Glass edge grinding device

A glass edging and glass technology, which is used in automatic grinding control devices, grinding machines, machine tools suitable for grinding workpiece edges, etc., can solve the problems of manual edging, low efficiency and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

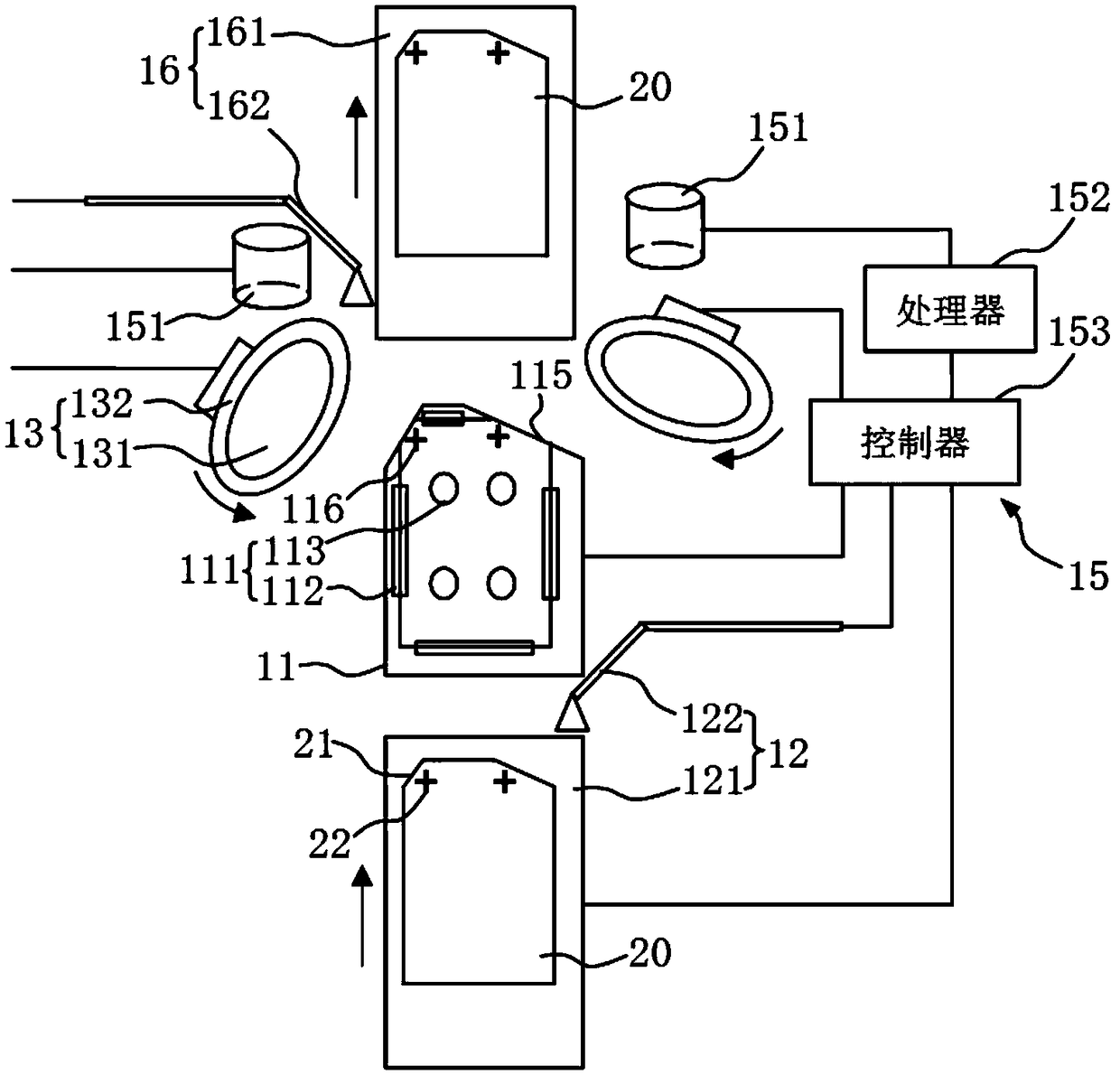

[0018] figure 1 It is a schematic structural diagram of a glass edging device in an embodiment of the present invention. Such as figure 1 As shown, the glass edging device of the embodiment of the present invention includes a loading mechanism 12 , a carrier 11 , a grinding mechanism 13 , a monitoring system 15 and a feeding mechanism 16 .

[0019] Monitoring system 15 comprises industrial camera 151, processor 152 and controller 153, and in the present embodiment, industrial camera 151 is a CCD (Charge Coupled Device, Charge Coupled Device) camera, and the quantity of industrial camera 151 and the chamfering 21 of glass 20 The numbers are equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com