Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Improve edging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Edging device applicable to glass in various shapes and glass edging method

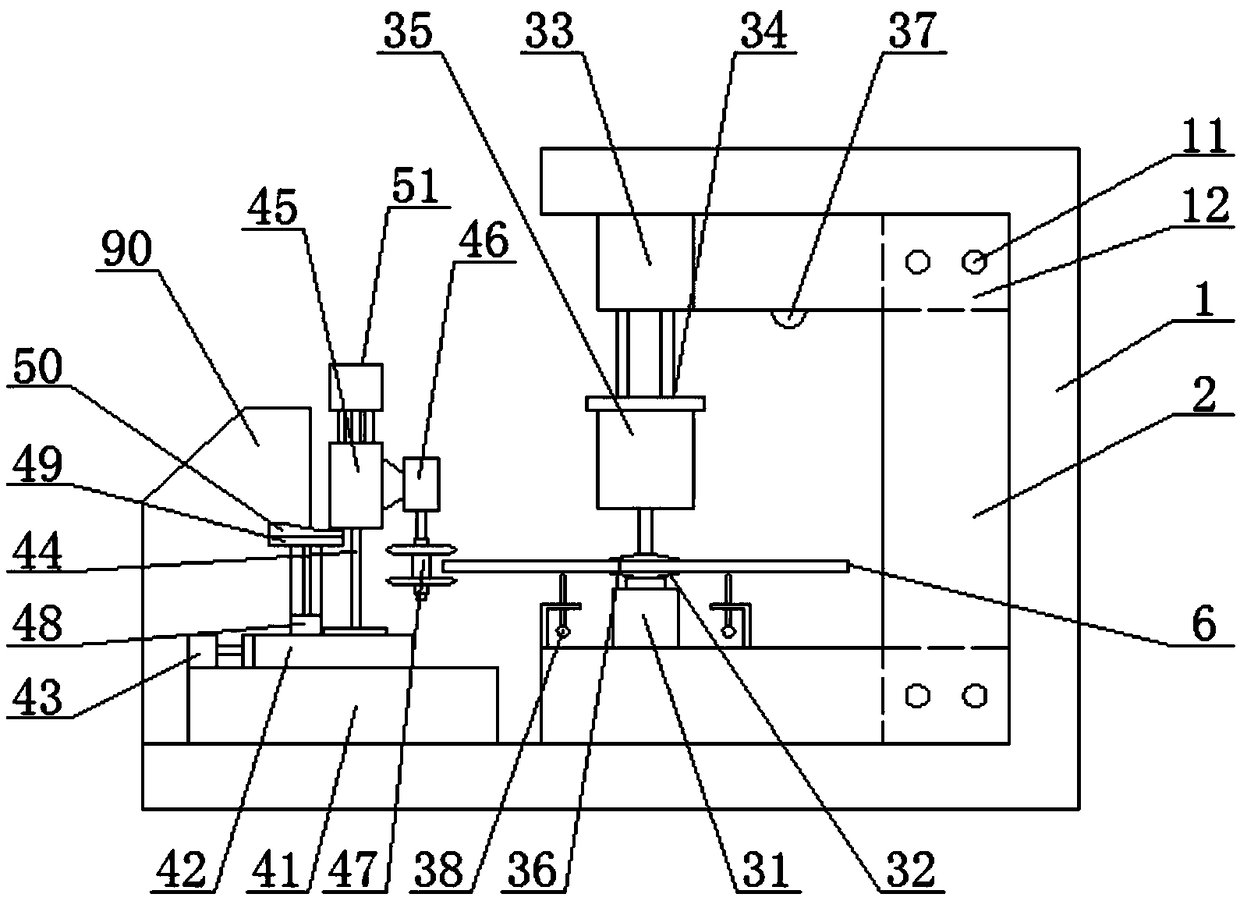

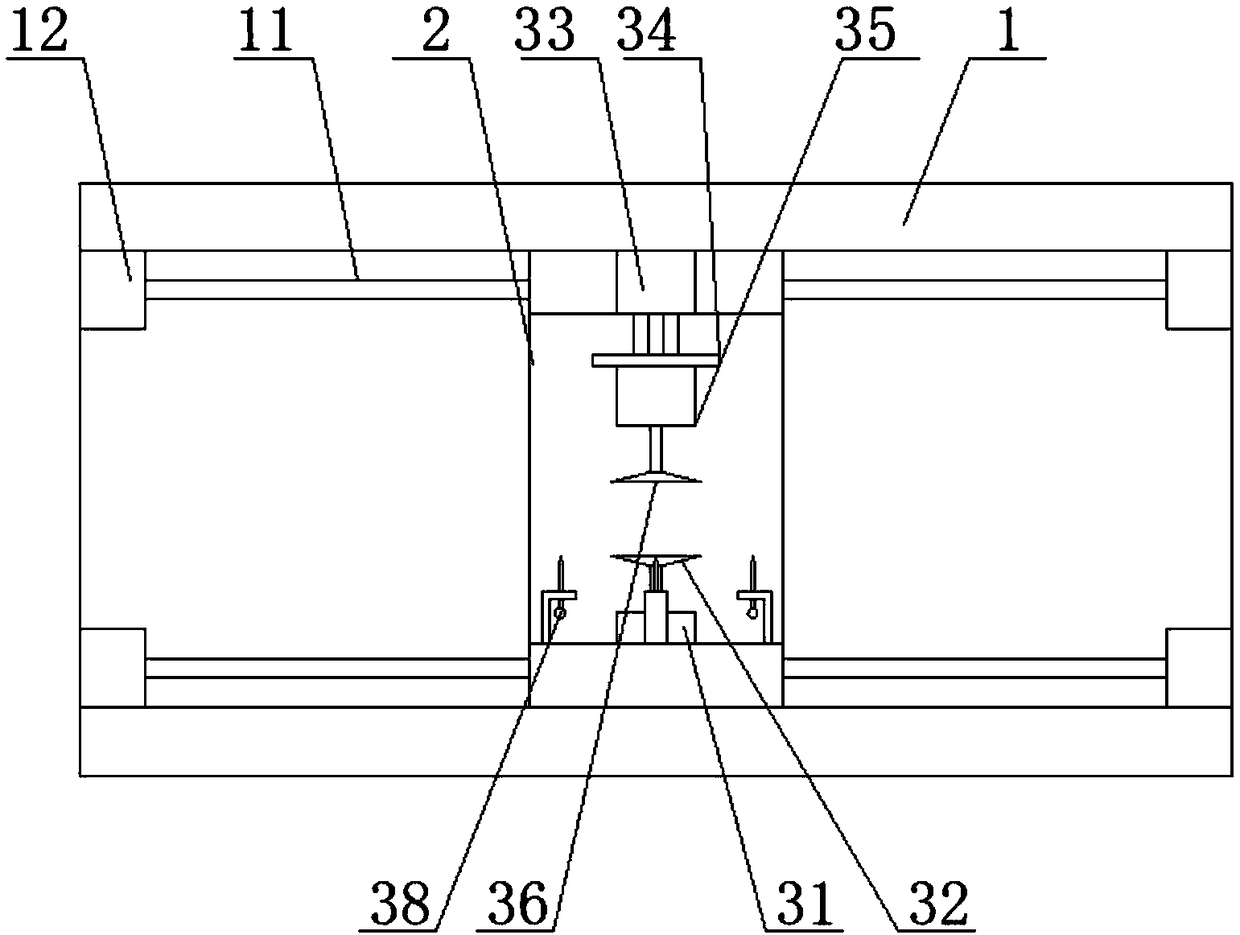

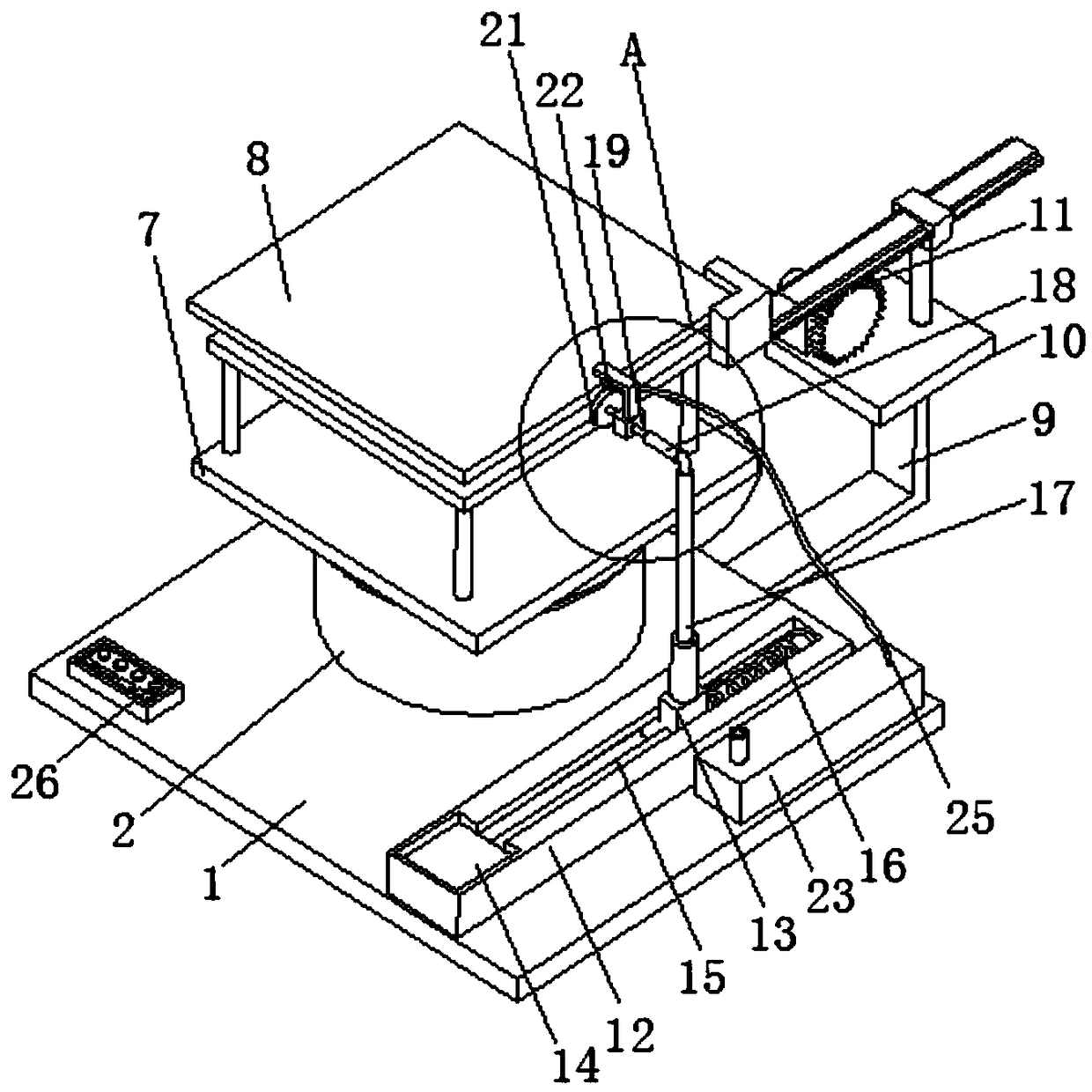

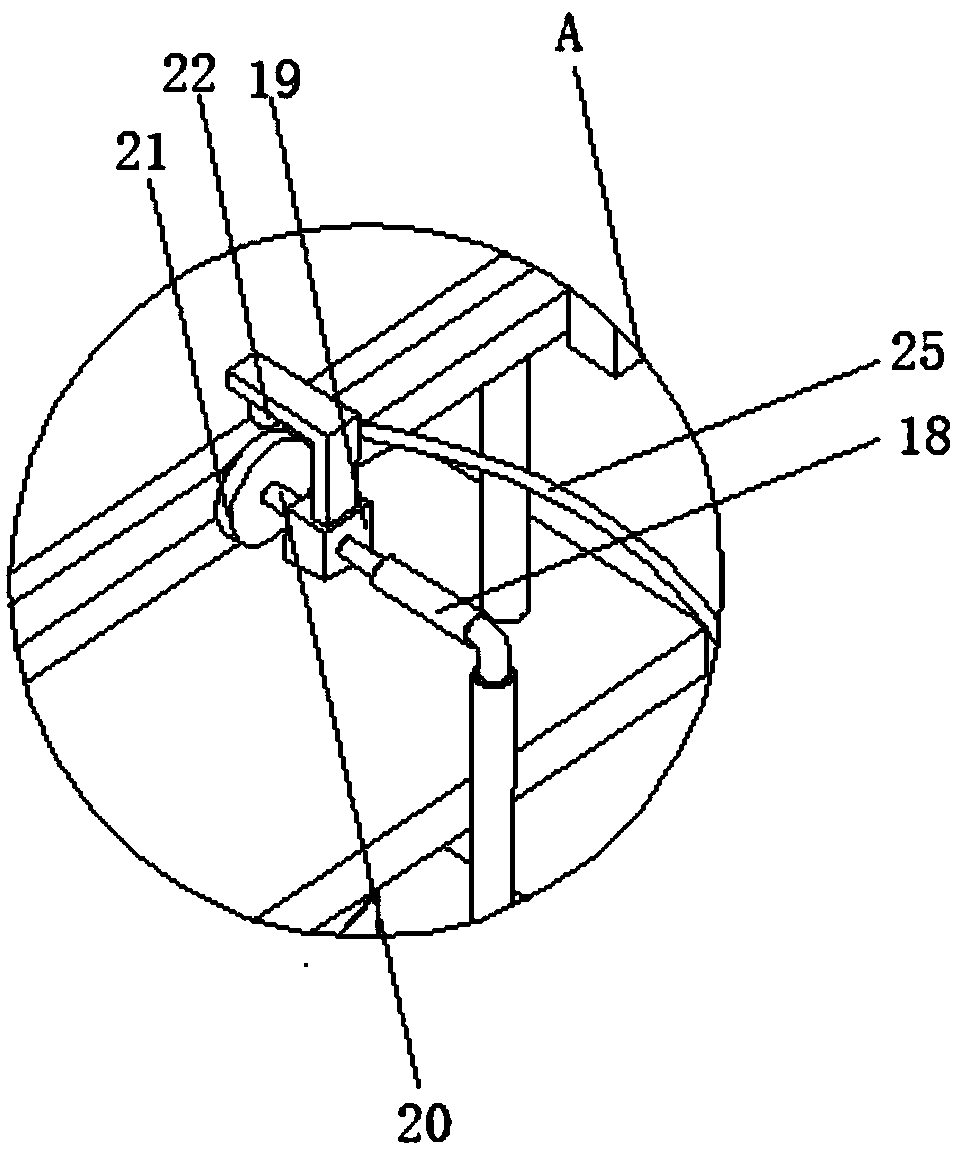

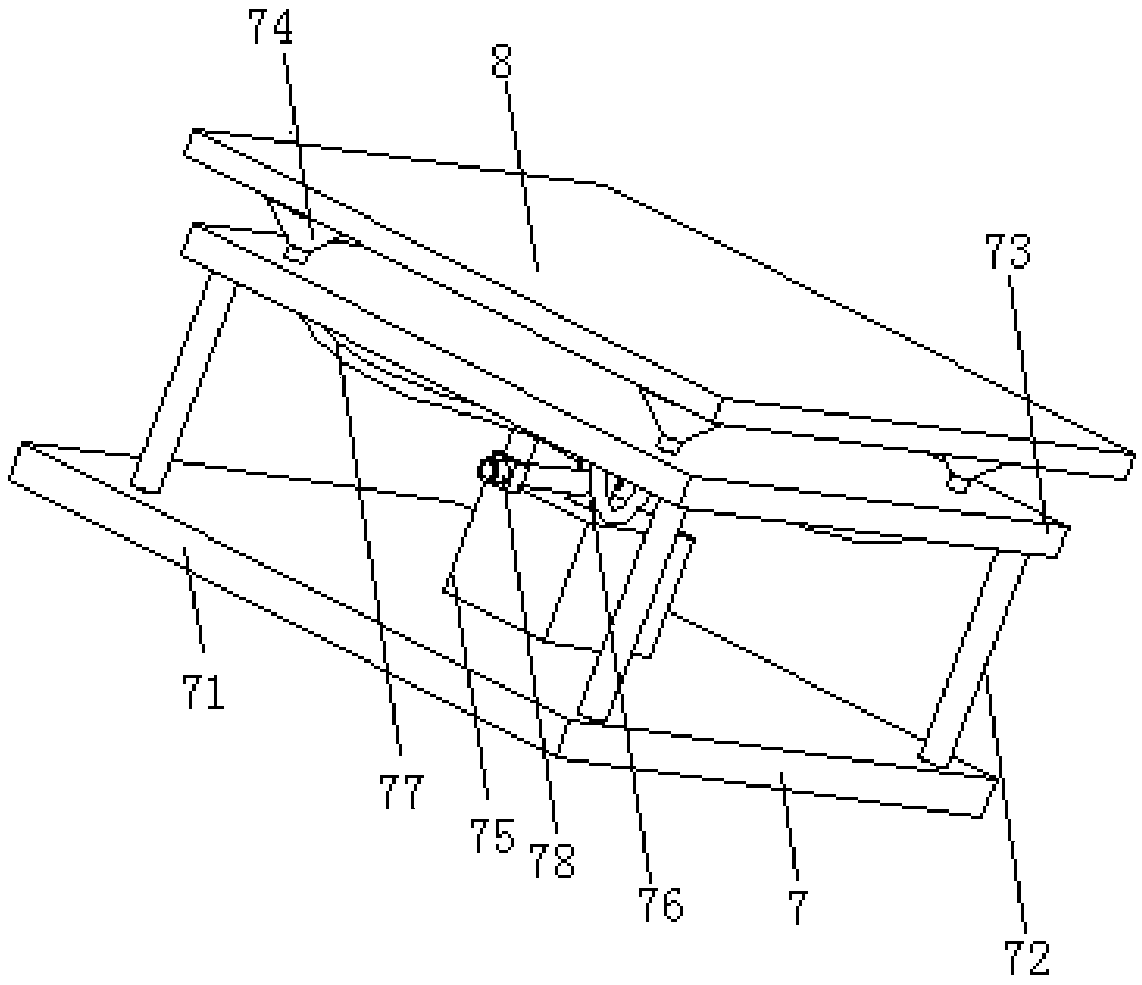

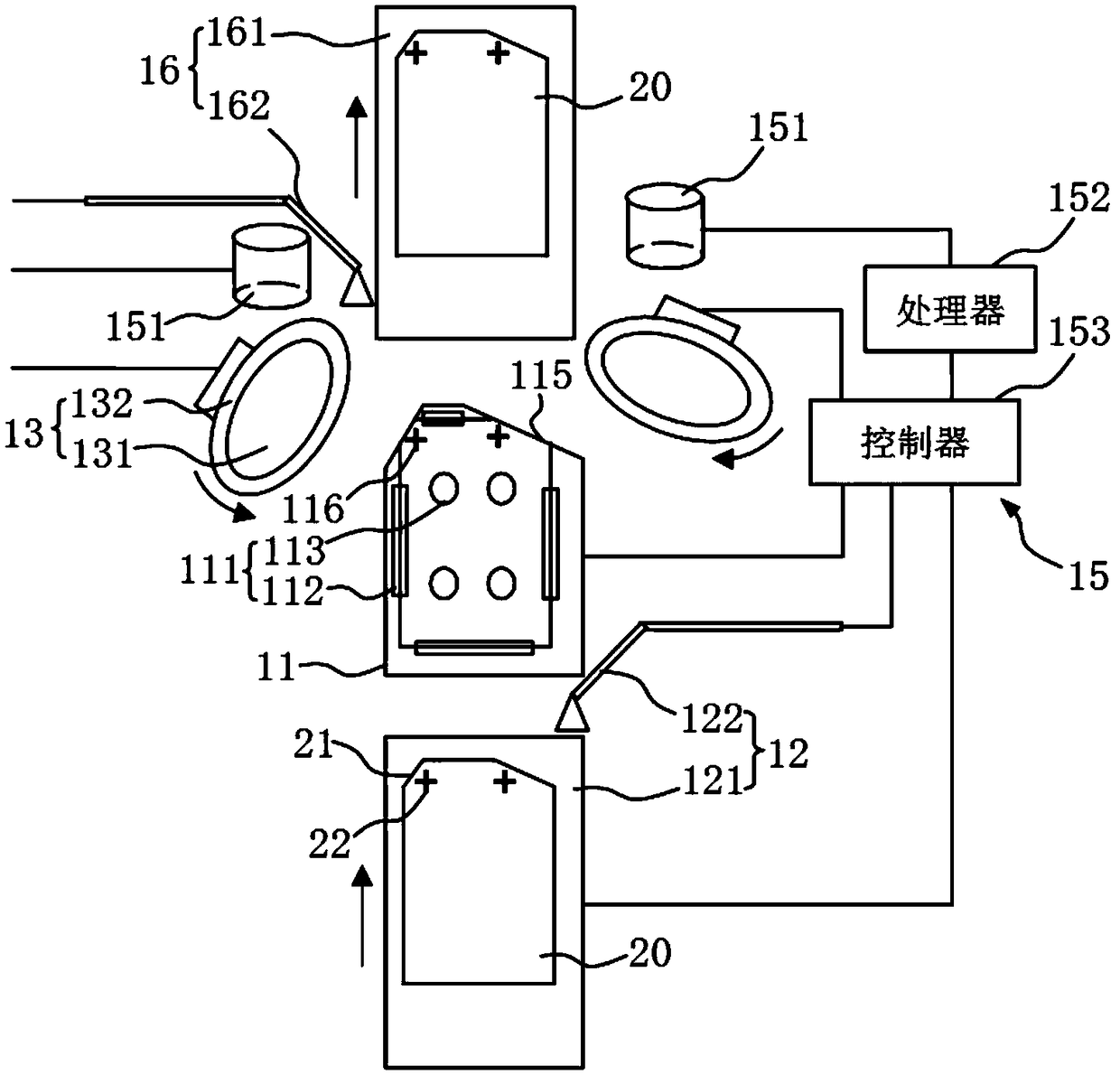

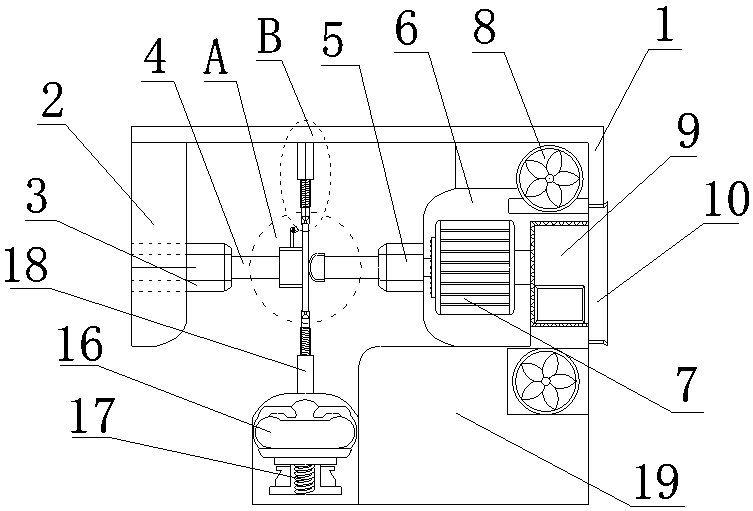

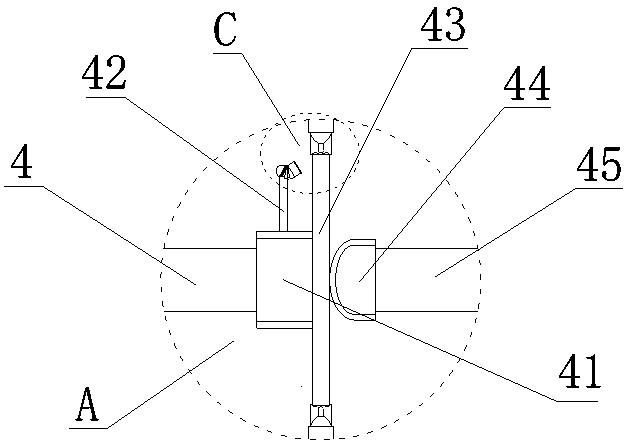

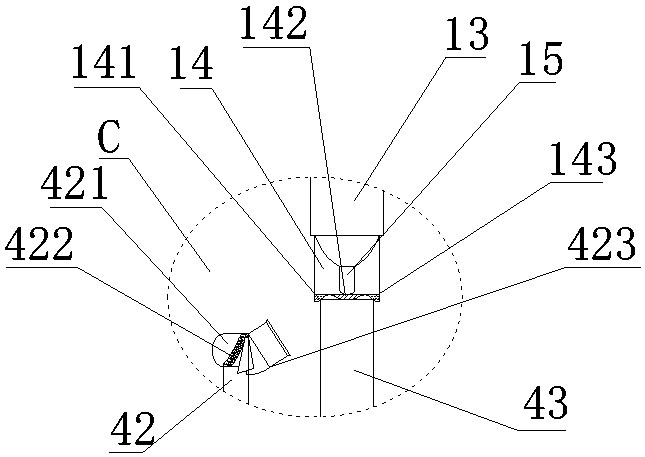

The invention relates to an edging device applicable to glass in various shapes and a glass edging method. The device comprises a case, a clamping mechanism, an edging mechanism and a control system;the clamping mechanism is mounted in the case, is used for clamping the glass and can enable the glass to move left and right and to rotate through the control system; the edging mechanism is used foredging the upper corners, the lower corners and outer rings of the glass simultaneously and can move back and forth through the control system; and the edging mechanism can fluctuate up and down according to laws. The glass is photographed through a camera and modeled, proper edging procedures are selected according to a modeled structure through the control system, then edging of the glass in various shapes can be achieved through the device, the equipment cost is reduced, moreover, the edging device provided by the invention simulates the manual edging mode, the edging effect is better, automatic operation is adopted, and the efficiency is higher.

