Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Improve extrusion strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

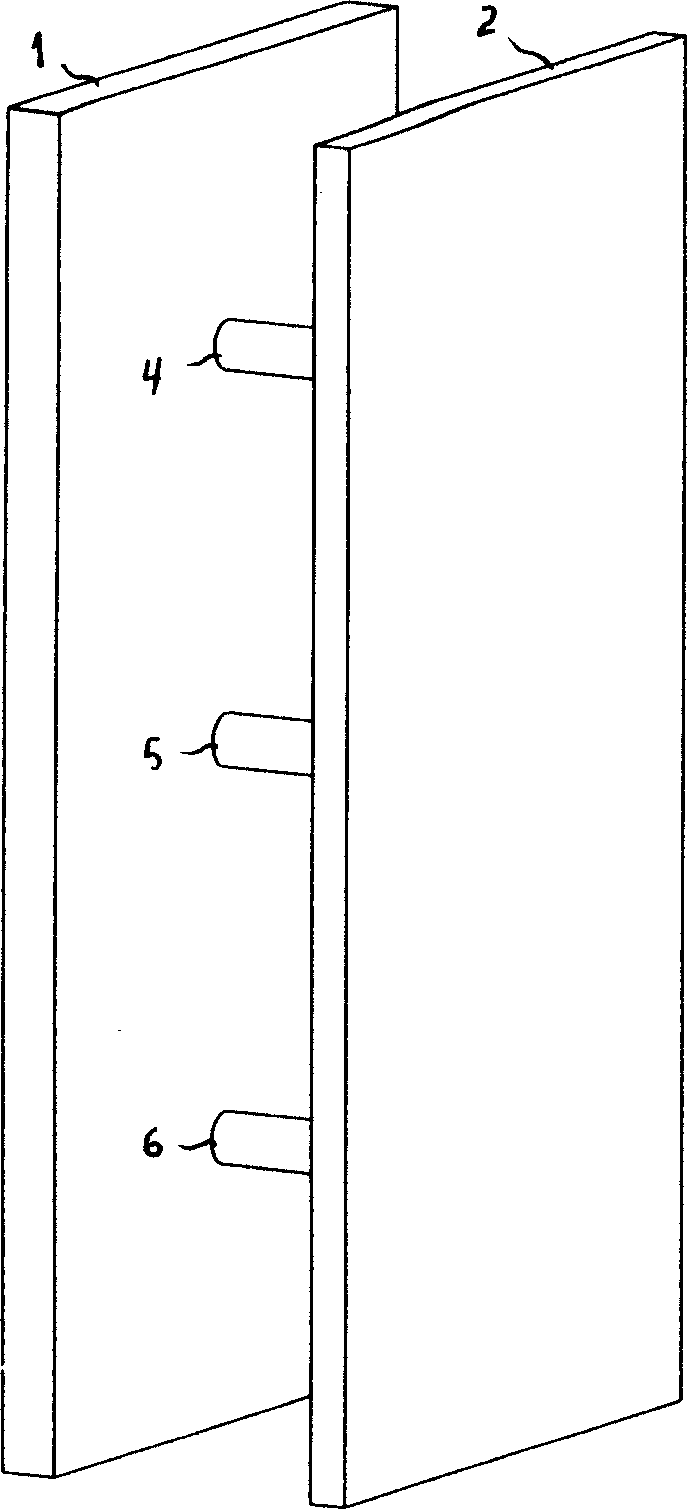

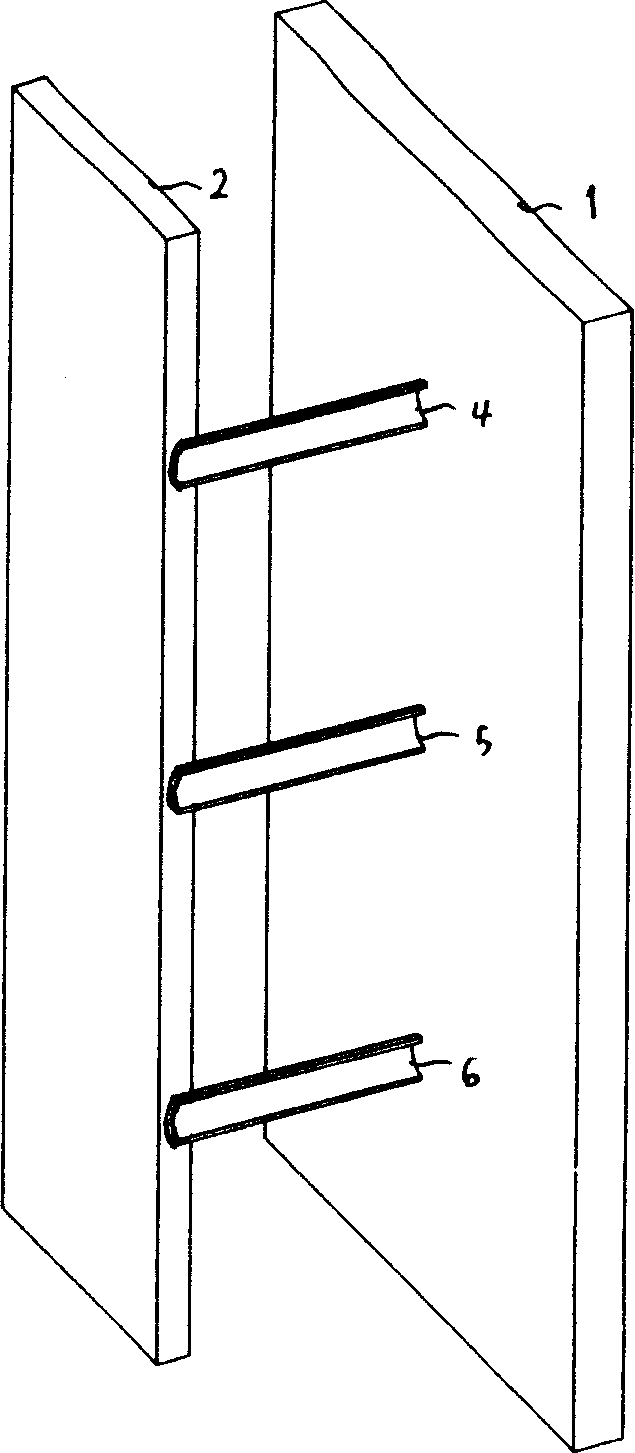

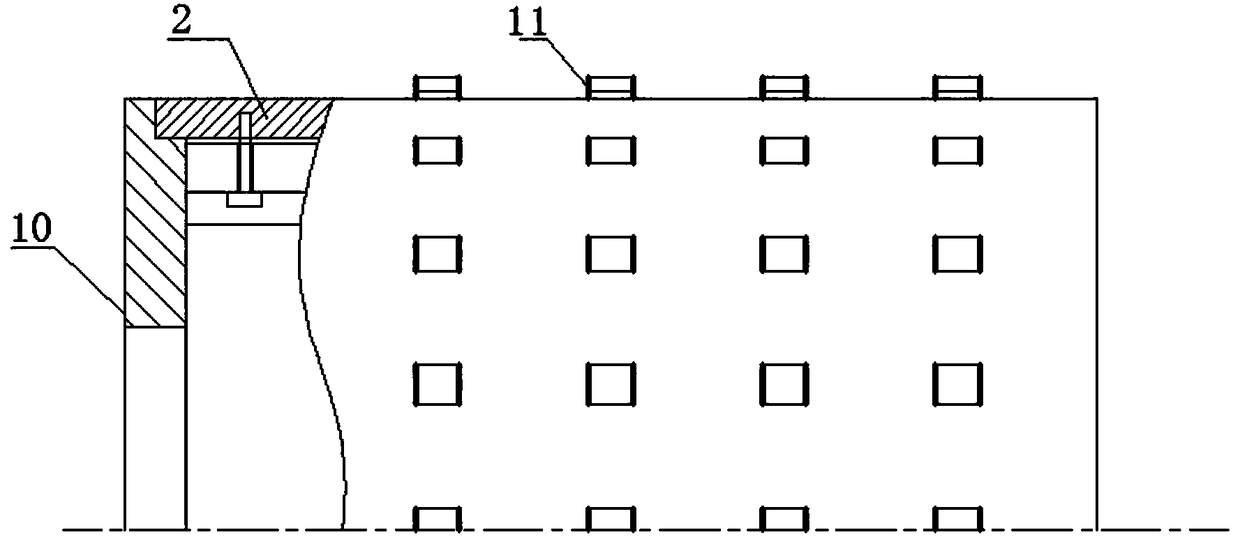

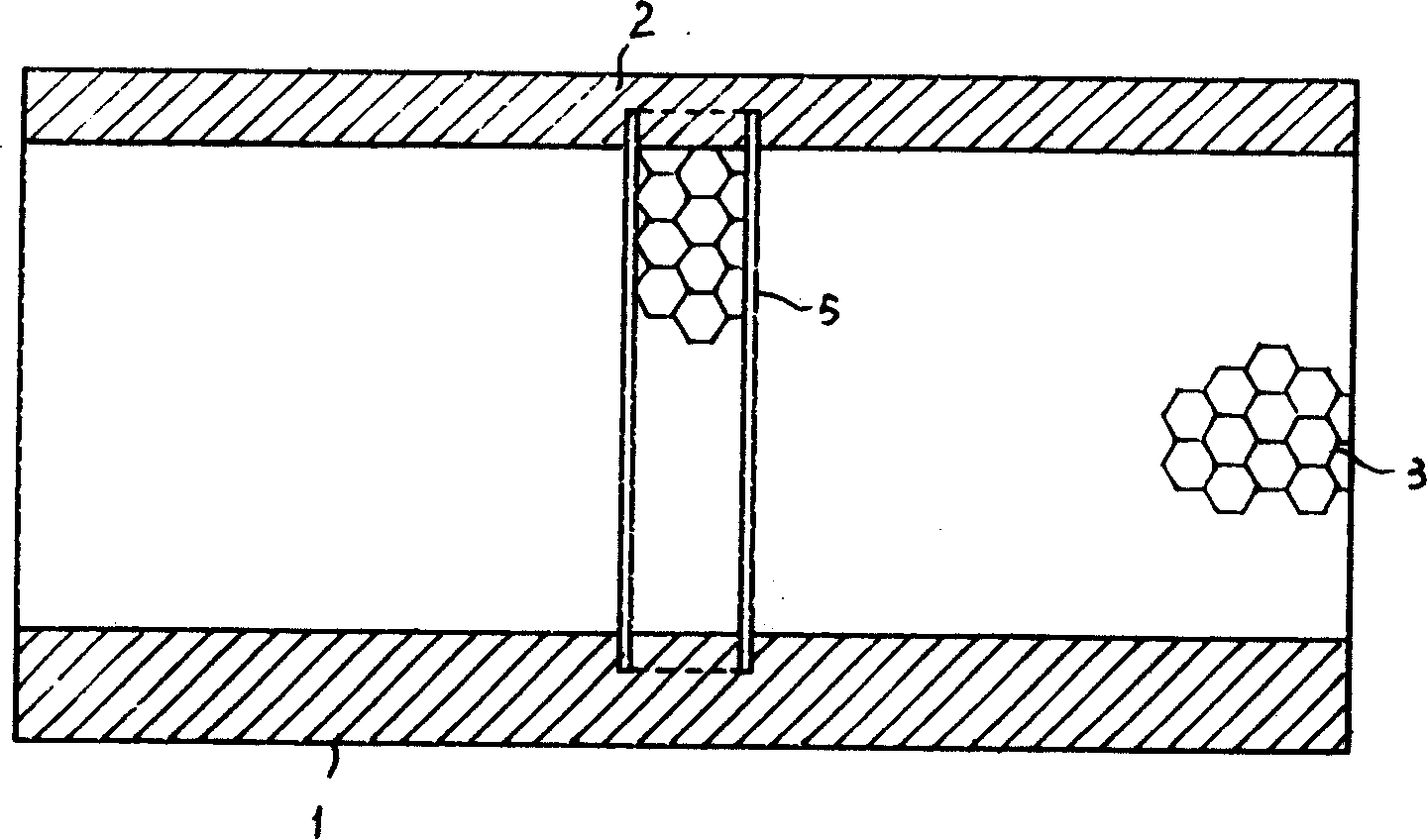

Lightweight heatproof porous wall material and building blocks

InactiveCN1915891ALight weightLow thermal conductivitySolid waste managementHeat proofingCompressive resistanceFoaming agent

This invention relates to a lightweight heat-insulating porous wall material and its blocks. The lightweight heat-insulating porous wall material is composed of: Portland cement 20-50 parts, lightweight sintered magnesium oxide 10-20 parts, hydrogen peroxide foamer 5-10 parts, rosin soda soap 5-10 parts, calcium stearate stabilizer 2-6 parts, naphthalene 1-5 parts, straw or wood powder or fly ashes filler 10-20 parts, and water. The block comprises a concrete inner-interlayer, a concrete outer-interlayer, more than two insulating connecting bars disposed between the concrete inner-interlayer and the concrete outer-interlayer, and the lightweight heat-insulating porous wall material filled between the concrete inner-interlayer and the concrete out-interlayer. The lightweight heat-insulating porous wall material has such advantages as small volume and low heat conductivity. The block has such advantages as high compressive strength, stable morphology, good fire and water resistance, easy cutting and good heat insulation.

Owner:周正华

Method for producing phenol adsorbent resin

InactiveCN102229710ALarge particlesImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesPhenol adsorptionGranularity

The invention provides a preparation method of phenol adsorbent resin. The preparation method comprises the following steps of: with small-granularity waste polymerization white spheres of macroporous ion exchange resin within the granularity range of 45-60 meshes adopted, extracting to obtain a porogenic agent, stoving, carrying out chloromethylation according to a macroporous anion resin standard process until chloride content is 15-25%, washing chloride spheres with water until no chloride ion exist after reaction is finished, stoving, then carrying out Friedel-Crafts reaction and then crosslinking, and then carrying out surface fluorination to generate the adsorbent resin with high specific surface area. The phenol adsorbent resin obtained by the preparation method provided by the invention has high adsorption capacity, the phenol adsorption capacity is more than 100mg per ml of the resin, and the phenol adsorbent resin has high strength, is difficult to break and has short regeneration time.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

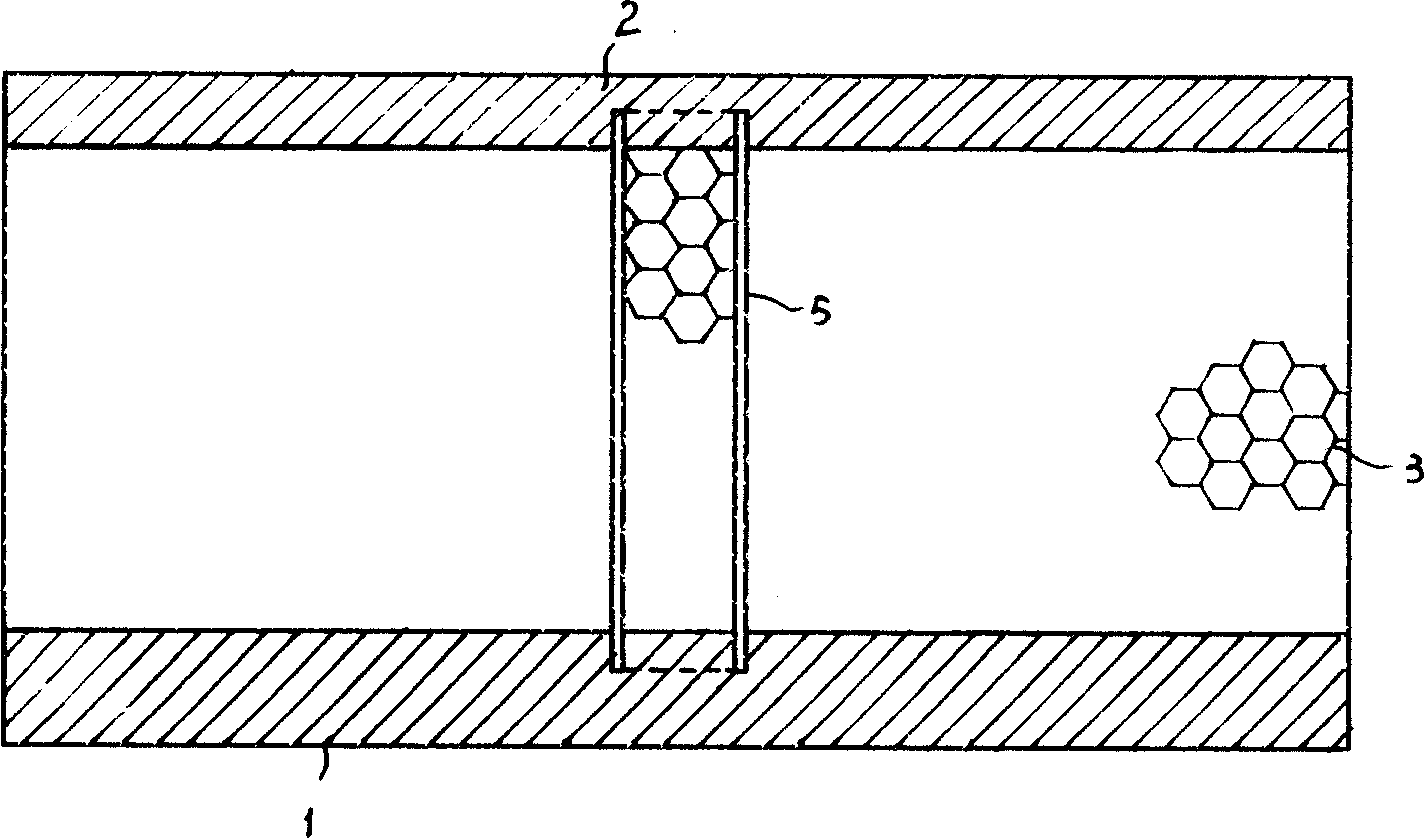

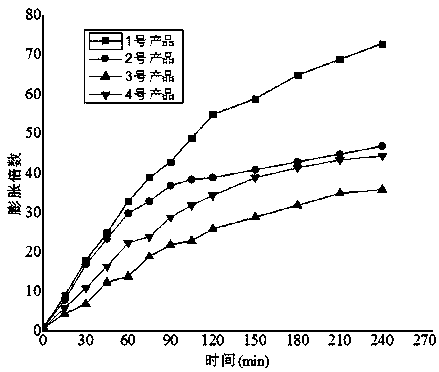

Delay water absorption expansion leakage blocking agent and preparation method thereof

InactiveCN108727535AGood toughnessHigh extrusion strengthDrilling compositionChemistryMethylene bisacrylamide

The invention relates to a preparation method of a leakage blocking auxiliary agent in the field of oil field well drilling. The method comprises the following steps of (1) firstly weighing a certainamount of acrylamide, 2-acrylamide-2-methallyl sulfonate, N,N-methylene bisacrylamide and initiators; putting the materials into a reactor; adding the corresponding amount of distilled water and ice water bath; performing stirring to complete dissolution; (2) slowly adding enhancing agents and hydrophobic monomers; performing low-temperature stirring; introducing N2 for protection; (3) lowering the temperature to 0 to 10 DEG C; dripping an initiator solution; (4) after the dripping completion, continuously performing stirring for 15min; raising the temperature to 50 DEG C; performing still state reaction for 2 to 5h to obtain an elastic gel body; (5) taking out the elastic gel body; performing vacuum drying at 60 to 90 DEG C and shearing to obtain a delay water absorption expansion leakageblocking agent product. The method has the advantages that the obvious delay expansion features are realized; the expansion in a shaft is slow; after reaching the leakage zone, the expansion can be continuously performed, so that the leakage zone can be effectively improved; the restoration effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

