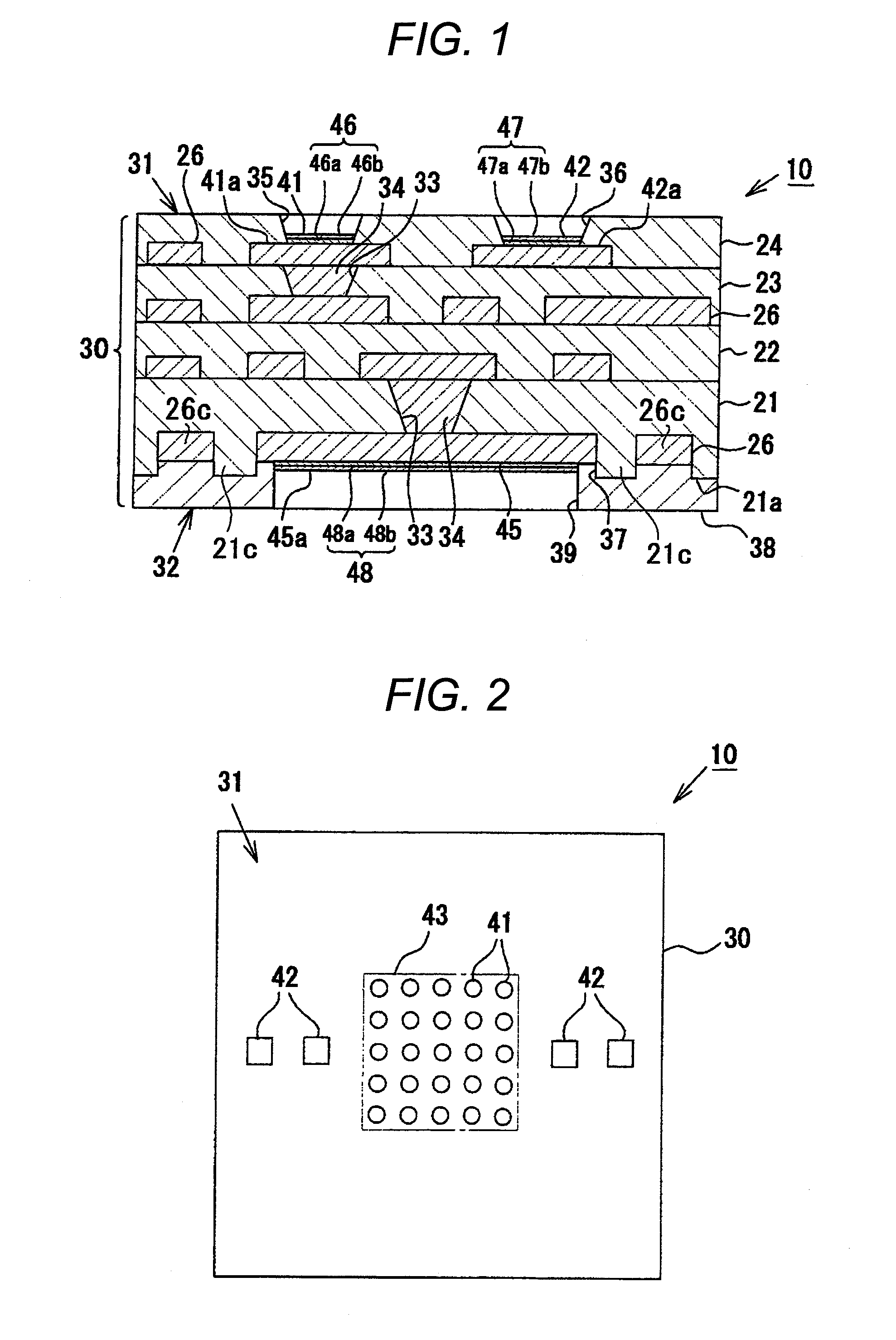

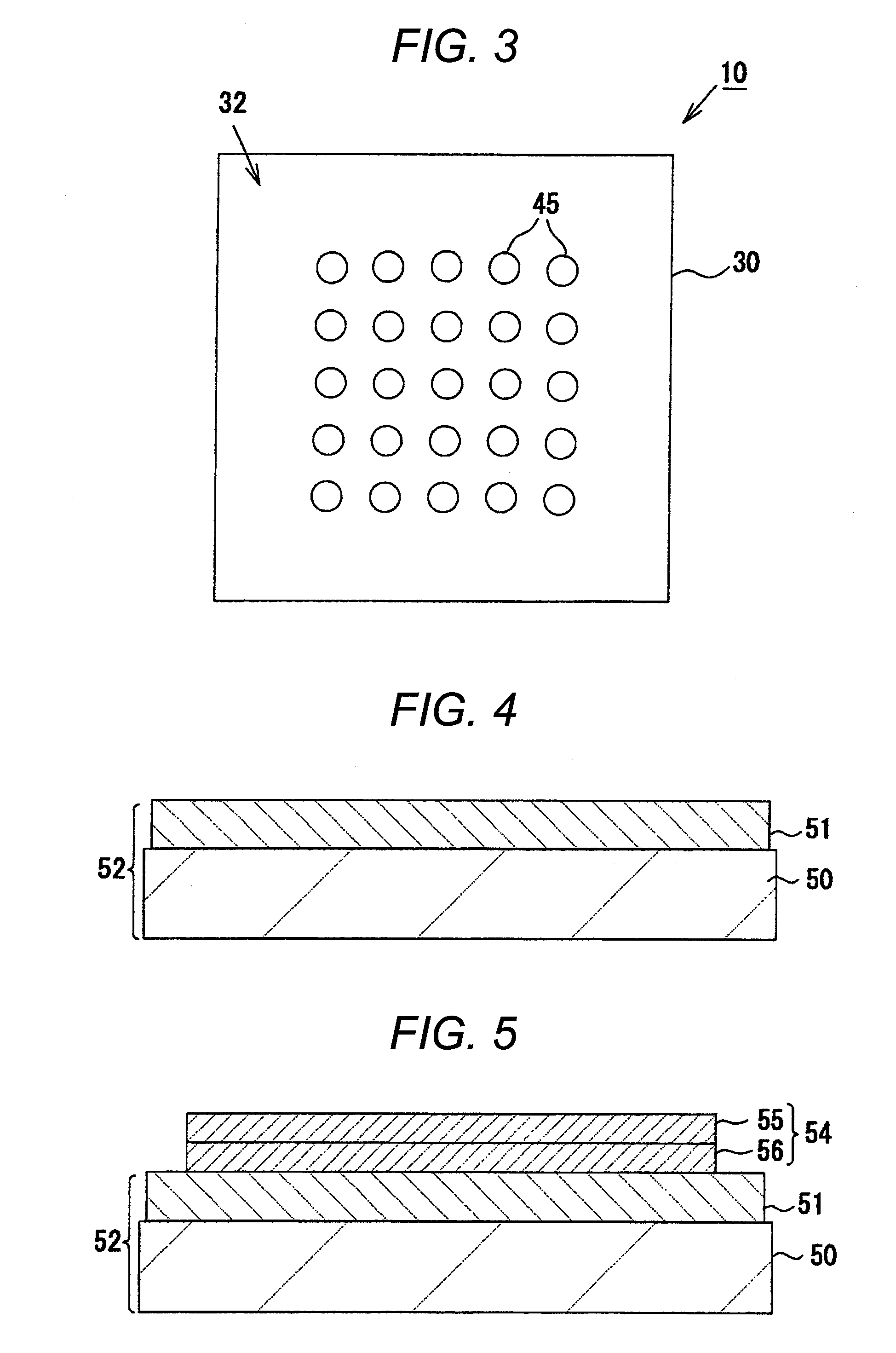

Multilayered Wiring Board and Method of Manufacturing the Same

InactiveUS20110209910A1High bonding strengthHigh strengthElectrically conductive connectionsPrinted circuit aspectsResistInsulation layer

A multilayered wiring board having a stack structure multilayered by alternately stacking a plurality of conductor layers and a plurality of resin insulation layers, wherein a solder resist is provided on at least one of a first main surface side and a second main surface side of the stack structure, a plurality of openings are formed in an outermost resin insulation layer that contacts with the solder resist, a plurality of the first main surface side connecting terminals or a plurality of the second main surface side connecting terminals being made of a copper layer as a main component and positioned in a plurality of the openings, terminal outer surfaces being positioned inwardly from an outer surface of the outermost resin insulation layer, and the solder resist extends into the plurality of openings and makes contact with an outer circumference portion of each of the terminal outer surfaces.

Owner:NGK SPARK PLUG CO LTD

Optical module and process for manufacturing the same

An optical module includes a lens-containing optically-transmissive member and a receptacle. The receptacle includes: an optical connector-inserting section; a fixing section for fixing the member; and an device-installing section for installing a semiconductor device serving as a light emitting device or a light receiving device. The fixing section communicates with the device-installing section. The member includes a main body and a lens. The main body includes a first section and a second section, the first section having a first outer diameter, which is substantially equal to a internal diameter of said fixing section, and said second section having a second outer diameter, which is smaller than the first outer diameter, and at least containing an end of said main body in a side of the device-installing section.

