Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Improve vaporization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

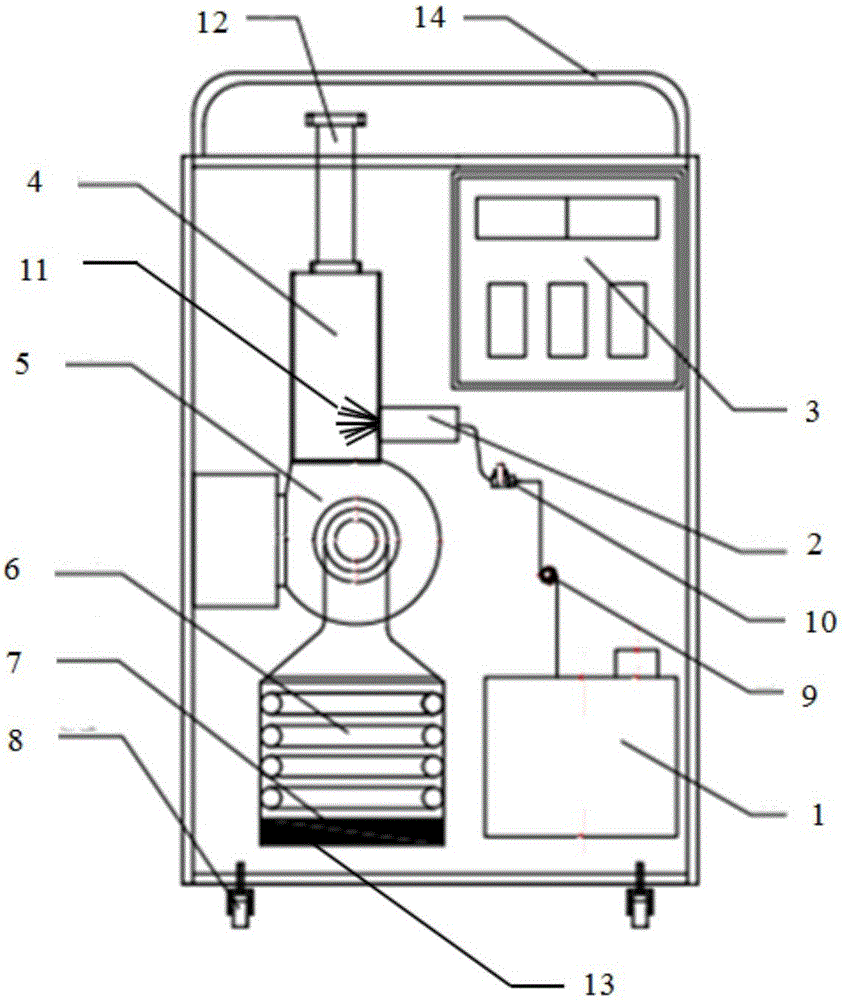

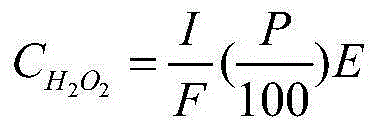

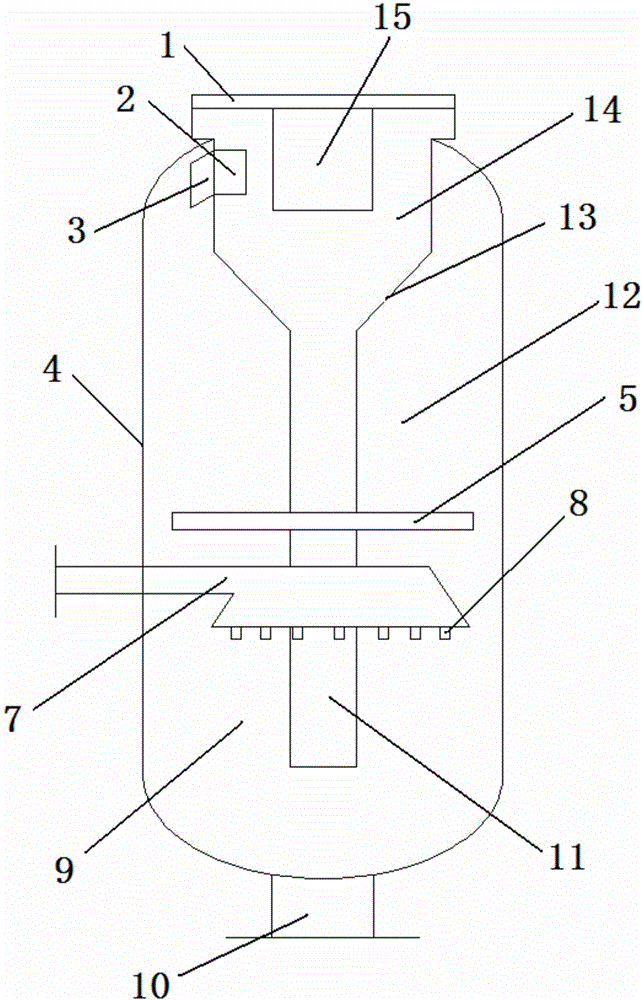

Hydrogen peroxide sterilization device and method

InactiveCN104984378AReduce the temperatureSuitable for sterilizationGaseous substancesChemicalsUltrasonic nozzleAir blower

A hydrogen peroxide sterilization device comprises a hydrogen peroxide liquid storage barrel, an ultrasonic atomizer, an electrical control unit, a vaporizing chamber, a metering pump, an solenoid-controlled valve, an air blower, a heater, a filter device, an air inlet and a steam outlet pipe; the ultrasonic atomizer is further provided with an ultrasonic nozzle provided with an air flue to evenly diffuse atomized hydrogen peroxide microdroplets in the vaporizing chamber, the vaporization efficiency is improved, the atomized hydrogen peroxide microdirplets can be vaporized rapidly at a lower temperature, and the energy is saved. Indoor air serves as carrier gas, outside air is not introduced, and secondary pollution is avoided. Hydrogen peroxide big droplets which are not vaporized in the vaporizing chamber can drop back on the heater under the action of gravity to be vaporized again. By controlling various related parameters, a dew point temperature of output vaporized hydrogen peroxide is made to be lower than the indoor temperature all the time, a steady flow is guaranteed for the vaporized hydrogen peroxide, and the water mist condensation phenomenon which occurs in the transport process are avoided.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV

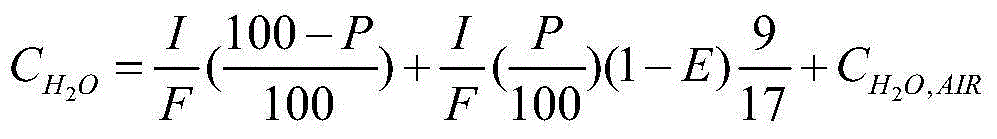

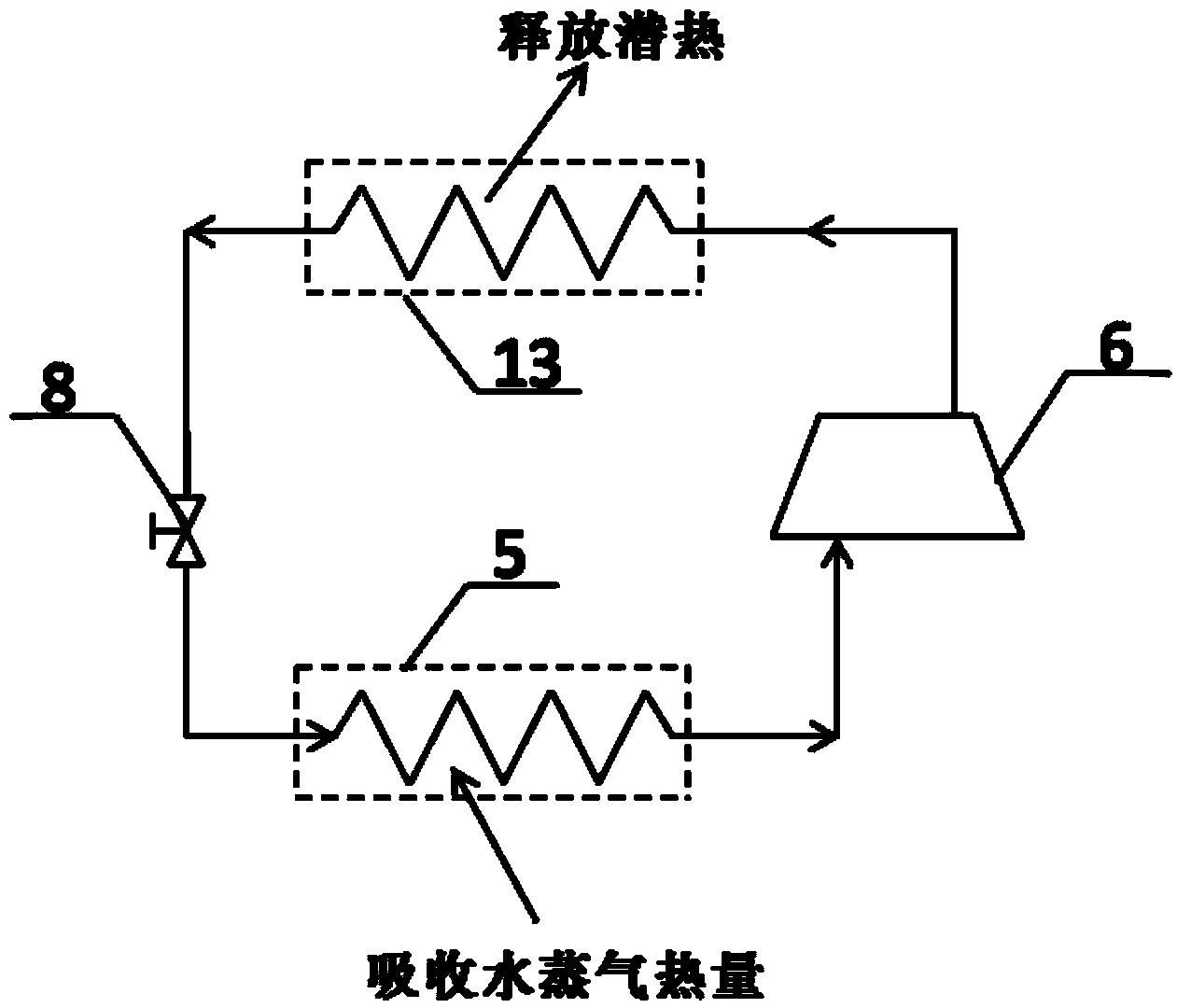

Vacuum membrane distillation type sewage treatment device capable of recycling heat

InactiveCN103663590AImprove cleanlinessIncrease membrane fluxWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by heatingLiquid wasteWater vapor

The invention discloses a vacuum membrane distillation type sewage treatment device capable of recycling heat. The vacuum membrane distillation type sewage treatment device comprises a heating tank which is provided with a heater and used for heating sewage, wherein a sewage outlet of the heating tank is communicated with a sewage inlet of a membrane evaporator through a liquid circulating pump, and a sewage outlet of the membrane evaporator is communicated with a sewage backflow inlet of the heating tank; a refrigerant inlet and a refrigerant outlet of a heat pump condenser in the membrane evaporator are communicated with a refrigerant inlet and a refrigerant outlet of a heat pump evaporator through pipelines; and a steam inlet of the heat pump evaporator is communicated with a steam outlet of the membrane evaporator, a liquid water outlet of the heat pump evaporator is connected with a steam-water separator, and a gas outlet of the steam-water separator is connected with a circulating water vacuum pump, so that a vacuum system is formed. The vacuum membrane distillation type sewage treatment device is suitable for treating waste liquids containing heavy metal ions or purified seawater, has three functions of recycling water, concentrating waste liquid and saving energy and is characterized in that a refrigerant is used for recycling heat emitted by phase change of water steam, and the heat is used for heating sewage in the evaporator, so that the heat recycling effect is realized.

