Device and method for recycling tail gas from thionyl chloride production

A thionyl chloride, tail gas recycling technology, applied in thionyl chloride, chemical industry, climate sustainability and other directions, can solve the problems of gas can not enter the synthesis kettle, complex process, difficult to obtain high purity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] In this embodiment, in the fully closed cycle process of synthesizing thionyl chloride, the crude thionyl chloride after synthesis is used as raw material, and the tail gas discharged from the gas-liquid separator is recycled. The crude thionyl chloride can be It is synthesized in the process of production cycle, and the crude product containing 50-75% of thionyl chloride synthesized by sulfur dichloride, chlorine gas and sulfur dioxide can also be purchased directly.

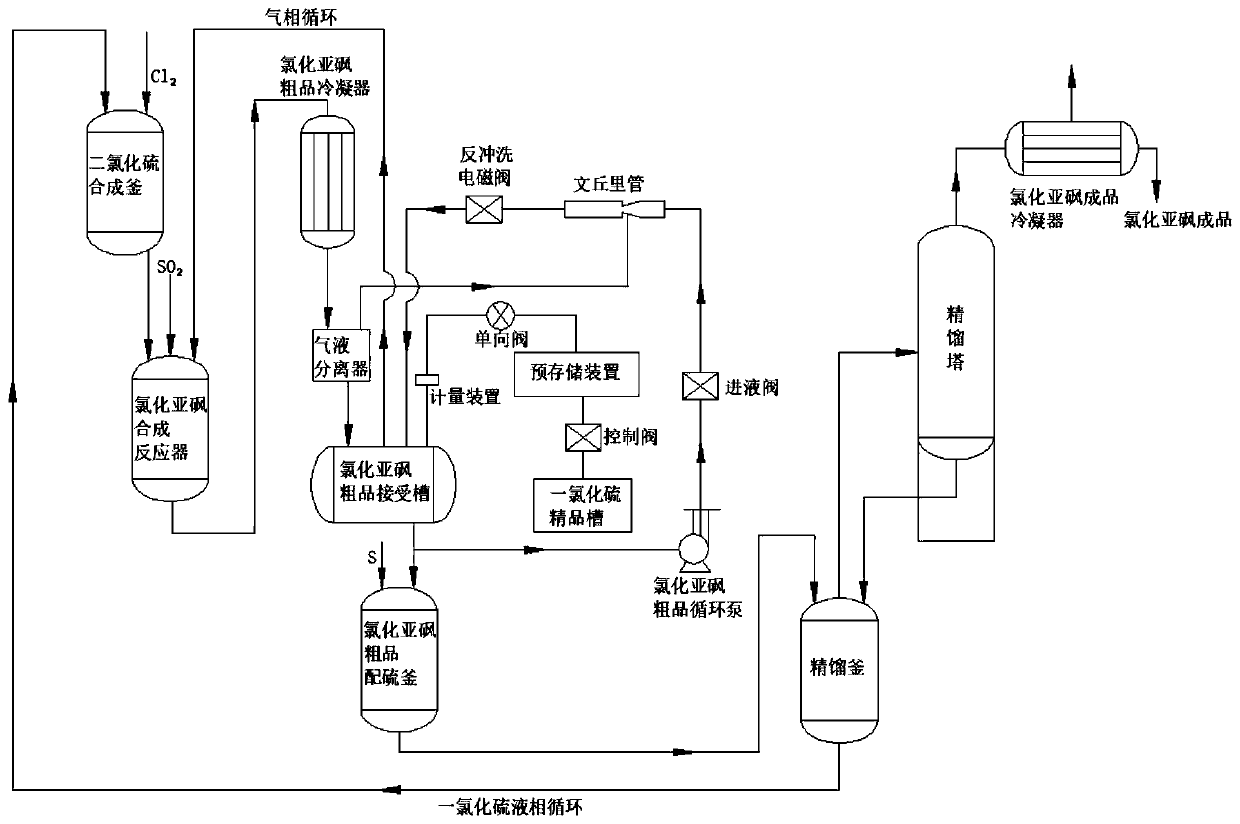

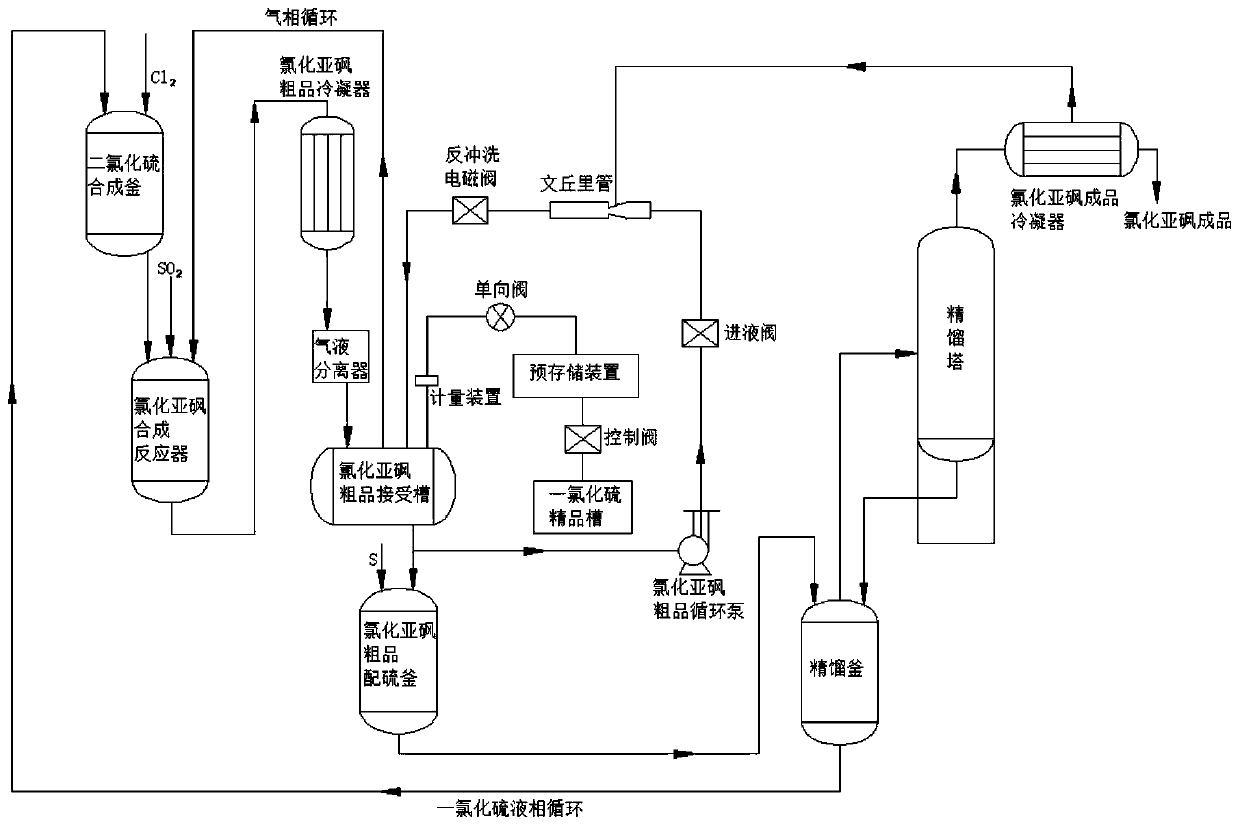

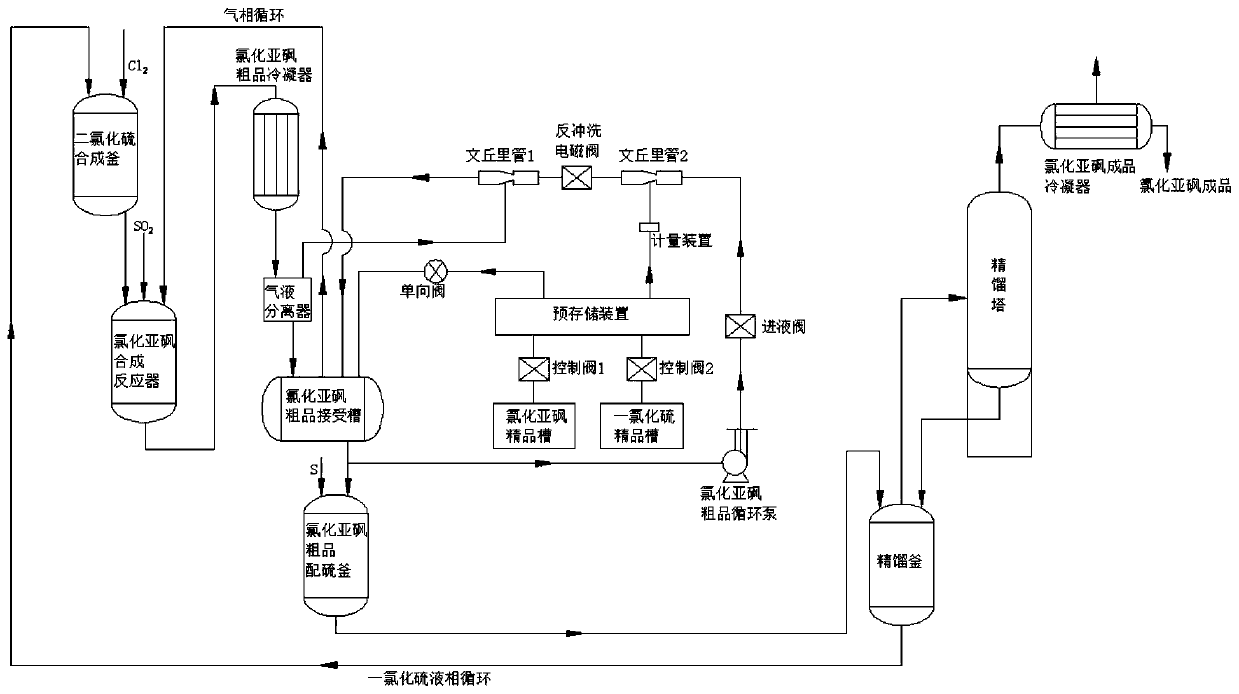

[0081] The tail gas recycling device for the production of thionyl chloride provided in this embodiment includes a sulfur dichloride synthesis kettle, a thionyl chloride synthesis reactor, a thionyl