Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about "Thionyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

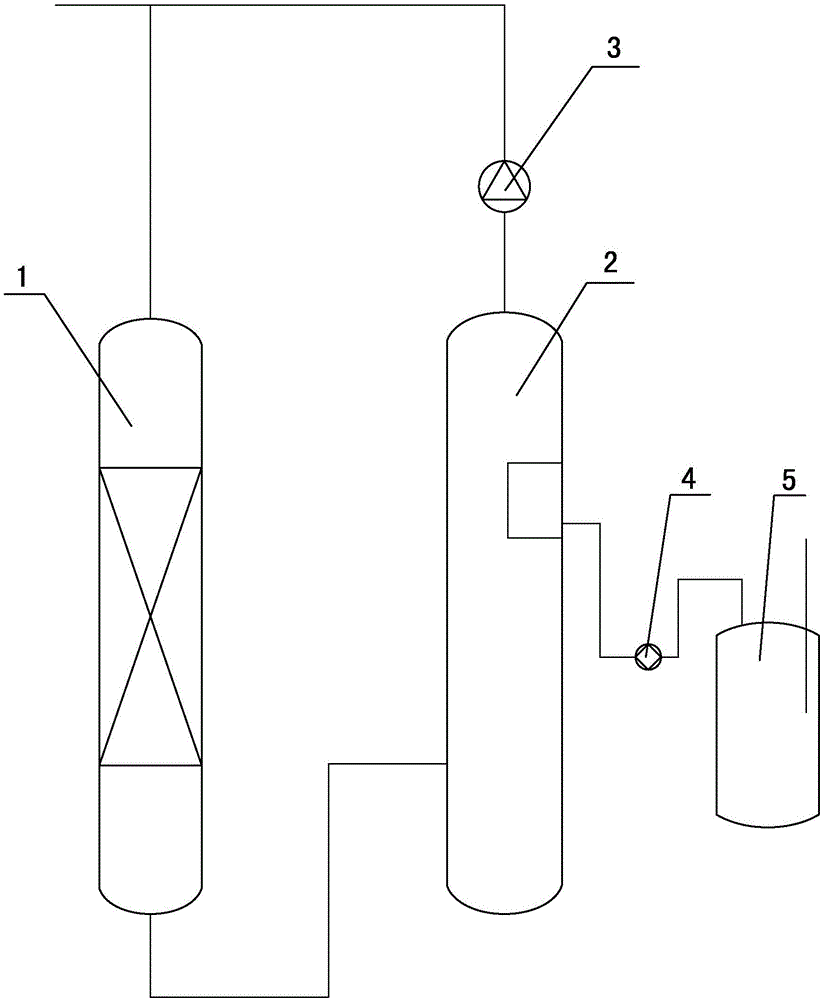

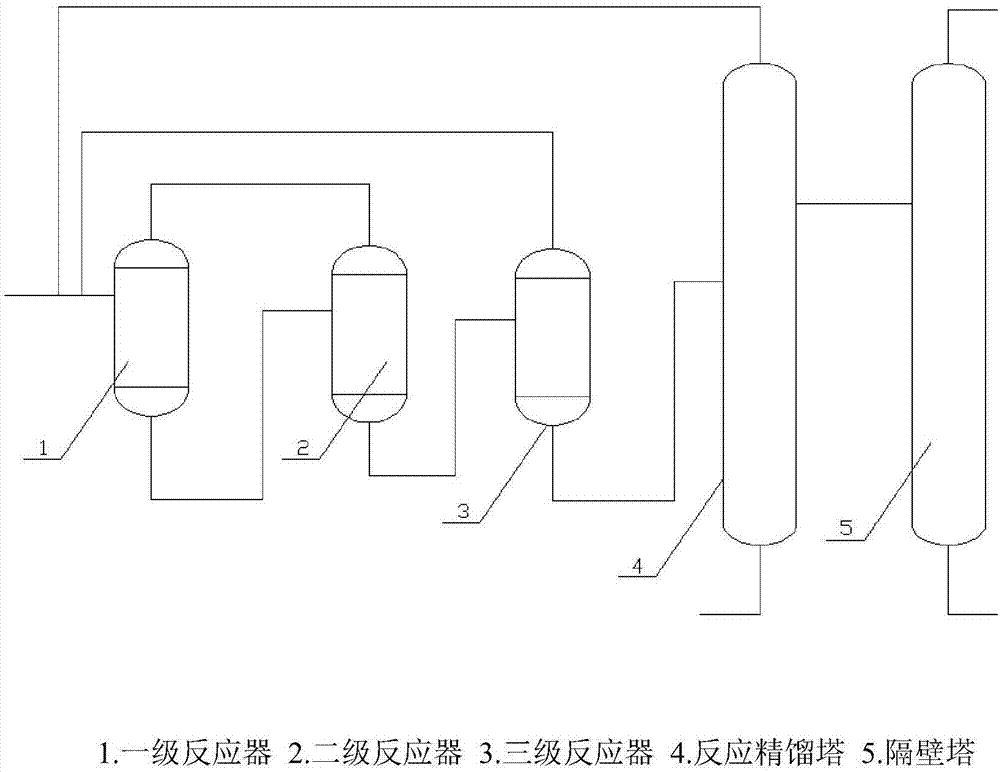

Method for preparing thionyl chloride

InactiveCN106315519ASimple processReduce energy consumptionThionyl chlorideChemical synthesisGas phase

The invention belongs to the technical field of chemical synthesis, and particularly relates to a method for preparing thionyl chloride. Raw material mixed gas composed of sulfur dioxide, chlorine and sulfur dichloride enters a reactor from the upper portion, a crude product thionyl chloride gas phase directly enters a rectifying tower from the lower portion of the reactor, the gas phase on the top of the rectifying tower is recycled back to the reactor, a product is produced in the middle of the rectifying tower and enters a blowdown tank so that light components in the product can be blown away by nitrogen, and a qualified product is obtained. The pressure of the reactor and the pressure of the rectifying tower are normal pressure. The process for preparing thionyl chloride through a sulfur dioxide method is simplified, normal-pressure reaction is conducted, the process is simple, energy consumption is low, system safety is high, and the product yield is improved and reaches 99.95% or above.

Owner:SHANDONG KAISHENG NEW MATERIALS

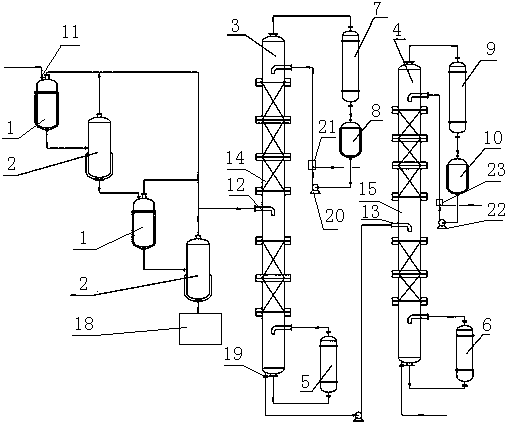

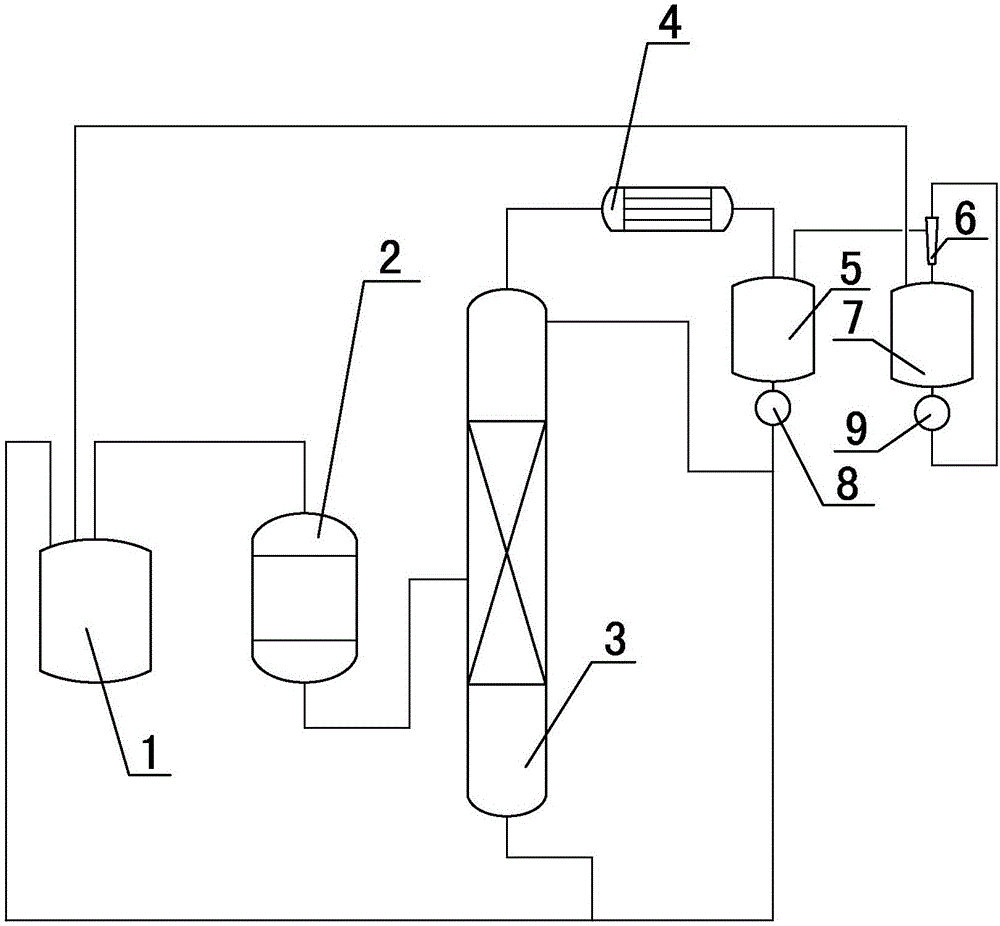

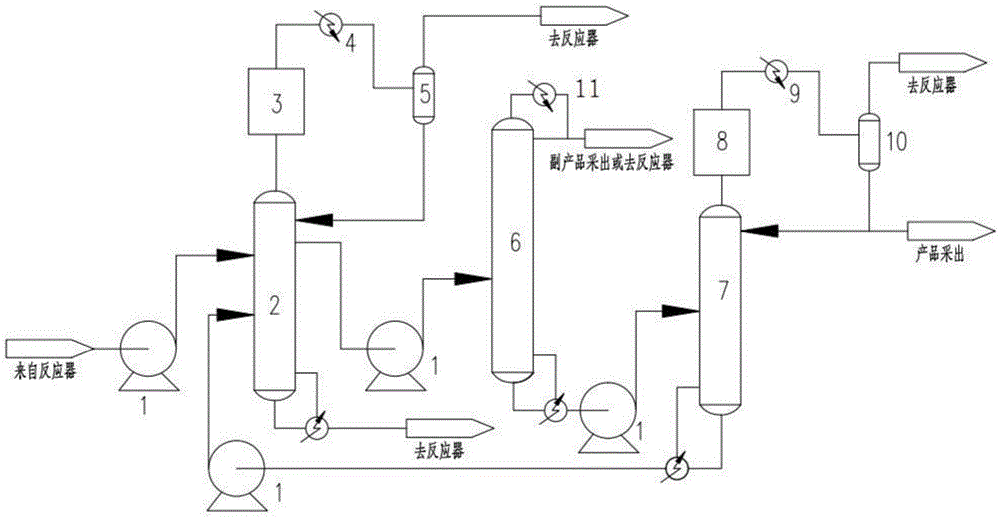

Recovering and purifying device and recovering method of thionyl chloride in acyl chloride production

ActiveCN104261355AEfficient separationReasonable structural designThionyl chlorideAcyl chlorideLiquid phase

The invention relates to a recovering and purifying device and a recovering and purifying method of thionyl chloride in acyl chloride production and belongs to the technical field of recovery and purification of thionyl chloride. The device comprises an evaporating device, a thionyl chloride light-component-removal tower and a thionyl chloride refining tower which are sequentially connected in series. The recovering method of thionyl chloride in acyl chloride production comprises the following steps: 1) introducing an acyl chloride synthetic liquid into the evaporating device to be heated; 2) introducing the liquid into the thionyl chloride light-component-removal tower, wherein the light components vaporized are condensed by a condensing device of the light-component-removal tower arranged at the top of the tower into a liquid phase which returns to the light-component-removal tower by virtue of a return tank of the light-component-removal tower; and 3) conveying to the thionyl chloride refining tower for further purification, wherein steam rises to the top of the thionyl chloride refining tower, and the synthetic liquid which is condensed to liquid phase partially returns to the thionyl chloride refining tower and is partially discharged and collected as a thionyl chloride product. The device provided by the invention is reasonable in structural design, can be used for effectively recovering thionyl chloride, can be used for continuous treatment and is simple, convenient to operate and easy for control on the process.

Owner:YANTAI YUXIANG FINE CHEM

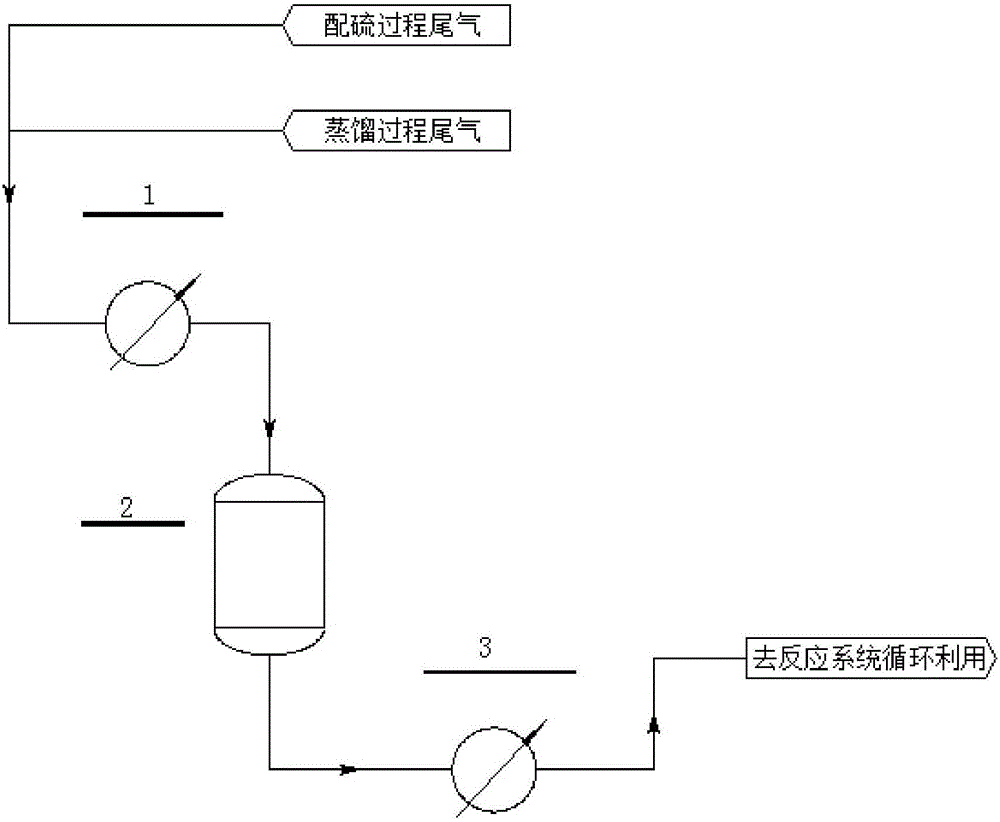

Method for recycling sulfur dioxide in thionyl chloride production

The invention belongs to the technical field of thionyl chloride production, and mainly relates to a method for recycling sulfur dioxide in the production of thionyl chloride. The method comprises the following steps: (a) the tail gas produced by the sulfur compounding process and the distillation process enters the tail gas condenser to condense the sulfur dioxide gas therein; (b) the condensed sulfur dioxide liquid enters the sulfur dioxide recovery tank; (c) adopts a sulfur dioxide vaporizer The recovered sulfur dioxide liquid is vaporized to a pressure slightly higher than the pressure of the reaction system and then returned to the reaction system for recycling. The invention greatly improves the utilization rate of sulfur dioxide and product yield, and has small equipment investment and simple operation.

