Screw extruder for plant straw dehydration

A screw extruder and plant straw technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of no extrusion dehydrator, etc., and achieve the effect of large detachment resistance, increased radial thickness, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

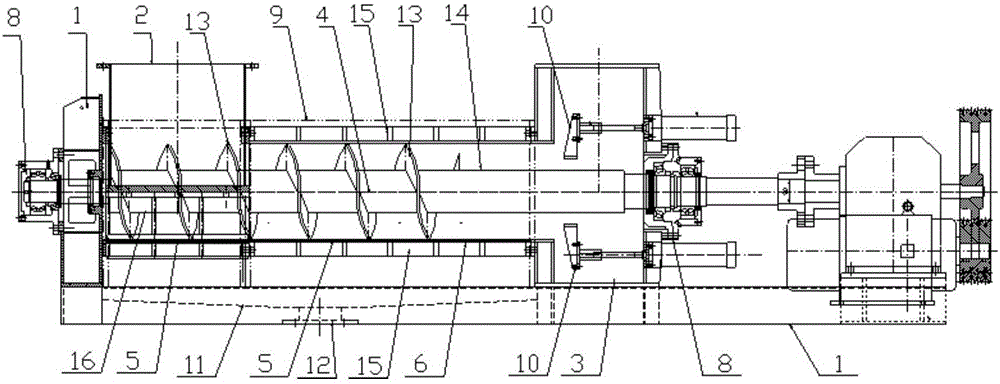

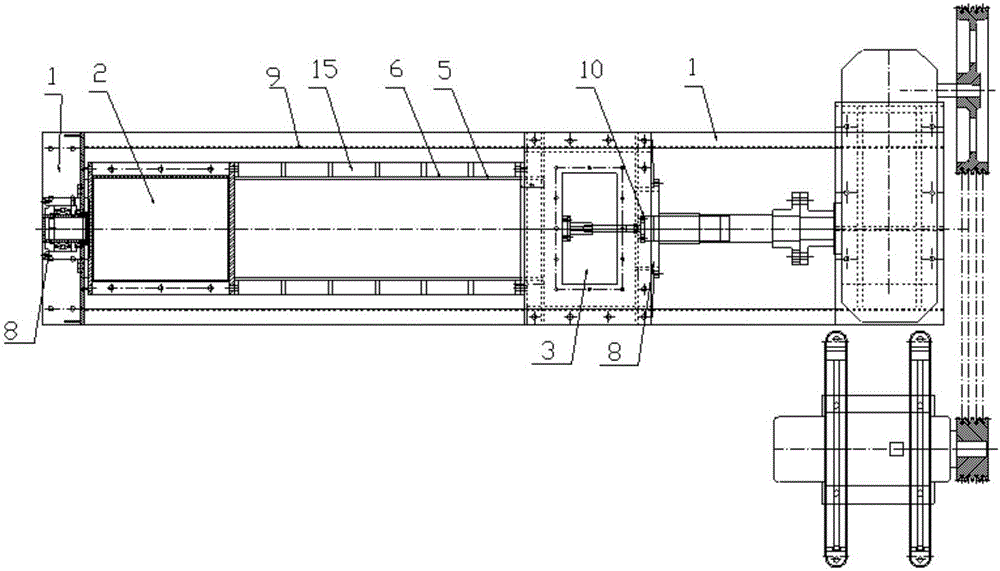

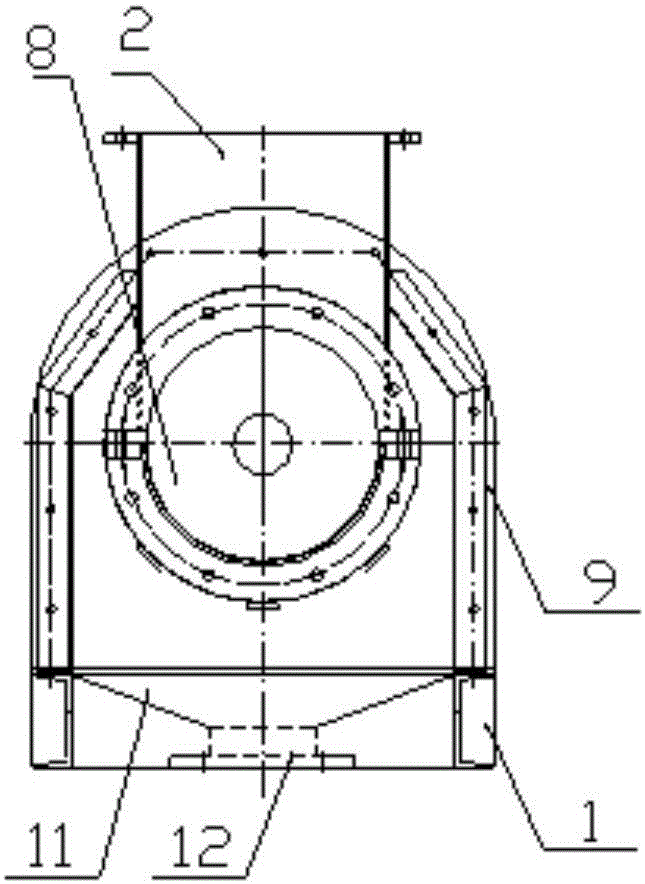

[0036] like Figure 1-Figure 3 Shown are the front view, top view and right side view of the screw extruder used for plant straw dehydration provided by the present invention respectively. As can be seen from the figure, the screw extruder of the present invention includes: frame 1; The screw main shaft on the top and rotates relative to the frame 1; the driving device for driving the rotation of the screw main shaft; the screen cylinder 15 located on the frame 1 and covered outside the screw main shaft; installed on the frame 1 and covered outside the screen cylinder 15 The sealing cover 9; the feed port 2 and the discharge port 3 arranged at the two ends of the frame 1; wherein, the screw spindle includes: a feed straight line located below the feed port 2 of the seal cover 9 for adapting to large fluctuations in the amount of feed Shaft section 16; the conveying section 4 connected to the end of the feed straight shaft section 16 for extruding and conveying materials; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com