LCD panel manufacturing method

A technology for a liquid crystal panel and a manufacturing method, applied in nonlinear optics, instruments, optics, etc., can solve problems such as low panel extrusion strength, and achieve the effect of improving extrusion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

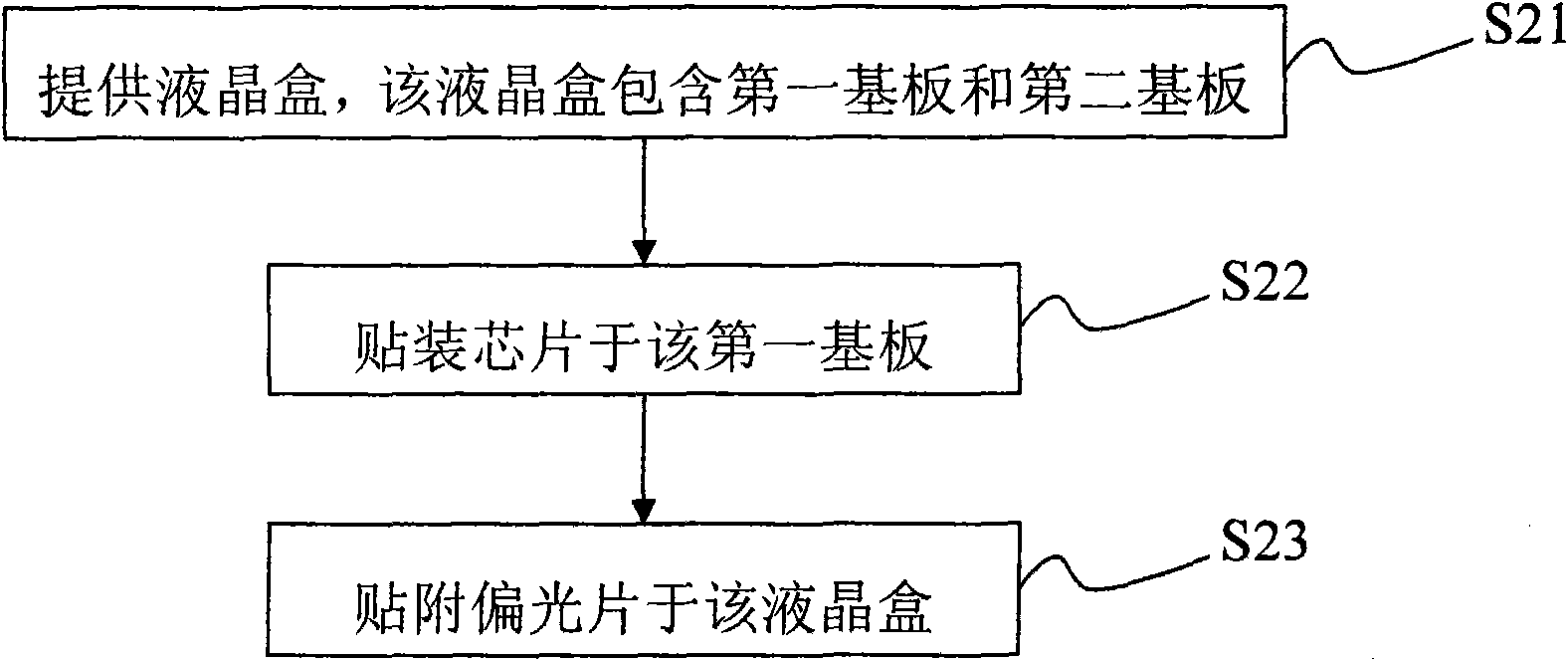

[0018] See image 3 , image 3 It is a flowchart of a method for manufacturing a liquid crystal panel according to an embodiment of the present invention. The manufacturing method of the liquid crystal panel includes the following steps. S21, providing a liquid crystal cell, where the liquid crystal cell includes a first substrate and a second substrate. S22, mounting chips on the first substrate. S23, attaching a polarizer to the liquid crystal cell. In one embodiment, the first substrate has a thin film transistor array, and the second substrate has a color filter layer. Before the step of mounting the chip on the first substrate, other steps may also be included, such as laser cutting, cleaning the end face of the liquid crystal cell, and the like. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com