Owner:HUIZHI ENG SCI & TECH CO LTD

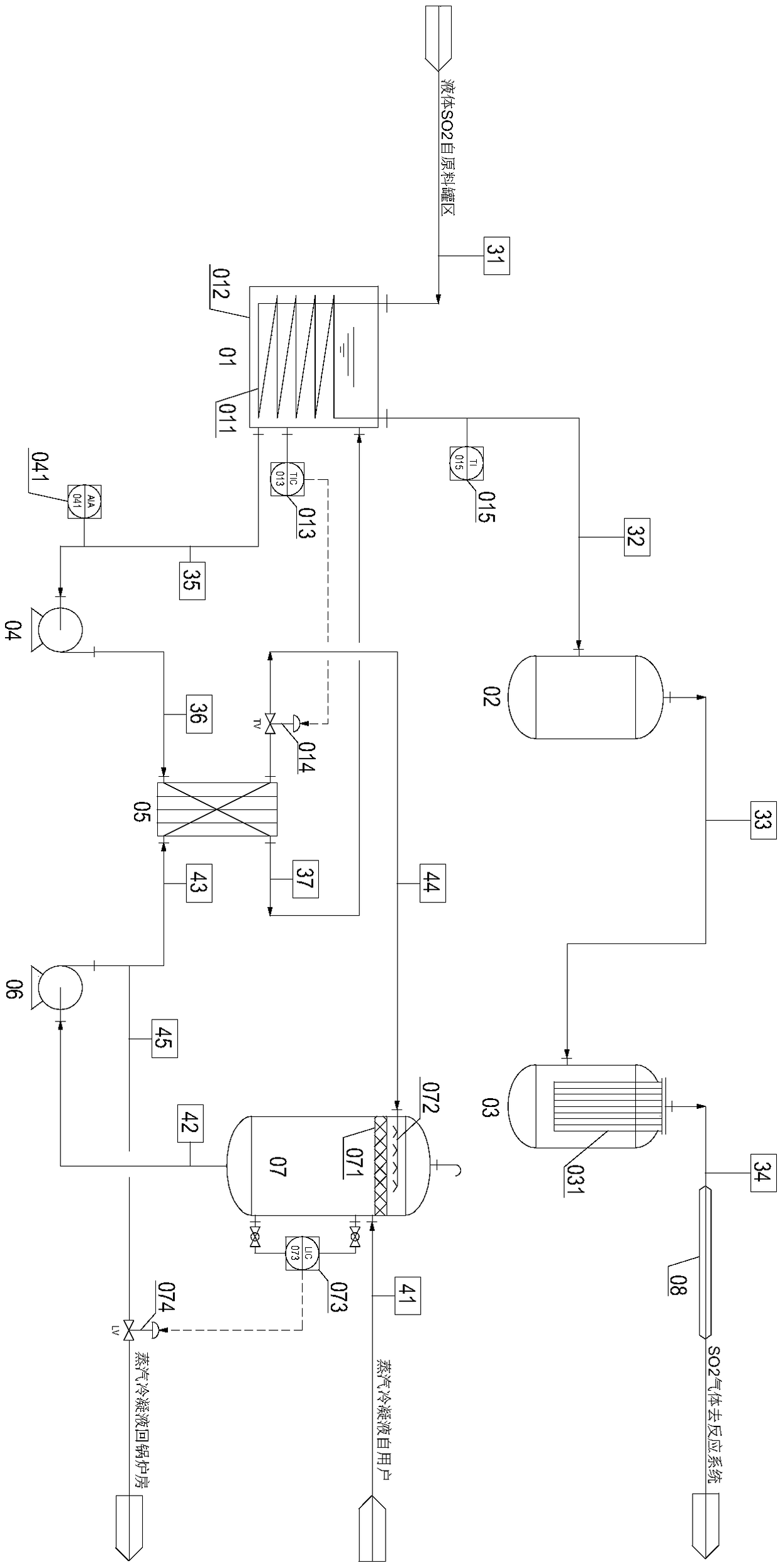

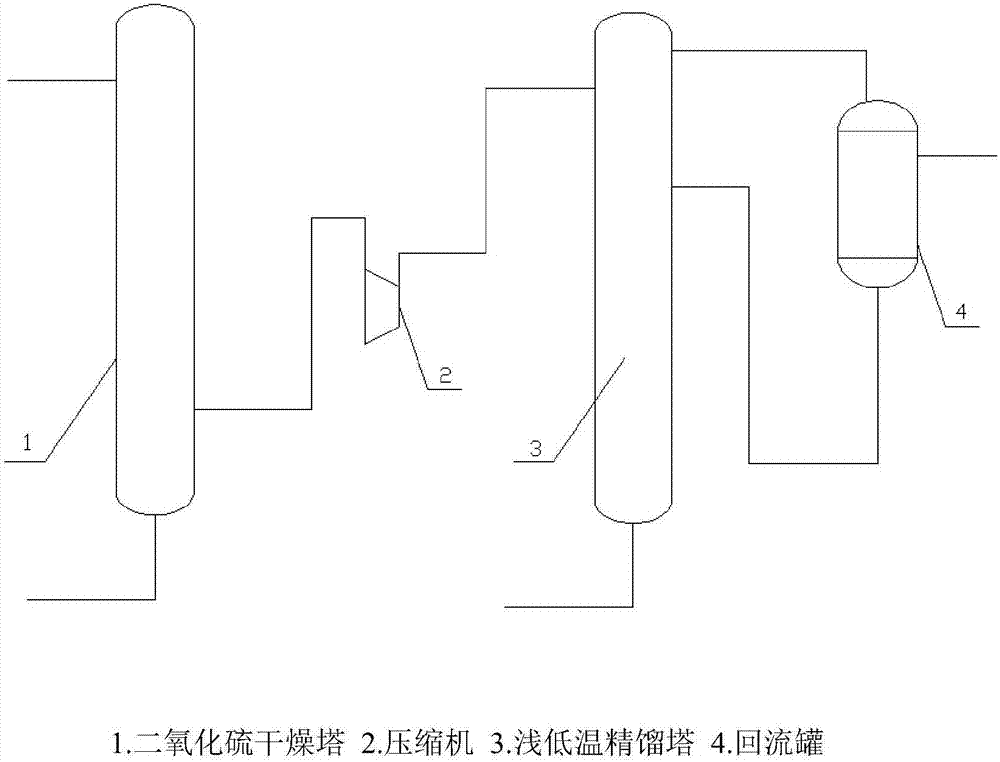

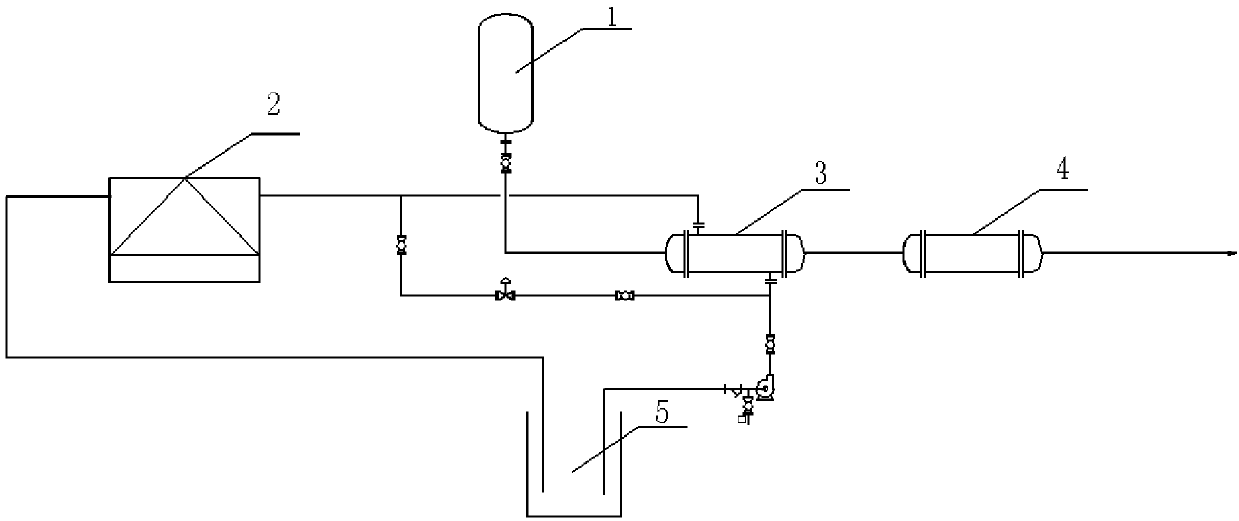

Sulfur dioxide vaporization technology for thionyl chloride production

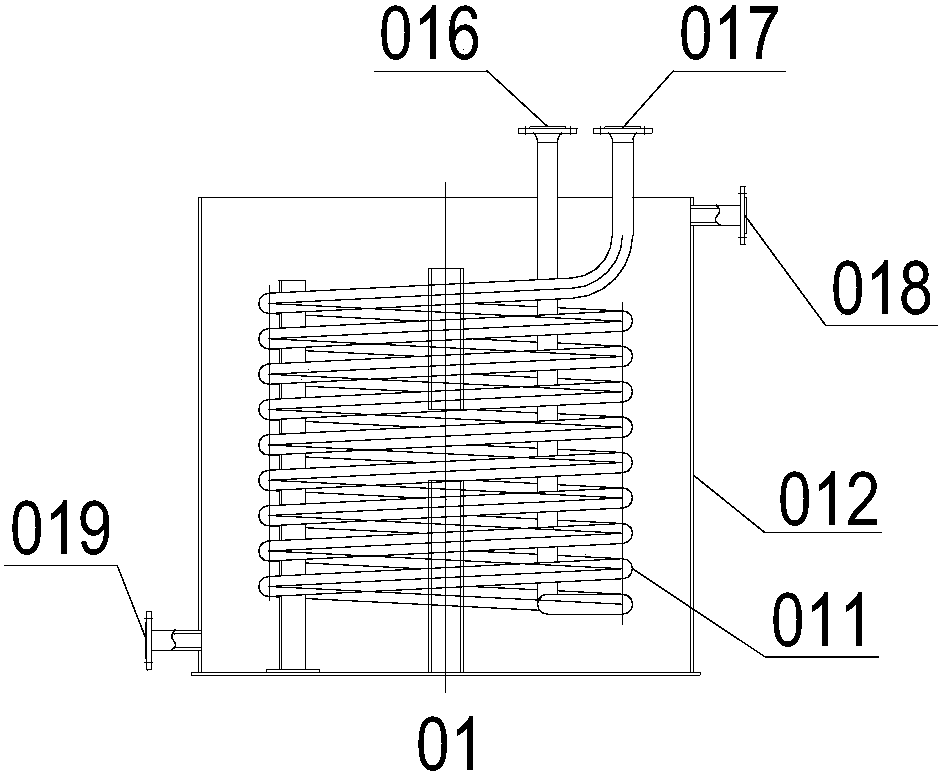

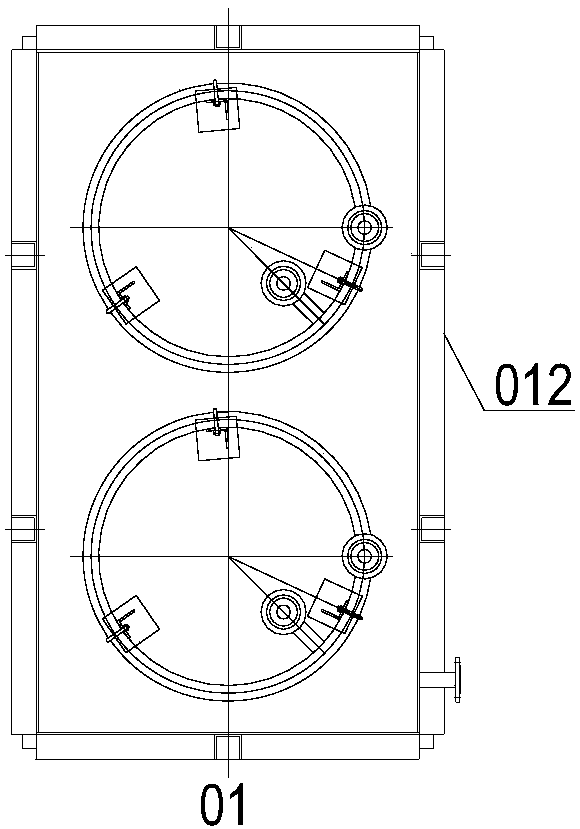

ActiveCN108467017AImprove heat transfer coefficientImprove vaporization efficiencyThionyl chlorideBuffer tankVaporization

The invention provides a sulfur dioxide vaporization technology for thionyl chloride production. The technology comprises steps as follows: step 1, liquid sulfur dioxide enters a vaporizer for vaporization, and the vaporizer is a coil pipe type vaporizer; step 2, sulfur dioxide gas obtained after vaporization enters a buffer tank for gas-liquid phase separation, and large-diameter liquid drops inthe gas are removed; step 3, the sulfur dioxide gas enters a gas-liquid separation tank, and tiny droplets and oil mist entrained in the gas are removed. The technology is simple to control, equipmentinvestment is low, popularization is facilitated, heat transfer coefficient in a sulfur dioxide vaporization process is effectively increased, the service life of equipment is prolonged, and meanwhile, energy consumption is substantially reduced.

Owner:CHINA TIANCHEN ENG

Method for inhibiting generation of chlorosulfuric acid in thionyl chloride preparation process

InactiveCN104445091AQuality improvementSulfuryl chloride content decreasedSulfur-halogen-hydrogen-oxygen compoundsThionyl chlorideChlorosulfuric acidSulfur dichloride

The invention relates to a method for inhibiting generation of chlorosulfuric acid in a thionyl chloride preparation process. The method comprises the following steps: feeding a raw material gas mixture prepared from sulfur dioxide, sulfur dichloride and chlorine to a catalytic reactor after pre-heating, and reacting to obtain thionyl chloride; and preheating the gas mixture to 120-180 DEG C. Chlorosulfuric acid in a crude product thionyl chloride is inhibited within 1% from 2%, so that the quality of the crude product thionyl chloride is greatly improved; reduction of the content of chlorosulfuric acid in subsequent refined products is facilitated; and the generation condition through chlorosulfuric acid is avoided.

Owner:SHANDONG KAISHENG NEW MATERIALS

Sulfur putting method in thionyl chloride refining process

InactiveCN105819405AAvoid generatingHigh precisionSulfur preparation/purificationThionyl chlorideSulfurImpurity

The invention relates to a method for adding sulfur in the refining process of thionyl chloride. The water and impurities in the sulfur are removed through sulfur selection, pulverization, feeding, heating and melting sulfur, filtration of crude sulfur, and thionyl chloride refining and batching. The reaction of water and thionyl chloride to generate waste gas can be avoided, and the precision of the product can be improved at the same time, and the invention has the advantages of simple process operation, high precision of the finished product, resource saving and environmental protection.

