Method and equipment for refining of thionyl chloride

A technology of thionyl chloride and sulfur dichloride, which is applied in the direction of thionyl chloride, sulfur and halogen compounds, can solve problems such as instability, low utilization rate of raw materials, low yield and purity of thionyl chloride, and achieve The effect of reducing pressure, reducing equipment investment and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

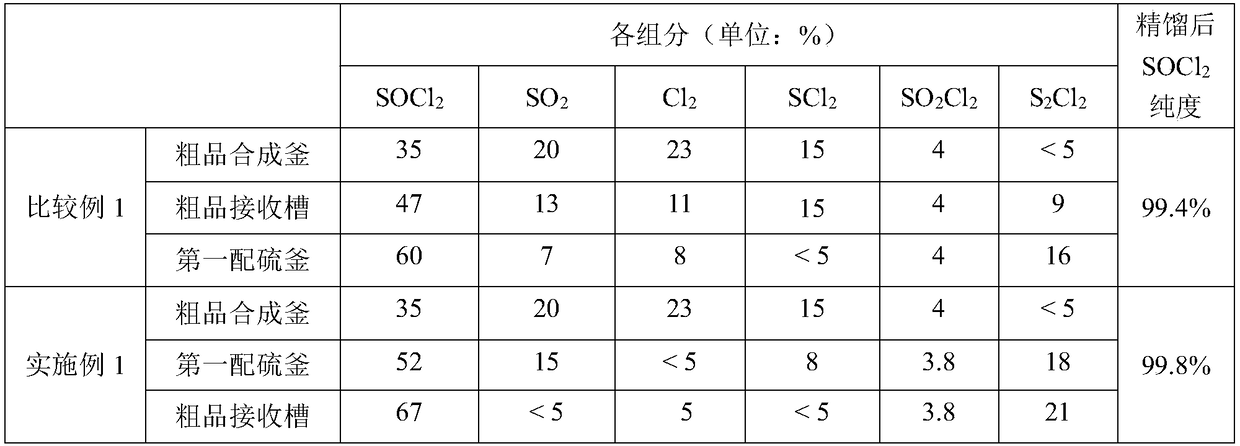

Embodiment 1

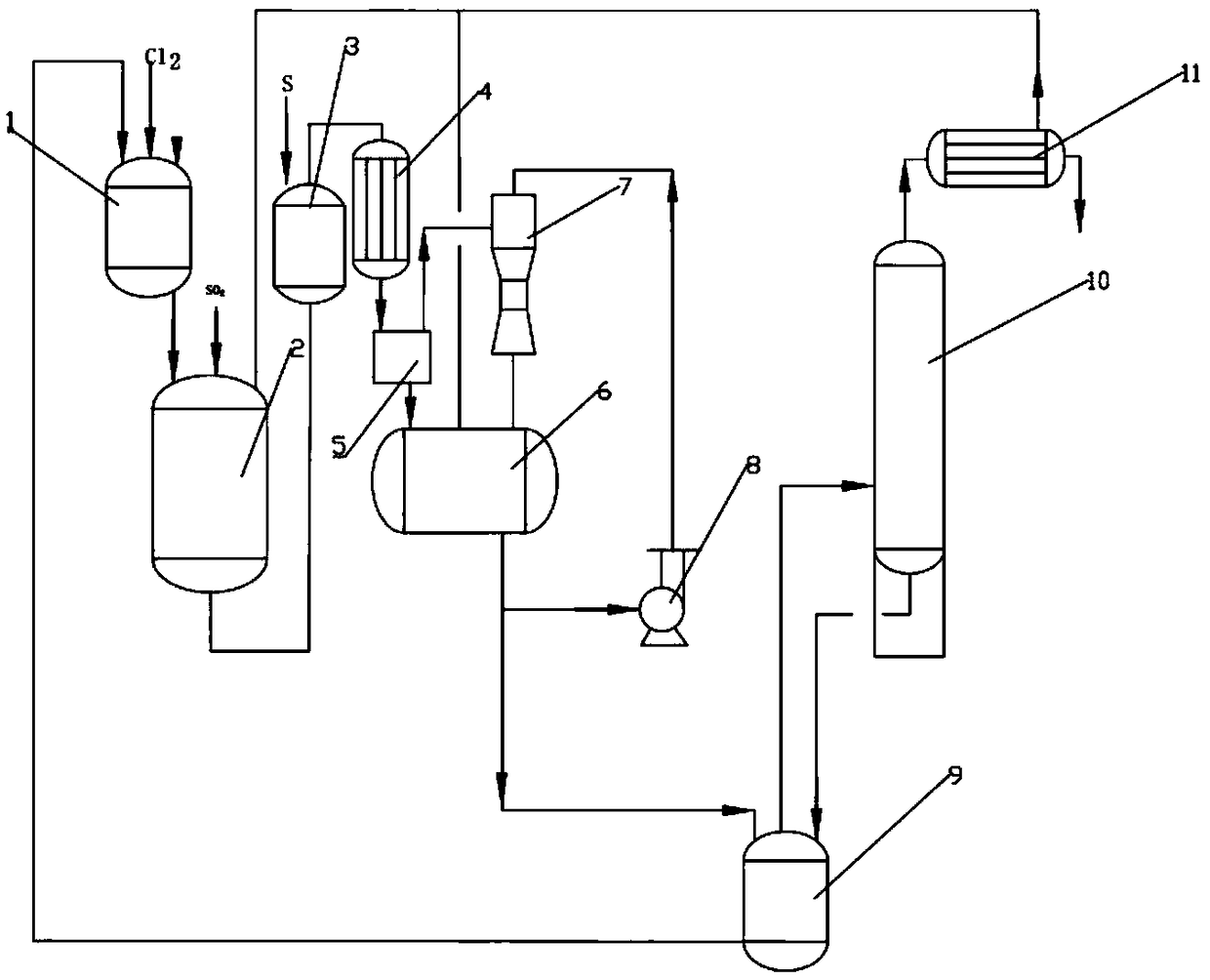

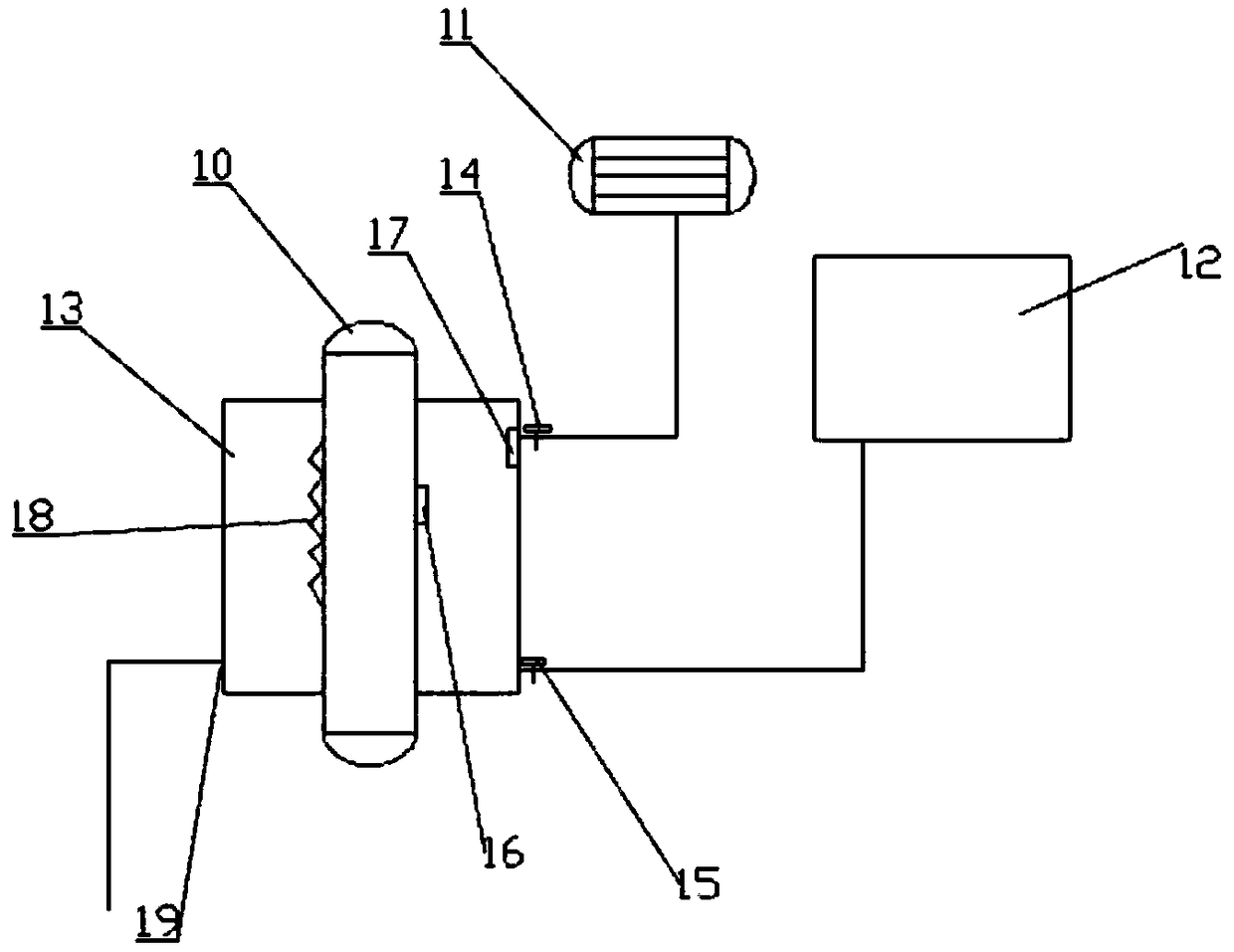

[0049] In this embodiment, the first step of sulfidation reaction is carried out before the mixed gas produced in the thionyl chloride synthesis reactor is condensed. At the same time, a secondary sulfidation bed is set in the rectification device to further purify the crude thionyl chloride to achieve Refining of sulfone. The specific method is as follows:

[0050] (1) Synthesis of sulfur dichloride

[0051] Use liquid sulfur monochloride and chlorine to react in the sulfur dichloride synthesis kettle, wherein part of the liquid sulfur monochloride comes from the product generated in the sulfur monochloride reaction