Wear-resistant tooth roll shell for roll crusher

A technology of roller crushers and toothed rollers, which is applied in the direction of grain processing, etc., can solve the problems of asynchronous wear rate of roller teeth and roller sleeves, reduced service life of roller crushers, chipping and wear of roller teeth, and achieves High impact strength, high wear resistance and hardness, enhanced wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

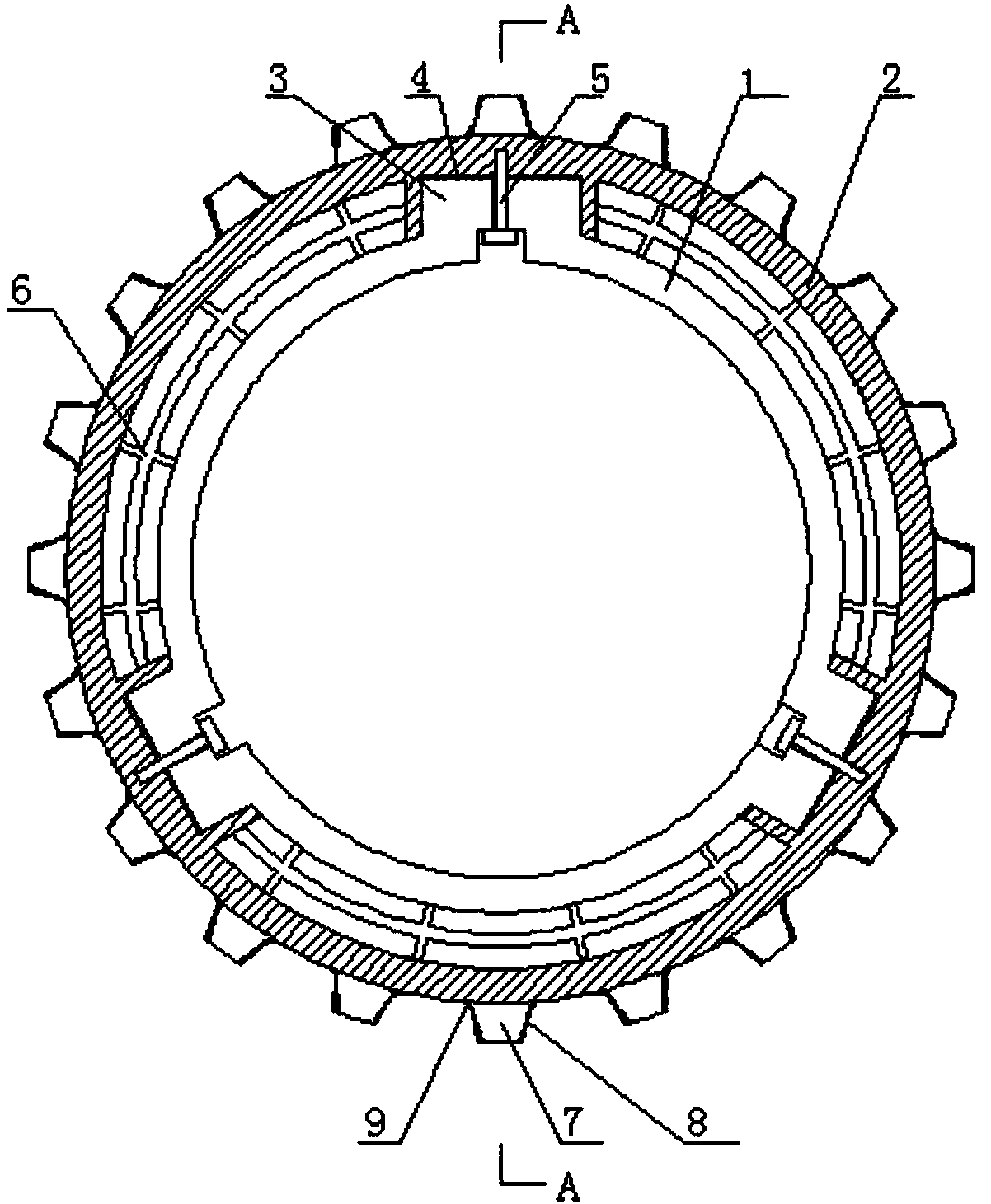

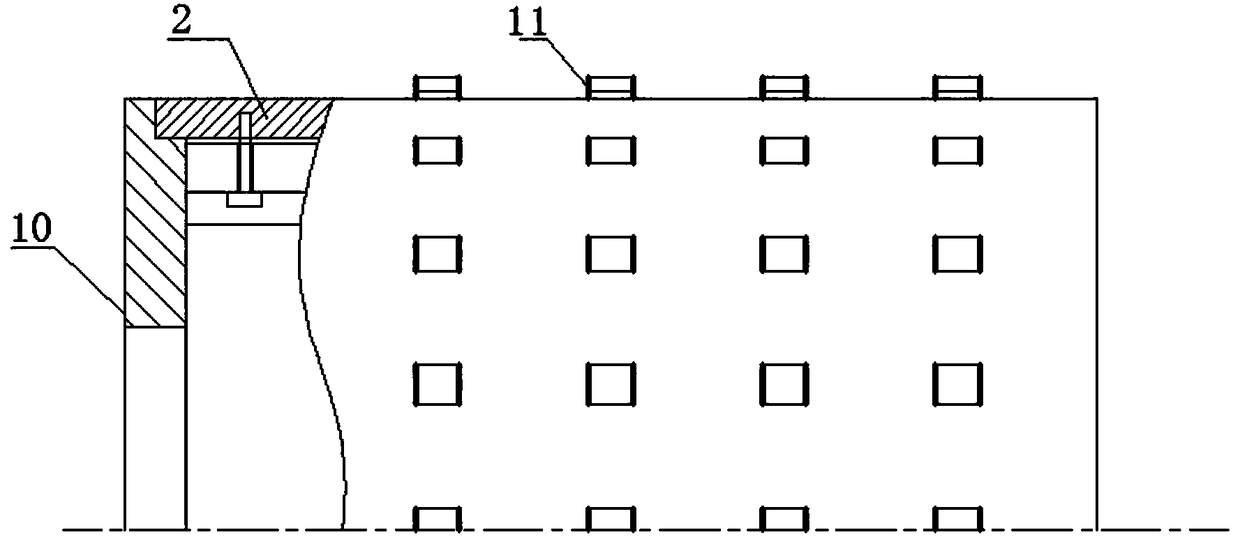

[0021] Such as figure 1 and figure 2 As shown in the figure, a wear-resistant toothed roller sleeve of a roller crusher is composed of a roller core (1) and a roller sleeve (2) from the inside to the outside. The roller sleeve (2) is set on the roller core (1), and Stay on-axis. A plurality of rings of roller teeth (7) are radially distributed on the outer peripheral surface of the roller sleeve (2), and each ring of roller teeth (7) is equidistantly arranged.

[0022] The roller core (1) includes a cylinder ring, which is used to be installed on the rotating shaft and kept relatively fixed; the outer surface of the cylinder ring is provided with three elongated bosses (3) in the axial direction , the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com