Owner:XINXIANG RUICHENG TECH DEV

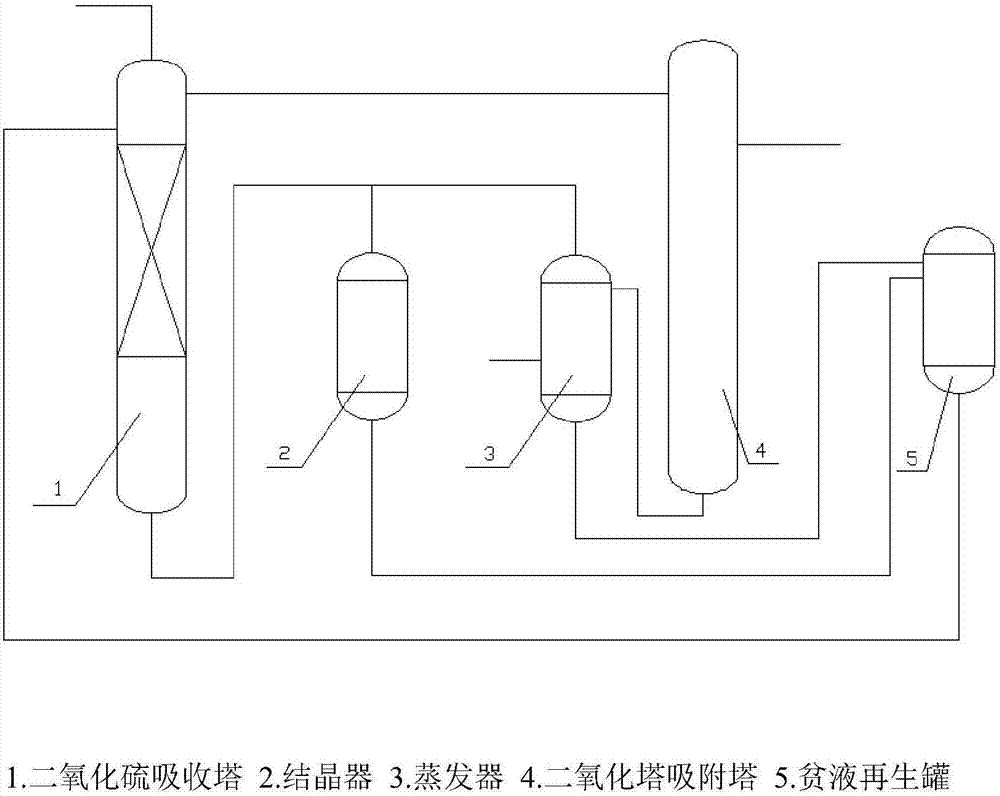

Technology for deeply removing and recycling SO2 in high-sulfur coal-fired power plant tail gas

InactiveCN107349750ARealize resource utilizationAchieve deep removalCombination devicesProductsParticulatesSulfur

The invention relates to a technology for deeply removing and recycling SO2 in high-sulfur coal-fired power plant tail gas. Na2SO3 is used to absorb sulfur dioxide in smoke, so complete recycling of an absorbent is realized, and the recycling of sulfur dioxide and the production of high-added value products are also realized. The technology solves a series of problems of much salt-containing wastewater, easy obstruction and poor absorption effect of existing wet desulphurization, realizes the deep removal of sulfur dioxide (the sulfur dioxide content is reduced to below 35 mg / m<3>) and the high removal of solid particles (the solid particle content is reduced to below 5 ppm), and makes the carbon dioxide recovery rate reach 50-60%. Recovered SO2 is purified to make the purity meet the thionyl chloride production requirements, and is processed to obtain thionyl chloride with the purity of 99.6%.