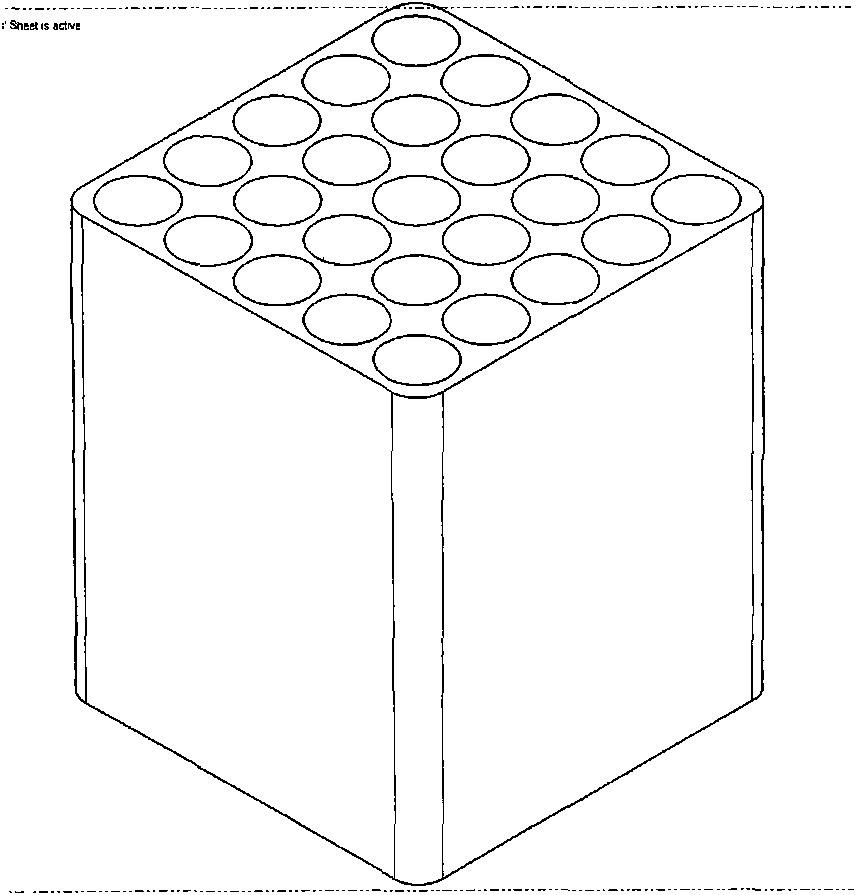

Method for manufacturing diatomite porous thermal insulation brick

InactiveCN101105060ASave resourcesImprove densification performanceCeramic shaping apparatusBuilding componentsBrickSolid structure

The invention relates to a manufacturing method of diatomite porous brick. The weight percentages of raw materials of the brick are as follows: diatomite 55-75 percent, fly ash 20-30 percent and wood dust 5-15 percent. The manufacturing method comprises the steps of compounding, melting, extrusion molding, brick blank drying, brick blank calcination, and final production inspection and preservation. The inventive brick utilizes diatomite as main ingredient and fly ash and wood dust as adjuvant, has a plurality of uniformly-distributed round or square hole on the front surface, and has hollow structure instead of solid structure of the prior wall brick. Therefore, the inventive brick has the advantages of higher strength, good fire-proof and heat-insulating effects, less waste of diatomite resource and low cost. The diatomite porous heat-insulating brick is, so far, the better light-weight wall material with effects of both heat insulation and heat preservation.

Owner:ZHEJIANG UNIV +1

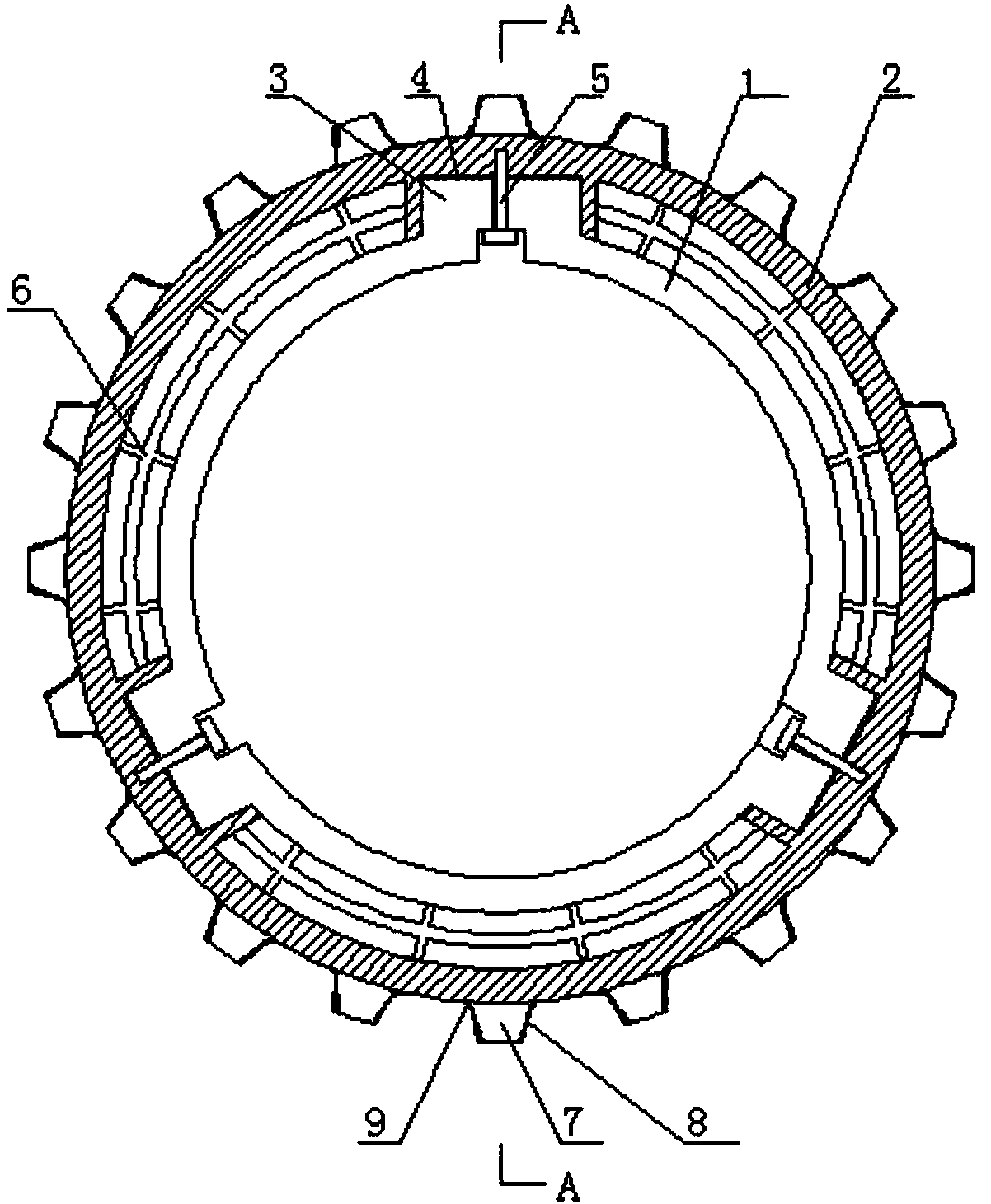

Wear-resistant tooth roll shell for roll crusher

The invention discloses a wear-resistant tooth roll shell for a roll crusher, which comprises a roll core and a roll shell. The roll shell sleeves the outer peripheral surface of the roll core and isfixed by a fastener; a plurality of rows of roll teeth are formed on the outer peripheral surface of the roll shell in the circumferential direction; in the circumferential direction, opposite tooth profiles on two adjacent roll teeth are covered with a first wear-resistant layer; in a radial direction, opposite tooth profiles on two adjacent roll teeth are covered with a second wear-resistant layer; the outer surface of the roll shell is covered with a first impact-resistant layer; sealing flanges are arranged on both left and right end faces of the roll shell. The wear-resistant tooth roll shell for the roll crusher, which is provided by the invention, has the advantages of long service life, easiness for processing and easiness for repair.

Owner:渠县金城合金铸业有限公司

Juicer

The invention relates to the field of daily use household articles, in particular to a juicer. The juicer comprises a rocker, a screw rod, a first filter screen, a squeezing cavity, a cavity cover and a supporting seat. One end of the screw rod is fixedly connected with the rocker, a cylinder is arranged at the other end of the screw rod, the screw rod is fixedly arranged on the cavity cover through the cylinder, the outer diameter of the screw rod is enlarged gradually, the screw rod is provided with zigzag helical blades, the spaces among the zigzag helical blades are reduced gradually, the cylinder penetrates through the first filter screen, a first ball bearing is arranged at the front end of the squeezing cavity, the cavity cover is provided with a second ball bearing, the screw rod is arranged on the first ball bearing and the second ball bearing in a sleeved mode, and the supporting seat is fixedly arranged at the bottom end of the squeezing cavity. According to the juicer, the screw rod is driven by a handle to carry out squeezing and juicing, and the juicer has the advantages of reducing producing cost, reducing noise, and improving safety factors.

Owner:沈洪新

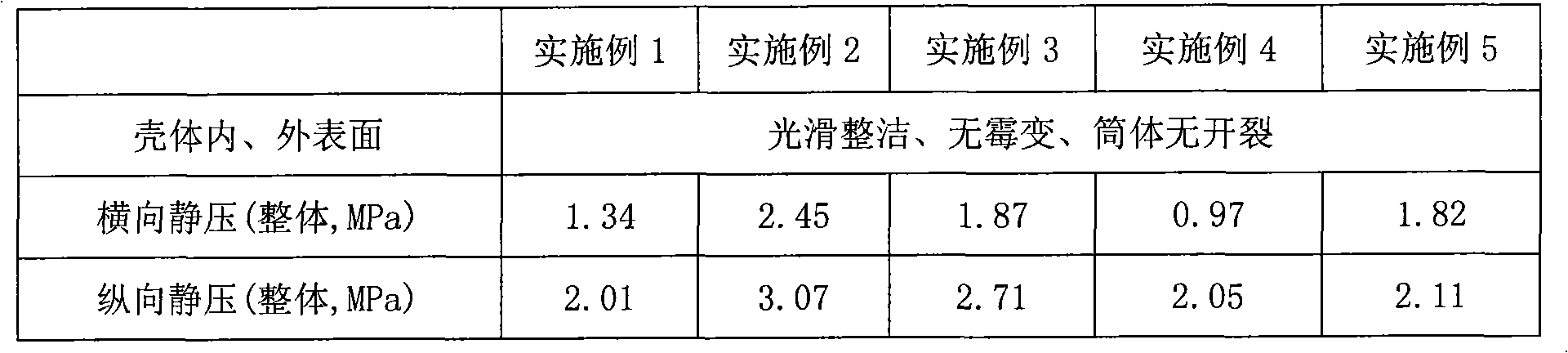

Set-off shell material for fireworks and crackers and preparation method thereof

InactiveCN101592460AHigh mechanical strengthImprove stress resistanceFireworksFireworksVegetable fibers

The invention discloses a set-off shell material for fireworks and crackers, which is prepared from the following raw materials in portion by weight: 1 to 2.5 portions of starch, 1.5 to 3 portions of vegetable fiber, 4.5 to 8 portions of clay, 0.09 to 1.0 portion of activating agent, and 0.1 to 0.9 portion of stabilizing agent. The shell material takes the clay as a base material and the starch and the vegetable fiber as auxiliary materials and can be biodegraded in the natural environment, which is advantageous for environmental protection, and the prepared shells of the fireworks and the crackers have high strength, are high-temperature resistant, reduce the possibility of undershooting during the of setting off, and reach the standard of 'method for compression and stacking tests by a compression testing machine' of GB / T4857.4-2008. The fireworks and the crackers made from the set-off shell material prepared by the method have high strength, strong set-off performance and high safety performance, and reach the standards of GB10631-2004, GB19593-2004 and GB19594-2004.

Owner:王会军

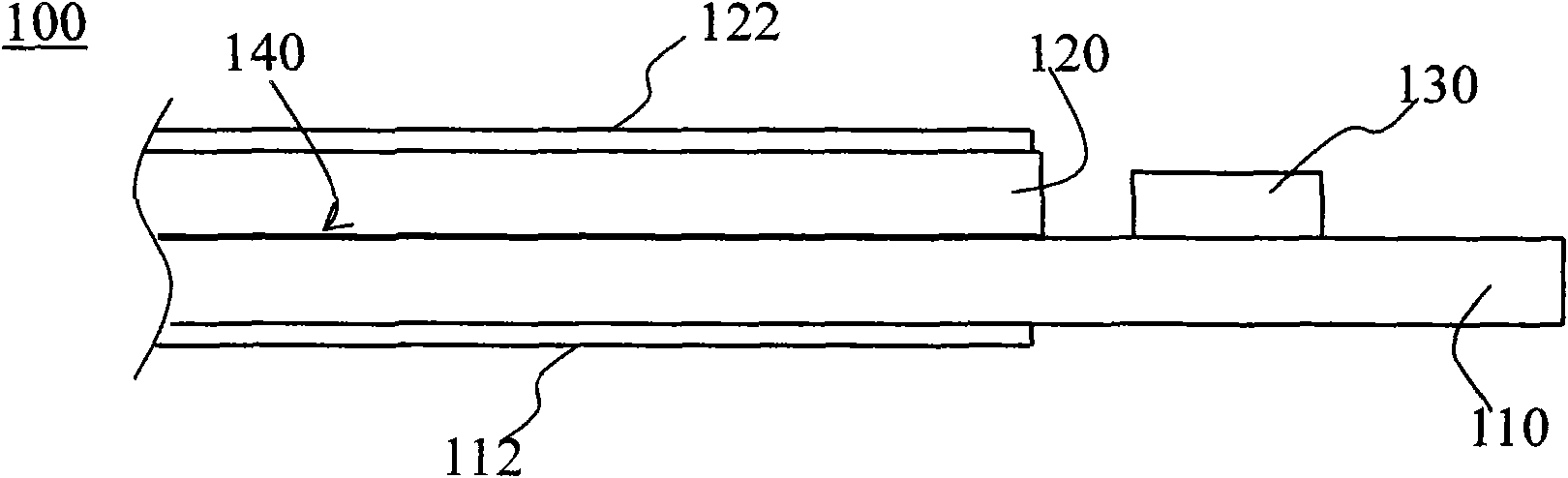

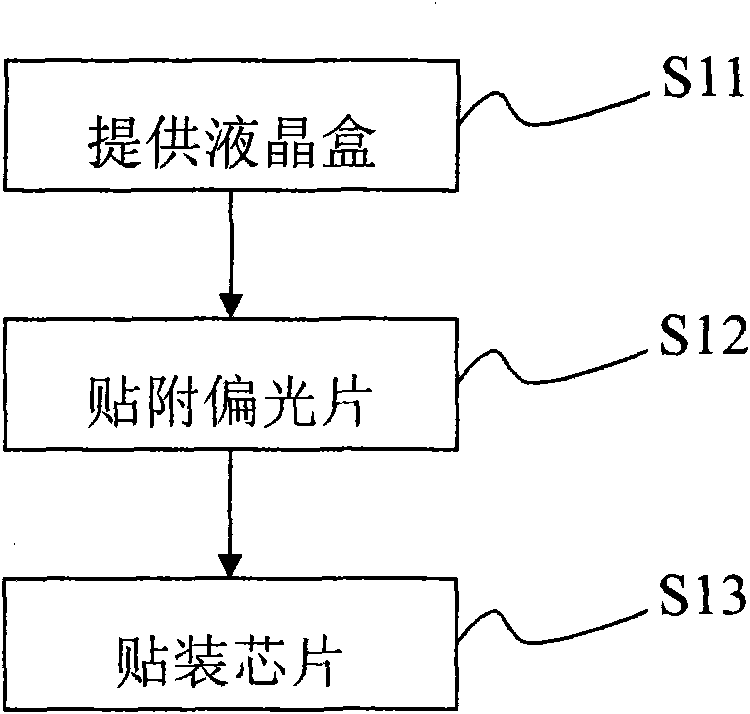

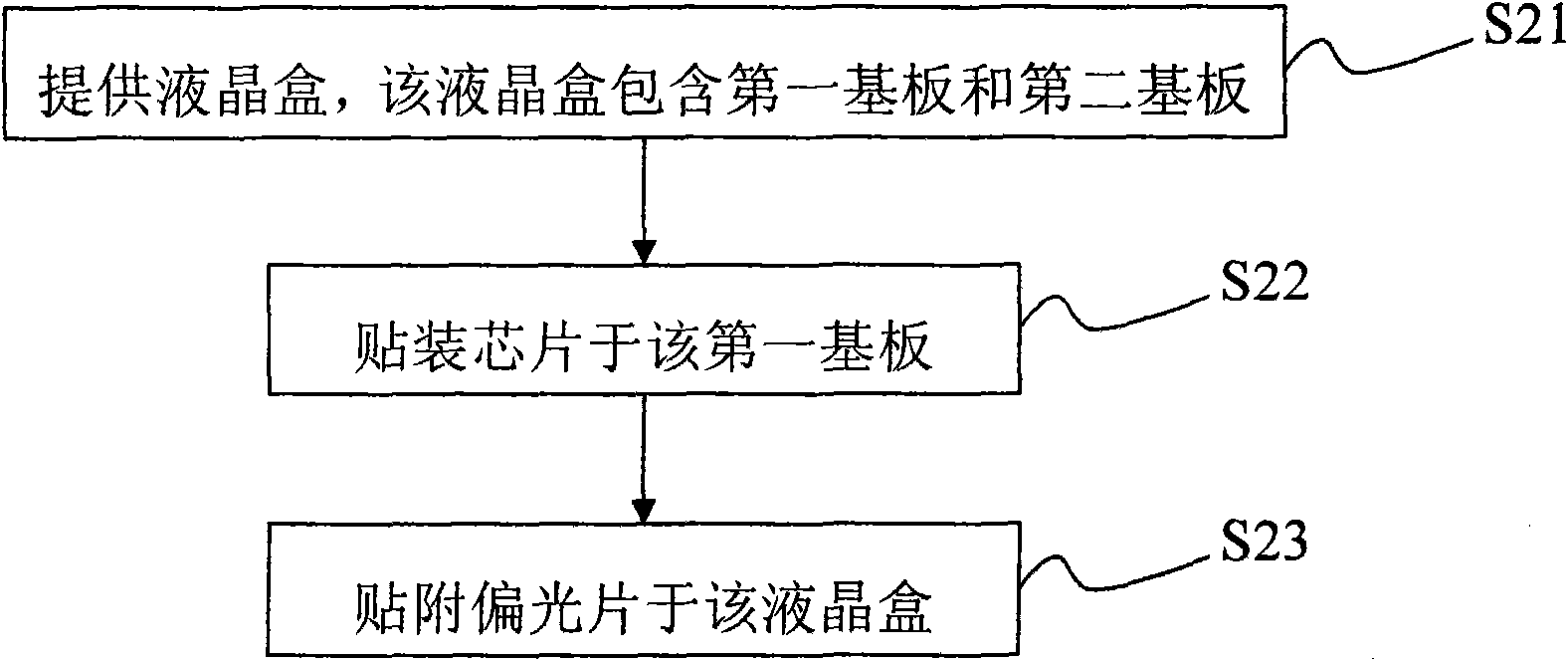

LCD panel manufacturing method

The invention discloses an LCD panel manufacturing method, comprising the following steps: providing an LCD box which comprises a first base plate and a second base plate; sticking a chip on the first base plate; and attaching a polaroid in the LCD box. The invention can greatly promote anti-compressive strength without influencing capacity and yield.