Owner:湖州精耕农机有限公司

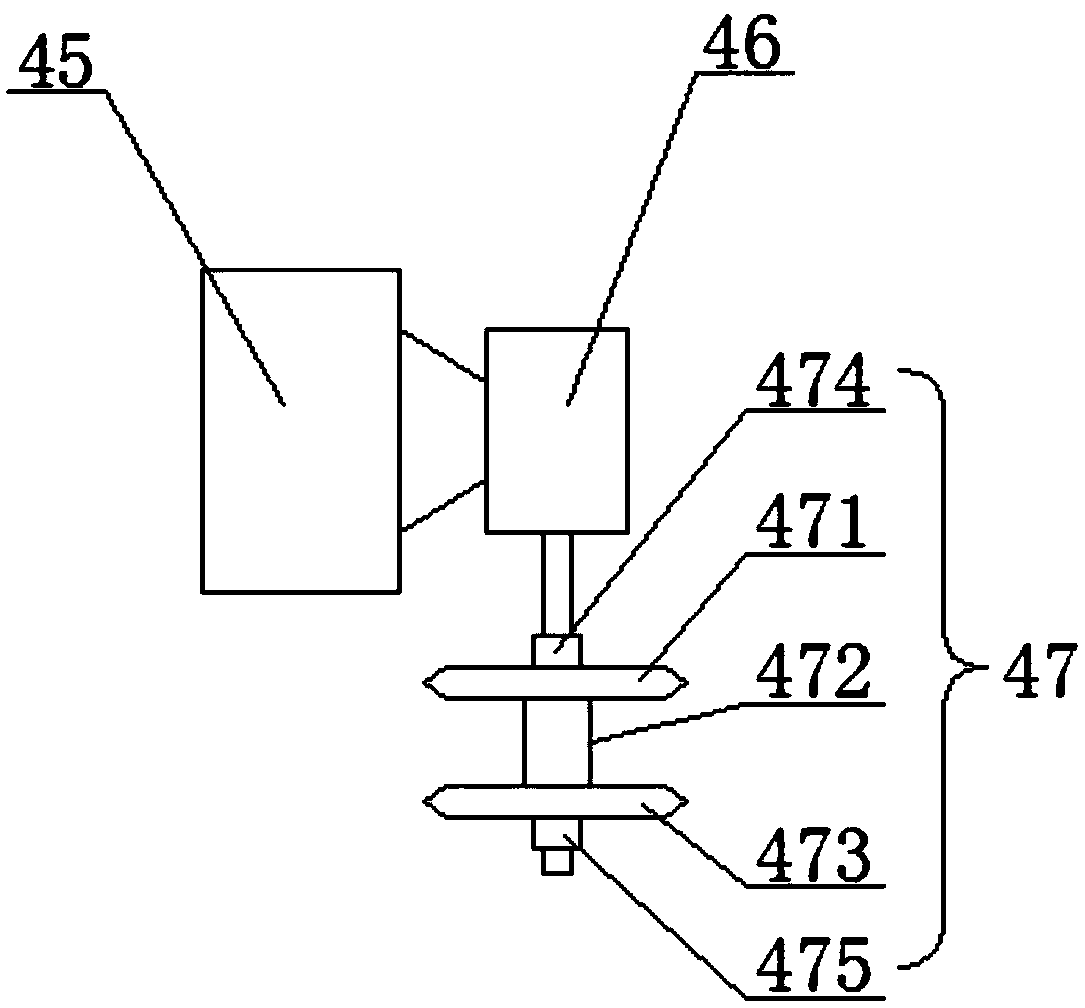

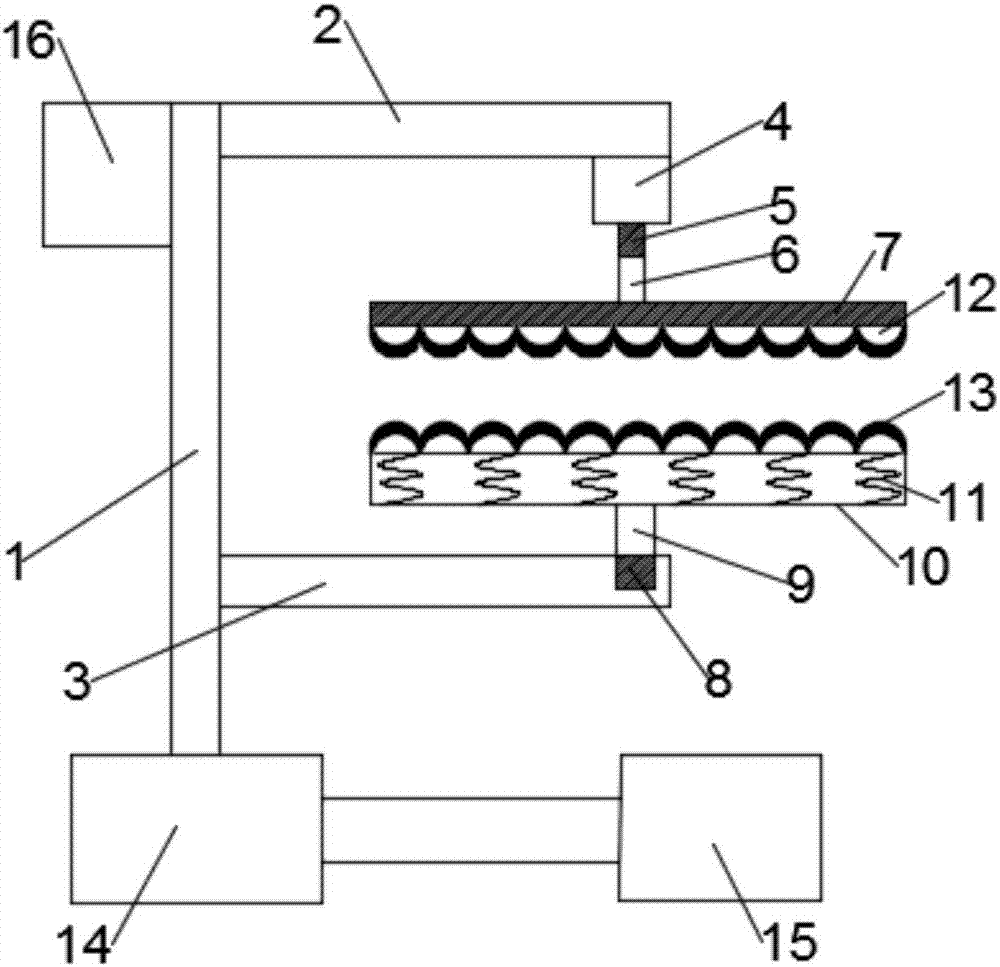

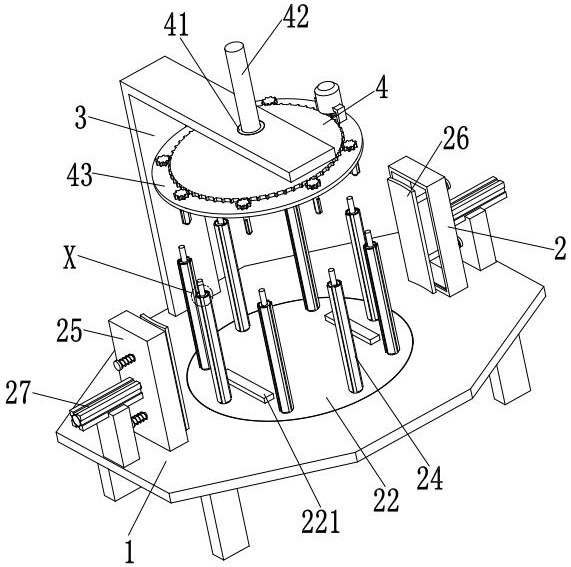

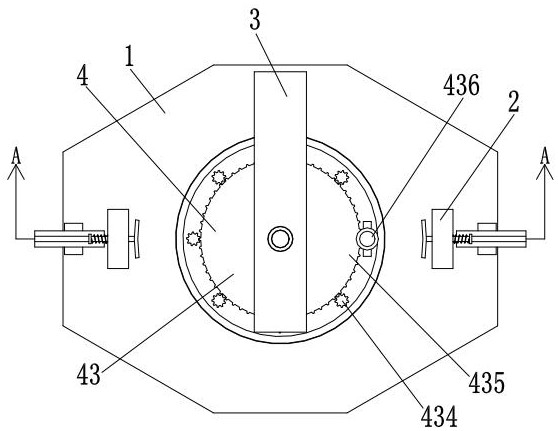

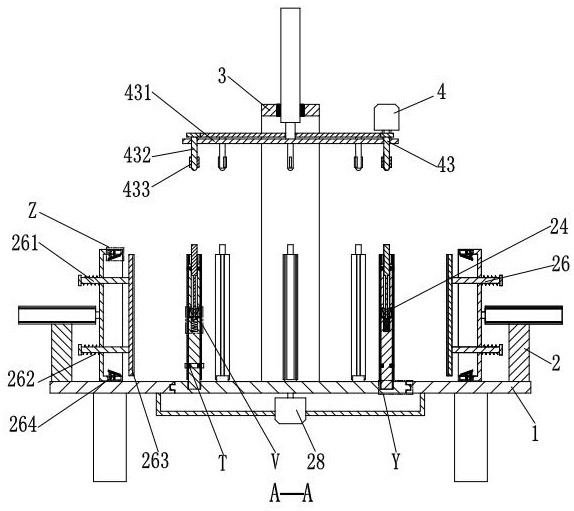

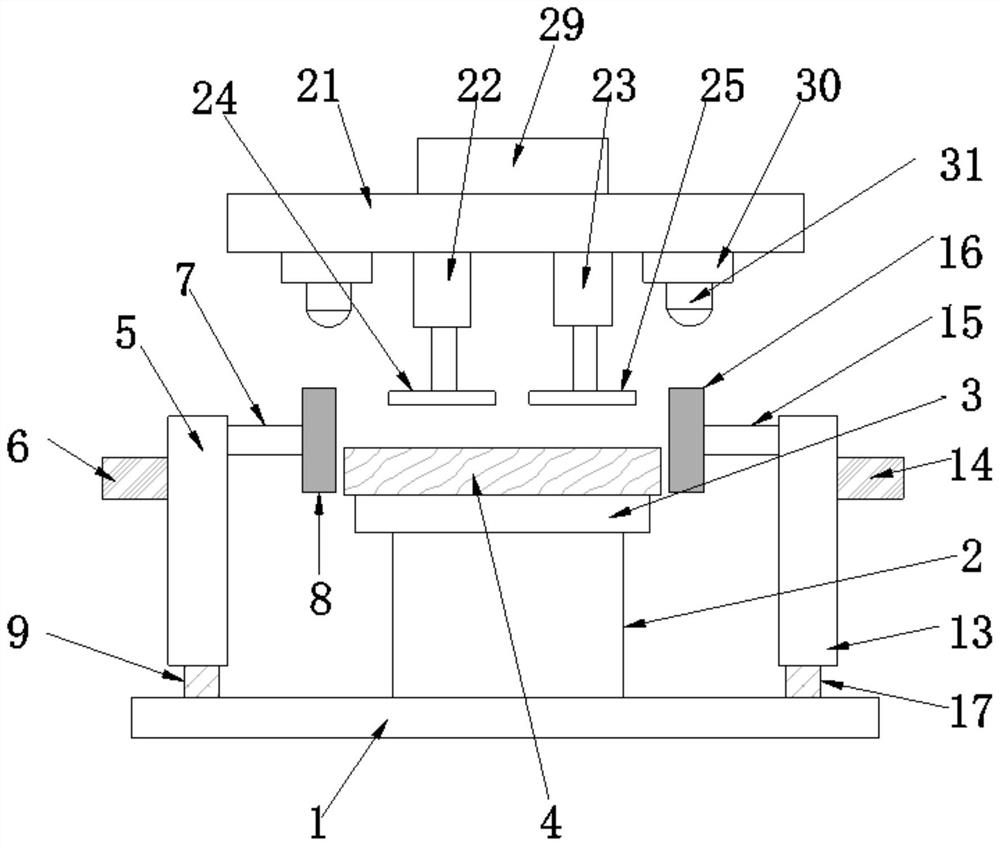

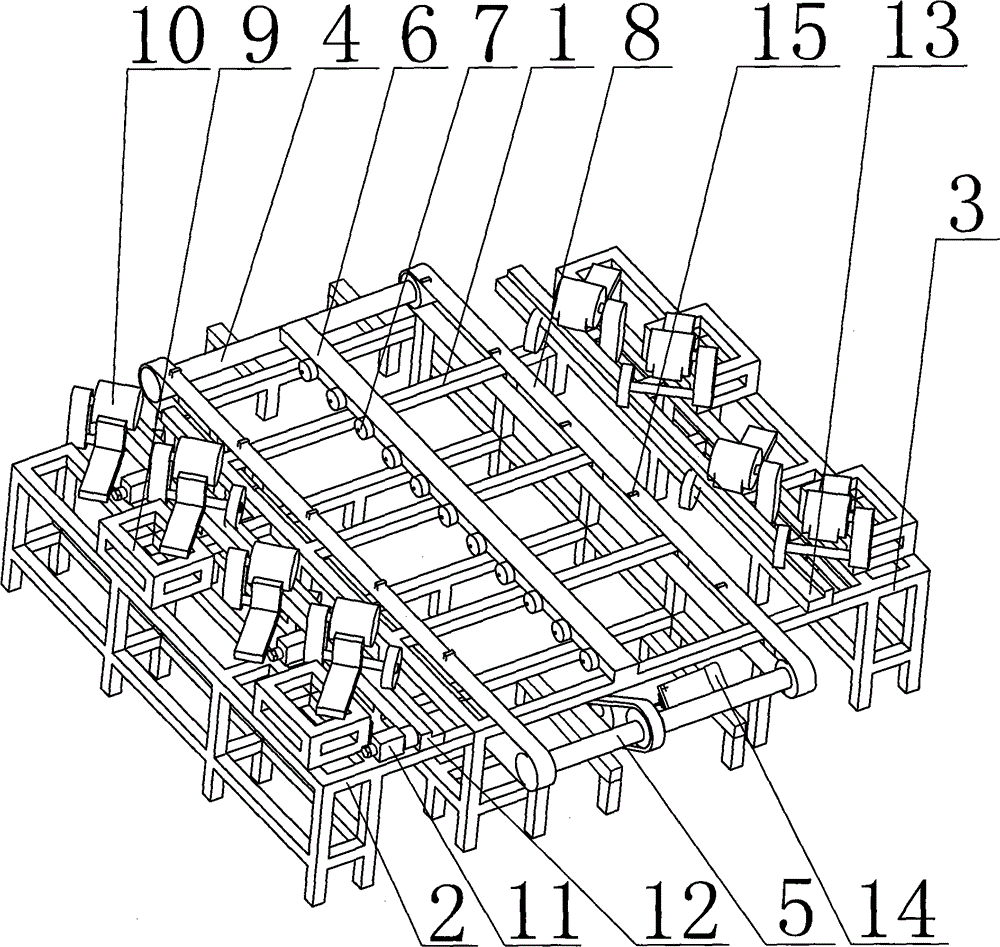

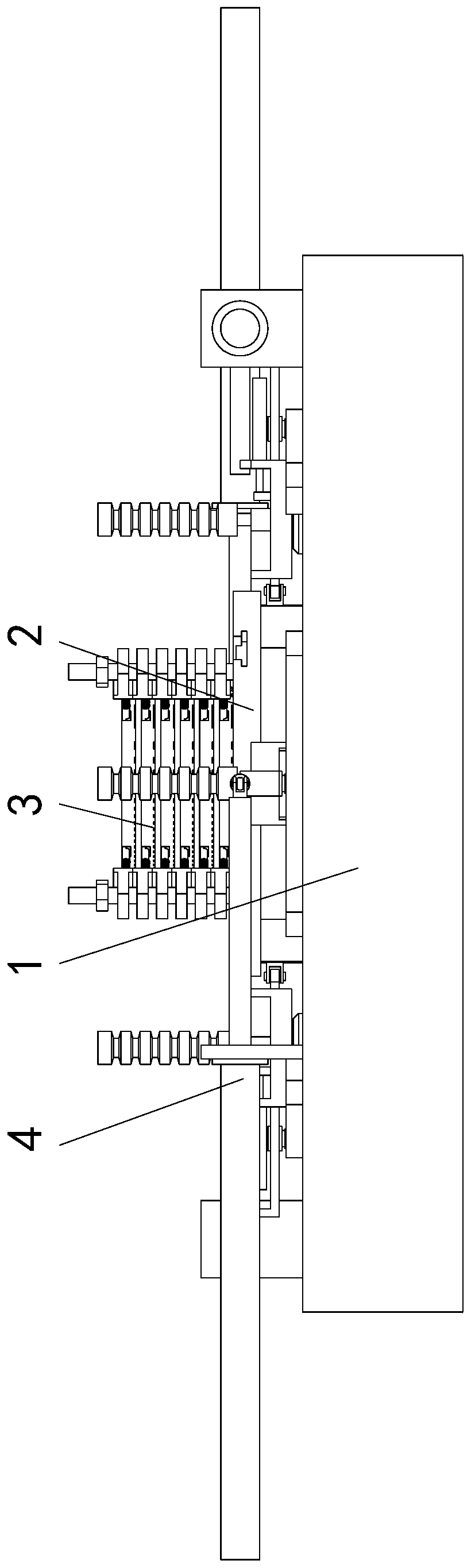

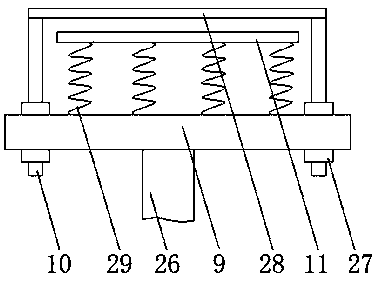

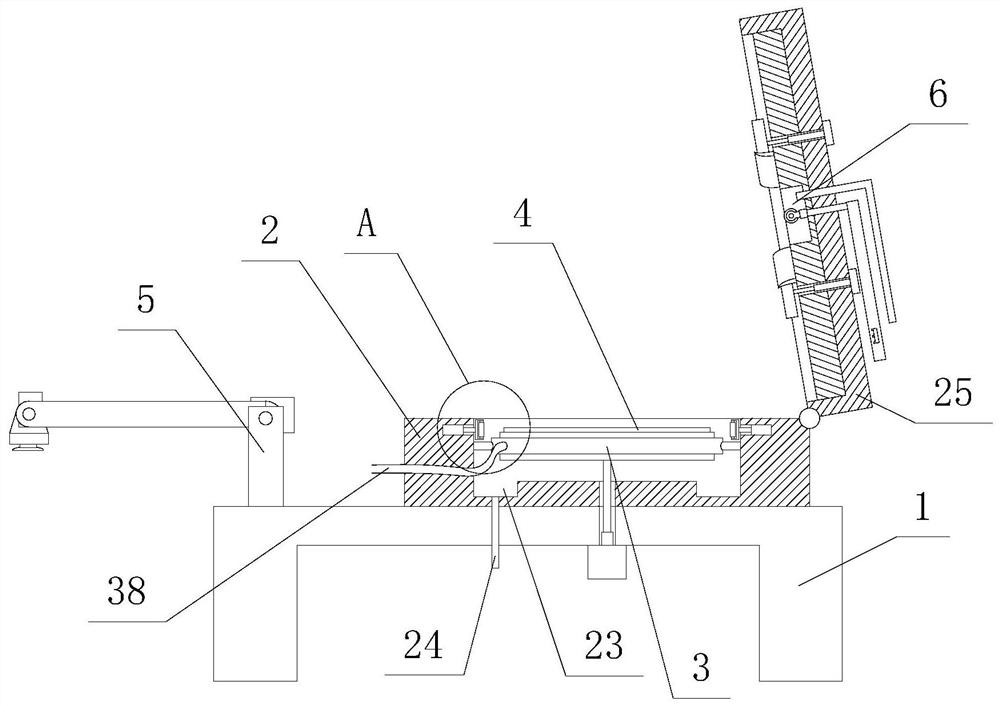

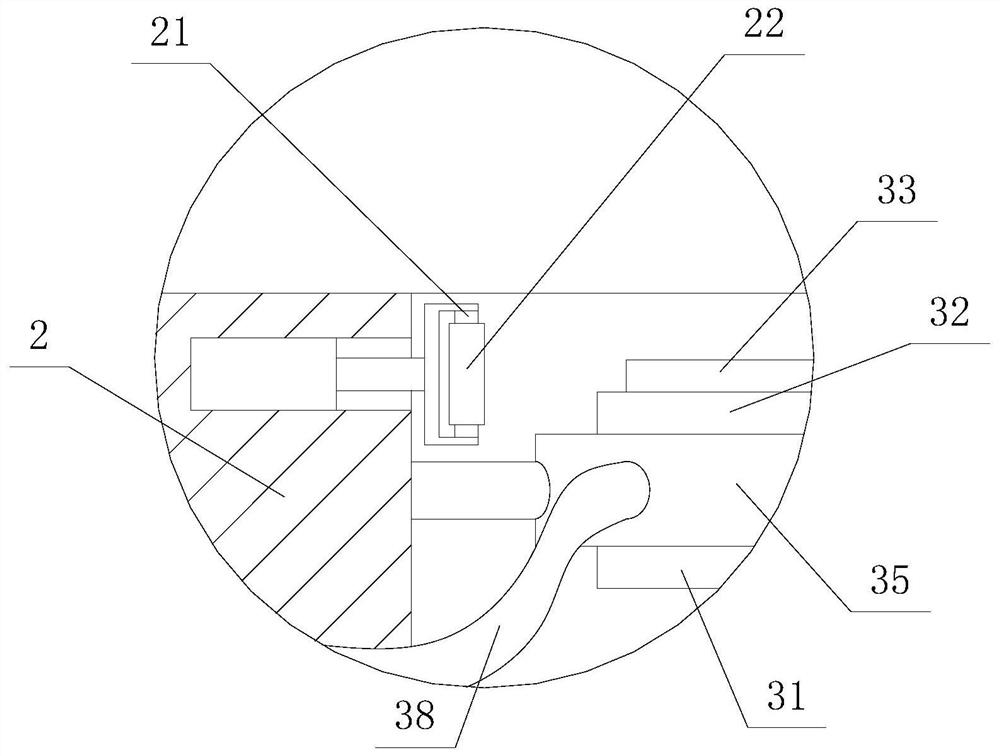

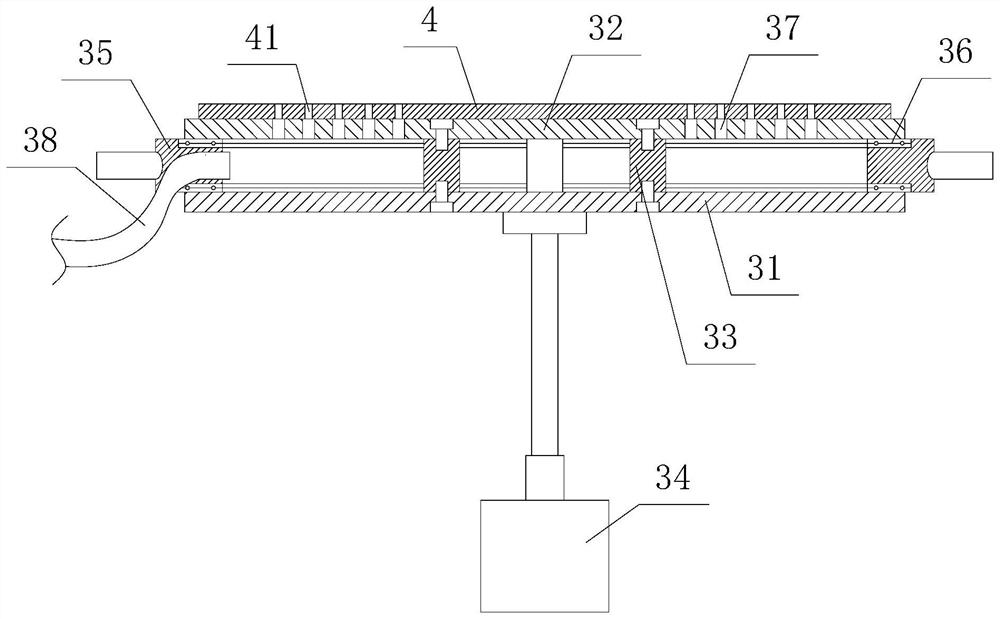

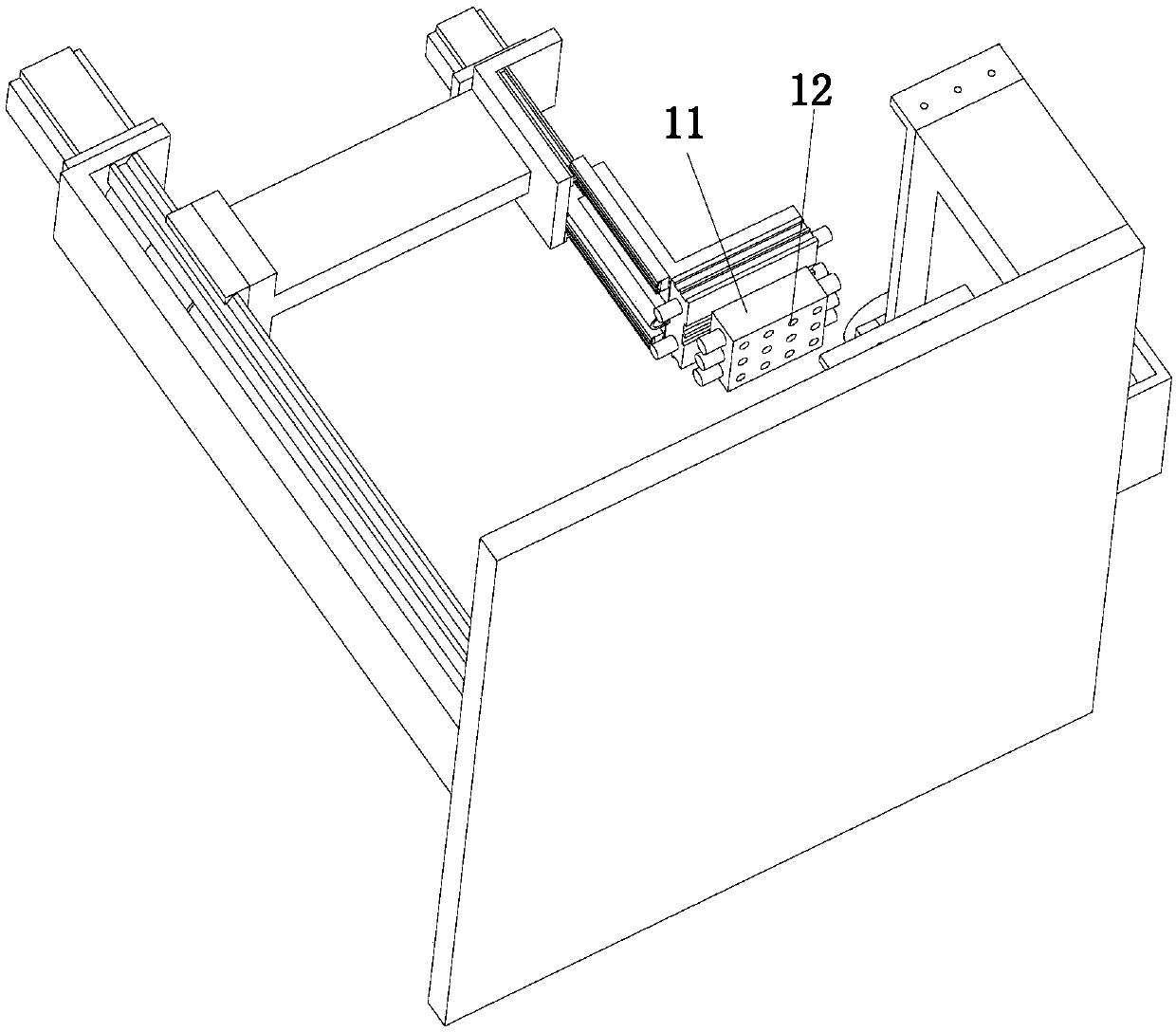

Clamping mechanism for automatic glass edger

InactiveCN107378771ASmooth rotationHigh degree of automationEdge grinding machinesGrinding drivesEngineeringMechanical engineering