Owner:CHANGZHOU UNIV

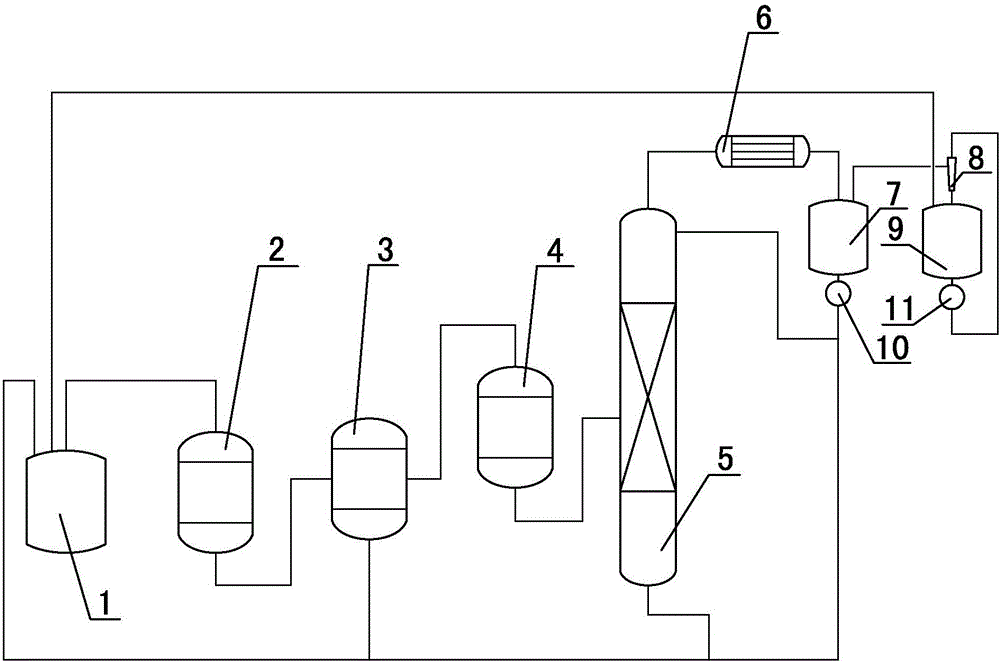

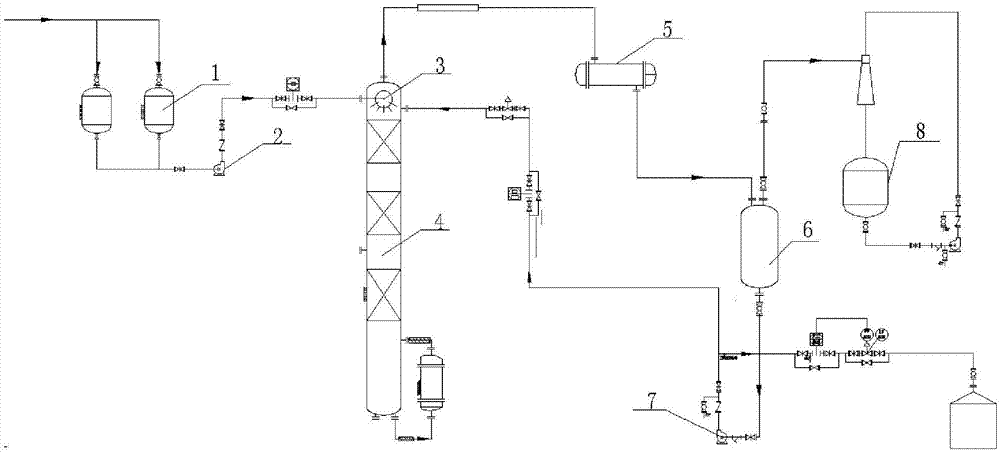

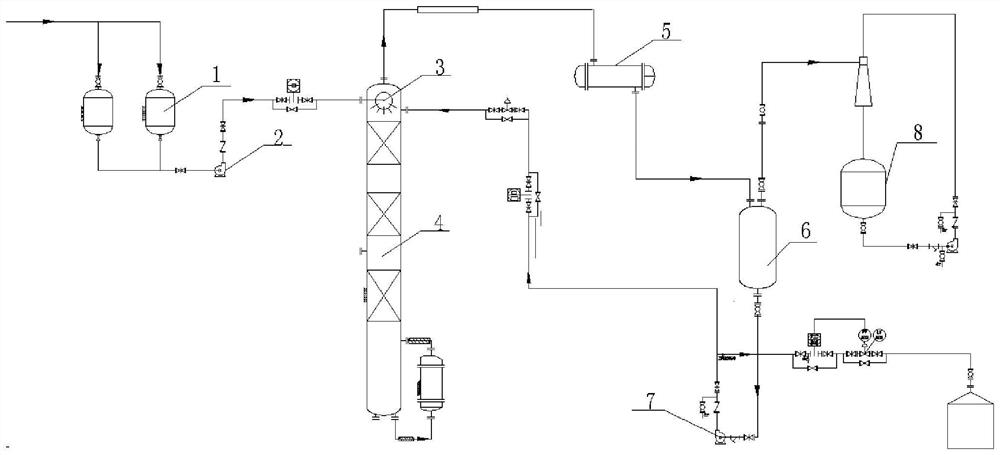

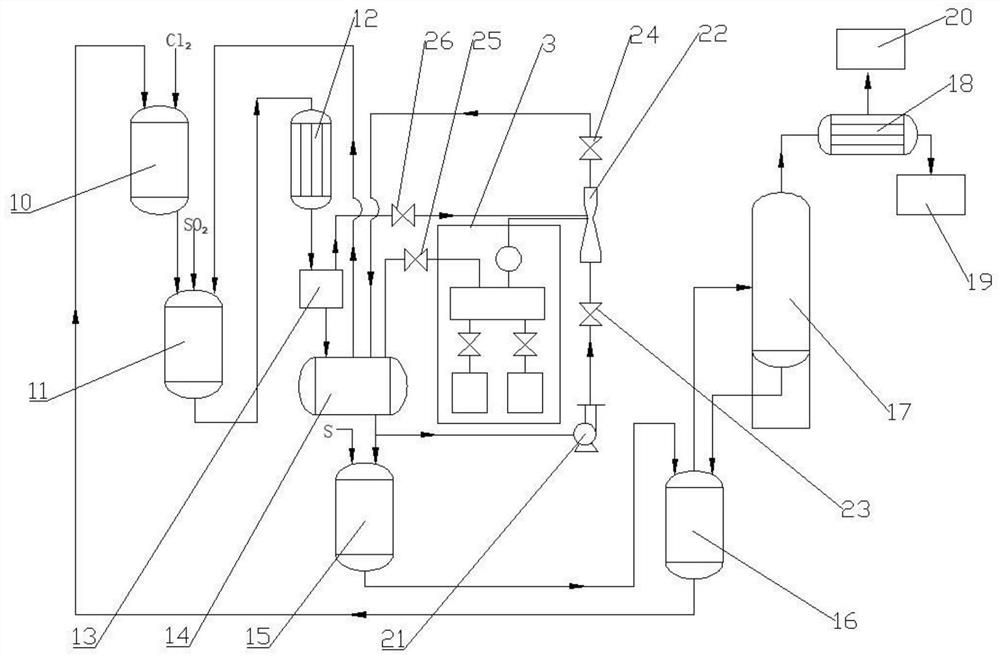

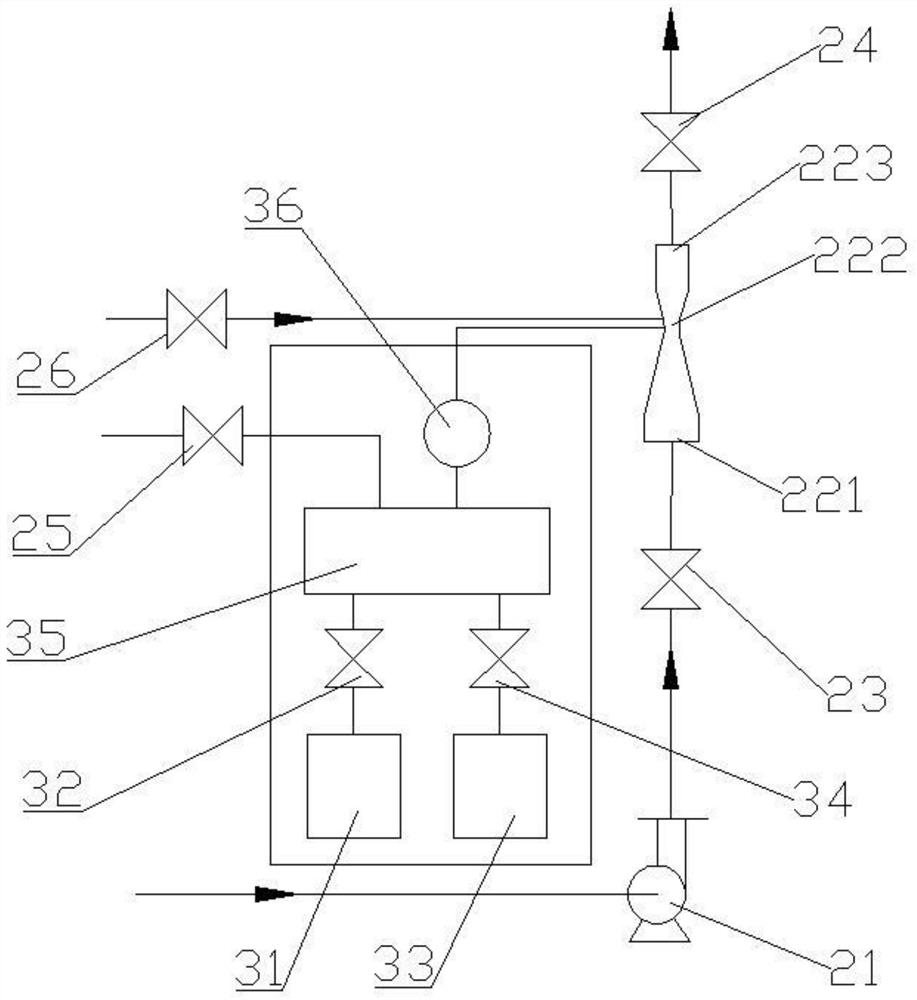

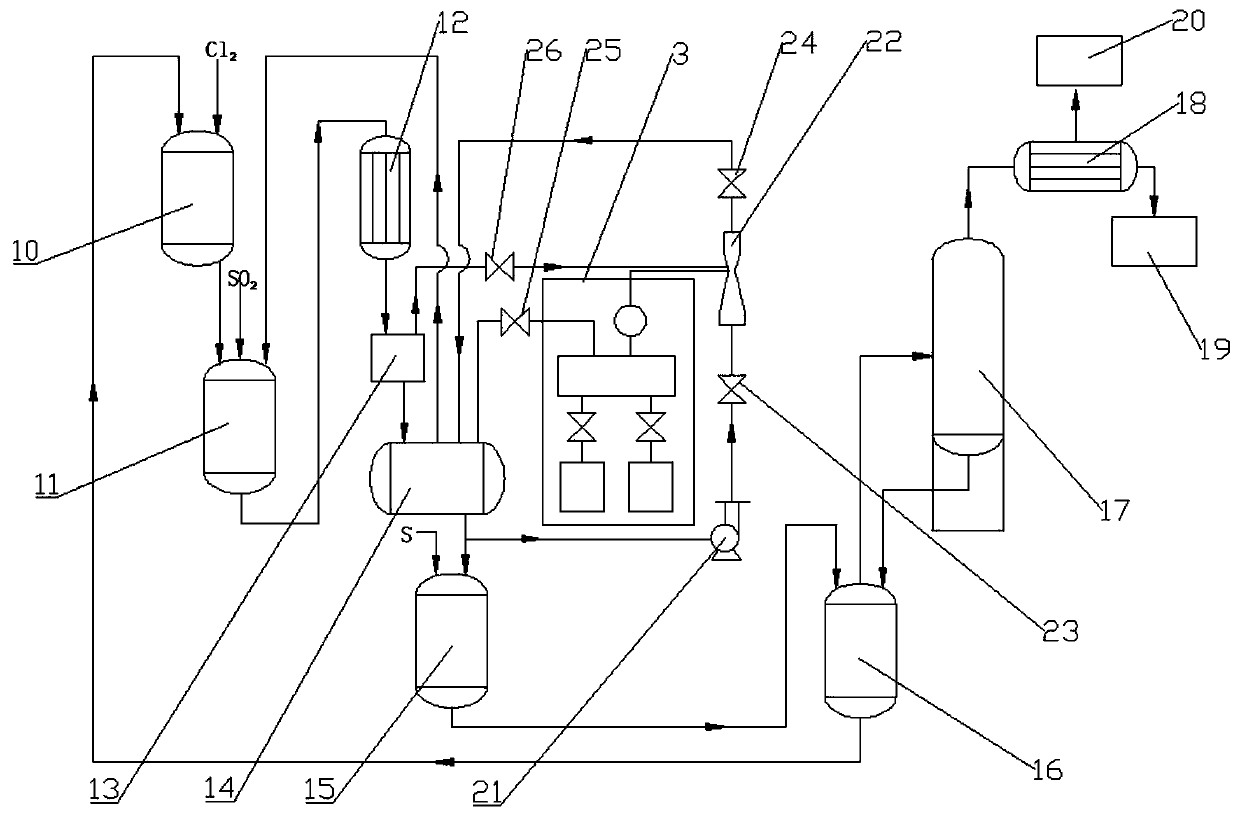

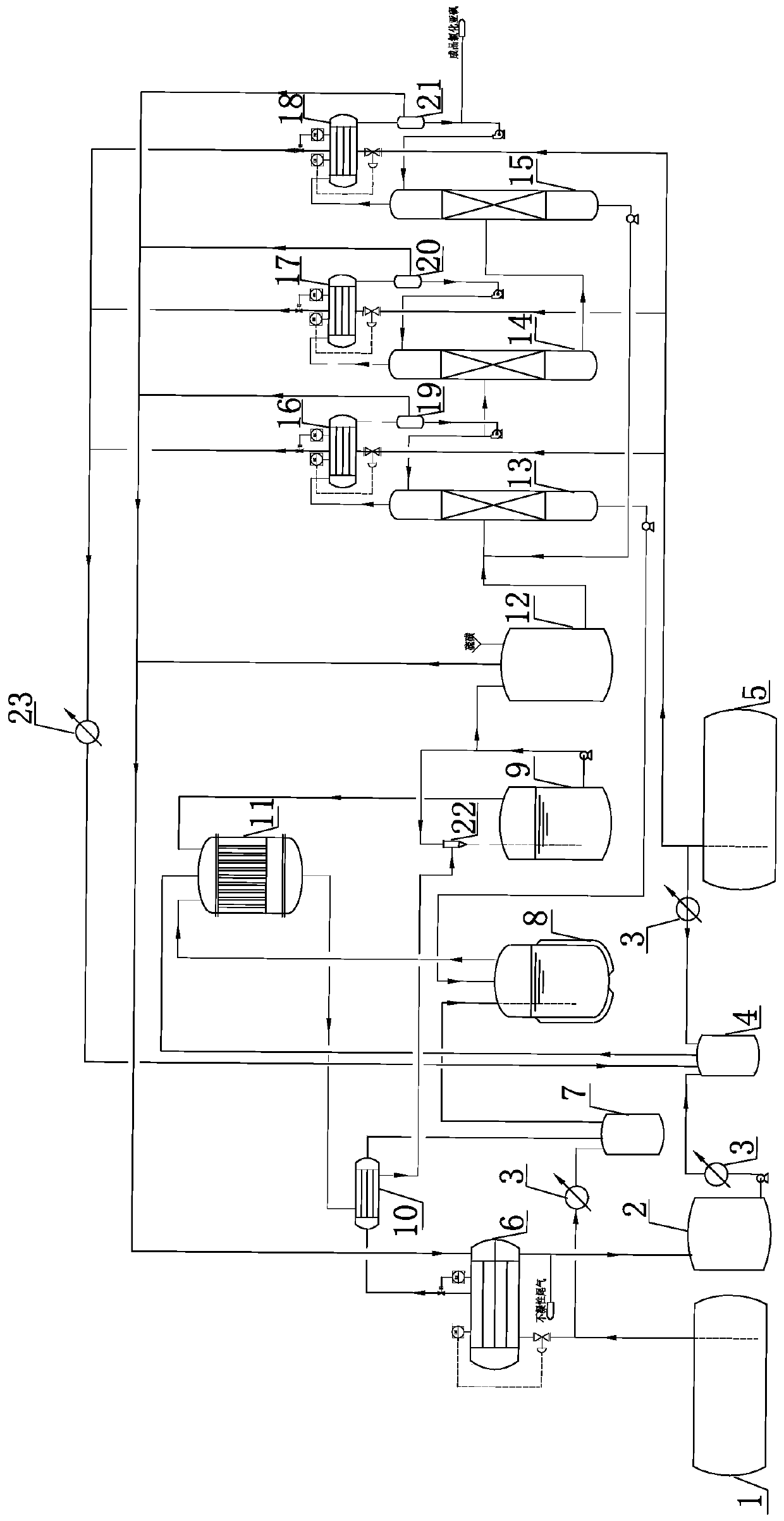

Production technology of thionyl chloride

ActiveCN106629626AAchieving zero emissionsReduce the probability of exposure to waterThionyl chlorideChemical industryGas phase

The present invention relates to the technical field of chemical industry production and in particular relates to a production technology of thionyl chloride. Sulfur and chlorine gas are reacted in a synthesis reactor to produce synthesis gas, the synthesis gas and sulfur dioxide gas enter together into a reactor, produced crude products of the thionyl chloride after the reaction in the reactor directly enter into a distillation column in a gas state, and gas phase from the top of the distillation column is condensed, the condensed gas enters into a reflux tank; and gas phase in the reflux tank enters into an evacuation tank via an ejector, the treated gas is recycled into the synthesis reactor, and qualified products are collected at the middle part of the distillation column. The production technology is simplified and the technologies of condensation, sulphur combining, light component recycling, etc. of the reacted crude products of the thionyl chloride are saved. Due to the reduction of the condensation and regasification, the technology is relatively short in routes and minimal in heat loss, and greatly reduces energy consumptions of the devices.

Owner:SHANDONG KAISHENG NEW MATERIALS

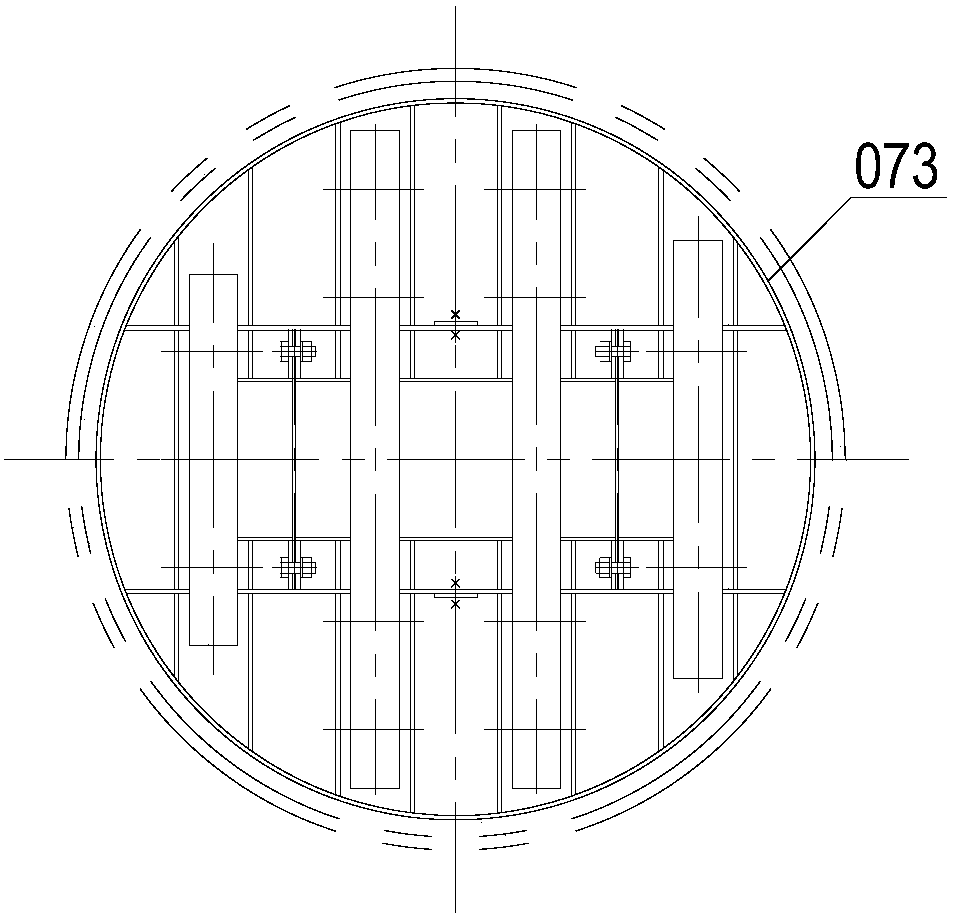

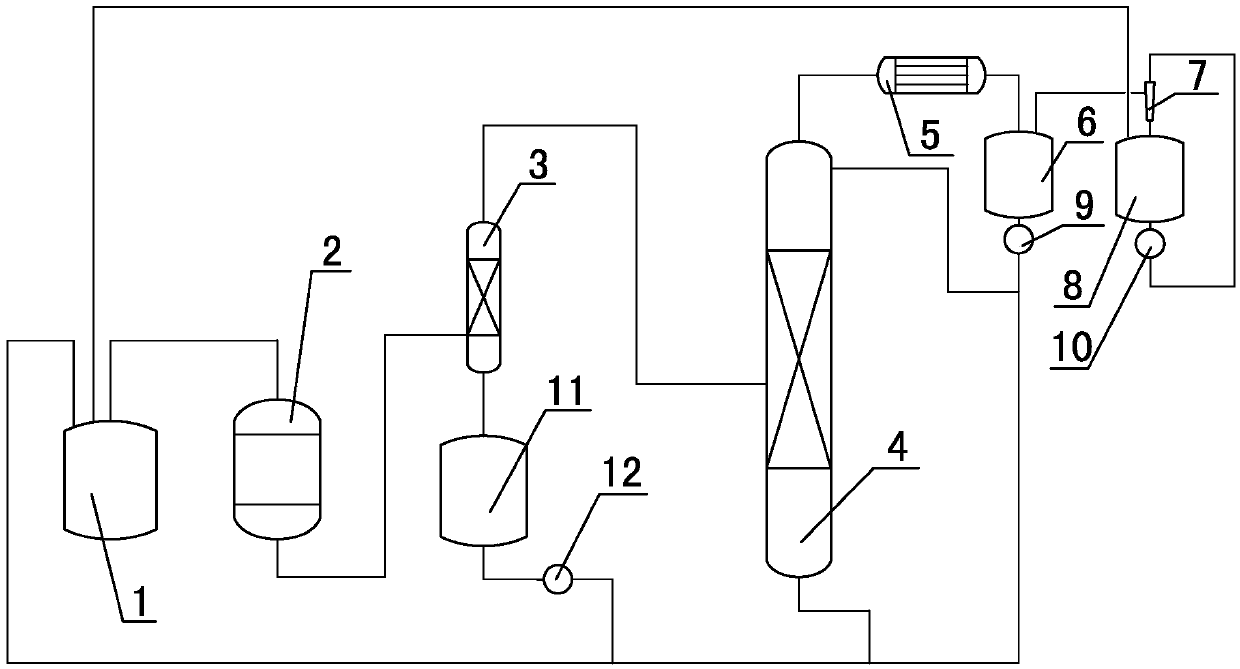

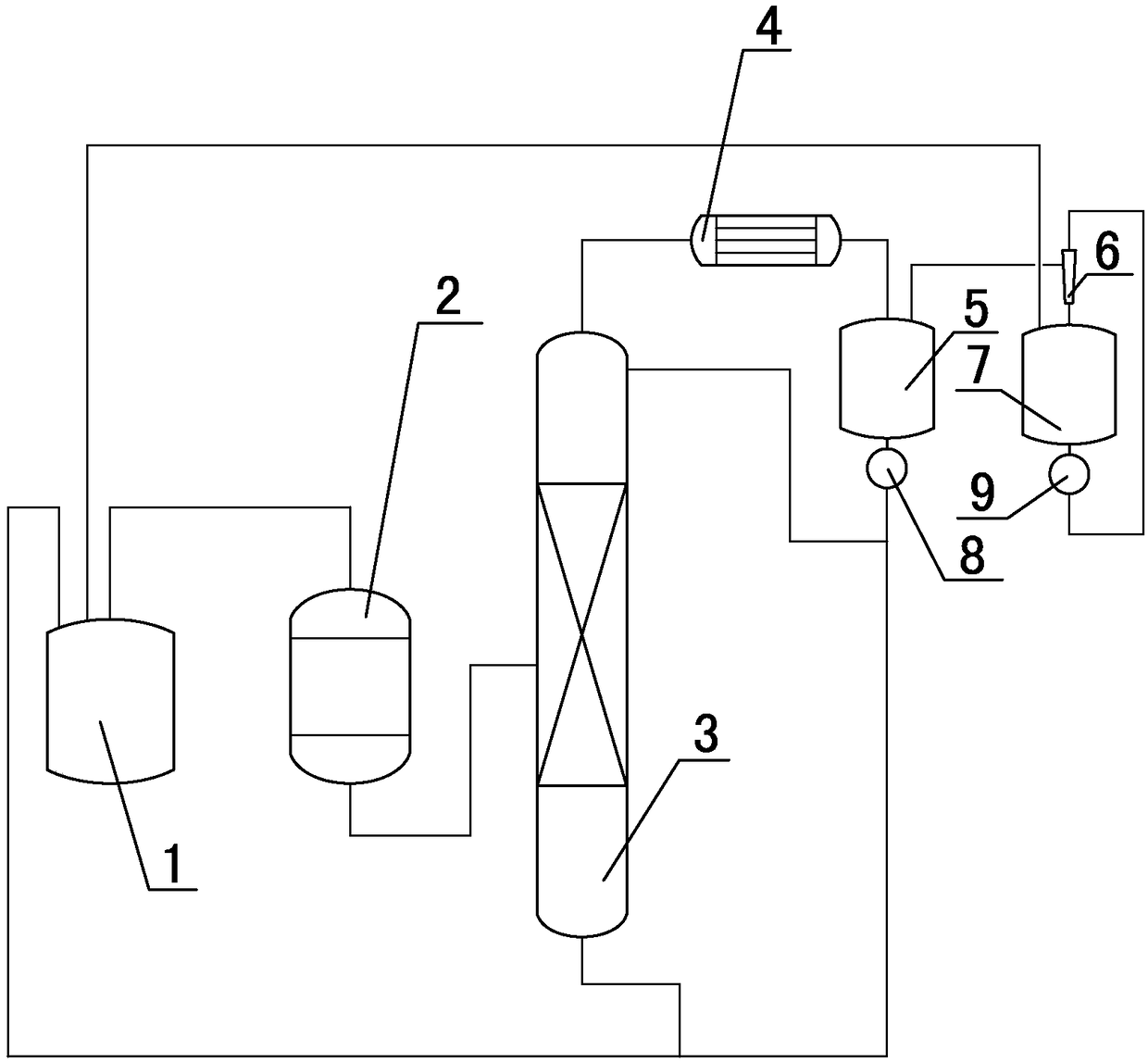

Continuous sulfur adding device and continuous sulfur adding process for thionyl chloride rectification systems

InactiveCN108553933AGuaranteed continuityIncrease productivityThionyl chlorideHigh temperature liquid-gas reactionRefluxMelting tank

The invention provides a continuous sulfur adding device and a continuous sulfur adding process for thionyl chloride rectification systems. The continuous sulfur adding device comprises a sulfur melting and liquid sulfur delivering system, a rectification system and a liquid sulfur blending reflux system. The sulfur melting and liquid sulfur delivering system comprises a sulfur melting tank and aliquid sulfur buffer tank which are communicated with each other; the rectification system comprises a first rectification tower; the liquid sulfur blending reflux system comprises a reflux tank; theliquid sulfur buffer tank is communicated with the reflux tank, and the reflux tank is communicated with a tower top of the first rectification tower. The continuous sulfur adding device and the continuous sulfur adding process have the advantages that the continuous sulfur adding process is easy to control, low in equipment investment and convenient to popularize, the sulfur dichloride and chlorine conversion rate can be effectively increased, rectification and separation effects can be enhanced, operational risks of staffs can be reduced to a great extent, and workload on the staffs can be relieved to a great extent.