Owner:AU OPTRONICS (XIAMEN) CORP +1

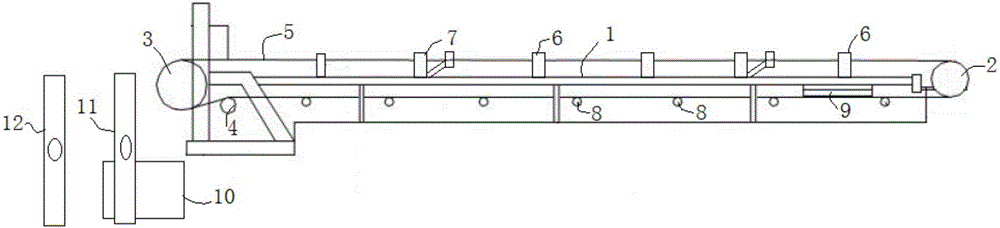

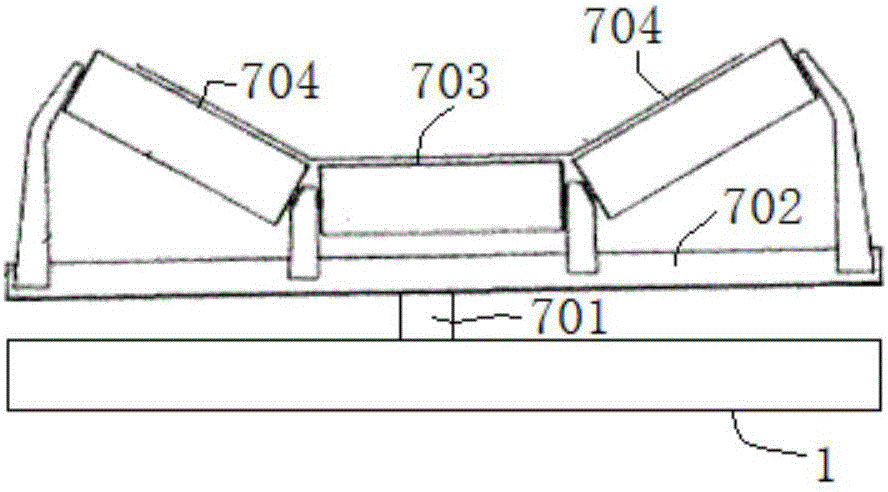

Belt conveying system for transportation of bulk materials

The invention discloses a belt conveying system for transportation of bulk materials, and belongs to the field of conveyers. The belt conveying system comprises a rack, and a driving head wheel and a driving tail wheel are arranged at the two ends of the rack respectively; a conveyer belt coats the driving head wheel and the driving tail wheel and conveys the materials around the driving head wheel and the driving tail wheel; the upper layer conveyer belt is supported by top carrier rollers; the lower layer conveyer belt is supported by bottom carrier rollers; the top carrier rollers comprise fixed carrier rollers and movable carrier rollers; a sweeper is arranged above the lower layer conveyer belt; the materials conveyed by the conveyer belt are collected by a material mover; and a primary material arranging device and a secondary material arranging device are sequentially arranged in the transportation direction of the material mover. According to the belt conveying system, flying dust can be decreased, the production environment is improved, material transportation efficiency is improved, and efficient and stable operation of the conveyers is guaranteed.

Owner:ANHUI TAIFU HEAVY IND MFG CO LTD

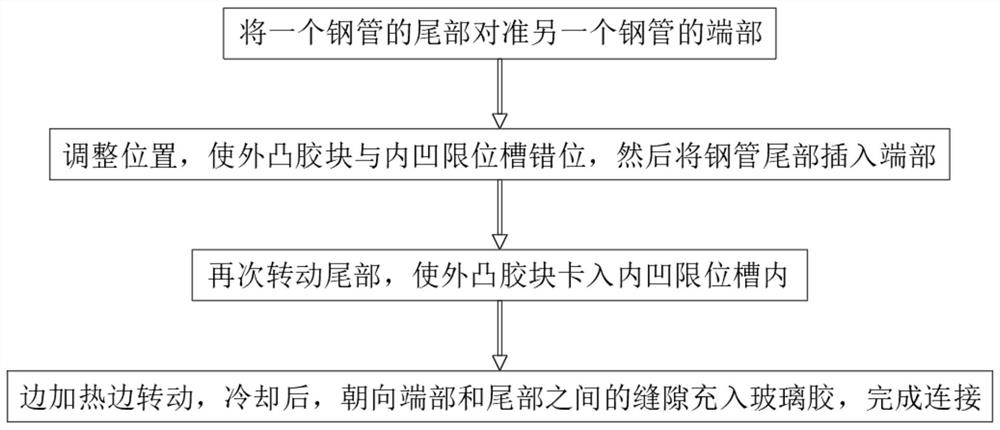

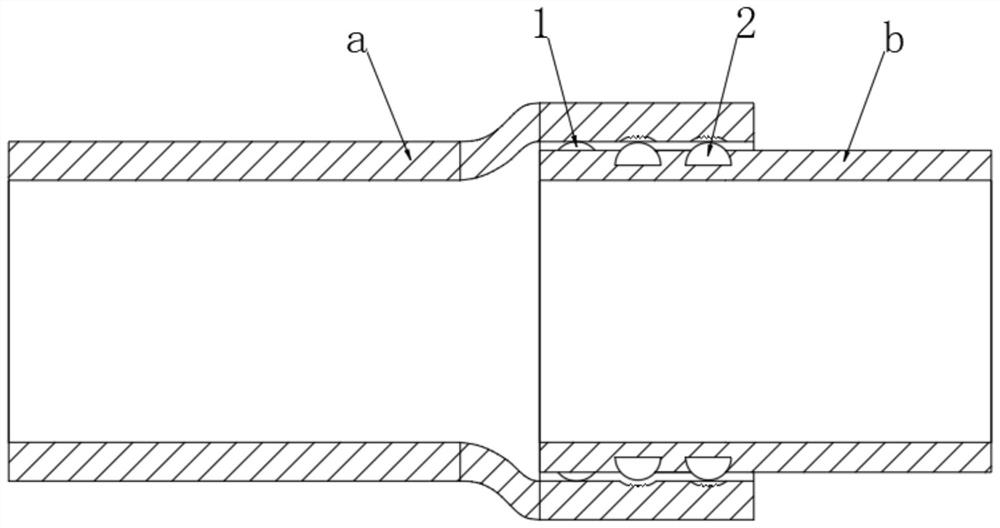

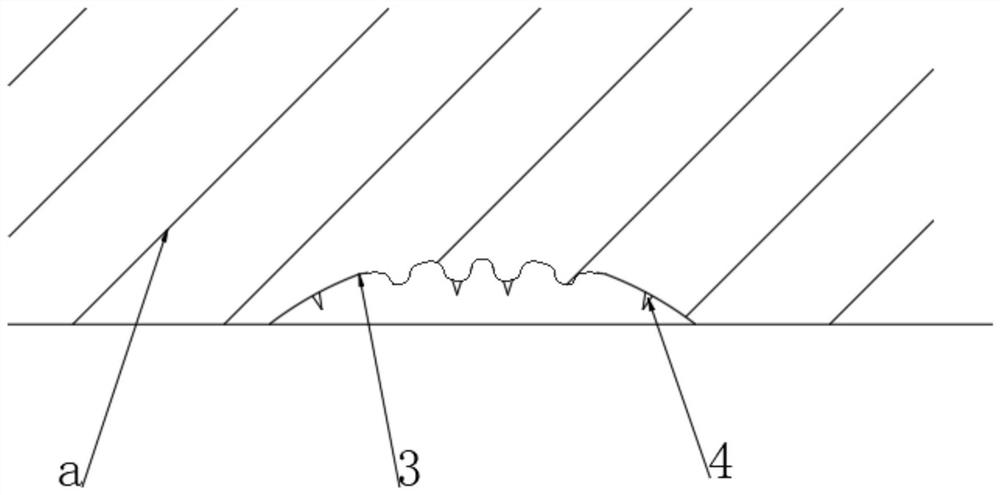

Welding-free steel pipe connecting process

InactiveCN113146145AImprove extrusion strengthNot easy to moveNon-disconnectible pipe-jointsMetal working apparatusPipeUltimate tensile strength

The invention discloses a welding-free steel pipe connecting process, and belongs to the field of steel pipes. The welding-free steel pipe connecting process comprises the following steps of through extrusion matching of an outer convex rubber block and an inner concave limiting groove, enabling the head and the tail of steel pipes to be in extrusion connection, and matching with heating operation, enabling part of the outer convex rubber block to be molten in a flowing state and permeate into a semispherical clamping ring to form a sealing layer, and effectively ensuring the sealing effect. Compared with the prior art, welding operation is not needed, the connecting efficiency is higher, under the action of the uneven inner concave limiting groove, on one hand, the extrusion contact area of the outer convex rubber block and the inner concave limiting groove is increased, the extrusion strength of the outer convex rubber block and the inner concave limiting groove is enhanced, on the other hand, sharp thorns pierce a rubber storage bag to enable metal quick-drying rubber to overflow, therefore, the connecting strength of the outer convex rubber block and the inner concave limiting groove is effectively enhanced, part of the sharp thorns pierce into the outer convex rubber block, the outer convex rubber block is effectively limited to be not prone to moving in the inner concave limiting groove, and the connecting strength between the two steel pipes is effectively guaranteed through multiple actions.

Owner:朱少强

Lightweight heatproof porous wall material and building blocks

InactiveCN100398483CLight weightLow thermal conductivitySolid waste managementHeat proofingMaterials scienceNaphthalene

Owner:周正华

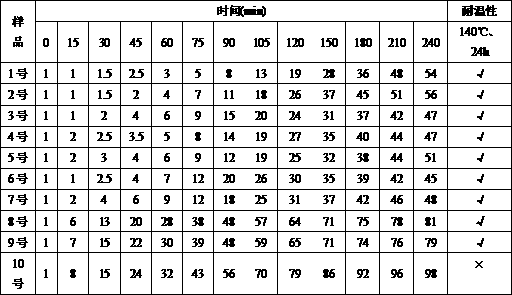

High-temperature-resistant slow-expansion water-absorbing expansion resin plugging aid used in the field of oilfield drilling

The invention relates to a high-temperature-resistant slow-expansion water-absorbing expansion resin plugging aid used in the field of oilfield drilling. The preparation method comprises: putting water into a reaction tank, adding bentonite, completely dispersing, sequentially adding acrylamide, acrylic acid and 2-acrylamido-2-methylpropanesulfonic acid, completely dissolving, introducing nitrogenat a low temperature, sequentially adding a cross-linking agent and an initiator, heating to 30-70 DEG C, reacting for 2-5 h, drying, granulating, and screening; and adding a wrapping agent and a solvent into the reactor, slowly heating, adding a water-swelling resin after the wrapping agent is completely dissolved, and removing the solvent after the reaction is finished so as to obtain the high-temperature-resistant slow-expansion water-absorbing expansion resin. According to the invention, the obtained product can slowly expand in the early stage of water absorption, can rapidly achieve water absorption expansion within a short time in the later stage, has a delay time of longer than 1 h, has temperature resistance of 140 DEG C, can effectively plug at a high temperature, and can achieve good repairing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