Owner:RENESAS ELECTRONICS CORP

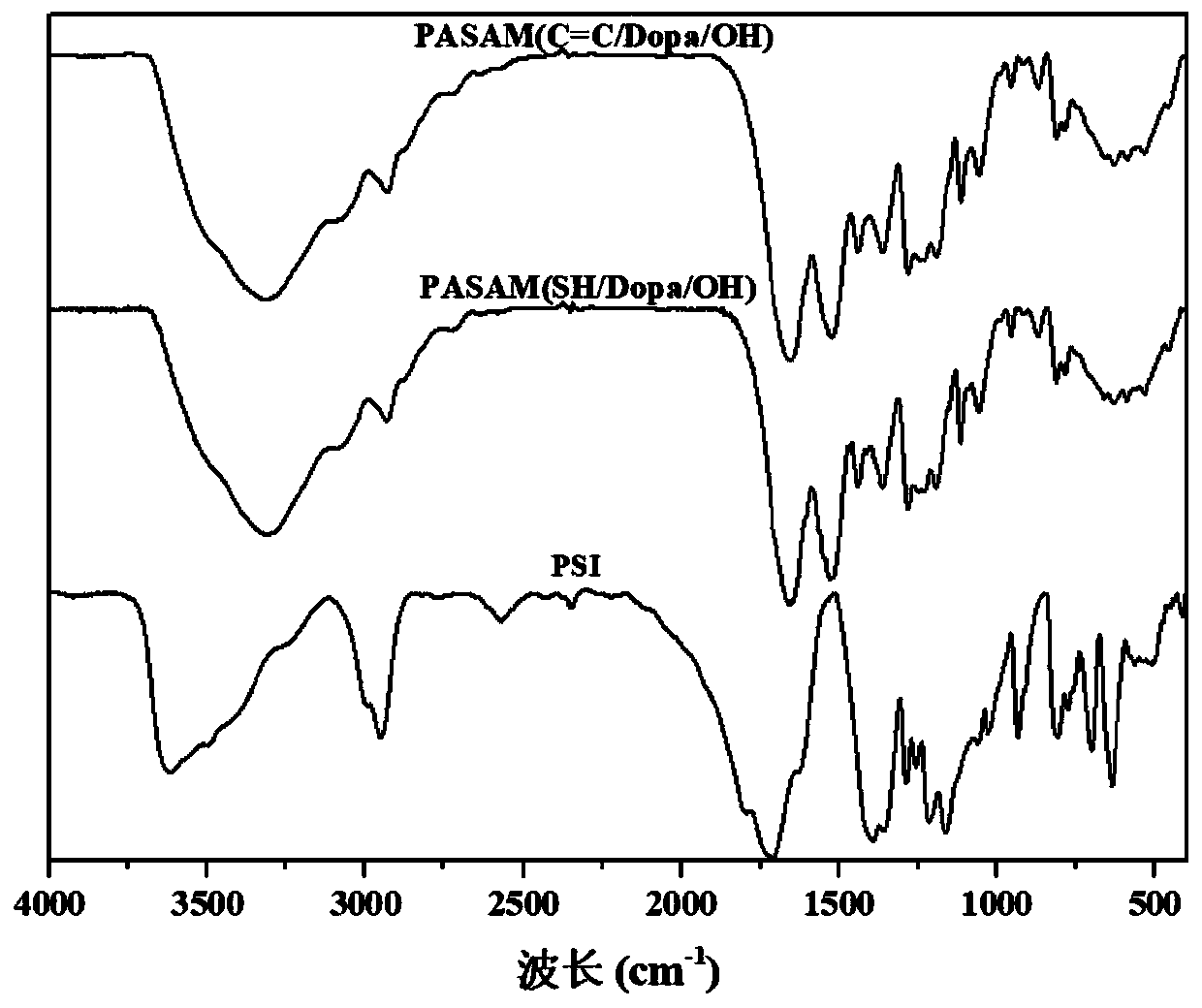

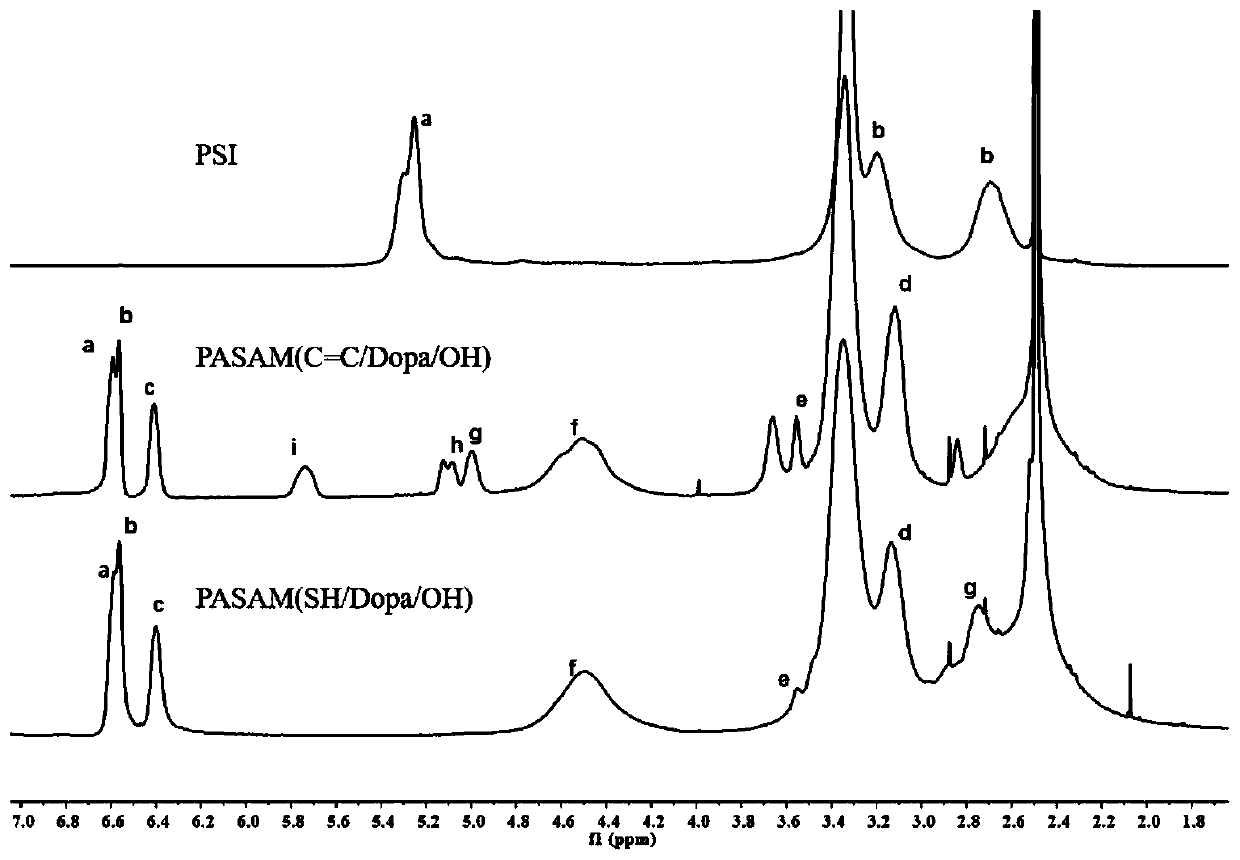

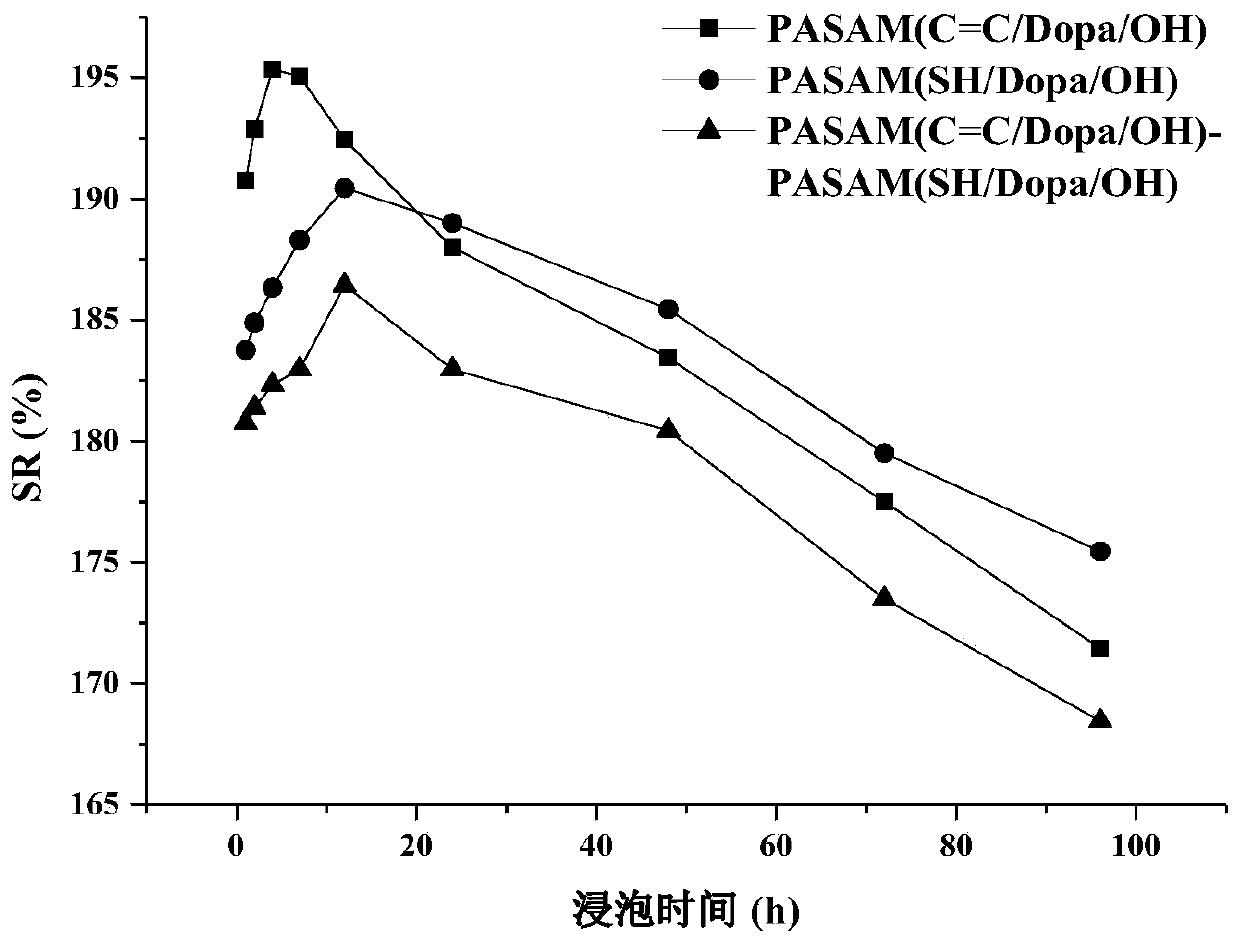

Dual-component in-situ injection type polyasparagine bionic tissue adhesive and preparing method thereof

ActiveCN110101898AImprove water solubilityImprove adhesionSurgical adhesivesPharmaceutical delivery mechanismPolyasparagineSolvent

The invention discloses a dual-component in-situ injection type polyasparagine bionic tissue adhesive and a preparing method thereof. The tissue adhesive is composed of a first polyasparagine component solution and a second polyasparagine component solution with different reactive functional groups. A first component is polyasparagine with a vinyl functional group, a catechol functional group anda hydroxyl functional group, a second component is polyasparagine with a sulfydryl functional group, a catechol functional group and a hydroxyl functional group, a solvent of the first component is ahydrogen peroxide solution, and a solvent of the second component is a horse radish peroxidase solution. The catechol functional groups in the first component and the second component have the marinemussel imitation adhesion characteristic and can have noncovalent interaction with a tissue surface, the adhesive has tissue adhesiveness, and tissue repairing is realized. The tissue adhesive has excellent tissue adhesive strength and use convenience and has important significance in replacing surgical sutures and healing wounds.