Owner:CHINA TIANCHEN ENG

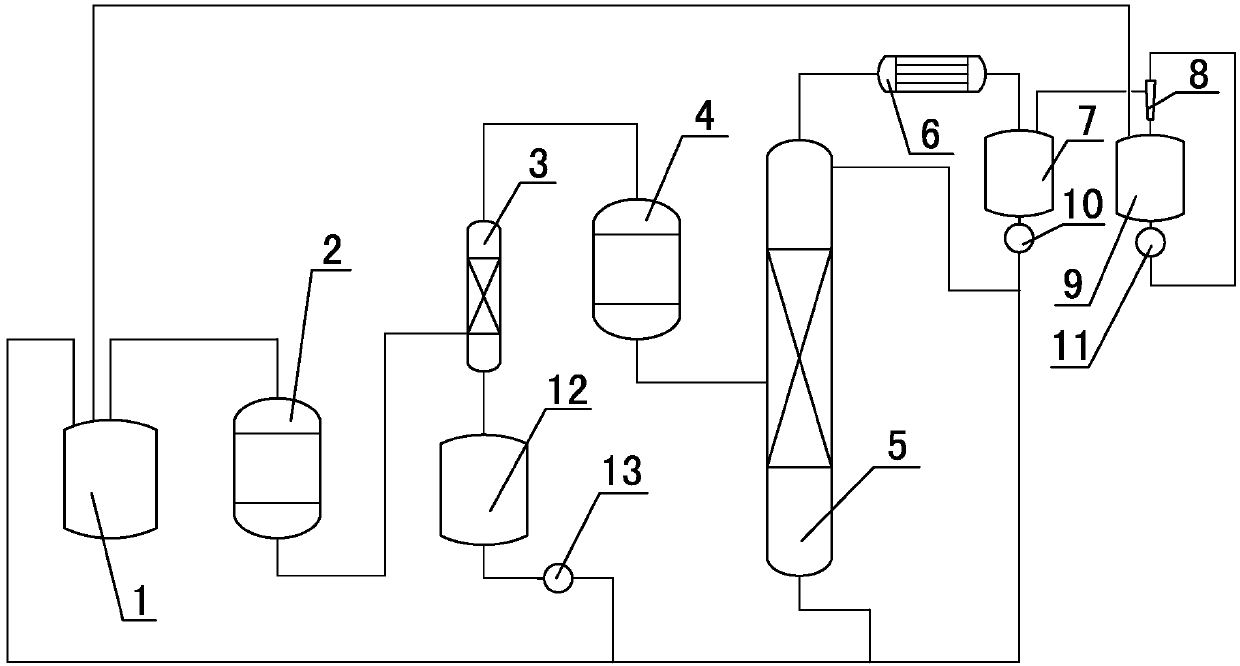

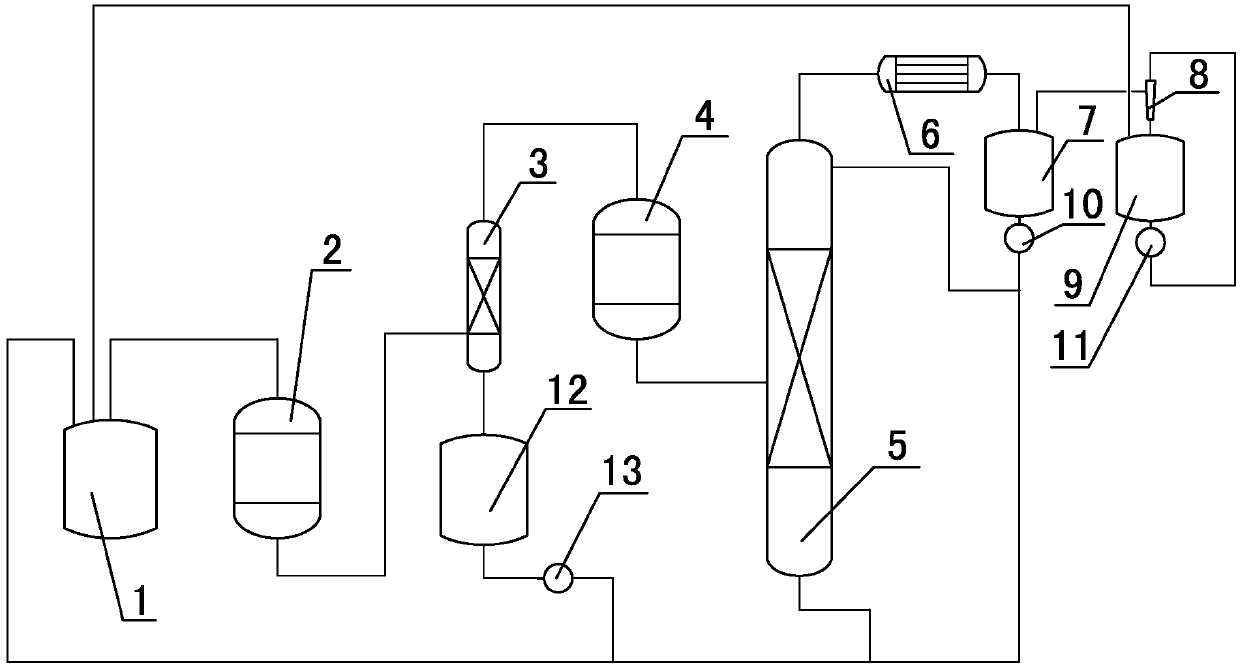

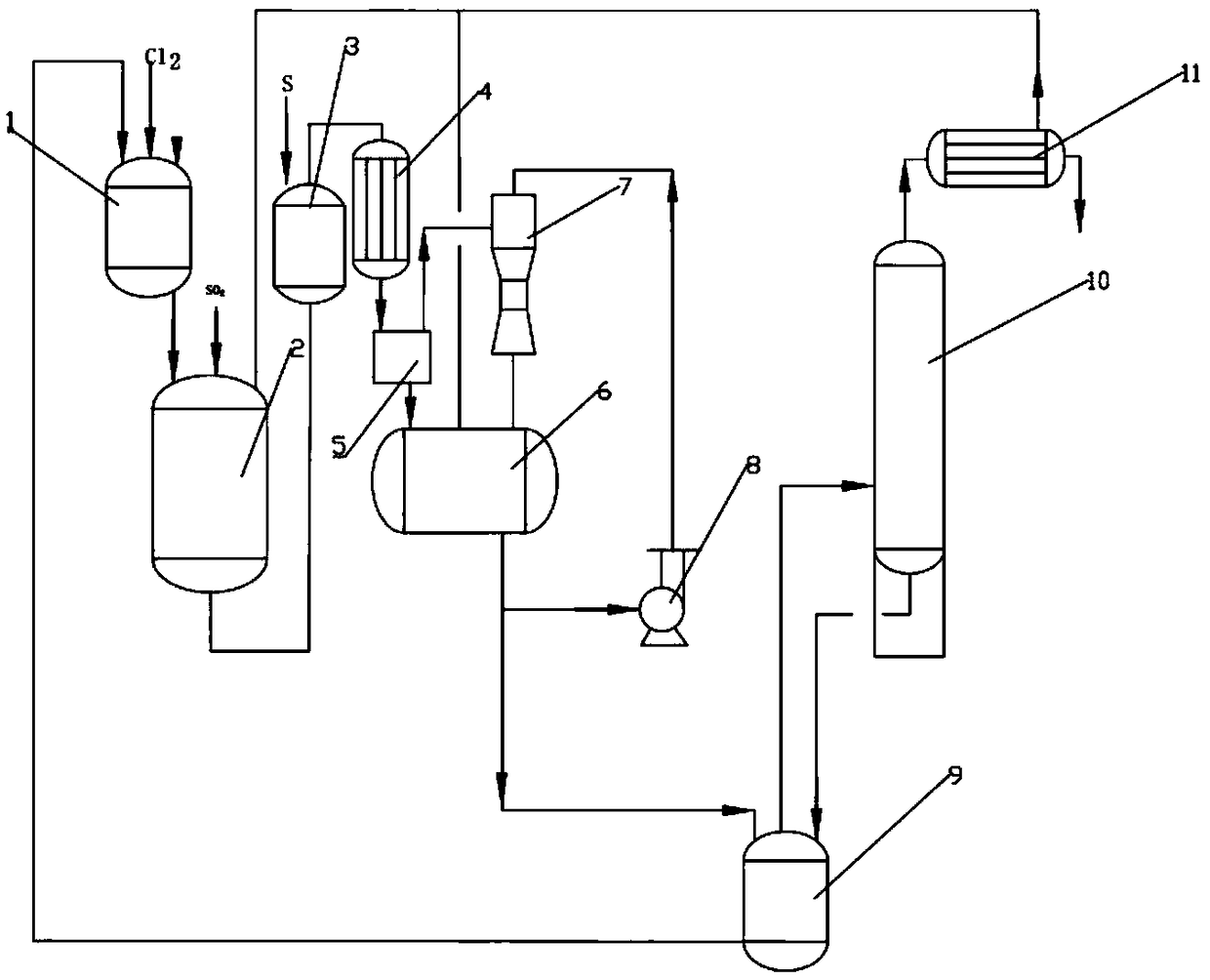

Production process of sulfoxide chloride

ActiveCN106672916AReduce the probability of exposure to waterReduce usageThionyl chlorideGas phaseSulfur dioxide

The invention belongs to the technical field of chemical production, and in particular relates to a production process of sulfoxide chloride. The production process comprises the following steps: enabling synthetic gas generated by reaction of sulfur and chlorine gas in a synthesis kettle, and sulfur dioxide gas to enter a reactor together; directly de-coloring a crude product sulfoxide chloride, generated by reaction in the reactor, through a sulfur tank in a gas-state form, and then conveying the crude product into a decomposer; enabling a gas-phase crude product sulfoxide chloride from the decomposer to enter a rectifying tower; after condensing a gas phase at the top of the rectifying tower, enabling the gas phase to enter a refluxing tank; after enabling the gas phase in the refluxing tank to enter an evacuation tank through an injector, recycling the gas phase back into the synthesis kettle, and taking out a qualified product from the middle part of the rectifying tower. The production of the sulfoxide chloride is fully sealed circulating production, and no wastewater, waste gas and waste dreg are discharged; the yield of the product basically reaches 100 percent.

Owner:SHANDONG KAISHENG NEW MATERIALS

Production method for thionyl chloride

The invention belongs to the technical field of chemical production, and particularly relates to a production method for thionyl chloride. The production method comprises the following step: introducing synthesis gas generated by reaction, in a reaction kettle, of sulfur and chlorine gas, and sulfur dioxide gas into a reactor, and enabling a crude product thionyl chloride generated by the reactor to directly enter a splitter in the form of gas after passing through an absorption tower; introducing gas-phase crude product thionyl chloride from the splitter to enter a rectifying column, condensing gas-phase on the top of the rectifying tower, and introducing the condensed gas-phase into a reflux tank; introducing the gas phase in the reflux tank to enter a vacuum-pumping tank through an ejector and alloying a synthesis kettle in a circulating mode, and recovering a qualified product from the middle part of the rectifying column. According to the production method, a light component in the crude product thionyl chloride is converted into a heavy component through the adsorption tower, and pressure drop before and after conversion is relatively small, operation is easy, automation is easily realized and conversion is more complete by adopting the tower, so that the load of the rectifying system is greatly reduced.

Owner:SHANDONG KAISHENG NEW MATERIALS

Cooling capacity cyclic utilization process for producing thionyl chloride

InactiveCN107930546APrevent evaporationReduce energy consumptionLighting and heating apparatusThionyl chlorideLiquid storage tankCooling capacity

The invention relates to a cooling capacity cyclic utilization process for producing thionyl chloride and belongs to the field of chemical technology production. A cold liquid which is deeply cooled by a cold liquid storage tank enters a heat exchanger. A circulating pump pumps out water in a circulation water pool, and the pumped water enters the heat exchanger. The cold liquid and circulating water perform heat exchange in the heat exchanger. The cold liquid subjected to heat exchange is vaporized by a vaporizer and then enters a production system. Circulating water subjected to heat exchange enters a refrigerator, so that the water return temperature of circulating water is reduced. According to the process, cooling capacity carried by the cold liquid in the production process of thionyl chloride is fully utilized, so that the energy consumption is reduced, and meanwhile, vaporization of lots of circulating water is avoided. The operating load of the refrigerator in high-temperatureseason is reduced, and favorable equipment operation is guaranteed.

Owner:SHANDONG KAISHENG NEW MATERIALS

Regenerating method of waste thionyl chloride

ActiveCN108439350AHigh selectivityImprove stabilityOther chemical processesThionyl chlorideRecovery methodPolyacrylamide

The invention discloses a regenerating method of waste thionyl chloride. A polyacrylamide / zeolite crosslinking compound adsorption material is prepared from polyacrylamide and zeolite in the absence of a coupling agent, the polyacrylamide / zeolite crosslinking compound adsorption material and waste thionyl chloride are placed in a mixer at normal temperature to be evenly mixed, adsorption is conducted for 60-120 min, depressurized distilling is conducted at 78 DEG C, and the first-grade thionyl chloride with the concentrationof 99.5% is obtained. The problems that waste thionyl chloride is highin recovery energy consumptiom, the process is complex and the environment is polluted are solved; the waste thionyl chloride recovery method which is low in cost, simple in production process, beneficial for industrialization and free of pollution is provided and can be used for recovering the waste thionyl chloride generated in different acylating chlorination production processes.

Owner:LUDONG UNIVERSITY

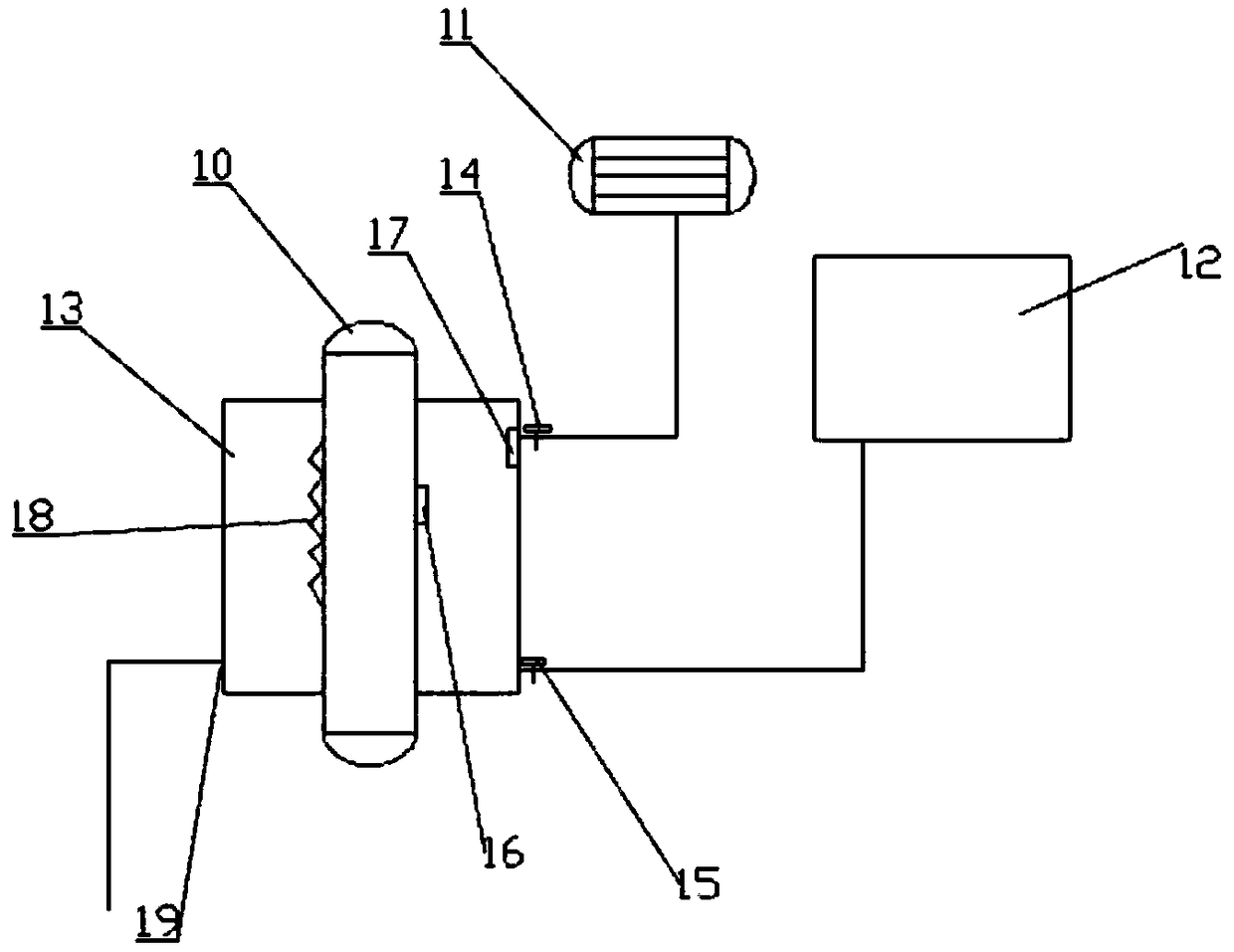

Method for optimizing production process of thionyl chloride

ActiveCN107954400AImprove disposal capacityReduce usageThionyl chlorideFractionating columnSulfur monochloride

The invention relates to a method for optimizing a production process of thionyl chloride and belongs to the technical field of chemical engineering. Liquid sulfur in a liquid sulfur tank is metered by a metering pump and then pumped into an atomizing device in a distillation column; a crude thionyl chloride product is mixed with the liquid sulfur at the top of the distillation column; sulfur dichloride in the crude thionyl chloride product and the liquid sulfur are subjected to a reaction, a heavy component, namely, sulfur monochloride, is produced and withdrawn from the bottom of the distillation column, remaining crude thionyl chloride product is condensed by a condenser and enters a return tank, a part of liquid phase in the return tank is pumped into the distillation column by a reflux pump to be recycled, and the remaining liquid-phase material is recovered from the return tank. By means of the method, automatic sulfur addition is realized, time and labor cost are saved, and thedecoloration effect is better.