Owner:XI AN JIAOTONG UNIV

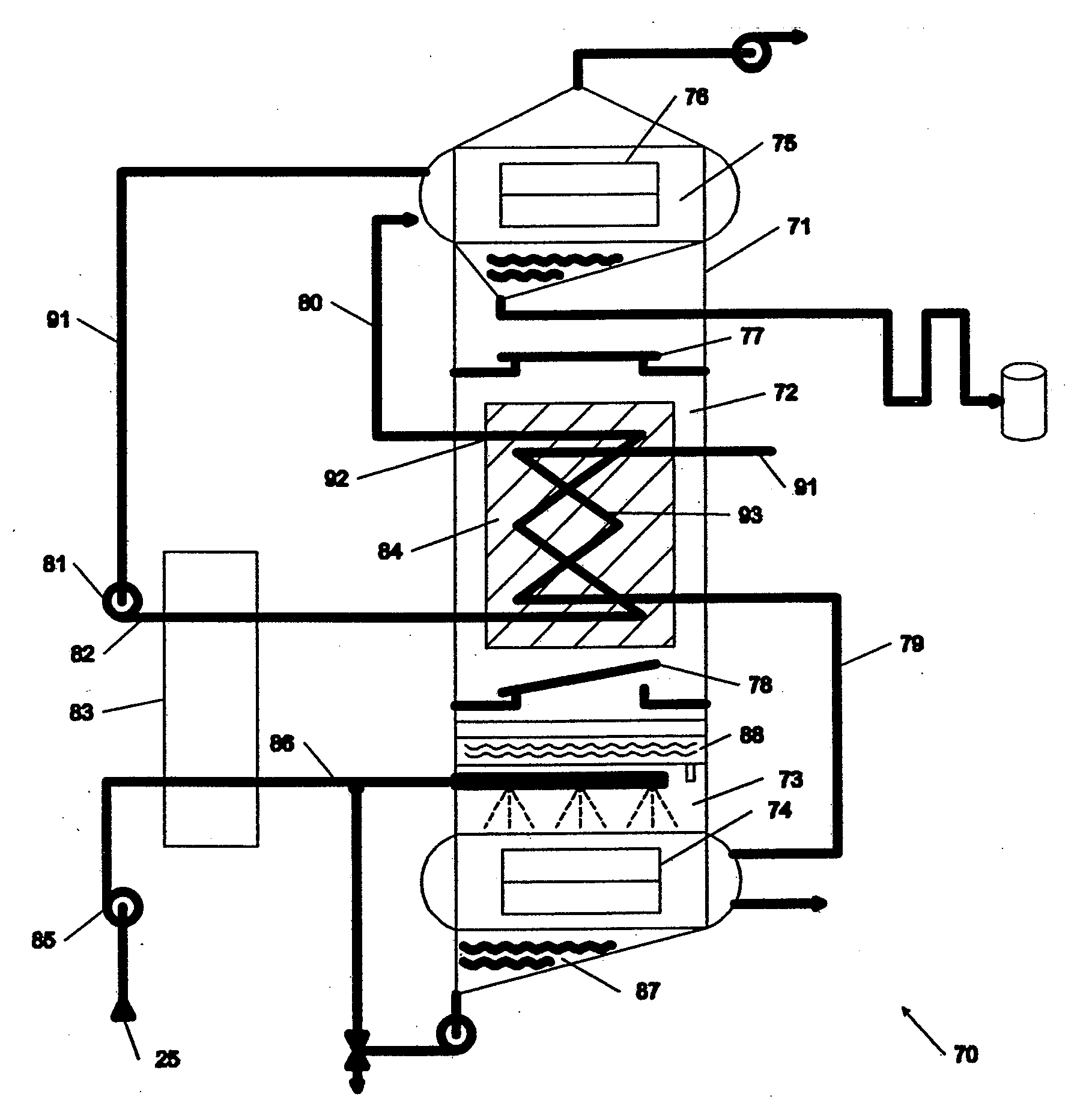

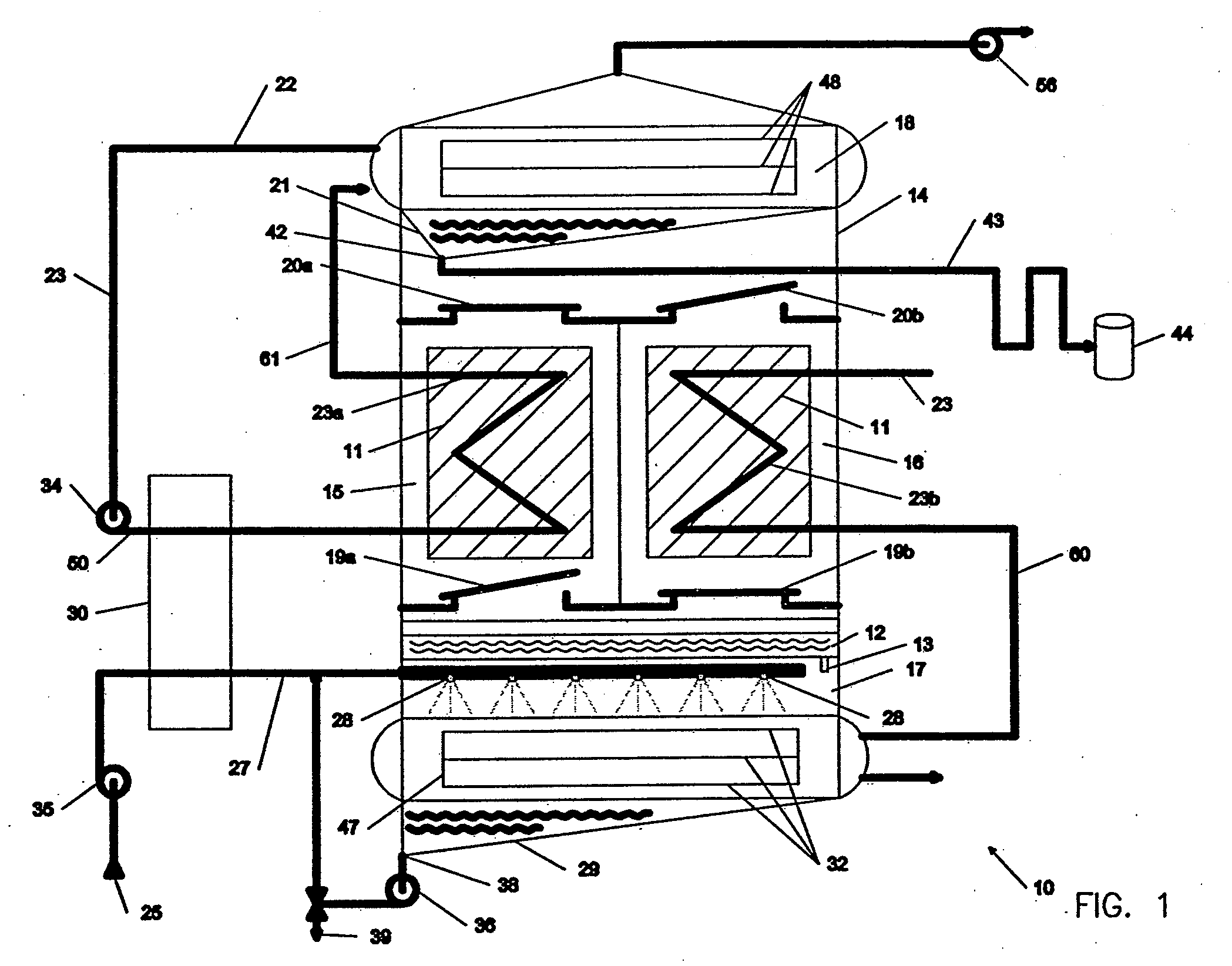

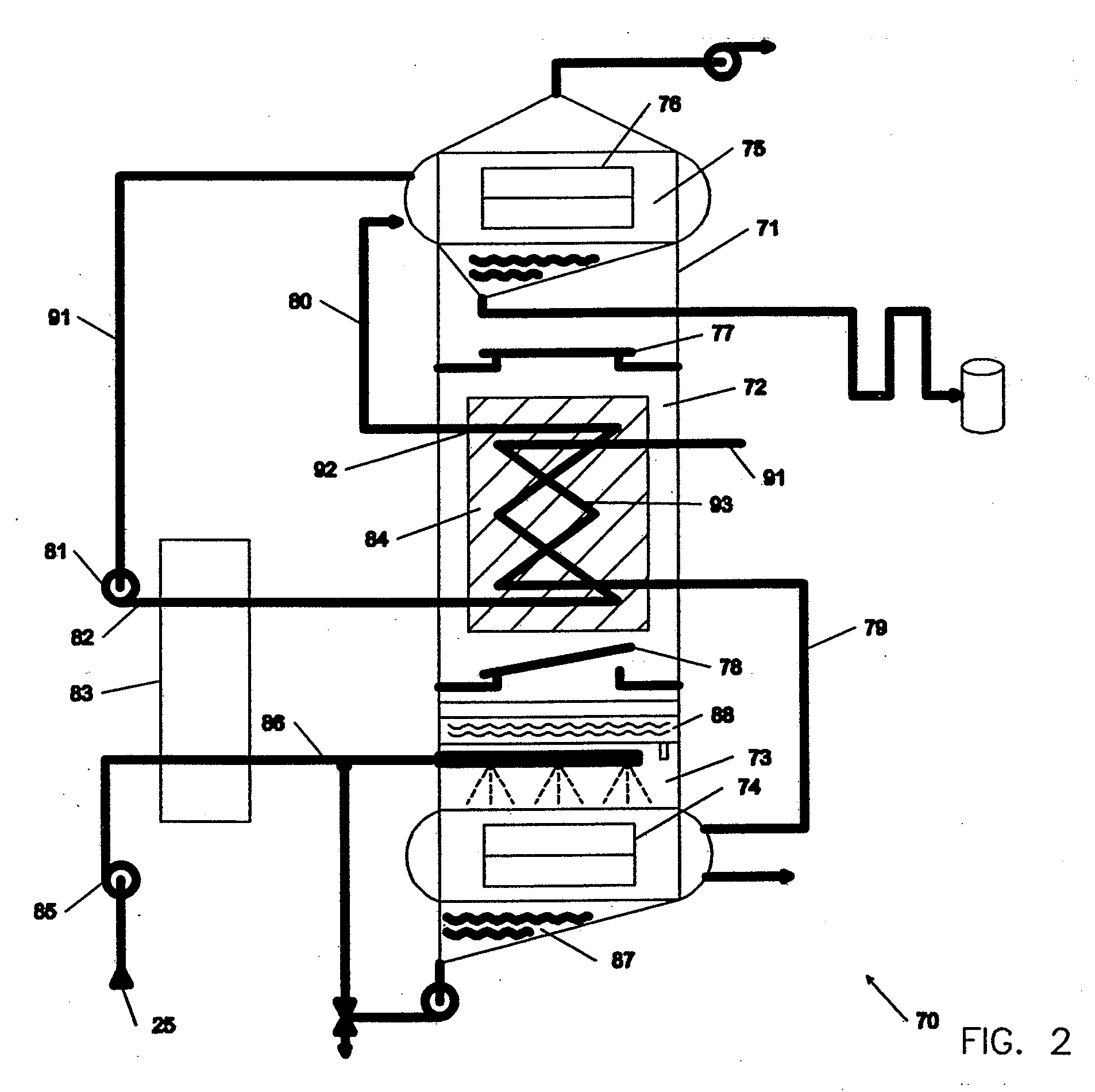

Adsorbent - Adsorbate Desalination Unit and Method

InactiveUS20110048920A1Reduce demandImprove efficiencyGeneral water supply conservationAuxillariesSeawaterEvaporator

An adsorption-desalination unit utilizing a silica gel—water working pair adsorbent—adsorbate having an economizing heat exchanger to pre-heat the incoming source seawater to be desalinated in an evaporator from about 8° C. to about 1° C. above the ambient seawater temperature. The economizing heat exchanger employs heat captured during the adsorption cycle to pre-heat incoming source seawater, thereby increasing the efficient use of energy in the unit. The heating fluid utilized to drive the desorption cycle is further utilized to heat the evaporator. A mist eliminator positioned intermediate the evaporator and the adsorbent heat exchanger chambers prevents non-vaporized water from entering the adsorbent heat exchanger chambers.

Owner:INDAL IDEA PARTNERS

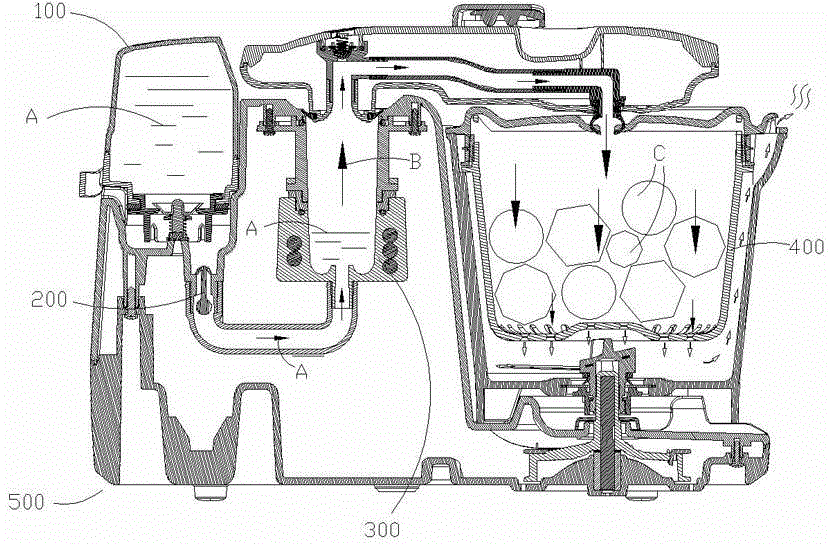

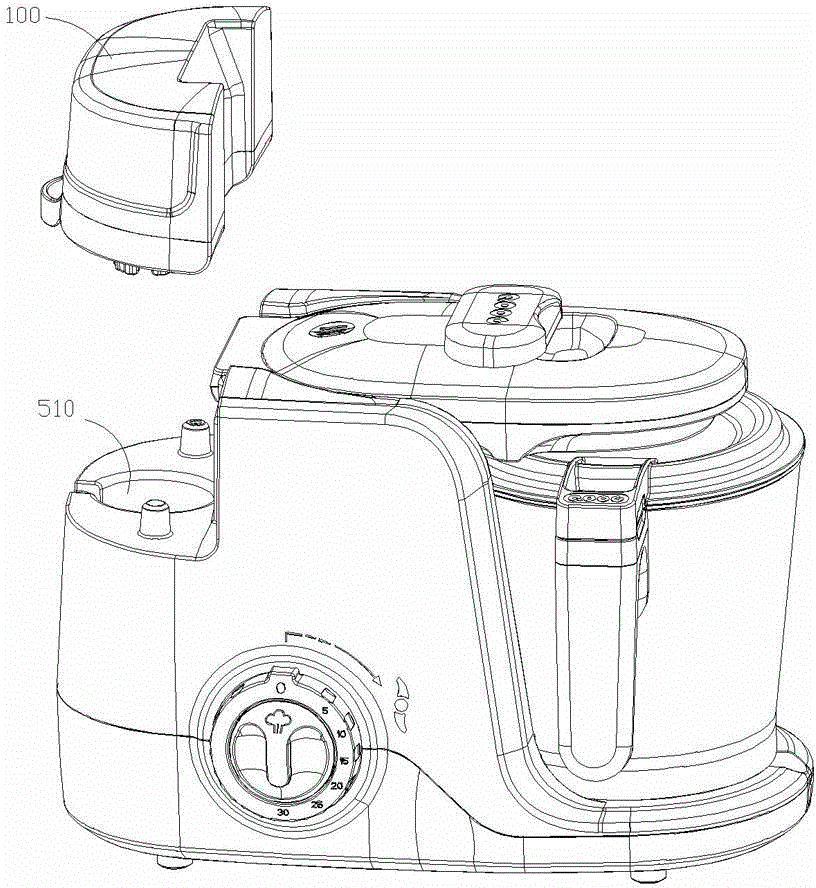

Rapid food cooking device and rapid cooking method thereof

InactiveCN104523138AImprove vaporization efficiencyReduce lossesSteam cooking vesselsFood scienceBoiling pointLiquid water