The invention discloses a clamping mechanism for an automatic glass edging machine, which includes a bracket. The side of the bracket is fixedly connected with a first support rod and a second support rod. The first support rod is located directly above the second support rod. The other end of the support rod is connected with a stepper motor, the stepper motor includes an output shaft, the output shaft is vertically arranged downwards, the bottom end of the output shaft is connected with a telescopic rod, the bottom end of the telescopic rod is connected with a first clamping plate, and the bottom end of the telescopic rod is connected with a first clamping plate. The other end of the two support rods is provided with a rotating groove, and a rotating shaft is installed in the rotating groove, and the other end of the rotating shaft extends out of the rotating groove, and the top of the rotating shaft is connected with a second clamping plate, and the second clamping plate is Double-layer hollow structure, the inside of the second clamping plate is equipped with several shock-absorbing springs, this device can realize the rotation of the glass during edging easier and with a higher degree of automation, and at the same time make the clamping of the glass more stable, so that the glass does not There will be looseness or offset, which improves the quality of glass edging and is worth promoting.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Adjustable glass edge-grinding machine

InactiveCN109176219ARapid positioningGuarantee the quality of edgingEdge grinding machinesAutomatic grinding controlCouplingPulp and paper industry

The invention discloses an adjustable glass edge-grinding machine, which comprises a bottom plate. A cylinder is arranged in the middle of the upper end of the bottom plate, a rotating motor is arranged at the cylinder bottom of the cylinder, and an output shaft at the upper end of the rotating motor is fixedly connected with the bottom end of a rotating shaft through a coupling; a rotating disc is arranged at the top end of the rotating shaft, and an annular sliding block is arranged on the bottom face of the rotating disc and slidably connected with an annular groove in the upper end of thecylinder; and a fixing device is arranged at the upper end of the rotating disc, and a glass body is arranged at the upper ends of suction cups in the fixing device. The adjustable glass edge-grindingmachine is convenient to operate and complete in function and brings great convenience to using of a user; and edge-grinding glass is fixed firmly and positioned rapidly through the fixing device anda positioning device according to the using demands, the edge-grinding quality of the glass is ensured, the working burden of personnel is relieved, the labor expenditure cost is saved, and the edge-grinding efficiency of the glass is improved.

Owner:安徽玻扬节能钢化玻璃有限公司

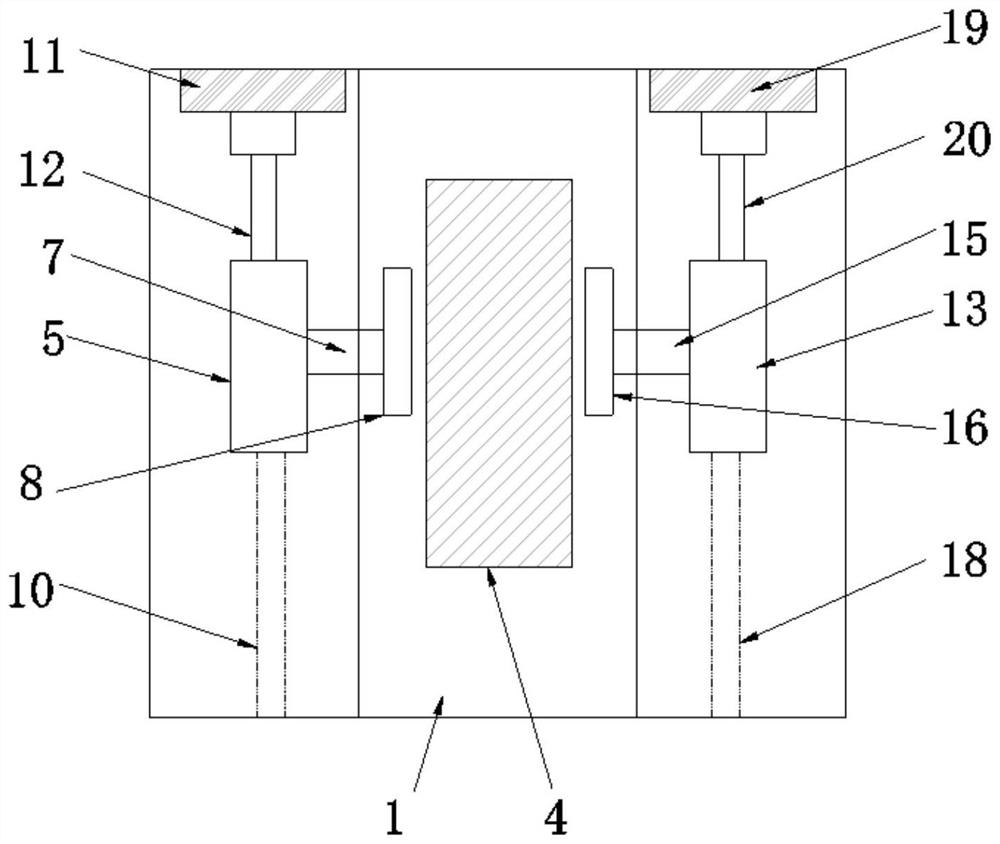

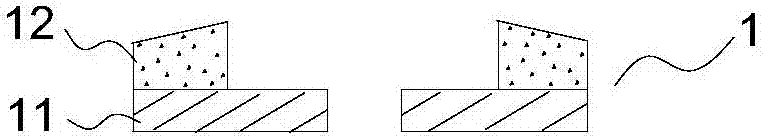

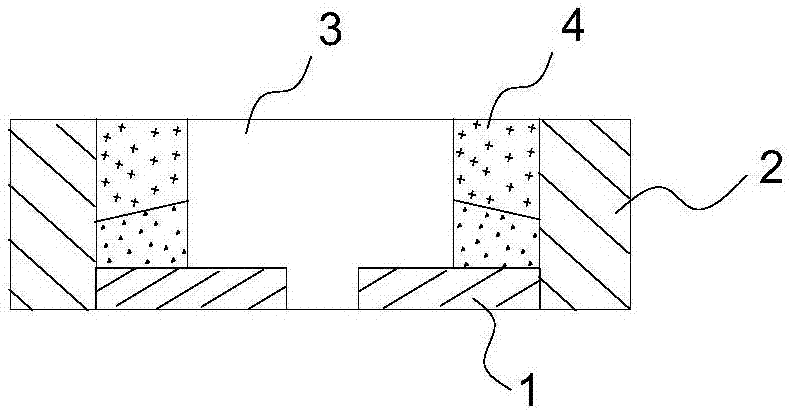

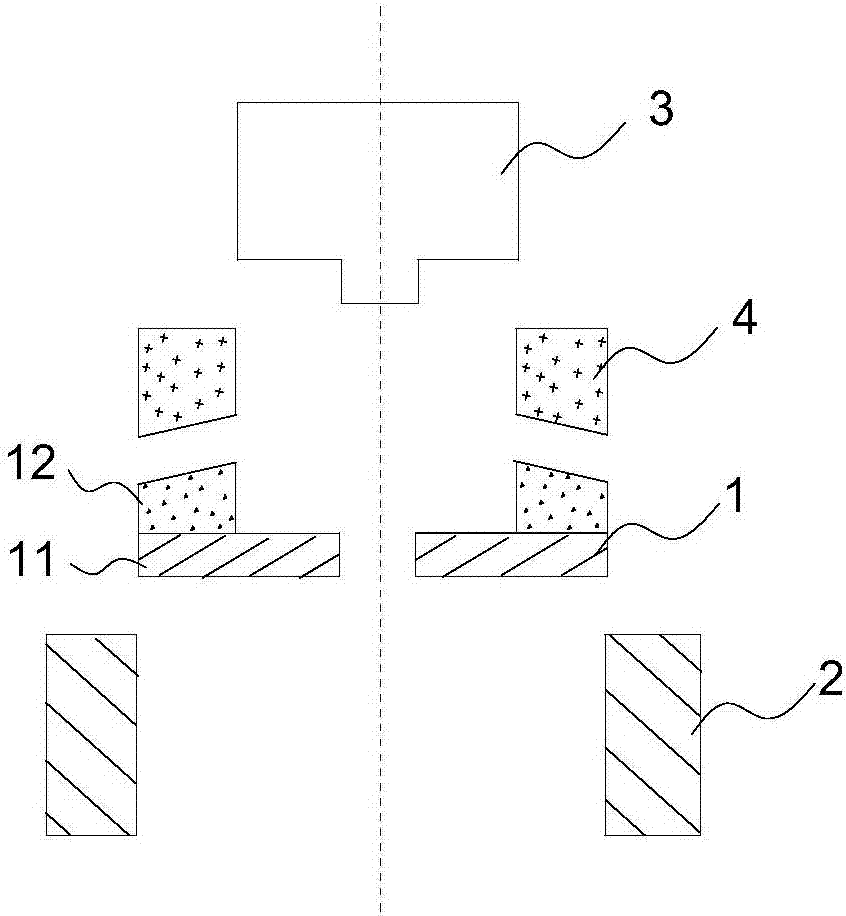

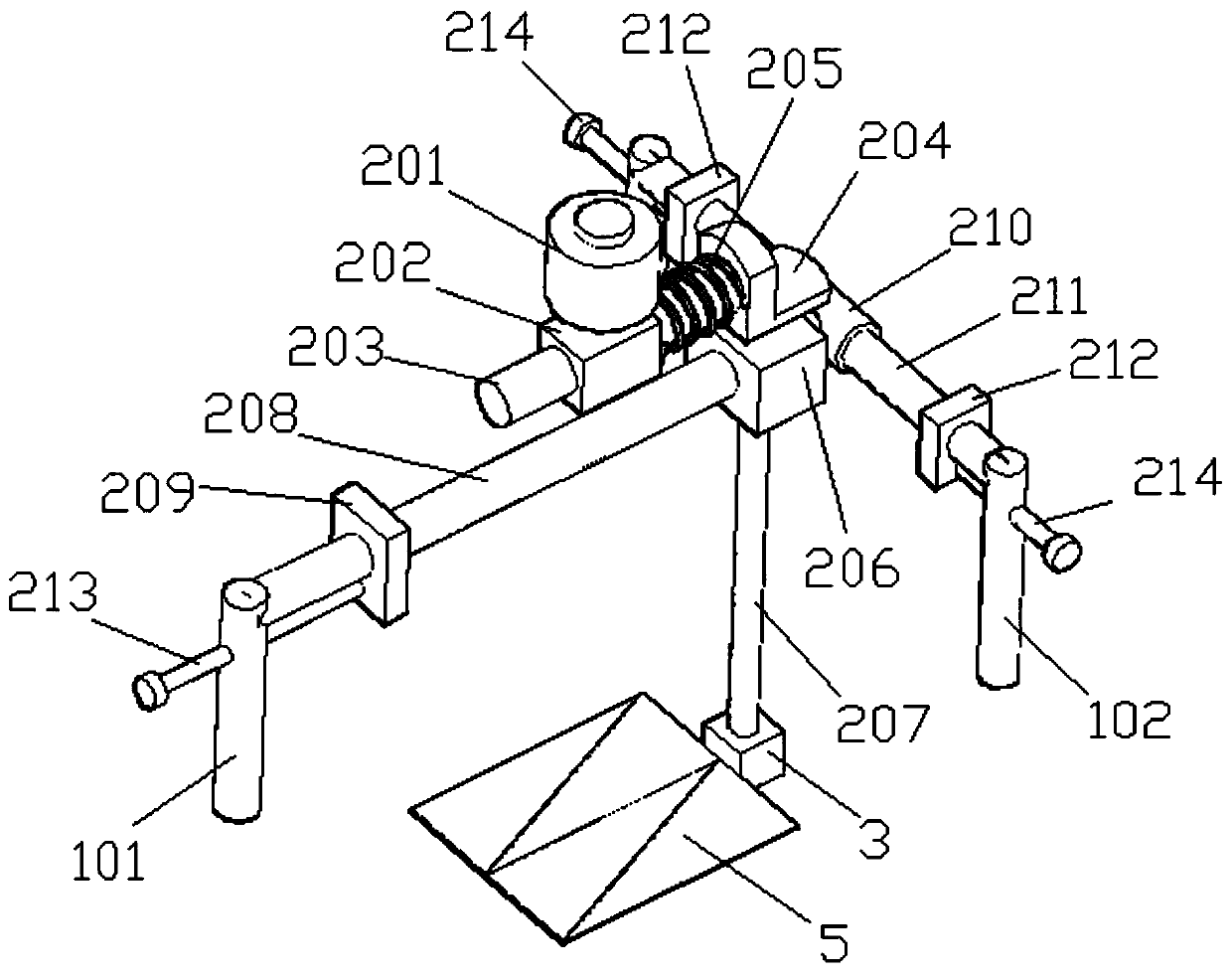

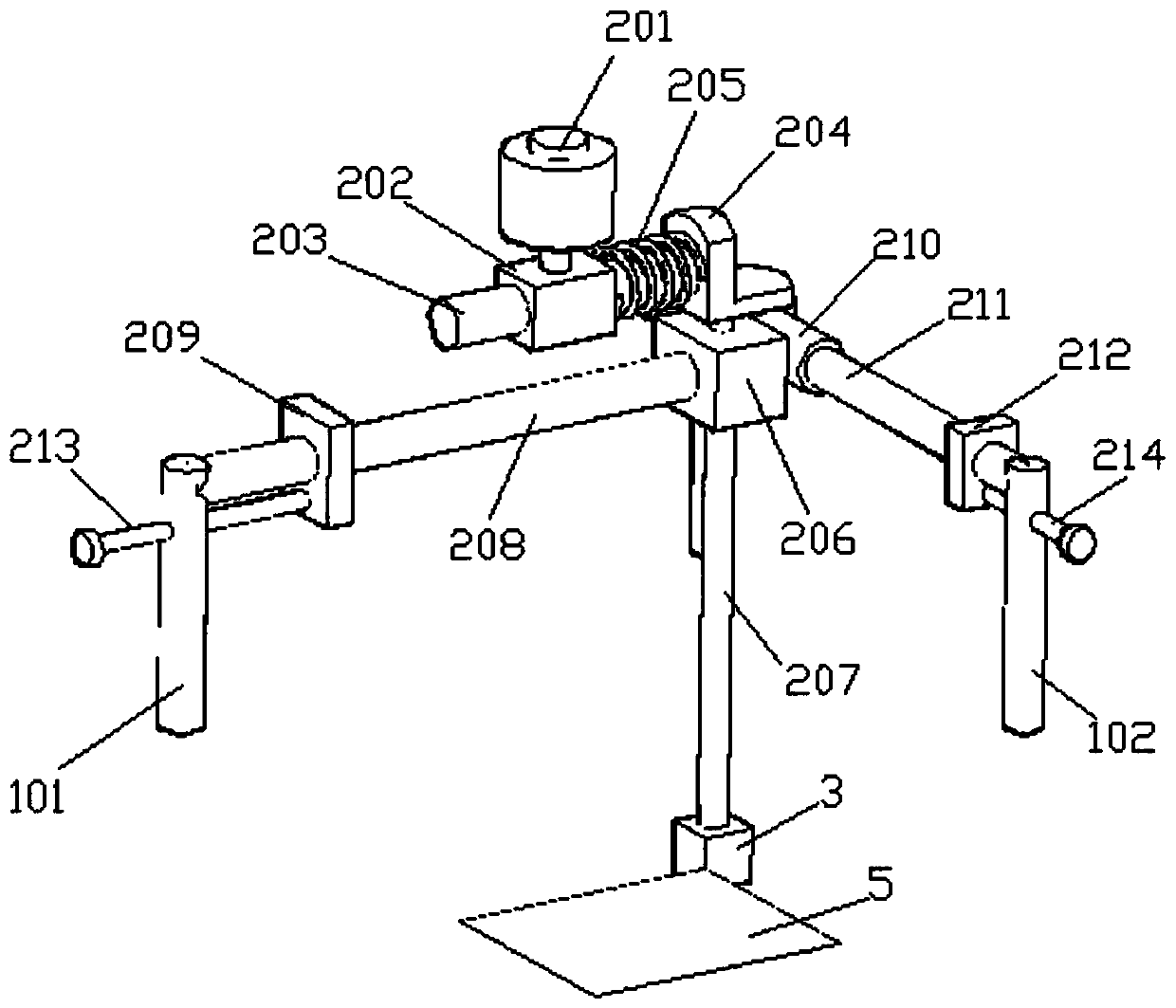

Edging device for meniscus lens centering and edging method thereof

ActiveCN103659516AImprove edging efficiencyMeet mass production needsEdge grinding machinesGrinding feed controlGrinding wheelMachine tool

The invention discloses an edging device for meniscus lens centering and an edging method thereof. The edging device is cylindrical. The top end of the edging device is provided with an arc-shaped lens cementing face. A through hole is formed in the edging device and communicated with the edging device. The edging method comprises the following steps of starting lens edging, cementing and loading a plate, splicing a meniscus lens work-piece and the lens cementing face of the edging device through bonding glue, adjusting the parallelism between the bottom edge of the edging device and the end face of the work-piece after cementing, installing the edging device and the work-piece which are integrally bonded in a machine tool, calibrating the coaxiality of the edging device and a main shaft of the machine tool, carrying out edging on the work-piece through a machine tool grinding wheel, polishing the work-piece until the diameter of the outer circle and the total height reach the specified numerical range, unloading the plate, separating the edging device and the work-piece which are integrally bonded, cleaning the work-piece, and finishing the edging process of a meniscus lens.

Owner:SHANGHAI XINYUE METER FACTORY

Glass edge grinding device

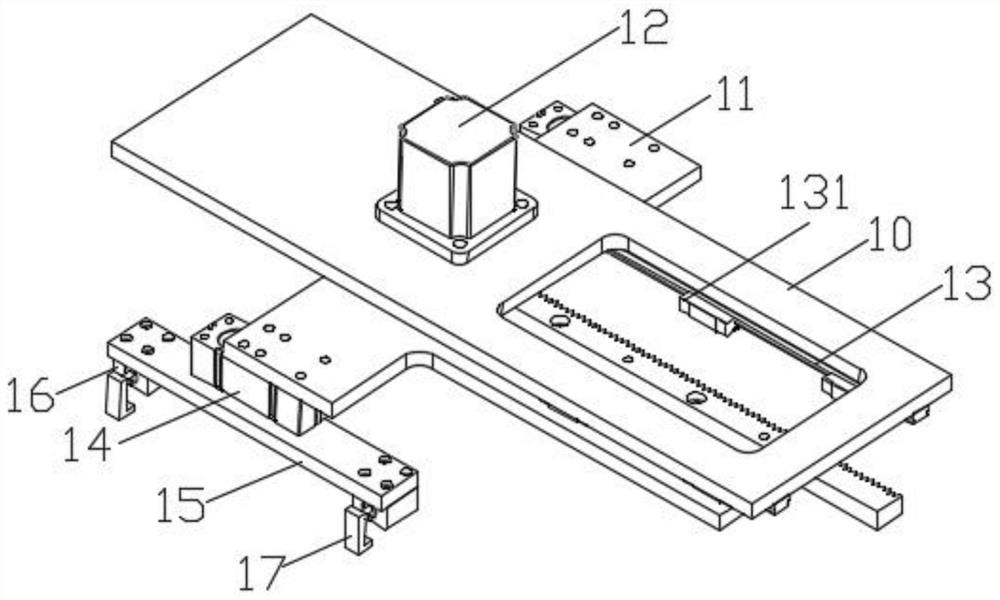

ActiveCN108705407APrecise edgingPrecision grindingEdge grinding machinesAutomatic grinding controlEngineeringSurface shape

A glass edge grinding device comprises a feeding mechanism, a carrying platform, a grinding mechanism and a monitoring system; the carrying platform is provided with a positioning mechanism; the grinding mechanism is used for grinding chamfers of glass fixed to the carrying platform; the monitoring system comprises an industrial camera; and the monitoring system is used for controlling the feedingmechanism to place the glass in the positioning mechanism during feeding according to glass positioning information shot by the industrial camera and is used for adjusting working parameters of the grinding mechanism during grinding according to end surface shapes, shot by the industrial camera, of the chamfers of the glass. According to the glass edge grinding device, the positioning mechanism is arranged on the carrying platform, the monitoring system provided with the industrial camera is used for monitoring the glass positioning information and the end surface shapes of the chamfers of the glass to complete automatic feeding and accurate grinding, and thus the edge grinding efficiency and accuracy are effectively improved.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