Owner:SOUTH CHINA UNIV OF TECH

Self-luminous temperature testing patch

InactiveCN105675155ATroubleshoot Overtemperature Monitoring IssuesSimple structureThermometer detailsEmbedded systemTemperature testing

The invention provides a self-luminous temperature testing patch. The self-luminous temperature testing patch comprises an over-temperature warning device and a pasting piece. The over-temperature warning device is arranged on the pasting piece. According to the invention, the pasting piece is formed by a pressure-sensitive adhesive, and the patch is enabled to be attached to a corresponding test position conveniently and rapidly. When a tested temperature exceeds a preset temperature, the over-temperature warning device is capable of emitting light, and patrol persons determine a temperature measurement position through the light and judge whether a serious overheating phenomenon happens in the test position, so that a corresponding processing measure is adopted.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

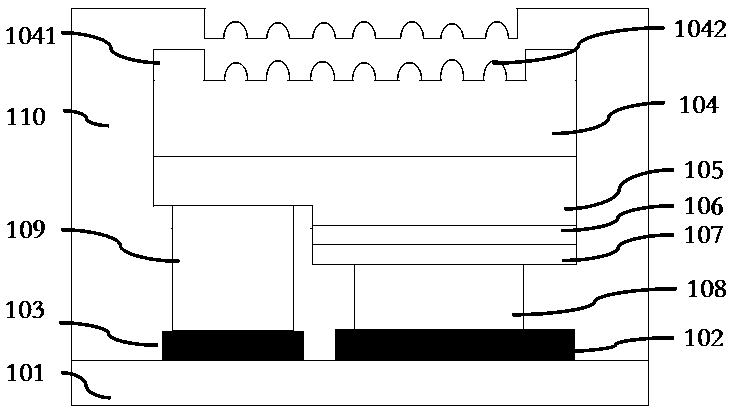

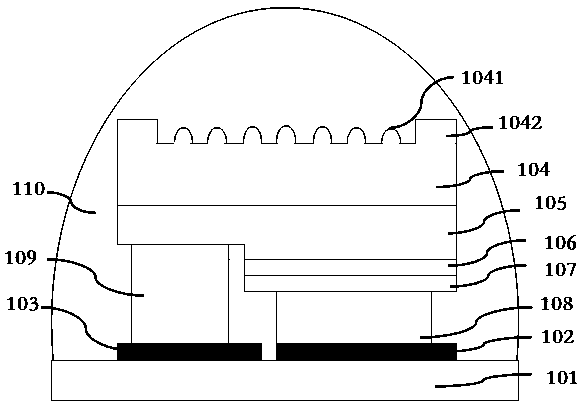

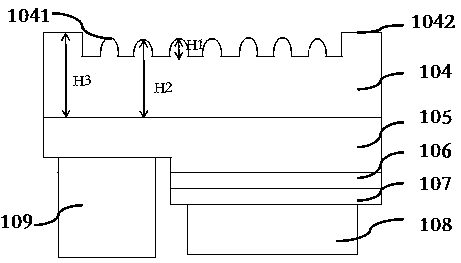

Ultraviolet light-emitting element, ultraviolet light-emitting element packaging body and manufacturing method thereof

ActiveCN110364604AIncrease stickinessGood adhesionSemiconductor devicesUltraviolet lightsSemiconductor

An ultraviolet semiconductor light-emitting element includes: a light-transmitting substrate, a semiconductor layer, and an electrode with opposite electrical properties, wherein the semiconductor layer and the electrode with opposite electrical properties are positioned on the first surface side of the light-transmitting substrate. The ultraviolet semiconductor light-emitting element is characterized in that the light-transmitting substrate is provided with a second surface side which is laterally opposite to the first surface and is a light-emitting surface side; the second surface side is divided into a first area on the inner side and a second area on the outer periphery; the first region is patterned or coarsened to be uneven; the second area is a relatively flat area relative to thefirst area; and the thickness of the substrate of the first area is smaller than that of the substrate of the second area or the thickness from the bottom of the uneven morphology of the first area tothe first surface side of the substrate is equal to or larger than the thickness of the substrate of the second area. Through the uneven morphology of the first area, the adhesion of the packaging resin is effectively improved; the second area effectively prevents the resin from being damaged and achieves a buckling effect on the packaging resin; and the light emitting effect is improved.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