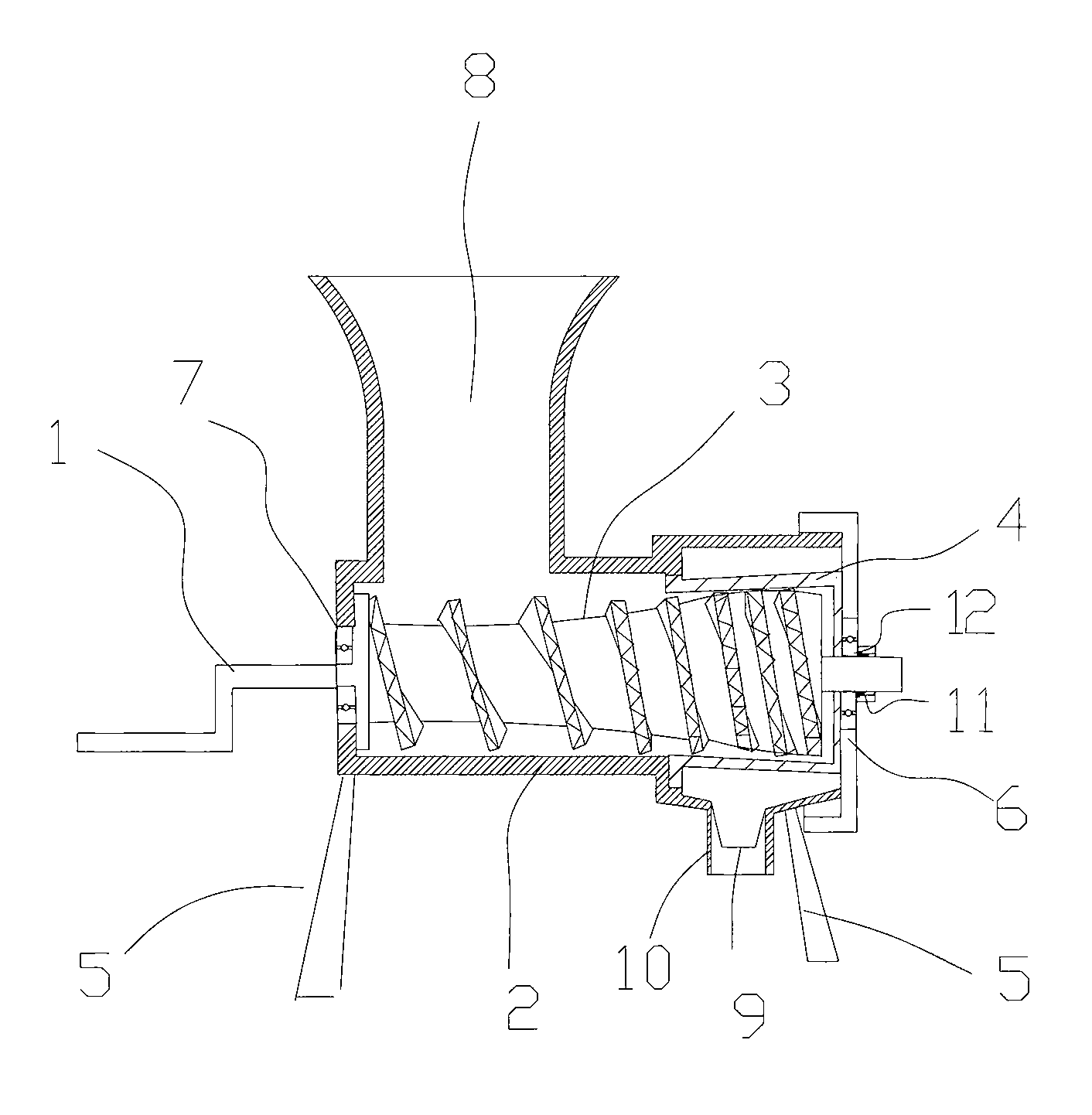

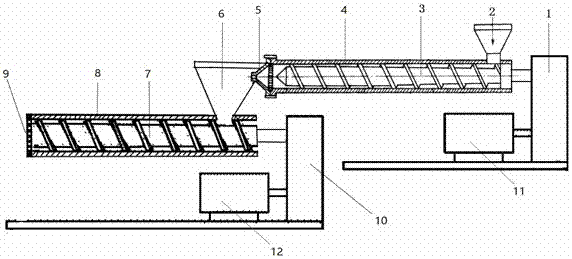

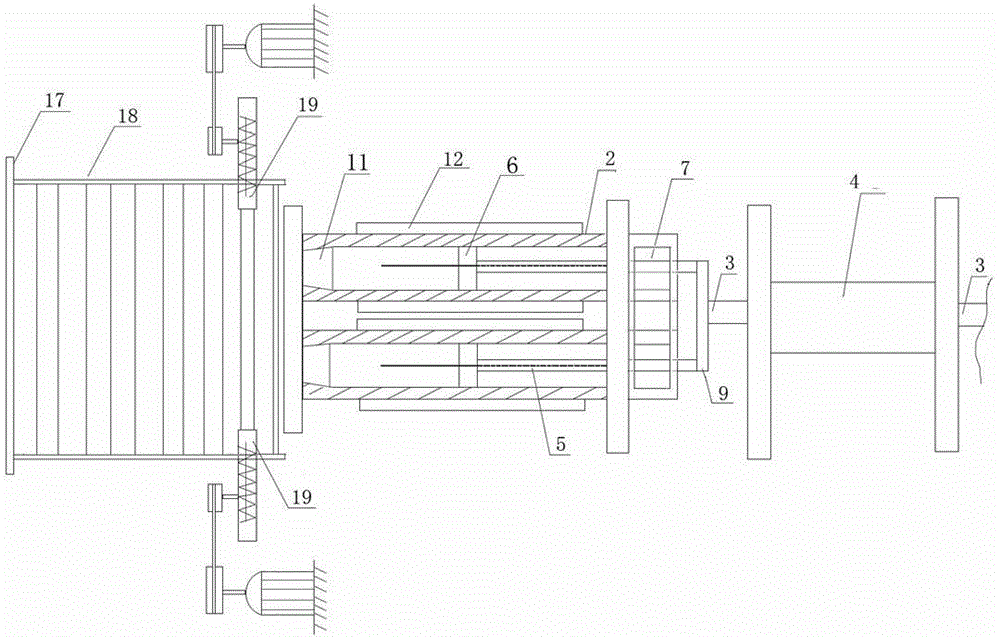

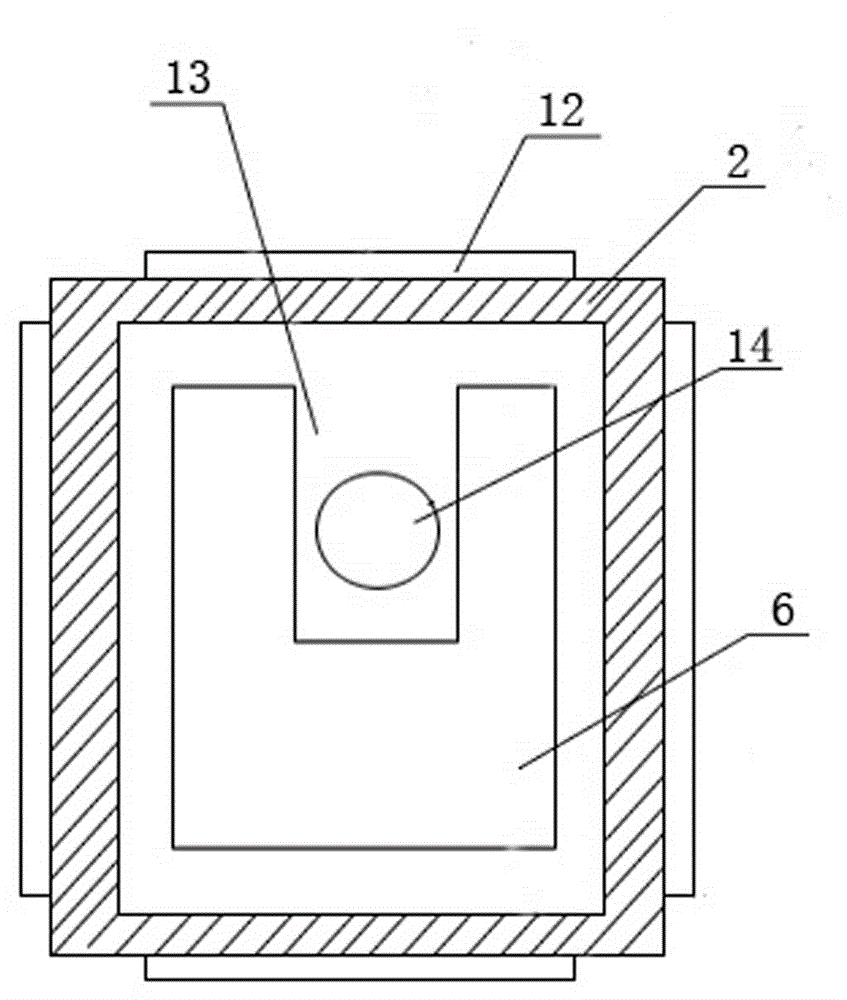

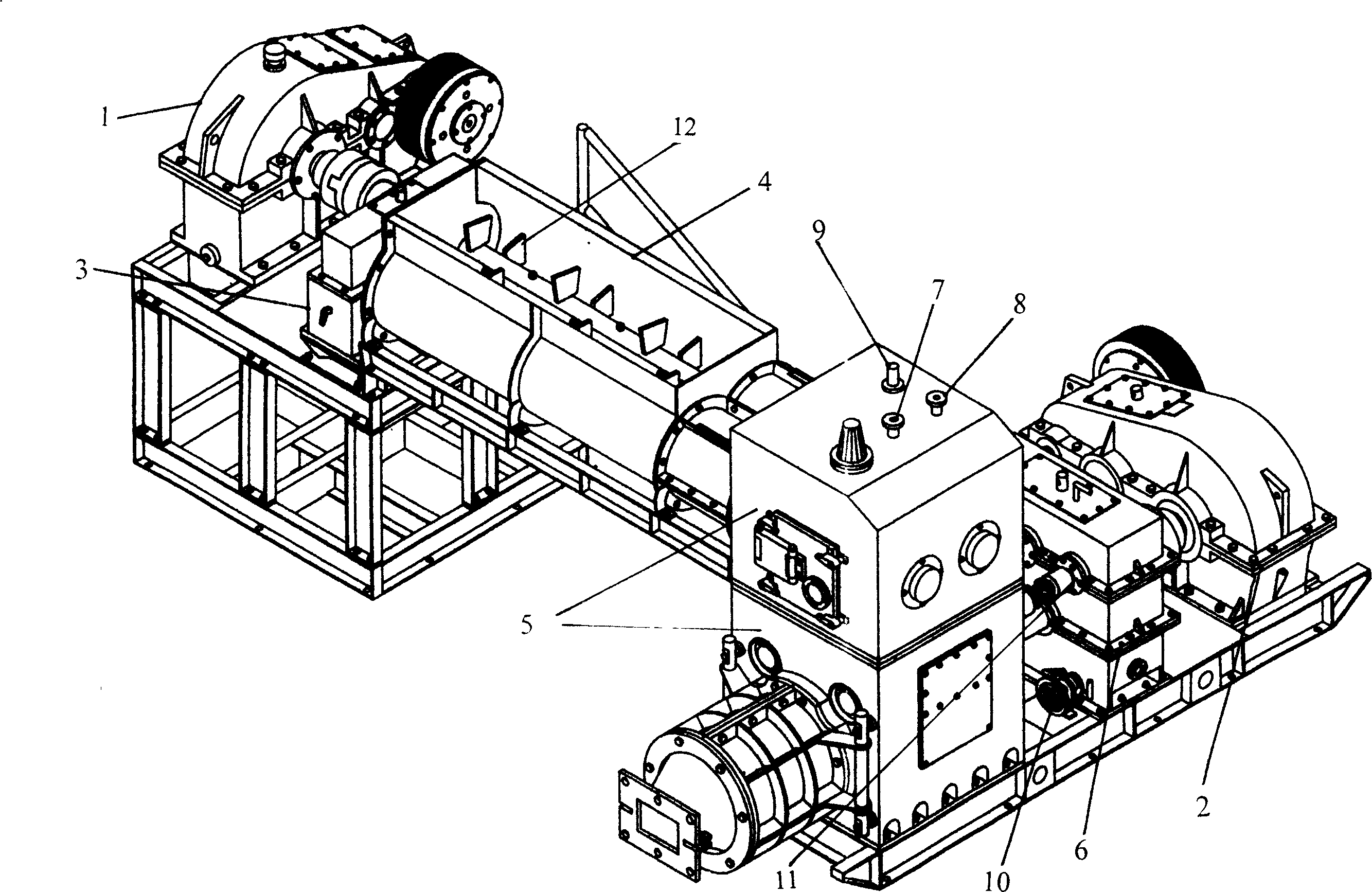

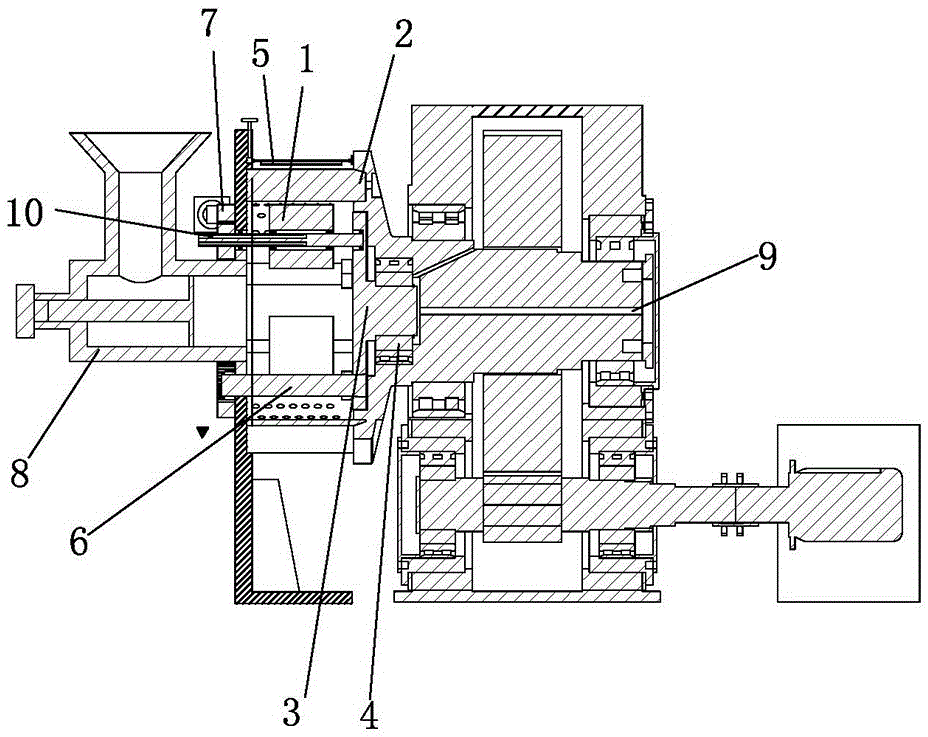

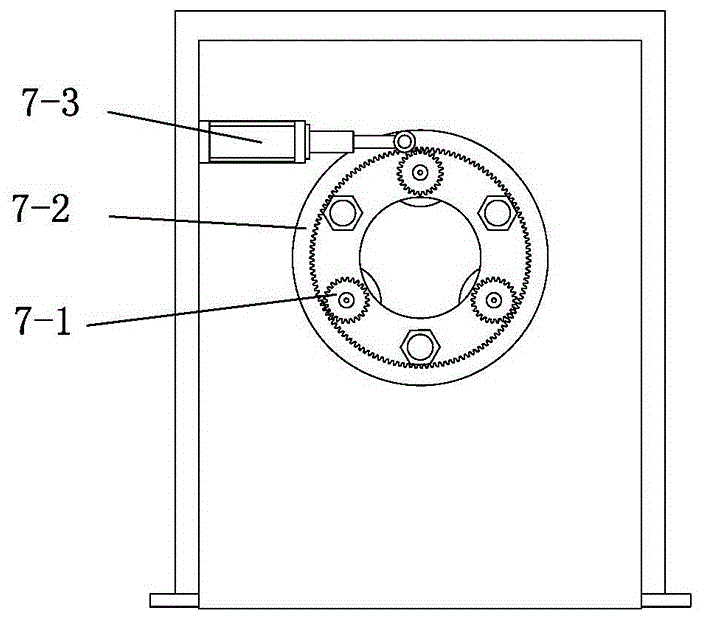

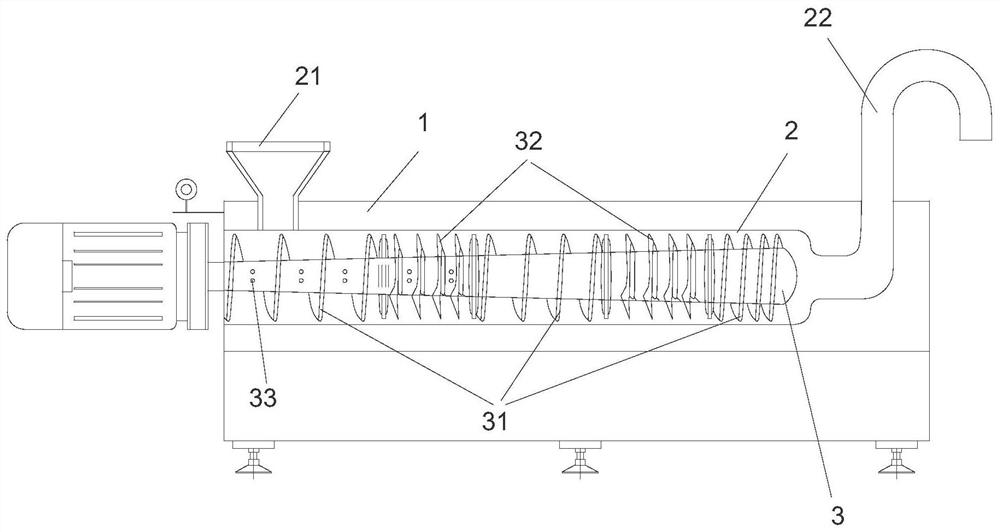

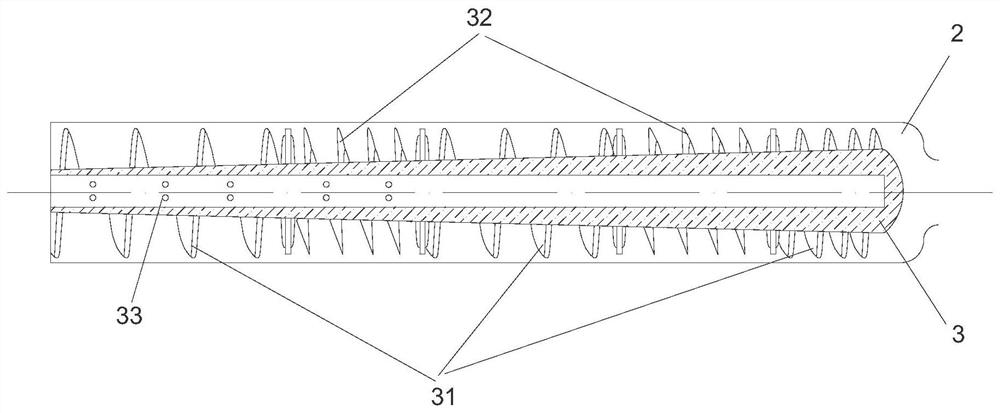

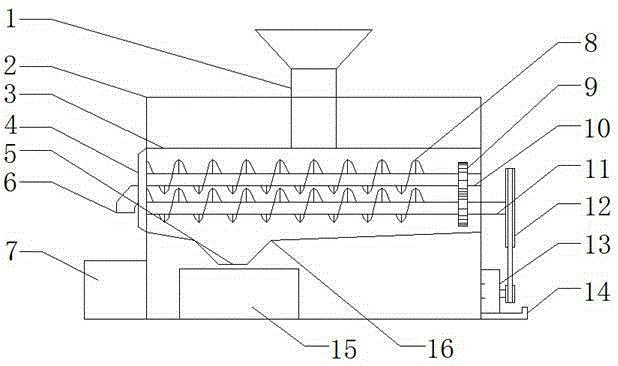

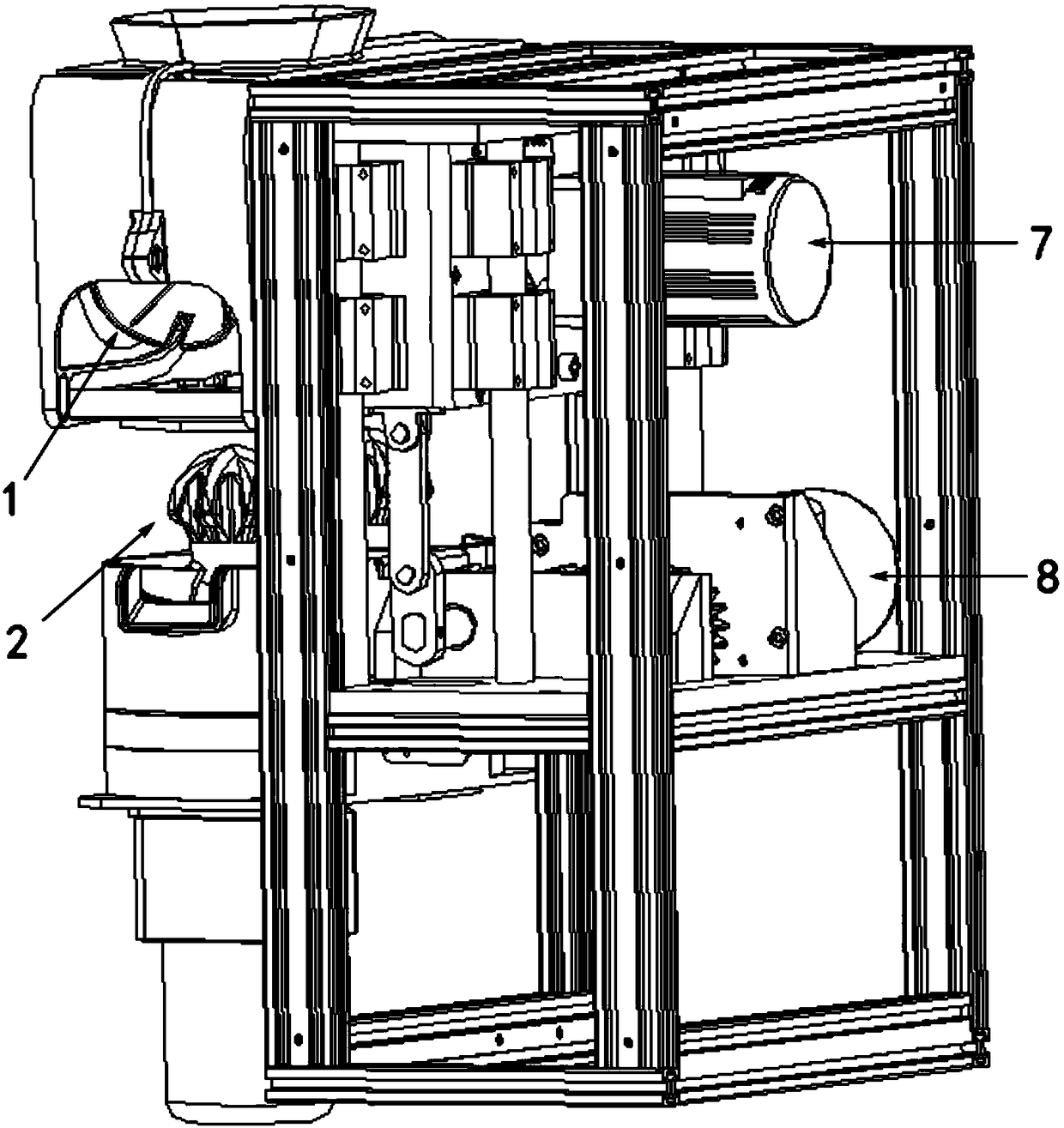

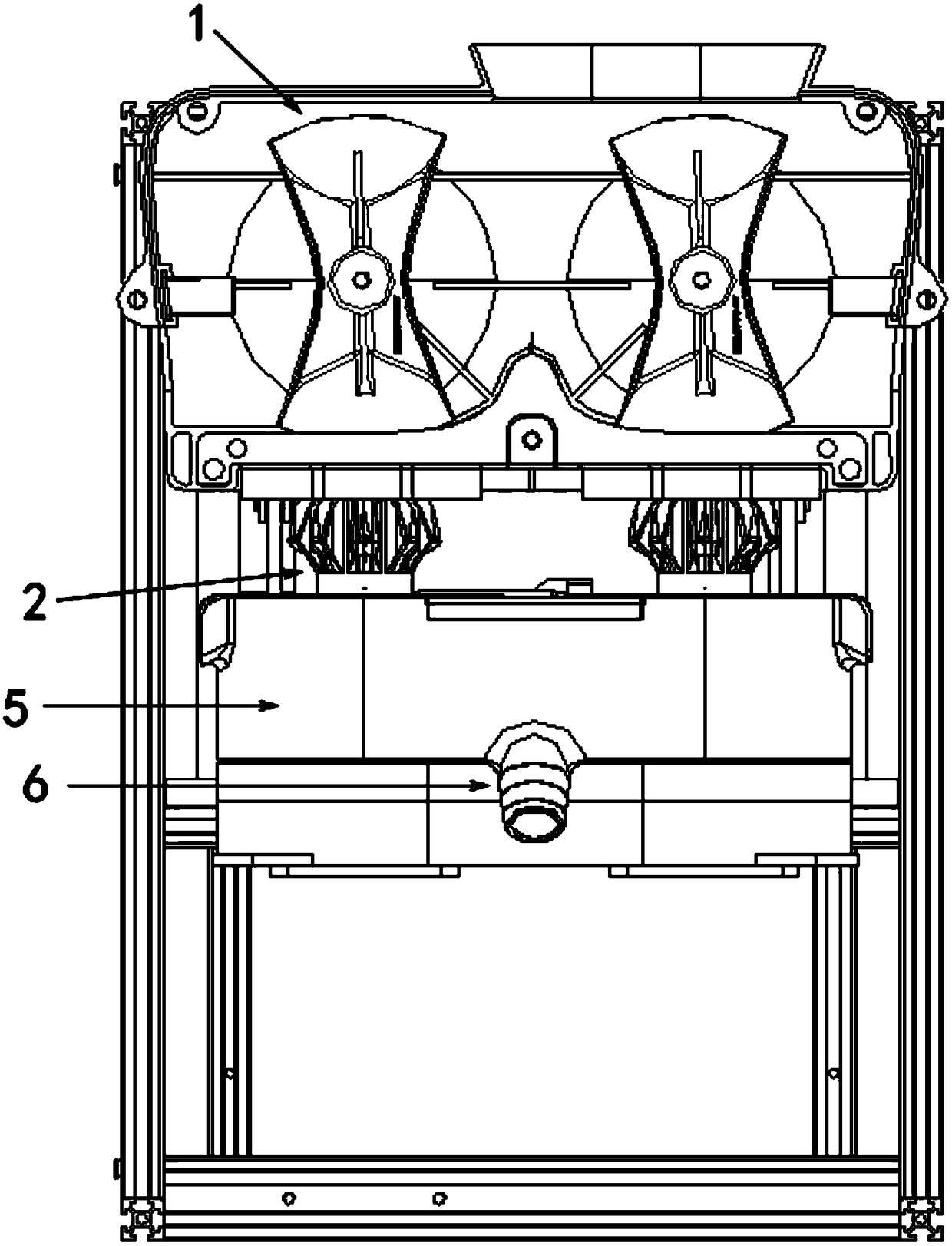

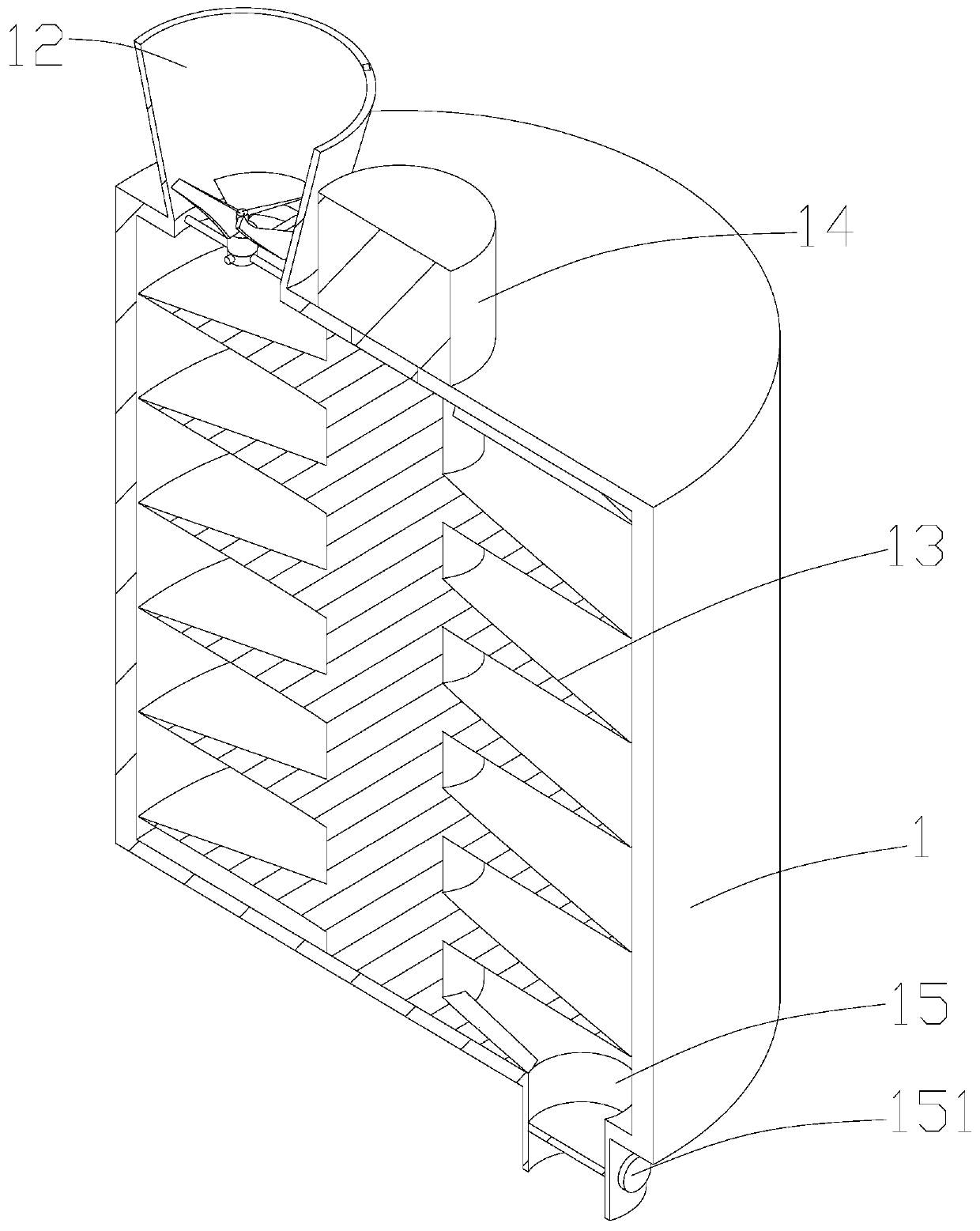

Screw series curing extrusion equipment and screw series curing extrusion method for rice noodle production

InactiveCN107319616AReasonable structureImprove performanceFood shapingSelf curingUltimate tensile strength

The invention discloses screw series curing extrusion equipment and a screw series curing extrusion method for rice noodle production. The equipment comprises a first-order screw self-curing extruder and a second-order screw extruder, wherein the first-order screw self-curing extruder comprises a first-order charging barrel; a first-order feeding opening is formed in one end of the first-order charging barrel, and a first-order discharge opening is formed in the other end of the first-order charging barrel; a self-curing screw is arranged in the first-order charging barrel; one end of the self-curing screw is connected with a driving device I; the second-order screw extruder comprises a second-order charging barrel; a second-order feeding opening is formed in one end of the second-order charging barrel, and a second-order discharge opening is formed in the other end of the second-order charging barrel; an extrusion screw is arranged in the second-order charging barrel and connected with a driving device II; and the first-order discharge opening is connected with the second-order feeding opening. The invention further discloses a screw series curing extrusion method and method for rice noodle production. According to the rice noodles produced by the invention, the curing extrusion strength can be increased, the shear force is enhanced, the produced rice noodles are rich in gel, high in capacity and obvious in energy conservation, the production efficiency can be improved, and the equipment is convenient to maintain.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +2

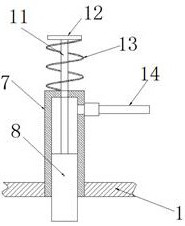

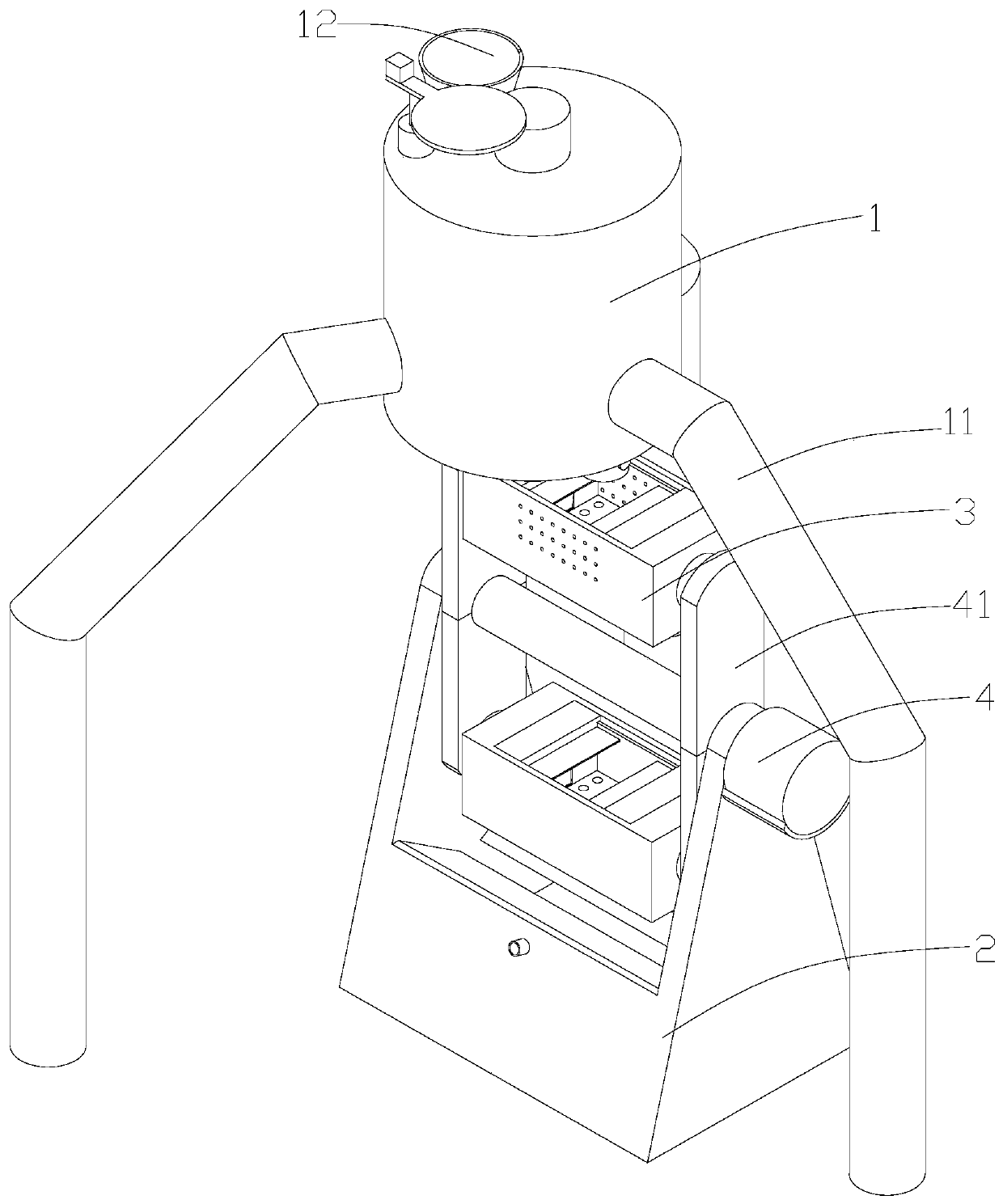

Rod forming machine

ActiveCN103817760AHigh and even pressureReasonable structureWood compressionUltimate tensile strengthMechanical engineering

A rod forming machine at least comprises a frame. At least one horizontal extrusion forming barrel is mounted on the frame, a hydraulic oil cylinder with piston rods is mounted on one sides of feed inlets of the barrels. The piston rods are connected with extrusion blocks through connected extrusion rods, and the extrusion blocks with the section same with the cross section of an extrusion cavity in each barrel are in movable fit with the extrusion cavities. Discharge outlets communicated