Owner:SHANDONG KAISHENG NEW MATERIALS

Process for producing thionyl chloride

ActiveCN106744712BReduce the probability of exposure to waterReduce usageThionyl chlorideRefluxSyngas

Owner:SHANDONG KAISHENG NEW MATERIALS

A kind of regeneration method of waste thionyl chloride

ActiveCN108439350BHigh selectivityImprove stabilityOther chemical processesThionyl chlorideDistillationEnvironmental engineering

The invention discloses a regeneration method using waste thionyl chloride, which uses polyacrylamide and zeolite to prepare polyacrylamide / zeolite cross-linked composite adsorption materials in the presence of a coupling agent, and cross-links polyacrylamide / zeolite at normal temperature. Combined composite adsorption material and waste thionyl chloride were placed in a stirrer, mixed evenly, adsorbed for 60-120 minutes, and subjected to vacuum distillation at 78°C to obtain more than 99.5% of the first-grade thionyl chloride. The present invention solves the problems of high energy consumption, complex process, and environmental pollution in the recovery of waste thionyl chloride, and provides a waste thionyl chloride recovery method with low cost, simple production process, easy industrialization and no pollution, which can be used in Recovery of waste thionyl chloride from different acyl chloride production processes.

Owner:LUDONG UNIVERSITY

The production method of thionyl chloride

ActiveCN106853958BReduce the probability of exposure to waterReduce usageThionyl chlorideSyngasSulfur

The invention belongs to the technical field of chemical production and particularly relates to a production method of thionyl chloride. Synthesis gas produced by sulfur and chlorine through a reaction in a synthesis kettle and sulfur dioxide gas enter a reactor together, and crude thionyl chloride generated through the reaction in the reactor is directly decolorized by a sulfur tank in a gas state and then enters a rectifying tower; a gas phase at the top of the rectifying tower enters a return tank after being condensed, a gas phase in the return tank enters an exhaustion tank through an ejector and is cyclically and mechanically applied to the synthesis kettle, and a qualified product is produced from the middle of the rectifying tower. Thionyl chloride is produced in a fully-closed circulation manner, no wastewater, waste gas or waste residues are discharged, and the product yield basically reaches 100%.

Owner:SHANDONG KAISHENG NEW MATERIALS

Method for optimizing production process of thionyl chloride

Owner:SHANDONG KAISHENG NEW MATERIALS

The production process of thionyl chloride

ActiveCN106629626BReduce the probability of exposure to waterReduce usageThionyl chlorideChemical industryDistillation

The present invention relates to the technical field of chemical industry production and in particular relates to a production technology of thionyl chloride. Sulfur and chlorine gas are reacted in a synthesis reactor to produce synthesis gas, the synthesis gas and sulfur dioxide gas enter together into a reactor, produced crude products of the thionyl chloride after the reaction in the reactor directly enter into a distillation column in a gas state, and gas phase from the top of the distillation column is condensed, the condensed gas enters into a reflux tank; and gas phase in the reflux tank enters into an evacuation tank via an ejector, the treated gas is recycled into the synthesis reactor, and qualified products are collected at the middle part of the distillation column. The production technology is simplified and the technologies of condensation, sulphur combining, light component recycling, etc. of the reacted crude products of the thionyl chloride are saved. Due to the reduction of the condensation and regasification, the technology is relatively short in routes and minimal in heat loss, and greatly reduces energy consumptions of the devices.

Owner:SHANDONG KAISHENG NEW MATERIALS

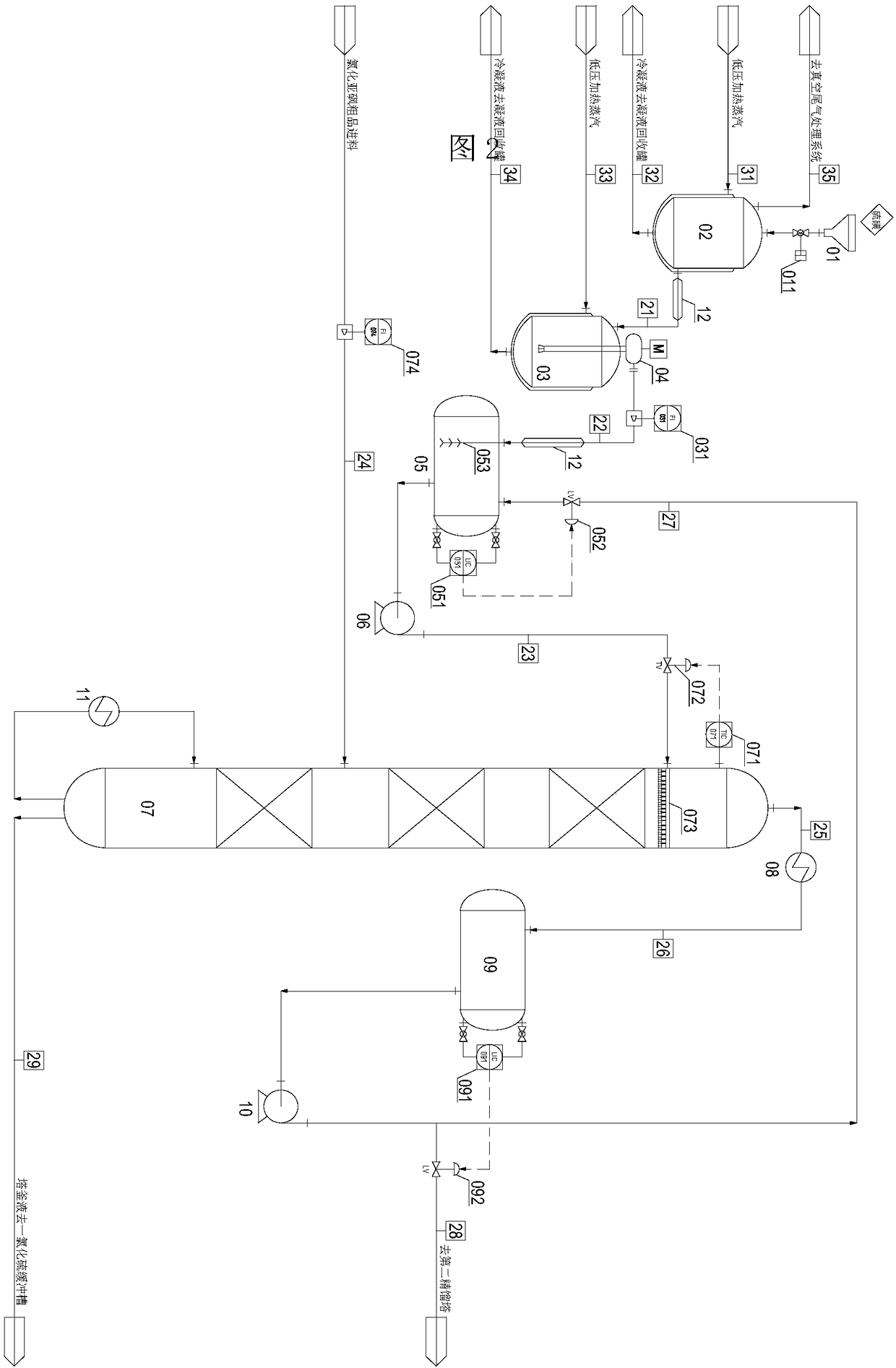

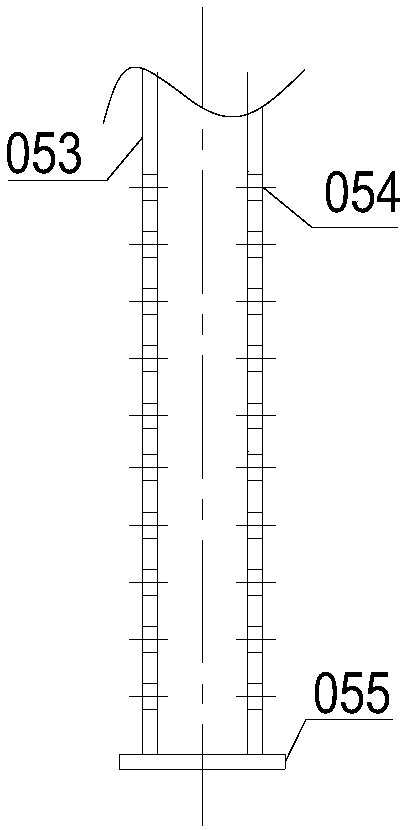

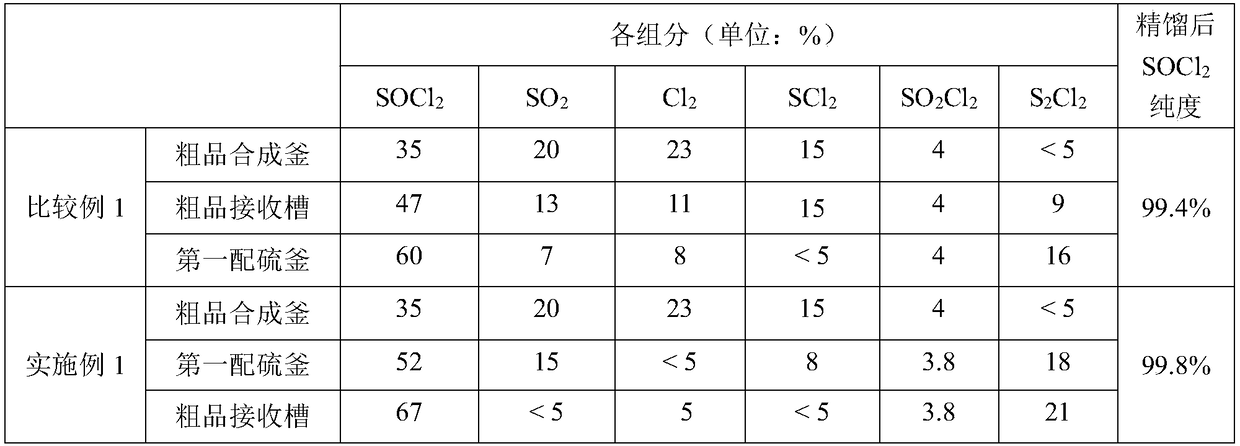

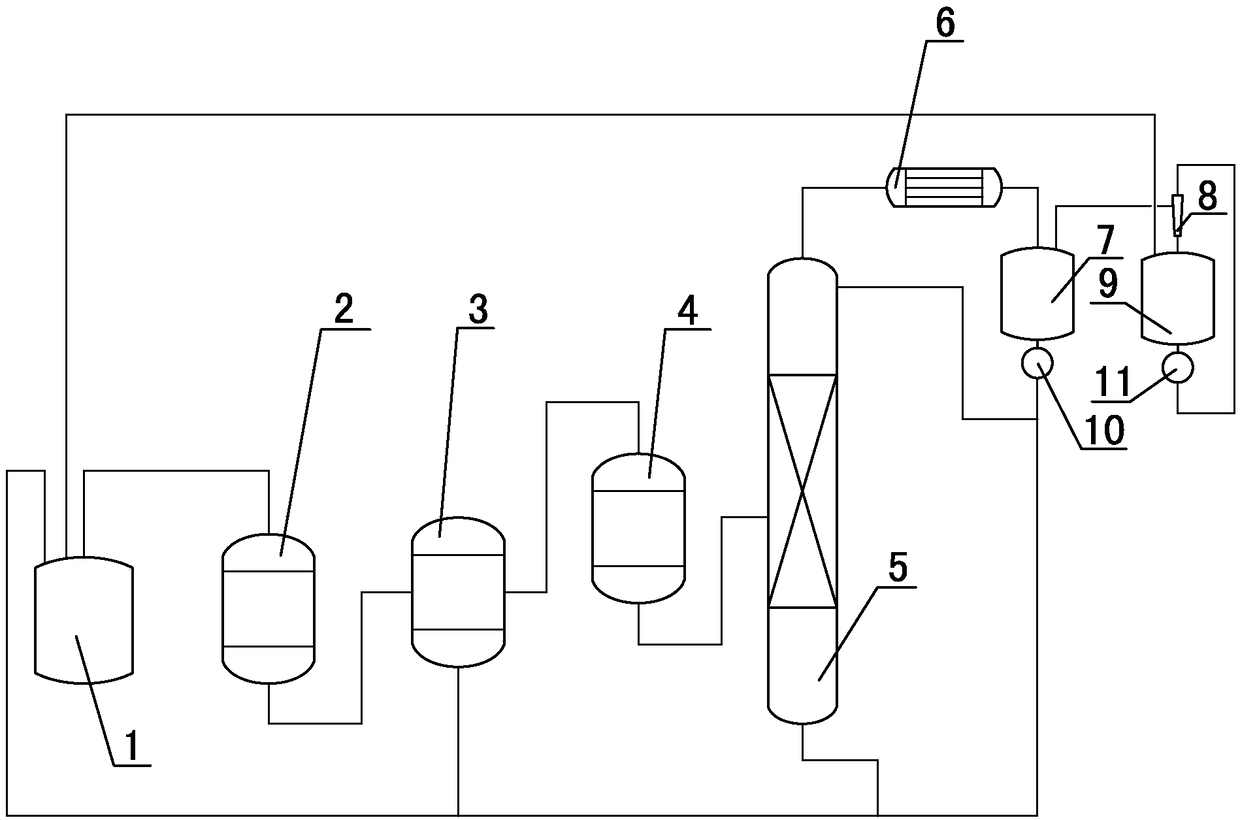

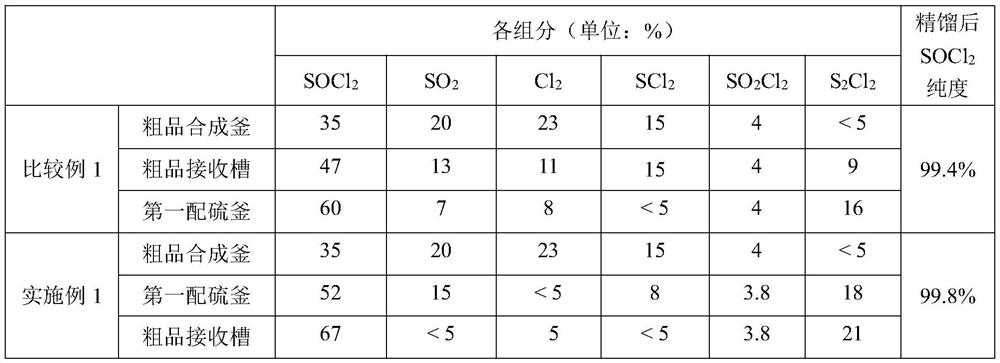

Method and equipment for refining of thionyl chloride

The invention provides method and equipment for refining of thionyl chloride. A gas mixture generated from a thionyl chloride synthesis kettle is subjected to two steps of sulfur mixing reaction in the process of purifying; particularly, the two steps of sulfur mixing reaction includes firstly, directly introducing the gas mixture discharged from the thionyl chloride synthesis kettle into a firstsulfur mixing kettle for realizing sulfuration, and purifying sulfuretted gas mixture through condensing and degassing to obtain crude thionyl chloride product; secondly, arranging a secondary sulfuration bed on the top of a rectifying apparatus, rectifying and purifying the crude thionyl chloride product for secondary sulfuration, and arranging catalysts in the secondary sulfuration bed. Since the gas discharged from the thionyl chloride synthesis kettle is of high temperature, heating before sulfur mixing reaction is omitted, equipment input is reduced, and decomposition of thionyl chlorideduring heating is reduced; besides, sulfur and drying agents are mixed and added, the circumstance of introducing moisture along with adding of sulfur is avoided, content of impurity of products is reduced, non-condensable gas in the production process is extracted fully, and utilization rate of raw materials is increased.