kettle, and the other part comes from the high-boiling liquid phase extracted from the rectification tower The volume ratio of chlorine gas to liquid sulfur monochloride is 150:(0.15-0.25), the reaction temperature is controlled at 60-85°C, and the generated SCl 2 and excess Cl 2 The mixed gas is discharged from the gas outlet, and the pressure in the sulfur di...

Embodiment 2

[0065] This embodiment adopts the process of Example 1, the difference is that when sulfur is added to the first sulfur compounding kettle, sulfur is mixed with a desiccant to carry out the first sulfur compounding reaction, other processes are the same as in Example 1, and the specific methods are as follows:

[0066] (3) The first sulfur matching reaction

[0067] The crude mixed gas produced by the thionyl chloride synthesis kettle is directly passed into the first sulfur compounding kettle without any heating process, and the first sulfur compounding reaction is carried out. The reaction temperature in the first sulfur compounding kettle is from oxychloride to Add sulfur to the residual temperature of the crude product mixed gas discharged from the sulfone synthesis kettle. The method of adding sulfur is: crush the selected sulfur block and the desiccant calcium chloride particles together, and the crushed particles reach 30-50 meshes, and then Send the pulverized mixed po...

Embodiment 3

[0070] The present embodiment adopts the technique of embodiment 2, and the difference is that in the first sulfur matching kettle, a catalyst is added to catalyze the first sulfur matching reaction, and other techniques are the same as in example 2, and the specific methods are as follows:

[0071](3) The crude product mixed gas produced by the thionyl chloride synthesis kettle does not directly pass into the first sulfur matching still through any heating process, and carries out the first sulfur matching reaction, and the reaction temperature in the first sulfur matching still is from The residual temperature of the crude product mixed gas discharged from the thionyl chloride synthesis kettle, wherein, an activated carbon bed is arranged in the first sulfur mixing kettle, and the activated carbon is used as a catalyst for the primary vulcanization reaction, and dry sulfur is added thereto, wherein the addition of the sulfur The amount is 70-80% of the amount of sulfur needed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com