Owner:DONGGUAN XIQIN ELECTRICAL APPLIANCE

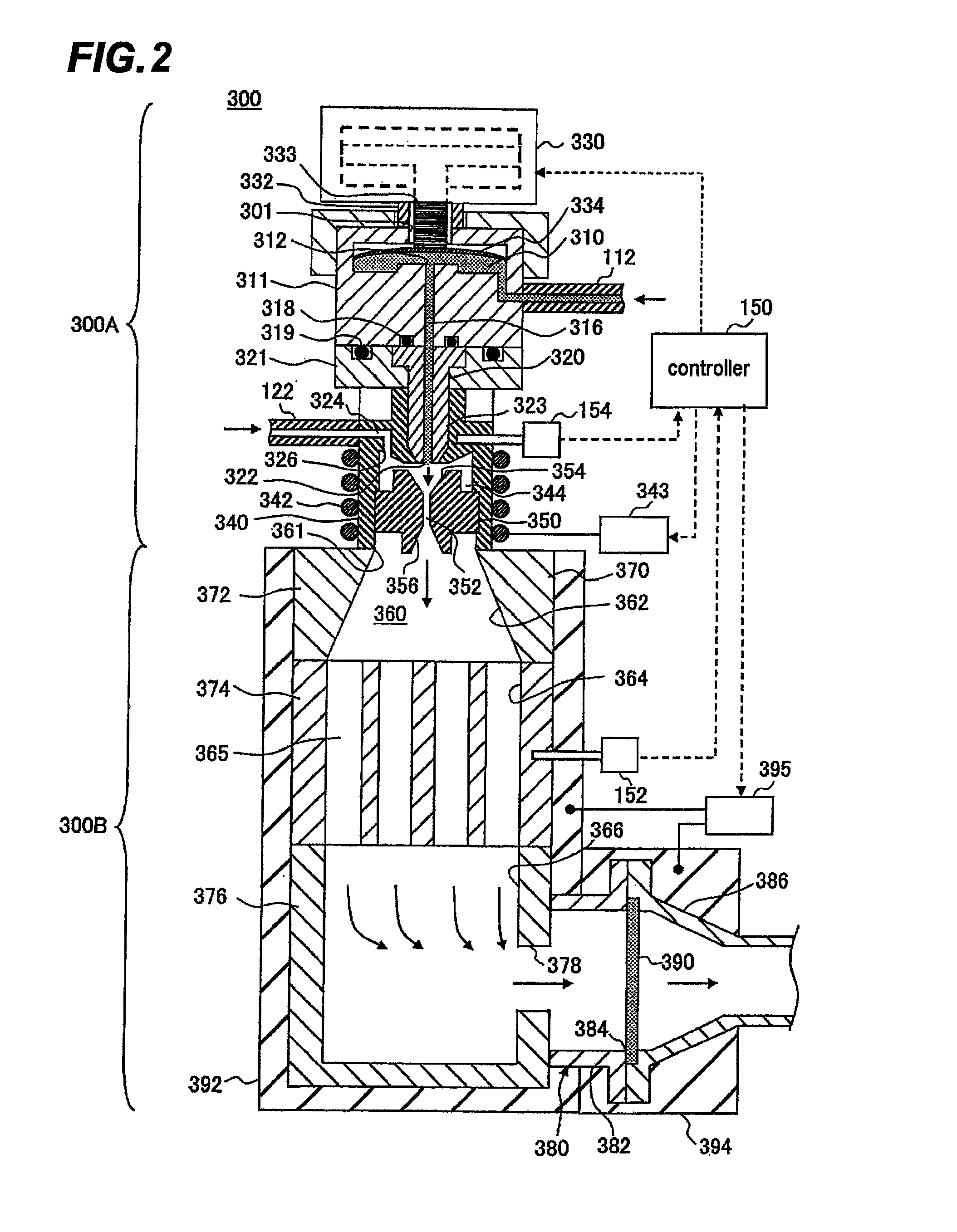

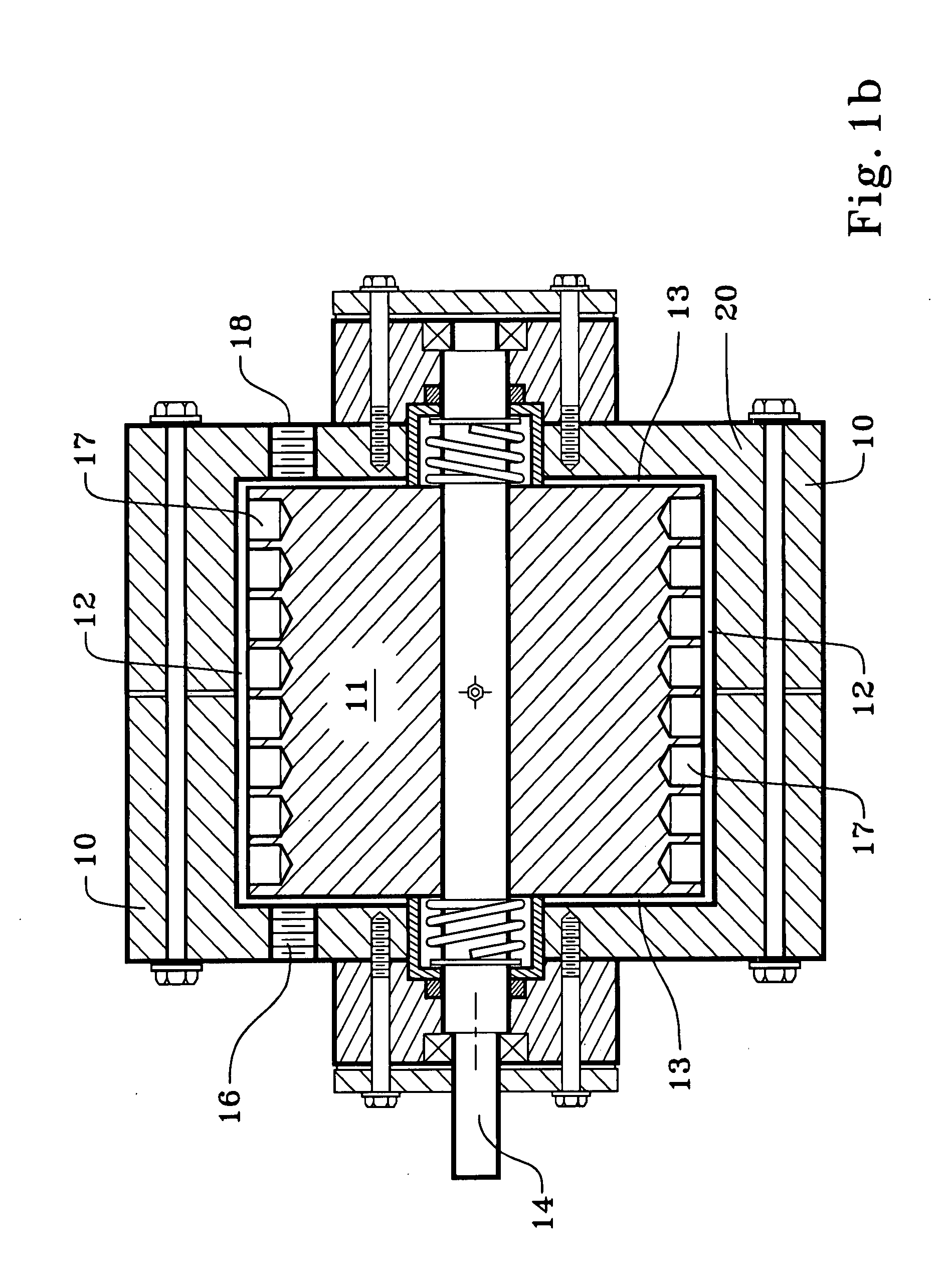

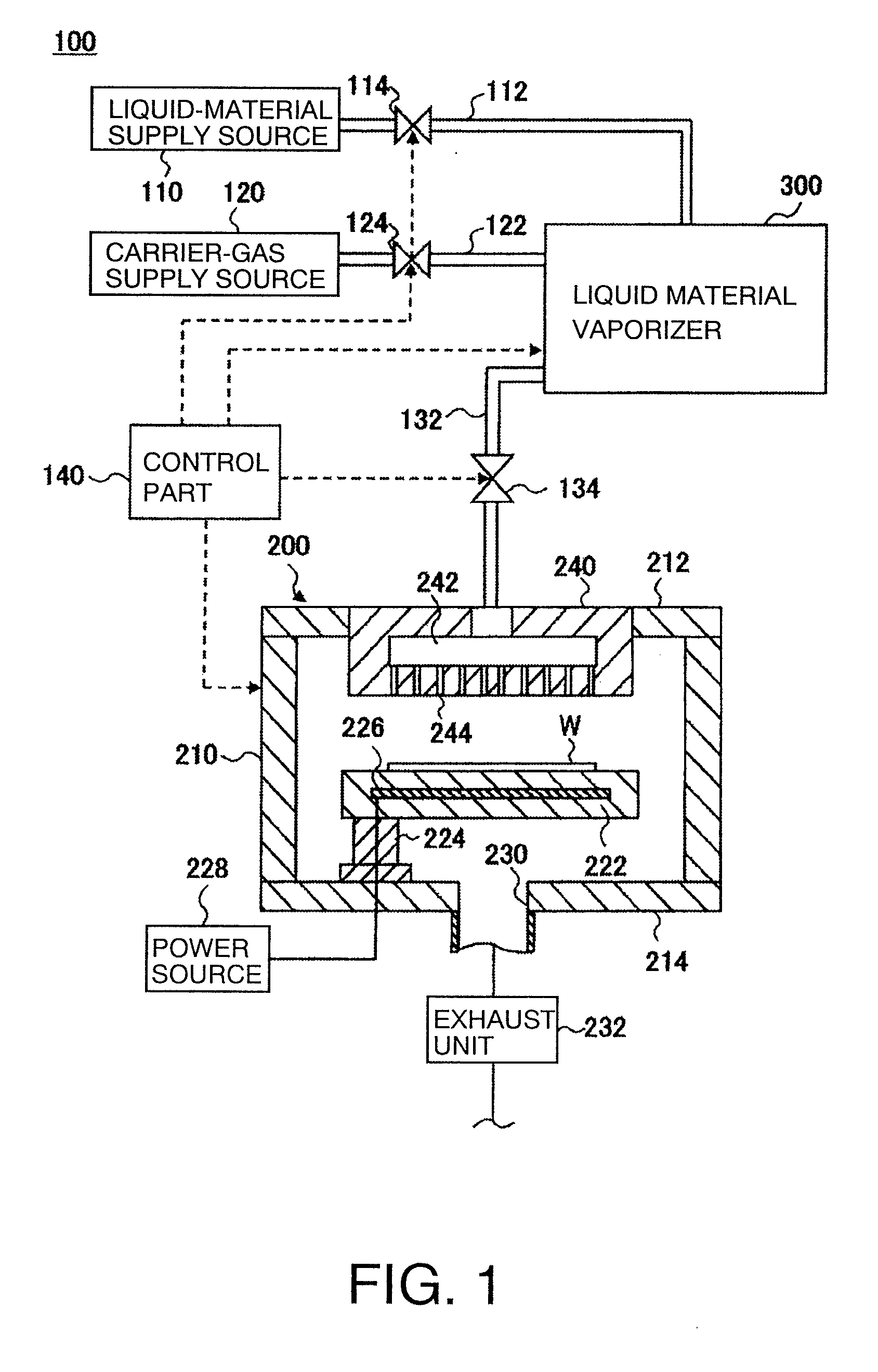

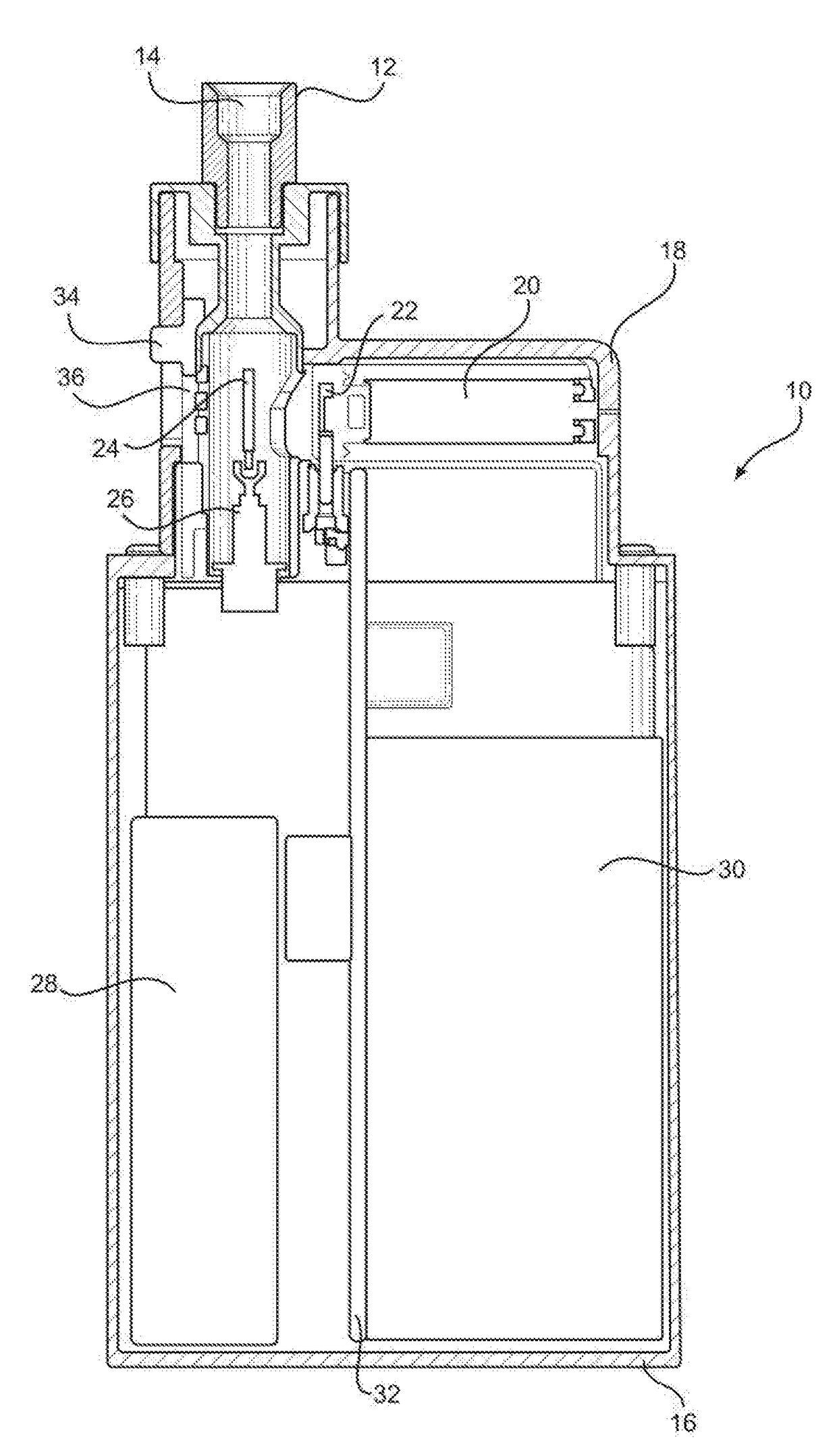

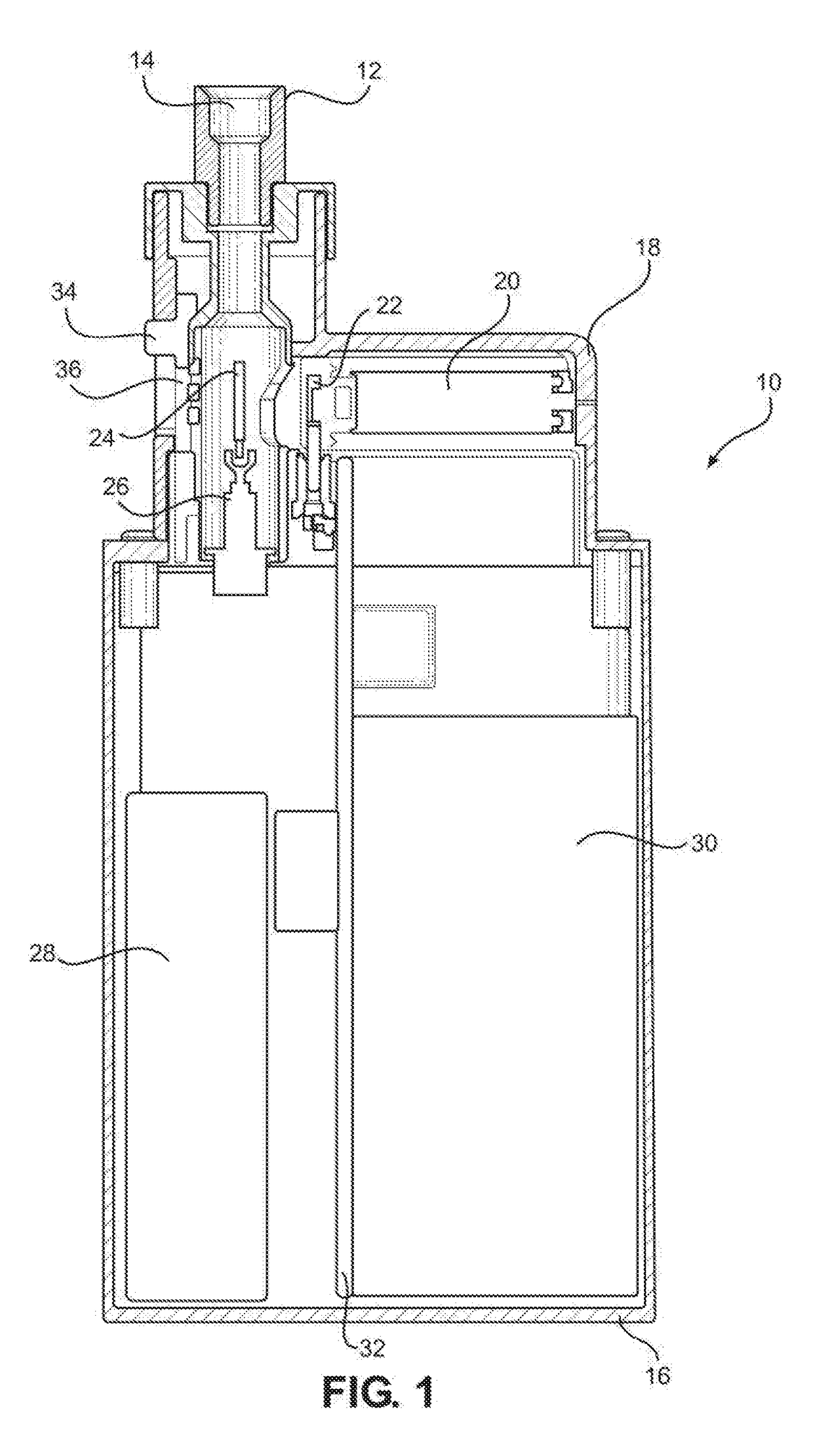

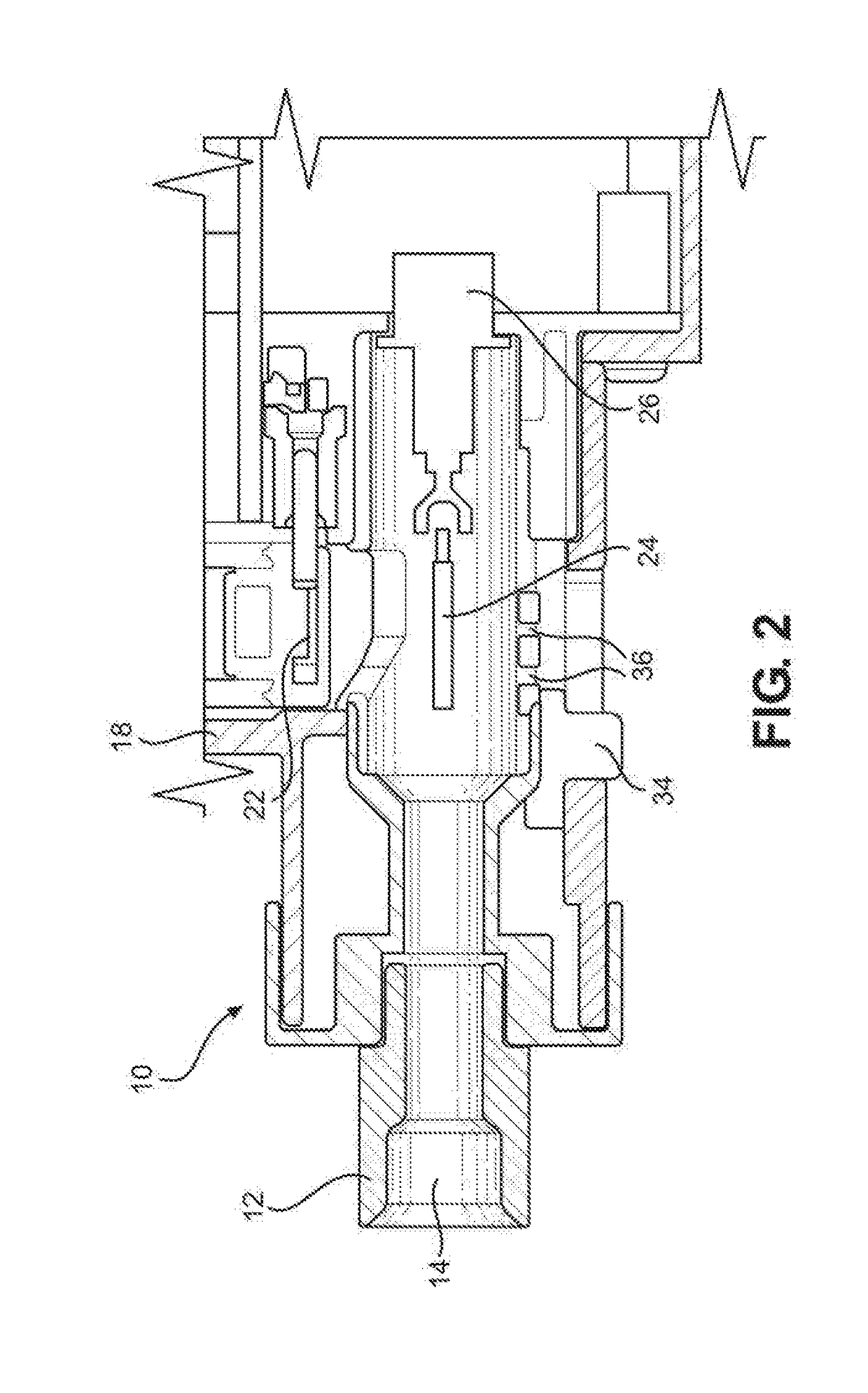

Vaporizer and deposition system using the same

InactiveUS20110180002A1Improve vaporization efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingVaporizationMixing chamber

To prevent a liquid material outlet from being clogged with accretion. Disclosed is a vaporizer, which vaporizes a liquid material, discharged from the outlet of a nozzle, in a heated vaporization chamber to produce a raw gas, and which is provided with a cylindrical heated member, which is disposed between the front end of the nozzle and the vaporization chamber so as to cover the perimeter of the outlet, a carrier gas ejection port, which ejects a carrier gas from the vicinity of the outlet, a mixing chamber, wherein the liquid material discharged from the outlet is mixed with the carrier gas, which ejects the mixture toward the vaporization chamber, a first heating part, which heats the vaporization chamber from its exterior, and a second heating part, which heats the heated member from its exterior.

Owner:TOKYO ELECTRON LTD

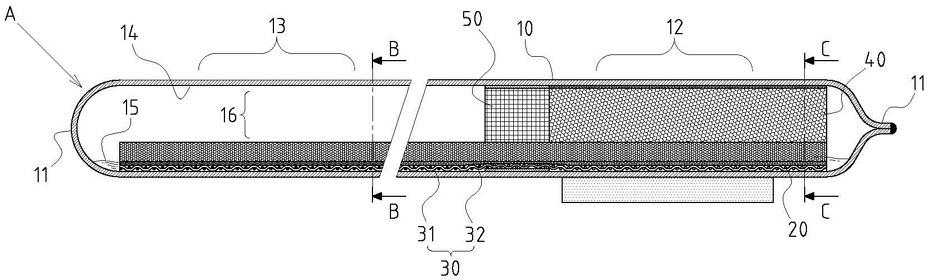

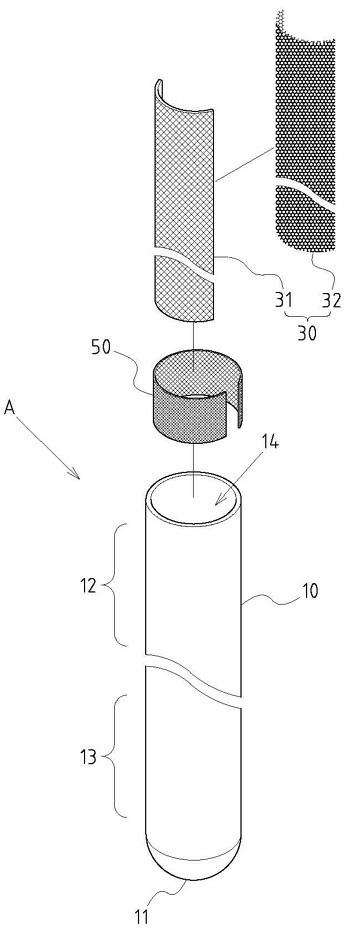

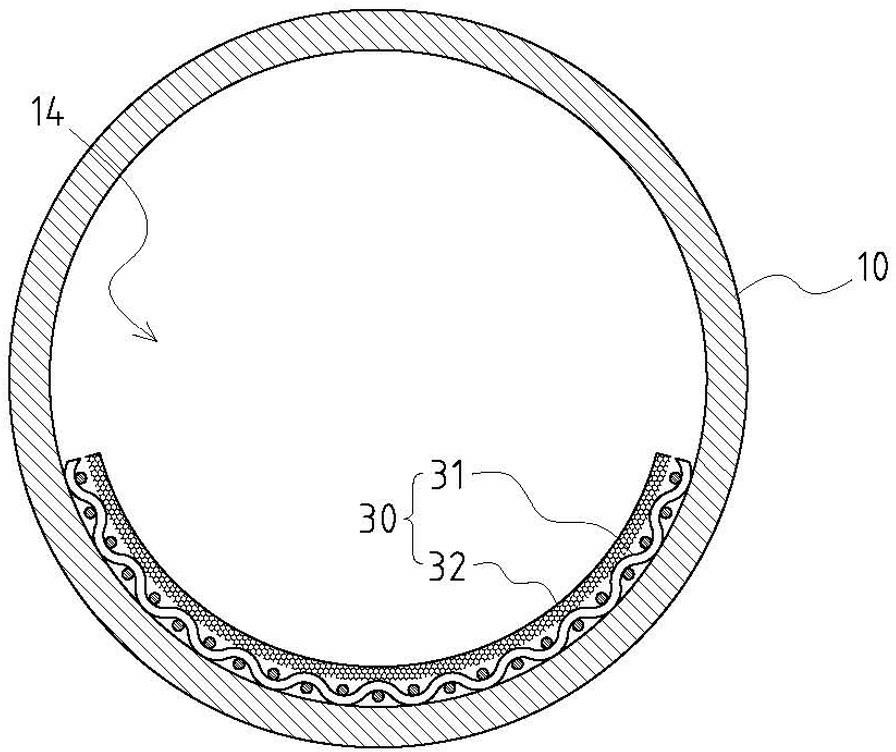

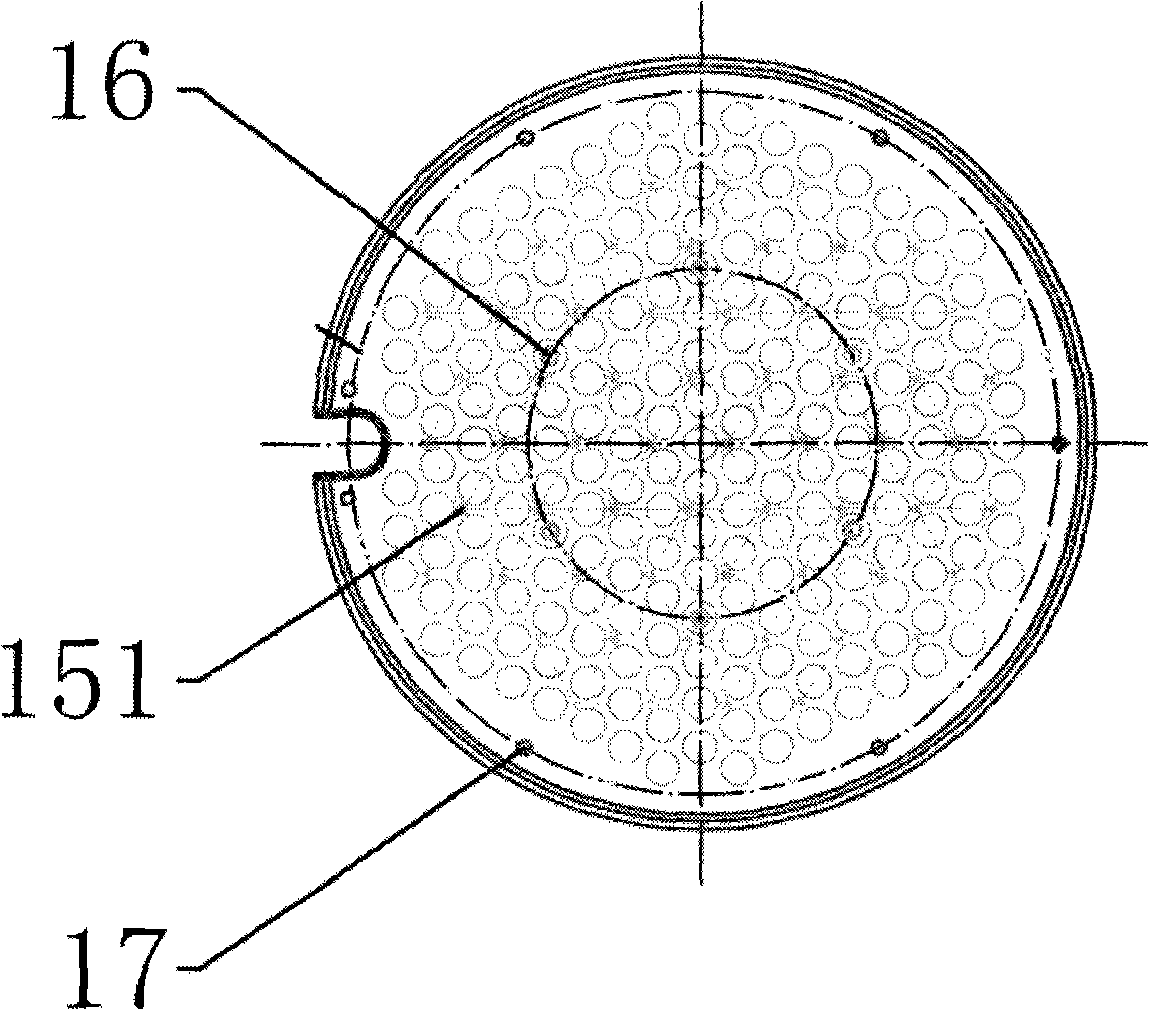

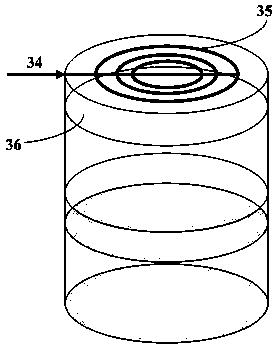

Heat pipe structure capable of controlling sintering position of capillary tissue and preparation method thereof

InactiveCN102435084AEnlarging the channel spaceConducive to pipe wall bending processingIndirect heat exchangersCapillary pressureInterior space

The invention discloses a heat pipe structure capable of controlling a sintering position of a capillary tissue and a preparation method thereof. The structure part mainly is that: an evaporation section sintering capillary tissue is arranged on an evaporation section of a pipe body, wherein the evaporation section sintering capillary tissue is at least formed by sintering and fixing metal powders on the inner wall of the evaporation section; the structure part further comprises a net body sintering composite capillary tissue which is in an embedding shape; the net body sintering composite capillary tissue is arranged in a cooling section of the pipe body and is formed by a metal net body and a powder sintering layer; the powder sintering layer is formed by pre-sintering metal powders and fixing on at least one side surface of a metal net body; and then the net body sintering composite capillary tissue is arranged in the interior space of the pipe body; and a powder position-limiting net body which is connected, spliced or engaged with the net body sintering composite capillary tissue is arranged in parallel with one end of the evaporation section sintering composite capillary tissue. By using the design, the heat pipe can achieve to the advantages of that: the sintering position of the capillary tissue is accurately controlled, a steam channel space is enlarged, the curved process of a coping pipe wall is more conducive, the manufacturing and forming are easier, the work liquid evaporation efficiency is increased and the like.