Owner:JIANGXI SELON INDAL

Method for producing thionyl chloride

ActiveCN106744712AAchieving zero emissionsReduce the probability of exposure to waterThionyl chlorideChemical industryGas phase

The invention belongs to the technical field of chemical industry production, and in particular relates to a method for producing thionyl chloride. The method comprises the following steps: sulfur dioxide gas and synthetic gas generated by reaction of sulfur and chlorine gas in a synthesis reactor enter a reactor together, the crude product thionyl chloride in a gaseous form generated by reaction in the reactor directly enters a rectifying tower through an absorbing tower; the gas phase at the top of the rectifying tower enters a reflux drum after condensation; the gas phase in the reflux drum enters an evacuated drum through an ejector, and then is cyclically nested back to the synthesis reactor; and a qualified product is obtained in the middle part of the rectifying tower. According to the method for producing thionyl chloride, because the process pipeline is short and a process of condensing regasification is saved, heat in the system can be utilized more sufficiently, and the energy consumption of devices is greatly reduced.

Owner:SHANDONG KAISHENG NEW MATERIALS

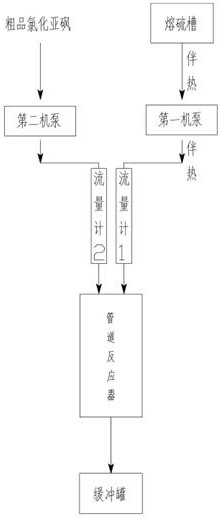

Continuous sulfur addition device and method for sulfur oxychloride sulfur compounding system

ActiveCN112169711BStrong disturbanceSimple structureThionyl chlorideChemical/physical processesDistillationPhysical chemistry

The present invention is a continuous sulfur adding device and method for sulfur oxychloride sulfur mixing system, which is characterized in that: (1) the liquid sulfur in the sulfur melting tank is pumped into the pipeline reactor through the jacket pipe by the first machine pump, and the flow rate is controlled At 350-500kg / h, the temperature of the steam in the jacketed tube is 160-168°C, and the pressure is 0.4-0.6MPa; (2) The crude sulfur oxychloride liquid is pumped into the pipeline reactor by the second machine, and the control The flow rate is 4600-4800 kg / h; (3) Control the mixing of crude thionyl chloride and liquid sulfur at the inlet of the pipeline reactor, and control the temperature of the pipeline reactor by controlling the opening of the circulating water inlet valve of the pipeline reactor jacket The temperature is 45~65°C. After the reaction, it enters the buffer tank and waits for the rectification system to carry out rectification and purification of thionyl chloride. The advantages of the present invention are that the reactor is a pipeline reactor, compared with kettle-type sulfur blending, it reduces power consumption, is convenient for maintenance, the fluid is strongly disturbed in the reactor, and the mixing is more uniform, which can ensure the continuity of operation and improve production efficiency.

Owner:安徽金轩科技有限公司

Production process of thionyl chloride

ActiveCN106672916BReduce the probability of exposure to waterReduce usageThionyl chlorideGas phaseSulfur dioxide

Owner:SHANDONG KAISHENG NEW MATERIALS

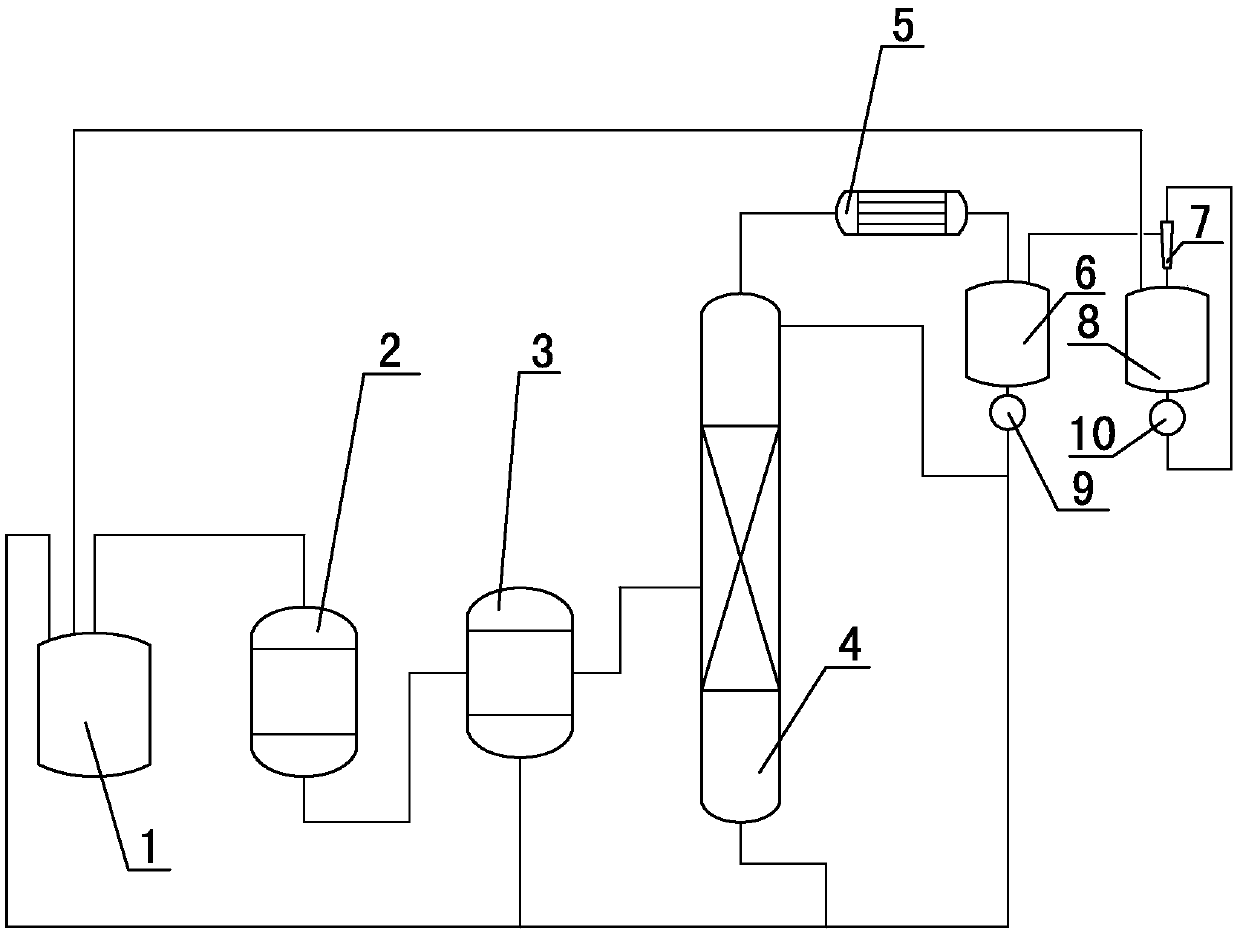

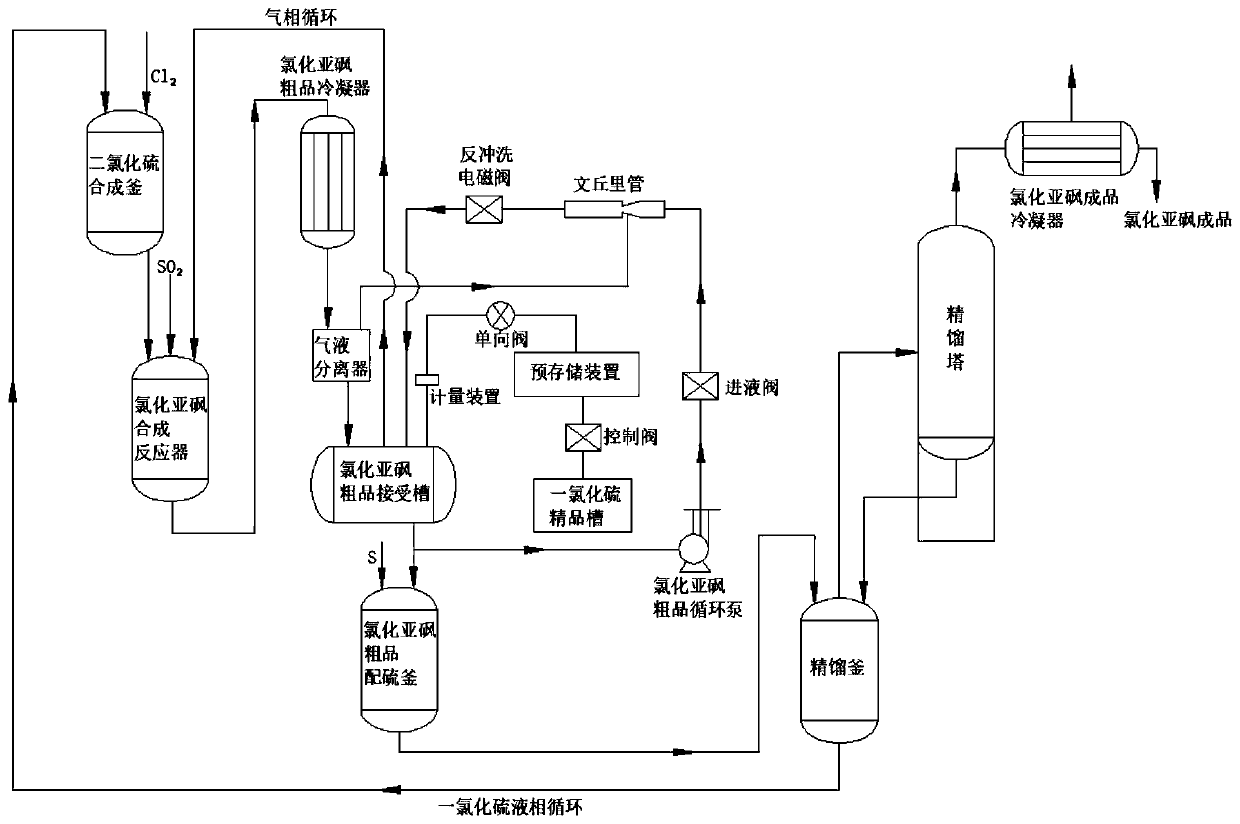

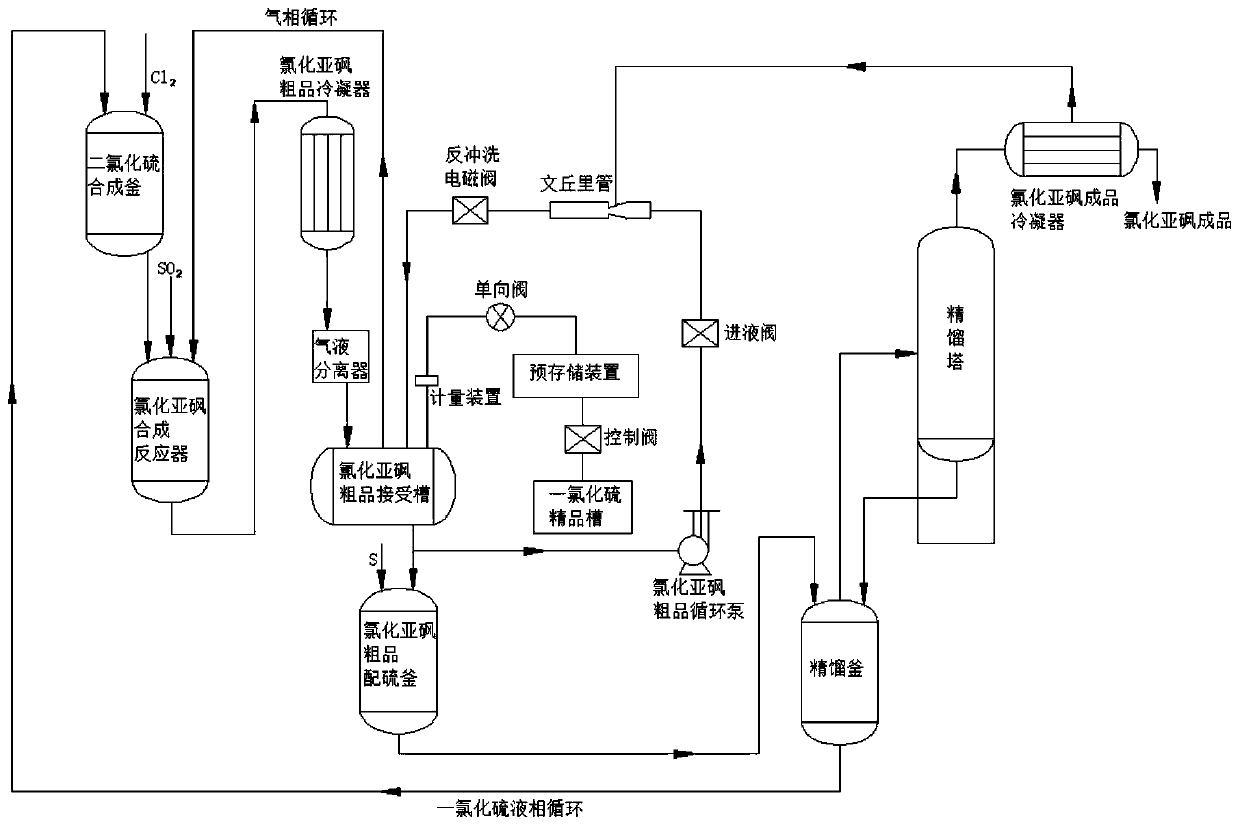

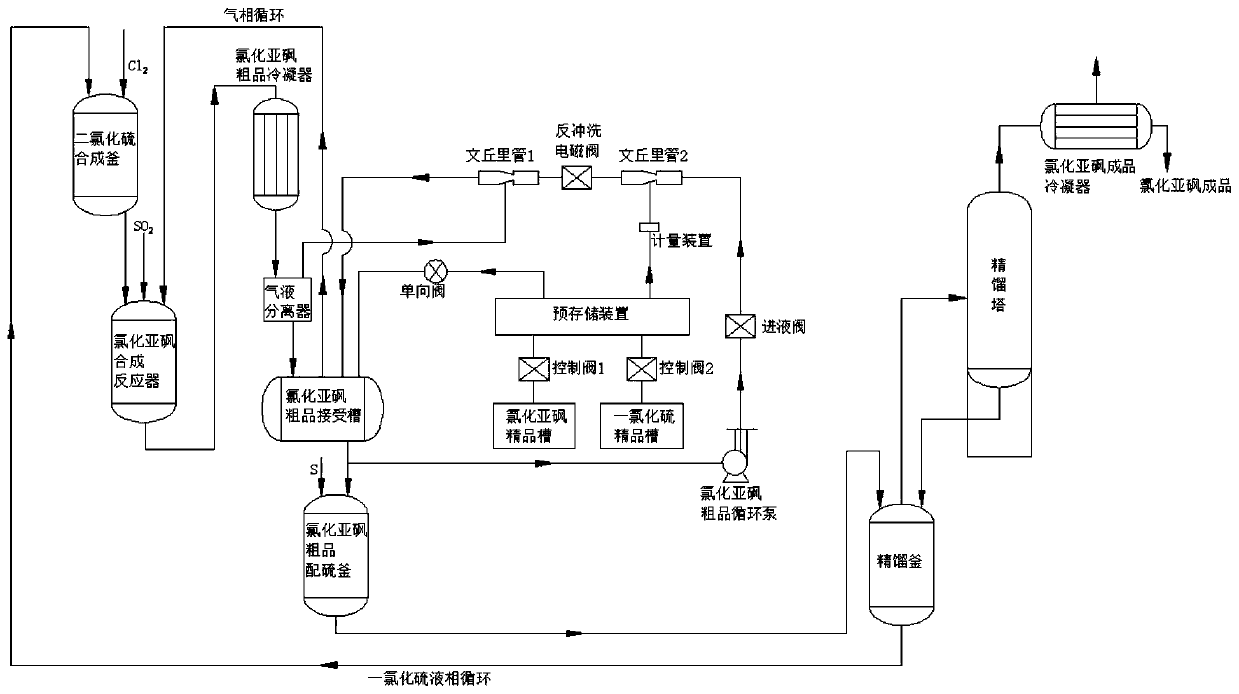

A kind of thionyl chloride production system and start-up method thereof

ActiveCN111320140BEnsuring a continuous loop processPromote circulationThionyl chlorideVapor–liquid separatorProcess engineering

