Thionyl chloride production system and starting method thereof

A technology of thionyl chloride, production system, applied in the direction of thionyl chloride, sulfur and halogen compounds, etc., can solve the problem of long time consumption, achieve the effect of reducing circulation, ensuring continuous circulation process, and increasing continuous circulation process

Active Publication Date: 2020-06-23

JIANGXI SELON INDAL

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In view of this, the present invention aims to propose a thionyl chloride production system and its start-up method, to solve the problem in the prior art, in the actual production process of the chemical plant, the thionyl chloride production system starts to run from start-up Between stability, it takes too long

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0100] On the basis of the thionyl chloride production system and the start-up method described in the present invention, the production system with an annual output of 5000t is used to start the start-up operation, and the required time between the start-up operation and the completion of the system start-up is counted, the result See Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

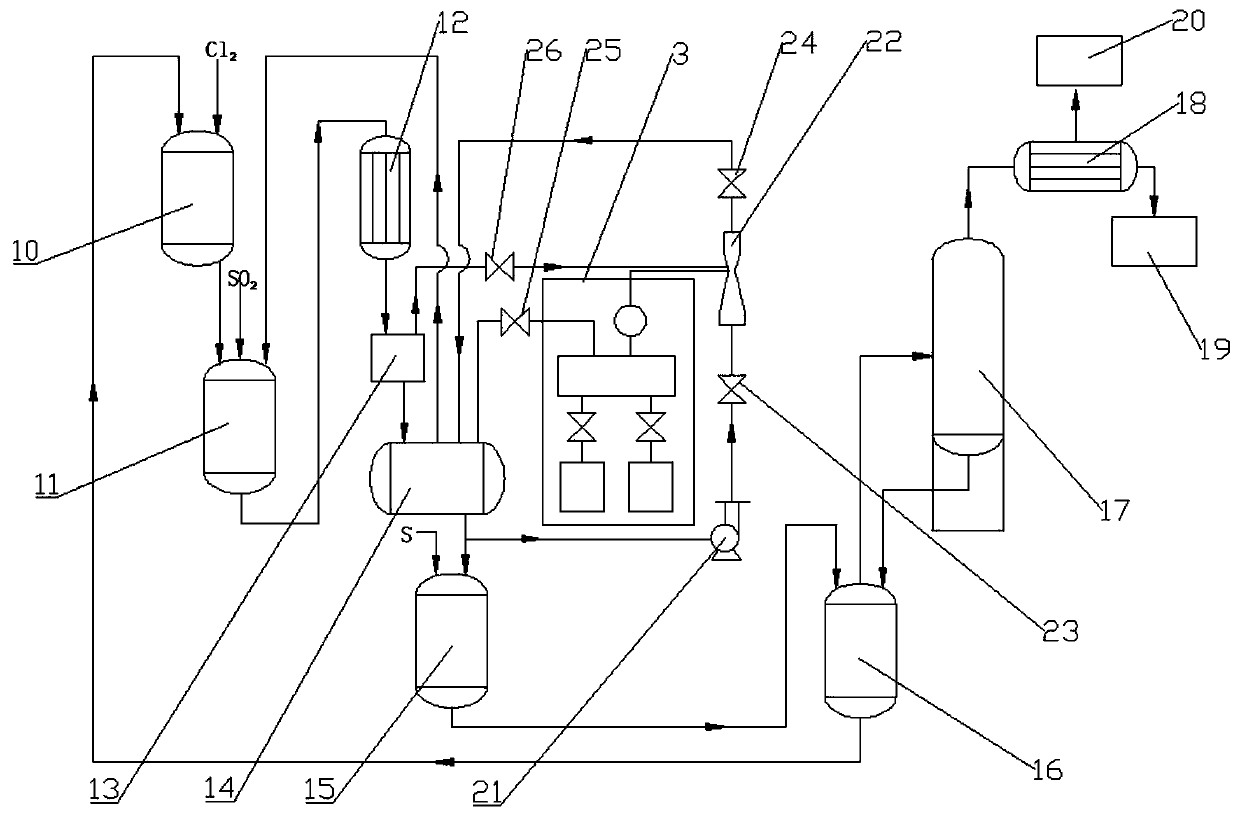

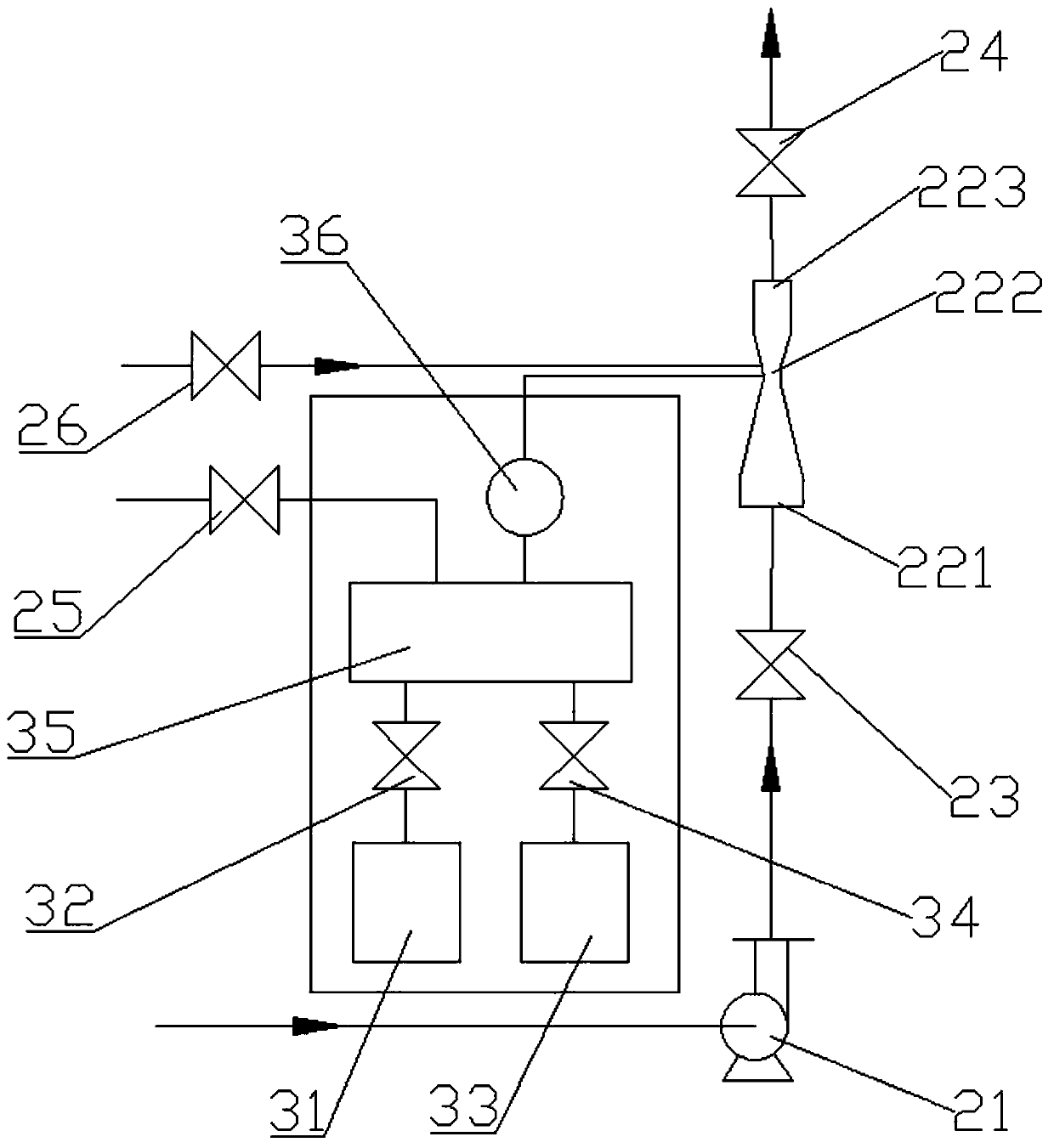

The invention provides a thionyl chloride production system and a starting method thereof. The thionyl chloride production system comprises a sulfur dichloride synthesis kettle, a thionyl chloride synthesis kettle, a crude product condenser, a gas-liquid separator, a crude product receiving tank, a sulfur dosing kettle, a rectifying kettle, a rectifying tower, a rectifying condenser, a finished product tank, a crude product circulating device and a stability promoting device, which are connected in sequence. The liquid inlet of the crude product circulating device is connected with the liquidoutlet pipeline of the crude product receiving tank. The