with the extrusion cavities of the barrels are arranged on the inner sides of the feed inlets of the barrels. The discharge outlets are provided with feed hoppers and form a rod extrusion and forming device. The extrusion forming barrels are square columnar barrels. The rod forming machine has the advantages of reasonable structure, and convenience and reliability in use and the advantages that extrusion intensity can be increased, service life is prolonged, using cost is reduced, using efficiency and effect are improved and the like.

Owner:福建省永阳国有资本投资集团有限公司

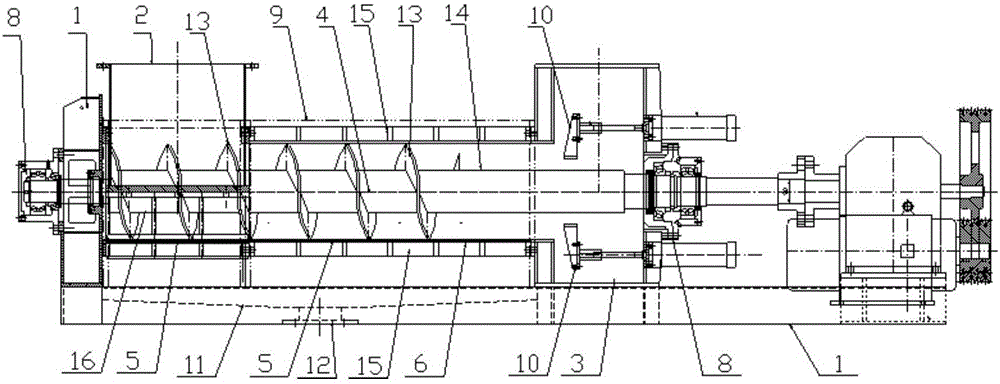

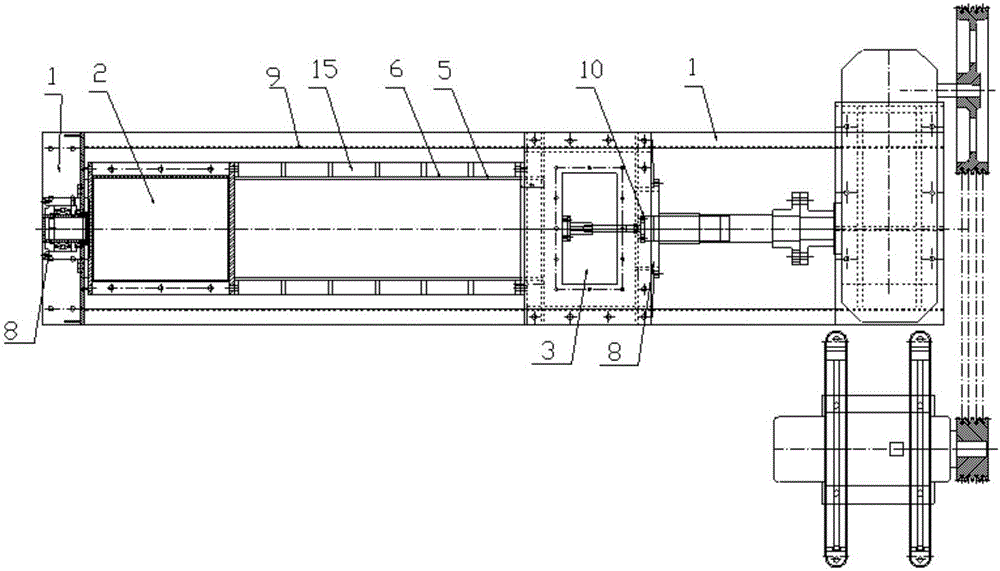

Screw extruder for plant straw dehydration

The invention discloses a screw extruder for plant straw dehydration. The screw extruder comprises a rack, a spiral main shaft, a driving device, a screen barrel, a seal cover, a feeding opening and a discharging opening. The spiral main shaft comprises a feeding straight shaft section, a conveying section and a discharging straight shaft section, wherein the feeding straight shaft section is located below the feeding opening and used for being adapted to the situation when the feeding amount is high in fluctuation; the conveying section is connected with the tail end of the feeding straight shaft section and used for extruding conveyed materials; and the discharging straight shaft section is connected with the tail end of the conveying section and used for forming continuous material stuffing so that dryness of discharged materials can be improved, and part of the discharging straight shaft section is located above the discharging opening. Spiral vanes on the feeding straight shaft section and spiral vanes on the conveying section are unchanged in screw pitch. A backpressure disc structure provided with a backpressure disc is arranged at the discharging opening. The screw extruder is applicable to the pretreatment process for comprehensively utilizing plant straw for producing biomass fuel and suitable for the feeding mode large in fluctuation quantity; dryness of the extruded straw materials reaches 40-55%; and the screw extruder is stable in operation, free of blocking and low in power consumption.

Owner:包头国士鼎盛投资有限公司

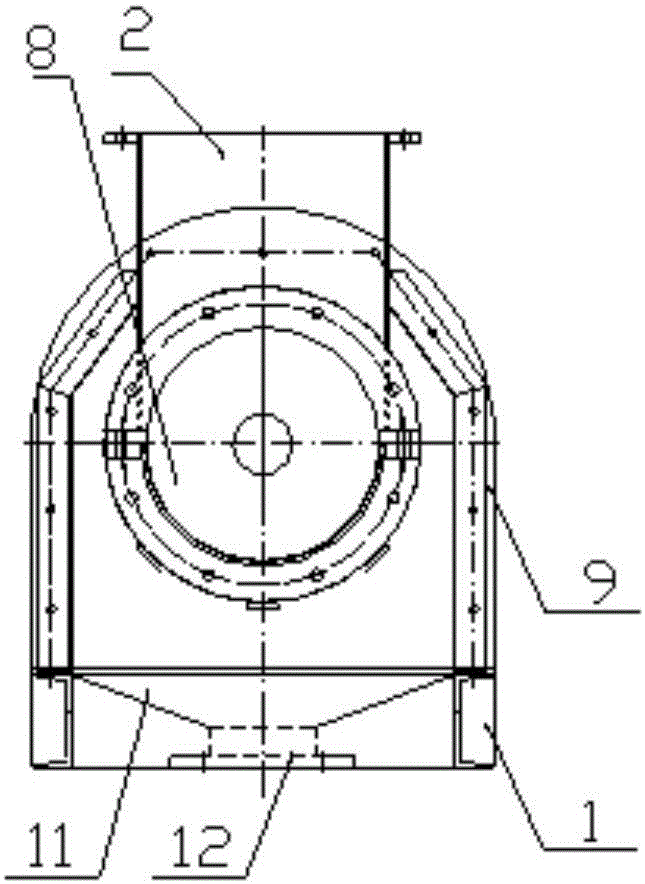

Two-stage vacuum brick and tile extruding machine

InactiveCN1887554AExtended service lifeImproved vacuumCeramic shaping apparatusElectric machineryClutch

The two-stage vacuum brick and tile extruding machine has two motors to drive through axial pneumatic clutches two reducers, including one transverse reducer to drive the stirring barrel for stirring and extruding and one longitudinal reducer to drive the forming extruder, one large two-stage vacuum machine with two crossly arranged stages, one stirring member and one spiral cast with 16Mn material. The two-stage vacuum brick and tile extruding machine has high work efficiency, stable product quality, long service life and high extrusion strength, and the extruded products may be used for various bearing and non-bearing walls.

