Continuous sulfur addition device and method for sulfur oxychloride sulfur compounding system

A technology of thionyl chloride and sulfur adding device, which is applied in the direction of chemical instruments and methods, thionyl chloride, sulfur and halogen compounds, etc., to achieve the effects of ensuring continuity, convenient maintenance, and easy popularization and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

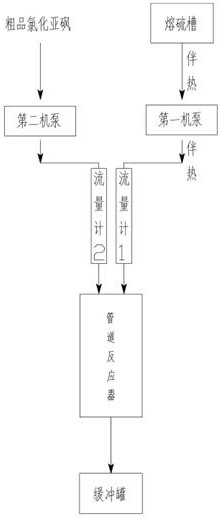

Image

Examples

Embodiment 1

[0026] A method for continuously adding sulfur to a sulfur oxychloride compounding system, the specific implementation steps are as follows:

[0027] (1) The liquid sulfur in the sulfur melting tank is pumped into the pipeline reactor through the jacket pipe by the first machine pump, and the flow rate is controlled at 350kg / h. The temperature of the steam in the jacket pipe is 160°C. In the jacket pipe, pay attention to Hydrophobic to prevent uneven steam flow, forming a dead zone, and causing sulfur plugging accidents;

[0028] (2) The crude thionyl chloride (temperature 50°C, containing 70% thionyl chloride, 25% sulfur dichloride, the rest is a small amount of chlorine and sulfur monochloride) is pumped into the pipeline reactor by the second machine , control flow at 4600kg / h;

[0029] (3) Control the mixing of the crude thionyl chloride and the liquid sulfur in the molten sulfur tank at the entrance of the pipeline reactor, and control the temperature of the pipeline rea...

Embodiment 2

[0031] A method for continuously adding sulfur to a sulfur oxychloride compounding system, the specific implementation steps are as follows:

[0032] (1) The liquid sulfur in the sulfur melting tank is pumped into the pipeline reactor through the jacketed pipe by the first pump, and the flow rate is controlled at 300kg / h. The temperature of the steam in the jacketed pipe is 160°C. In the jacketed pipe, pay attention to Hydrophobic to prevent uneven steam flow, forming a dead zone, and causing sulfur plugging accidents;

[0033] (2) The crude thionyl chloride (temperature 55°C, containing 71% thionyl chloride, 24% sulfur dichloride, the rest is a small amount of chlorine and sulfur monochloride) is pumped into the pipeline reactor by the second machine , control flow at 4000kg / h;

[0034] (3) Control the mixing of the crude thionyl chloride and the liquid sulfur in the molten sulfur tank at the entrance of the pipeline reactor, and control the temperature of the pipeline react...

Embodiment 3

[0036] A method for continuously adding sulfur to a sulfur oxychloride compounding system, the specific implementation steps are as follows:

[0037] (1) The liquid sulfur in the sulfur melting tank is pumped into the pipeline reactor through the jacketed pipe by the first machine pump, and the flow rate is controlled at 250kg / h. The temperature of the steam in the jacketed pipe is 162°C. In the jacketed pipe, pay attention to Hydrophobic to prevent uneven steam flow, forming a dead zone, and causing sulfur plugging accidents;

[0038] (2) The crude thionyl chloride (temperature 53°C, containing 74% thionyl chloride, 20% sulfur dichloride, and the rest is a small amount of chlorine and sulfur monochloride) is pumped into the pipeline reactor by the second machine , control flow at 4000kg / h;

[0039] (3) Control the mixing of the crude thionyl chloride and the liquid sulfur in the molten sulfur tank at the entrance of the pipeline reactor, and control the temperature of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com