Flat heat pipe with hook capillary tissue

a capillary tissue and heat pipe technology, applied in the field of heat pipes, can solve the problems of poor thermal conduction efficiency of the heat pipe, insufficient supply of working fluid, and reduced capillary tissue installed on the surface at the bottom of the pipe,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The technical characteristics, features and advantages of the present invention will become apparent in the following detailed description of the preferred embodiments with reference to the accompanying drawings. The drawings are provided for reference and illustration only, but not intended for limiting the present invention.

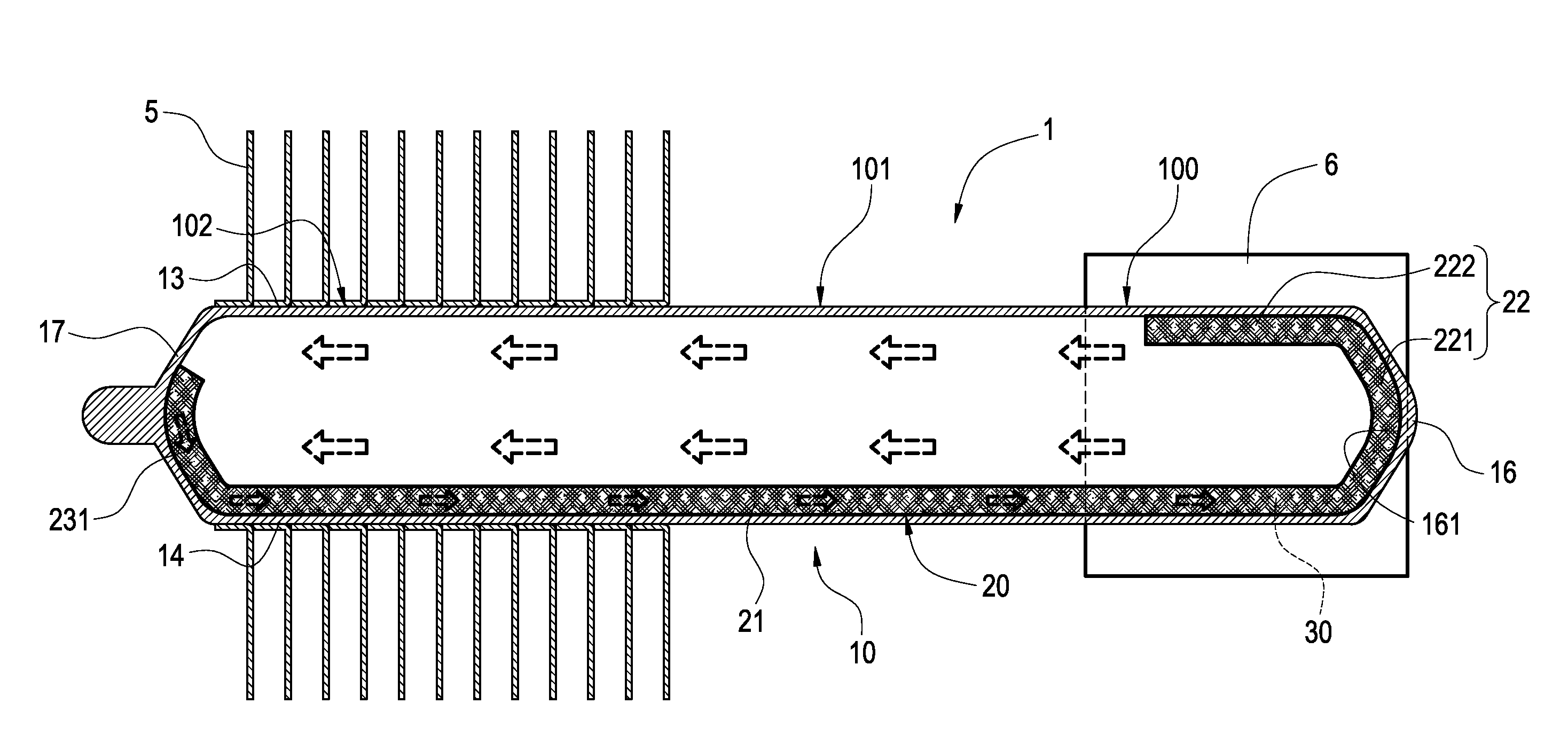

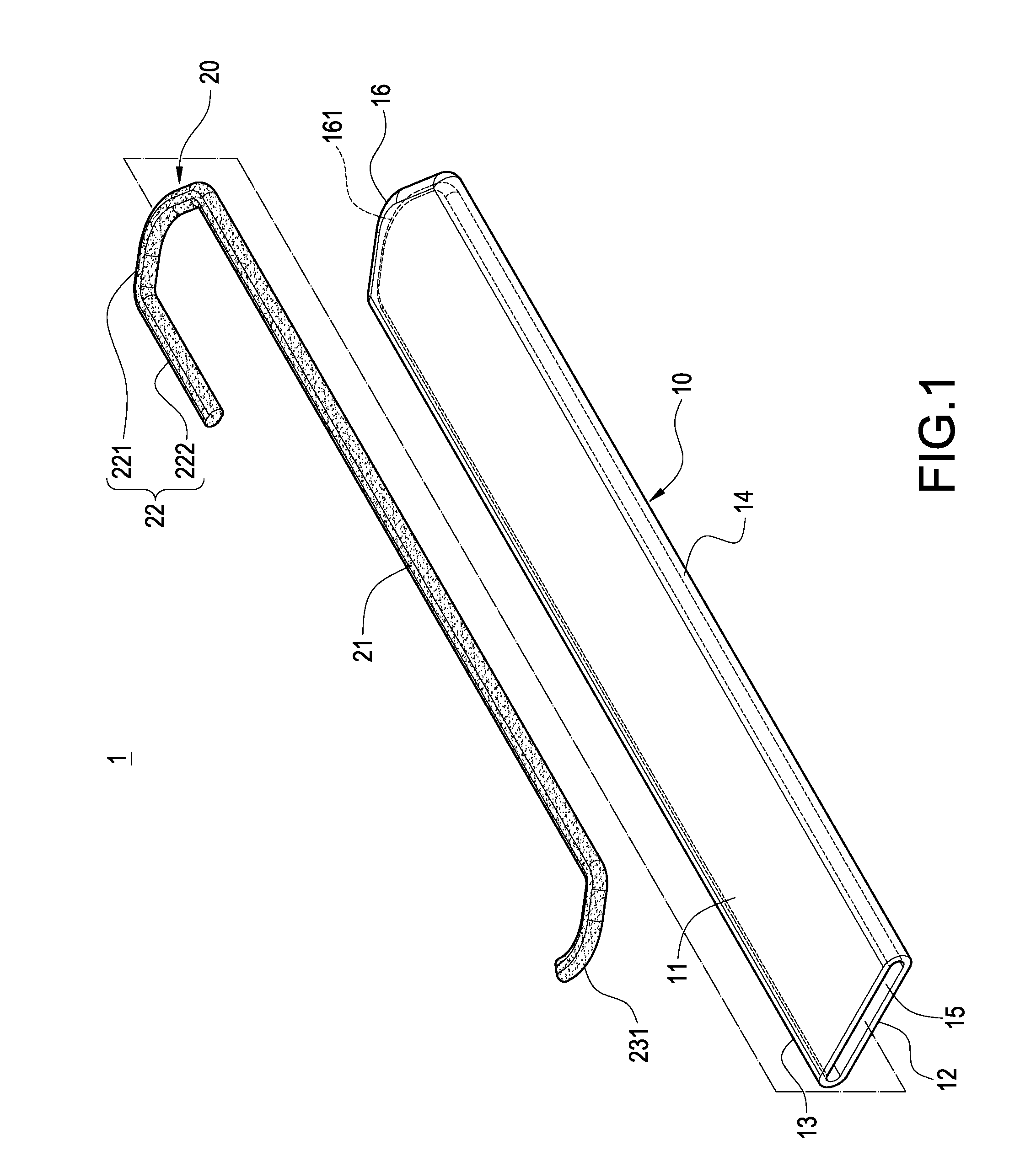

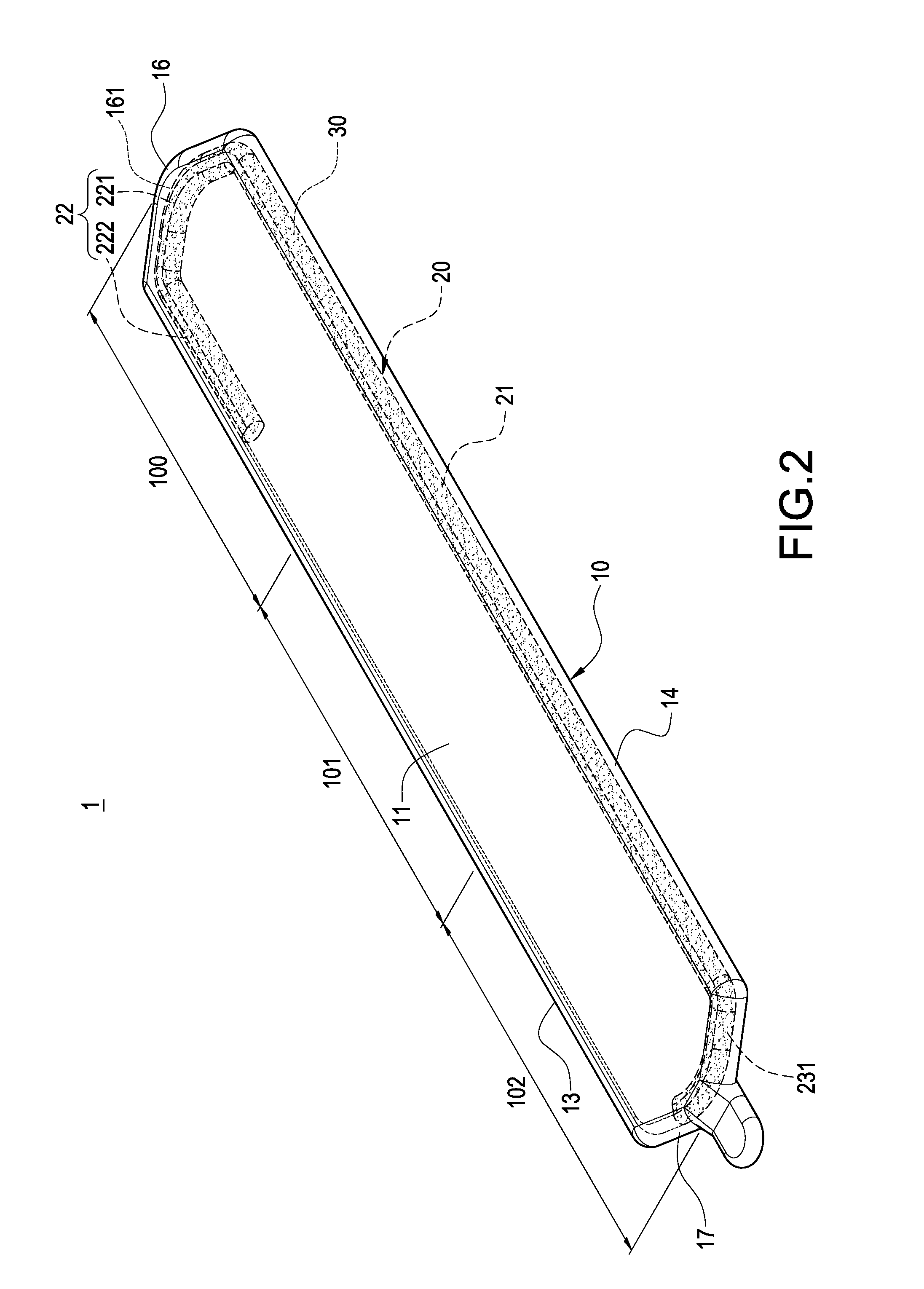

[0021]With reference to FIGS. 1 to 4 for a flat heat pipe with hook capillary tissue in accordance with the present invention, the heat pipe 1 comprises a metal pipe 10, a capillary tissue 20 and a working fluid 30.

[0022]The metal pipe 10 is made of a material having a high thermal conductivity such as copper, and manufactured into a flat shape, and the flat shape metal pipe 10 is formed by enclosing an upper panel 11, a lower panel 12, a left sidewall 13 and a right sidewall 14, and a hollow chamber 15 is formed in the metal pipe 10, and both left and right sidewall 13, 14 are in a semicircular shape. In addition, an end of the metal pipe 10 is soldered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com