Owner:福建省新东方机械有限公司

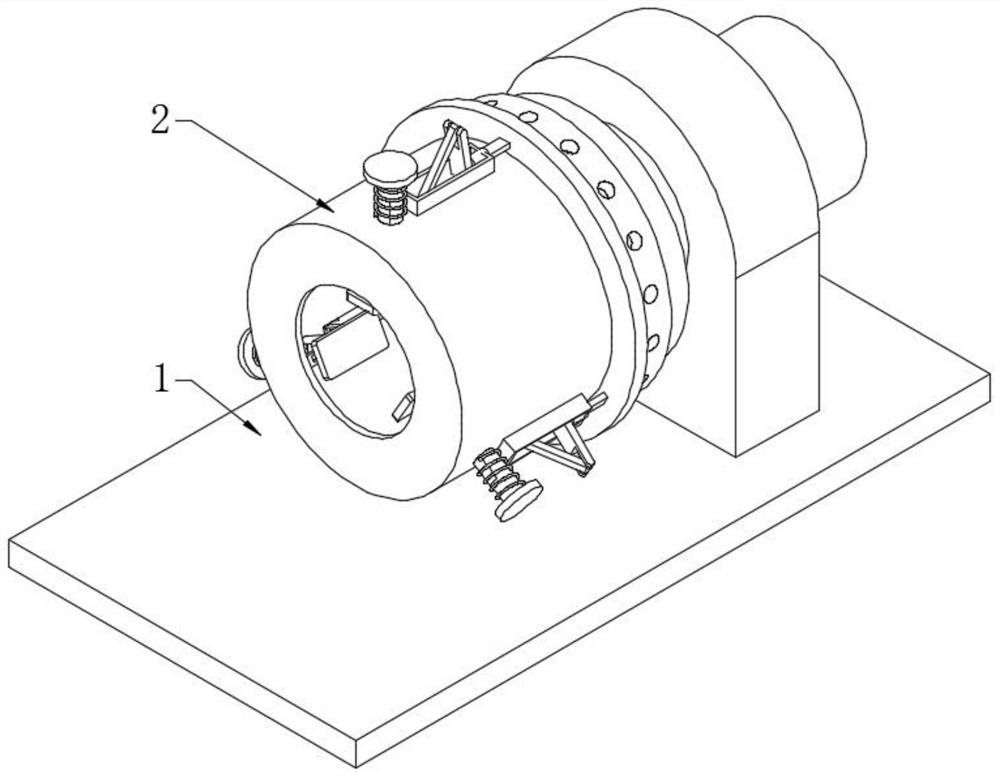

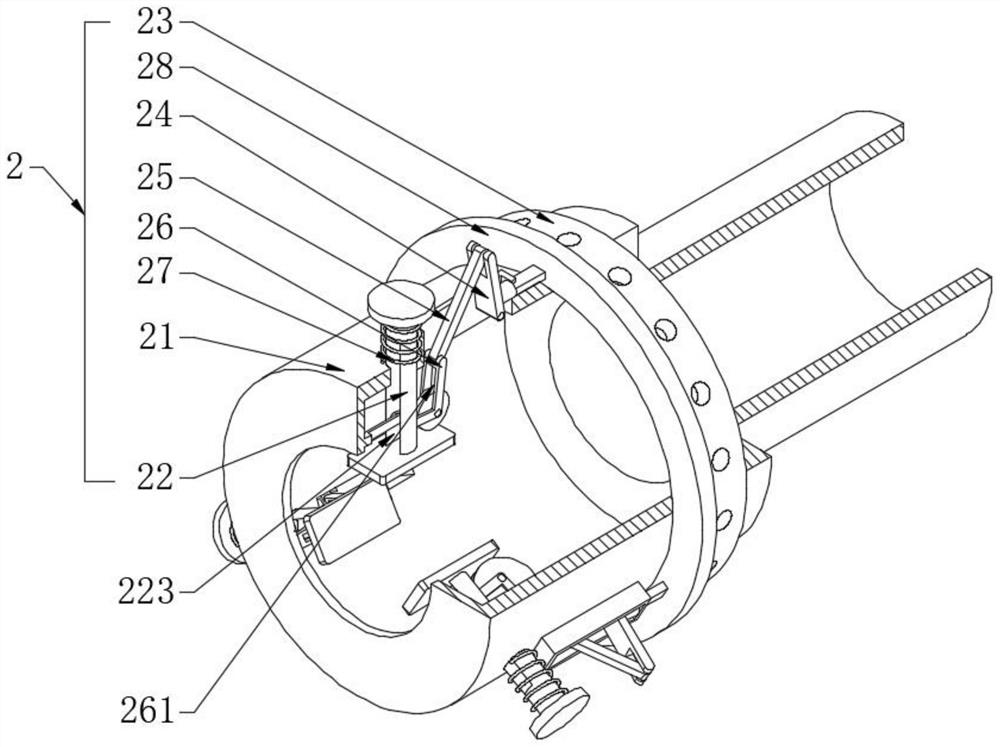

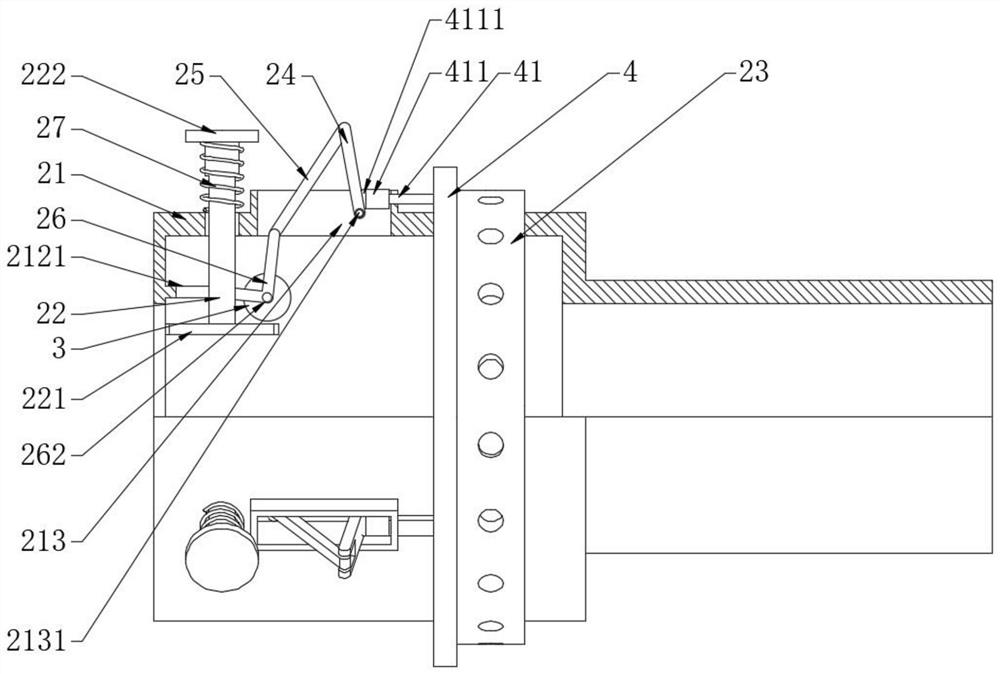

Metal cutting machine tool with quick response secondary clamping function

InactiveCN112917212AAchieve clampingQuick clampingPositioning apparatusMetal-working holdersEngineeringLever pressing

The invention discloses a metal cutting machine tool with a quick response secondary clamping function. The metal cutting machine tool comprises a workbench and a clamping mechanism arranged on the workbench, the clamping mechanism comprises a positioning sleeve, a clamping rod, a driving sleeve, a transmission rod I, a transmission rod II, a pressing rod, a reset spring and a pressing ring, the positioning sleeve is in running fit with the workbench, and three guide holes which are uniformly distributed in the circumferential direction are formed in the outer surface wall of the positioning sleeve. The clamping mechanism is arranged, the clamping mechanism comprises the positioning sleeve, the clamping rod, the driving sleeve, the transmission rod I, the transmission rod II, the pressing rod, the reset spring and the pressing ring, the driving sleeve is controlled to rotate to drive the pressing ring to push the transmission rod I to swing, then the pressing rod is driven to swing through the transmission effect of the transmission rod II, the pressing rod swings to drive the clamping rod to act to achieve clamping or loosening control over a workpiece, and the clamping rod is controlled to clamp the workpiece in a swinging mode, so that clamping is quick, and the clamping stroke is short.

Owner:陈首君

Method for preparing uniformly-distributed and large-thickness polyester reinforced acrylic ester plate

ActiveCN108189433AIncreasing the thicknessEvenly distributedFibre treatmentFlat articlesPolyester resinSlurry

The invention relates to a novel method for preparing a large-thickness polyester reinforced acrylic ester plate with uniformly distributed polyester silk, and particularly relates to a method for preparing polyester sheets by infiltration polymerization of single-layer polyester silk and enabling the polyester sheets to be subjected to secondary polymerization after being laminated to form the polyester reinforced acrylic ester plate with large thickness and the uniformly-distributed polyester silk inside the polyester sheets. The method is a novel preparation method of composite materials. According to the method, 655 type polyester silk and MMA are adopted, the polyester sheets are polymerized by using a composite initiator, and the polyester sheets are cut and laminated and are fixed in a specially-made model, MMA slurry with certain viscosity is injected, and the secondary polymerization is carried out. The mass ratio of the polyester silk to methyl methacrylate is 70 (+ / -10): 100. The polyester-reinforced acrylic ester plates with the thickness up to 50 mm and uniformly distributed in the inner structure of the plates are prepared.

Owner:锦西化工研究院有限公司

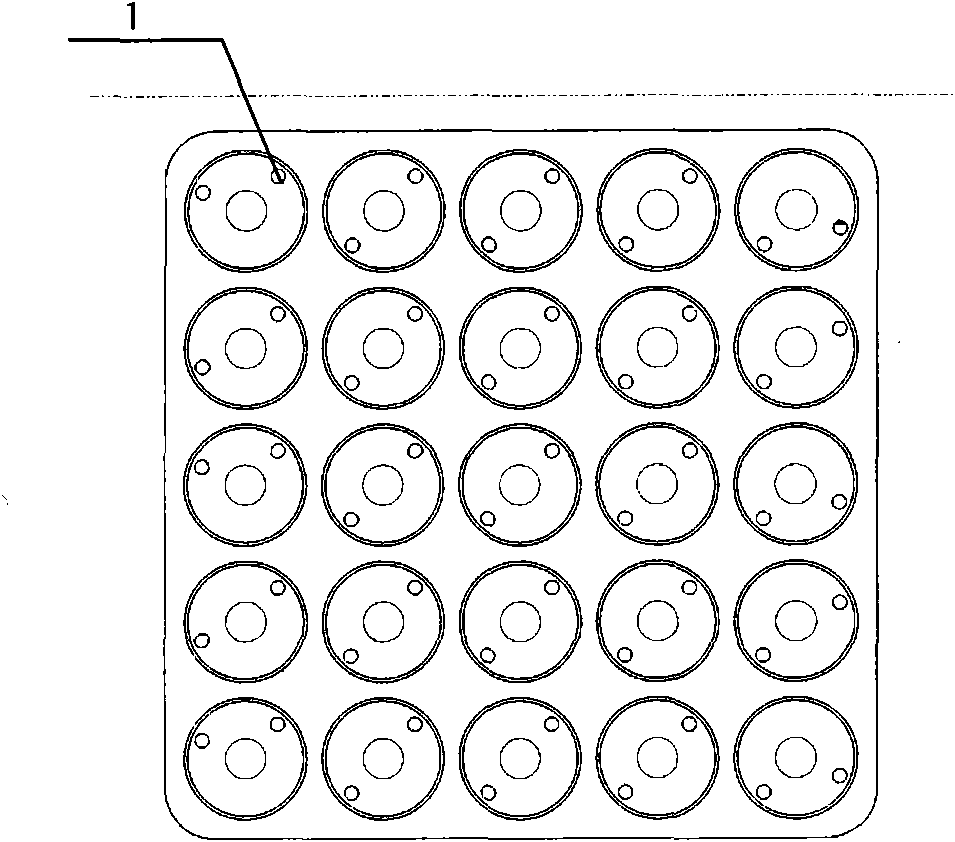

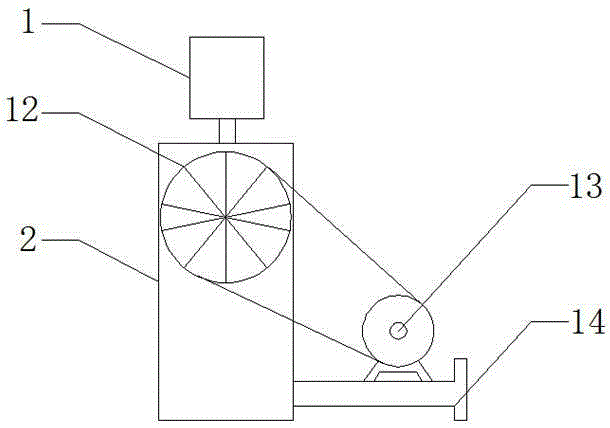

Molding machine for producing high-strength wood particles

InactiveCN105921070AGuaranteed coaxialityGuaranteed smoothnessGranulation by material expressionMolding machineUltimate tensile strength

The invention relates to a molding machine and particularly relates to a molding machine for producing high-strength wood particles. The molding machine for producing the high-strength wood particles comprises a compaction wheel assembly, a mold assembly, a conversion connector and a movable cutting assembly, wherein the compaction wheel assembly comprises a compaction wheel shaft, a compaction wheel and a bracket; the mold assembly comprises a main shaft and an annular mold; the annular mold is provided with a mold cavity; a plurality of extruding holes are formed in an annular surface; the movable cutting assembly comprises a screw rod arranged on the bracket, a movable nut which sleeves the screw rod, a slide rail arranged on the main shaft, a slide seat arranged on the slide rail and a cutting tool; one end of the cutting tool is fixed on the movable nut and the other end of the cutting tool is fixed on the slide seat; and each extruding hole comprises a material storage part and a molding part connected onto the material storage part. With the adoption of the molding machine, the length of the particles is consistent; the strength of the extruded particles is improved, the granulation effect is improved and the stress on the mold is relatively uniform; and the molding machine is simple in structure and convenient to operate and the service life of the equipment is prolonged.

Owner:HUZHOU TUOGAO MACHINERY CO LTD

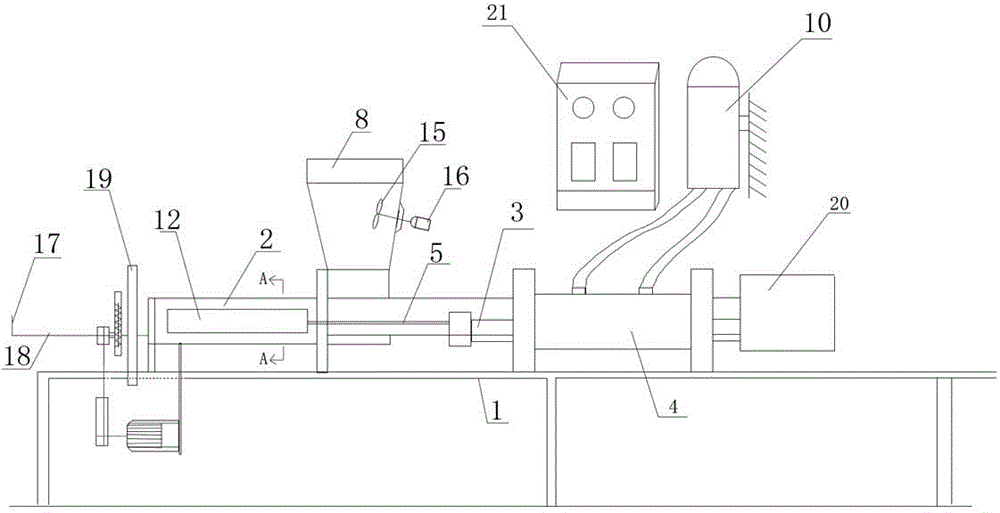

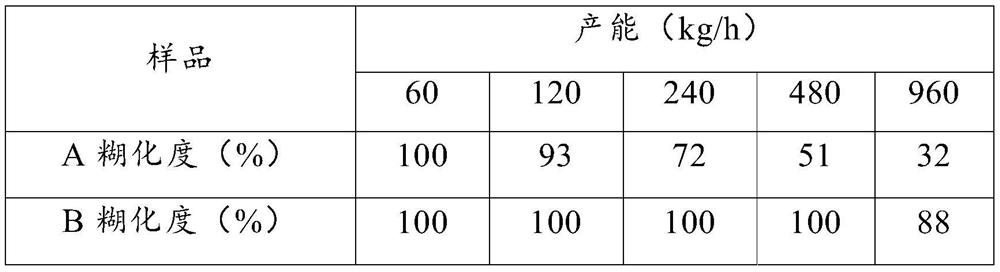

Extrusion gelatinization device and system

ActiveCN113273711AImprove gelatinizationGuaranteed gelatinizationFood shapingMechanical engineeringPhysics

The invention provides an extrusion gelatinization device and a system. The device comprises a heating cavity, an extrusion cavity and a screw rod. The heating cavity is provided with a steam inlet and a steam outlet. The extrusion cavity is located in the heating cavity, and provided with a feeding port and a discharging port which extend out of the heating cavity. The screw rod is of a hollow structure, can rotate in the circumferential direction and comprises a driving section and a working section. The working section is located in the extrusion cavity and used for fitting with the cavity wall of the extrusion cavity when rotating the screw rod so that materials can be extruded and gelatinized while being conveyed from the feeding port to the discharging port. The driving section extends out of the extrusion cavity, and is provided with an opening on the end for communicating with an external steam source and connecting with an external rotary driving mechanism. A through hole for overflowing steam into the extrusion cavity is arranged on the working section. Therefore, materials in the extrusion cavity can be heated at extremely high heating rate with extremely high heating uniformity under the action of the double-layer steam, thereby ensuring gelatinization of the materials under high productivity.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

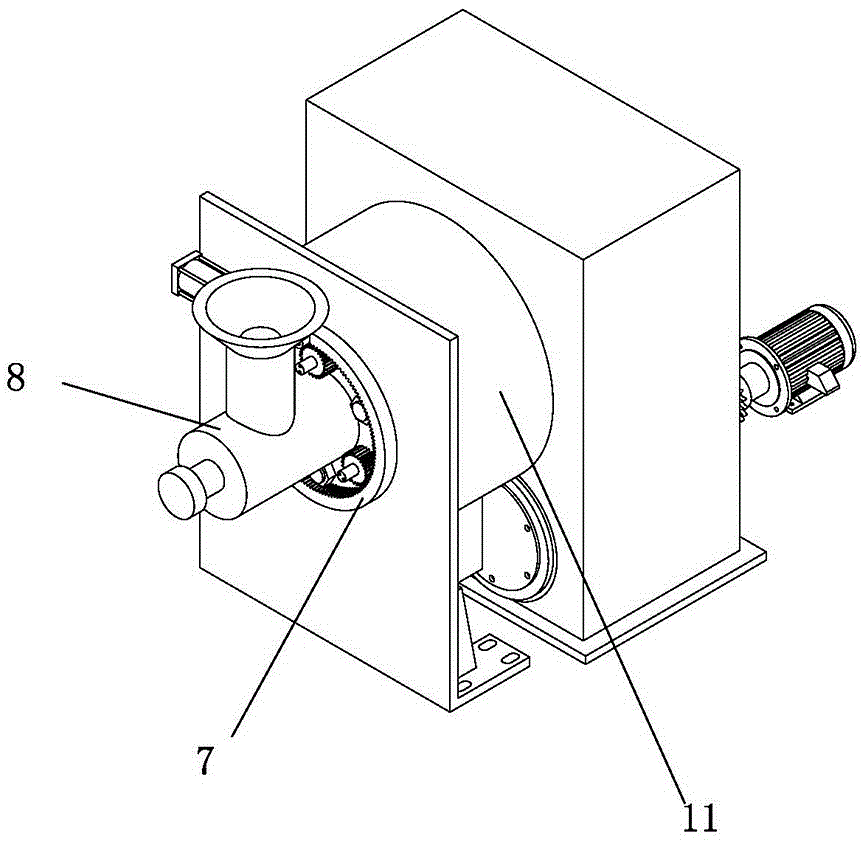

Small-sized spiral tea oil squeezer

InactiveCN106675770AScientific and reasonable structureEasy to useFatty-oils/fats refiningFatty-oils/fats productionDrive shaftFuel tank

The invention discloses a small-sized spiral tea oil squeezer. The small-sized spiral tea oil squeezer comprises a feeding opening, a safe protective box body, a prepressing box, an oil residue outlet, a driving shaft, a supporting base and an oil storage tank, wherein the feeding opening is formed in the upper surface of the safe protective box body; the prepressing box is arranged inside the safe protective box body; in addition, a driven shaft and the driving shaft are arranged inside the prepressing box; a belt wheel is fixed to the driving shaft by dowels; the oil residue outlet is formed in the left side of the safe protective box body; in addition, a waste material collecting box is arranged at a position, corresponding to the oil residue outlet, of the bottom of the left side of the safe protective box body; the oil storage tank is arranged at the bottom end inside the safe protective box body; the supporting base is arranged behind the safe protective box body. According to the small-sized spiral tea oil squeezer disclosed by the invention, a twin screw structure is arranged inside the prepressing box, and one group of involute-type spiral pinion shaped cutters which are mutually meshed to rotate oppositely rotate, so that the extrusion strength of oil is increased, and the oil producing effect is better; the oil yield of same raw materials is improved, and the investment cost is reduced.