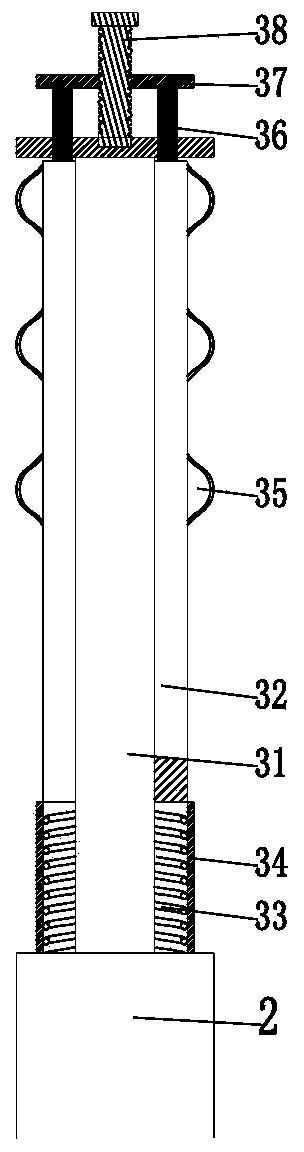

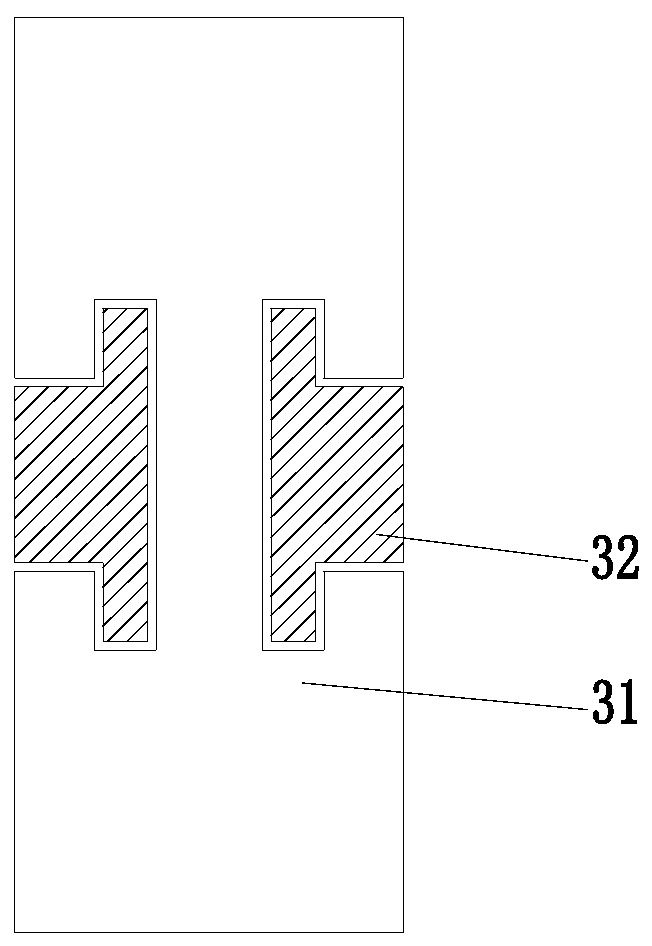

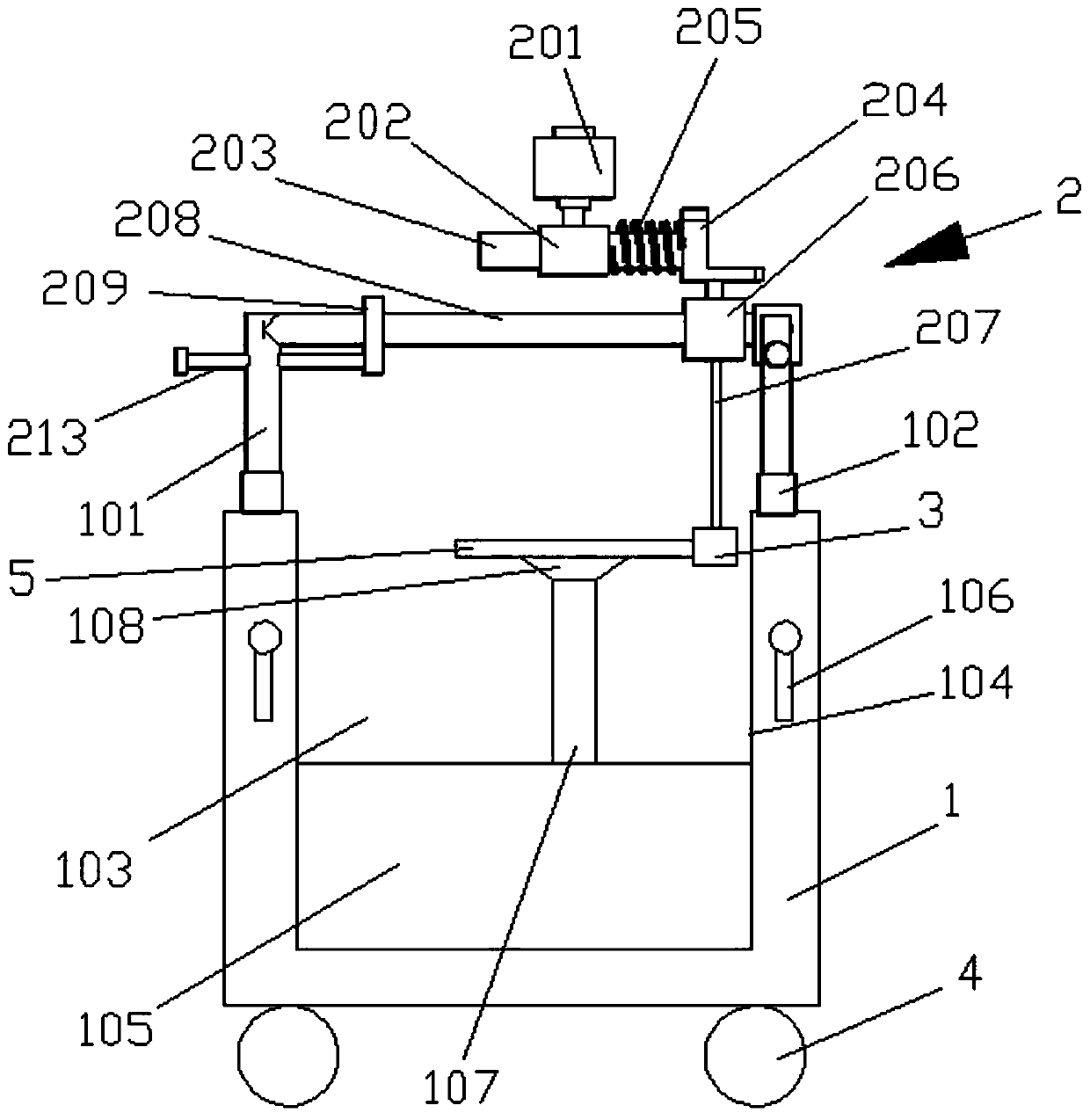

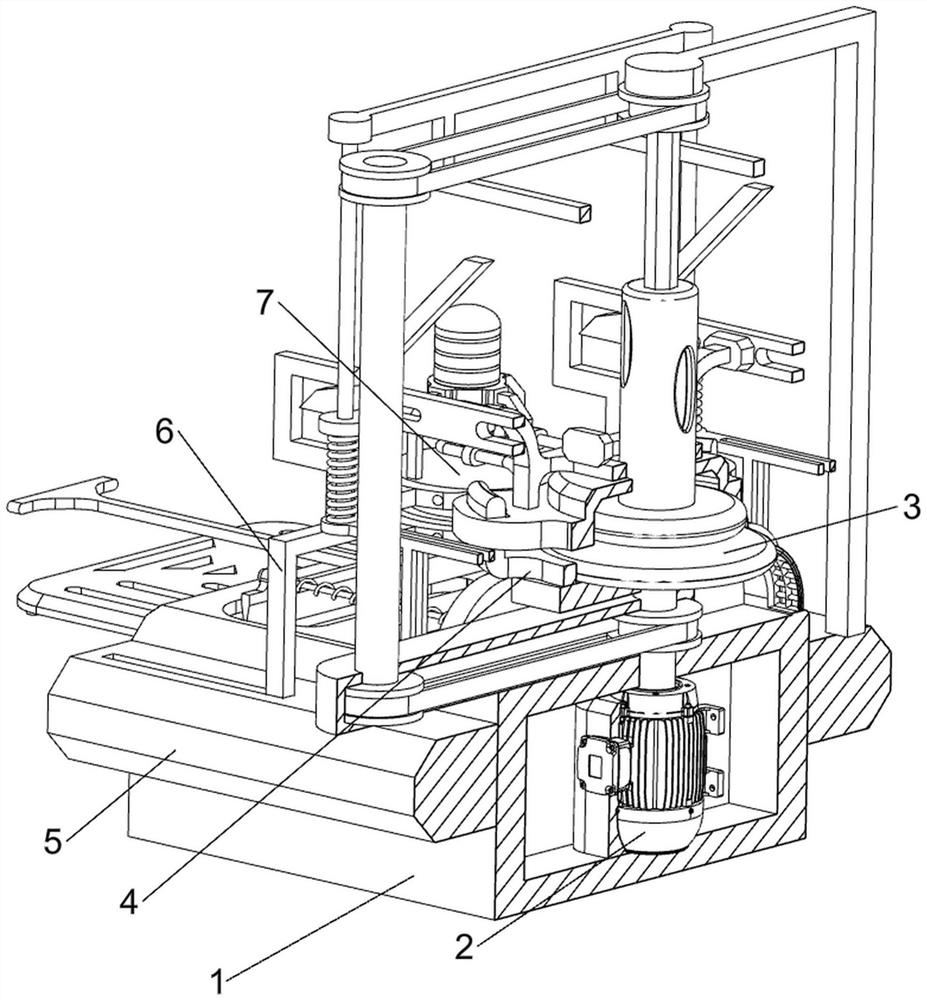

Three-axis numerical-control stone round bottom arc edge grinding machine

InactiveCN105666276ASmooth liftRealize moving up and downEdge grinding machinesGrinding carriagesNumerical controlThree degrees of freedom

The invention provides a three-axis numerical control stone circular bottom arc edging machine, which relates to the technical field of numerical control machine tools. The three-axis CNC stone circular bottom arc edging machine includes a work platform, a single-arm beam and an edging machine head; the work platform is horizontally arranged and can move along the left and right length directions; the single-arm beam is horizontally set on the work platform In the sky above, the length direction of the single-arm crossbeam is perpendicular to the length direction of the work platform; the edging machine head is arranged on the single-arm crossbeam, which can not only move in the vertical direction, but also move along the single-arm crossbeam. Movement along the length of the beam. The three-axis CNC stone circular bottom arc edging machine of the present invention uses the edging machine head that can move up and down and along the length direction of the single-arm beam, and cooperates with the independent movement of the working platform to realize the rapid operation of the three degrees of freedom of the edging machine. Adjustable, efficient and accurate round-bottom arc grinding of stone.

Owner:唐山宇洁科技有限公司

Edge grinding machine for cut insulating glass fiber board

ActiveCN113523950AReduce installation difficultyIncrease profitEdge grinding machinesRevolution surface grinding machinesGlass fiberFiber

The invention relates to the technical field of fiber board edge grinding, in particular to an edge grinding machine for a cut insulating glass fiber board, which comprises a fixed bottom plate, an edge grinding device, an L-shaped mounting frame and a driving device, wherein the edge grinding device is arranged at the upper end of the fixed bottom plate, and the L-shaped mounting frame is mounted on the rear side of the upper end of the fixed bottom plate; and the driving device is arranged on the front side of the upper end of the L-shaped mounting frame. The problems that according to a traditional edge grinding method, an edge grinding machine needs to be replaced, the utilization rate of the edge grinding machine and the edge grinding efficiency are low; and when edge grinding is conducted on a round hole of the glass fiber board, the edge grinding effect is difficult to guarantee through traditional edge grinding equipment can be solved. According to the machine, unified side wall grinding and hole wall grinding can be conducted on a plurality of circular plate type insulating glass fiber boards, the working positions of the glass fiber boards and an edge grinding machine do not need to be replaced, the utilization rate and the edge grinding efficiency of the edge grinding machine are improved, and meanwhile, the edge grinding effect of the inner wall of a circular hole is improved.

Owner:江苏科华新材料有限公司

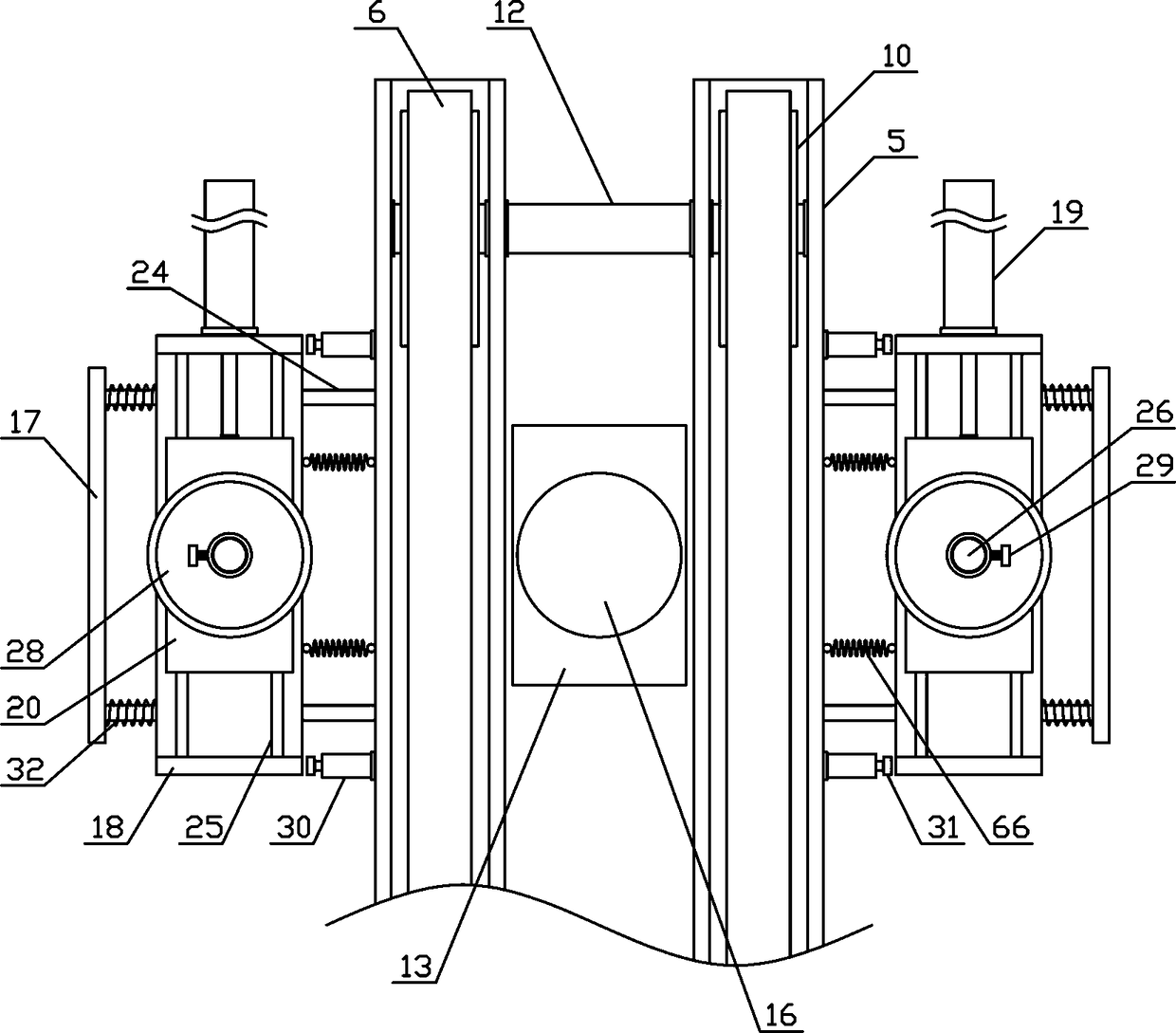

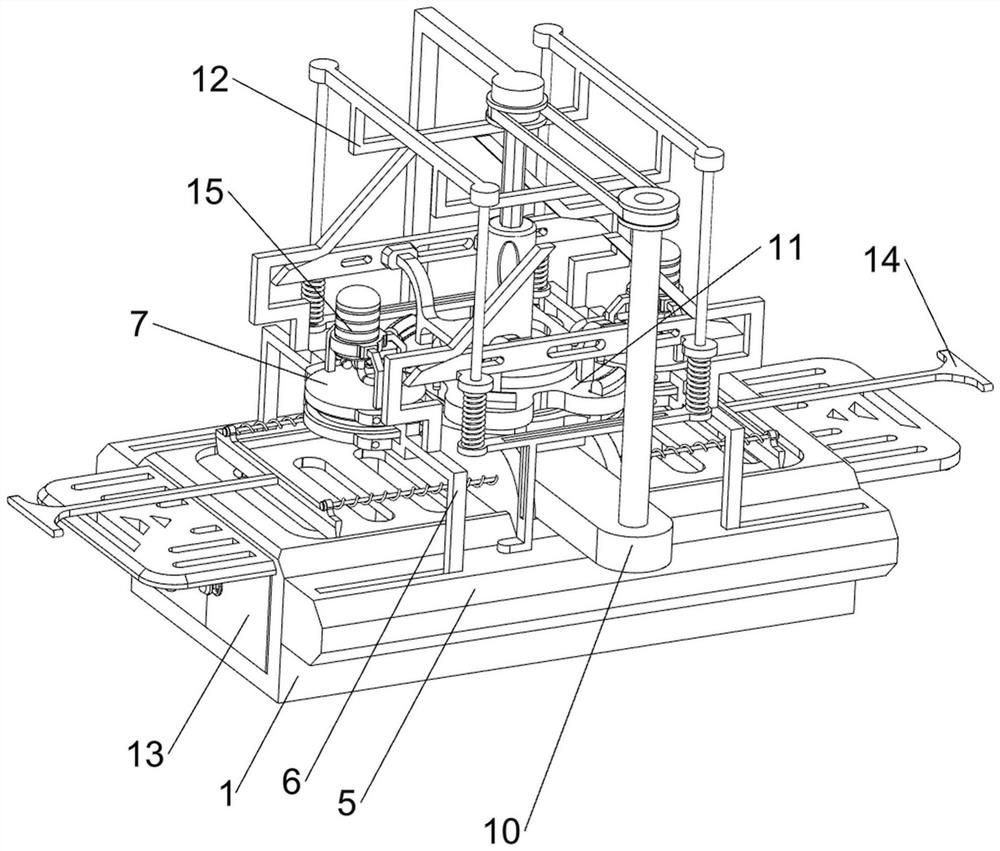

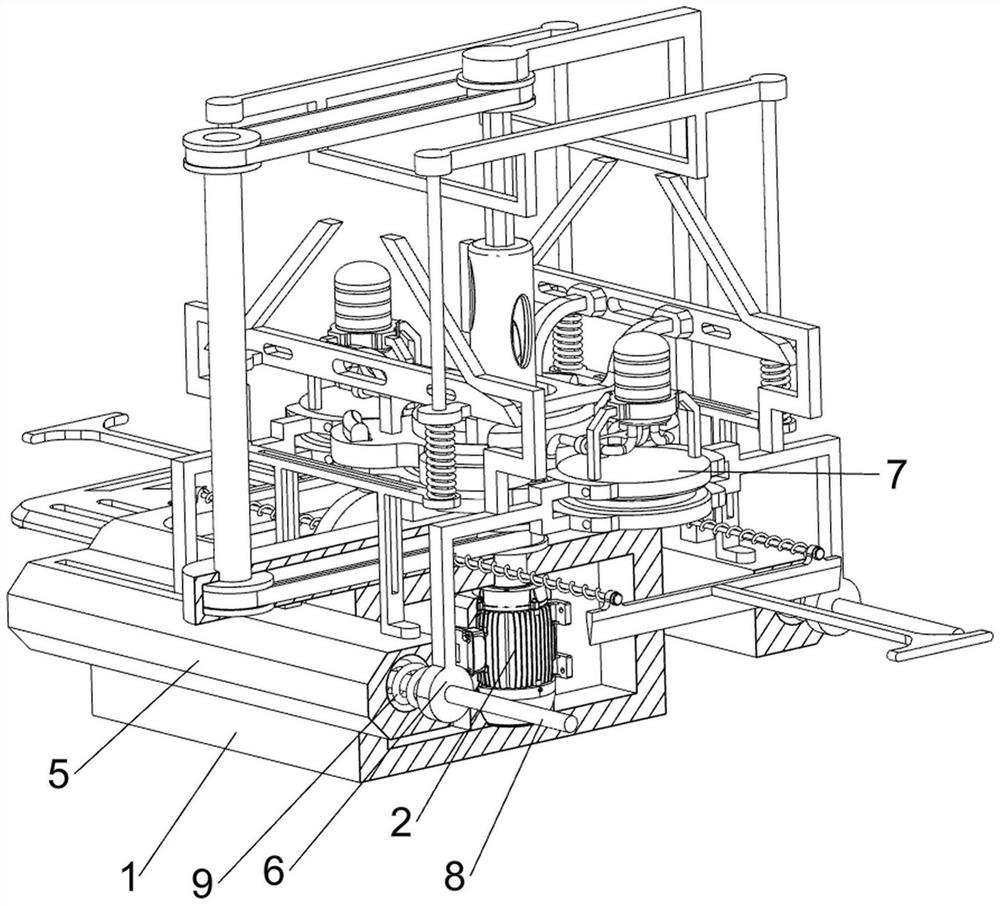

Automatic edge grinding machine for tempered glass after shaping and cutting

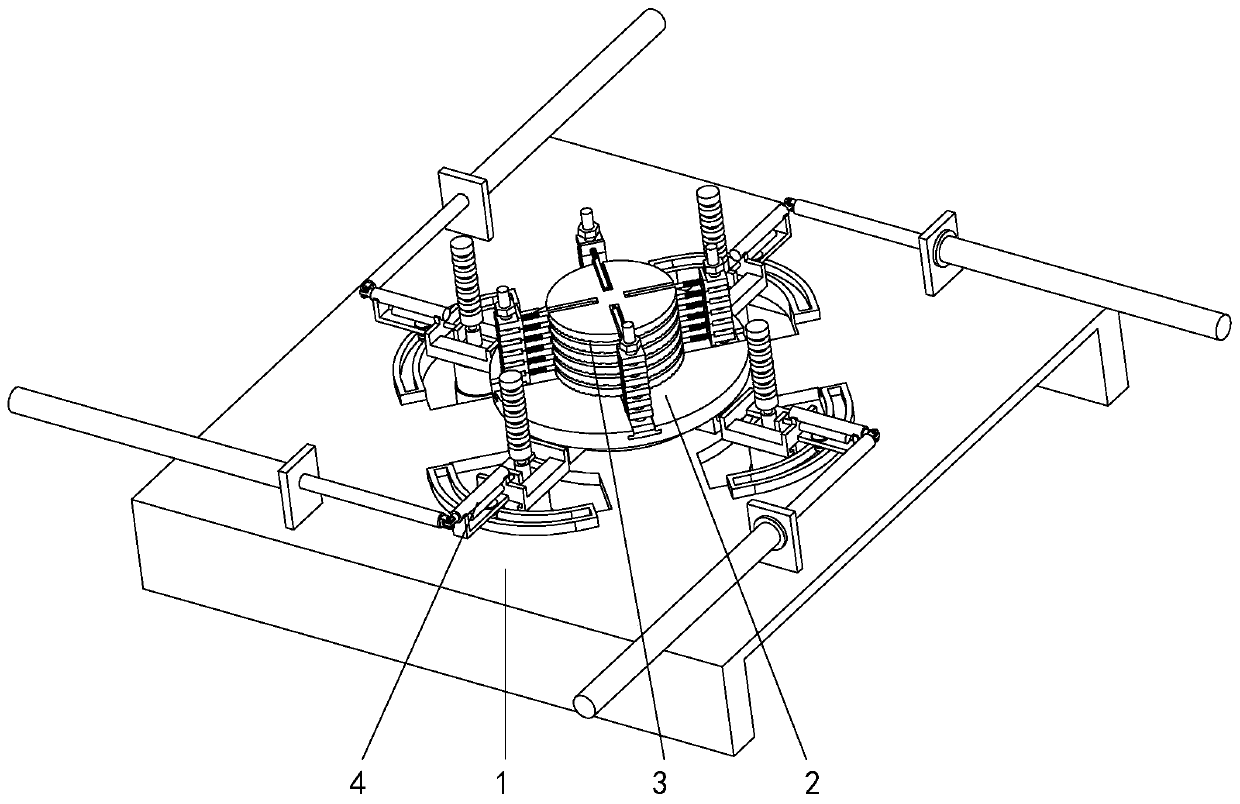

ActiveCN111390697AImprove edging efficiencyEasy to cleanEdge grinding machinesGrinding drivesElectric machineryStructural engineering

The invention relates to an automatic edge grinding machine for tempered glass after shaping and cutting. The automatic edge grinding machine for the tempered glass after shaping and cutting comprisesa base, a supporting seat, a supporting mechanism, locking mechanisms, a driving adjustment mechanism, driving sliding blocks, driving motors, grinding mechanisms and grinding adjustment mechanisms.The supporting seat is arranged on the upper end surface of the middle of the base, the supporting mechanism is installed on the upper end surface of the supporting seat, the locking mechanisms are installed at the front end and the rear end of the supporting mechanism, the driving adjustment mechanism is located under the locking mechanisms, the driving sliding blocks are installed at the front end and the rear end of the driving adjustment mechanism, the driving motors are arranged on the upper end surfaces of the driving sliding blocks, output shafts of the driving motors are connected withthe lower parts of the outer ends of the locking mechanisms, the grinding mechanisms are arranged on the left side and the right side of the supporting seat, and the grinding adjustment mechanisms are arranged at the lower ends of the grinding mechanisms. The problems that when round glass is subjected to edge grinding, only one piece can be ground at a time, and the residue on the glass needs tobe cleaned twice after edge grinding are solved; when round glass of different specifications is subjected to edge grinding, a fixture is required to be replaced.

