Simulated liquid absorbing core for heat uniformizing plate

A vapor chamber and liquid-absorbing core technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of reduced strength of vapor chamber, unfavorable heat dissipation efficiency, and reduced evaporation area, etc., to achieve fast flow speed, Increased heat dissipation area and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

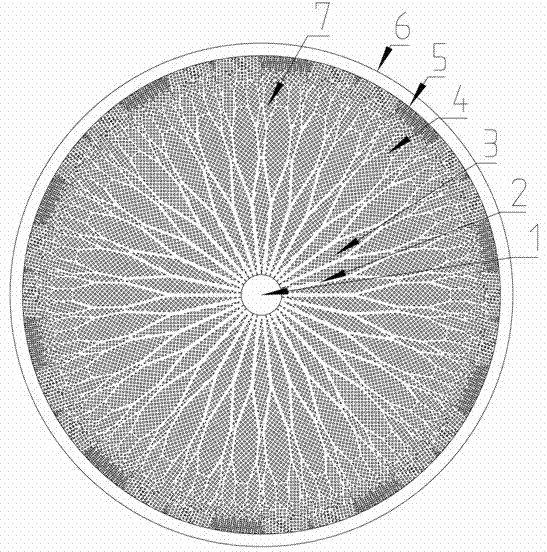

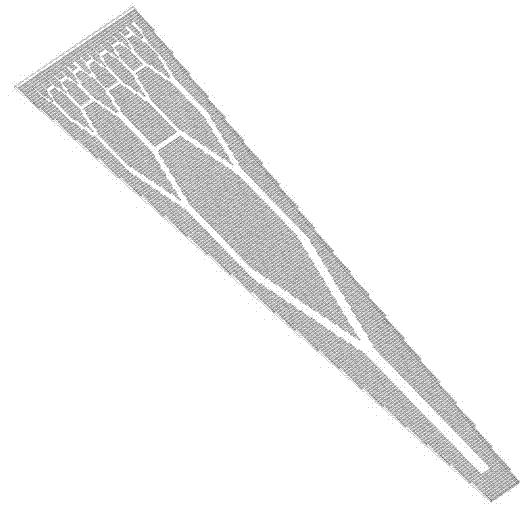

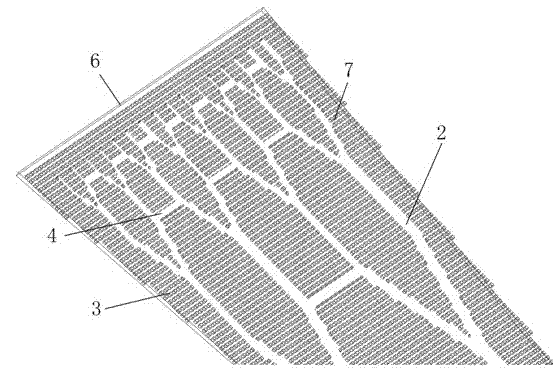

[0045] see figure 1 , figure 2 , image 3 As shown, a bionic vapor chamber liquid-absorbing core includes a central condensation area 1 for containing liquid working fluid, a main transport channel 2, a support column 3, a connecting channel 4, an annular flange 5, a condensation base plate 6, and a fine channel 7. The condensing substrate 6 is provided with a boss area, and the central condensing area 1 is arranged in the middle of the boss area of the condensing substrate 6 in a circular groove shape, and the main transportation channel 2 is connected to the central condensing area 1 and Taking the central condensation area 1 as a common starting point, the leaf veins of binary tree structure are evenly distributed on the condensation substrate 6 toward the edge of the condensation substrate 6, and the main transport channels 2 are connected horizontally by the connecting channel 4, so that all the main transport channels The transportation channel 2 forms a network cha...

Embodiment 2

[0051] see picture figure 1 , figure 2 , image 3 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the boss area is formed by uniformly sintering the silk screen on the condensation substrate 6 using vacuum sintering technology, and the bifurcation angle of the main transport channel 2 is 45°. The length ratio of the latter branch to the adjacent previous branch is 0.7, and the width ratio is 0.5.

[0052] Further, the liquid working medium is any one of purified water, methanol, ethanol, and acetone.

Embodiment 3

[0054] see figure 1 , figure 2 , image 3 , Image 6 As shown, a bionic vapor chamber liquid-absorbing core includes a central condensation area 1 for containing liquid working fluid, a main transport channel 2, a support column 3, a connecting channel 4, an annular flange 5, a condensation base plate 6, and a fine channel 7. The condensing substrate 6 is provided with a boss area, and the central condensing area 1 is arranged in the middle of the boss area of the condensing substrate 6 in a circular groove shape, and the main transportation channel 2 is connected to the central condensing area 1 and Taking the central condensation area 1 as a common starting point, the leaf veins of binary tree structure are evenly distributed on the condensation substrate 6 toward the edge of the condensation substrate 6, and the main transport channels 2 are connected horizontally by the connecting channel 4, so that all the main transport channels The transportation channel 2 forms a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com