Heat pipe structure capable of controlling sintering position of capillary tissue and preparation method thereof

A capillary and heat pipe technology, used in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of heat pipe heat dissipation efficiency discount, steam flow channel space blockage, blocking, difficult to improve and overcome, etc. Conducive to pipe wall warping processing and improving the effect of practical progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

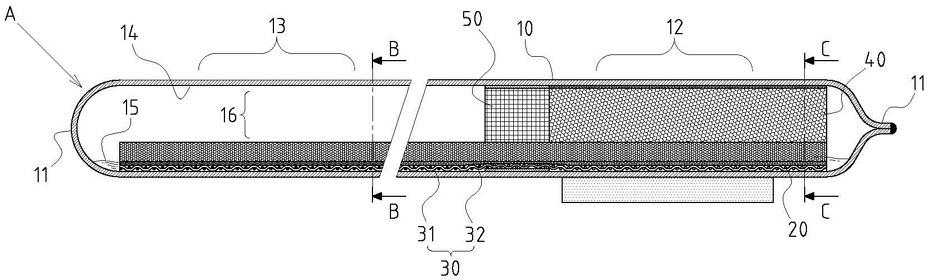

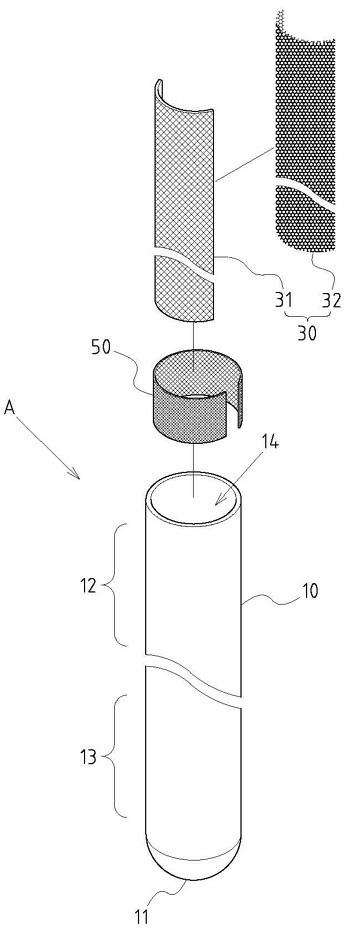

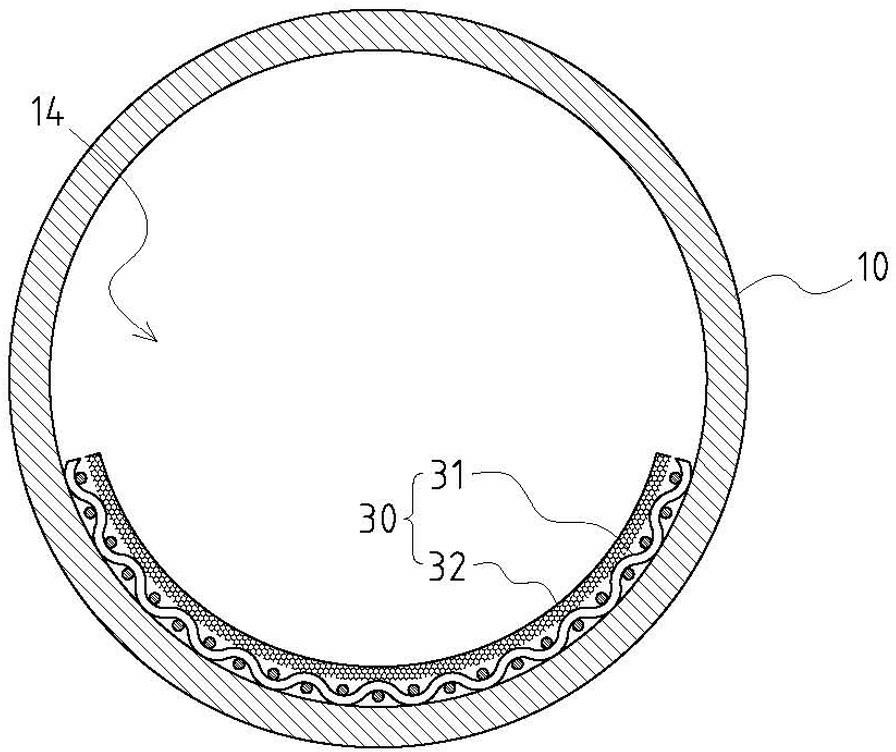

[0039] Example: see attached Figure 1~5 As shown, a heat pipe structure and its manufacturing method that can control the sintering position of the capillary structure, first of all, as far as the structural surface is concerned, the heat pipe A includes:

[0040] A tube body 10 is a hollow closed tube body with two sealed ends 11, which is divided into an evaporation section 12 and a condensation section 13 according to the heat dissipation effect, and the inner space 14 of the tube body 10 is in a vacuum state and accommodates Working fluid 15 (only marked on figure 1 );

[0041] An evaporating section sintered capillary structure 20, located in the evaporating section 12 of the tube body 10, is composed of at least metal powder 40 sintered and fixed on the inner wall of the evaporating section 12;

[0042] A network body sintered composite capillary structure 30 in an embedded form is located in the condensation section 13 of the tube body 10, and is composed of a metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com