liquid outlet of the crude product circulating device is connected with the liquid inlet pipeline of the crude product receiving tank. The crude product circulating device is used for circulating a thionyl chloride crude product after the system is started. The stability promoting device is respectively connected with the crude product receiving tank and the crude product circulating device, and is used for controlling the purity of the thionyl chloride crude product from the start-up stage to the operation stability stage of the system.According to the thionyl chloride production system and the starting method thereof, the thionyl chloride production system can be promoted to reach a stable operation state as soon as possible, andthe time required by the system from starting to stable operation is shortened.

Description

technical field [0001] The invention relates to a thionyl chloride production system and a start-up method thereof. Background technique [0002] Thionyl chloride is an intermediate raw material for the synthesis of pesticides, medicines, photosensitive materials and polymer intermediates. In the prior art, there are more than a dozen methods for synthesizing thionyl chloride, but there are basically three processes for large-scale industrial production , Phosphorus pentachloride method, chlorosulfonic acid method and gas phase synthesis method. Among these methods, the gas-phase synthesis of sulfur dioxide is widely used due to its simple process, low investment and high product purity, which is produced by a closed internal circulation device and has no environmental pollution. [0003] In the early research process of the gas phase synthesis method of sulfur dioxide, the applicant submitted a number of patent applications such as CN200810004779.9, CN200810004781.6, CN200...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B17/45

CPCC01B17/4584

Inventor 张海清潘英曙朱卫昌

Owner JIANGXI SELON INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com