Owner:恩迪(山东)智能装备有限公司

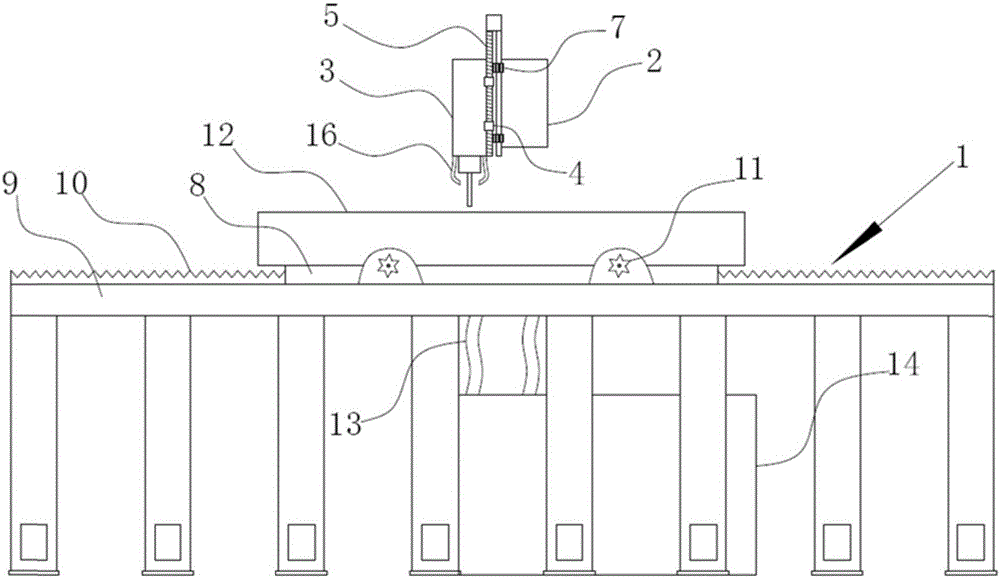

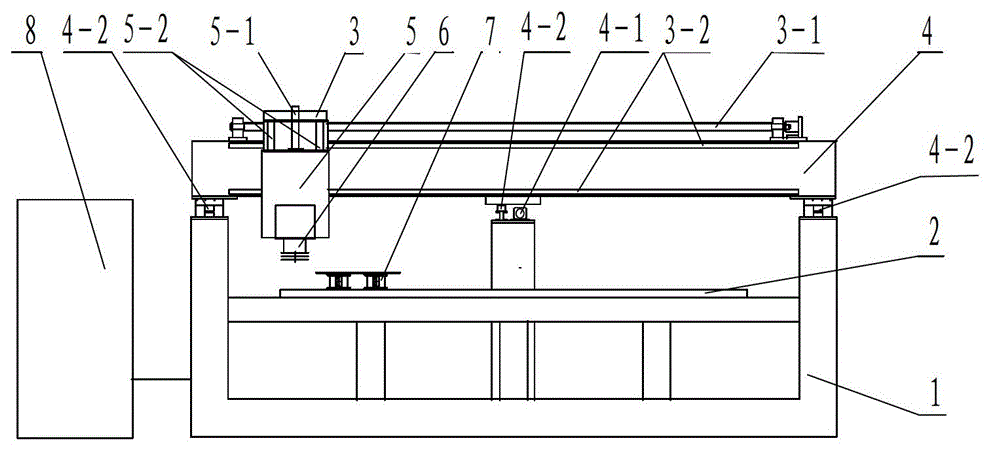

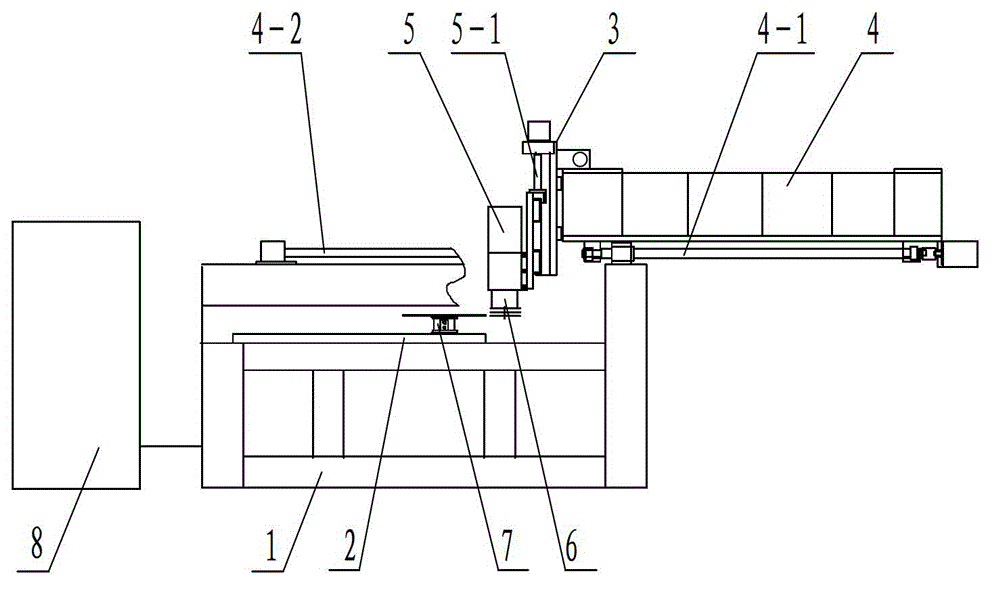

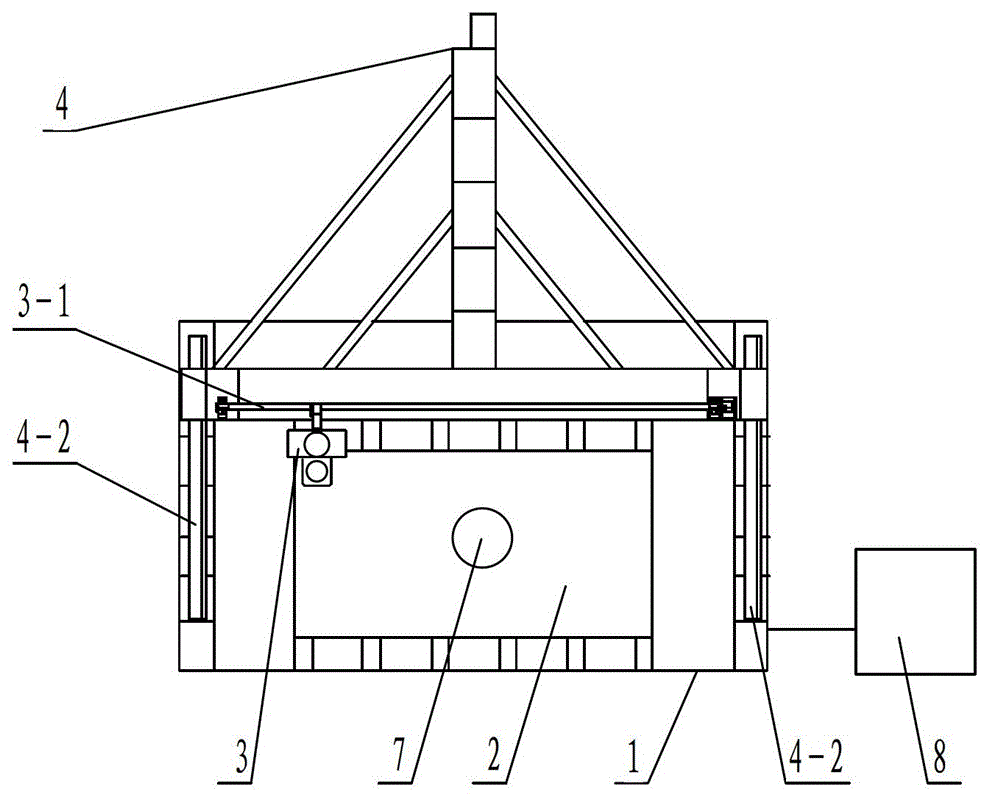

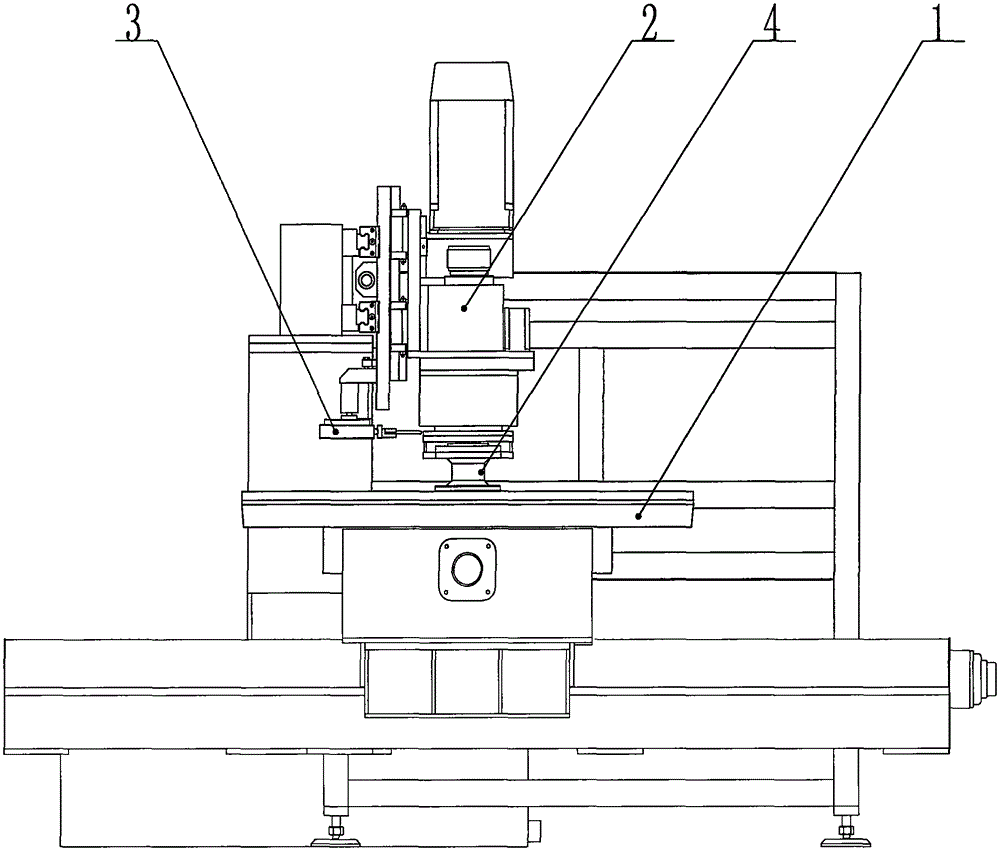

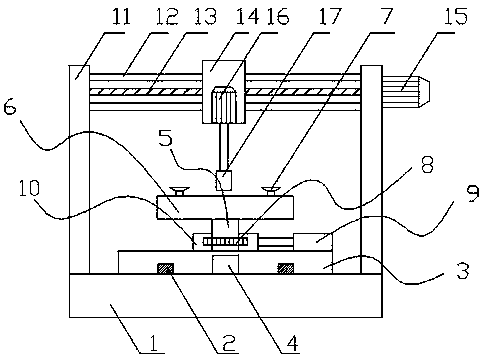

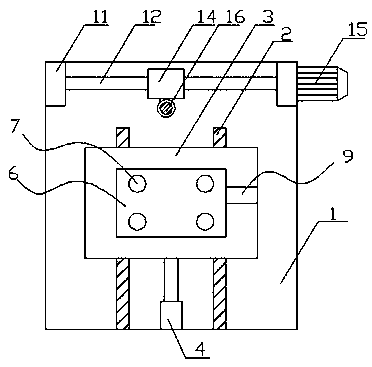

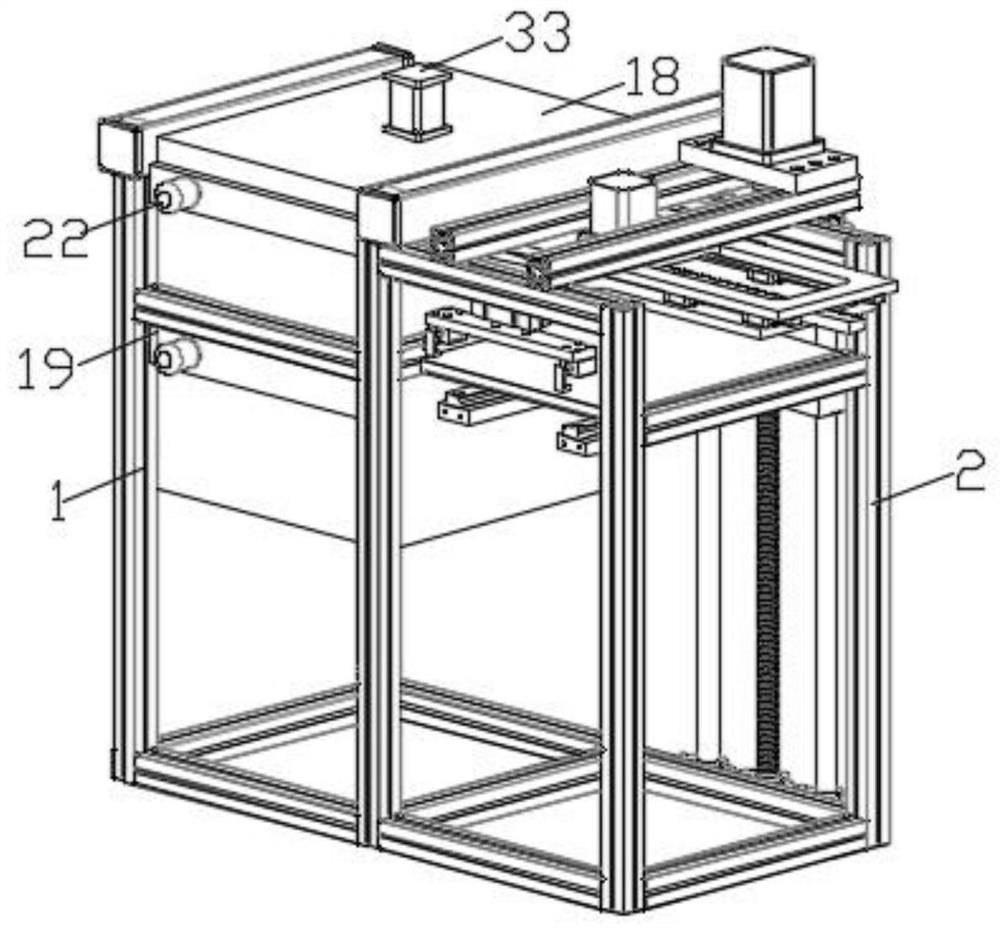

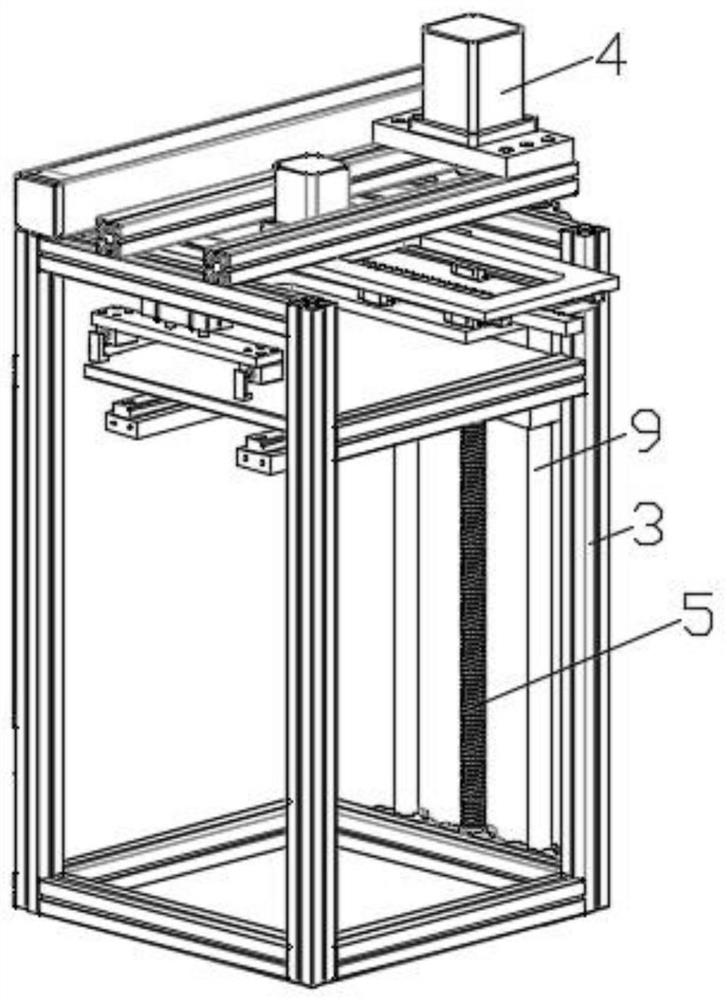

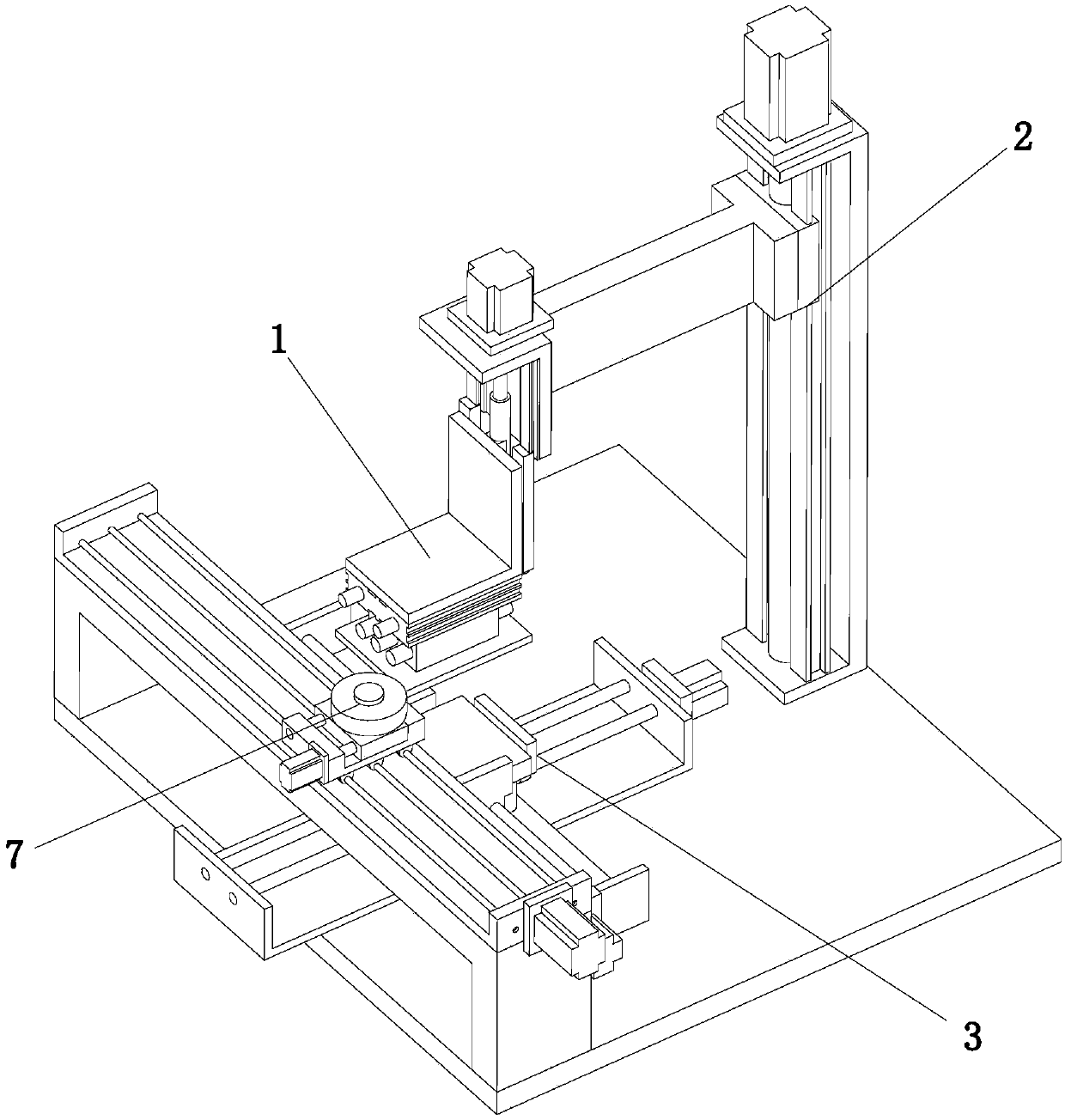

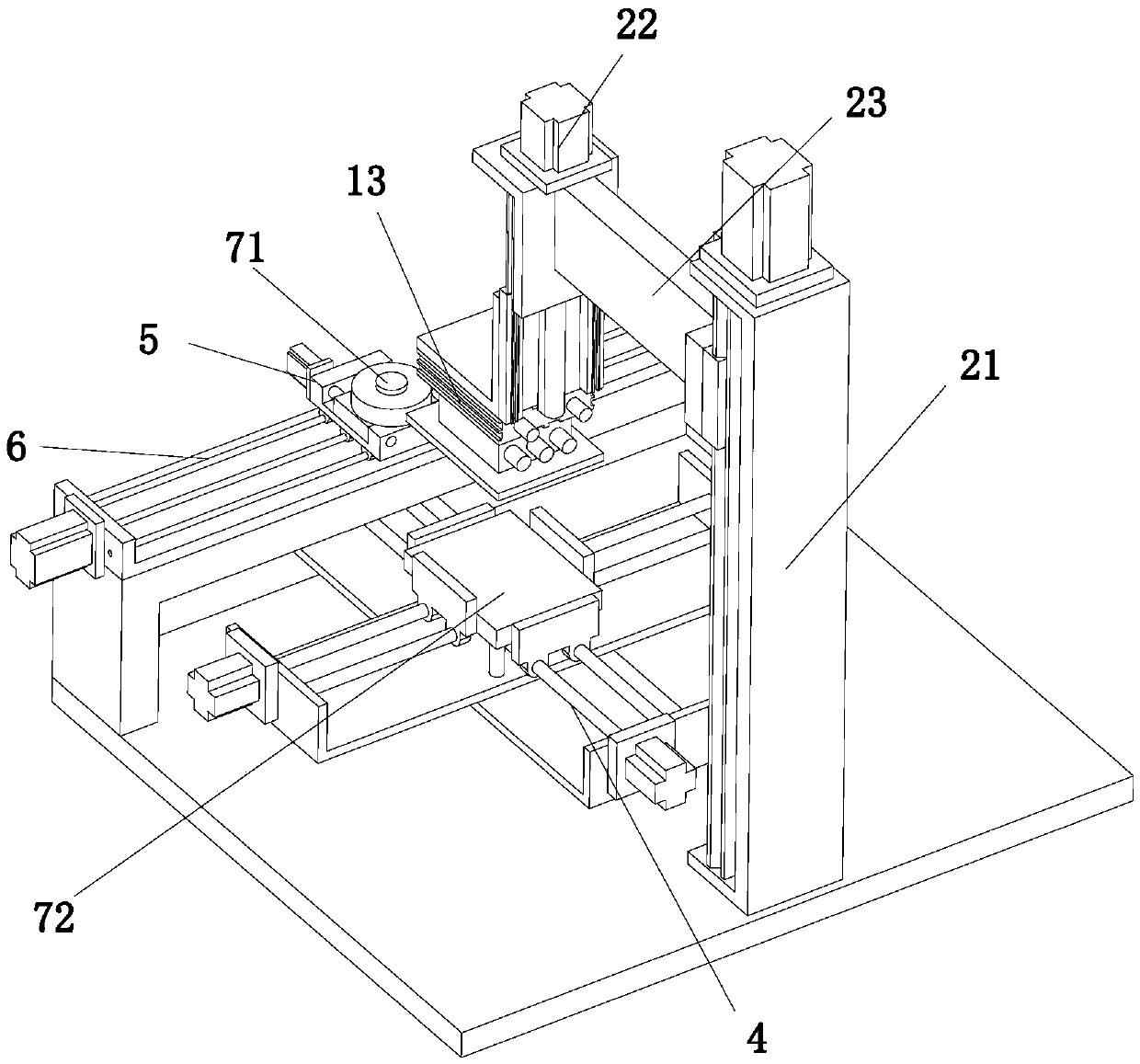

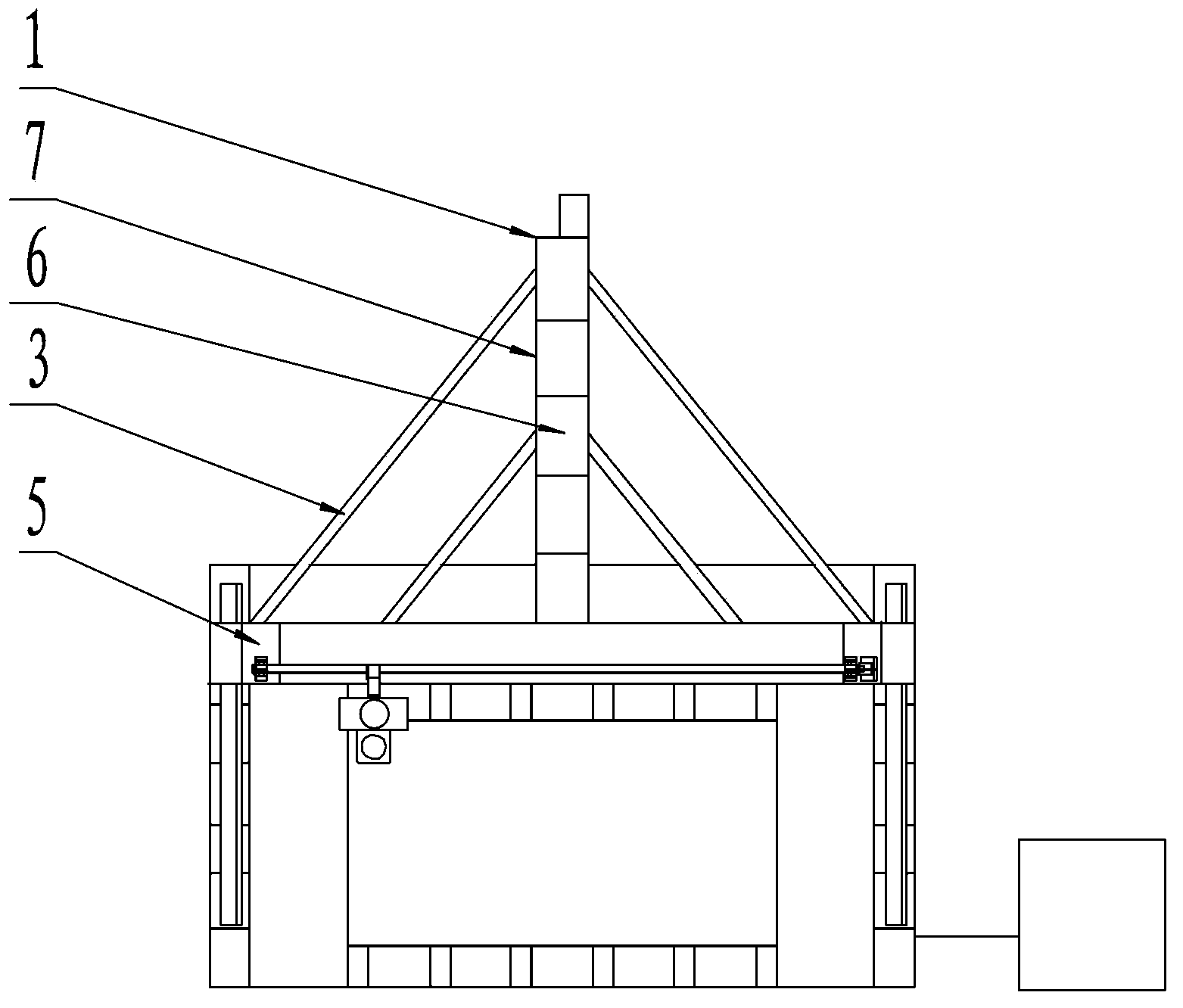

Machining method of T-shaped movable beam irregularly-shaped glass machining system

