Cooling capacity cyclic utilization process for producing thionyl chloride

A thionyl chloride, cooling technology, applied in cooling fluid circulation devices, applications, thionyl chloride and other directions, can solve problems such as insufficient heat exchange, increased compressor load, and inability to condense exhaust gas, avoiding a large amount of evaporation, Reduce the operating load and ensure the effect of good operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Main parameter settings:

[0026] The liquid level of the cold liquid storage tank 1 is 100mm, and the pressure of the cold liquid storage tank 1 is 0.3Mpa;

[0027] The outlet temperature of heat exchanger 3 is 0°C, and the outlet pressure is ≤0.4Mpa;

[0028] The temperature of vaporizer 4 is 90°C, and the pressure is ≤0.4Mpa.

[0029] The refrigeration cycle utilization process of producing thionyl chloride of the present invention, the steps are as follows:

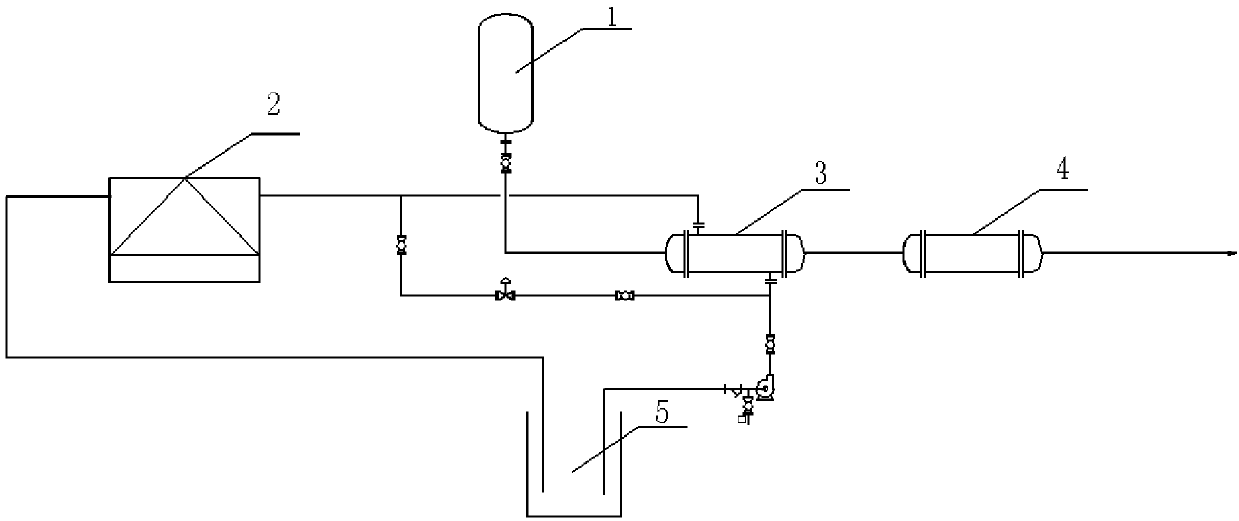

[0030] The cold liquid after being cryogenically cooled by the cold liquid storage tank 1 enters the heat exchanger 3, and the circulating pump pumps the water in the circulating pool 5 into the heat exchanger 3, and the cold liquid and the circulating water exchange heat in the heat exchanger 3, The cold liquid after heat exchange is vaporized by the vaporizer 4 and then enters the production system, and the circulating water after heat exchange enters the refrigerator 2 to reduce the return temperature of t...

Embodiment 2

[0032] Main parameter settings:

[0033] The liquid level of the cold liquid storage tank 1 is 700mm, and the pressure of the cold liquid storage tank 1 is 0.2Mpa;

[0034] The outlet temperature of heat exchanger 3 is 10°C, and the outlet pressure is ≤0.4Mpa;

[0035] The temperature of vaporizer 4 is 97°C, and the pressure is ≤0.4Mpa.

[0036] The refrigeration cycle utilization process of producing thionyl chloride of the present invention, the steps are as follows:

[0037] The cold liquid after being cryogenically cooled by the cold liquid storage tank 1 enters the heat exchanger 3, and the circulating pump pumps the water in the circulating pool 5 into the heat exchanger 3, and the cold liquid and the circulating water exchange heat in the heat exchanger 3, The cold liquid after heat exchange is vaporized by the vaporizer 4 and then enters the production system, and the circulating water after heat exchange enters the refrigerator 2 to reduce the return temperature of ...

Embodiment 3

[0039] Main parameter settings:

[0040] The liquid level of the cold liquid storage tank 1 is 1000mm, and the pressure of the cold liquid storage tank 1 is 0.2Mpa;

[0041] The outlet temperature of heat exchanger 3 is 20°C, and the outlet pressure is ≤0.4Mpa;

[0042] The vaporizer 4 has a temperature of 100°C and a pressure of ≤0.4Mpa.

[0043] The refrigeration cycle utilization process of producing thionyl chloride of the present invention, the steps are as follows:

[0044] The cold liquid after being cryogenically cooled by the cold liquid storage tank 1 enters the heat exchanger 3, and the circulating pump pumps the water in the circulating pool 5 into the heat exchanger 3, and the cold liquid and the circulating water exchange heat in the heat exchanger 3, The cold liquid after heat exchange is vaporized by the vaporizer 4 and then enters the production system, and the circulating water after heat exchange enters the refrigerator 2 to reduce the return temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com