Hydrogen combustion-supporting device and method

A hydrogen and vaporization device technology, applied in the combustion method, liquid fuel supply/distribution and other directions, can solve the problems such as the inability to flexibly adjust the evaporation temperature and speed, the difficulty in sensitively controlling the amount of alcohol vapor feed, and the difficulty in immediate cooling, etc. Improve vaporization efficiency, adjust quickly and sensitively, reduce the effect of contamination impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

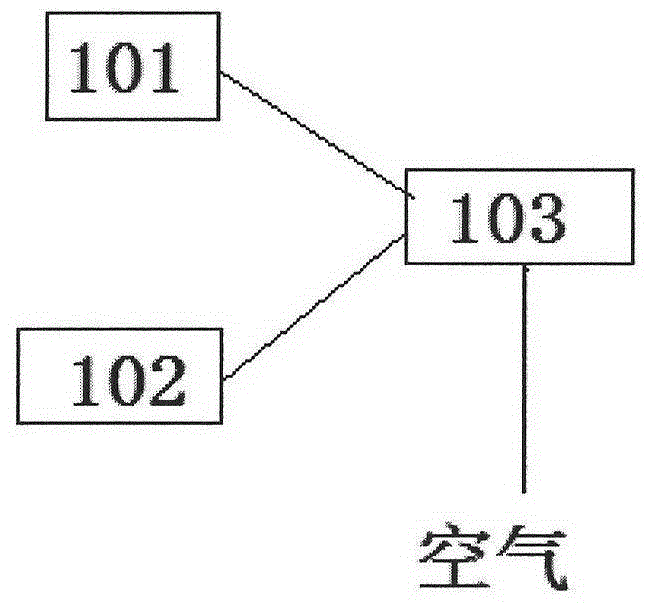

Image

Examples

Embodiment 1

[0023] The above-mentioned alcohol vaporization device, wherein the body is an aluminum alloy body, the heating catalyst includes a porous metal carrier, a boron nitride accelerator and a platinum metal catalyst layer, the size of the body is 300X200X450mm, and the diameter of the circular tube is The diameter is 15mm, the diameter of the micropore is 8mm, the diameter of the steel ball is 5mm, the alcohol is ethanol, and the vaporization temperature is 90°C; the above-mentioned hydrogen generator uses methanol as fuel.

Embodiment 2

[0025] Repeat Example 1, the difference is that the catalyst layer replaces the above-mentioned platinum metal with palladium metal, the size of the body is 450X350X750mm, the diameter of the circular tube is 30mm, the diameter of the micropore is 12mm, and the diameter of the steel ball is 8mm , the alcohol is methanol, and the vaporization temperature is 68° C.; the above-mentioned hydrogen generator uses ethanol as fuel.

Embodiment 3

[0027] Repeat Example 1, wherein the porous metal carrier is alumina, the size of the body is 375X275X600mm, the diameter of the round tube is 20mm, the diameter of the micropore is 10mm, the diameter of the steel ball is 6mm, and the alcohol is isopropanol. The above-mentioned hydrogen generator uses methane as fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com