Redox catalyst for metal-air fuel cells and preparation method of redox catalyst

A fuel cell and metal-air technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high noble metal catalysts and obstacles to the large-scale commercialization of fuel cells, and achieve low prices and reduce transmission resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A metal-air fuel cell oxygen reduction catalyst, the formula of the metal-air fuel cell oxygen reduction catalyst is as follows:

[0028] Pt / c platinum carbon: 20g;

[0029] Melamine: 40g;

[0031] Potassium hydroxide: 20g;

[0032] Methanol: 15g;

[0033] Nafion solution: 20g;

[0034] Aluminum oxide polishing powder: 10g.

[0035] Preferably, the weight percentage of the Pt / c platinum carbon is 20 wt%, and the weight percentage of the Nafion solution is 15 wt%.

[0036] Preferably, the particle size of the alumina polishing powder is 0.3 μm.

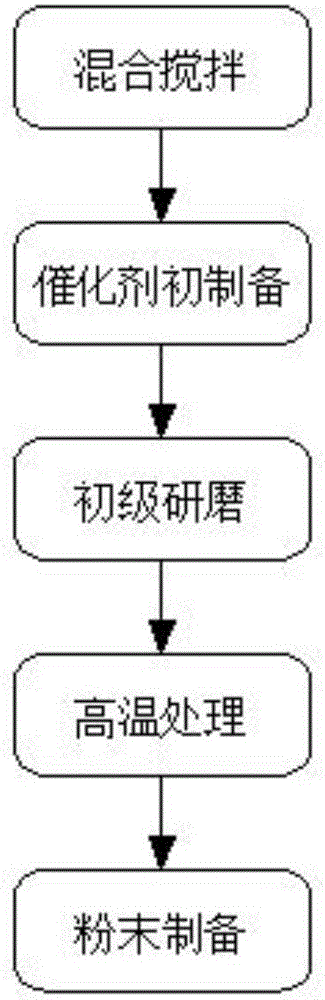

[0037] The present invention also provides a method for preparing an oxygen reduction catalyst for a metal-air fuel cell. The specific steps of the method for preparing an oxygen reduction catalyst for a metal-air fuel cell are as follows:

[0038] S1: Mix 20g of Pt / c platinum carbon and 40g of ferric chloride in an aqueous solution, and obtain a platinum carbon mixture after the solution is...

Embodiment 2

[0044] A metal-air fuel cell oxygen reduction catalyst, the formula of the metal-air fuel cell oxygen reduction catalyst is as follows:

[0045] Pt / c platinum carbon: 50g;

[0046] Melamine: 50g;

[0047] Ferric chloride: 60g;

[0048] Potassium hydroxide: 40g;

[0049] Methanol: 30g;

[0050] Nafion solution: 30g;

[0051] Aluminum oxide polishing powder: 20g.

[0052] Preferably, the weight percentage of the Pt / c platinum carbon is 30 wt%, and the weight percentage of the Nafion solution is 30 wt%.

[0053] Preferably, the particle size of the alumina polishing powder is 0.5 μm.

[0054] The present invention also provides a method for preparing an oxygen reduction catalyst for a metal-air fuel cell. The specific steps of the method for preparing an oxygen reduction catalyst for a metal-air fuel cell are as follows:

[0055] S1: Mix 50 g of Pt / c platinum carbon and 60 g of ferric chloride in an aqueous solution, and obtain a platinum carbon mixture after the solution ...

Embodiment 3

[0061] A metal-air fuel cell oxygen reduction catalyst, the formula of the metal-air fuel cell oxygen reduction catalyst is as follows:

[0062] Pt / c platinum carbon: 40g;

[0063] Melamine: 45g;

[0064] Ferric chloride: 50g;

[0065] Potassium hydroxide: 30g;

[0066] Methanol: 20g;

[0067]Nafion solution: 25g;

[0068] Aluminum oxide polishing powder: 15g.

[0069] Preferably, the weight percentage of the Pt / c platinum carbon is 25 wt%, and the weight percentage of the Nafion solution is 20 wt%.

[0070] Preferably, the particle size of the alumina polishing powder is 0.4 μm.

[0071] The present invention also provides a method for preparing an oxygen reduction catalyst for a metal-air fuel cell. The specific steps of the method for preparing an oxygen reduction catalyst for a metal-air fuel cell are as follows:

[0072] S1: Mix 40g of Pt / c platinum carbon and 50g of ferric chloride in an aqueous solution, and obtain a platinum carbon mixture after the solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com