Owner:HENGYANG ZHIYUAN AGRI TECH

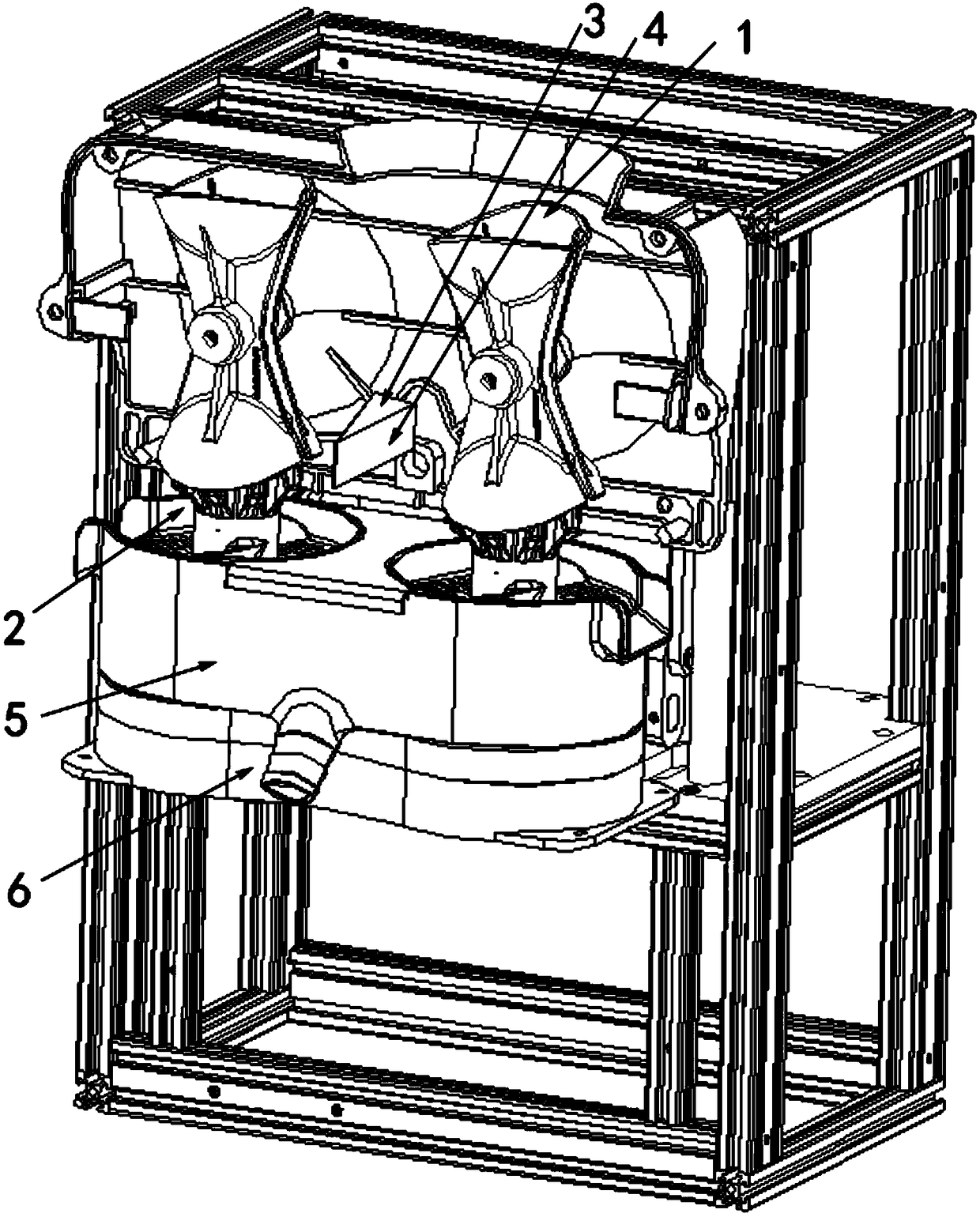

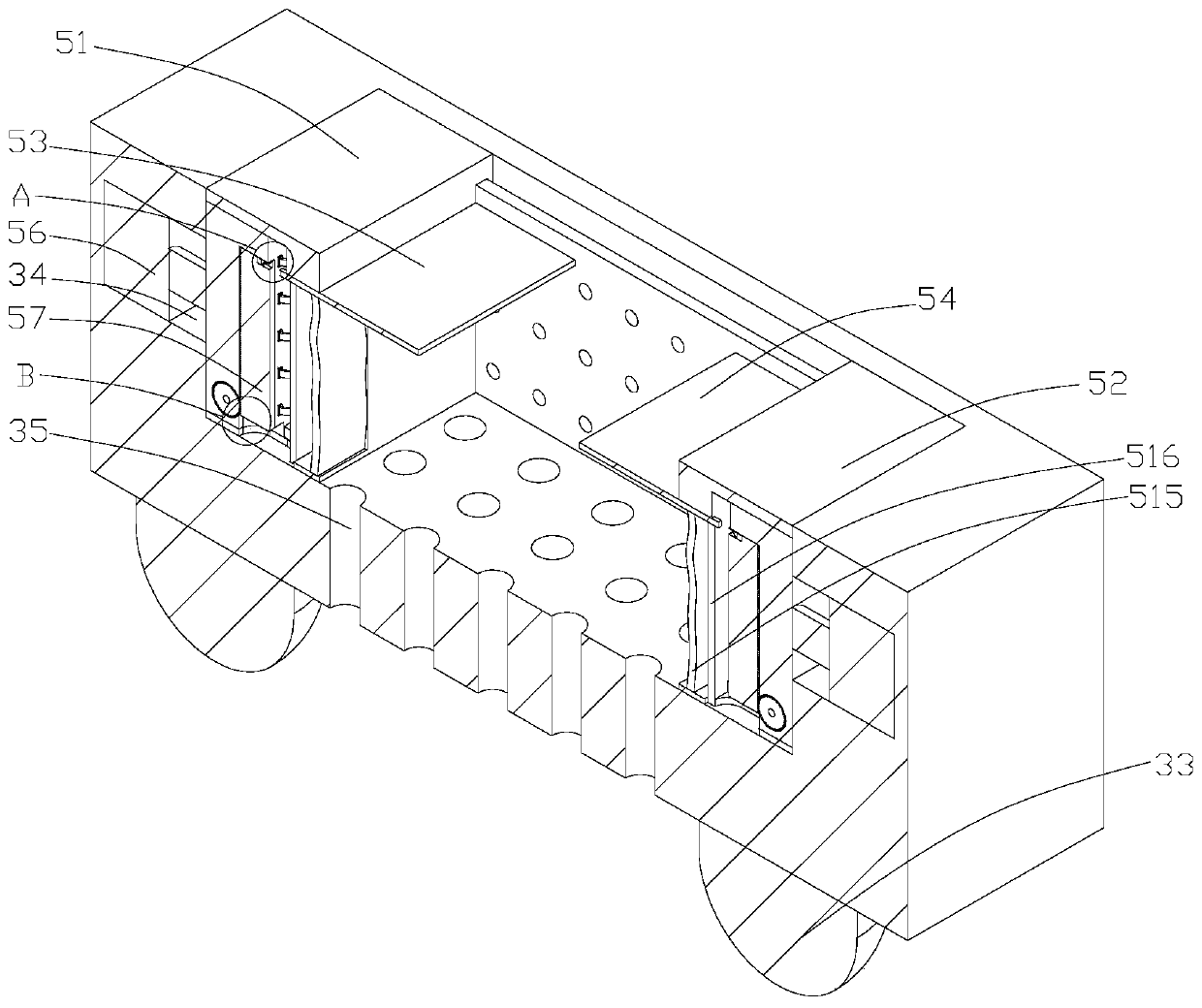

Juicing device for a juice extractor

ActiveCN105982500BImprove extrusion strengthIncrease the juice yieldStrainersEngineeringElectrical and Electronics engineering

The invention discloses a juicing device of a juicer. The juicing device comprises at least one containing slot, at least one extrusion ball, a blade, a blade holder and a filtered juice slot, wherein the blade is positioned on the blade holder; the filtered juice slot comprises a filtered juice outlet; the containing slot can rotate around a center; the opening of the containing slot can be rotated to approach the blade; the extrusion ball is positioned below the containing slot and can be driven up and down and can rotate around the axle center; and the opening of the containing slot is larger than the extrusion ball.

Owner:SHANGHAI JUANG IND

Sealed fermentation device for biotechnology research and development

InactiveCN112175803AImprove the effectiveness of analysis workImprove extrusion strengthBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnology researchElectric machinery

The invention discloses a sealed fermentation device for biotechnology research and development. The sealed fermentation device comprises a box body, wherein a material guiding table is fixed to the center of the inner wall of the top of the box body, motors are fixed to the two sides of the outer wall of the bottom of the box body, the top ends of output shafts of the motors penetrate through theinner wall of the box body, stirring mechanisms are fixed, and a sleeve is fixed to the center of the outer wall of the top of the box body; A piston rod is inserted into the sleeve, an extrusion mechanism is fixed to the bottom end of the piston rod, a reset mechanism is fixed to the top end of the piston rod, and an air storage mechanism fixedly communicates between one side of the sleeve and the box body. The solid waste is extruded by utilizing air pressure power generated by air, so that the fermentation completeness is improved.

Owner:刘立强

Method for producing phenol adsorbent resin

InactiveCN102229710BLarge particlesImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesPhenol adsorptionGranularity

The invention provides a preparation method of phenol adsorbent resin. The preparation method comprises the following steps of: with small-granularity waste polymerization white spheres of macroporous ion exchange resin within the granularity range of 45-60 meshes adopted, extracting to obtain a porogenic agent, stoving, carrying out chloromethylation according to a macroporous anion resin standard process until chloride content is 15-25%, washing chloride spheres with water until no chloride ion exist after reaction is finished, stoving, then carrying out Friedel-Crafts reaction and then crosslinking, and then carrying out surface fluorination to generate the adsorbent resin with high specific surface area. The phenol adsorbent resin obtained by the preparation method provided by the invention has high adsorption capacity, the phenol adsorption capacity is more than 100mg per ml of the resin, and the phenol adsorbent resin has high strength, is difficult to break and has short regeneration time.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Method for preparing large-size large-thickness polyester reinforced acrylic ester plate

The invention relates to a novel method for preparing an uniformly distributed large-thickness polyester reinforced acrylic ester plate. The method is a method for preparing the large-thickness uniformly distributed acrylic ester plate through polymerization by infiltrating a methyl methacrylate solution on the polyester silk, is a method for making the polyester silk and the methyl methacrylate solution to be uniformly and stably polymerized to the large-thickness uniformly distributed acrylic ester plate by performing constant-speed turnover polymerization through a 360-degree turnover machine, and is a novel preparation method for the composite material. The acrylic ester plate is formed through casting polymerizing of 655-type polyester silk and methyl methacrylate, and the mass ratioof the polyester silk to the methyl methacrylate is 90(+ / -10):100 (mass ratio); and according to the method, the polyester reinforced acrylic ester plate with the thickness capable of reaching up to 50 mm and the polyester silk capable of being uniformly distributed in the inner structure of the plate can be prepared.

Owner:锦西化工研究院有限公司

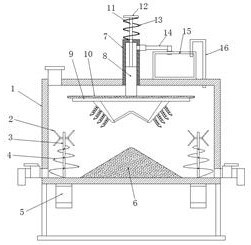

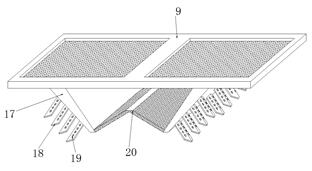

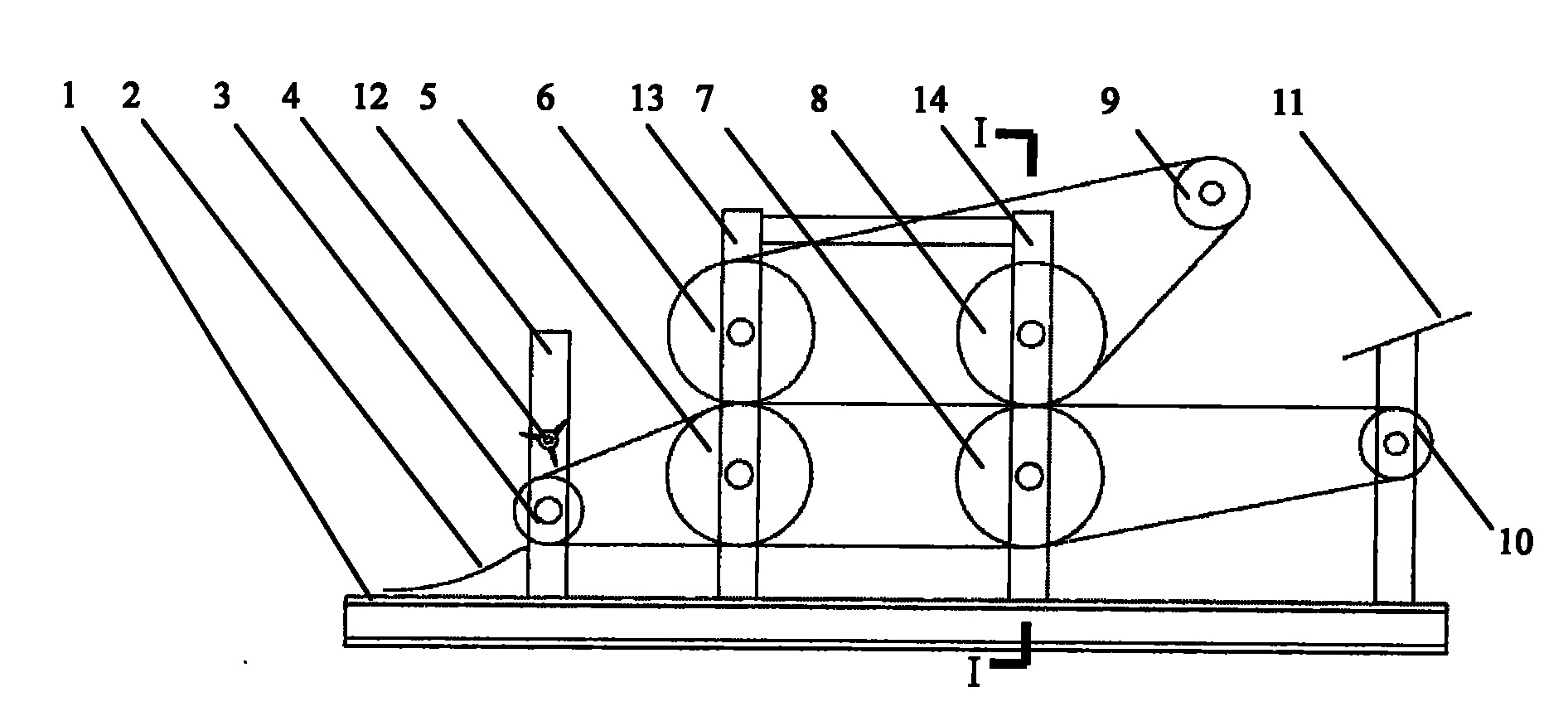

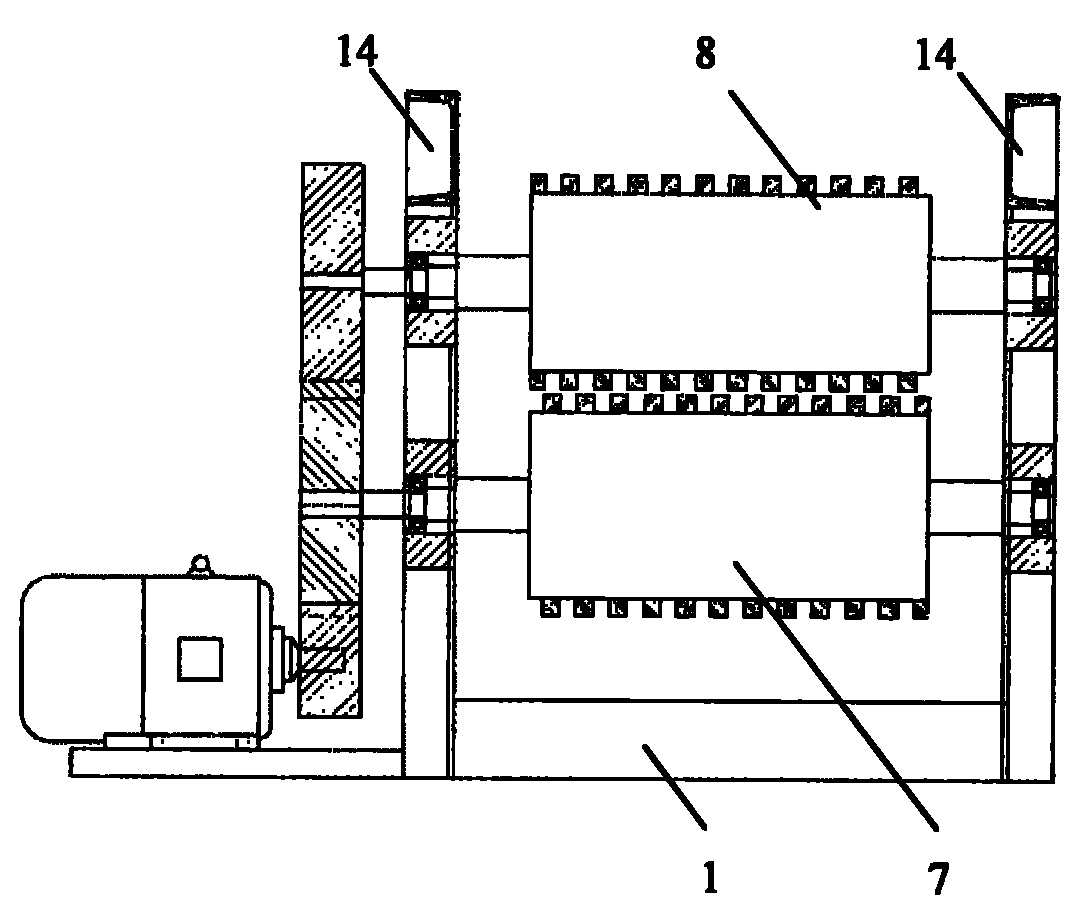

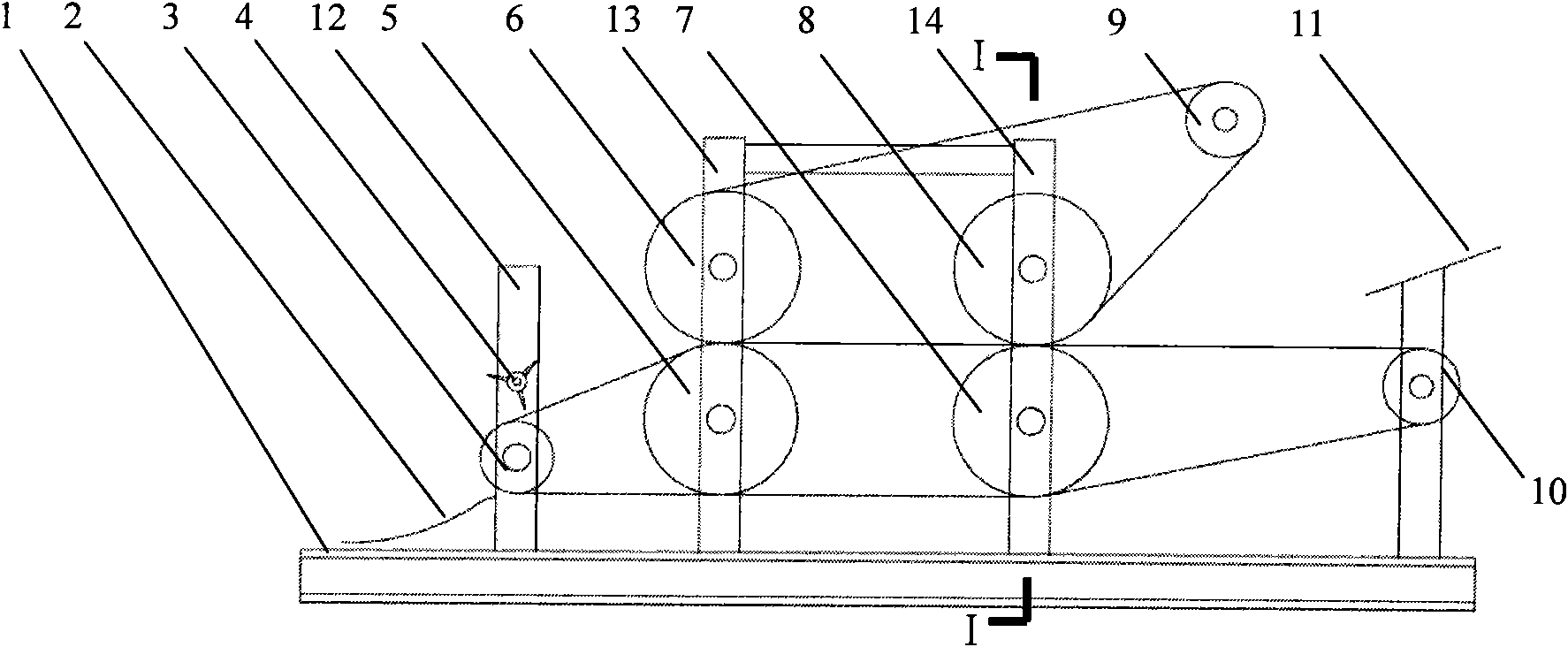

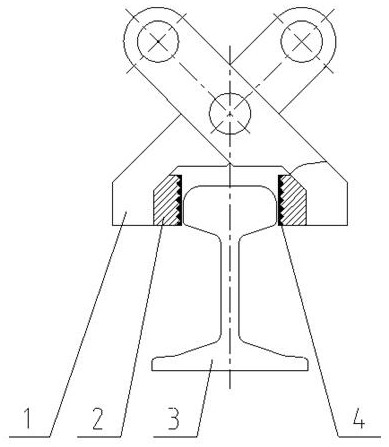

Belt rolling sludge granulator

InactiveCN101829522AEasy to transportEnsure safetySludge treatment by de-watering/drying/thickeningGranulation by pressingSludgeHigh intensity

The invention discloses a belt rolling sludge granulator which comprises a body, a discharge hopper, a front guide wheel, a triangle cutter, a lower rolling roller, an upper rolling roller, a lower pilot rolling roller, an upper pilot rolling roller, an upper bend wheel, a lower tail wheel, a feed hopper, a motor and a bracket. The granulator adopts a secondary rolling roller shaping mode and the triangle cutter to cut and granulate by rotating and has the advantages of simple structure, low manufacturing cost, high continuous operation rate, large extrusion acting force, good granule forming stability, high granulating intensity, high output, and the like, can realize the functions of continuous feeding, high-intensity forming, and the like, and increases the output of sludge granules. The granulator solves the problems of difficult treatment because of the characteristics of the sludge and extruding discharge of dry sludge dust and is suitable for continuously granulating various kinds of sludge with lower water content.

