Technology for deeply removing and recycling SO2 in high-sulfur coal-fired power plant tail gas

A technology of SO2 and electrostatic dust removal, applied in the field of resource utilization process development, can solve the problem of ammonium sulfate sales, high ability to absorb sulfur dioxide, secondary pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

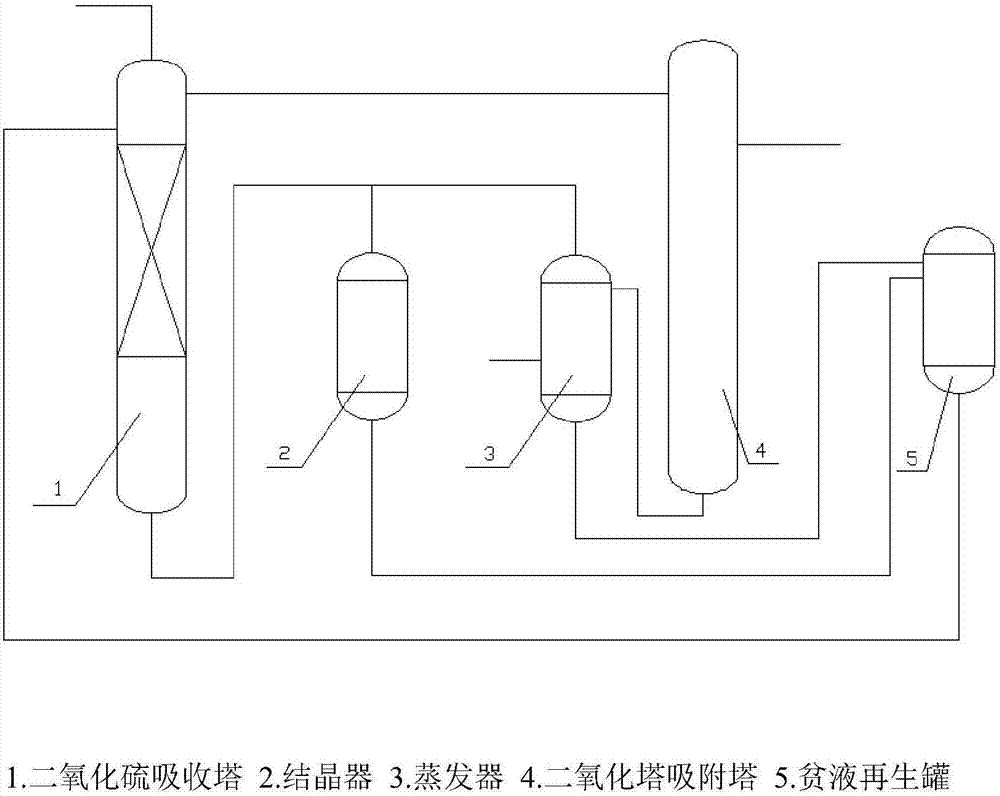

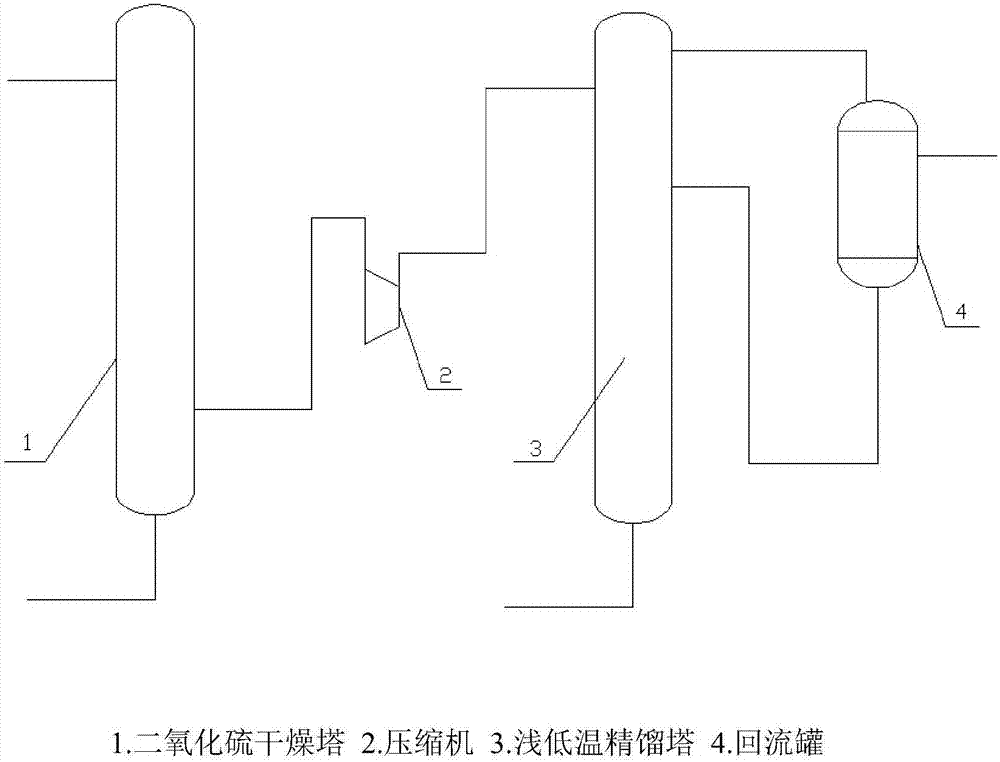

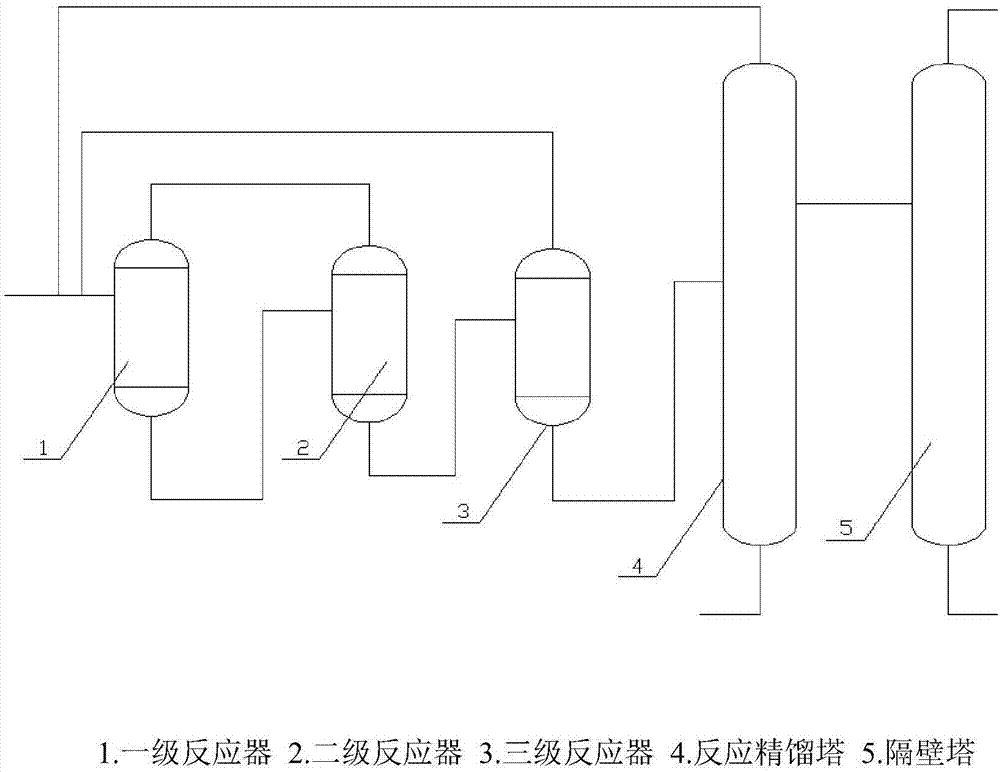

Method used

Image

Examples

Embodiment 1

[0031] 1. The flue gas from the boiler passes through the electrostatic precipitator and Venturi scrubber once, so that the temperature finally entering the absorption tower reaches 60°C.

[0032] 2. The flue gas enters the packing absorption tower, and the corrugated plastic plate packing is selected. The absorbent uses 13% sodium sulfite solution, and the volume ratio of the absorbent to the flue gas is kept at 0.2:1.

Embodiment 2

[0034] 1. The flue gas from the boiler passes through the electrostatic precipitator and Venturi scrubber once, so that the temperature finally entering the absorption tower reaches 70°C.

[0035] 2. The flue gas enters the spray absorption tower, and the absorbent uses 10% sodium sulfite solution to keep the volume ratio of the absorbent to the flue gas at 0.4:1.

Embodiment 3

[0037] 1. The flue gas from the boiler passes through the electrostatic precipitator and Venturi scrubber once, so that the temperature finally entering the absorption tower reaches 80°C.

[0038] 2. The flue gas enters the sieve plate tower, and the absorbent uses 15% sodium sulfite solution to keep the volume ratio of the absorbent to the flue gas at 0.3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com