Owner:SUZHOU FORCECON ELECTRIC

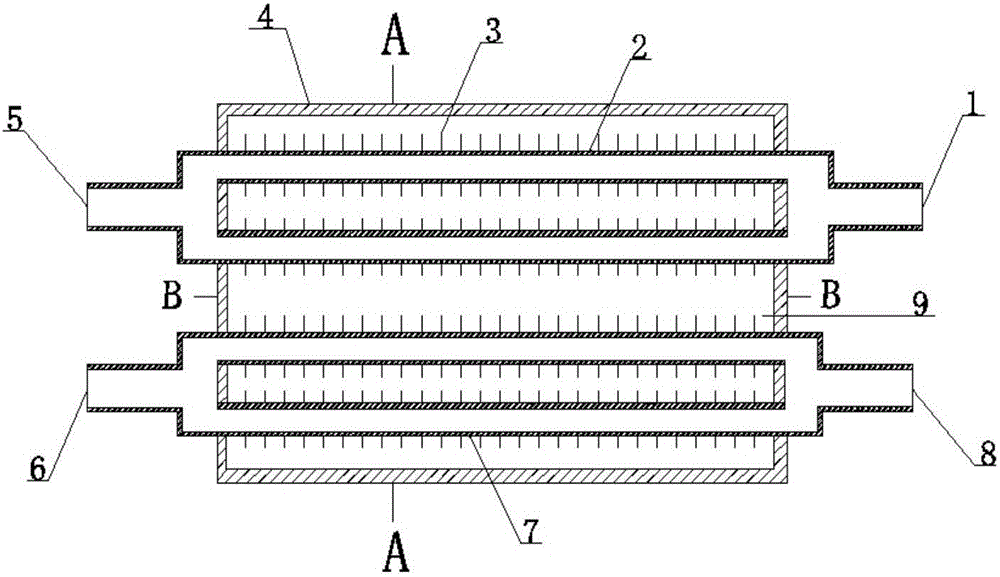

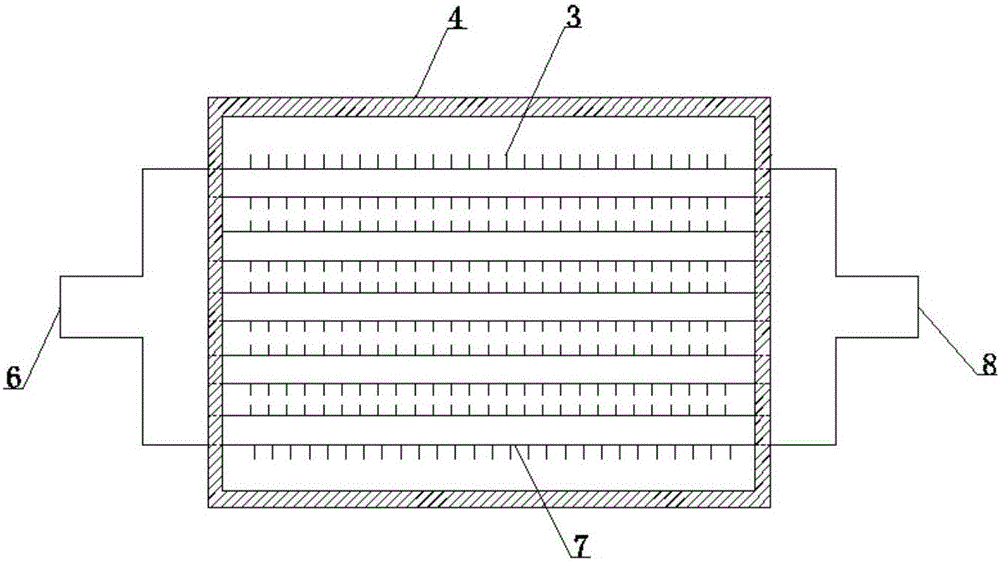

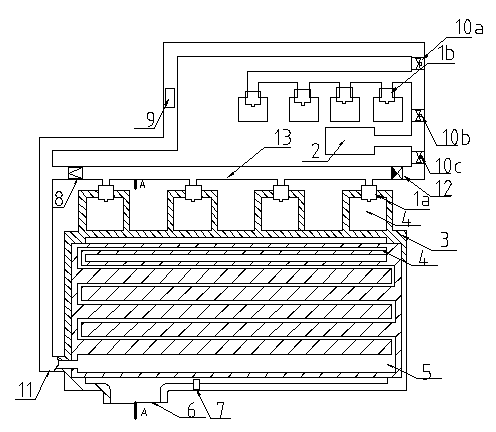

Feed liquid distribution film forming device of falling film evaporator

ActiveCN101898045AImprove uniformityIncrease the heat exchange areaEvaporator accessoriesStationary conduit assembliesVaporizationEngineering

The invention discloses a feed liquid distribution film forming device of a falling film evaporator, which comprises a liquid distribution mechanism and heat exchange tube inserters formed into an array, wherein the liquid distribution mechanism is connected with a feed inlet through a liquid tube and is in two-stage cascade connection; the heat exchange tube inserters are uniformly distributed and fixed at the lower side of the liquid distribution mechanism; the liquid distribution mechanism comprises a liquid inlet buffer, a first-stage V-shaped groove overflow liquid distribution device and a second-stage hole-shaped liquid distribution device; and each heat exchange tube inserter is provided with a flexible center positioning mechanism and three lateral liquid inlet holes for equally dividing the circumference. In the invention, two-stage cascade connection liquid distribution of combination of the overflow with a buffering mechanism and the small holes which are uniformly distributed is adopted, and the semicircular hole lateral liquid inlet and the flexible center positioning mechanism are combined, so that the feed liquid distribution film forming device is automatically centered in a heat exchange tube, thereby ensuring that the gap between the liquid distribution device and the tube wall is always uniform and consistent; the liquid distribution mechanism in two-stage cascade connection improves the uniformity of the formed film, thereby improving the heat exchange area and the vaporization efficiency of the heat exchange tube; and in addition, liquid distribution heads can be produced in batches, thereby increasing the exchangeability of products and being convenient in assembly and disassembly.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

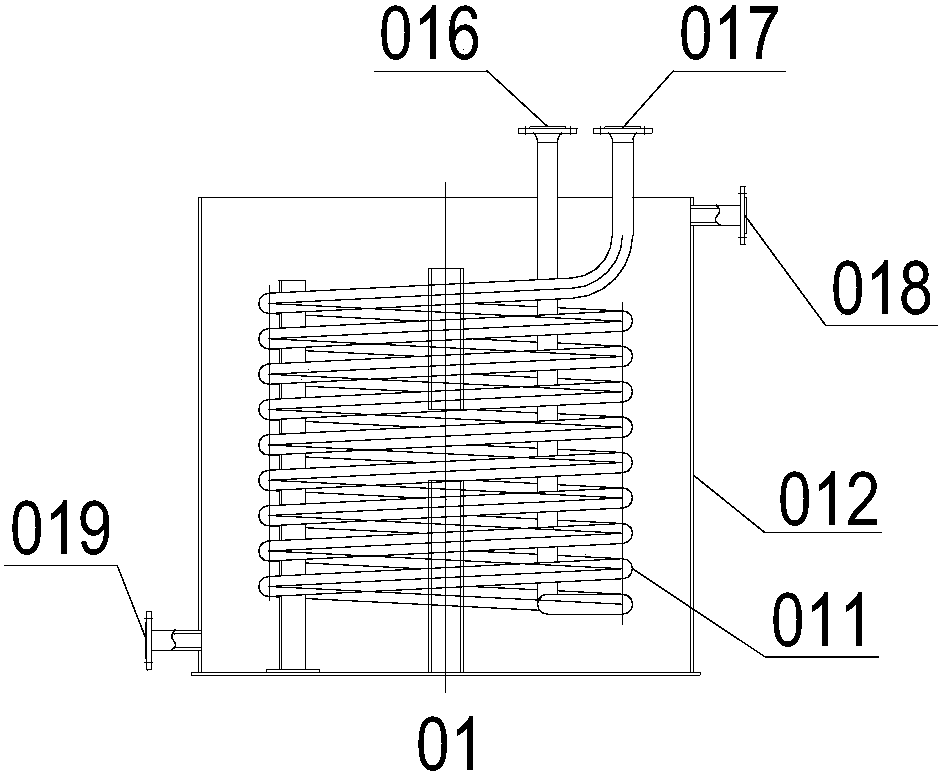

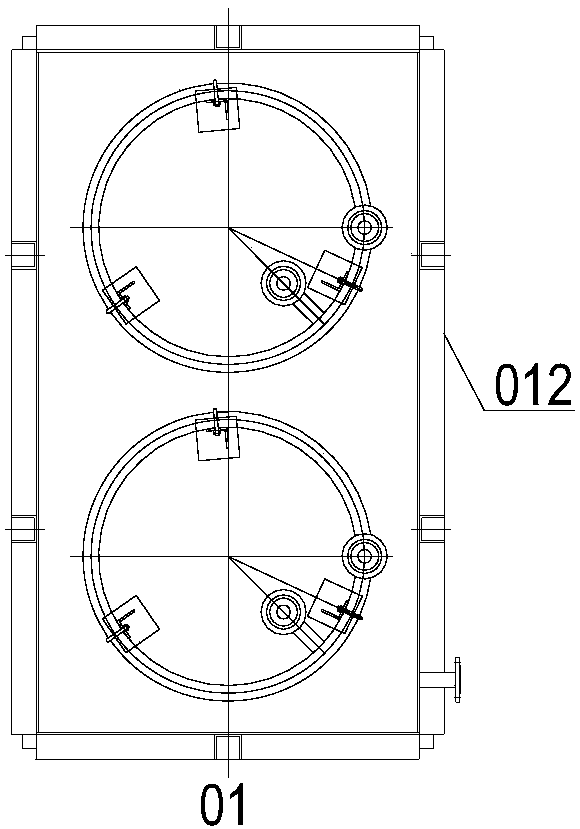

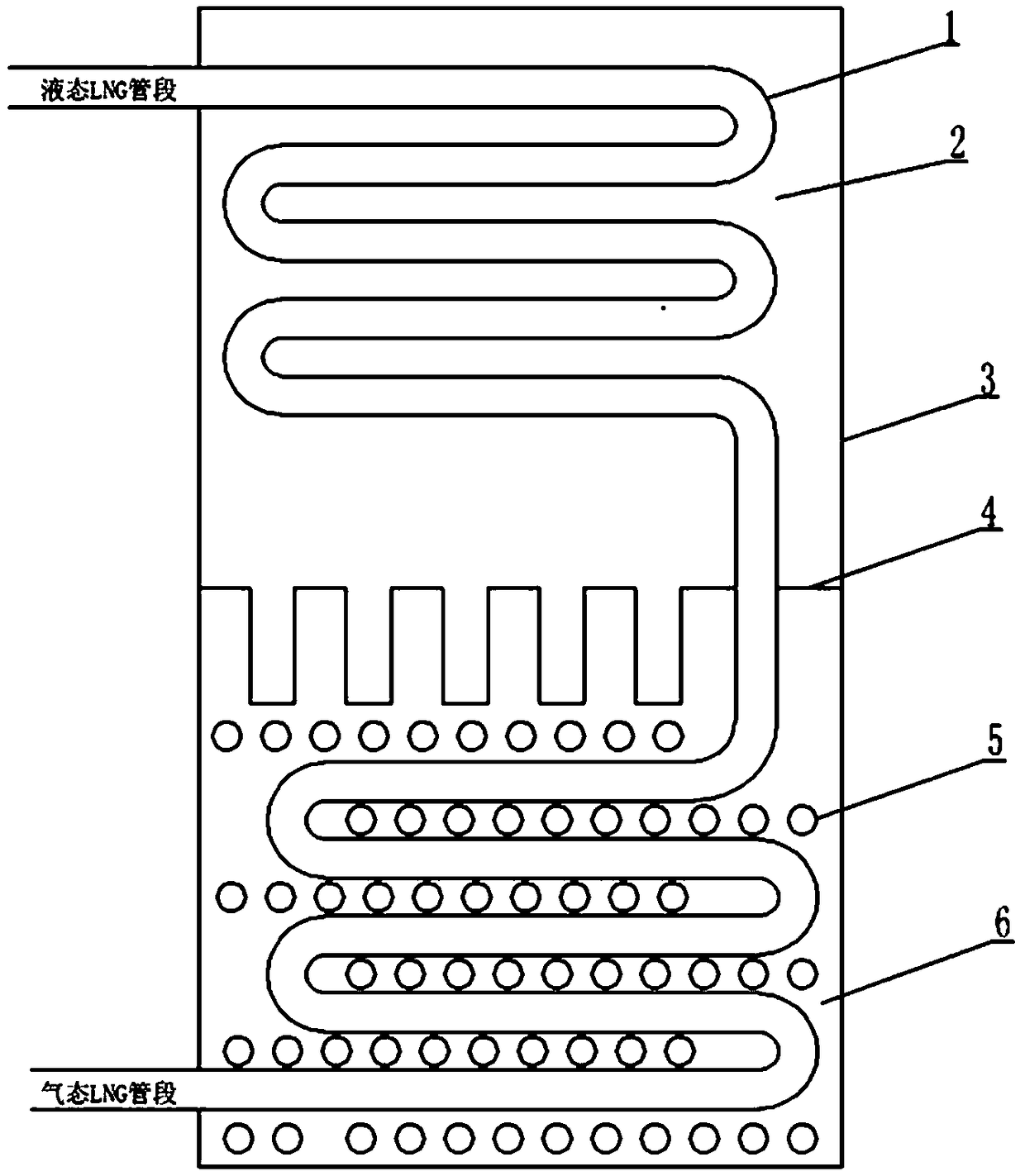

LNG vaporizer utilizing phase-change heat transfer technology and vaporization method

InactiveCN106017168ASolve the problem of deteriorating vaporization performanceSimple structureIndirect heat exchangersEngineeringVaporization

The invention discloses an LNG vaporizer and a vaporization method using phase-change heat technology. The vaporizer includes a shell with a heat exchange chamber for a first heat exchange medium. On the upper side wall of the first heat exchange medium heat exchange chamber with a height of half and on the lower side wall with a height less than half of the first heat exchange medium heat exchange chamber are respectively provided with at least one row of corresponding Through holes, one end of the upper through hole is connected to the LNG heat exchange pipe connected to the LNG inlet and the other end is connected to the LNG outlet, and the lower through hole is connected to one end connected to the second heat exchange medium inlet, and the other end is connected to the second heat exchange medium inlet. The second heat exchange medium heat exchange pipe of the second heat exchange medium outlet, wherein the outer walls of the LNG heat exchange pipe and the second heat exchange medium heat exchange pipe are respectively fitted with several vertical fins along the axial direction. The invention solves the problem that the vaporization performance of the vaporizer deteriorates due to the freezing of the heat exchange medium due to the low temperature of the LNG, and has a simple structure.