InactiveCN103331669ARapid positioningImprove rigidityEdge grinding machinesGrinding work supportsControl systemEngineering

The invention relates to a machining method of a T-shaped movable beam irregularly-shaped glass machining glass. The T-shaped movable beam irregularly-shaped glass machining glass consists of a gantry framework, a fixed platform, a transverse stepper / servo mechanism, an X-axis screw rod, an X-axis lead rail, a T-shaped longitudinal stepper / servo mechanism, a Y-axis screw rod, a Y-axis lead rail, an upper stepper / servo mechanism, a lower stepper / servo mechanism, a Z-axis screw rod, a Z-axis lead rail, a grinding head mechanism, a positioning adsorption disc, a control box, a polishing grinding wheel, a fine grinding heel and a coarse grinding wheel; the T-shaped longitudinal stepper / servo mechanism moves along the Y-axis direction of three Y-axis lead rails, and a three-axis linked data control system is used for machining the irregularly-shaped glass; and a T-shaped movable beam adopts an integral framework structure, the rigidness of the T-shaped movable beam is good, the stability is good, and the T-shaped movable beam is not deformed when being ground under a large torque, the three lead rails are used as support, so that the T-shaped movable beam is faster to run in the running process, more stable to run and better in synchronous effect, the working efficiency is efficiently improved, and the dimensional precision of a final product can be improved.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

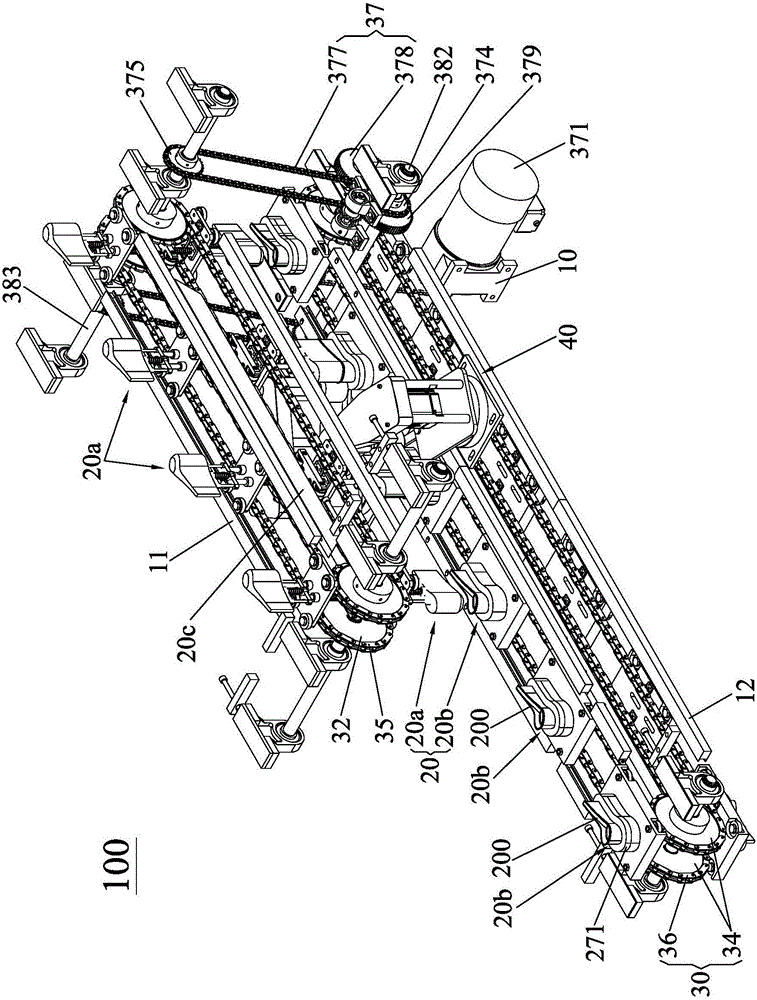

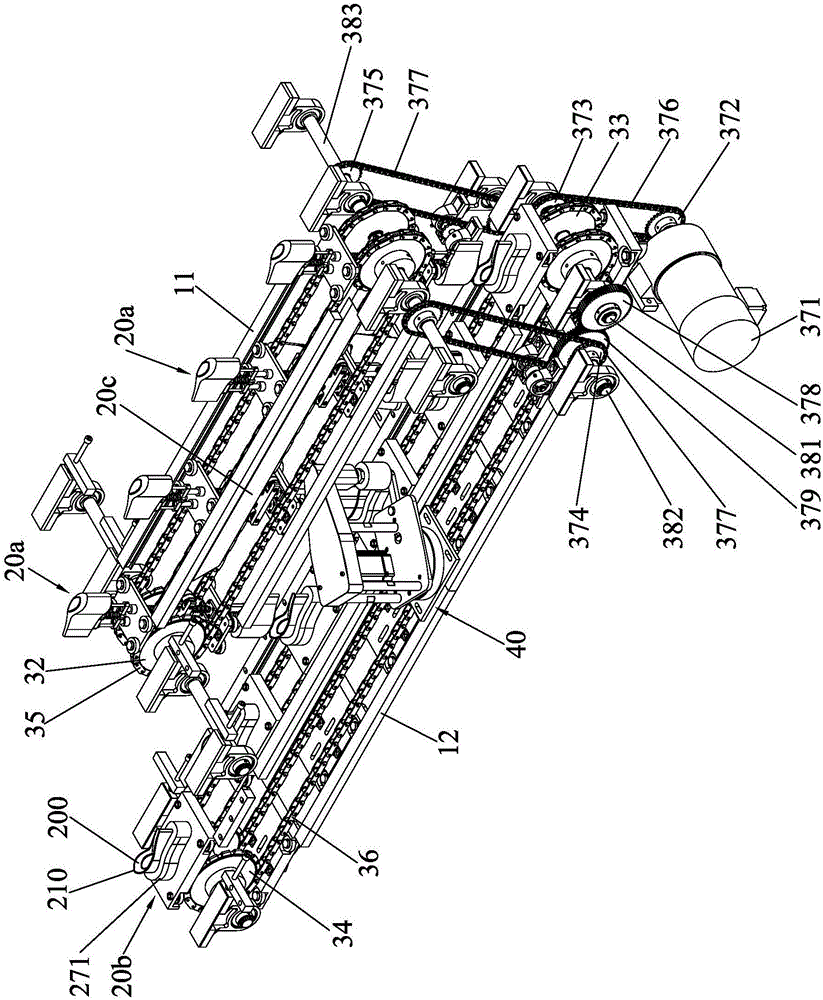

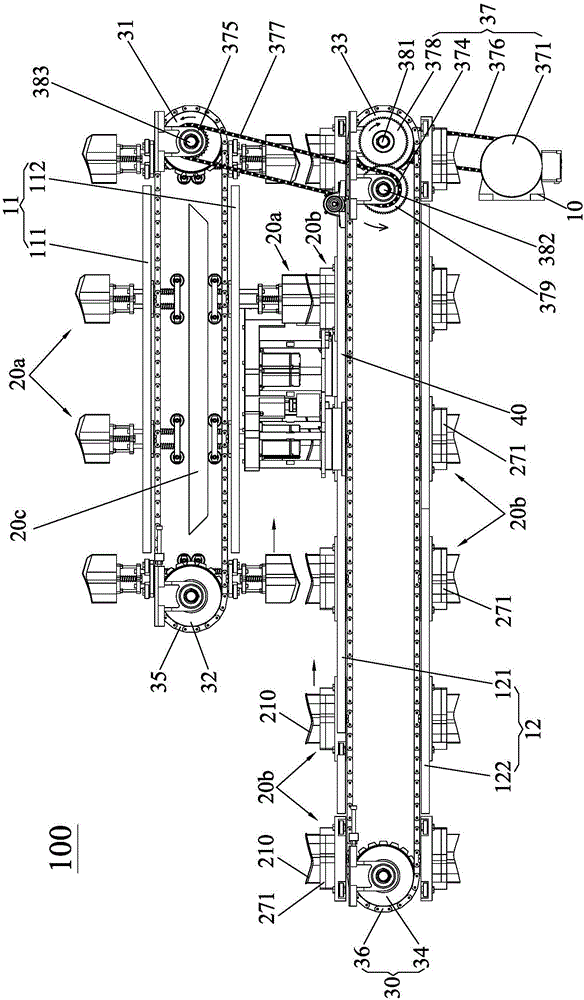

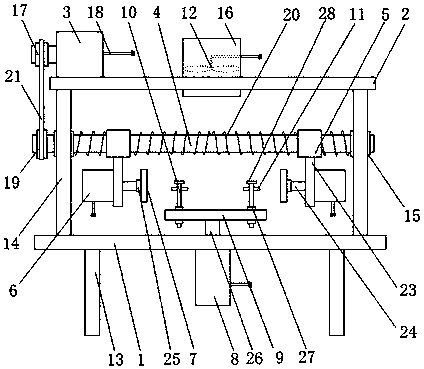

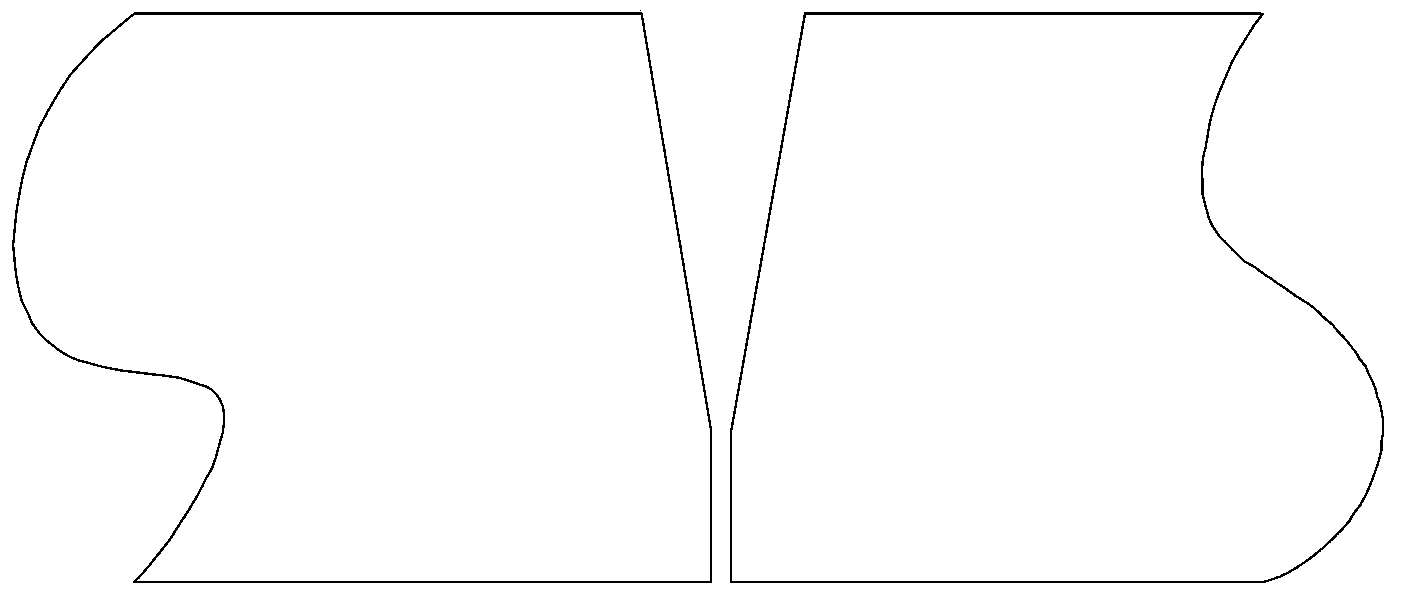

Full-automatic spoon edge grinding machine

InactiveCN104985501AFully automatedImprove edging efficiencyEdge grinding machinesGrinding drivesEngineeringHead moving

The invention discloses a full-automatic spoon edge grinding machine. The full-automatic spoon edge grinding machine comprises a machine frame, a clamping device, a driving device and a polishing device; the machine frame is provided with an upper guide rail and a lower guide rail; the clamping device comprises upper clamp assemblies, lower clamp assemblies and a pushing assembly for allowing the upper clamp assemblies and the lower clamp assemblies to clamp a spoon; the upper clamp assemblies are arranged along the upper guide rail and move along the upper guide rail, the lower clamp assemblies are arranged along the lower guide rail to form a line and move along the lower guide rail, and the upper clamp assemblies or the lower clamp assemblies are provided with molding parts matched with the edge of the spoon; and the edge of the spoon is exposed out when the spoon is clamped. The driving device is installed on the machine frame and drives the upper clamp assemblies and the lower clamp assemblies to do the coordinate exercise. The polishing device is installed on the machine frame and is provided with a positioning guide head, the positioning guide head is in contact with the molding parts and moves along the molding parts in the conveying process from the molding parts to the polishing devices, and the edge of the spoon jointly clamped by the upper clamp assemblies and the lower clamp assemblies is polished by the polishing device under the guidance that the positioning guide head moves along the molding parts, and therefore the full-automatic edge polishing function on the edge of the spoon is achieved.

Owner:DONGGUAN CHUANJIN MECHANICAL

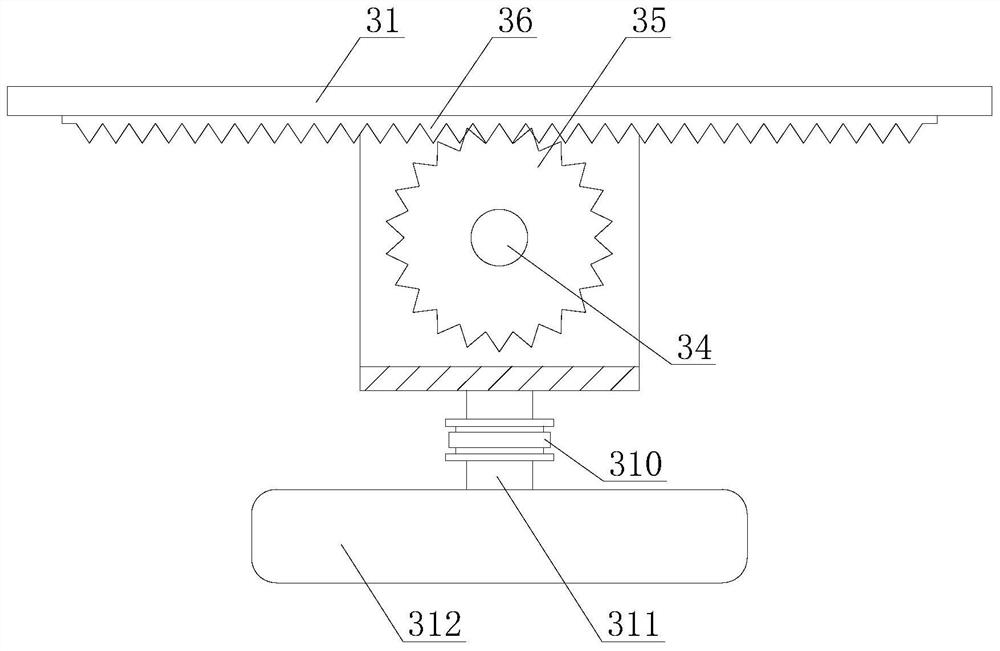

Sheet conveying and edge grinding mechanism

InactiveCN108527053AImprove efficiencyQuality improvementEdge grinding machinesGrinding feedersMechanical equipmentEngineering

The invention discloses a sheet conveying and edge grinding mechanism, and belongs to the field of material conveying and machining mechanical equipment. The sheet conveying and edge grinding mechanism comprises a fixed base, a front conveying mechanism, a front edge grinding mechanism, a back edge grinding mechanism, an overturning mechanism, an unloading mechanism and a back conveying belt; thefront conveying mechanism and the back conveying belt are horizontally fixed on the two sides above the fixed base; the front conveying mechanism and the back conveying belt are in parallel; the frontedge grinding mechanism, the back edge grinding mechanism and the overturning mechanism are arranged on the front conveying mechanism in sequence in the horizontal direction; and the unloading mechanism is horizontally arranged on the fixed base on one side of the back conveying belt. The sheet conveying and edge grinding mechanism is reasonable in structural design, can grind four side edges ofsheets in the sheet conveying process in sequence, can continuously convey the sheets after stable overturning, improves the sheet production automation degree, and meets the production and application demands.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

Special-shaped glass edge grinding machine

InactiveCN112318271AQuick EdgingWon't hurtEdge grinding machinesGrinding drivesIndustrial engineeringSupport plane

The invention discloses a special-shaped glass edge grinding machine. The machine comprises a base, a supporting frame, a special-shaped glass placing platform and an edge grinding mechanism, whereinthe supporting frame is installed on the base, the special-shaped glass placing platform is installed on the supporting frame, the edge grinding mechanism comprises a first edge grinding assembly anda second edge grinding assembly, the first edge grinding assembly and the second edge grinding assembly are installed on the two sides of the base, and a pressure plate assembly is mounted above the special-shaped glass placing platform. The special-shaped glass edging device is novel in structural design, capable of achieving rapid edging treatment on special-shaped glass, high in edging efficiency and free of damage to the special-shaped glass.

