Sulfur dioxide vaporization technology for thionyl chloride production

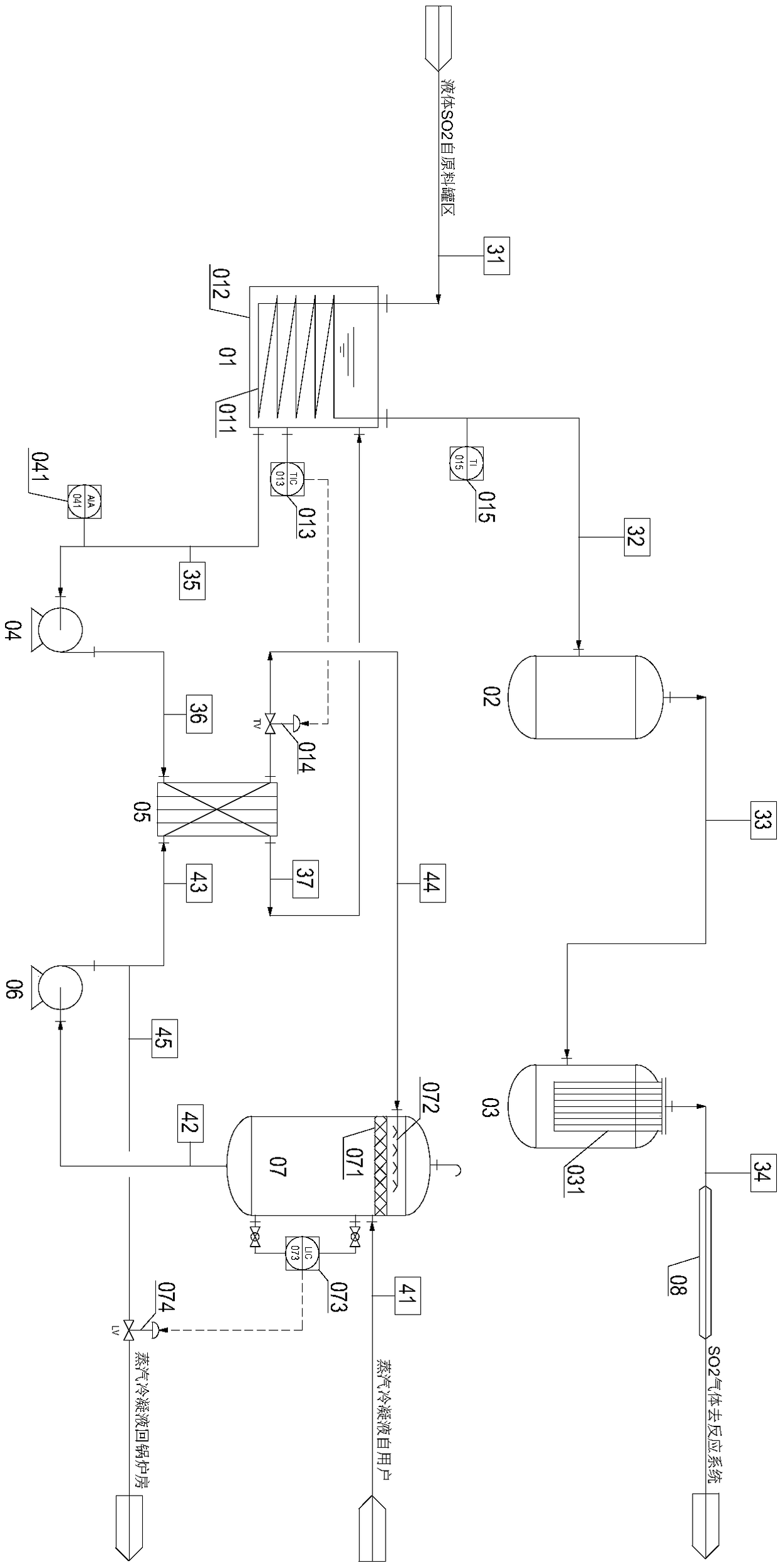

A technology of sulfur dioxide and thionyl chloride, used in inorganic chemistry, thionyl chloride, sulfur compounds, etc., can solve the problems of difficult replacement of heating rods, short service life of heating rods, increase production costs, etc., and achieve low equipment investment and operating costs. , The equipment has a long service life and achieves the effect of recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