Owner:JIANGSU UNIV OF SCI & TECH

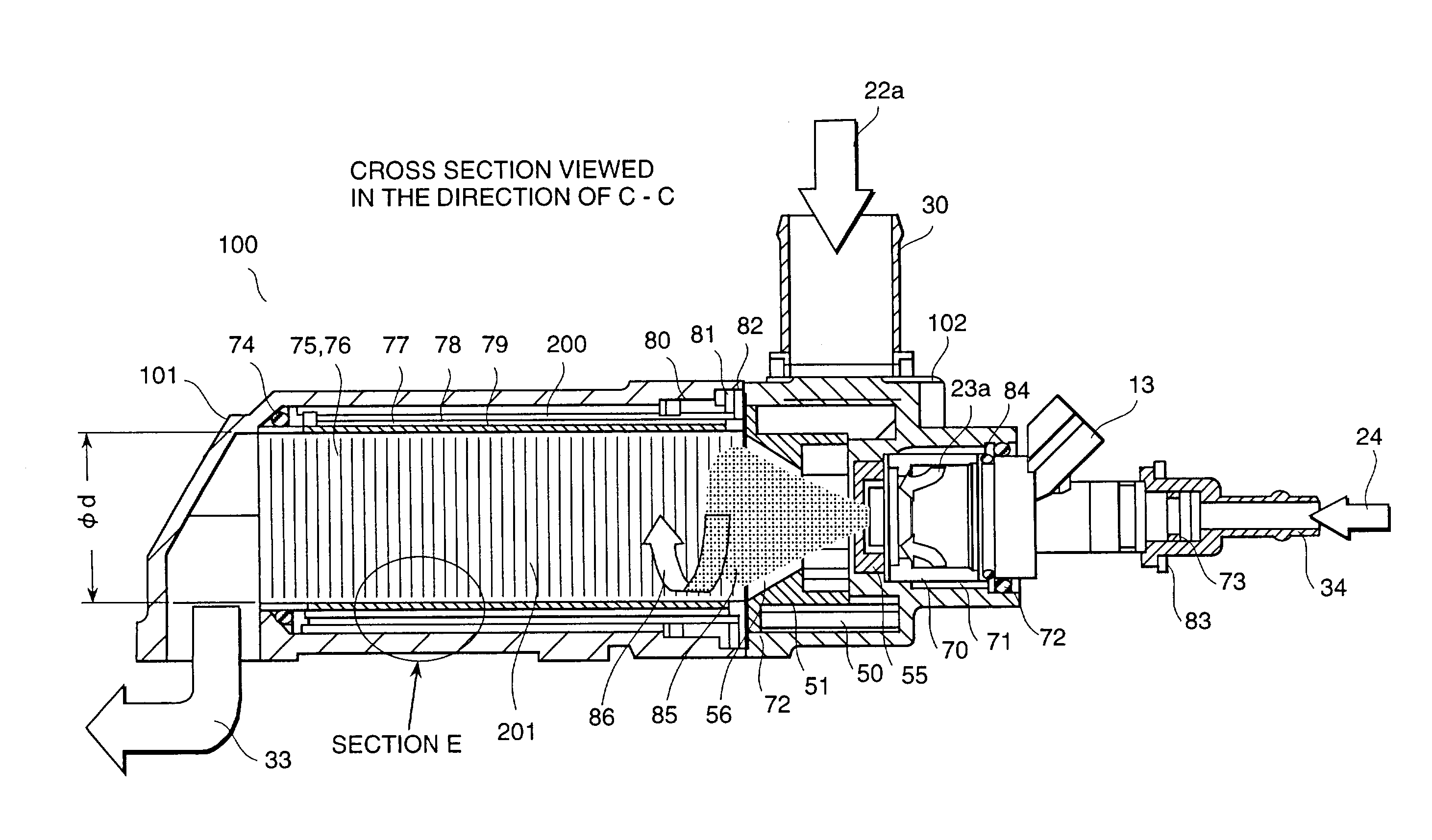

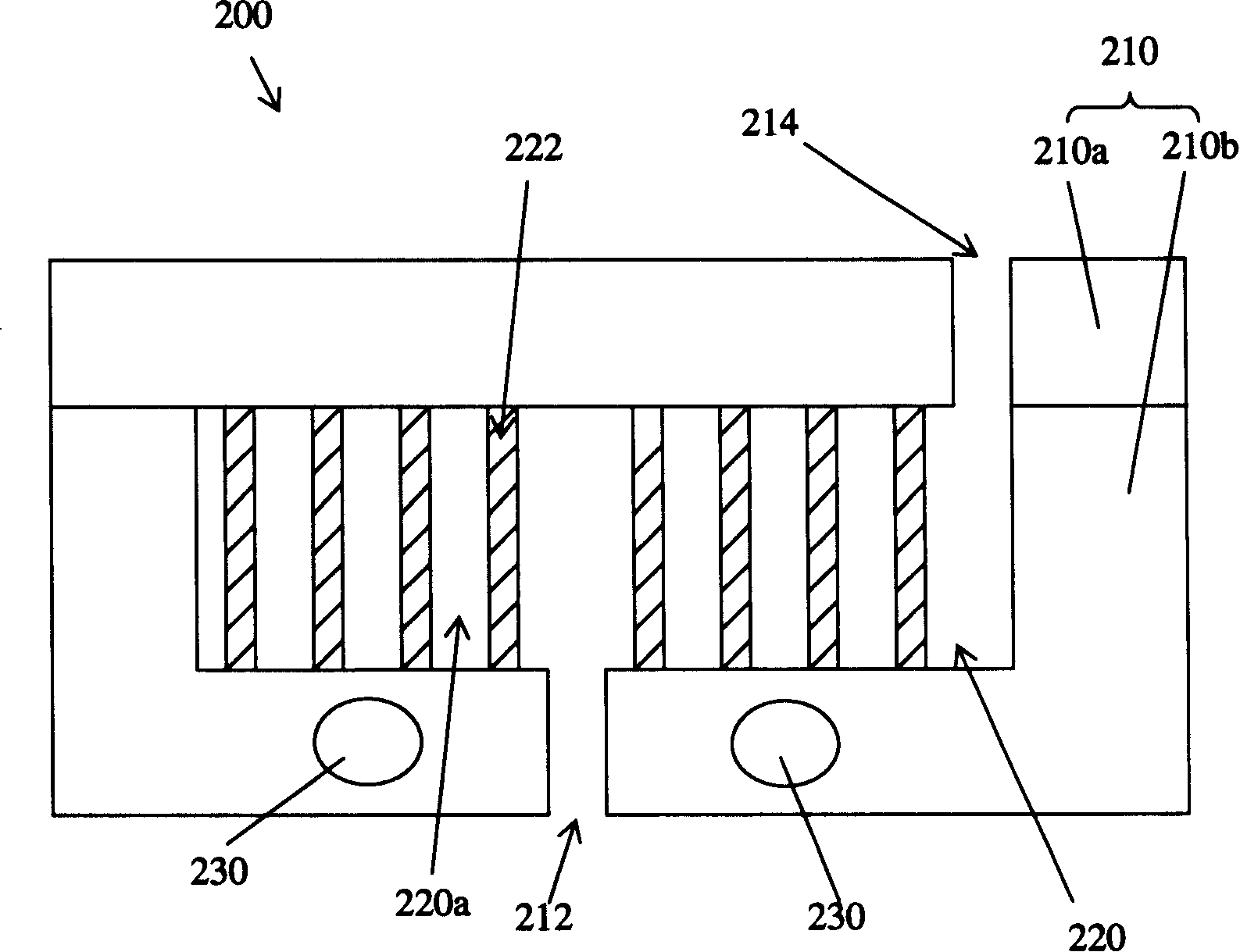

Fuel vaporization promoting apparatus and fuel carburetion accelerator

InactiveUS20030155666A1Improve vaporization efficiencyThin layerCarburetting airInternal combustion piston enginesVaporizationInlet manifold

The present invention promotes atomization and vaporization of spray at the time of cold startup and reduces the amount of fuel depositing on the inner wall of the intake manifold, thereby ensuring improved startability of an internal combustion engine of a car, reduced fuel costs and improved purification of exhaust gas. A very fine groove 201 is formed on a heat transfer surface 76 in a fuel vaporization promoting apparatus 100, wherein this groove 201 is shaped in such a way that fuel 24 is dispersed by the surface tension of a heat transfer surface 76 and fuel 24. This configuration ensures uniform dispersion of fuel 24 on the heat transfer surface 76 and effective promotion of vaporization

Owner:HITACHI LTD +1

Scale-inhibited water reduction in solutions and slurries

InactiveUS20070193739A1Improve efficiencyHeat energy readily available for reuseSurveyFlushingThermal energyCavitation

A cavitation device is used to reduce the water content of used or wastep solutions and slurries, including oil well fluids and muds, solution mining fluids, industrial oil / water emulsions, and other used or wastep aqueous industrial fluids. A main reason for reducing the water content of such fluids is to facilitate their disposal or reuse. Thermal energy from the steam and vapor produced by the non-scaling cavitation device is recycled in steam turbines or piston expander engines, or otherwise facilitates evaporation through a membrane or condensation to useful fresh water; the efficiency of the process can be enhanced by mechanical vapor recompression.

Owner:TOTAL SEPARATION SOLUTIONS

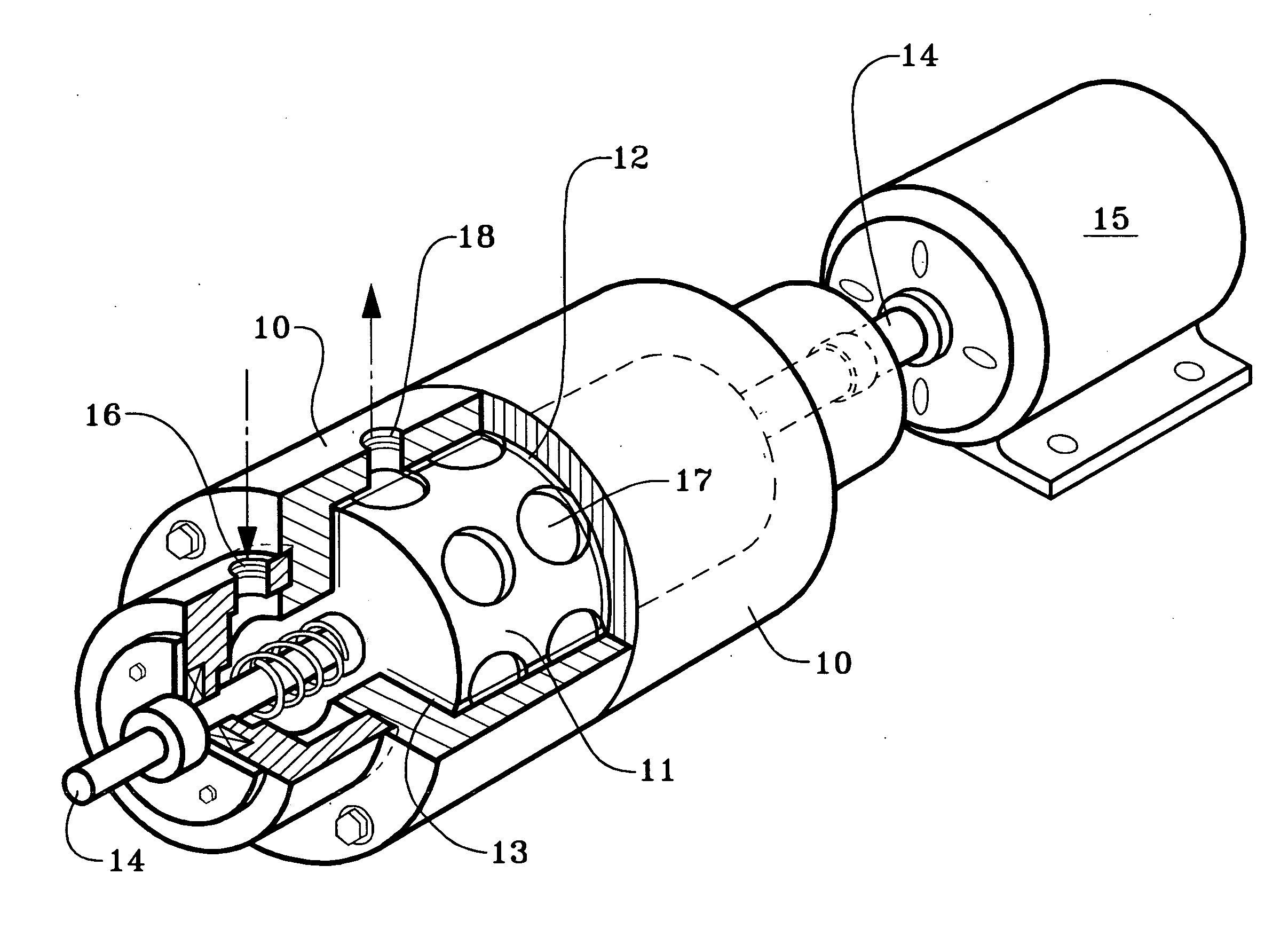

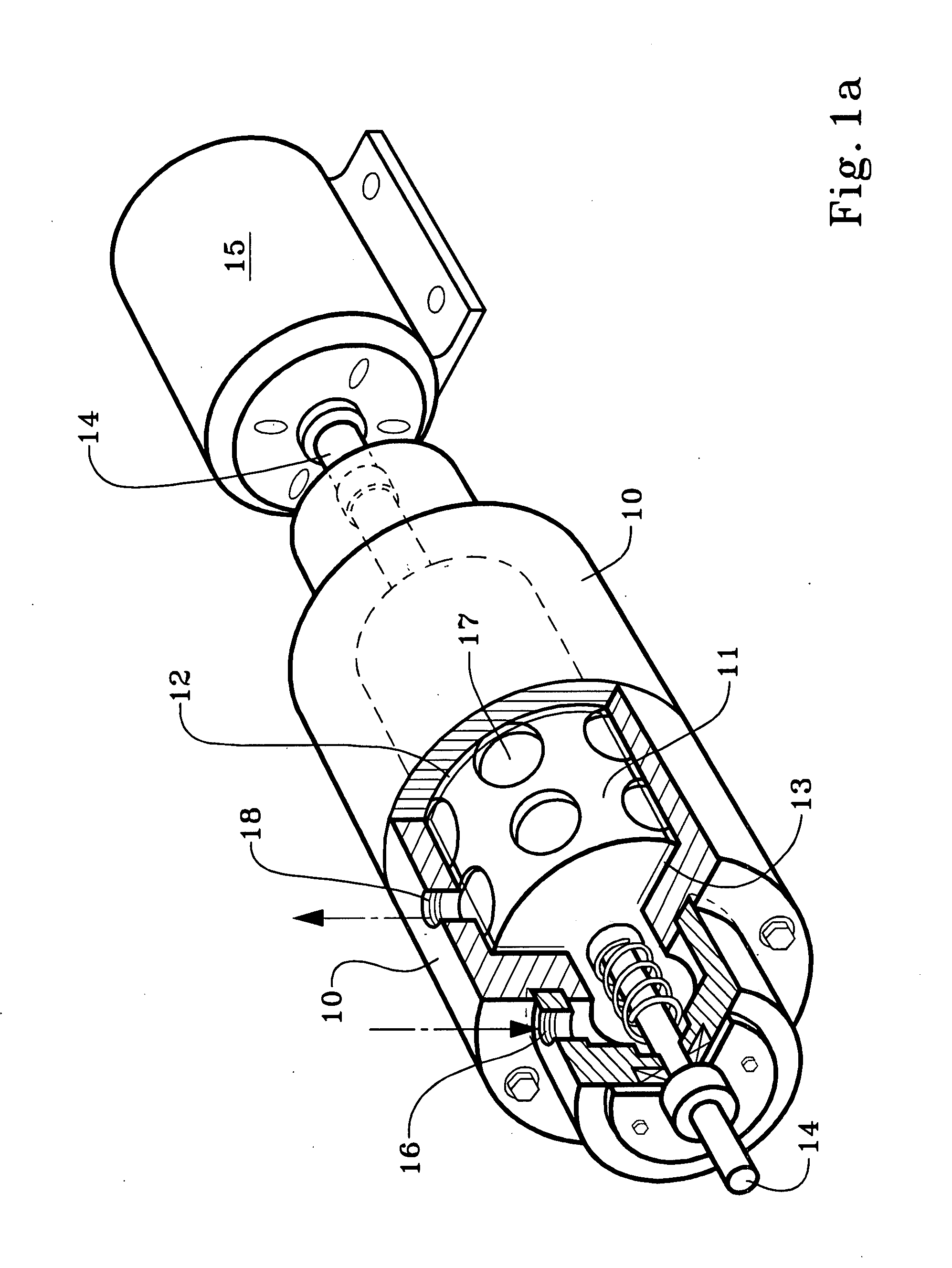

Gasoline vaporizer

InactiveCN103527356ASmall modificationImprove vaporization efficiencyInternal combustion piston enginesThermal treatment of fuelInjector nozzleSolenoid valve

The invention provides a gasoline vaporizer, and aims to overcome the defects that an existing gasoline vaporizer is low in vaporization efficiency and an integrated vaporization system can not be formed. The gasoline vaporizer is characterized in that an original oil supply system of an engine is reserved and is directly connected with a gas vent of the engine, and waste heat of the engine is used for vaporizing gasoline; a temperature sensor installed below a vaporizing chamber is used for detecting whether the temperature of the vaporizing chamber reaches 700 DEG C or not, and if yes, an oil spray nozzle above the vaporizing chamber starts to work; when gas pressure in a gas storage chamber reaches the oil supply pressure of an oil supply pump, the original oil supply system of the engine is closed through a solenoid valve, and gasoline gas supplies fuel. According to the gasoline vaporizer, vehicle refitting amount is small, the efficiency, degree and quality in liquid gasoline vaporization are high, an integrated control system is formed, convenience is brought to use and adjustment, safety and reliability in use are guaranteed, and the fuel consumption and harmful gas emission load of the engine in the use process can be substantially lowered.

