Method for optimizing production process of thionyl chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

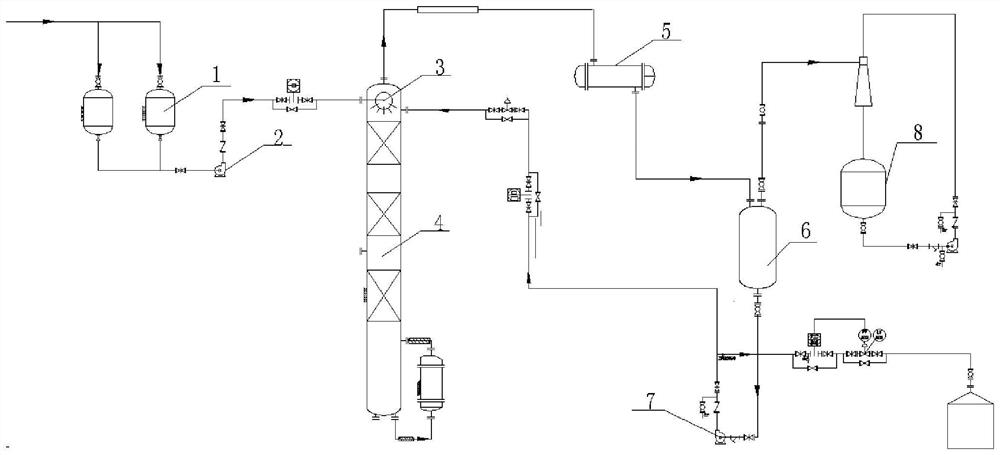

[0025] The method for optimizing the production process of thionyl chloride of the present invention comprises the following steps:

[0026] (1) The liquid sulfur level in the liquid sulfur tank 1 is 100mm, and after the liquid sulfur is metered by the metering pump 2, it is 160kg / h according to the feed rate and squeezed into the distillation tower 4 (the tower top temperature is 70 ℃, and the pressure is -5Kpa; The temperature at the bottom of the tower is 120 DEG C) in the atomization device 3;

[0027] (2) Thionyl chloride crude product feed rate is 7m 3 / h, mixed with liquid sulfur at the top of distillation tower 4;

[0028] (3) Sulfur dichloride in the crude thionyl chloride reacts with liquid sulfur to generate a heavier component, sulfur monochloride, which is extracted from the bottom of the distillation tower 4, and the remaining crude thionyl chloride enters reflux after being condensed by the condenser 5 In the tank 6 (the reflux ratio is 1:1.5), part of the liq...

Embodiment 2

[0030] The method for optimizing the production process of thionyl chloride of the present invention comprises the following steps:

[0031] (1) The liquid sulfur liquid level in the liquid sulfur tank 1 is 700mm, and after the liquid sulfur is measured by the metering pump 2, it is 170kg / h according to the feed rate and squeezed into the distillation tower 4 (the temperature at the top of the tower is 73°C, and the pressure is 10Kpa; The bottom temperature is 130 ℃) in the atomization device 3;

[0032] (2) Thionyl chloride crude product feed rate is 7.5m 3 / h, mixed with liquid sulfur at the top of distillation tower 4;

[0033] (3) Sulfur dichloride in the crude thionyl chloride reacts with liquid sulfur to generate a heavier component, sulfur monochloride, which is extracted from the bottom of the distillation tower 4, and the remaining crude thionyl chloride enters reflux after being condensed by the condenser 5 In the tank 6 (the reflux ratio is 1:2), part of the liqui...

Embodiment 3

[0035] The method for optimizing the production process of thionyl chloride of the present invention comprises the following steps:

[0036] (1) The liquid sulfur liquid level in the liquid sulfur tank 1 is 1000mm, and after the liquid sulfur is measured by the metering pump 2, it is 200kg / h according to the feed rate and squeezed into the distillation tower 4 (the temperature at the top of the tower is 80°C, and the pressure is 20Kpa; The bottom temperature is 135°C) in the atomization device;

[0037] (2) Thionyl chloride crude product feed rate is 8m 3 / h, mixed with liquid sulfur at the top of distillation tower 4;

[0038] (3) Sulfur dichloride in the crude thionyl chloride reacts with liquid sulfur to generate a heavier component, sulfur monochloride, which is extracted from the bottom of the distillation tower 4, and the remaining crude thionyl chloride enters reflux after being condensed by the condenser 5 In the tank 6 (the reflux ratio is 1:3), part of the liquid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com