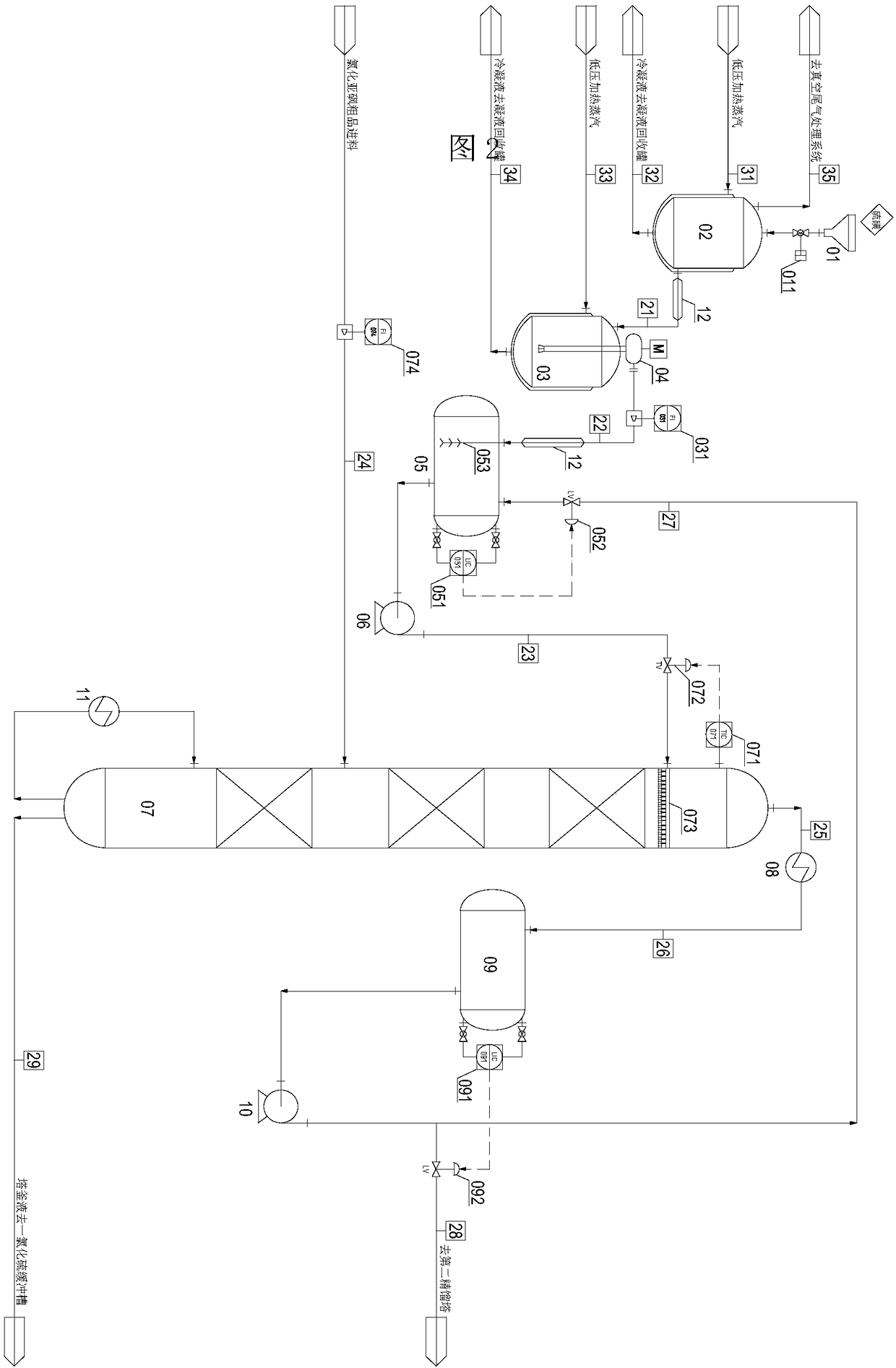

Continuous sulfur adding device and continuous sulfur adding process for thionyl chloride rectification systems

A technology of rectification system and thionyl chloride, which is applied in the field of continuous sulfur addition device of thionyl chloride rectification system, can solve the problems of destroying the pressure of the rectification system, affecting the separation effect, and the drift of gas phase at the top of the tower, so as to avoid the potential Risk, strengthen separation effect, reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The solid sulfur used in this embodiment is sulfur powder, and the packaging bag specification is 25kg / bag. First of all, the sulfur is artificially broken into the sulfur hopper, and then the sulfur automatic discharge valve is opened by operating the switch, and the sulfur powder enters the molten sulfur tank. Repeat the above operation, add sulfur powder into the molten sulfur tank, in order to reduce the frequency of operation, according to production experience, make the amount of sulfur in the molten sulfur tank meet the production needs of at least one day.

[0044]0.5MPaG low-pressure steam is introduced into the outer jacket of the molten sulfur tank to heat and melt the solid sulfur. The temperature in the molten sulfur tank is monitored in real time by a temperature instrument, and the temperature in the molten sulfur tank is maintained at 120-140°C in order to ensure the best flow performance of liquid sulfur. The molten liquid sulfur enters the liquid sulf...

Embodiment 2

[0050] For the continuous sulfur addition process of the sulfur oxychloride rectification system involved in the present invention, the operation process of embodiment 2 and embodiment 1 and the composition of the crude thionyl chloride feed are the same. The differences between embodiment 2 and embodiment 1 are: the operating reflux ratio of the rectification system is 1.8; the amount of sulfur added is 3 times of the reaction stoichiometry.

[0051] The content of sulfur dichloride and chlorine in the composition of the top discharge of the first rectifying tower in this embodiment is less than 100 ppm, and the content of impurity components is even lower. Compared with Example 1, the separation effect of Example 2 is significantly improved, but due to the increased reflux ratio and more sulfur input, the operating cost is increased. This embodiment is applicable to occasions where downstream users have higher requirements on the impurity content of the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com