Owner:洛阳希诺能源科技有限公司

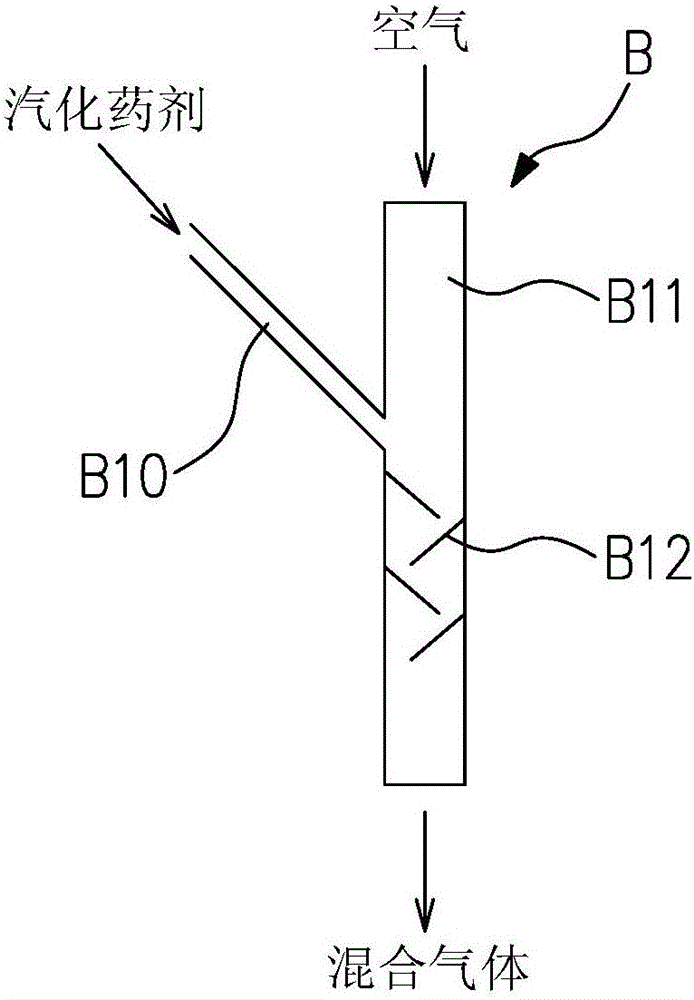

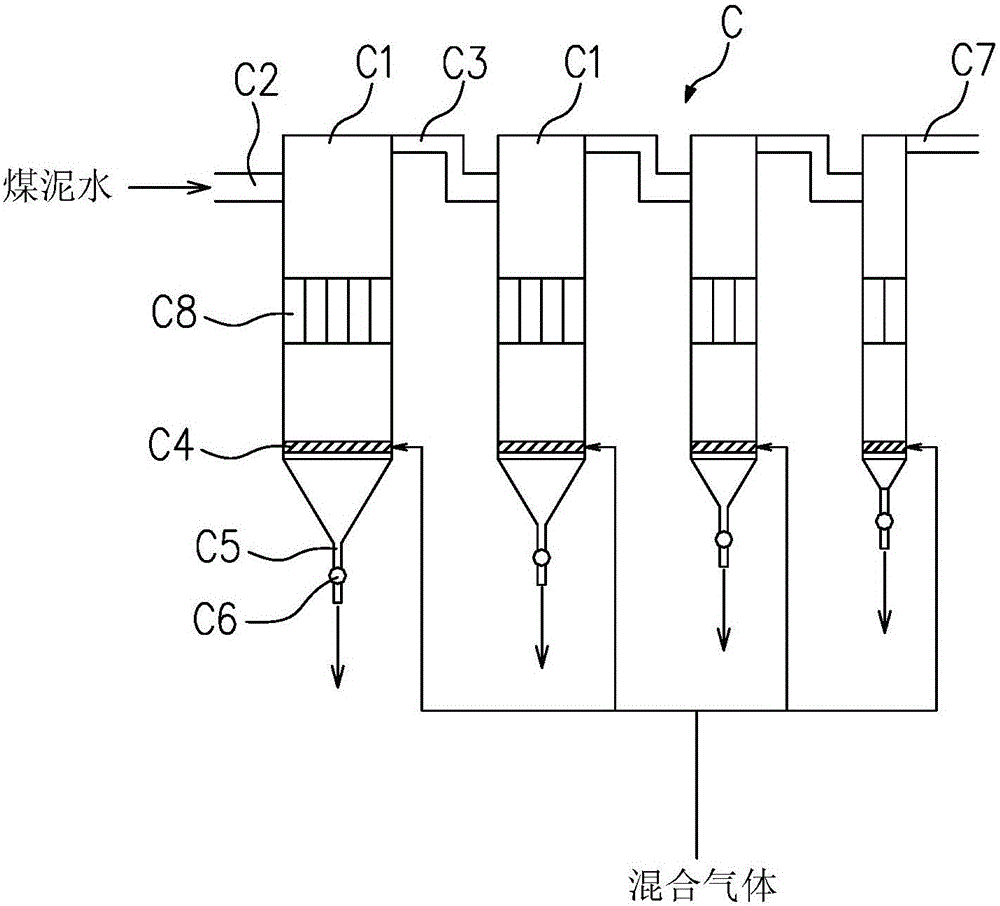

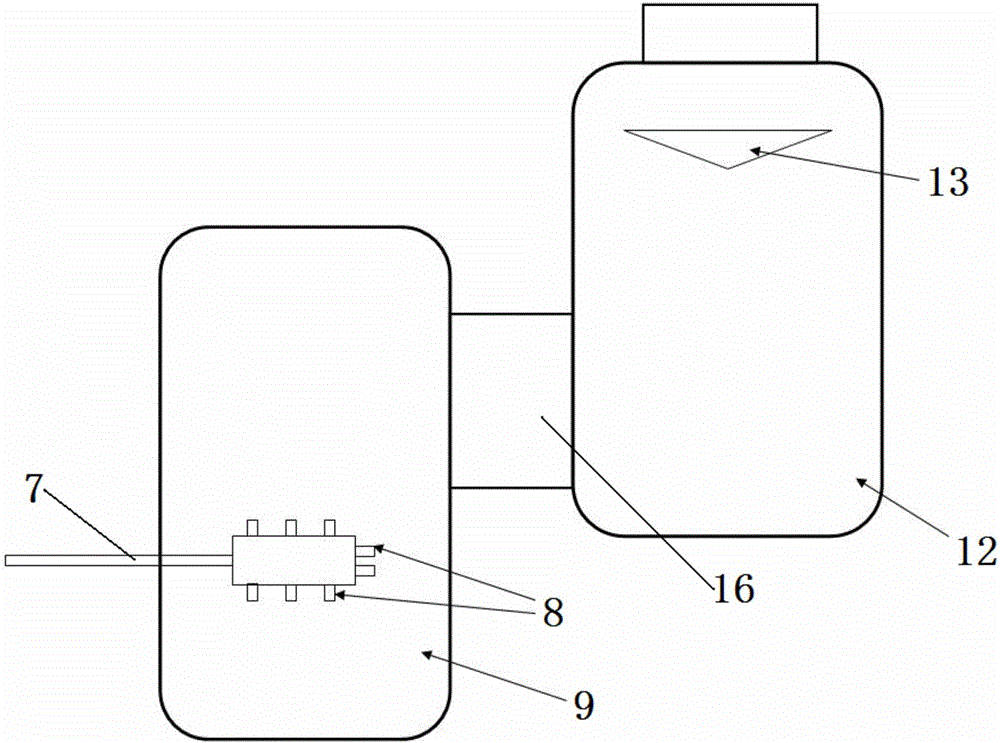

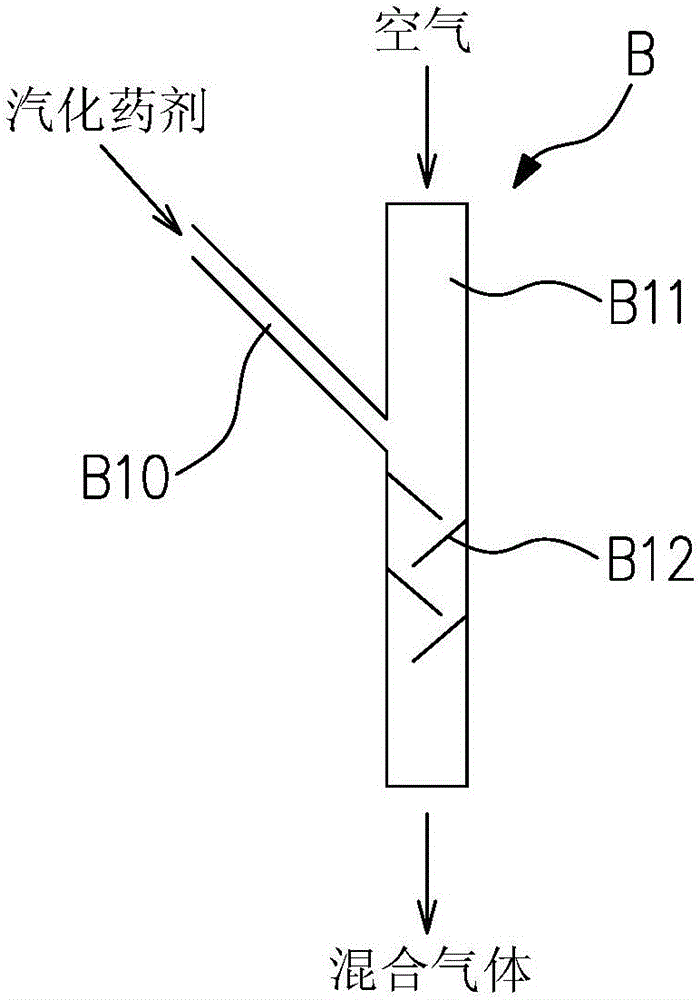

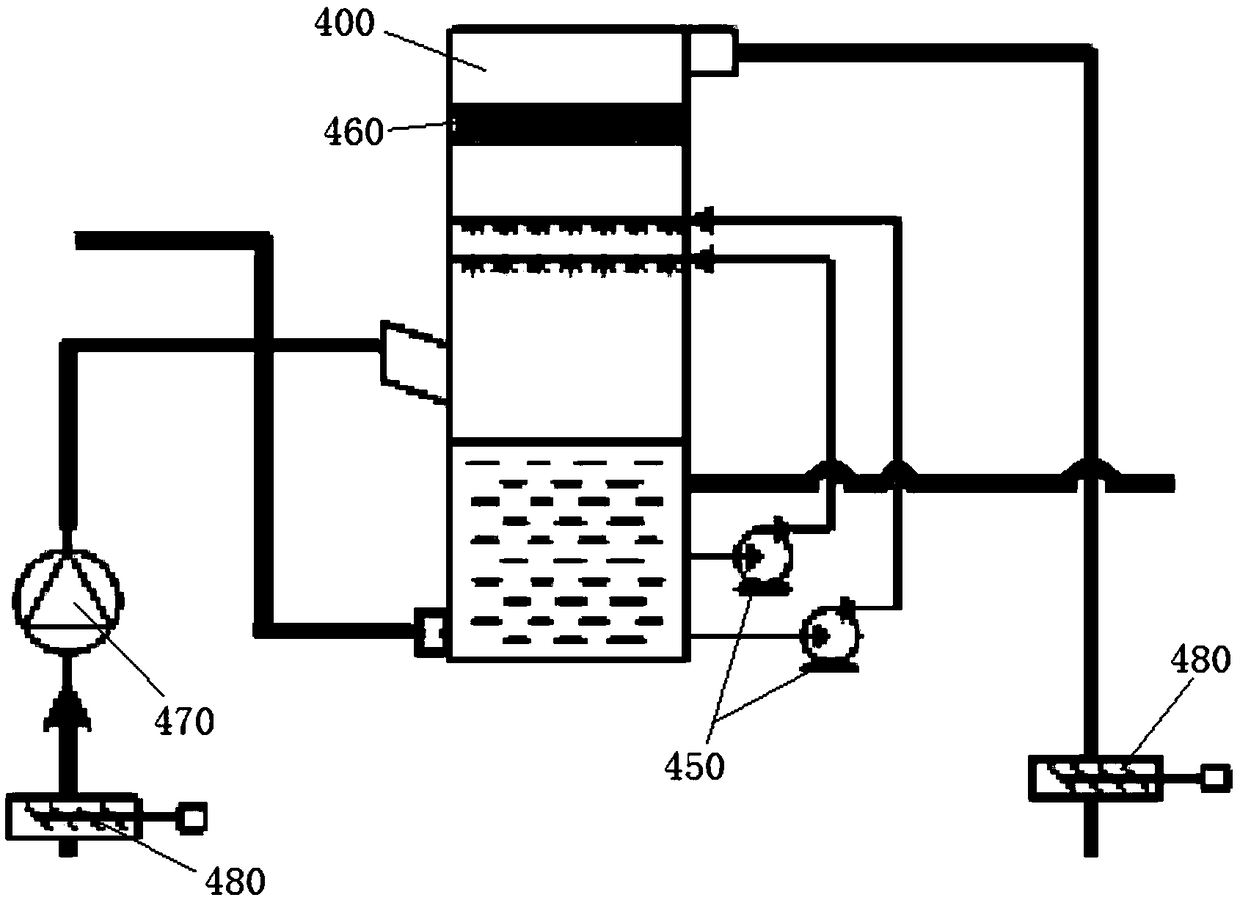

Slime water flotation device and technology

The invention discloses a slime water flotation device and technology. The slime water flotation device comprises a chemical pre-vaporization device, a chemical and air mixing device, a slime water pre-classifying device and flotation equipment. A vaporization chemical of the chemical pre-vaporization device is output to the chemical and air mixing device, the output end of the chemical and air mixing device communicates with the slime water pre-classifying device, and after being subjected to classifying flotation, the vaporization chemical flows into the flotation equipment. The flotation technology comprises the steps that firstly, the chemical is subjected to pre-vaporization and mixing, wherein a collecting agent and a foaming agent in a flotation chemical are subjected to pre-vaporization, and then the vaporization chemical and air are sufficiently mixed to form mixed gas; and secondly, slime water is subjected to pre-classifying and flotation, wherein the mixed gas is led into the slime water pre-classifying device to be subjected to classifying flotation. The slime water flotation device is simple in structure and stable in running, the contact area of the chemical and slime water is sufficiently increased, the slime water pretreatment effect is effectively improved, and the slime water classifying effect can be improved.

Owner:ANHUI UNIV OF SCI & TECH

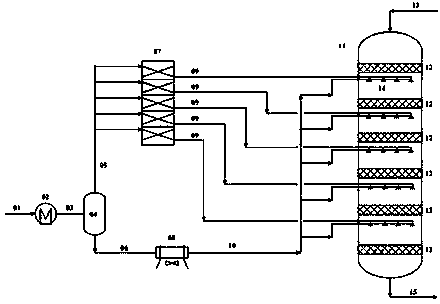

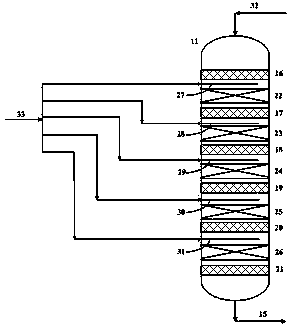

Methanol-to-olefin reaction apparatus and application thereof

ActiveCN104109072AHigh yieldImprove protectionHydrocarbon from oxygen organic compoundsReaction temperatureVaporization

The invention relates to a methanol-to-olefin reaction apparatus and an application thereof. The technical problems of high requirements and easy obstruction of chilled liquid phase nozzle equipment of a methanol-to-olefin multistage fixed bed reactor, mutual influences of the reaction temperature and the reaction air speed of the fixed bed reactor and low utilization rate of an intersegmental chilled liquid phase vaporization space existing in the prior art are mainly solved. The methanol-to-olefin reaction apparatus mainly comprises catalyst bed layers (16-21), distributors (27-31) and filler layers (22-26); and the top layer in the apparatus is the catalyst bed layer (16), the lower portion of the catalyst bed layer (16)is the distributor (27), the lower portion of the distributor (27)is the filler layer (22), the lower portion of the filler layer (22) is the catalyst bed layer (17), the bottom layer in the apparatus is the catalyst bed layer (21) in a same arrangement mode, a feed inlet is arranged between two adjacent bed layers, and the distributors are distributor pipe bustle pipe structures. The apparatus well solves the problems, and can be used in the industrial production of methanol-to-olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fine atomization flash tank

InactiveCN105727583AGood vaporization effectIncrease surface areaFlash distillationVaporizationFlash evaporation

The invention provides a fine atomization flash tank, which comprises an atomizing chamber and a vaporizing chamber, wherein the atomizing chamber is communicated with the vaporizing chamber; a feeding pipe of the fine atomization flash tank is arranged in the atomizing chamber and is provided with a plurality of atomization nozzles; a gas-liquid separator of the fine atomization flash tank is arranged on the vaporizing chamber; the inside of a tank body of the fine atomization flash tank is partitioned into two communicated chambers which are partitioned by a partition plate; the vaporizing chamber is arranged at the upper part of the partition plate; and the atomizing chamber is arranged at the lower part of the partition plate; or two tank bodies are taken as the atomizing chamber and the vaporizing chamber respectively and are communicated through a communicating channel. When the flash tank works, a material can be sprayed into the tank body through the atomization nozzles in a form of disperse droplets; the disperse droplets suspend in a space in the tank body; the surface area is large; vaporization is carried out on the surfaces of all droplets under the condition of low pressure in the tank body; a hydrostatic effect is avoided; the liquid vaporization effect is relatively good; and the defects that a traditional flash tank has the hydrostatic effect and is small in flash evaporation and vaporization surface area are overcome.

Owner:GUANGXI UNIV

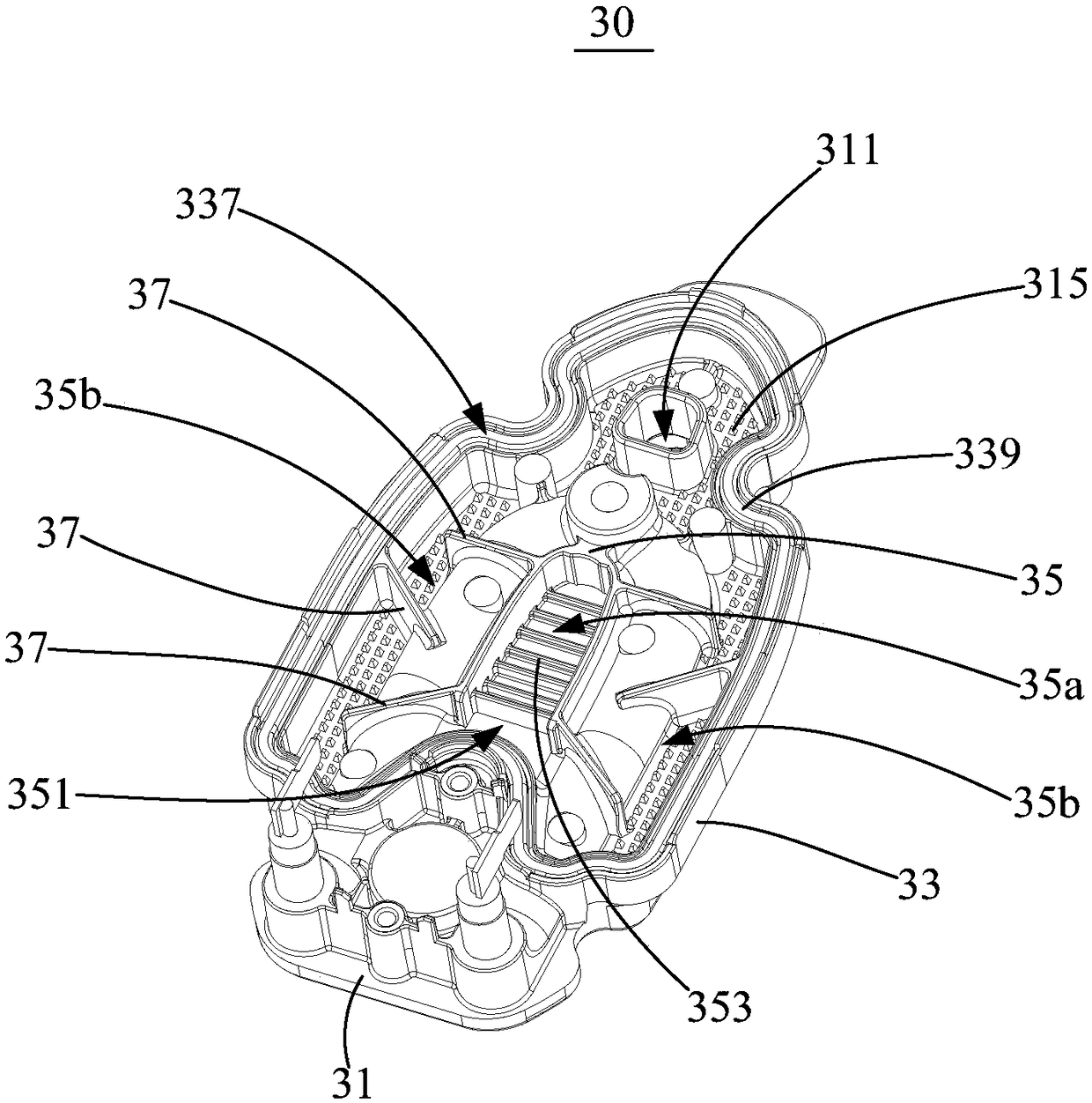

Heating body assembly, ironing head and ironing equipment

PendingCN108425225AIncrease pressureImprove continuityHand ironIroning apparatusIron panelEngineering

The invention discloses a heating body assembly, an ironing head using the heating body assembly, and ironing equipment using the ironing head. The heating body assembly comprises a heating body, a vaporizing chamber cover and an ironing panel, wherein the vaporizing chamber cover covers one side of the heating body and forms a first vaporizing cavity together with the heating body in an enclosingmanner; a steam inlet communicated with the first vaporizing cavity is formed in the vaporizing chamber cover; the ironing panel covers the other side of the heating body and forms a second vaporizing cavity together with the heating body in an enclosing manner; a steam outlet hole communicated with the second vaporizing cavity is formed in the ironing panel; a steam through hole communicated with the first vaporizing cavity and the second vaporizing cavity is formed in the heating body; a first limiting plate is arranged in the first vaporizing cavity and horizontally partitioned between thesteam inlet and the steam through hole. According to the technical scheme in the invention, the water dropping and injecting occurrence frequency of the ironing head of the ironing equipment in the using process can be reduced.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Hydrogen combustion-supporting device and method

ActiveCN104807031AFast heat transferAdjustment is quick and sensitiveLiquid fuel feeder/distributionAlcoholSteel ball

A hydrogen combustion-supporting device comprises an alcohol vaporization device, a hydrogen generator and a flame gun. The alcohol vaporization device comprises an evaporator and is characterized in that the evaporator comprises a body, a plurality of rows of circular tubes are arranged inside the body, heating catalytic agents are placed in the circular tubes, a plurality of micropores are formed in the peripheries of the circular tubes and filled with steel balls, and liquid alcohol flows through the micropores and is vaporized by the aid of heat energy released by the heating catalytic agents. According to a method for hydrogen combustion-supporting by the hydrogen combustion-supporting device, gas alcohol generated by the alcohol vaporization device and hydrogen generated by the hydrogen generator are jointly guided into the flame gun and combust after being mixed with air. The combustion efficiency of fuels is increased, and contaminants such as nitric oxide (nitric oxide) or carbon black in exhaust can be decreased.

Owner:上海万寅安全环保科技有限公司 +2

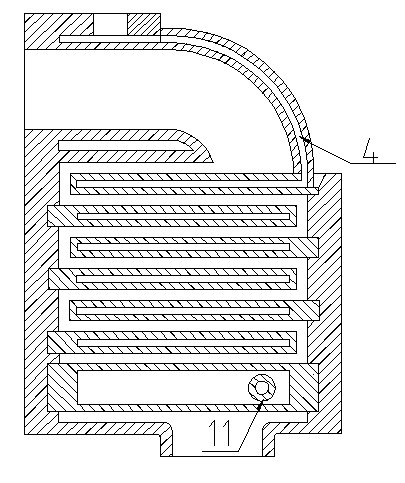

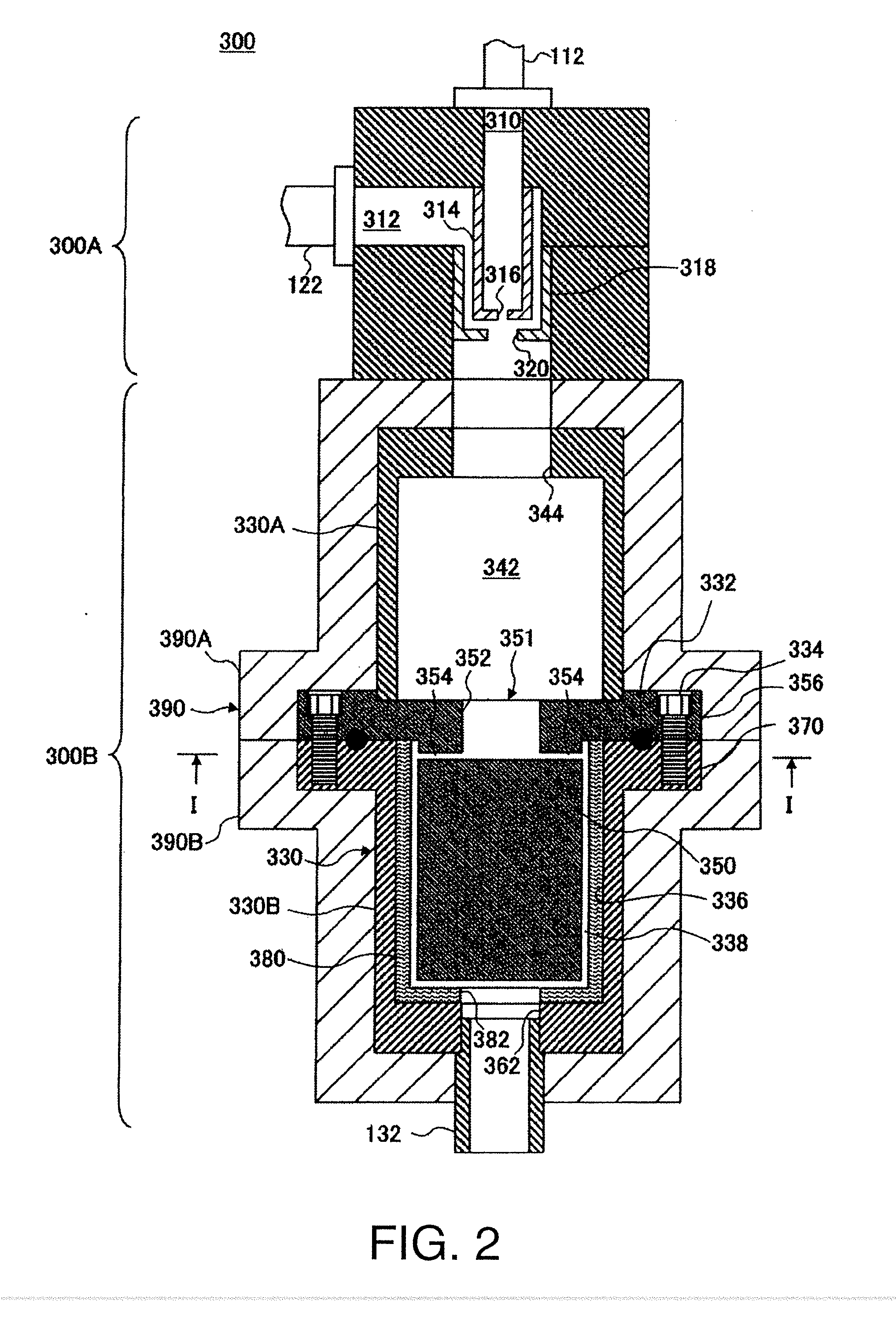

Liquid material vaporizer and film deposition apparatus using the same

InactiveUS20110079179A1Film deposition is inhibitedEfficient solutionSteam generation heating methodsSpray nozzlesEngineeringMaterial supply

The present invention is a liquid material vaporizer comprising a liquid-material supply part configured to make a liquid material into a droplet state and to discharge the same, and a vaporizing part configured to vaporize the liquid material in a droplet state so as to generate a source gas, the vaporizing part including: an inlet port to which the liquid material in a droplet state is introduced from the liquid-material supply part; a housing body of a bottomed tubular shape, the housing body having an opening end on a side of the inlet port; a columnar block having a flange for closing the opening end of the housing body, the columnar block being fitted in the housing body in such a manner that a gap serving as a vaporizing path is defined between the columnar block and an inside surface of the housing body; a breathable mist trap member disposed in the vaporizing path formed between the inside surface of the housing body and an outside surface of the columnar block, in such a manner that the mist trap member is in contact with the inside surface of the housing body and covers the outside surface of the columnar block; a heating part disposed to cover the housing body, the heating part being configured to heat the mist trap member through the housing body; a spout formed in the columnar block in such a manner that the spout is in communication with the inlet port, and passes through the columnar block from an end surface of the columnar block on the side of the inlet port to a side surface of the columnar block, the spout being configured to spout the liquid material in a droplet state, which has been introduced from the inlet port, toward an inside surface of the mist trap member; and an outlet port disposed in a bottom part of the housing body, the outlet port being configured to deliver a source gas generated by the mist trap member that vaporizes the liquid material in a droplet state in the vaporizing path.

