Indoor wooden door with sound insulation and squeezing resistance functions

An extrusion-resistant, wooden door technology, which is applied in the direction of soundproof doors/windows, door leaves, windows/doors, etc., can solve the problem of increased difficulty in assembly and processing of indoor wooden doors, poor toughness and resistance to stretching and extrusion, and affects user experience To achieve the effect of improving thermal insulation effect and sound insulation effect, improving flame retardant and heat insulation performance, and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

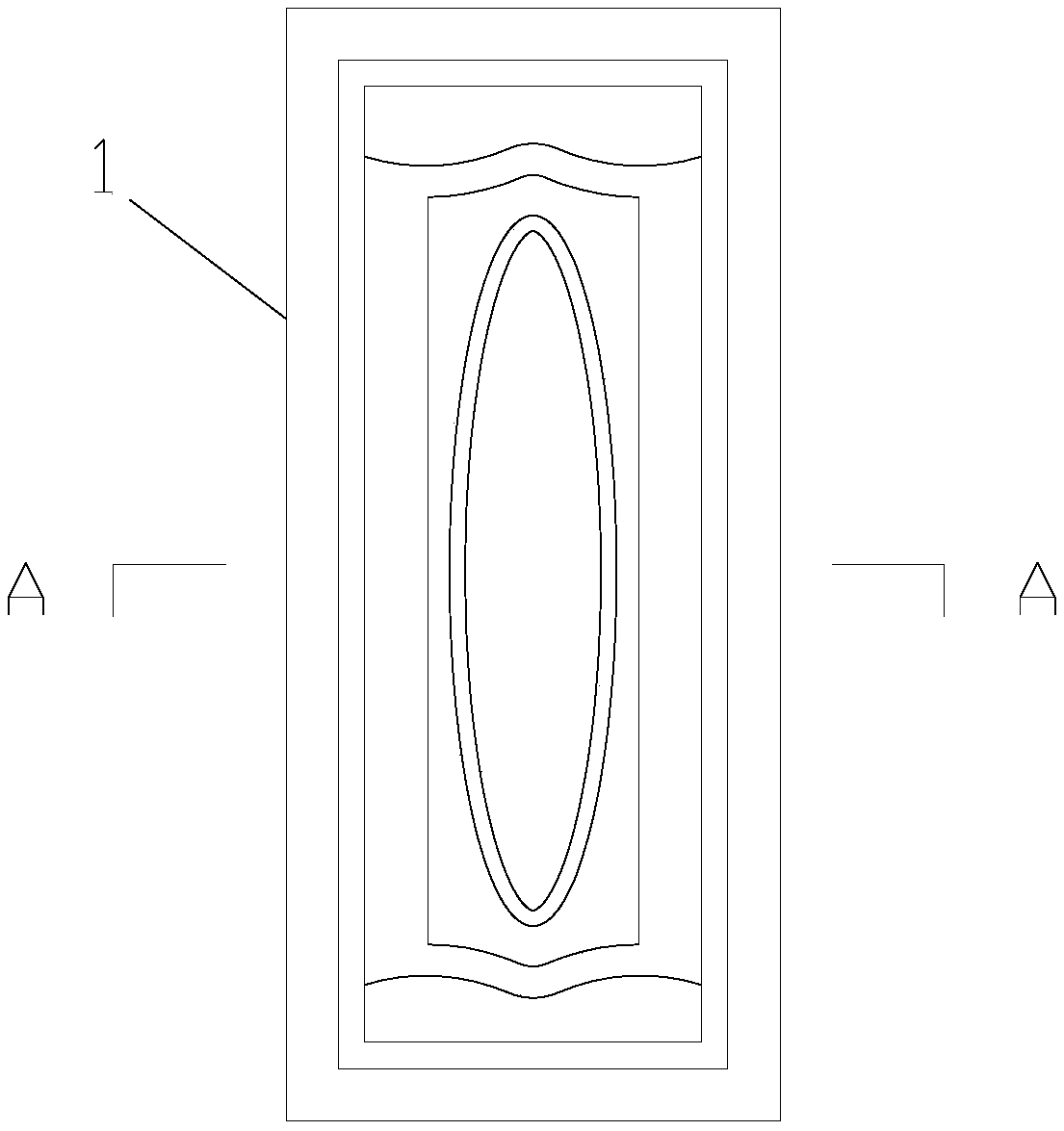

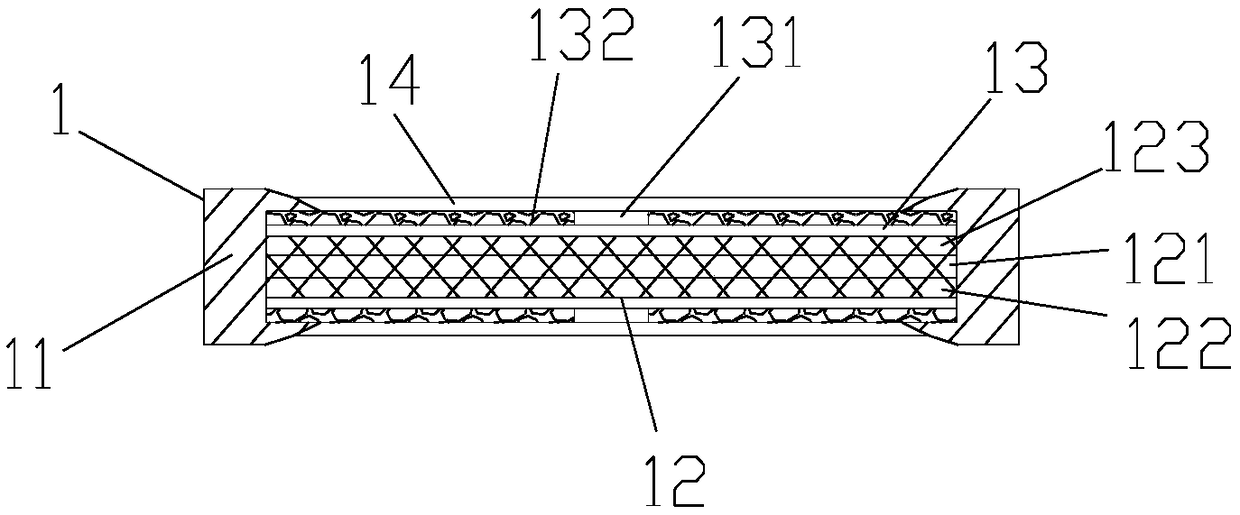

[0029] A sound-insulating and extrusion-resistant interior wooden door, such as figure 1 Shown, comprise wooden door body 1. like figure 2 As shown, the wooden door body 1 includes a door frame 11, and a splint group 12 arranged in the door frame 11 for enhancing the sound insulation and extrusion resistance of the wooden door body 1, and arranged on both sides of the splint group 12, and The solid wood board 13 that is connected with the plywood group 12 by screws to prevent the plywood group 12 from loosening, and the decorative layer 14 that is arranged on the outer surface of the solid wood board 13 and is used to cover the wooden door body 1 . The inner side of the door frame 11 is recessed inwardly, and the door frame bodies on both sides of the recess are rounded. The plywood group 12 includes a first plywood layer 121, and a second plywood layer 122 connected to the lower surface of the first plywood layer 121 by screws after bonding, and connected to the first plyw...

Embodiment 2

