Feed liquid distribution film forming device of falling film evaporator

An evaporating device and film forming technology, which is applied to evaporator accessories, evaporation, separation methods, etc., can solve the problems of large fluctuations in liquid film thickness, uneven liquid film distribution, and poor product interchangeability, and improve heat transfer Area and vaporization efficiency, improve the uniformity of film formation, and facilitate assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

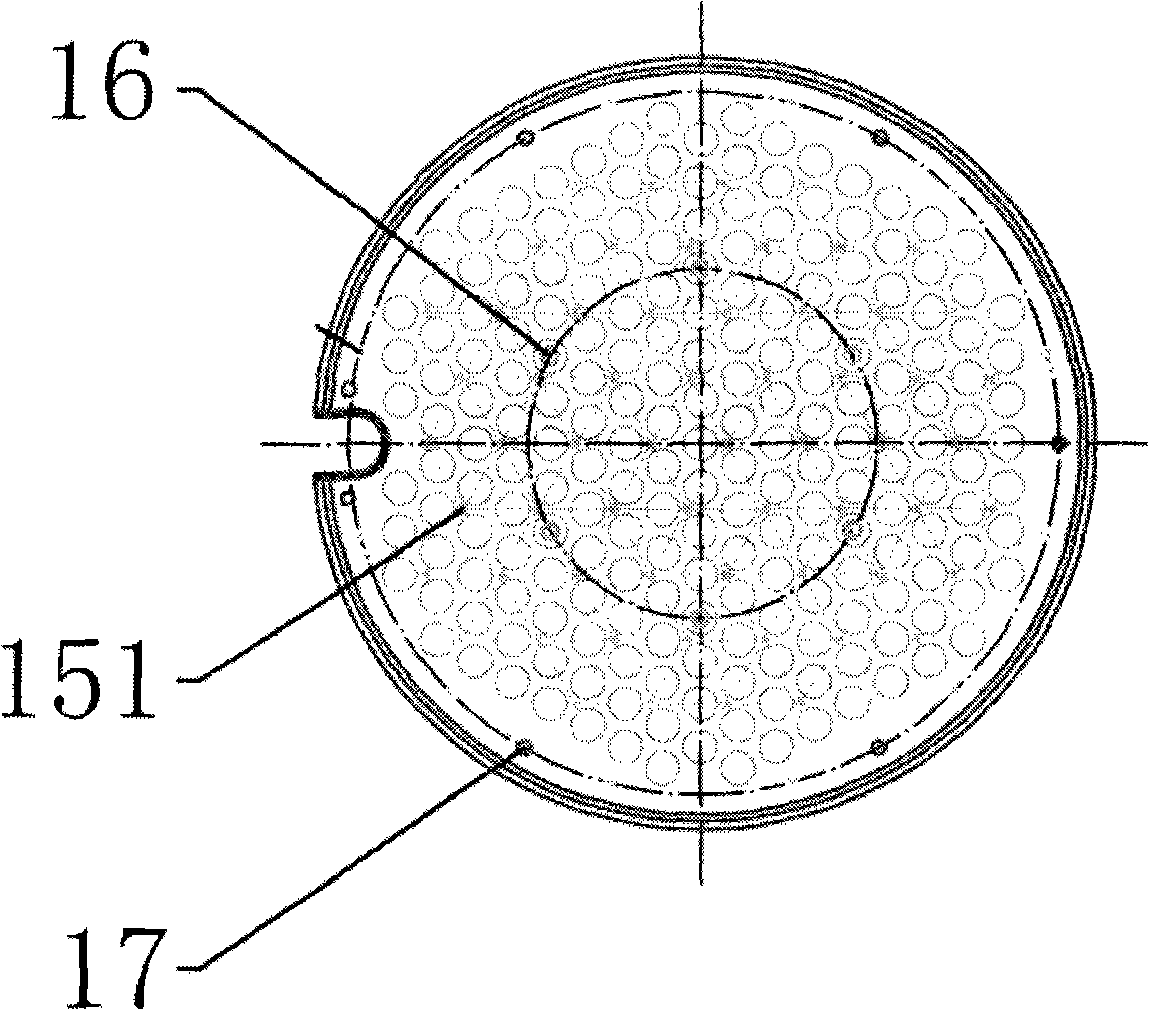

Embodiment Construction

[0021] The present invention provides a feed-liquid distribution film forming device of a falling film evaporator, which is installed at the upper end of the heat exchange tube of a vertical tube-and-tube falling film evaporator, and its structural features include feeding inlet 11 through liquid pipe 12 Connected and two-stage cascaded liquid distribution mechanism, and the uniformly distributed and fixed heat exchange tube insert array 2 on the lower side of the liquid distribution mechanism, wherein the liquid distribution mechanism includes a liquid inlet buffer 13, a first-stage V-shaped groove overflow The liquid distributor 14 and the hole-shaped liquid distributor 15 of the second stage; and the top of each heat exchange tube of the heat exchange tube insert array 2 is equipped with a heat exchange tube insert 3 with a flexible center positioning mechanism (hereinafter referred to as the liquid distribution device). head), the liquid distribution head 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com