Owner:常德康鸿玻璃制品有限公司

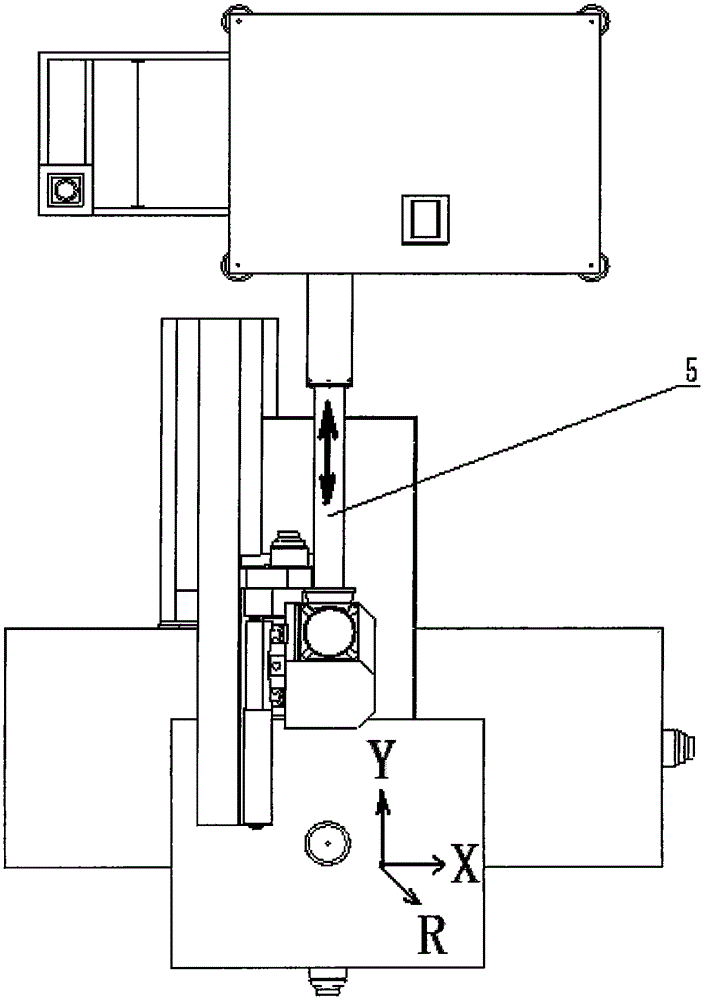

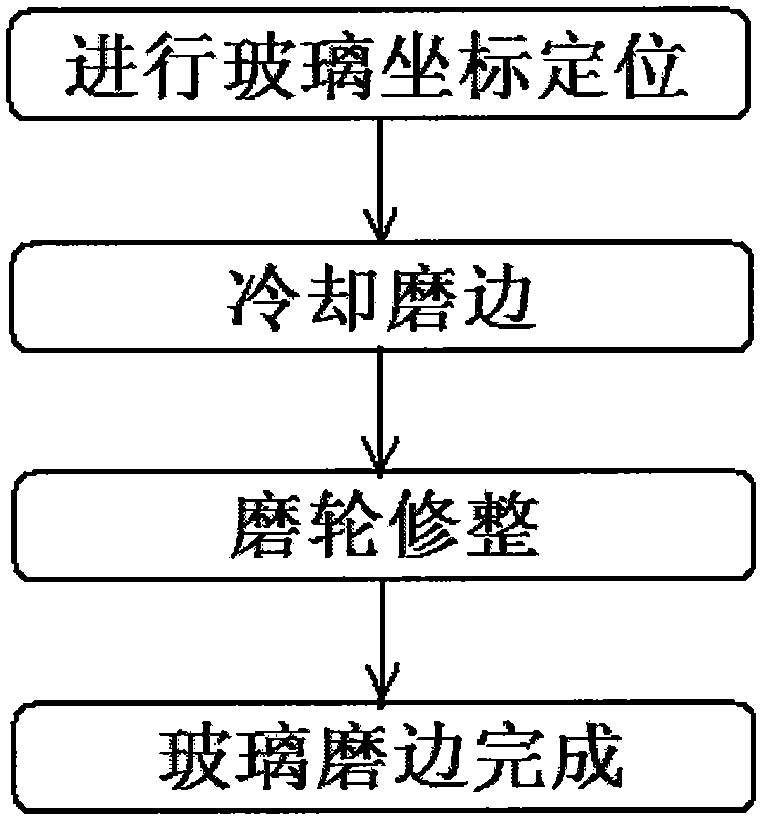

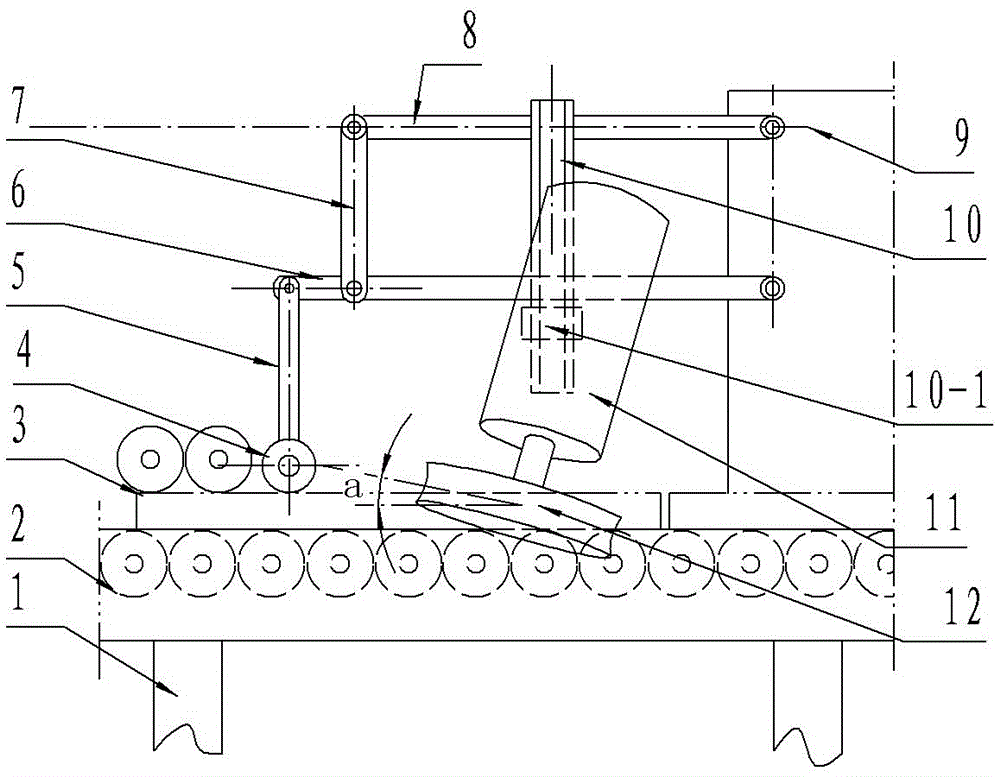

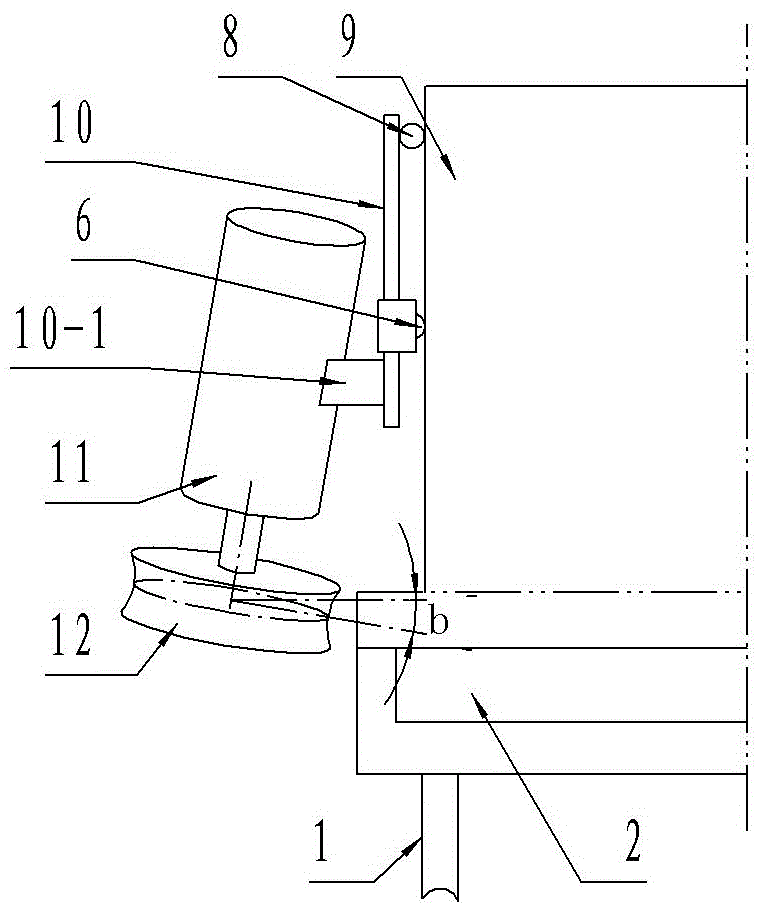

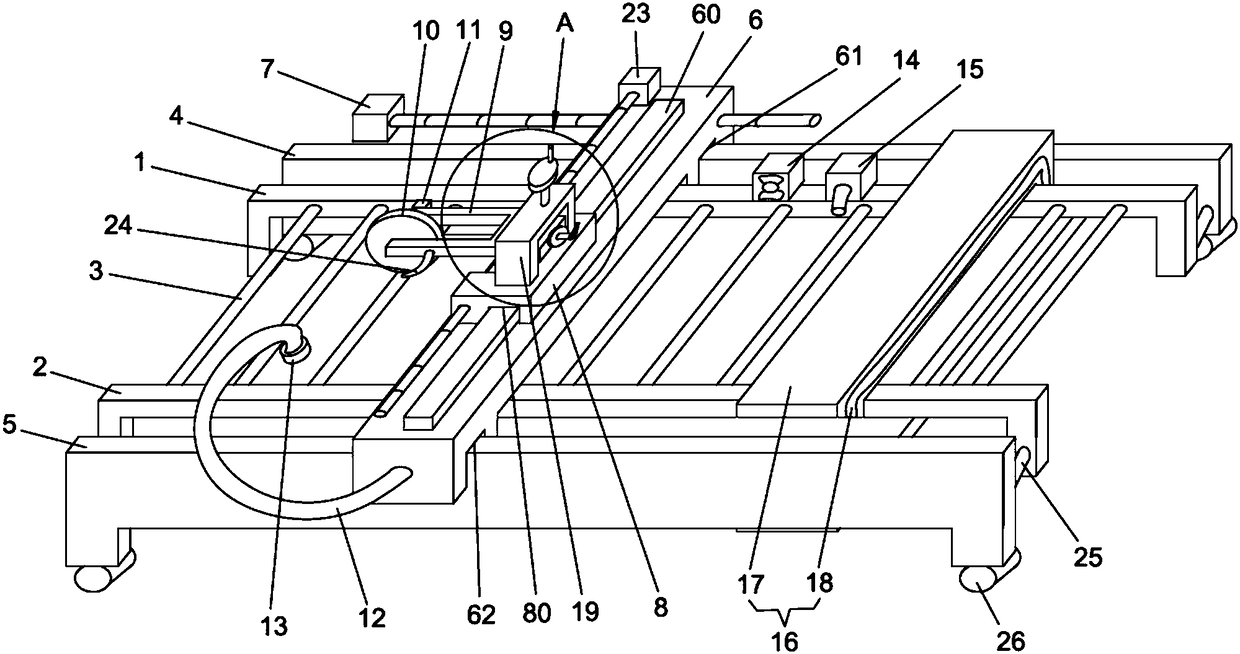

Edge grinding device for special-shaped glass remote control processing production line and operation method of edge grinding device

InactiveCN105598779AMeet the needs of rapid development and changeSimple structureEdge grinding machinesGrinding feedersProduction lineRemote control

Provided are an edge grinding device for a special-shaped glass remote control processing production line and an operation method of the edge grinding device. A remote control processing production line mechanical arm is adopted for positioning, programming is not needed, CAD drawing data of special-shaped glass processing is imported, edge grinding can be carried out, grinding precision is greatly improved, and the edge grinding efficiency is improved by 200% or above. Circulating and cooling edge grinning is efficient and clean, and waste water is automatically hidden and recycled. A grinding wheel can carry out automatic finishing and radius compensation during edge grinding, and energy saving and environment friendliness are achieved. Production cost is reduced by at least 30%, and the need of the special-shaped glass deep processing production line for fast development and changes is met. The edge grinding device for the special-shaped glass remote control processing production line is composed of an edge grinding movable workbench, a water cooling hidden grinding head device, an automatic finishing grinding wheel device, a vacuum suction cup and a cooling circulating water device hydraulic telescopic pipe. The water cooling hidden grinding head device is arranged at one end of the cooling circulating water device hydraulic telescopic pipe, the automatic finishing grinding wheel device is arranged at one side of the water cooling hidden grinding head device, and the edge grinding movable workbench is arranged below the automatic finishing grinding wheel device.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

Efficient dezincification edge grinding machine

InactiveCN104440451APrevent slippingReasonable structureEdge grinding machinesGrinding carriagesAngle grinderDrive shaft

The invention discloses an efficient dezincification edge grinding machine which comprises a first rack, a second rack, a third rack, a first rotary shaft, a second rotary shaft, a supporting rod, pulleys, transmission chains, cushion blocks, angle grinders, adjusting screws, a first edge grinding guide rod, a second edge grinding guide rod and a motor. The second rack and the third rack are fixed to the left side and the right side of the first rack respectively, the first rotary shaft and the second rotary shaft are fixed to the front end and the rear end of the first rack in parallel, the supporting rod is fixed to the middle portion, the pulleys are evenly arranged on one side of the supporting rod, the two ends of the first rotary shaft and the two ends of the second rotary shaft are provided with the transmission chains so as to be connected, the second rack and the third rack are each evenly provided with at least three angle grinders, the movable first edge grinding guide rod is arranged in front of the angle grinders on the second rack, the second edge grinding guide rod is fixed to the portion in front of the angle grinders on the third rack, and the adjusting screws are evenly arranged behind the first edge grinding guide rod. According to the efficient dezincification edge grinding machine, labor intensity is low, edge grinding efficiency is high, and the edge grinding effect is good.

Owner:SHANGYU YONGCHANG PACKAGING PROD

Multi-angle edge grinding device for LOW-E glass production

InactiveCN106965054AAvoid damagePlay a buffer roleEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention relates to a LOW-E glass edge grinding device, and provides a multi-angle edge grinding device for LOW-E glass production capable of performing multi-angle edge grinding and with high edge grinding efficiency and simple operation. The device comprises a baseplate, an L-shaped bracket, an electric wire winding wheel, a slide rail, a connecting plate, a grinding head motor, a vertical plate, a first spring, a grinding wheel, a cylinder, a transverse plate, a slide block, a pull rope and the like; and the L-shaped bracket, the electric wire winding wheel and the slide rail are arranged on the baseplate in sequence from left to right. The multi-angle edge grinding device for LOW-E glass production adopts a grinding head motor as drive to drive the grinding wheel to rotate, so that the grinding wheel grinds edges of LOW-E glass.

Owner:安徽万佳节能科技有限公司

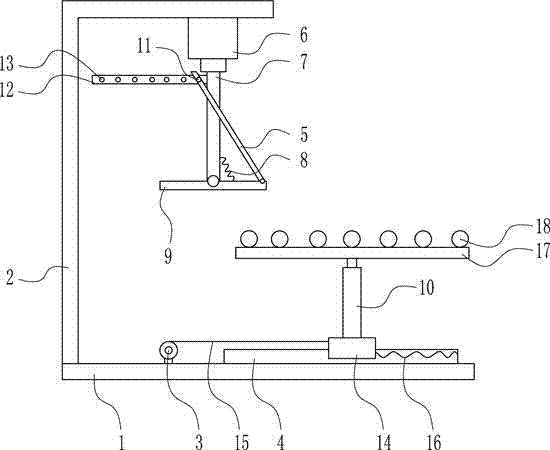

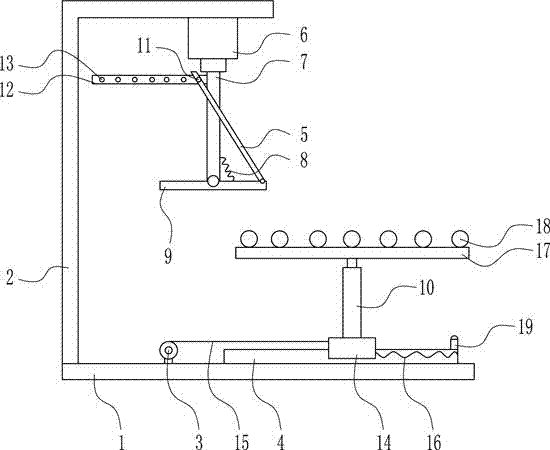

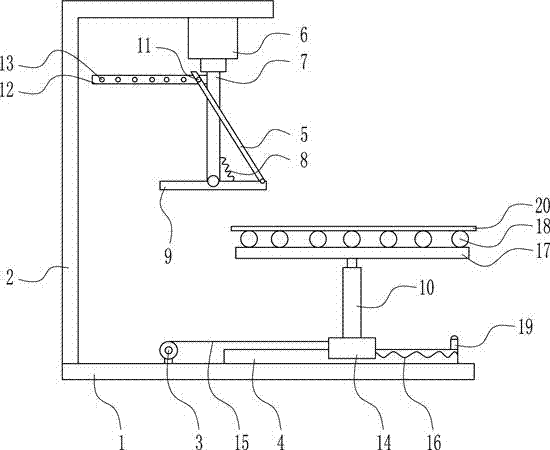

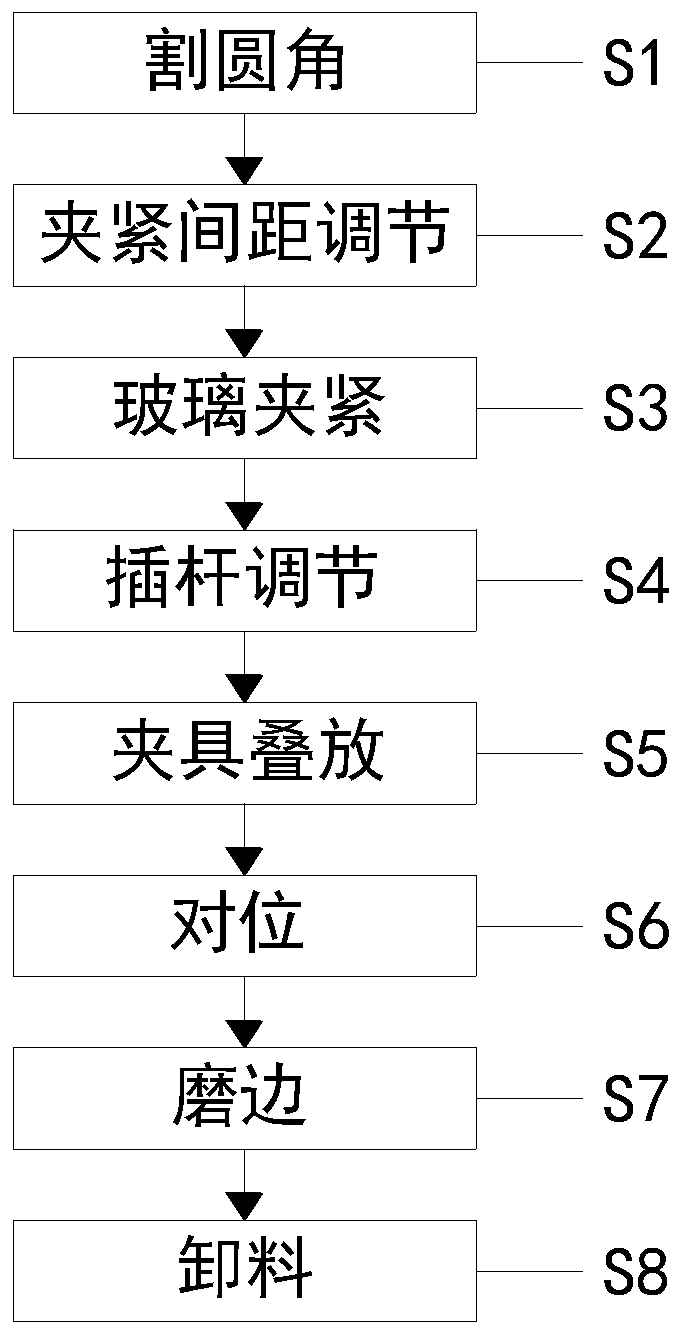

Refined edge grinding treatment process for tempered glass manufacturing and machining

InactiveCN111070005AQuick clampingSmooth transitionEdge grinding machinesGrinding drivesToughened glassGlass manufacturing

The invention relates to a refined edge grinding treatment process for tempered glass manufacturing and machining, in particular to a refined edge grinding treatment device for tempered glass manufacturing and machining. The edge grinding device specifically comprises a base, a limiting bearing table assembly fixedly installed on the base, a plurality of tempered glass partition plate clamps and four fillet edge grinding mechanisms evenly distributed on the limiting bearing table assembly. According to the treatment process, the four fillet positions of the tempered glass can be subjected to edge grinding treatment at the same time, the edge grinding efficiency is greatly improved, meanwhile, edge grinding treatment can be synchronously carried out on a plurality of pieces of tempered glass which are stacked in a separated mode, and batched edge grinding machining treatment is achieved.

Owner:江门市江海区远强安全玻璃有限公司

Edge grinding device suitable for metal label plate

InactiveCN108942462AImprove edging efficiencyImprove stabilityEdge grinding machinesGrinding drivesCounter rotationRotational axis

The invention discloses an edge grinding device suitable for a metal label plate. The edge grinding device suitable for the metal label plate comprises an operation table, a top plate, a first motor,a transmission shaft, an adjusting ring, a second motor, a grinding disc, an air cylinder, a fixing plate, an adjusting screw rod, a base plate and a fan, and is characterized in that the operation table is arranged on a support, a vertical plate is arranged on the top plate, the first motor is arranged on the top plate, the two ends of the transmission shaft penetrate through bearings, and internal threads and a connecting plate are arranged on the adjusting ring. According to the edge grinding device, external threads on the transmission shaft are arranged into two sections, moreover, the two sections of external threads are arranged to be of the structures with the opposite directions on the transmission shaft, the transmission shaft drives the external threads to rotate forwards or reversely, the external threads drive the internal threads to rotate, then the adjusting ring is enabled to move back and forth on the transmission shaft, then the connecting plate and the second motor on the connecting plate are driven to move back and forth, then the grinding disc on the rotating shaft on the second motor is enabled to carry out edge grinding on the metal label plate, the edge grinding efficiency of the metal label plate is improved, and the labor intensity of operators is reduced.