chloride crude product condenser, a gas-liquid separator, and a thionyl chloride synthesis reactor connected in sequence. Sulfone crude product receiving tank, sulfur oxychloride crude product sulfur mixing kettle, rectification kettle, rectification tower and thionyl chloride product condenser, a liquid injec...

Embodiment 2

[0088] Research in the actual production process has found that the purity of thionyl chloride in the thionyl chloride crude product receiving tank needs to be controlled between 50% and 75%, so that there are enough raw materials, including condensed and discharged through the gas-liquid separator Gas, and the subsequent addition of sulfur to the crude product thionyl chloride to convert the unreacted matter into sulfur monochloride. When participating in the recirculation, too low unreacted matter content will lead to insufficient sulfur monochloride, and the cycle cannot be carried out continuously; The unreacted substances lead to excess sulfur monochloride and lead to a significant decline in yield.

[0089] When the thionyl chloride production circulation device is in normal operation, by controlling the temperature and pressure of the reaction device, the purity of thionyl chloride in the thionyl chloride crude product receiving tank can be easily controlled between 50% ...

Embodiment 3

[0096] This embodiment provides a gas-phase circulation method for the production of thionyl chloride, including S1 sulfuration; S2 rectification; S3 synthesis; S4 condensation; S5 degassing and purification. The gas produced in the thionyl chloride production process is used as a part of the source of raw materials for the production of thionyl chloride, and then enters the thionyl chloride synthesis reactor for recycling. The gas recycled is the S5 degassing and purification step. The gas removed from the crude product condenser or the gas discharged from the rectification tower in the S2 rectification step; at least one of the gases in the source of raw materials for the production of thionyl chloride is extracted by a liquid injection device and sent back to the synthesis of thionyl chloride in the reactor.

[0097] Thionyl chloride crude product receiving tank is under the conditions of 50-90°C and pressure of 0.1Mpa, the purity of the sulfur oxychloride crude product is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com