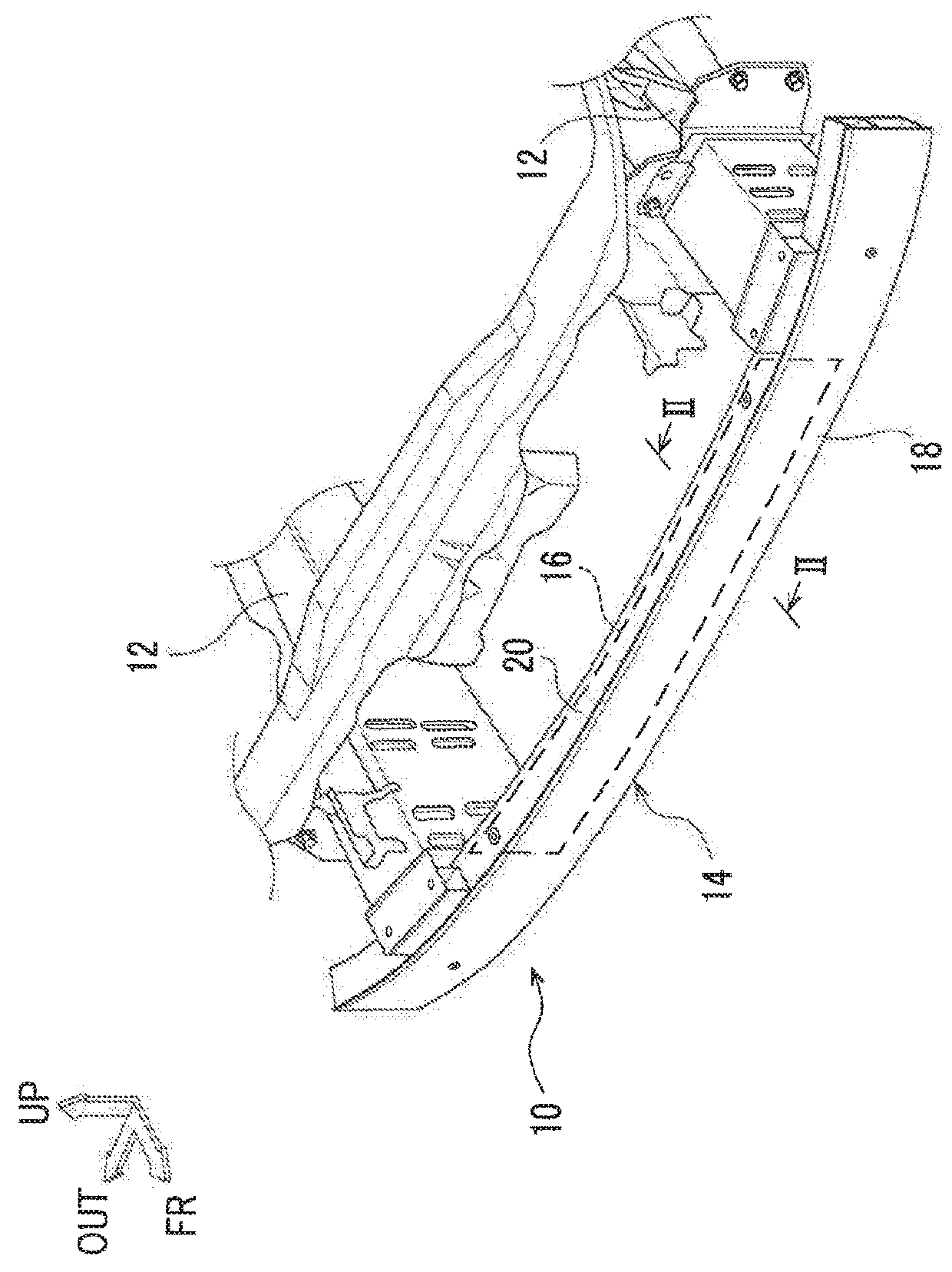

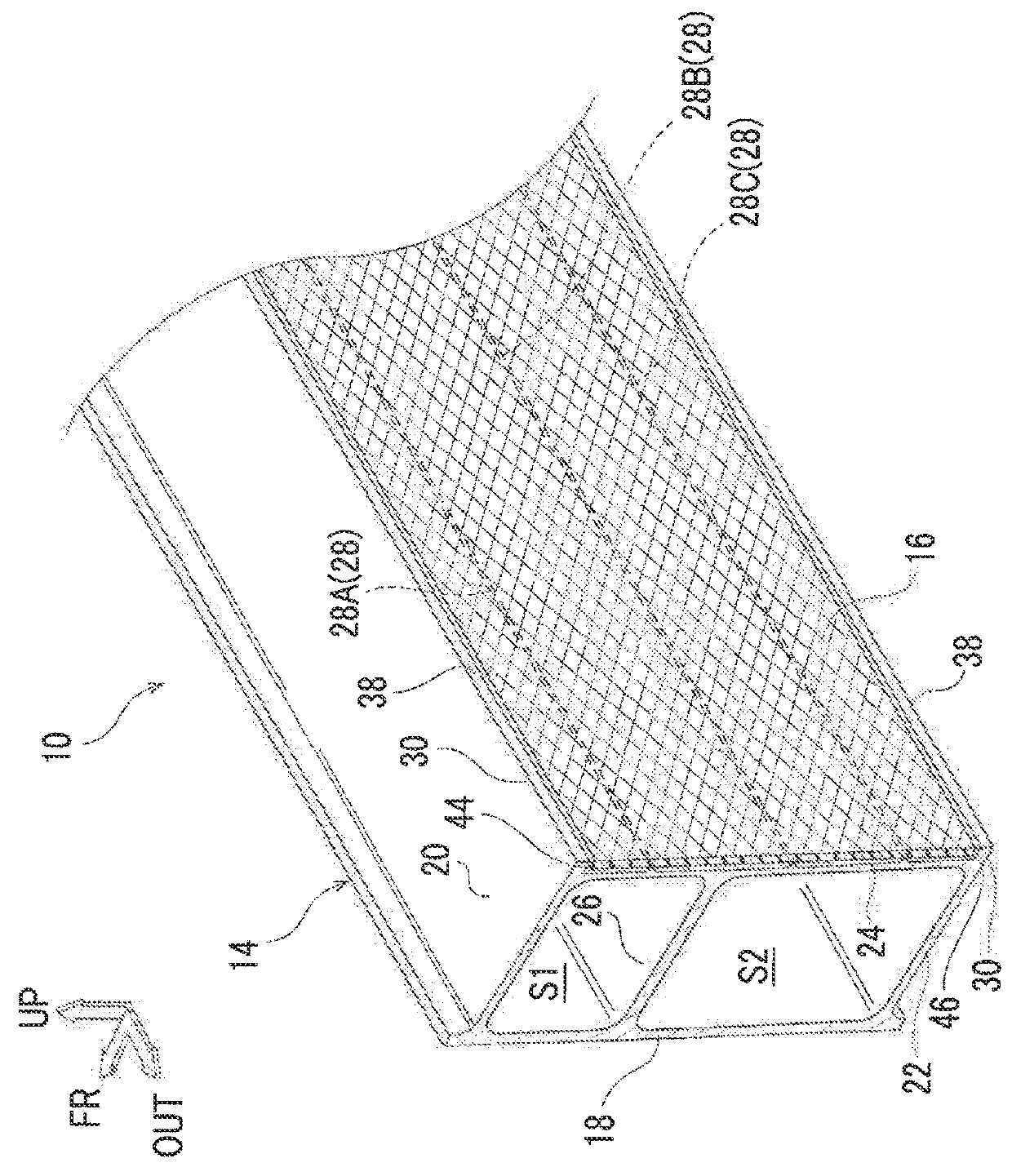

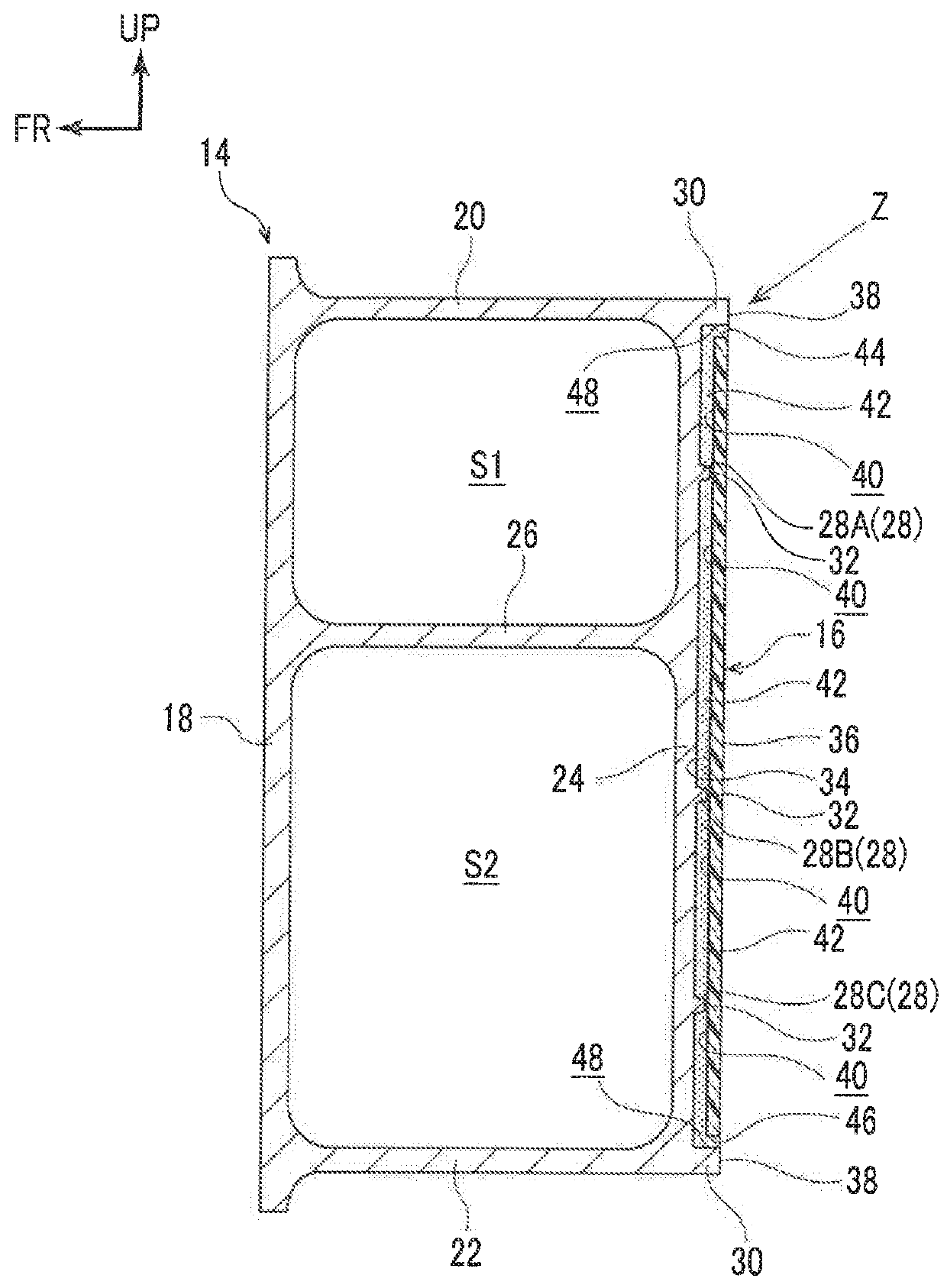

Vehicle body structure

A vehicle body structure includes a reinforcing member formed of a fiber reinforced resin and having a plate shape or a sheet shape and a metallic vehicle framework member. The vehicle framework member includes a rear wall portion and a reinforcing portion, one end face of the reinforcing member in a thickness direction of the reinforcing member being bonded to the rear wall portion and the reinforcing portion being disposed on the rear wall portion and protruding along a vertical direction from the rear wall portion.