[0042] A sound-insulating and extrusion-resistant interior wooden door, such as figure 1 Shown, comprise wooden door body 1. Such as figure 2 As shown, the wooden door body 1 includes a door frame 11, and a splint group 12 arranged in the door frame 11 for enhancing the sound insulation and extrusion resistance of the wooden door body 1, and arranged on both sides of the splint group 12, and The solid wood board 13 that is connected with the plywood group 12 by screws to prevent the plywood group 12 from loosening, and the decorative layer 14 that is arranged on the outer surface of the solid wood board 13 and is used to cover the wooden door body 1 . The inner side of the door frame 11 is recessed inwardly, and the door frame bodies on both sides of the recess are rounded. The plywood group 12 includes a first plywood layer 121, and a second plywood layer 122 connected to the lower surface of the first plywood layer 121 by screws after bonding, and connected to the first p...

Embodiment 3

[0055] A sound-insulating and extrusion-resistant interior wooden door, such as figure 1 Shown, comprise wooden door body 1. Such as figure 2 As shown, the wooden door body 1 includes a door frame 11, and a splint group 12 arranged in the door frame 11 for enhancing the sound insulation and extrusion resistance of the wooden door body 1, and arranged on both sides of the splint group 12, and The solid wood board 13 that is connected with the plywood group 12 by screws to prevent the plywood group 12 from loosening, and the decorative layer 14 that is arranged on the outer surface of the solid wood board 13 and is used to cover the wooden door body 1 . The inner side of the door frame 11 is recessed inwardly, and the door frame bodies on both sides of the recess are rounded. The plywood group 12 includes a first plywood layer 121, and a second plywood layer 122 connected to the lower surface of the first plywood layer 121 by screws after bonding, and connected to the first p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com