Owner:JIANGXI SELON INDAL

Refining method and device for refining thionyl chloride

The invention relates to a method and a device for refining sulfoxide chloride. The method comprises the following steps: after rectifying a crude product generated in a sulfoxide chloride synthesis step, performing overvulcanization and condensation on the rectified light component, putting a liquid-phase component obtained through gas-liquid separation into a rectification cycle and putting a gas-phase component obtained through gas-liquid separation into a synthesis step cycle; condensing the gas-phase component generated after the rectified light component is subjected to first vacuum distillation and then putting the condensed gas-phase component into the synthesis step cycle, and performing second vacuum rectification on a heavy component; performing overvulcanization and condensation on the light component obtained by virtue of the second vacuum rectification, returning the liquid-phase component obtained through gas-liquid separation to the second vacuum rectification step cycle, and returning the heavy component to the rectification step cycle; putting the gas-phase components obtained in the two stages of vacuum rectification steps into the synthesis step cycle, respectively. According to the method, a tower system sequence is arranged reasonably, the easily decomposable components are separated under vacuum and at a controlled temperature, and the components difficult to separate are cyclically rectified, and therefore, the separation accuracy and the product quality are improved; after multi-stage rectification, the purity of sulfoxide chloride is above 99.9%.

Owner:QINGDAO UNIV OF SCI & TECH

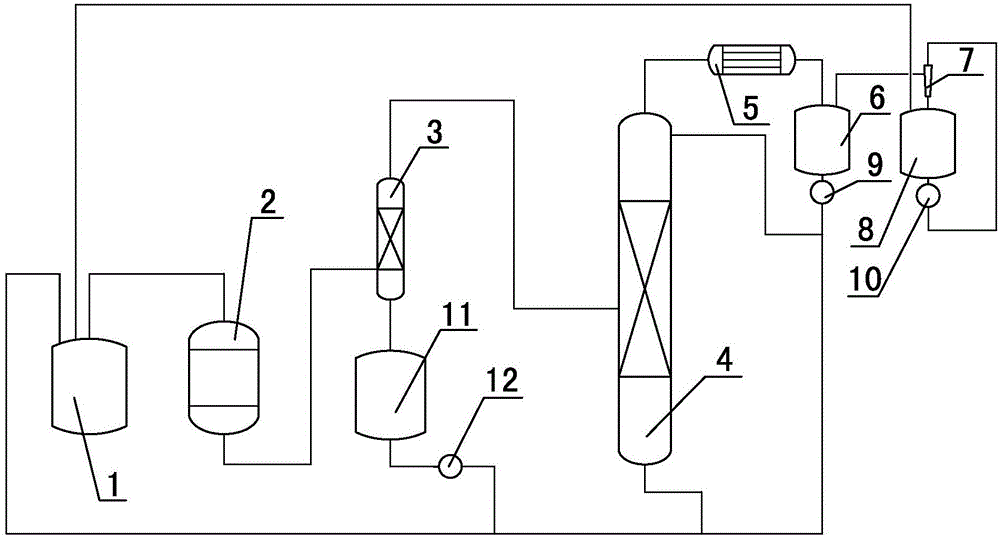

Thionyl chloride production system and starting method thereof

ActiveCN111320140AAdvantages of drivingEnsuring a continuous loop processThionyl chlorideVapor–liquid separatorProcess engineering

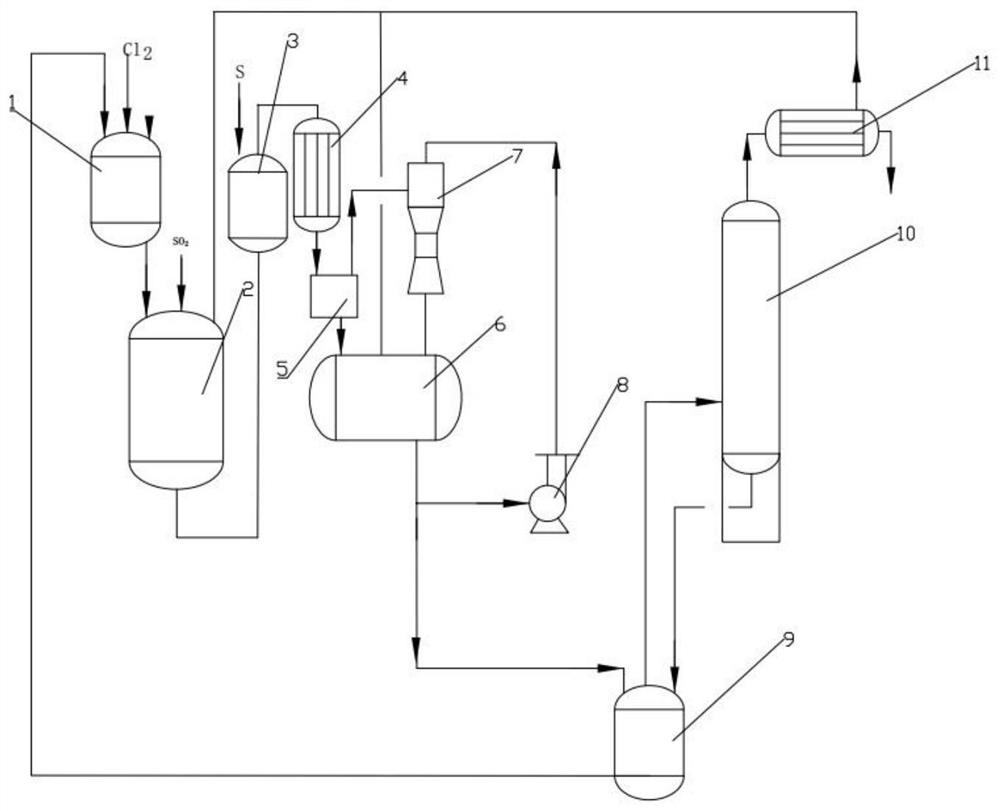

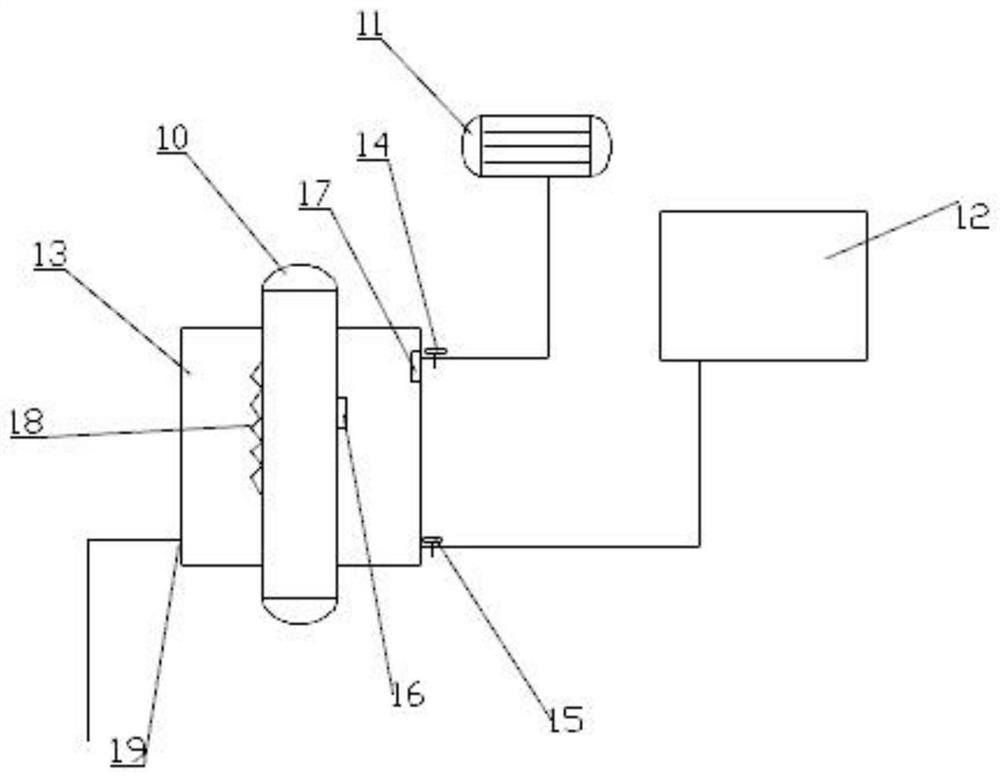

The invention provides a thionyl chloride production system and a starting method thereof. The thionyl chloride production system comprises a sulfur dichloride synthesis kettle, a thionyl chloride synthesis kettle, a crude product condenser, a gas-liquid separator, a crude product receiving tank, a sulfur dosing kettle, a rectifying kettle, a rectifying tower, a rectifying condenser, a finished product tank, a crude product circulating device and a stability promoting device, which are connected in sequence. The liquid inlet of the crude product circulating device is connected with the liquidoutlet pipeline of the crude product receiving tank. The liquid outlet of the crude product circulating device is connected with the liquid inlet pipeline of the crude product receiving tank. The crude product circulating device is used for circulating a thionyl chloride crude product after the system is started. The stability promoting device is respectively connected with the crude product receiving tank and the crude product circulating device, and is used for controlling the purity of the thionyl chloride crude product from the start-up stage to the operation stability stage of the system.According to the thionyl chloride production system and the starting method thereof, the thionyl chloride production system can be promoted to reach a stable operation state as soon as possible, andthe time required by the system from starting to stable operation is shortened.

Owner:JIANGXI SELON INDAL

Device and method for recycling tail gas from thionyl chloride production

ActiveCN111453704AImprove absorption rateTake advantage ofChemical industryThionyl chlorideWater chlorinationProcess engineering

The invention provides a device and a method for recycling tail gas from thionyl chloride production, and relates to the field of chemical technical production. According to the invention, tail gas from synthesis of thionyl chloride is used for closed cycle production; the tail gas comprises sulfur monochloride, sulfur dichloride, thionyl chloride, chlorine and sulfur dioxide; the tail gas is pumped into a thionyl chloride synthesis reactor through a liquid spraying device for cyclic utilization; when the whole set of production device is used in the actual production process, pressure fluctuation among the devices is reduced, basically no waste liquid or waste gas is discharged outwards, meanwhile, the whole set of production device can ensure that the purity of the crude thionyl chlorideproduct is maintained in a target range quickly within the time from starting to stable operation of the equipment, and the time required for stable operation of the whole set of system is shortened.

Owner:JIANGXI SELON INDAL

Method for preparing sulfoxide chloride from industrial chloride salt

InactiveCN108946676AEfficient recyclingEliminate the effects ofThionyl chlorideAlkali metal sulfites/sulfatesActivated carbonChloride salt

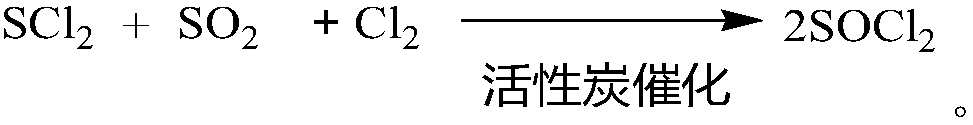

The invention provides a method for preparing sulfoxide chloride from industrial chloride salt, wherein the method includes the following steps: S1) carrying out a reaction of the industrial chloridesalt with sulfur trioxide at the temperature of 80-200 DEG C to obtain chlorosulfonate; S2) carrying out high temperature cracking of the chlorosulfonate at the temperature of 300-900 DEG C to obtainsulfate, chlorine gas and sulfur dioxide; and S3) mixing the chlorine gas and sulfur dioxide obtained in the S2) with sulfur dichloride, and carrying out a reaction under the catalytic action of activated carbon to obtain sulfoxide chloride. The sulfur trioxide is used as a strong oxidant at high temperature, the residence time of materials is prolonged, waste salt is converted into chlorosulfonate, and organic matters in the waste salt are oxidized to remove in the reaction process; then high temperature cracking is carried out, while chlorine gas and sulfur dioxide with equal moles are obtained, trace organic matters which are not oxidized by sulfur trioxide can be subjected to oxidative decomposition by high temperature again, the organic matters are treated more thoroughly, and sulfoxide chloride can be prepared by adding equimolar sulfur dichloride.

Owner:SHANDONG RUNBO BIOTECH CO LTD

A method for refining thionyl chloride

The invention provides method and equipment for refining of thionyl chloride. A gas mixture generated from a thionyl chloride synthesis kettle is subjected to two steps of sulfur mixing reaction in the process of purifying; particularly, the two steps of sulfur mixing reaction includes firstly, directly introducing the gas mixture discharged from the thionyl chloride synthesis kettle into a firstsulfur mixing kettle for realizing sulfuration, and purifying sulfuretted gas mixture through condensing and degassing to obtain crude thionyl chloride product; secondly, arranging a secondary sulfuration bed on the top of a rectifying apparatus, rectifying and purifying the crude thionyl chloride product for secondary sulfuration, and arranging catalysts in the secondary sulfuration bed. Since the gas discharged from the thionyl chloride synthesis kettle is of high temperature, heating before sulfur mixing reaction is omitted, equipment input is reduced, and decomposition of thionyl chlorideduring heating is reduced; besides, sulfur and drying agents are mixed and added, the circumstance of introducing moisture along with adding of sulfur is avoided, content of impurity of products is reduced, non-condensable gas in the production process is extracted fully, and utilization rate of raw materials is increased.

Owner:JIANGXI SELON INDAL

Thionyl chloride production system

The invention belongs to the technical field of acyl chloride production devices, and particularly relates to a thionyl chloride production system. According to the thionyl chloride production system,a liquid chlorine storage tank is connected with the synthesis kettle through a pipeline; the bottom of a de-heavy tower is connected with a catalytic reactor through a pipeline; a sulfur dioxide storage tank is connected with a first buffer tank through a pipeline; the first buffer tank is connected with the catalytic reactor through a pipeline; the bottom of the catalytic reactor is connected with a catalytic condenser through a pipeline, the bottom of the catalytic condenser is connected with an ejector through a pipeline, and the ejector is connected with a crude product receiving kettle.According to the thionyl chloride production system, gasification latent heat of raw materials chlorine and sulfur dioxide is fully utilized; a part of raw materials chlorine and sulfur dioxide are used as cooling cold sources of the whole production system, construction of public engineering of a circulating water system and a refrigeration system is avoided, process complexity and system energyconsumption (including electricity, water and steam) are reduced, access of circulating water is avoided in the process, and process risks of the whole system are reduced.

Owner:SHANDONG KAISHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com