Owner:武汉致衡环境安全工程技术有限公司

Brake brake shoe for brake device

PendingCN112762114AImprove extrusion strengthImprove braking effectBraking membersActuatorsBrake shoeBrake force

The invention discloses a brake brake shoe for a brake device. The brake brake shoe comprises a brake shoe base body and a covering layer, the covering layer serves as a friction body and is arranged on the braking force acting face of the brake shoe base body, at least two transverse V-shaped grooves and at least two longitudinal V-shaped grooves are formed in the braking force acting face of the brake block base body in a machined mode, and the transverse V-shaped grooves and the longitudinal V-shaped grooves are formed in a mutually crossed mode, so that a conical protrusion is formed on the braking force acting face of the brake block base body, and the covering layer is directly cast on the conical protrusion of the brake block base body in a casting mode, so that the brake block base body and the covering layer are cast into an integrated structure. According to the brake brake shoe for the brake device, on the basis that the abrasion performance of the bake brake block is effectively improved and the service life of the brake brake block is effectively prolonged, the reliability of the braking performance of the brake is improved, the structure is more compact, machining and manufacturing are easy and convenient, and replacement or disassembly and assembly are more convenient and faster.

Owner:邹城市广信科技开发有限责任公司

Sludge conveying and dewatering equipment used for sludge treatment

InactiveCN110002713AAchieve exclusion effectReduce moisture contentSludge treatmentSewageMaterial supply

The invention discloses sludge conveying and dewatering equipment used for sludge treatment. The equipment comprises a material conveying cylinder used for conveying sludge, a plurality of supportinglegs used for supporting the material conveying cylinder and a collecting box used for collecting the treated sludge; and the material conveying cylinder is provided with a material inlet hopper and aspiral material supply rod, at least one dewatering box used for dewatering treatment of the sludge and first driving member used for driving rotation of the dewatering box are arranged below the material conveying cylinder, the first driving member is fixedly arranged on the collecting box, and the dewatering box is provided with a dewatering device. According to the equipment provided by the invention, through arrangement of the above structure, the sludge can be uniformly conveyed through the material conveying cylinder, so that volume treatment of the sludge is realized, and blockage caused by a too large volume of the sludge is avoided; and at the same time, the sludge can be treated by the dewatering device, so that the sludge can be dried in a certain shape in batches, forming specifications of the sludge are substantially same, mutual adhesion of the sludge can be avoided, collection arrangement of the sludge is facilitated, and the control utilization rate of the collection container is improved.

Owner:杭州更蓝生物科技有限公司

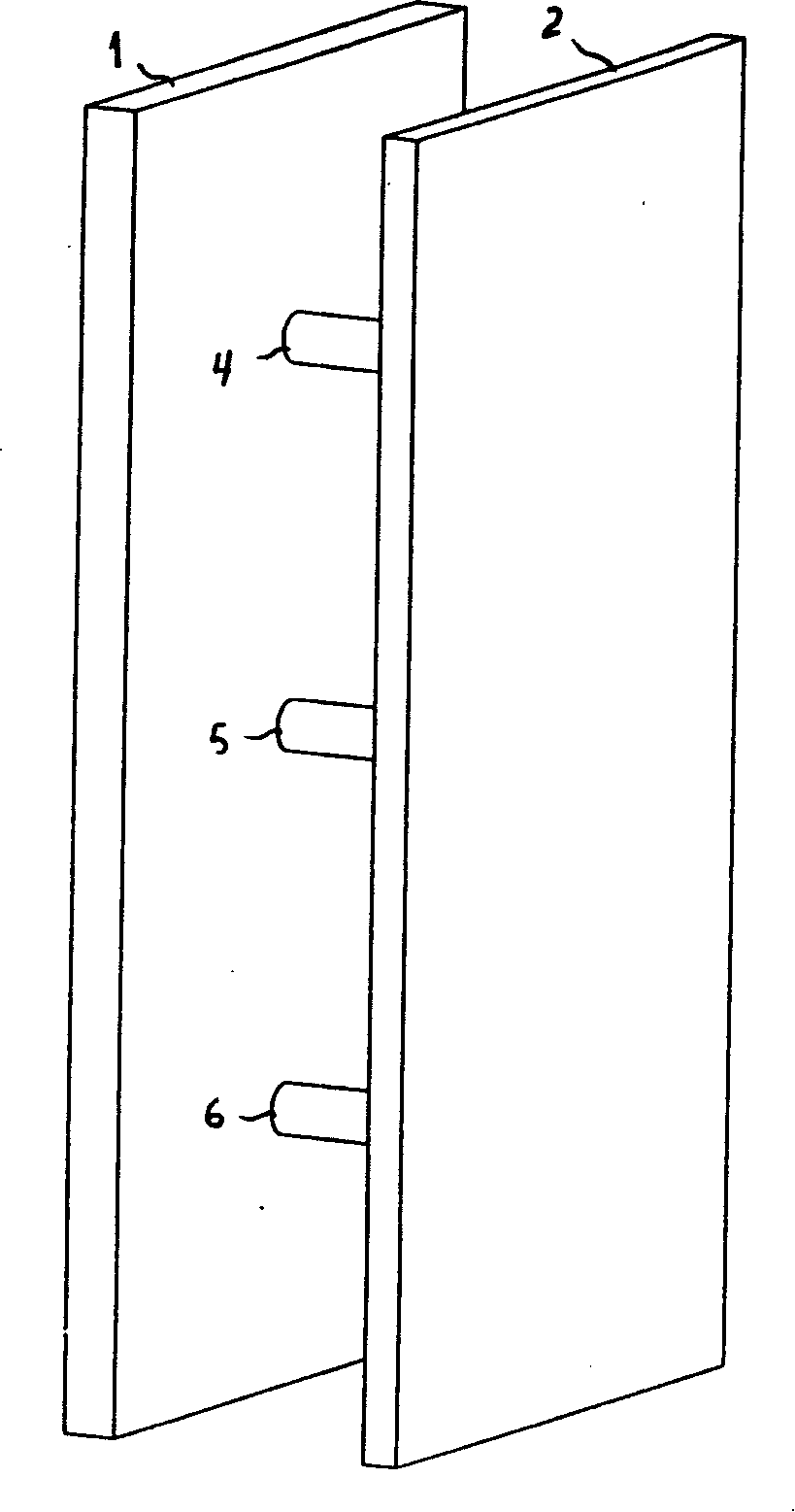

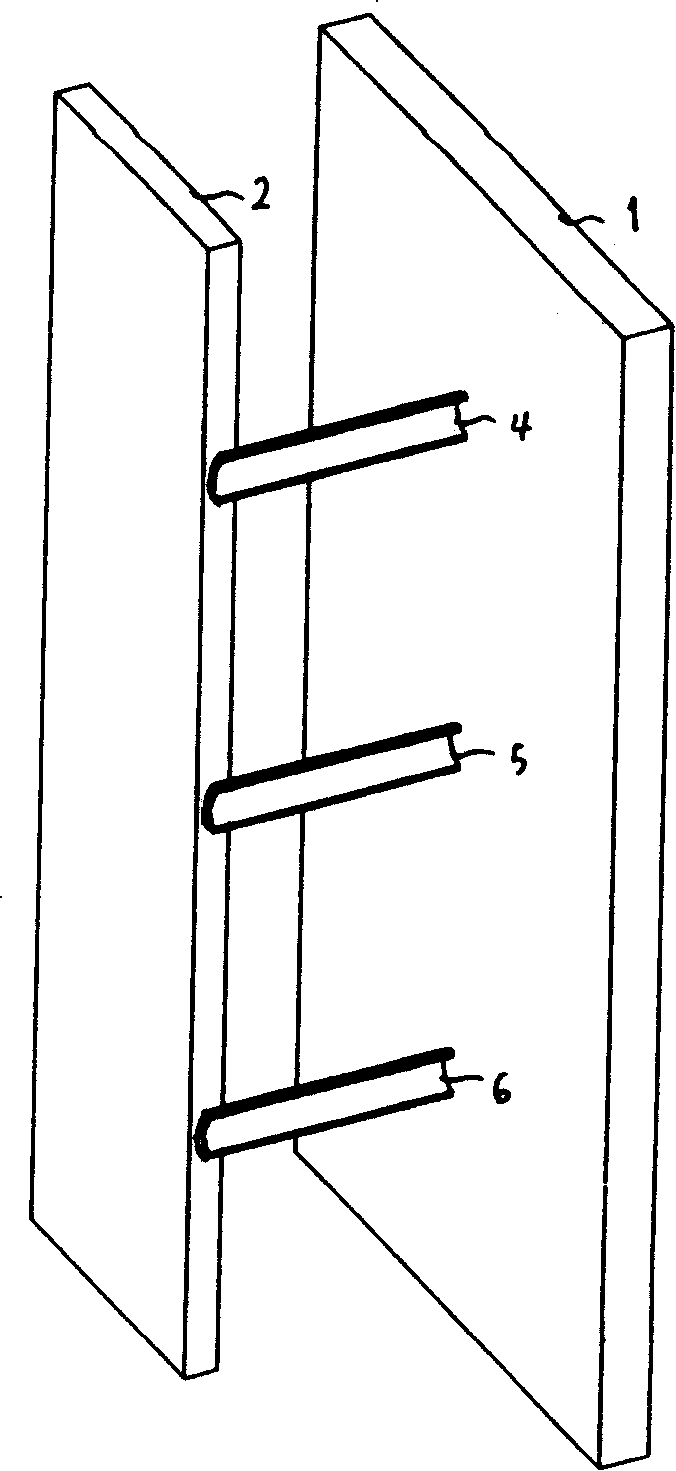

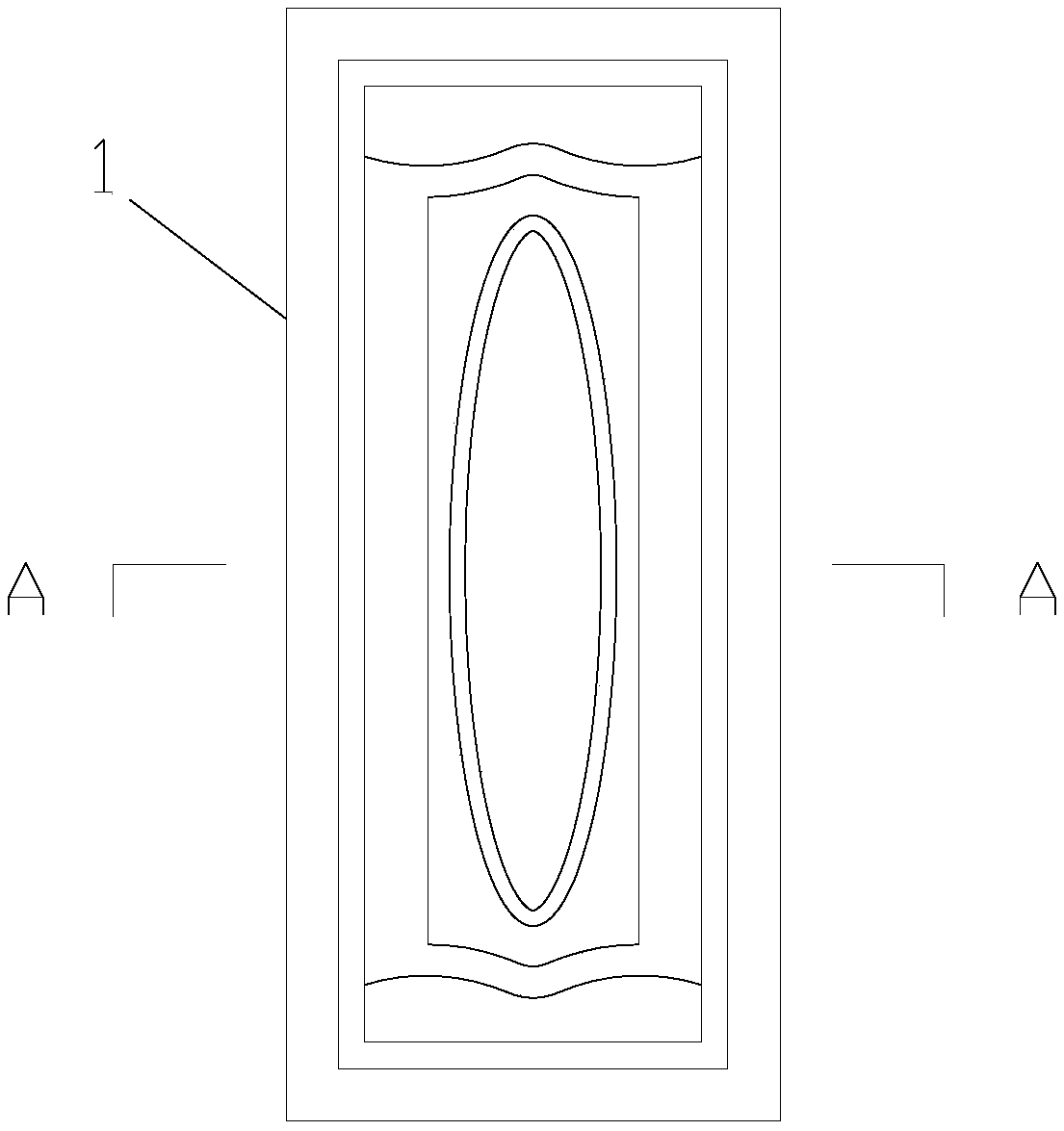

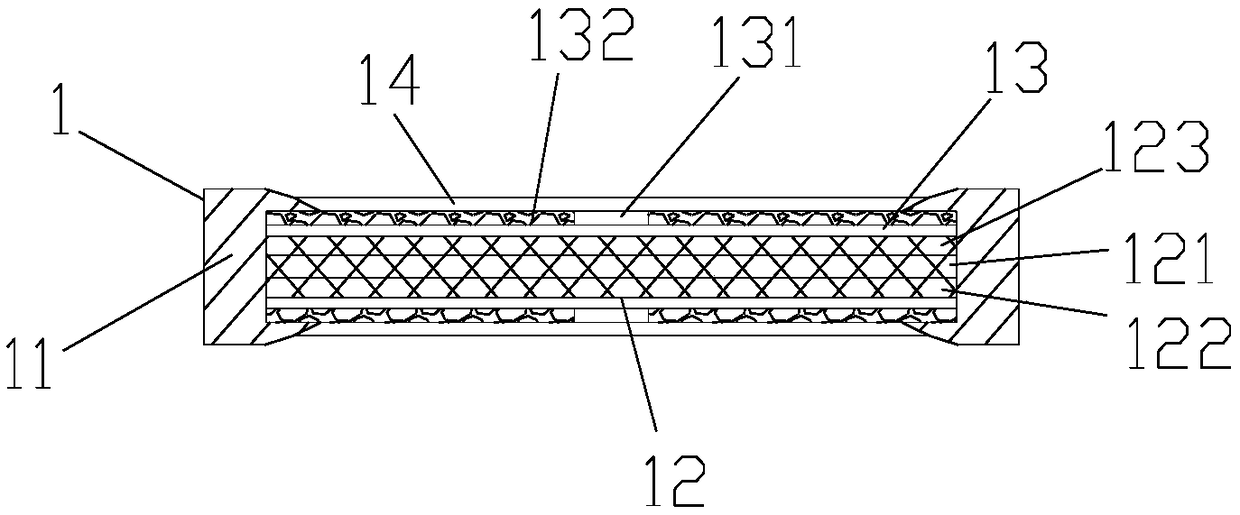

Indoor wooden door with sound insulation and squeezing resistance functions

InactiveCN109025736ASimple structureImprove sound insulationNoise insulation doors/windowsDoor leavesFiberEngineering

The invention discloses an indoor wooden door with sound insulation and squeezing resistance functions. The indoor wooden door comprises a wooden door body. The wooden door body comprises a door frame, a clamping plate assembly arranged in the door frame, solid boards arranged on the two sides of the clamping plate assembly, attached to the clamping plate assembly and used for preventing the clamping plate assembly from getting loose, and decoration layers arranged on the outer surfaces of the solid boards and used for covering the wooden door body, wherein the clamping plate assembly comprises a first clamping plate layer, a second clamping plate layer attached to the lower surface of the first clamping plate layer, and a third clamping plate layer attached to the upper surface of the first clamping plate layer. The indoor wooden door is formed by fixing the clamping plate assembly, the solid boards and the decoration layers through the door frame. The structure of an existing indoorwooden door can be simplified; meanwhile, primary sound insulation can be conducted through a sound absorption cotton layer, secondary sound insulation can be conducted through the clamping plate assembly, the sound insulation effect of the indoor wooden door can be improved, an asbestos board in the clamping plate assembly has the advantages of being good in fiber toughness, good in tensile stress resistance performance and high in temperature tolerance value, and the service life of the indoor wooden door can be prolonged.

Owner:石纯满

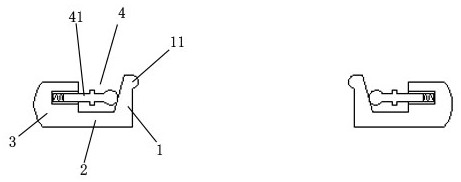

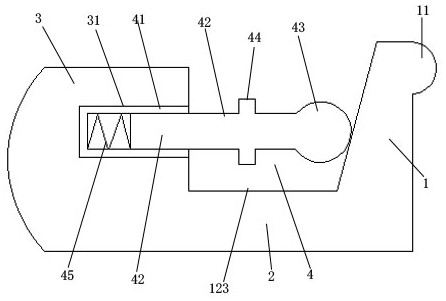

Rubber sealing device for pressure increasing valve of automobile brake device

InactiveCN112539276AImprove extrusion strengthImprove sealingEngine sealsMechanical engineeringEngineering

The invention discloses a rubber sealing device for a pressure increasing valve of an automobile brake device. The rubber sealing device comprises an outer side sealing ring body, an inner side adjusting ring body, a bottom connecting ring body and a rotary adjusting mechanism. For the rubber sealing device disclosed by the invention, a whole sealing main body is composed of the outer side sealingring body, the inner side adjusting ring body and the bottom connecting ring body, and the bottom connecting ring body is connected to the lower end between the outer side sealing ring body and the inner side adjusting ring body, so that the outer side sealing ring body, the inner side adjusting ring body and the bottom connecting ring body can define an adjusting annular groove; the adjusting annular groove enables radial extrusion strengths of the outer side sealing ring body and the inner side adjusting ring body to get an adjusting space; and an adjusting threaded column drives an abutting head to extrude the inner side adjusting ring body by rotating the adjusting threaded column, so that the outward extrusion strengths of the outer side sealing ring body and the inner side adjustingring body are improved, and then the sealing effect is greatly improved.

Owner:江苏德立密封科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com