Owner:TOKYO ELECTRON LTD

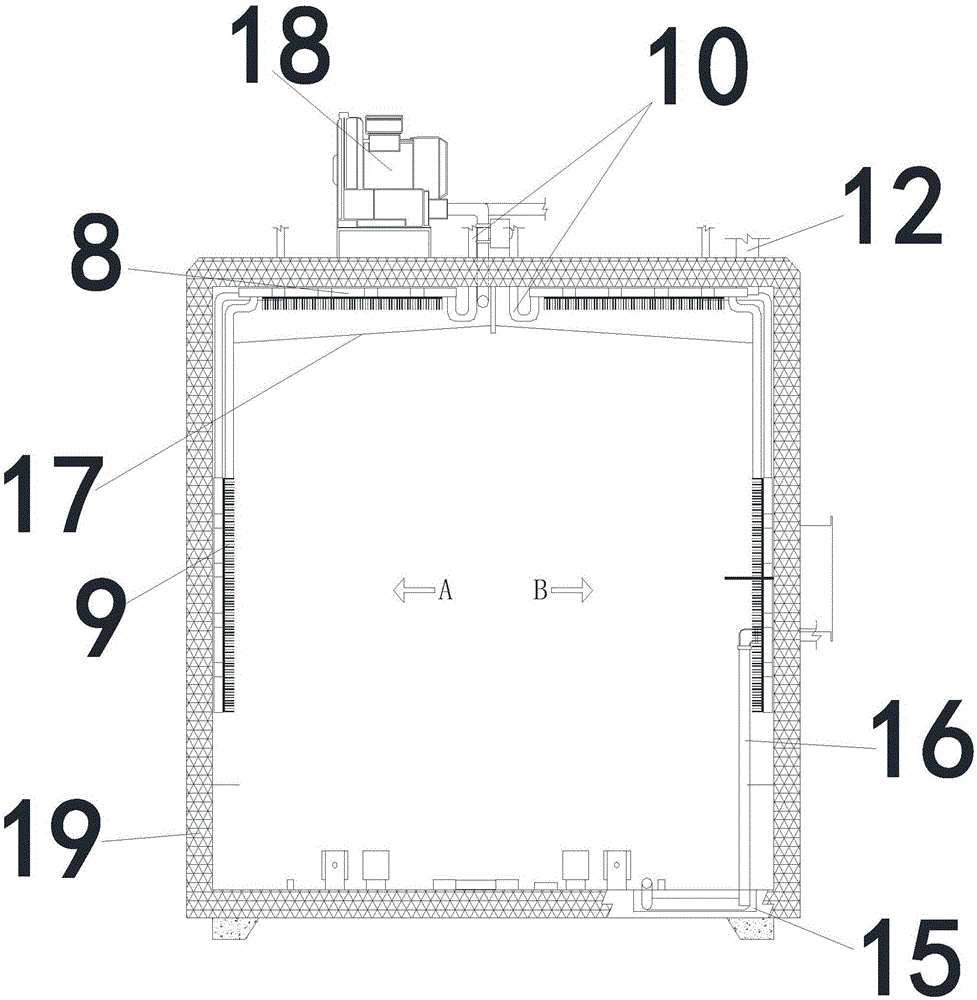

Double-station type high-frequency vacuum dryer and implementation method thereof

ActiveCN105157355AIncrease productivitySimple structureDrying solid materials without heatDrying machines with local agitationEngineeringCirculating pump

The invention discloses a double-station type high-frequency vacuum dryer. The double-station type high-frequency vacuum dryer comprises a box body which is provided with a front opening door and a back opening door, wherein a front material trolley is arranged at the front opening door, and a rear material door is arranged at the back opening door; a high-frequency machine is arranged on the side edge of the outer part of the box body; a water collecting box system is arranged on the side edge of the high-frequency machine; a water circulating pump, which is connected with a vacuum pump through a pipeline, is arranged on the water collecting box system; the vacuum pump is connected to the top part of a water filling box through the pipeline. The double-station type high-frequency vacuum dryer has the characteristics of being simple in structure, low in cost, high in production efficiency, wide in scope of application, and complete in circulating systems, saving energy and reducing emission, and being outstanding in condensing effect and good in use effect.

Owner:东阳市尚德电器机械有限公司

Application of carbon nanotube-grafted carbon fiber composite filiform filler in vaporizing chamber of gas chromatograph

ActiveCN105784855AGood chemical stabilityImprove thermal stabilityComponent separationBoiling pointCarbon nanotube

The invention discloses application of a carbon nanotube-grafted carbon fiber composite filiform filler in a vaporizing chamber of a gas chromatograph. The carbon nanotube-grafted carbon fiber composite filiform filler is placed in the vaporizing chamber of the gas chromatograph. The carbon nanotube-grafted carbon fiber composite filiform filler has the advantages of a great specific surface area, high temperature resistance, good chemical and thermal stability, long service life, etc., is applicable to detection of trace substances in low-boiling-point substances and complex matrixes, and has wide application prospects.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

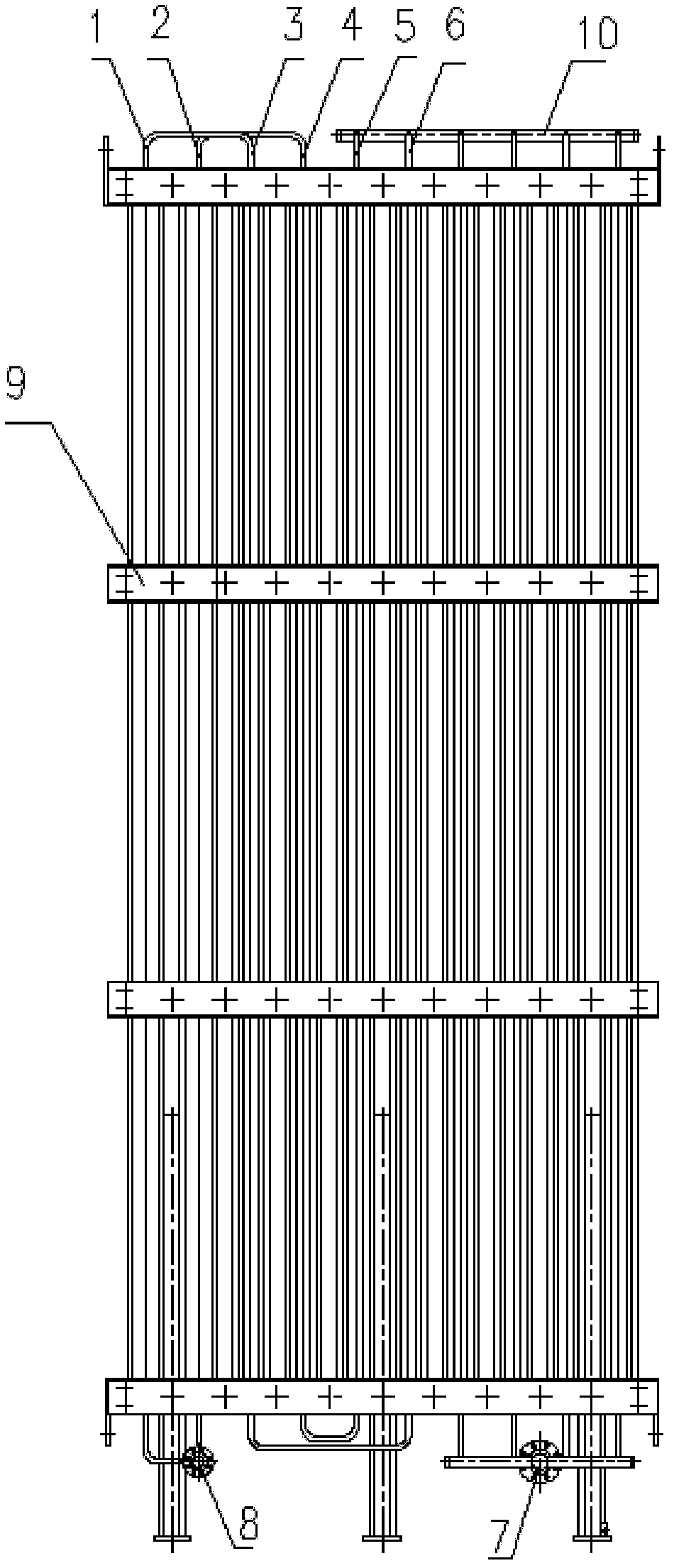

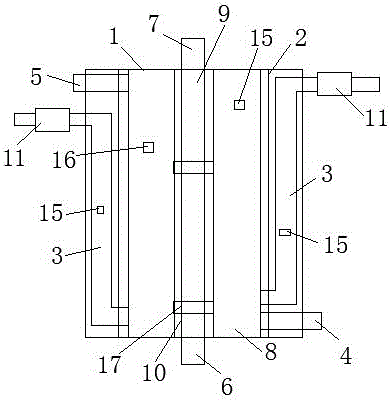

Communicating system for vaporizer

The invention provides a communicating system for a vaporizer, which comprises fin heat exchange pipes, a liquid inlet pipe, a vapor outlet pipe and a connecting pipe. A vaporization connecting system comprises a plurality of vaporization units in parallel connection and fixed on a frame, each vaporization unit comprises two rows of multi-line fin heat exchange pipes, a sixth fin heat exchange pipe, a fifth fin heat exchange pipe, a fourth fin heat exchange pipe, a third fin heat exchange pipe, a second fin heat exchange pipe and a first fin heat exchange pipe of each vaporization unit are sequentially arranged and alternately connected, namely, the fifth fin heat exchange pipe, the fourth fin heat exchange pipe and the second fin heat exchange pipe are sequentially connected end to end, and the sixth fin heat exchange pipe, the third fin heat exchange pipe and the first fin heat exchange pipe are sequentially connected end to end so that two mutually spaced branches are formed, and a vaporization effect is better. The communicating system for the vaporizer adopts the mode of alternately connecting the abreast heat exchange pipes to form the two mutually spaced branches, so that vaporization efficiency is improved.

Owner:WUXI PHAETON CRYOTECH CO LTD

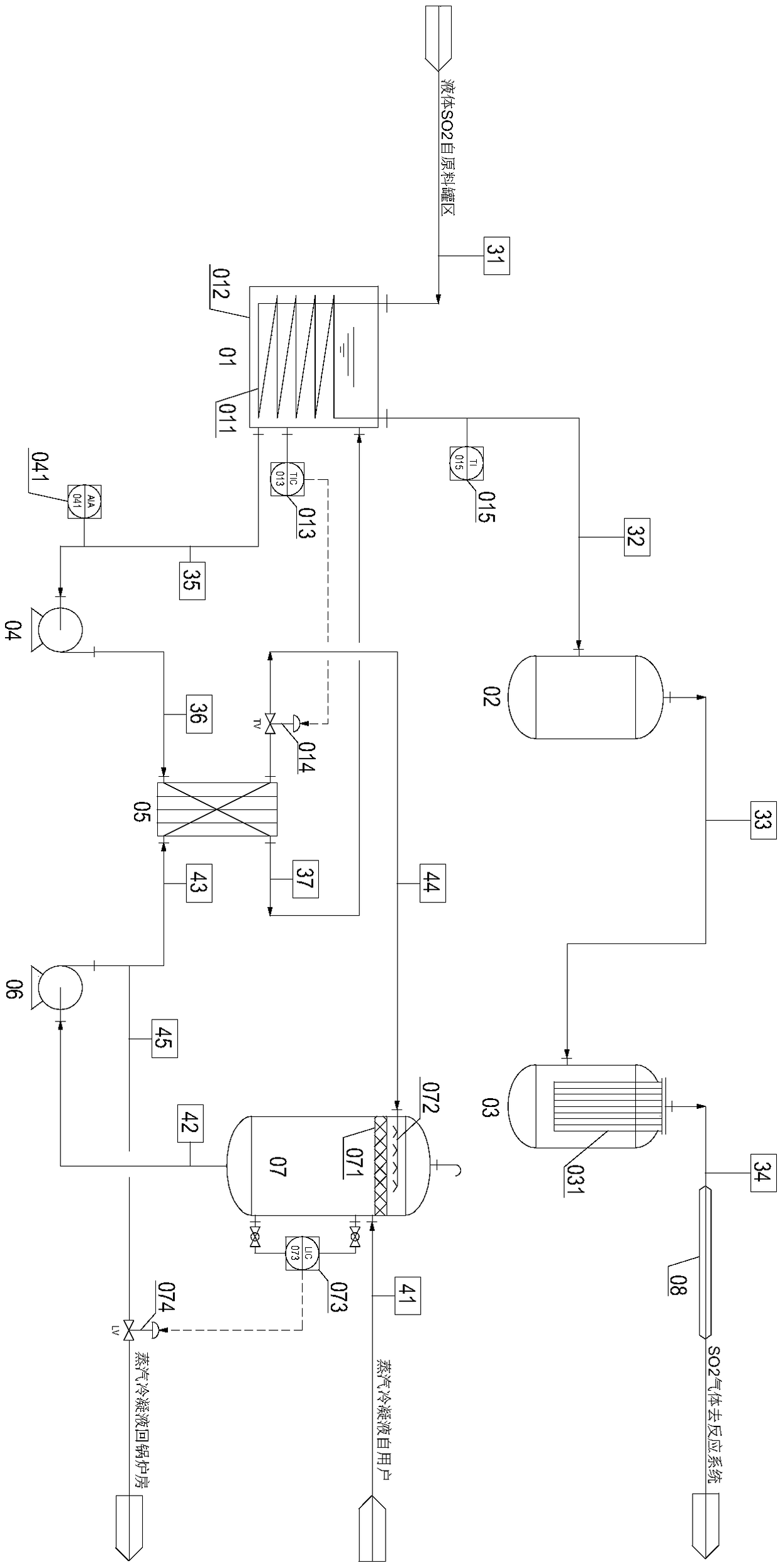

Sulfur dioxide vaporization technology for thionyl chloride production

ActiveCN108467017AImprove heat transfer coefficientImprove vaporization efficiencyThionyl chlorideBuffer tankVaporization

The invention provides a sulfur dioxide vaporization technology for thionyl chloride production. The technology comprises steps as follows: step 1, liquid sulfur dioxide enters a vaporizer for vaporization, and the vaporizer is a coil pipe type vaporizer; step 2, sulfur dioxide gas obtained after vaporization enters a buffer tank for gas-liquid phase separation, and large-diameter liquid drops inthe gas are removed; step 3, the sulfur dioxide gas enters a gas-liquid separation tank, and tiny droplets and oil mist entrained in the gas are removed. The technology is simple to control, equipmentinvestment is low, popularization is facilitated, heat transfer coefficient in a sulfur dioxide vaporization process is effectively increased, the service life of equipment is prolonged, and meanwhile, energy consumption is substantially reduced.

Owner:CHINA TIANCHEN ENG

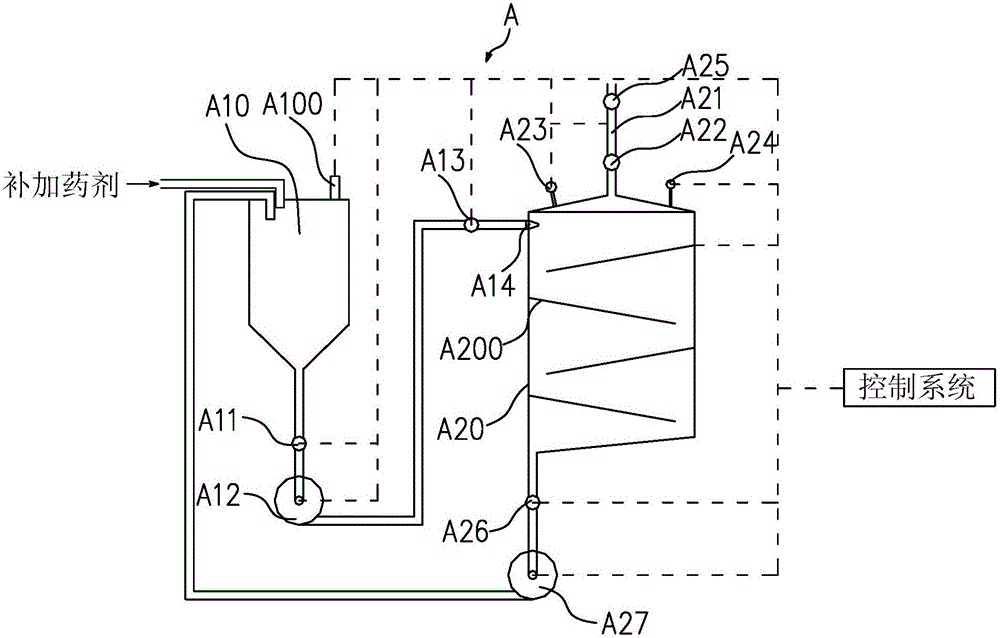

Coal slime water flotation reagent vaporizing device and vaporizing method thereof

ActiveCN105728201ASimple structural designIncrease contact areaFlotationElectric heatingControl system

The invention discloses a coal slime water flotation reagent vaporizing device and a vaporizing method thereof. The coal slime water flotation reagent vaporizing device comprises a reagent barrel, wherein the reagent barrel communicates with a vaporizing container through an electric control valve I, a high pressure pump, an electric control valve II and a spray nozzle; the part, at the upper end of the container, of the vaporizing container is connected to an electric heating tube; an electric control valve III used for collecting the vaporizing reagent is arranged on the electric heating tube; a temperature monitoring device and a pressure monitoring device for monitoring the temperature and the pressure of the inner part of the container are arranged on the vaporizing container; and the vaporizing container is further connected with a vacuum-pumping pipeline which communicates with the reagent barrel. The vaporizing container comprises a plurality of electric heating plates which are arranged on the inner part of the container, wherein the heating temperature of the electric heating plates is gradually increased from top to bottom; and the part, at the outlet of the electric control valve III, of the electric heating tube is further provided with a flow monitoring device. The device is further provided with a control system which is electrically connected to the monitoring devices, the electric control valve, the electric heating tube, the high pressure pump, the vacuum pump and the electric heating plate. The device is simple in structure, and is stable to operate, and the contact area of the reagent and coal slime water is sufficiently increased.