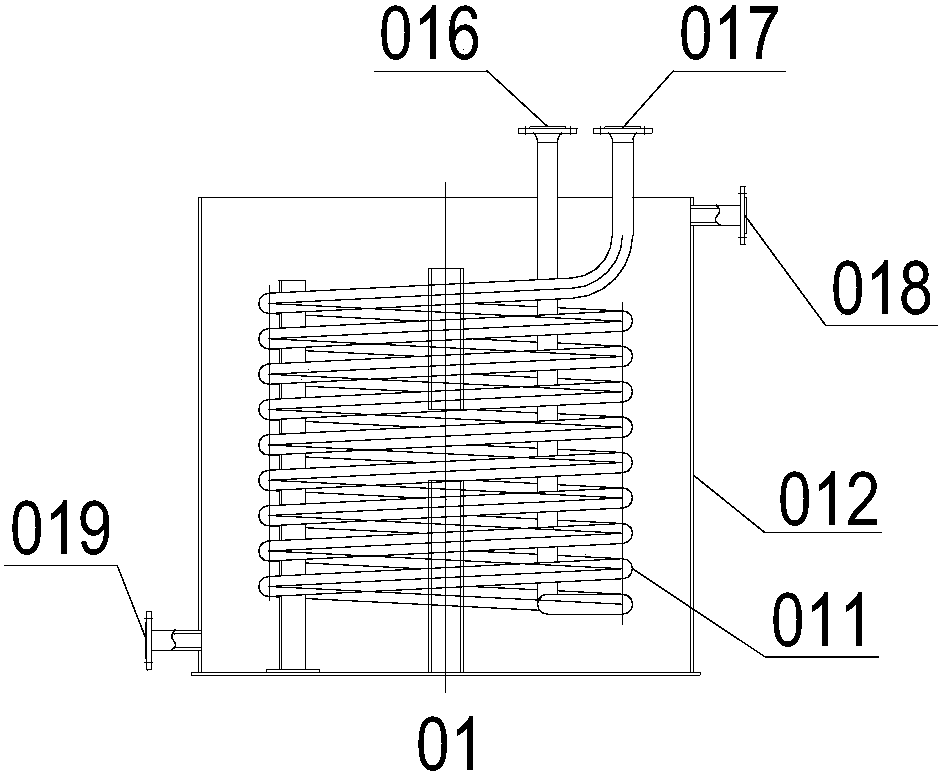

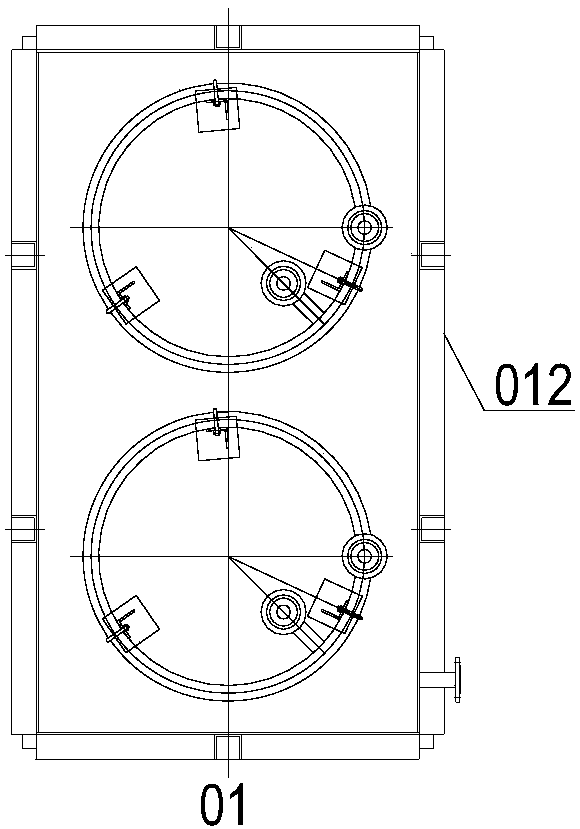

[0050] The feed rate of liquid sulfur dioxide from the raw material tank area is 750kg / h, and the temperature of the material at the outlet of vaporizer 01 is controlled at 40°C. The selected coiled coiled tube 011 has a specification of Φ50mm and a coiled diameter of 1000mm. The coiled coiled tube 011 has 20 coils and the heat exchange area is about 10m 2 . The width of the water tank 012 of the carburetor 01 is 1400 mm, and the height is 2600 mm. The length of the water tank 012 can be determined according to the number of coiled coils 011 used. In this embodiment, only one set of coiled coils is used.

[0051] The vaporized sulfur dioxide gas first enters the buffer tank 02 for preliminary gas-liquid phase separation to remove large-diameter droplets in the gas. The diameter of the tank is Φ500mm and the height is 700mm. Then, the sulfur dioxide gas enters the gas-liquid separation tank 03 to remove the tiny liquid droplets and oil mist entrained in the gas.

[0052] Gas-...

Embodiment 2

[0059] For the sulfur dioxide vaporization process involved in the present invention, the operation process of embodiment 2 is the same as that of embodiment 1. The difference between Example 2 and Example 1 is that the feed rate of liquid sulfur dioxide is 1500kg / h, two sets of coiled coiled tubes 011 are used, and the heat exchange area is about 20m 2 . The buffer tank 2 has a diameter of Φ1200mm and a height of 1400mm. The gas-liquid separation tank 3 has a diameter of Φ1600mm and a height of 1800mm. The inner cylinder has a diameter of Φ1000mm and a height of 1500mm. At the same time, there are strip-shaped holes in the inner cylinder on the side wall of the inner cylinder.

[0060] The total heat transfer coefficient of sulfur dioxide vaporization in this embodiment is 114W / m 2 .℃, there is no liquid phase component in the sulfur dioxide gas phase stream entering the thionyl chloride reaction system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com