Owner:ANHUI STARLIGHT LOGO SYST CO LTD

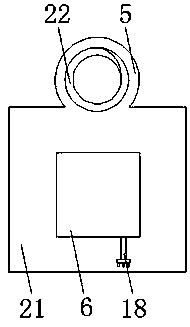

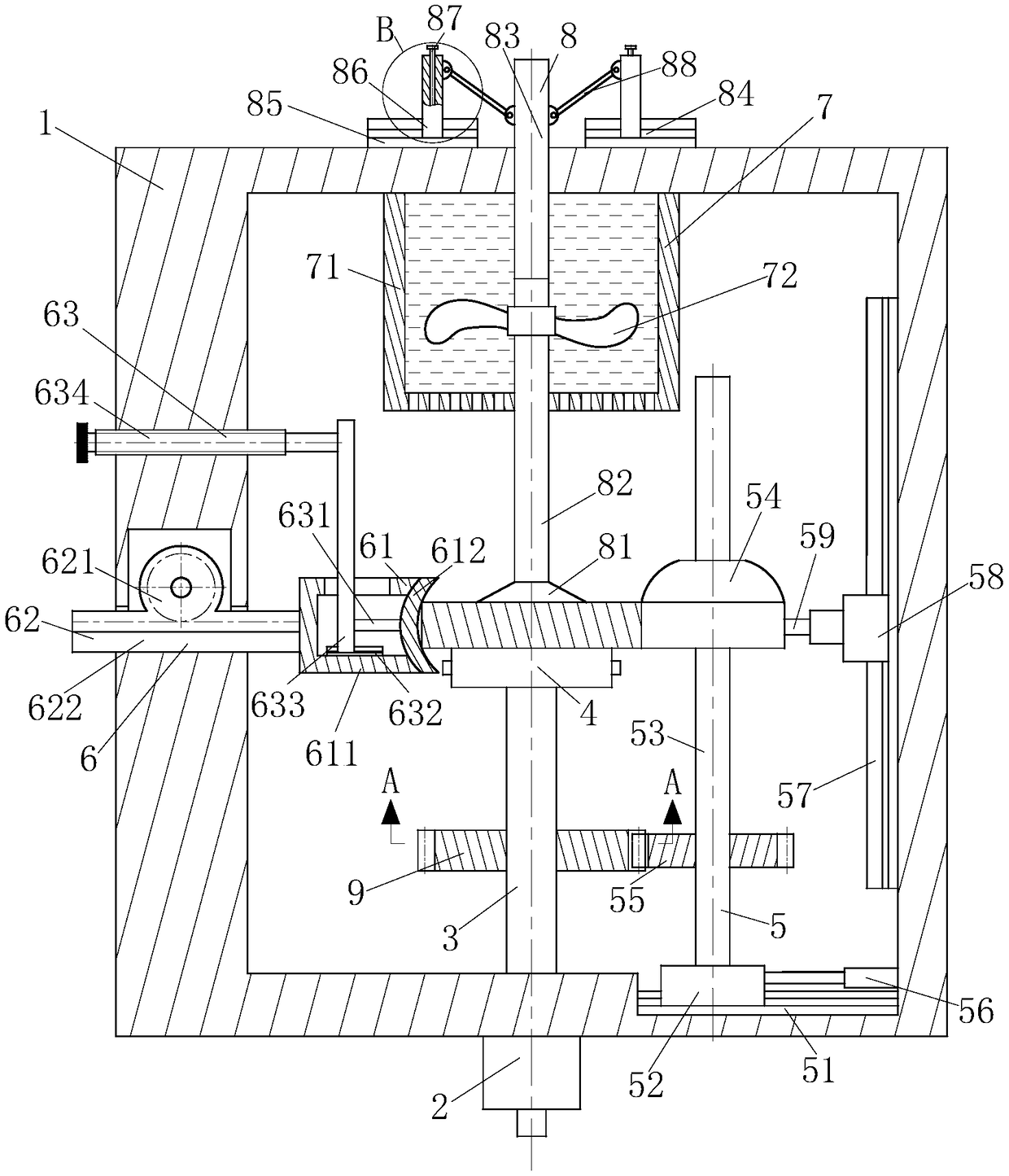

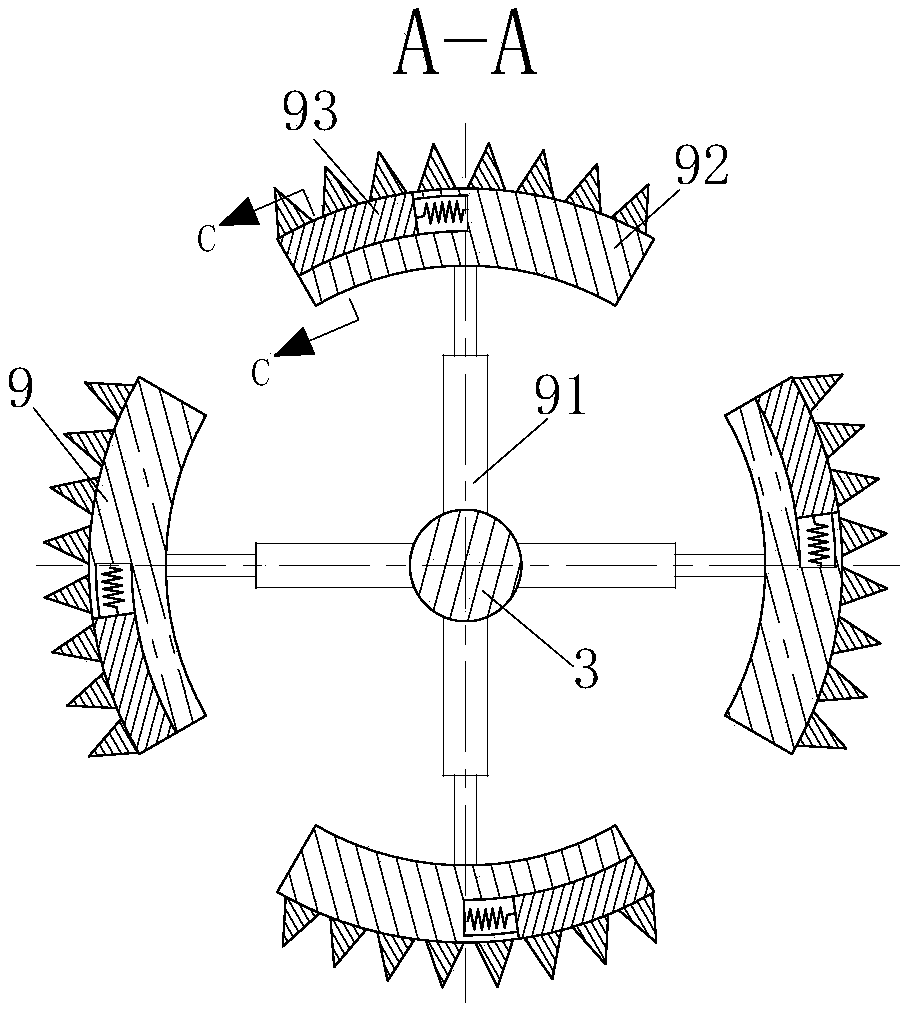

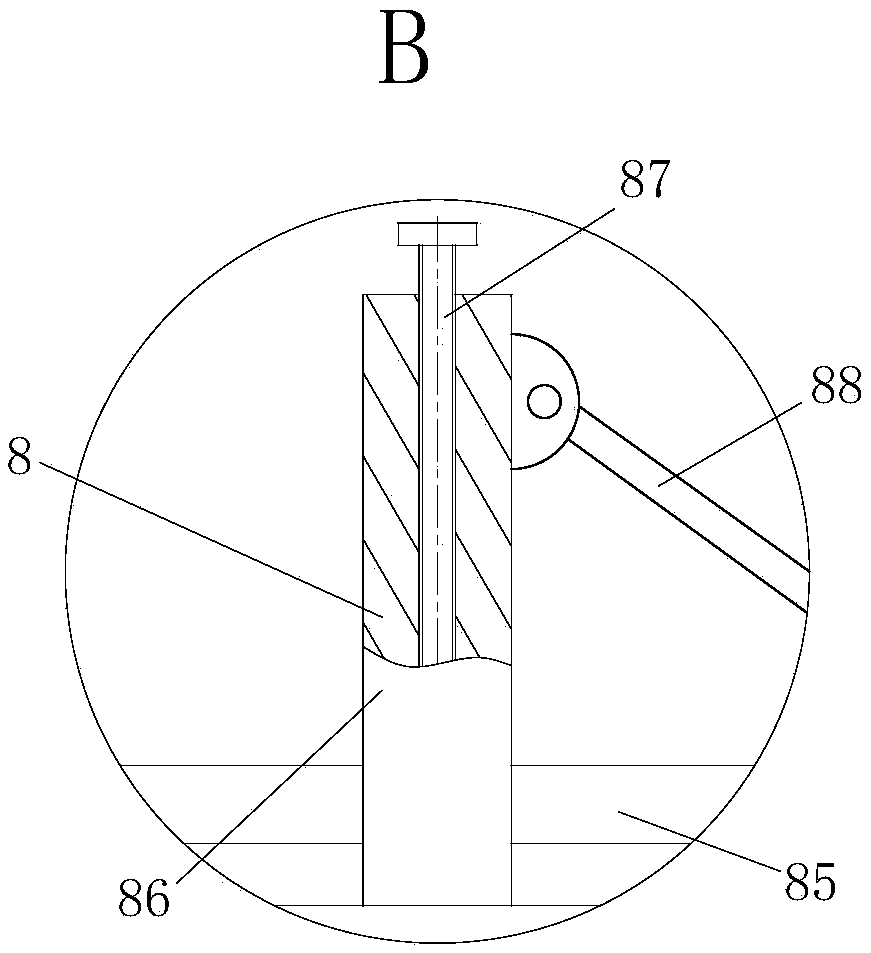

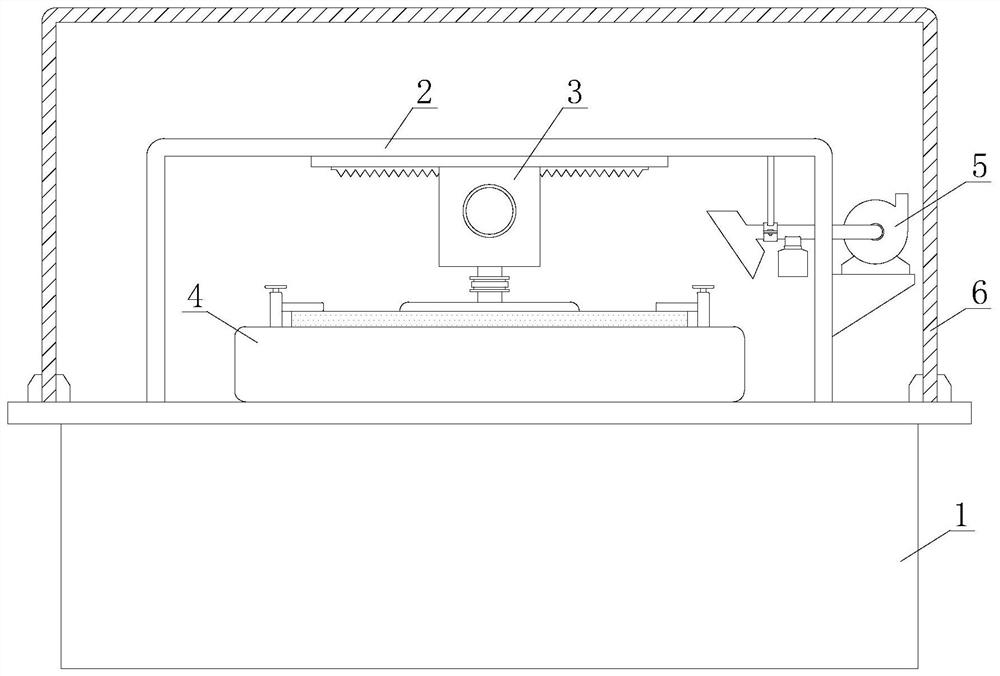

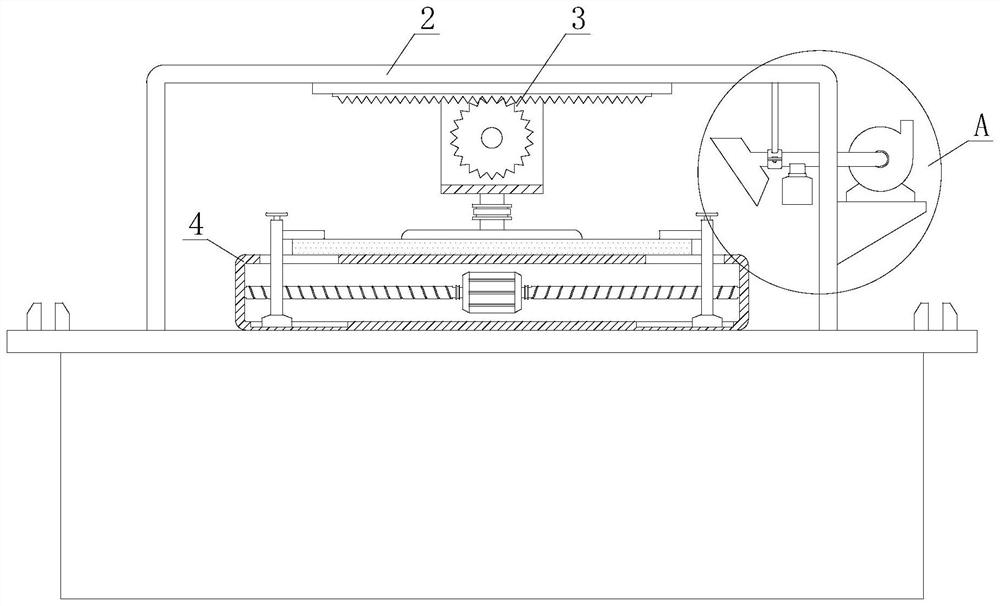

Automatic edge polishing equipment for optical glass

ActiveCN108747683AImprove edging efficiencyImprove cooling effectEdge grinding machinesGrinding/polishing safety devicesEngineeringOptical glass

The invention belongs to the technical field of optical glass production, and particularly relates to automatic edge polishing equipment for optical glass. The automatic edge polishing equipment for the optical glass comprises a tank, a first motor, a first connection shaft, a positioning base, a grinding module, an edge polishing module, a spraying module and a compressing module; the first motoris fixed to the bottom of the tank; the first connection shaft is located inside the tank; the lower end of the first connection shaft is connected with an output shaft of the first motor; the positioning base is located inside the tank and is in a disk shape; the lower surface of the positioning base is connected with the upper end of the first connection shaft; the axis of the positioning baseand the axis of the first connection shaft are located on the same straight line; the grinding module is located on the right side of the positioning base; the edge polishing module is located on theleft side of the positioning base; the spraying module is located above the positioning base and inside the tank; and the compressing module is located above the positioning base and used for compressing the optical glass.

Owner:TONGXIANG HESHAN CRAFT GLASSWARE FACTORY

Edge polishing follow-up device of edge polishing machine

ActiveCN106181669AChange the proportional difference arbitrarilyImprove edging efficiencyEdge grinding machinesGrinding carriagesManufacturing technologyEngineering

The invention discloses an edge polishing follow-up device of an edge polishing machine and relates to the technical field of manufacturing of stone machining equipment. The edge polishing follow-up device comprises a rack; a conveying channel is arranged beside the rack; an edge polishing grinding wheel machine is arranged at one side of the conveying channel; the conveying channel is provided with a pressing wheel for measuring the thickness of a slab stone; the pressing wheel is connected with the rack through a swinging arm; and the edge polishing grinding wheel machine is mounted on the swinging arm. Compared with the prior art, the problem of an existing edge polishing machine that the polishing height of each edge polishing grinding wheel needs to be manually adjusted when the thickness of a slab stone workpiece is changed can be solved.

Owner:岑溪市藤超机械有限公司

Glass edge-polishing tool

InactiveCN109129096AEfficientImprove edging efficiencyEdge grinding machinesMechanical engineeringEngineering

The invention discloses a glass edge-polishing tool. Two guiding rails are parallelly and fixedly connected to the upper end face of a base, a sliding seat is slidably connected with the guiding railsthrough grooves, a piston rod of a first air cylinder extends inwards, and the tail end of the piston rod of the first air cylinder is fixedly connected with the outer end face of the sliding seat; the lower end of a central shaft is rotatably connected with the center of the upper end face of the sliding seat through a bearing, the upper end of the central shaft is fixedly connected with a fixing seat, suction cups are evenly mounted on the upper end face of the fixing seat, and a gear is mounted on the lower side of the central shaft in a sleeving mode; a piston rod of a second air cylinderextends leftwards, and the tail end of the piston rod of the second air cylinder is fixedly connected with a rack, and the rack is engaged with the gear; two guiding rods are parallelly and fixedly connected between two supporting columns, a lead screw is arranged between the two guiding rods, the left and right ends of the lead screw are rotatably connected with the supporting columns on the left and right sides through bearings correspondingly, a mounting seat is slidably connected with the guiding rods through through holes, and the lead screw penetrates through the mounting seat and is inthreaded connection with the mounting seat; and the tail end of an output shaft of a first motor is fixedly connected with the right end of the lead screw, an output shaft of a second motor extends downwards, and the tail end of the output shaft of the second motor is fixedly connected with an edge polishing wheel. The glass edge-polishing tool has the advantages that the efficiency is high, andthe labor and time are saved.

Owner:安徽宇臻实业有限公司

Optical lens edging device and method

ActiveCN111390698AImprove edging efficiencyPrevent slippingEdge grinding machinesEngineeringOptic lens

The invention relates to the field of optical lens processing, and particularly discloses an optical lens edging device and method. The optical lens edging device comprises a rack, a first fixing seatand a second fixing seat; the first fixing seat is arranged at the bottom of the left end of the rack, a first connecting seat is arranged at the right end of the first fixing seat, and a telescopicconnecting rod is arranged at the right end of the first connecting seat; and the second fixing seat is arranged at the right end of the rack, a motor is arranged in the second fixing seat, a second connecting seat is arranged at the left end of the motor, a connecting rod is arranged at the left end of the second connecting seat, and a control panel is arranged at the outer end of the right sidewall of the rack. According to the lens edging device provided by the invention, the two ends of a lens are fixed through suction cups with inconsistent specifications, outer edges and edge strips atthe edges of the lens are simultaneously polished through a polishing disc assembly arranged at the bottom end of a polishing disc, and thus the lens edging efficiency is improved; and meanwhile, thelens edging effect can be judged through a lamp bead and an illumination intensity sensor, by combining with a controller, the lens edging process is scientifically controlled, thus lens polishing isguaranteed, and the edging efficiency is improved.

Owner:宁波丞达精机股份有限公司

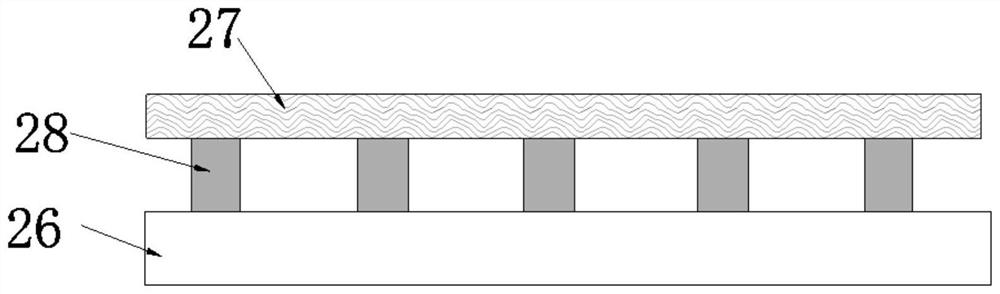

High-precision edge grinding device for monocrystalline silicon epitaxial wafer

ActiveCN113182971AImprove edging efficiencyIncrease the carrying areaEdge grinding machinesFinal product manufactureMonocrystalline siliconStructural engineering

The invention discloses a high-precision edge grinding device for a monocrystalline silicon epitaxial wafer. The high-precision edge grinding device for the monocrystalline silicon epitaxial wafer comprises a machine table, a bearing seat, a material taking device and a grinding mechanism. The bearing seat is installed on the machine table; a rotary table is machined in the middle of the bearing seat; a cover plate is hinged to the bearing seat; a grinding mechanism is installed on the bottom face of the cover plate, and the grinding mechanism comprises a pressing plate, a grinding roller, scraping plates, cleaning pieces and a liquid supply pipe; a groove for mounting the grinding roller is formed in the pressing plate; the liquid supply pipe for spraying a lubricant is arranged at the top in the groove; the scraping plates are arranged on the two sides of the grinding roller; the cleaning pieces are arranged on the two sides of the pressing plate; and the material taking device is mounted on one side of the rotary table. The rotary table is arranged in the bearing seat, the grinding mechanism for grinding the epitaxial wafer on the rotary table is installed on the bottom face of the cover plate on the bearing seat, the rotary table is used for driving the epitaxial wafer to rotate, edge grinding is conducted on the epitaxial wafer in cooperation with the grinding mechanism, and therefore the edge grinding efficiency of the epitaxial wafer can be improved; and meanwhile, by arranging a gasket, the bearing area of the epitaxial wafer can be increased, the stability is improved, and the safety of the epitaxial wafer in the edge grinding process is guaranteed.

Owner:四川雅吉芯电子科技有限公司

Recycled plastic tile cutting and edge grinding machine and using method thereof

InactiveCN112123121AEasy loadingHigh degree of automationBelt grinding machinesMetal working apparatusElectric machineryStructural engineering

The invention discloses a recycled plastic tile cutting and edge grinding machine and a using method thereof. The recycled plastic tile cutting and edge grinding machine comprises a machining frame, amaterial feeding mechanism is arranged on one side of the machining frame, the material feeding mechanism comprises a material feeding frame, a material feeding motor is installed on the material feeding frame, an output shaft of the material feeding motor is connected with a screw rod, the screw rod is in threaded connection with a lifting plate, two first sliding rails are horizontally installed on the lifting plate, each first sliding rail is slidably provided with two first sliding blocks, and the four first sliding blocks are all installed on the lower surface of a material feeding plate. According to the cutting and edge grinding machine, material feeding and discharging of recycled plastic tiles are more convenient, no operator participates in the whole cutting and edge grinding process, the automation degree is high, position-limiting is performed on the inner arc faces of the surfaces of the recycled plastic tiles through position-limiting rollers on upper position-limiting mechanisms and lower position-limiting mechanisms before the recycled plastic tiles are subjected to cutting and edge grinding, the position-limiting and fixing effects on the recycled plastic tiles are good, the fact that the recycled plastic tiles with different widths are efficiently ground can be met, the edge grinding can be performed on both sides at the same time, and the edge grinding efficiency is high.

Owner:ANHUI HUANJIA TIANYI RENEWABLE RESOURCES

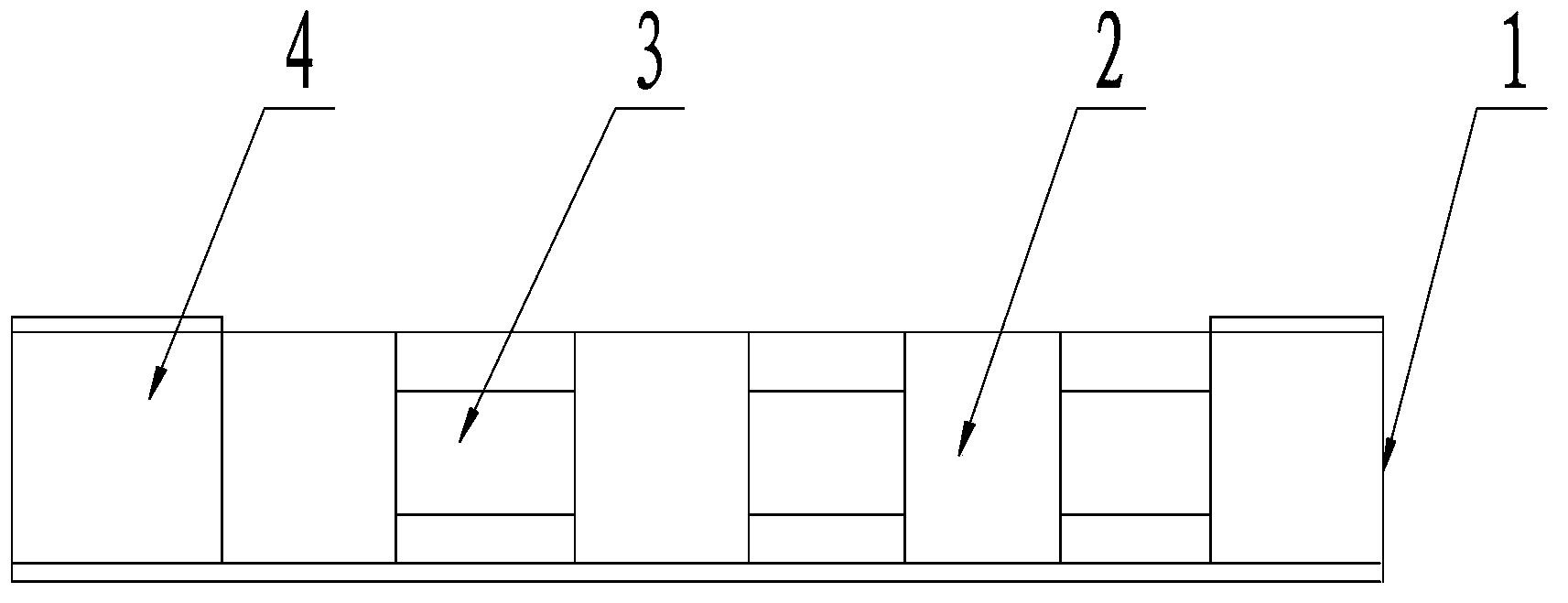

Automatic edge grinding device for semi-finished mobile phone screen

PendingCN109571174AImprove edging efficiencyImprove edge qualityEdge grinding machinesGrinding carriagesWork in processMechanical engineering

The invention belongs to the technical field of mobile phone screen processing, and particularly relates to an automatic edge grinding device for a semi-finished mobile phone screen. The automatic edge grinding device comprises a sucking-holding device, a limiting device, an edge grinding device body and a control device, wherein the sucking-holding device comprises a sucking-holding mechanism anda lifting mechanism, the limiting device comprises a limiting assembly arranged under the sucking-holding mechanism and a driving assembly for driving the limiting assembly to move, the edge grindingdevice body is arranged beside the sucking-holding mechanism and comprises an edge grinding mechanism and a moving assembly for driving the edge grinding mechanism to move, and the control device comprises a controller and a sensor assembly electrically connected with the controller. The sucking-holding mechanism comprises a vacuum sucking assembly and a rotating assembly for driving the vacuum sucking assembly to rotate. The automatic edge grinding device can improve mobile phone screen edge grinding efficiency and prevent a rotation condition during grinding of the semi-finished mobile phone screen, and edge grinding quality is improved.

Owner:芜湖华宇彩晶科技有限公司

Dry-wet type edge grinding wheel and manufacturing method thereof

InactiveCN107081689AImprove edging efficiencySolution to short lifeAbrasion apparatusGrinding devicesCopperIron powder

The invention discloses a dry-wet type edge grinding wheel and a manufacturing method thereof. The edge grinding wheel comprises a base body and a grinding block fixedly connected on one side of the base body, and the grinding block is formed by pressing powder materials, by weight, of 100 parts of diamond, 20-60 parts of silicon carbide, 600-1000 parts of iron powder, 400-600 parts of copper powder and 100-140 parts of mixed alloy powder for improving the sharpness. According to the dry-wet type edge grinding wheel obtained by manufacturing through the formula of the edge grinding wheel, the ground edge of the edge grinding wheel is sharp and resistant to abrasion, the edge grinding efficiency is high, and the life is long.

Owner:FOSHAN DINGSHUN TECH CO LTD

Disposable edge grinding device for rectangular glass

InactiveCN110238728ASmall footprintSimple structureEdge grinding machinesGrinding carriagesArchitectural engineeringPower output

The invention discloses a disposable edge grinding device for rectangular glass. The disposable edge grinding device comprises a base, a driving mechanism and a blocky grinding head, the base comprises an electric telescopic rod and an auxiliary telescopic rod, the base is provided with a processing cavity, a supporting column and a sucker are arranged in the processing cavity, the driving mechanism comprises a motor, a power output shaft end of the motor is connected with a first sliding block, a linkage rod penetrates through the first sliding block, one end of the linkage rod is provided with an L-shaped connecting plate, a spring is arranged between the first sliding block and the L-shaped connecting plate, the spring is arranged on the linkage rod in a sleeved mode, a second sliding block is hinged to the bottom of the L-shaped connecting plate through a rotating shaft, a connecting rod is arranged at the bottom of the second sliding block, and the bottom of the connecting rod is connected with a blocky grinding head; a transverse sliding rod is arranged on the second sliding block, a sliding sleeve is arranged at the right end of the transverse sliding rod, and a longitudinal sliding rod is arranged in the sliding sleeve in a sleeved mode. The edge grinding device is high in edge grinding efficiency, good in safety and adjustable in edge grinding size.

Owner:合肥协耀玻璃制品有限公司

Optical lens edge grinding device

PendingCN114178930AImprove efficiencyReduce labor intensityEdge grinding machinesGrinding work supportsElectric machineryMotor drive

The invention relates to an edge grinding device, in particular to an optical lens edge grinding device. According to the optical lens edge grinding device, the two ends of the optical lens can be ground at the same time, the optical lens edge grinding efficiency is relatively high, and sweeps generated in the optical lens edge grinding process can be recycled. An optical lens edge grinding device comprises a supporting block, a motor, a friction disc and a limiting ring, the motor is arranged in the middle of the supporting block, an output shaft of the motor is rotationally connected with the supporting block, the friction disc is connected to the output shaft of the motor, and the limiting ring is arranged on the outer side of the friction disc. The optical lens edge grinding device has the advantages that by starting the motor, the output shaft of the motor drives the friction disc, the optical lens on the friction disc rotates, and the grinding stone can grind the optical lens, so that the optical lens can be conveniently ground, and the efficiency of manually grinding the edge of the optical lens is improved to a certain extent.

Owner:江西宏欣光学科技有限公司

Glass automatic edge grinding device

InactiveCN108406499APrecision edgingReduce manpower inputEdge grinding machinesGrinding drivesEngineeringSlide plate

The invention provides a glass automatic edge grinding device. The glass automatic edge grinding device comprises a support A and a support B which are arranged side by side. Multiple rollers arrangedside by side are arranged between the support A and the support B. A guide plate A and a guide plate B are arranged on one side of the support A and one side of the support B correspondingly. An X-axis sliding plate is erected between the guide plate A and the guide plate B and is connected with a lead screw of a motor A. A Y-axis sliding plate in sliding connection with the X-axis sliding plateis arranged on the X-axis sliding plate. A grinding wheel frame is mounted on the Y-axis sliding plate. A grinding wheel is rotationally arranged on one side of the grinding wheel frame. A grinding wheel repair mechanism is arranged on one side of the X-axis sliding plate and comprises a metal sizing hose and an abrasive wheel. A fan and a water spray device are arranged on one side of the fan A.A drying mechanism is arranged on one side of the water spray device and comprises an annular metal frame. An electromagnetic coil is arranged in the annular metal frame. The glass automatic edge grinding device is simple in structure and convenient to use, the operation process of glass edge grinding, cleaning and drying can be completed, and the production efficiency of glass edge grinding can be improved.

Owner:东莞市银泰玻璃有限公司

Glass edge grinding device capable of collecting waste residues and implementation method thereof

InactiveCN113070772AReduce workloadImprove edging efficiencyEdge grinding machinesGrinding drivesProcess engineeringMechanical engineering

The invention discloses a glass edging device capable of collecting waste residues and an implementation method of the glass edging device, and belongs to the technical field of glass edging. The glass edging device comprises a machining table, wherein a fixing support is installed on the machining table, a glass edging mechanism is arranged on the fixing support, and a glass clamping mechanism is arranged below the glass edging mechanism; a glass waste residue collecting mechanism is further installed on the side surface of the fixing support and faces towards the polished glass edge, and the machining table is further covered with a transparent blocking cover. According to the glass edge grinding device capable of collecting the waste residues and the implementation method of the glass edge grinding device disclosed by the invention, glass is subjected to edge grinding through the rotating and transversely-moving glass edge grinding block, so that the workload of operators can be relieved, and the glass edge grinding efficiency is high; in the glass edge grinding process, a draught fan is started to generate negative pressure, a collecting cover sucks the glass waste residues and enables the glass waste residues to enter a residue collecting tube, and therefore, the glass edge grinding efficiency is improved. As the glass waste residues cannot pass through a filter screen and fall into a residue collecting box under the blocking effect of the filter screen, the glass waste residues are collected through the residue collecting box, and manual cleaning is not needed.

Owner:安徽晶晶玻璃制品有限公司

Method for welding T-shaped movable beam for deformed glass machining system

InactiveCN103358037AGuaranteed uptimeGood synchronizationWelding apparatusElectrical resistance and conductanceEngineering

The invention discloses a method for welding a T-shaped movable beam for a deformed glass machining system. The T-shaped movable beam consists of a longitudinal stepping / servo mechanism longitudinal beam, a rib plate, channel steel, a square pipe, a longitudinal stepping / servo mechanism transverse beam, a bottom plate and a vertical plate, and is characterized in that the rib plate, the channel steel, the square pipe, the bottom plate and the vertical plate are 10-15 millimeters in thickness. Automatic rotary welding equipment is adopted, electric resistance welding and carbon dioxide gas protection dual-gun balanced welding are adopted for welding, the welding way of the electric resistance welding includes point welding and backing welding, and the welding way of the carbon dioxide gas protection dual-gun balanced welding includes transverse welding and flat welding, so that the T-shaped movable beam has the advantages of high welding speed, no air hole in welding lines, small bevel angle, high quality, reliable performance and high mechanical performance of joints, and horizontal accuracies of upper and lower horizontal planes are ensured; and when the deformed glass machining system runs, the T-shaped movable beam has ideal synchronizing performance, is firm and highly rigid in structure, runs more stably, and can bear large-torque grinding without being deformed.

Owner:LUOYANG BAOHUAN NUMERICAL CONTROL PRECISE EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com