Owner:ANHUI UNIV OF SCI & TECH

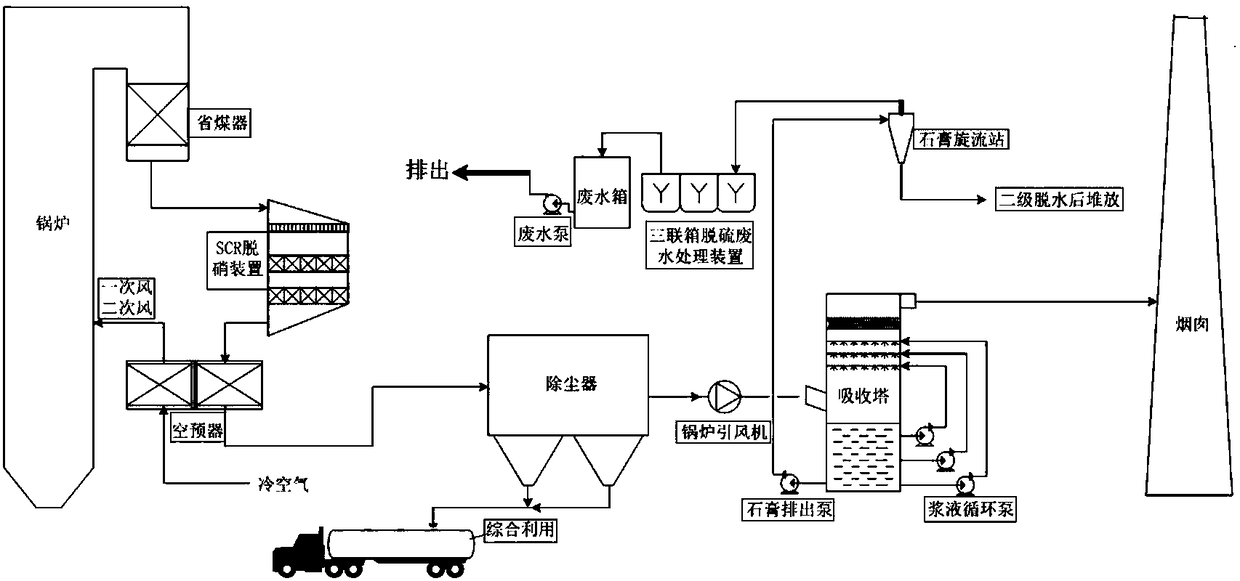

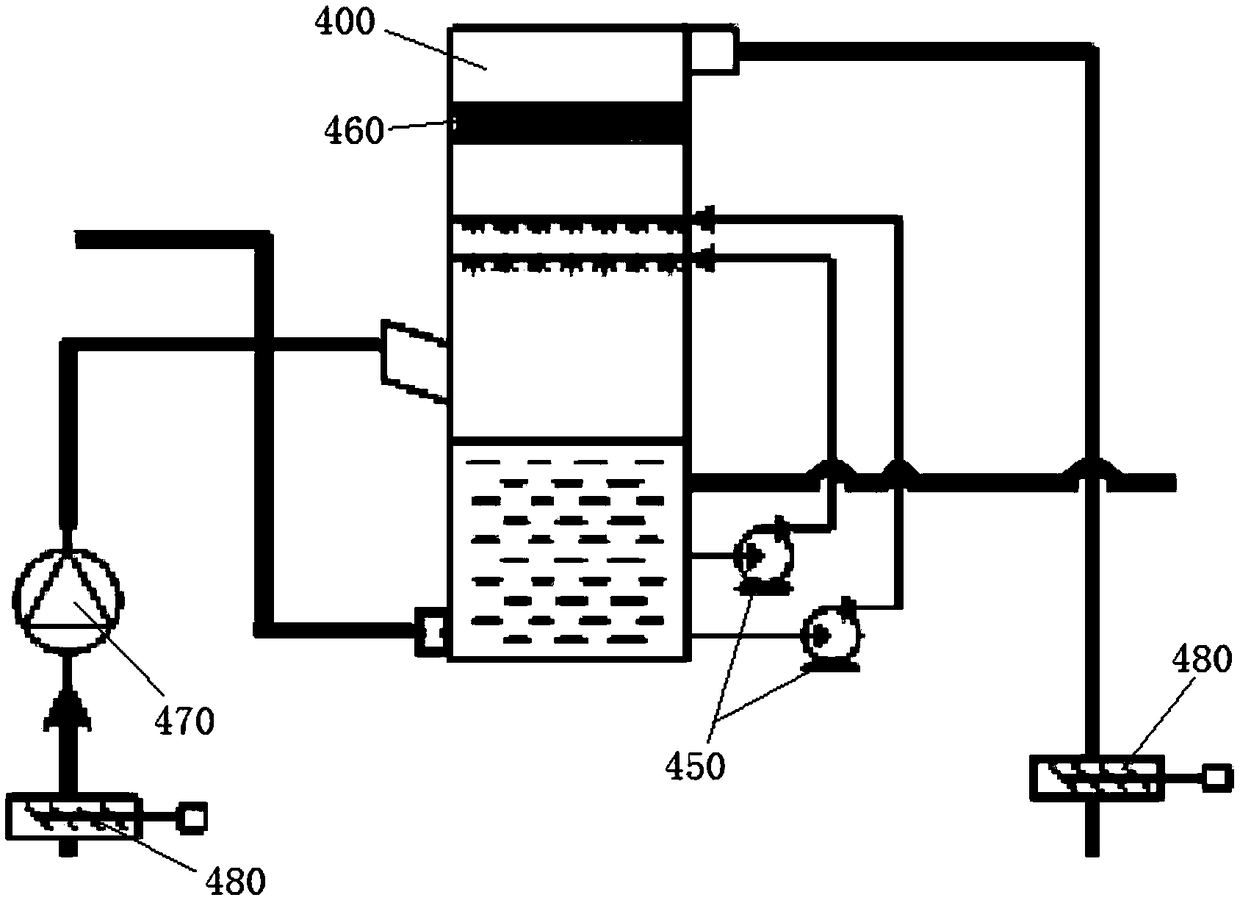

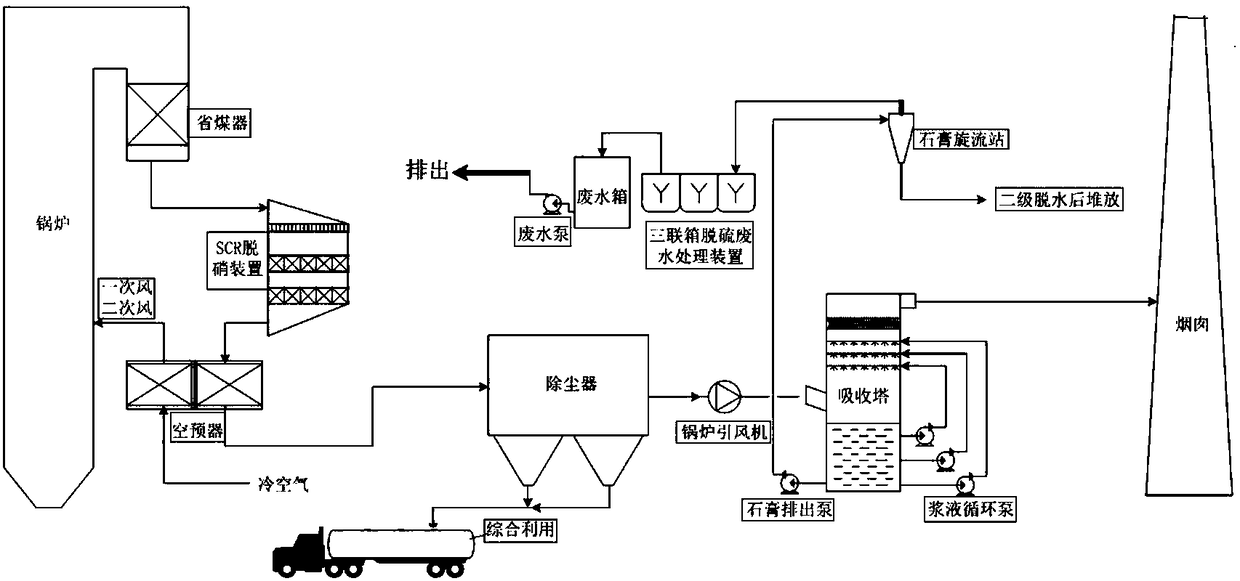

Device and method for treating power plant waste water

PendingCN108557932AImprove processing efficiencyGreatly reduce work pressureWaste water treatment from gaseous effluentsWater/sewage treatment by heatingFlue gasEvaporation

The invention provides a device for treating power plant waste water, aiming at solving the technical problem of how to achieve zero emission of the power plant waste water. The device has a structurecomprising an atomizing evaporation tower provided with a flue gas distributor and an evaporation tower tank; the evaporation tower tank is provided with a flue gas outlet and an ash discharge hole;the flue gas distributor is arranged on the top or the side wall of the evaporation tower tank; the flue gas distributor comprises a flue and a flue gas guide plate; the flue is communicated with an inner cavity of the evaporation tower tank; the flue of the flue gas distributor is internally provided with a rotary atomizer mounting sleeve; the rotary atomizer mounting sleeve is internally provided with a rotary atomizer; the rotary atomizer is communicated with the inner cavity of the evaporation tower tank; a concentrating tower is provided with a waste water input interface, a concentratedwater output interface, a concentrated flue gas inlet and a concentrated flue gas outlet; the concentrated water output interface is connected with the rotary atomizer in a sealing way by means of a pipeline; the concentrated flue gas inlet and the concentrated flue gas outlet are connected with a power plant flue gas discharge pipeline. The device has the technical advantage of realizing zero emission of the power plant waste water.

Owner:北京北科欧远科技有限公司

High-efficiency compact type LNG carburetor

InactiveCN104896986AImprove heat transfer efficiencyExtended service lifeNon-pressured vesselsContainer discharging from non-pressured vesselsEngineeringCarburetor

The invention discloses a high-efficiency compact type LNG carburetor. The high-efficiency compact type LNG carburetor comprises a shell and a heat exchange core body, the shell is a hexapetalous-flower-shaped cylinder with a cavity, cambered surfaces of the hexapetalous-flower-shaped cylinder are respectively provided with inflow openings and outflow openings used for heat exchange media, the heat exchange core body is formed by a plurality of groups of laminated regular hexagonal single boards, each group is formed by 4 regular hexagonal single boards, a plane between any corresponding two edges of the regular hexagonal single board is provided with a plurality of channels, opposite channel openings of the 4 regular hexagonal single boards in each group form 60 degrees and tightly attached and laminated in the shell in a staggered manner, and six corners of the regular hexagonal single boards are connected with the shell in a welding manner to form six mutually independent vertical sealed cavities respectively corresponding to the inflow openings and the outflow openings. According to the high-efficiency compact type LNG carburetor, heat exchange of three heat exchange media in the same carburetor is accomplished, the heat exchange area of the carburetor is increased, the work pressure and the vaporization efficiency for the operation of the LNG carburetor are increased, and the size and the weight of the LNG carburetor are reduced.

Owner:JIANGSU UNIV OF SCI & TECH

Device and method for treating power plant waste water

PendingCN108557930AImprove processing efficiencyShare work pressureWaste water treatment from gaseous effluentsWater/sewage treatment by heatingFlue gasEvaporation

The invention provides a device for treating power plant waste water, aiming at solving the technical problem of how to achieve zero emission of the power plant waste water. The device has a structurecomprising a rotary atomizer, an evaporation tower deduster, a concentrating tower and an atomizing evaporation tower; the atomizing evaporation tower is provided with a hot air distributor and an evaporation tower tank; the hot air distributor comprises an air flue and a hot air guide plate; an outlet of the air flue is communicated with an inner cavity of the evaporation tower tank; the air flue of the hot air distributor is internally provided with a rotary atomizer mounting sleeve, and the rotary atomizer mounting sleeve is internally provided with the rotary atomizer; the concentrating tower is provided with a waste water input interface, a concentrated water output interface, a concentrated flue gas inlet and a concentrated flue gas outlet; the concentrated water output interface isconnected with the rotary atomizer in a sealing way by means of a pipeline; the concentrated flue gas inlet and the concentrated flue gas outlet are connected with a power plant flue gas discharge pipeline; the evaporation tower deduster is provided with a dedusting interface and a dust-free air discharge hole; an air outlet is connected with the dedusting interface. The device has the technicaladvantage of realizing zero emission of the power plant waste water.

Owner:北京北科欧远科技有限公司

Heater element for a vaporization device

ActiveUS20180153215A1Reduce surface roughnessHeating up fastSteam generation heating methodsContainer filling methodsPorous layerHeating element

A heating element for a vaporizing device, a vaporizing device containing the heating element, and a method for vaporizing fluid ejected by an ejection head. The heating element includes a conductive material deposited onto an insulative substrate, a protective layer deposited onto the conductive layer, and a porous layer having a porosity of at least about 50% deposited onto the protective layer. The heating element has an effective surface area (ESA) for fluid vaporization that is greater than a planar surface area defined by dimensions of the heating element so that a fluid contact surface of the heating element is greater than the planar surface area of the heating element.

Owner:FUNAI ELECTRIC CO LTD

Flat-iron and steam generating device thereof

InactiveCN101196288AImprove vaporization efficiencyMeet needsSteam generation heating methodsHand ironEngineeringSteam generation

The invention discloses an electric iron and related steam generating device. The electric iron at least comprises a shell, a water tank, a steam generating device and an electric hot plate; wherein, the water tank is arranged on the shell; the electric hot plate is connected with the shell; the steam generating device is connected with the water tank, which at least comprises a device body and a blank wall; the device body has a steam generating chamber and a shell encircling the steam generating chamber; the blank wall is positioned in the steam generating device for parting the steam generating chamber into a flow channel; wherein, the flow channel is used for increase the conducting area, one end of which is used for communicating with a water inlet of the steam generating chamber and another end of which is used for communicating with an air outlet of the steam generating chamber; the hole diameter of the flow channel is smaller than the section area of the steam generating chamber.

Owner:TSANN KUEN CHINA ENTERPRISE

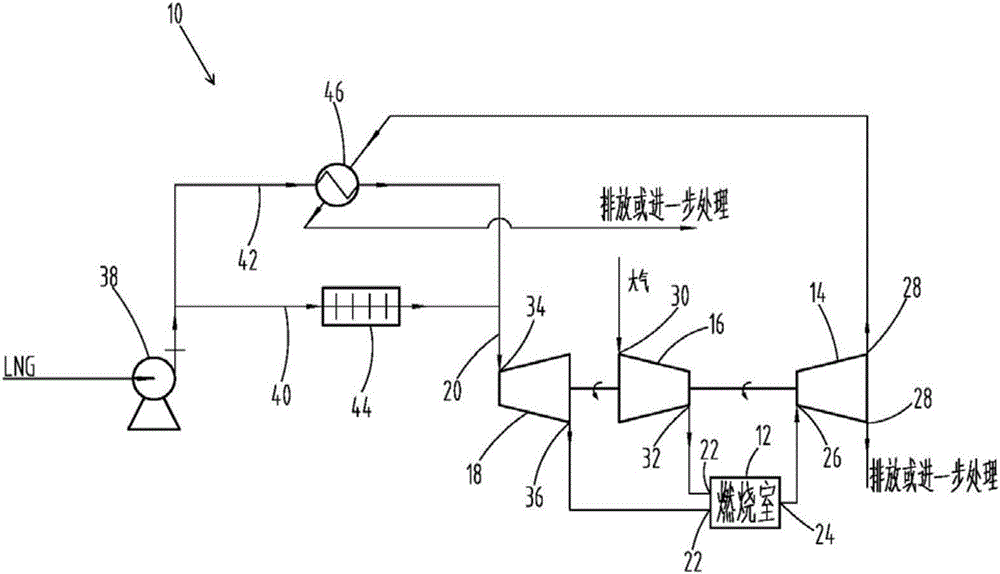

LNG gas turbine and starting system thereof

InactiveCN106640376AImprove vaporization efficiencyIncrease pressureTurbine/propulsion fuel flow conduitsTurbine/propulsion engine ignitionCombustion chamberGas compressor

The invention discloses an LNG gas turbine and a starting system thereof. A combustion chamber, a turbine and a gas compressor are included. The gas compressor is in drive connection with the turbine. The combustion chamber comprises a combustion chamber inlet and a combustion chamber outlet. The turbine comprises a turbine inlet and a turbine outlet. The turbine inlet communicates with the combustion chamber outlet. The gas compressor comprises a gas compressor inlet and a gas compressor outlet. The gas compressor inlet is used for receiving air. The gas compressor outlet communicates with the combustion chamber inlet. The LNG gas turbine further comprises a natural gas conveying channel for conveying natural gas into the combustion chamber. The LNG gas turbine further comprises a natural gas turbine. The natural gas turbine communicates with the natural gas conveying channel, and therefore gaseous natural gas in the natural gas conveying channel acts in the natural gas turbine and then leads to the combustion chamber. The natural gas turbine is connected with the gas compressor, and therefore the natural gas turbine drives the gas compressor to rotate when rotating in the acting process of the natural gas.

Owner:SHENZHEN WISDOM ENERGY TECH CO

High-efficiency liquefied natural gas vaporization and phase change cool storage device

PendingCN109186157AImprove vaporization efficiencySave energyDomestic cooling apparatusHeat storage plantsCompressed natural gasCool storage

The invention discloses a high-efficiency liquefied natural gas vaporization and phase change cool storage device. The high-efficiency liquefied natural gas vaporization and phase change cool storagedevice comprises a housing, a heat exchange baffle, a natural gas pipeline, a plurality of phase change cool storage spheres; the heat exchange baffle is arranged in the housing and used for dividingthe housing into a first cavity and a second cavity; liquefied natural gas is introduced into the natural gas pipeline; the natural gas pipeline extends into the first cavity, passes through the heatexchange baffle, and then extends out of the second cavity; the phase change cool storage spheres are arranged in the second cavity; gaps between the first cavity and the natural gas pipeline are filled with a first coolant; gaps among the second cavity, the natural gas pipeline and the phase change cool storage sphere are filled with a second coolant; and the interiors of the phase change cool storage spheres are filled with a phase change material. The vaporization efficiency of the liquefied natural gas can be improved, cold energy in the vaporization process is recovered, and the energy issaved. The high-efficiency liquefied natural gas vaporization and phase change cool storage device is simple in structure and easy to realize, and can be widely applied to small liquefied and compressed natural gas gasification stations.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Novel liquid chlorine vaporizer

InactiveCN106152832ASimple structureEasy to useThermal insulationStationary tubular conduit assembliesThermal insulationHeat losses

The invention relates to a new type of liquid chlorine vaporizer, which comprises a casing, an interlayer is arranged inside the casing, an insulation pipe is arranged between the casing and the interlayer, a water inlet is arranged at the right end of the casing, and a water inlet is arranged at the left end of the casing. There is a water outlet, the lower end of the casing is provided with a liquid chlorine inlet, the upper end of the casing is provided with a chlorine gas outlet, a hot water pipe and a vaporization pipe are arranged inside the casing, the water inlet is connected to the water outlet through a hot water pipe, and the The hot water pipe is provided with a through hole, the vaporization pipe is arranged in the through hole, the liquid chlorine inlet is connected with the chlorine gas outlet through the vaporization pipe, the lower end of the hot water pipe is connected with the heat preservation pipe, and the heat preservation pipe is provided with There is a filter; in the present invention, the device can be kept warm, which can effectively prevent certain influence on the vaporization of liquid chlorine due to the low temperature in the back section of the vaporization pipeline, can effectively prevent heat loss caused in the heating process, and effectively improve the Production efficiency, saving production costs.

Owner:NANJING ZHONGTENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com