Owner:TOYOTA JIDOSHA KK

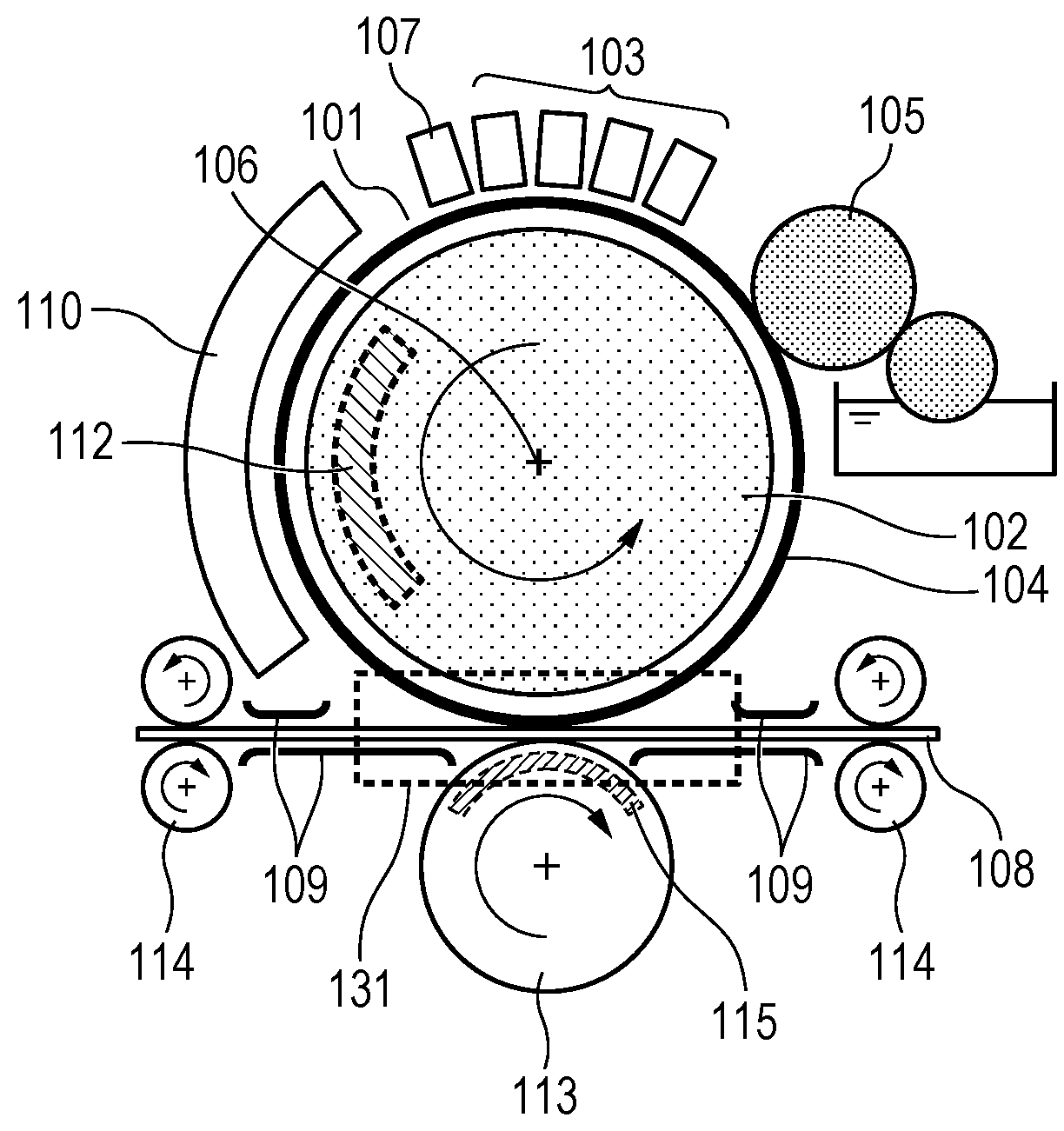

Image recording method, and transfer assisting liquid and liquid set used therefor

ActiveUS20180093469A1Improve transmission efficiencyStable recording of imageInksOther printing apparatusIntermediate imageImage recording

An image recording method includes a first intermediate image forming step of applying an ink onto an intermediate transfer member to form a first intermediate image, a second intermediate image forming step of applying a transfer assisting liquid containing thermoplastic resin particles and rosin-based resin particles to the first intermediate image formed on the intermediate transfer member to form a second intermediate image, and a transfer step of bringing the second intermediate image formed on the intermediate transfer member into contact with a recording medium, peeling off the second intermediate image from the intermediate transfer member while the contact state with the recording medium is maintained, and transferring the second intermediate image to the recording medium. In the transfer step, the second intermediate image brought into contact with the recording medium has a temperature not less than the glass transition temperature of the thermoplastic resin particles.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com